Non-oriented electrical steel sheet excellent in magnetic permeability and method for manufacturing the same

A technology of oriented electrical steel sheet and its manufacturing method, which is applied in the field of non-oriented electrical steel sheet and its manufacturing, can solve the problems of magnetic reduction of fine precipitates and increase of manufacturing cost, and achieve the effect of improving magnetic permeability and reducing iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Example 1: Manufacture of non-oriented electrical steel sheet

[0099] A slab composed of the composition shown in Table 1 below was heated at 1150°C and hot-rolled to a thickness of 2.5 mm, and then coiled at 650°C. For the hot-rolled sheet cooled in air, it is annealed at 1080°C for 3 minutes, pickled and then cold-rolled to a thickness of 0.35mm. The annealing of the cold-rolled sheet is final annealed at 1050°C for 1 minute.

[0100] 【Table 1】

[0101]

[0102] In the above Table 1, the unit of component content is wt%.

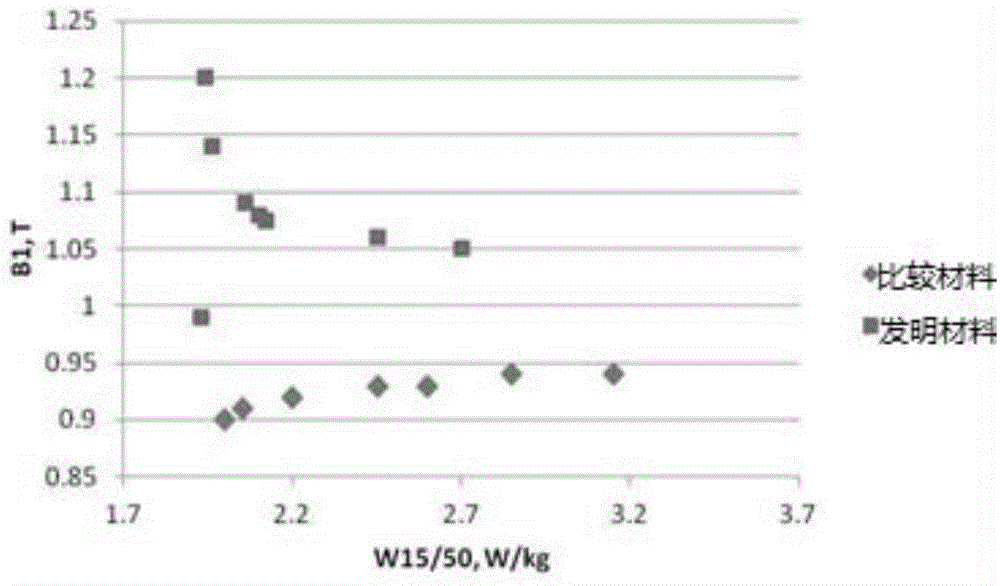

[0103] Evaluation Example 1: Iron loss and magnetic flux density of Example 1

[0104] For each test piece, take 5 or more test pieces, and measure the iron loss W by using a single-plate magnetic measuring instrument as follows 15 / 50 and magnetic flux density B 1 、B 10 、B 50 , and the results are shown in Table 2 below.

[0105] 1) Iron loss (W 15 / 50 ) represents the average loss (W / kg) in the rolling direction and the direction per...

Embodiment 2

[0116] Embodiment 2: Manufacture of non-oriented electrical steel sheet

[0117] Slabs (slabs) having compositions shown in Table 3 below were heated at 1150°C and hot-rolled to a thickness of 2.5 mm, and then coiled at 650°C. The hot-rolled sheet cooled in air was annealed at 1100°C for 3 minutes, pickled, cold-rolled to a thickness of 0.35 mm, and finally annealed at 1050°C for 1 minute to produce a non-oriented electrical steel sheet.

[0118] Among them, the temperature increase condition in the hot-rolled sheet annealing step is to change the temperature increase rate to 16°C / s for 700°C or less and 13°C / s for 700°C or more. In addition, the temperature increase condition in the cold-rolled sheet annealing step is to change the temperature increase rate to 20°C / s for 700°C or lower, and 15°C / s for 700°C or higher.

[0119] 【table 3】

[0120]

[0121]

[0122] In the above-mentioned Table 3, the content units of Si, Mn, P, Al, Sn and Sb are wt%. In addition, the c...

Embodiment 3

[0134] Embodiment 3: Manufacture of non-oriented electrical steel sheet

[0135] The non-oriented electrical steel sheet was made from the slab containing the components of the inventive example 6, and the annealing conditions of the hot-rolled sheet and the cold-rolled sheet were changed to the following Table 5.

[0136] The hot-rolled sheet annealing and cold-rolled sheet annealing conditions in the inventive examples 8 to 10 and comparative examples 9 to 12 are shown in Table 5 below. Furthermore, for the non-oriented electrical steel sheets produced by the respective production methods, the magnetic permeability of μ10 and μ15 were measured by the following method, and the results are shown in Table 5 below.

[0137] 1) Magnetic permeability (μ10, μ15) means the average magnetic permeability in the rolling direction and the direction perpendicular to the rolling direction when magnetic flux densities of 1.0 Tesla and 1.5 Tesla are respectively excited at a frequency of 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com