Iron-based nanometer crystal magnetically soft alloy and preparation method thereof

A technology of iron-based nanocrystals and soft magnetic alloys, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of high cost, limited application scope, inability to achieve high saturation magnetization at the same time, and reduce processing costs. The effect of easy promotion and application and excellent application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, the molecular formula of the iron-based nanocrystalline soft magnetic alloy is Fe 83.25 P 10 C 6 Cu 0.75 , the following is the specific preparation method:

[0050] Step 1: Raw materials such as Fe, P, C and Cu with a purity greater than 99% are calculated according to the alloy composition and the atomic percentage content of each composition, and the molecular formula is Fe 83.25 P 10 C 6 Cu 0.75 Perform batching, wherein C is added in the form of iron-carbon alloy, and the mass percentage of C in the iron-carbon alloy is 4.05%;

[0051] Step 2: Put the raw materials proportioned in step 1 into the ceramic crucible of the induction melting furnace, and high-frequency induction melting to obtain an alloy ingot with uniform composition;

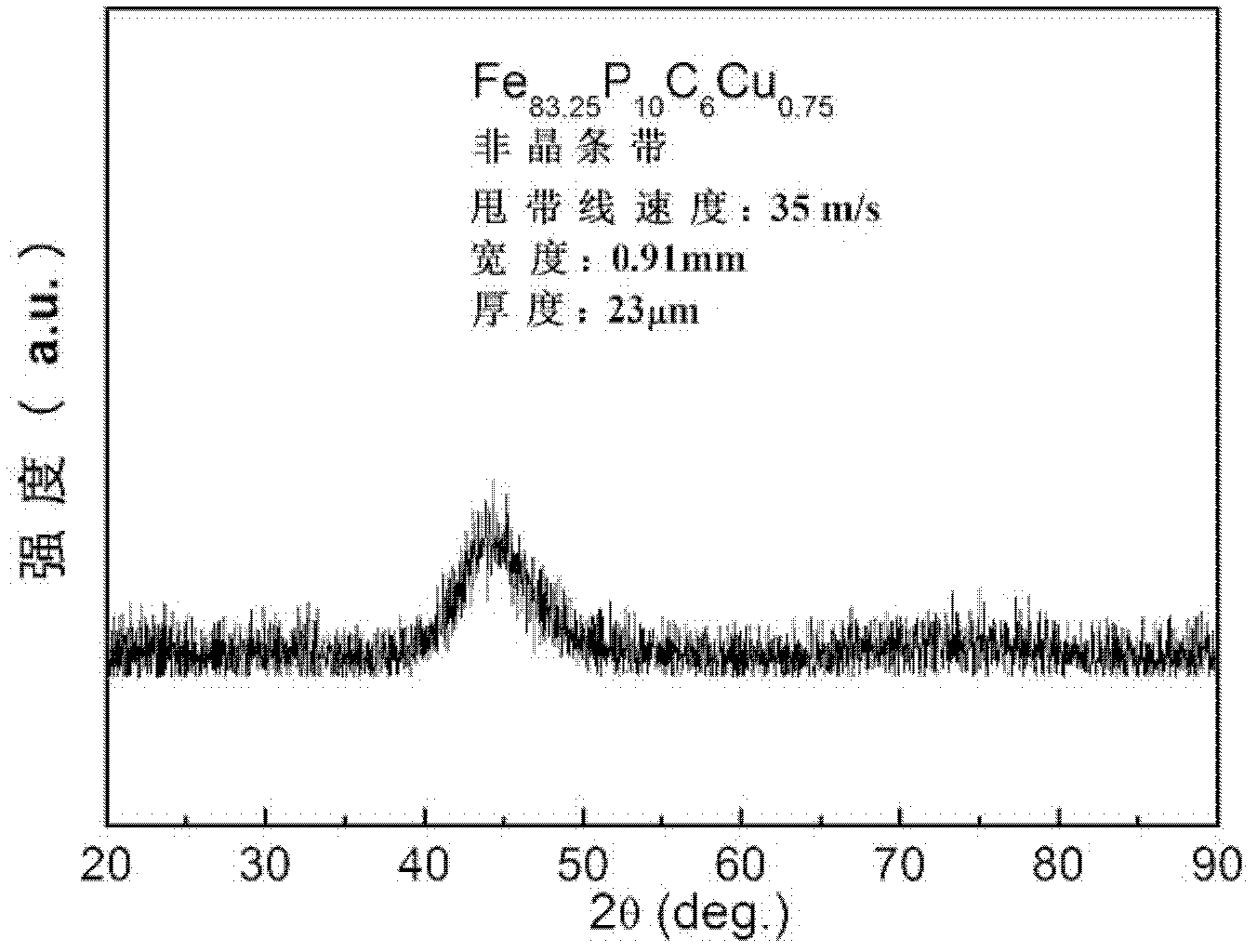

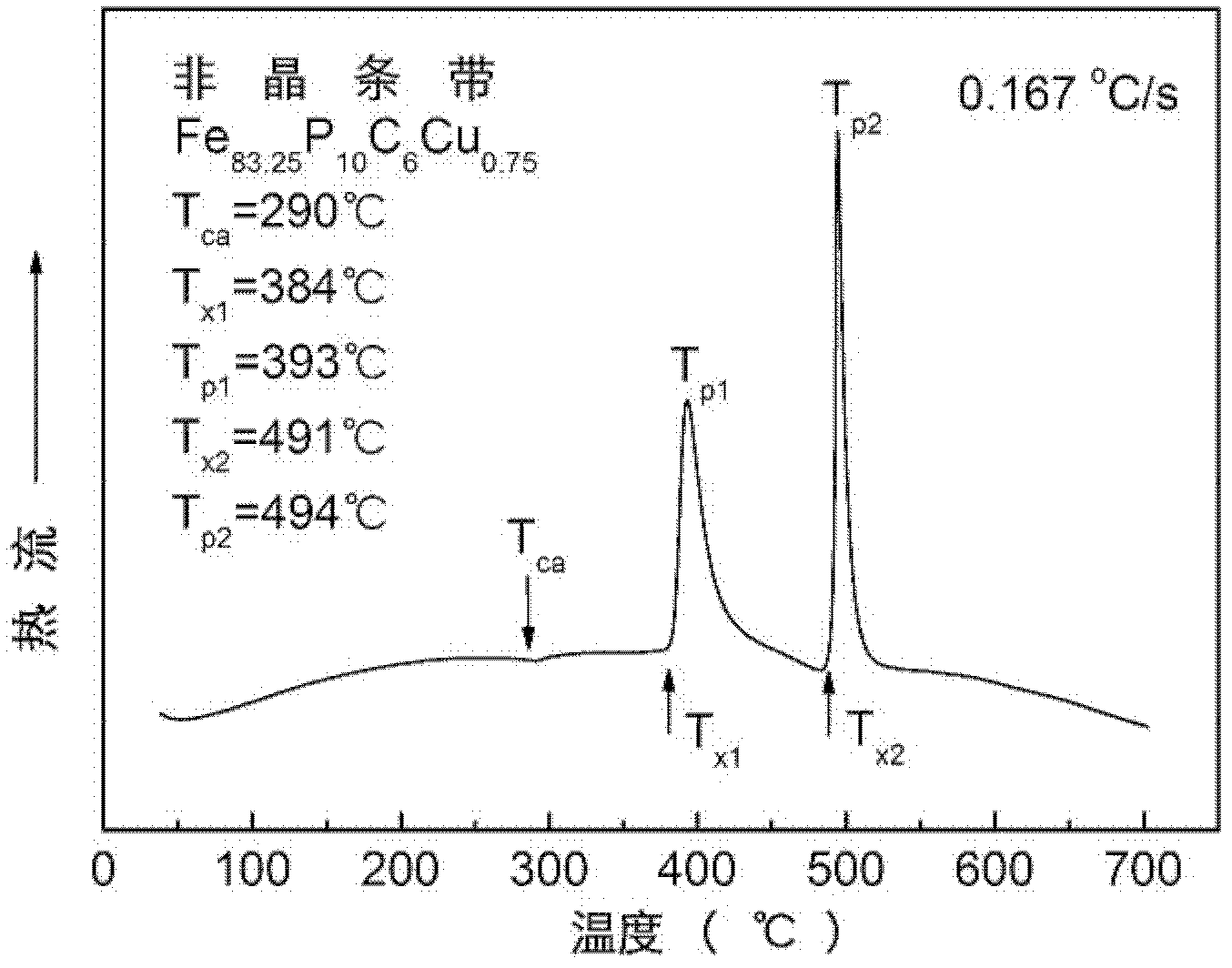

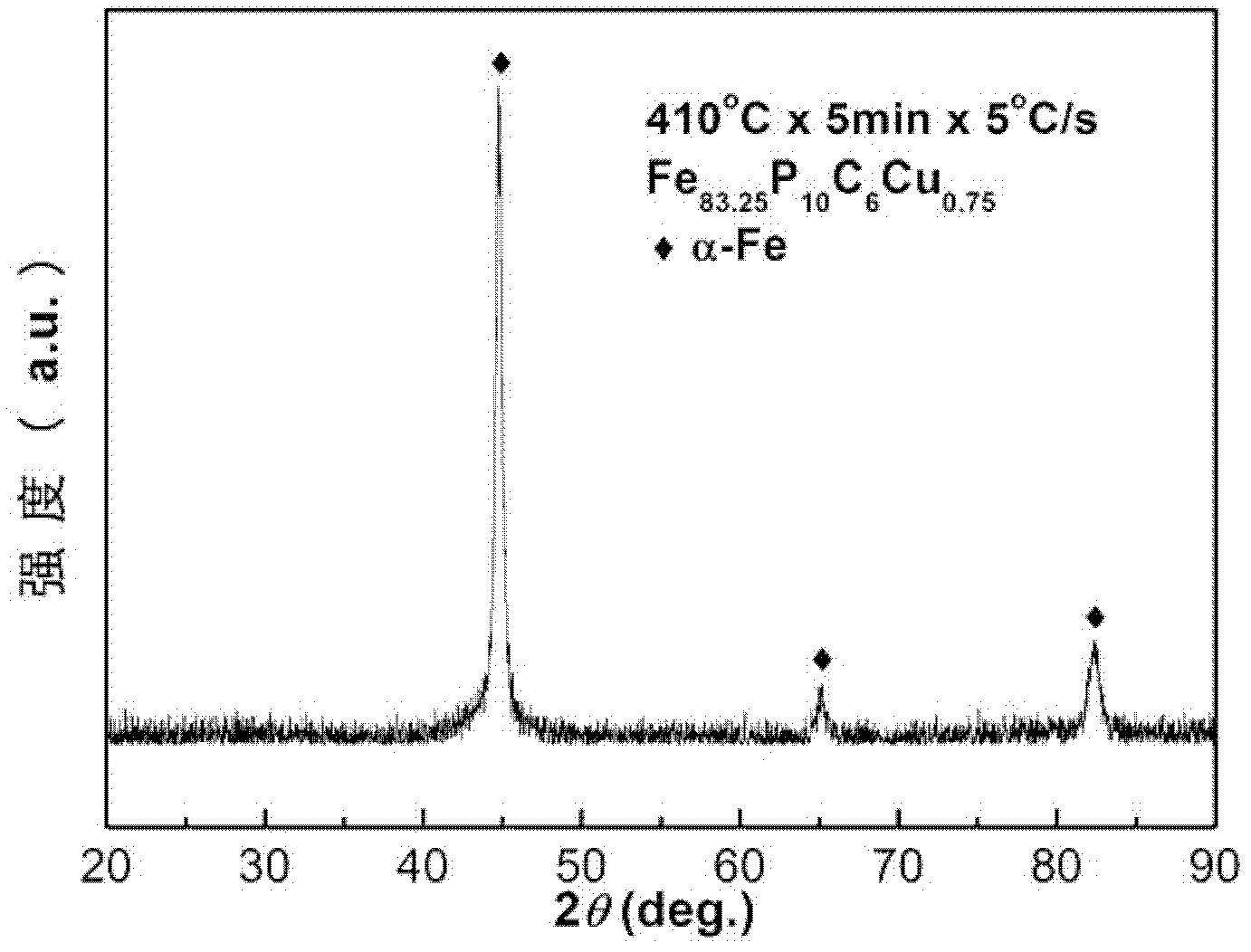

[0052] Step 3: crush the alloy ingot obtained in step 2 and put it into a quartz tube, and use a single-roller quenching and stripping process at a rate of 35m / s in an Ar atmosphere to obtain an amorphous al...

Embodiment 2

[0060] In this embodiment, the molecular formula of the iron-based nanocrystalline soft magnetic alloy is Fe 83 P 10 C 6 Cu 1 , the following is the specific preparation method:

[0061] Step 1: Raw materials such as Fe, P, C, and Cu with a purity greater than 99% are calculated according to the alloy composition and the atomic number content of each composition, and the molecular formula is Fe 83 P 10 C 6 Cu1 Perform batching, wherein C is added in the form of iron-carbon alloy, and the mass percentage of C in the iron-carbon alloy is 4.05%;

[0062] Step 2: Put the raw materials proportioned in Step 1 into the ceramic crucible of the induction melting furnace, and high-frequency induction melting to obtain the finished product. process, the strip is thrown at a speed of 35m / s in an Ar atmosphere, and an amorphous alloy strip with a width of 1.2mm and a thickness of 23μm is produced;

[0063] Step 4: Put the amorphous alloy strip obtained in step 3 on the quartz sample...

Embodiment 3

[0069] In this embodiment, the molecular formula of the iron-based nanocrystalline soft magnetic alloy is Fe 83.5 P 10 C 6 Cu 0.5 , the preparation method is the same as in Example 1, that is, first according to the molecular formula Fe 83.5 P 10 C 6 Cu 0.5 The batching is carried out, and then put into the ceramic crucible of the induction melting furnace, and the alloy ingot with uniform composition is obtained by high-frequency induction melting; then the alloy ingot is crushed and put into the quartz tube, and the single-roller quenching and stripping process is adopted, and the alloy ingot is 35m in the Ar atmosphere. / s speed throwing strips to make amorphous alloy strips; finally, the amorphous alloy strips are placed in a rapid heating furnace, and the temperature rises to 410°C at a rate of 5°C / s in an argon atmosphere, and is kept for 5 minutes. Then it is cooled to room temperature in air to obtain iron-based nanocrystalline soft magnetic alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com