Device and method for eliminating turriform of band steel roll

A steel coil and tower-shaped technology, which is applied in the field of strip steel coil tower-shaped elimination devices, can solve the problems of insufficient pressing of the circular platen, short service life, and poor uniformity of force, etc., to prolong the service life and improve efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

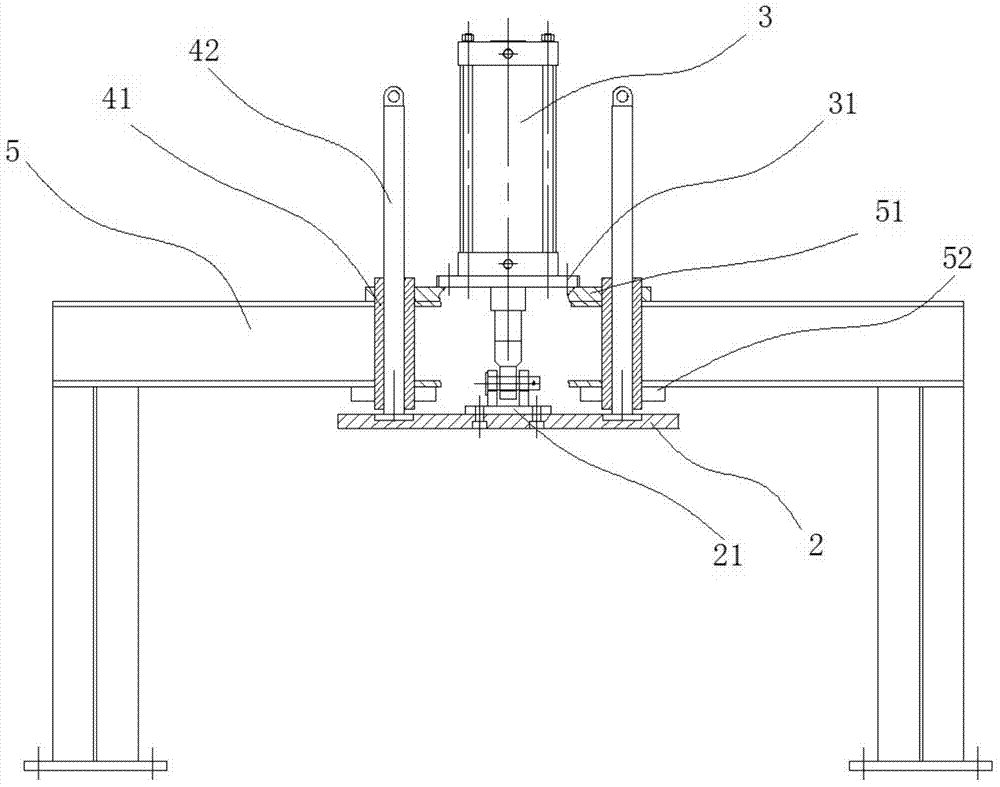

[0027] see figure 1 As shown, a strip steel coil tower shape elimination device is used to eliminate the tower shape generated when the strip steel coil 1 is coiled, and includes a pressure plate 2, a driving cylinder 3, a support 5 and a control system.

[0028] The upper side of the bracket 5 is provided with a mounting plate 51 , and the lower side of the bracket 5 is provided with a bottom plate 52 .

[0029] The cylinder block of the driving cylinder 3 is mounted on the mounting plate 51 through the flange 31 .

[0030] There are two guide mechanisms arranged symmetrically with respect to the piston rod of the driving cylinder 3. Each of the guide mechanisms consists of a guide sleeve 41 fixedly connected to the bracket 5 and a guide sleeve 41 fixedly connected to the pressure plate 2 and connected to the guide sleeve 41. A slidingly connected guide rod 42 is formed.

[0031] The telescopic direction of the piston rod of the driving cylinder 3 is the same as the sliding...

Embodiment 2

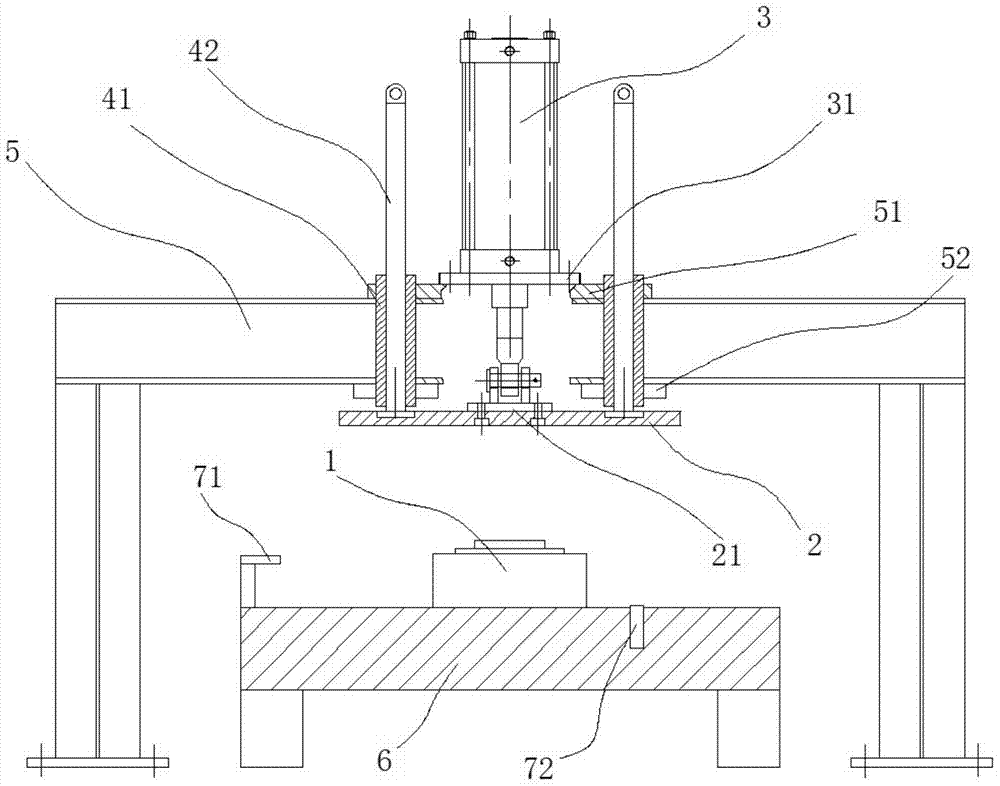

[0034] see figure 2 As shown, a strip steel coil tower shape elimination device is used to eliminate the tower shape generated when the strip steel coil 1 is coiled, including a pressure plate 2, a driving cylinder 3, a support 5, a carrier 6 and a control system.

[0035] The upper side of the bracket 5 is provided with a mounting plate 51 , and the lower side of the bracket 5 is provided with a bottom plate 52 .

[0036] The cylinder block of the driving cylinder 3 is mounted on the mounting plate 51 through the flange 31 .

[0037] There are two guide mechanisms arranged symmetrically with respect to the piston rod of the driving cylinder 3. Each of the guide mechanisms consists of a guide sleeve 41 fixedly connected to the bracket 5 and a guide sleeve 41 fixedly connected to the pressure plate 2 and connected to the guide sleeve 41. A slidingly connected guide rod 42 is formed.

[0038] The telescopic direction of the piston rod of the driving cylinder 3 is the same as...

Embodiment 3

[0053] The rest are the same as the second embodiment, the difference is that the setting positions of the first sensor 71 and the second sensor 72 are different from the second embodiment. side (can also be set on the same side as the case may be), and the height of the first sensor 71 from the stage 6 is slightly larger than the height of the strip coil 1, so as to detect whether the tower shape of the strip coil appears, and the distance from the second sensor 72 The height of the stage 6 is the same as that of the steel strip coil 1, both of which are photoelectric sensors that receive and emit photoelectric sensing signals in the horizontal direction.

[0054] The strip steel coil tower elimination method based on such setting comprises the following steps:

[0055] S1, the first sensor 71 detects the strip steel coil 1 in real time, if not detected, then continue monitoring, if the strip steel coil 1 is detected, then a first detection signal is formed, and enters S2;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com