An online flatness quality evaluation device and method for skin pass unit

A technology for quality assessment and skin pass mill, applied in the field of hot rolling, can solve the problems of high wave shape secondary pass pass rate, affecting production rhythm, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

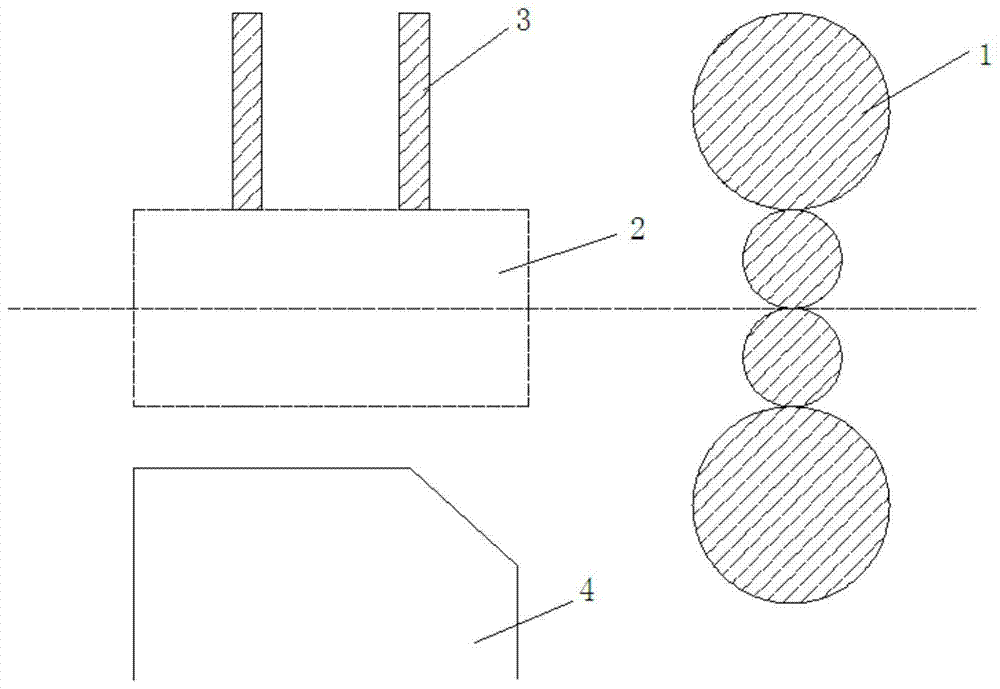

[0020] see figure 1 , An online flatness quality assessment device for a skin pass unit provided by an embodiment of the present invention includes: an online quality inspection platform 2 , an observation ruler and an operating platform 4 .

[0021] The on-line quality inspection platform 2 is set at the exit of the tempering machine 1 .

[0022] The observation ruler is set on the online quality inspection platform 2 .

[0023] The operating table 4 is opposite to the online quality inspection platform 2 .

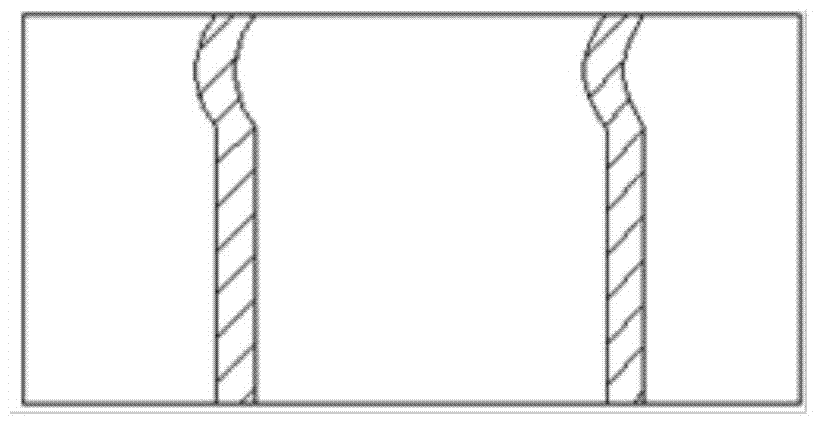

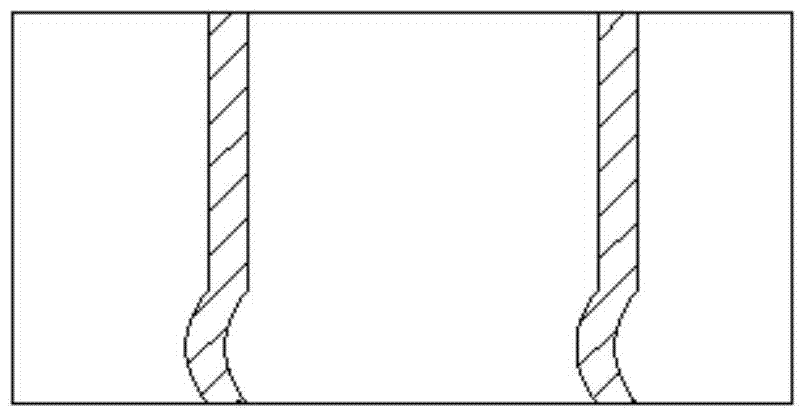

[0024] Wherein, the online quality inspection platform 2 checks the surface quality of the steel strip after the tempering machine 1 has been leveled, the operating table 4 is convenient for checking the operation status of the steel strip, the observation ruler is columnar, and the observation ruler is cylindrical. The ruler is vertically arranged on the online quality inspection platform 2, and the shape quality of the steel strip is judged according to the projectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com