Long-distance pushing construction method of thee-main-truss steel truss beam in single-connection and double-span modes without guide beam

A technology of jacking construction and steel truss girder, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of adding temporary connecting rods and guide beam rods, consuming manpower, material resources, financial resources, unfavorable shipping and environment. protection and other issues, to achieve the benefits of safe production and quality assurance, reduce high-altitude operations, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] An embodiment of the present invention provides a long-distance jacking construction method for single-connected double-span steel truss girders with three main trusses without guide girders, including the following steps:

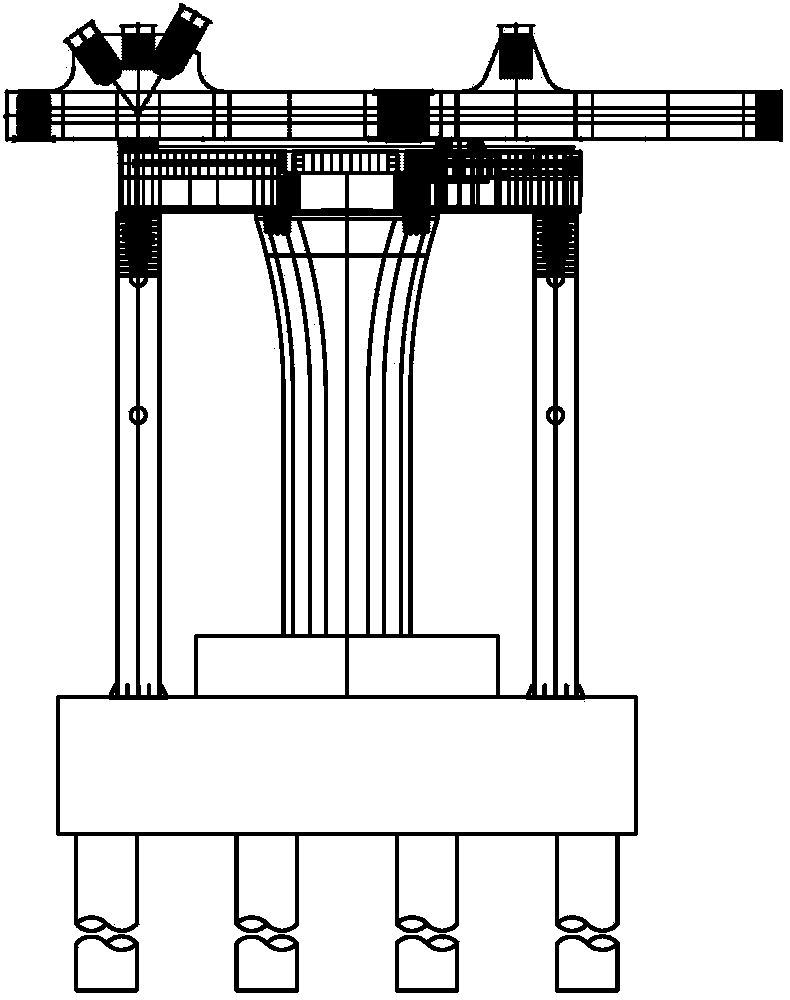

[0042] S1. Erection of steel truss beam assembly brackets, brackets beside piers, installation of slideway beams, steel strand anchoring devices, and lateral deviation correction devices;

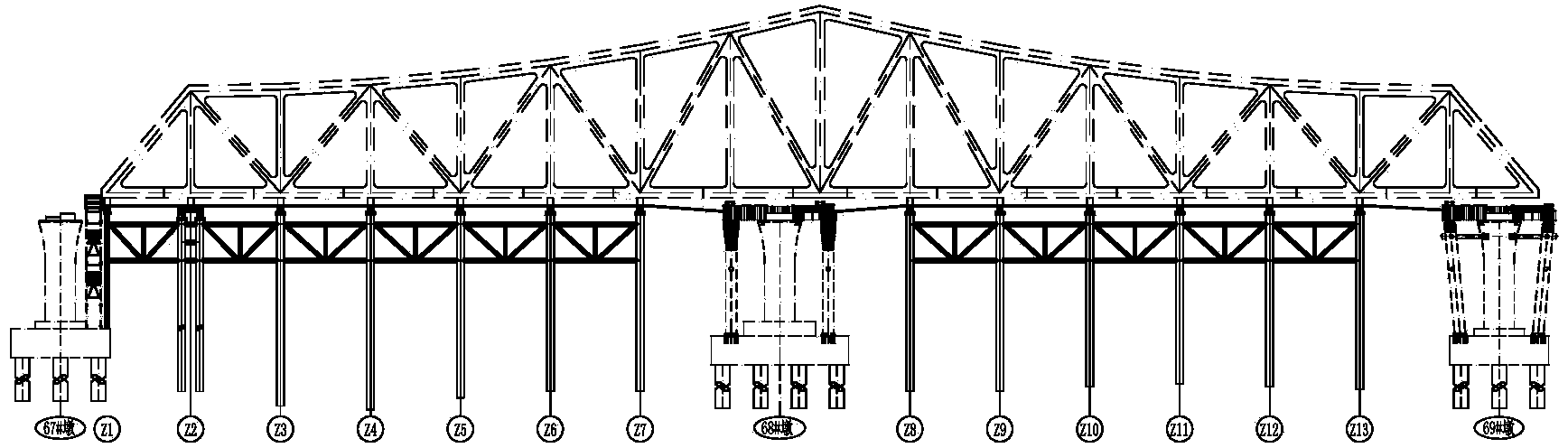

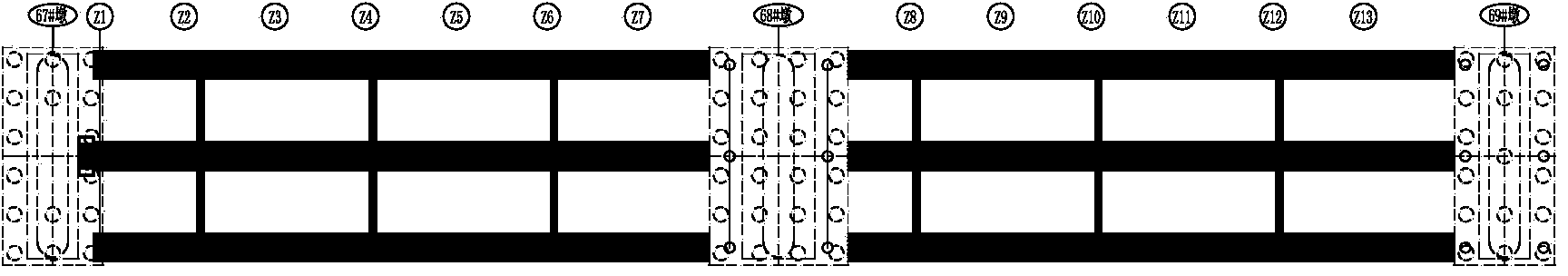

[0043] According to the structural forms of the three main trusses and node positions of the steel truss girders, erect a steel truss girder assembly support on the beach, see figure 1 , figure 2 As shown, the steel truss girder assembly bracket includes pile foundations, vertical and horizontal connection systems, pile top distribution beams and construction platforms. The pile foundations are connected by vertical and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com