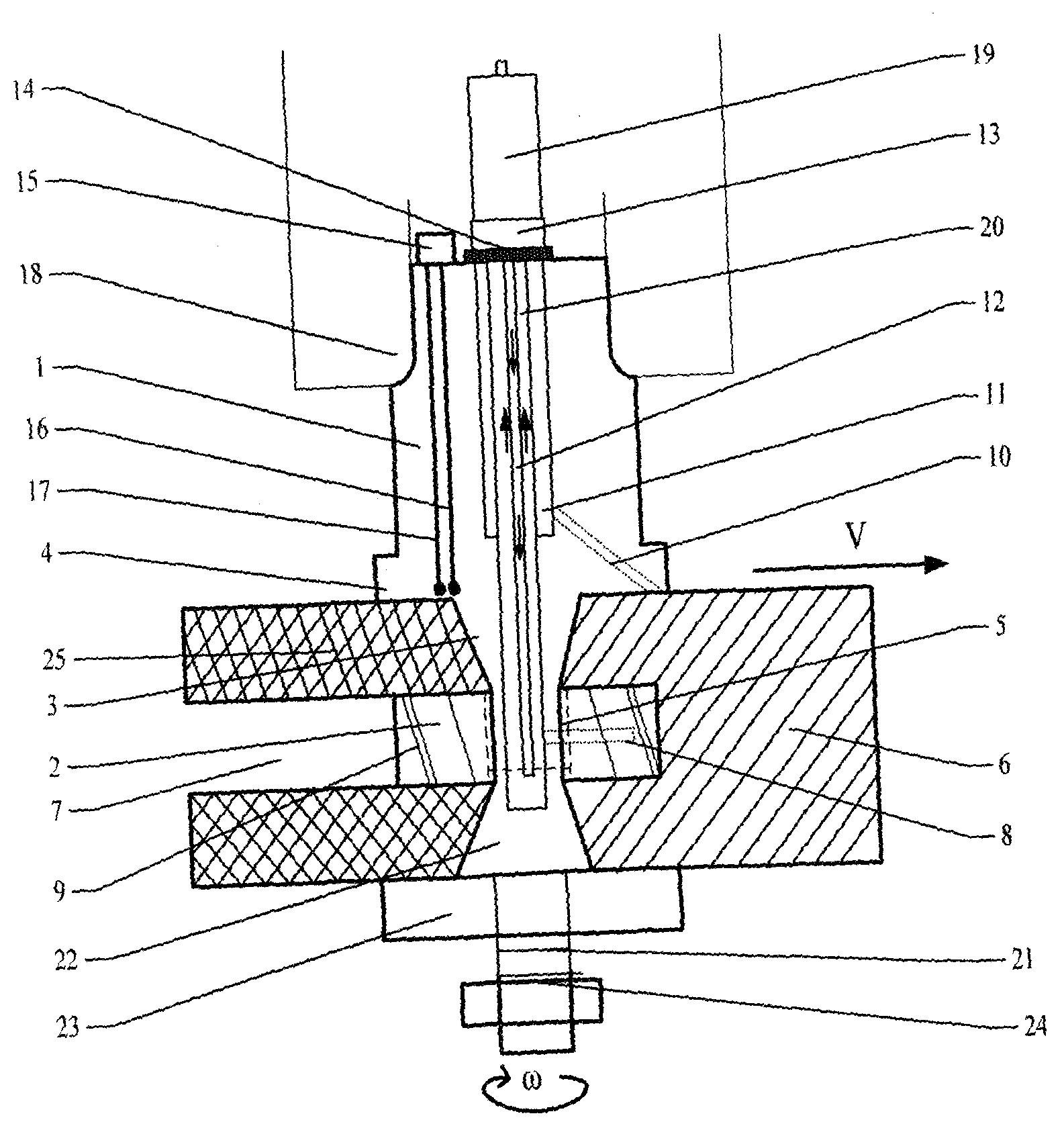

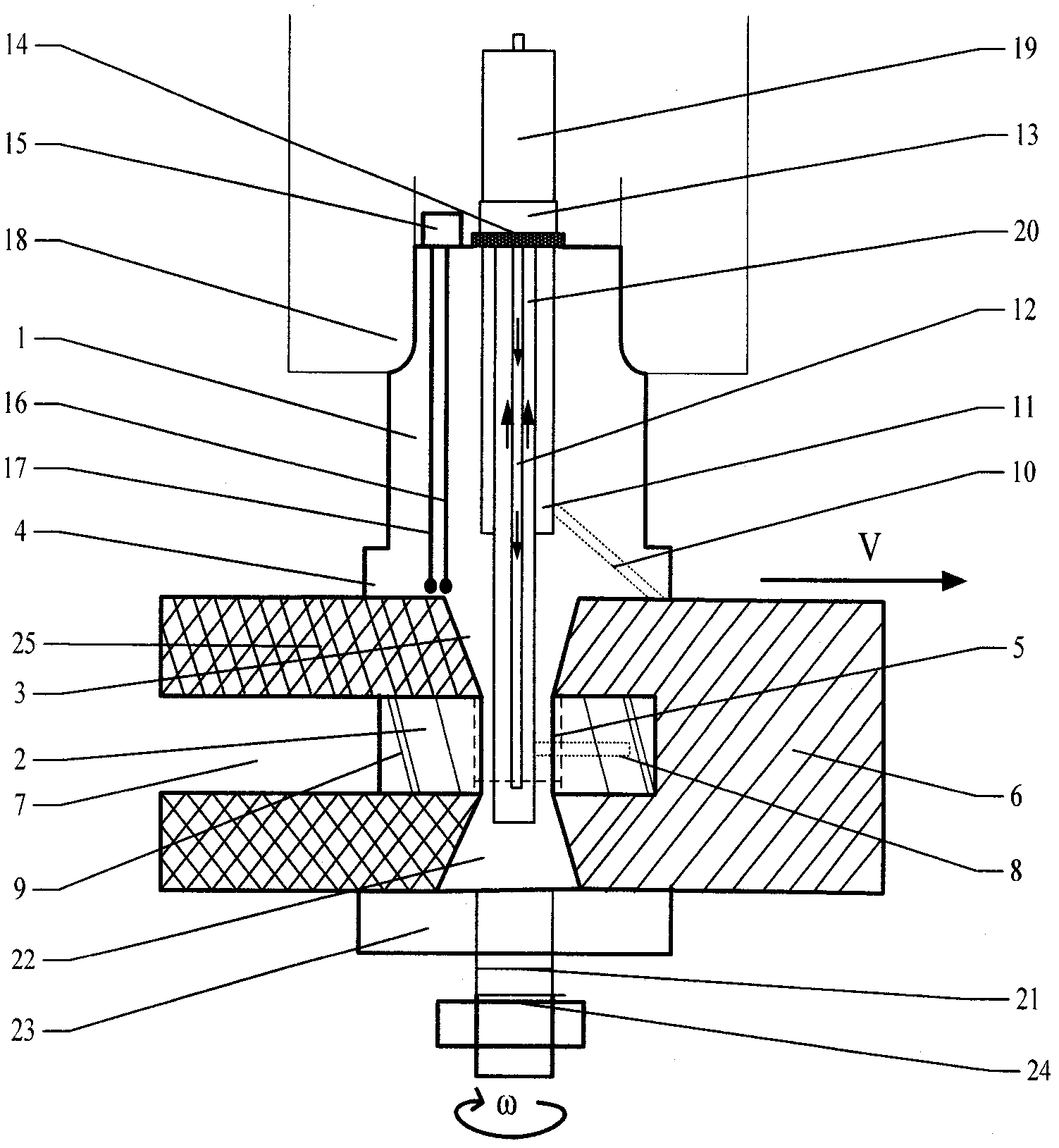

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

A friction stir and double stirring technology, applied in the field of mechanical manufacturing parts processing, can solve the problems of difficulty in designing friction stir welding fixtures and lack of processing methods, and achieve the effect of promoting easy chip removal, good cooling, and avoiding burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0084] Example 1: Manufacturing and processing of marine aluminum alloy serpentine channel ice-making plates. 3003 aluminum alloy material, the size of which is 1.8m in length, 1.2m in width, and 12mm in thickness, is processed by floating double-shaft shoulder double-stirring needle cutting-friction stir welding combined processing equipment and its method, floating double-shaft shoulder double-stirring needle cutting- Friction stir welding composite processing technology: the rotation speed of the stirring head and the cutting knife is 1200r / min, the welding speed is 70mm / min, argon is used as the shielding gas, and the flow rate is 60L / min, and water-based environmentally friendly milling fluid is used for milling Processing, use the lead-out plate to take out the floating double-shaft shoulder double-stirring needle cutting-friction stir welding composite processing tool, so that no keyhole is left on the aluminum alloy plate, and use high-pressure gas to clean the hollow s...

example 2

[0085]Example 2: Manufacturing and processing of aluminum alloy honeycomb channel ice-making plates for ice energy storage. 6061 aluminum alloy material, its size is 2.4m in length, 1.6m in width, and 10mm in thickness. The aluminum alloy thick plate is fixed on the workbench through the clamp, so that the back of the aluminum alloy thick plate is solid and there is no gap. The use adopts cutting-stir friction Welding joint processing equipment and its method are used for processing; cutting-friction stir welding composite processing technology is adopted: the rotation speed of the stirring head and the cutting knife is 1000r / min, the welding speed is 50mm / min, and argon is used as the shielding gas. The flow rate is 42L / min, and the water-based environmentally friendly milling fluid is used for milling. The cutting-friction stir welding composite processing tool is taken out with the lead-out plate, so that no keyhole is left on the aluminum alloy plate, and the hollow honeyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com