Efficient air exhaust cooler

A cooler and high-efficiency technology, applied in the direction of exhaust devices, machines/engines, noise reduction devices, etc., can solve the problems of high power consumption and bulky cooling devices, and achieve the effect of low manufacturing cost, small size and high-efficiency cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

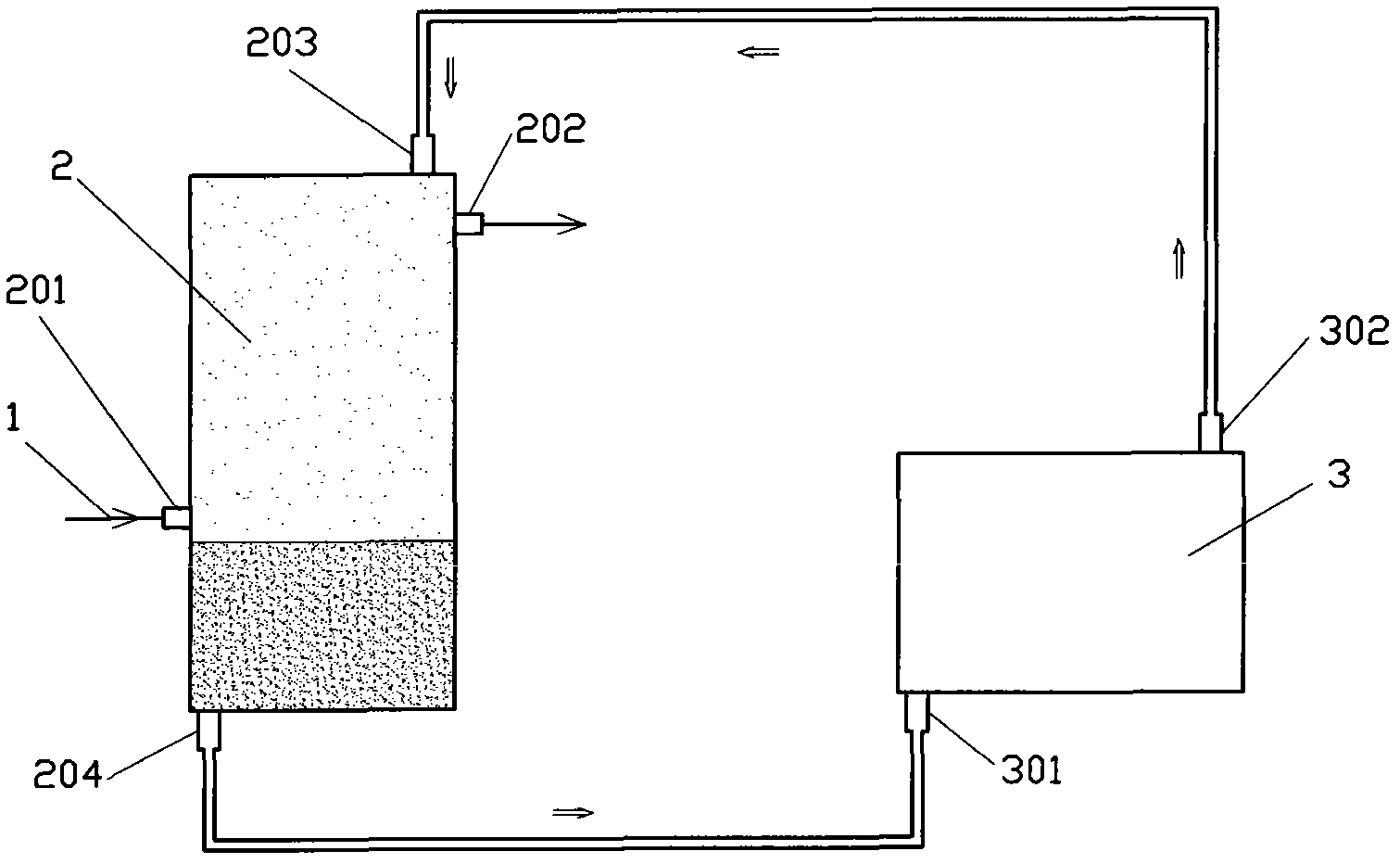

[0020] Such as figure 1 The exhaust gas high-efficiency cooler shown includes an engine exhaust passage 1, a mixer 2 and a heat exhauster 3, and an exhaust inlet 201, an exhaust outlet 202, a cooling liquid inlet 203 and a cooling liquid outlet 204 are arranged on the mixer 2 , the engine exhaust passage 1 communicates with the exhaust inlet 201 , the cooling liquid outlet 204 communicates with the cooled liquid inlet 301 of the heat exchanger 3 , and the cooled liquid outlet 302 of the heat exchanger 3 communicates with the cooling liquid inlet 203 .

Embodiment 2

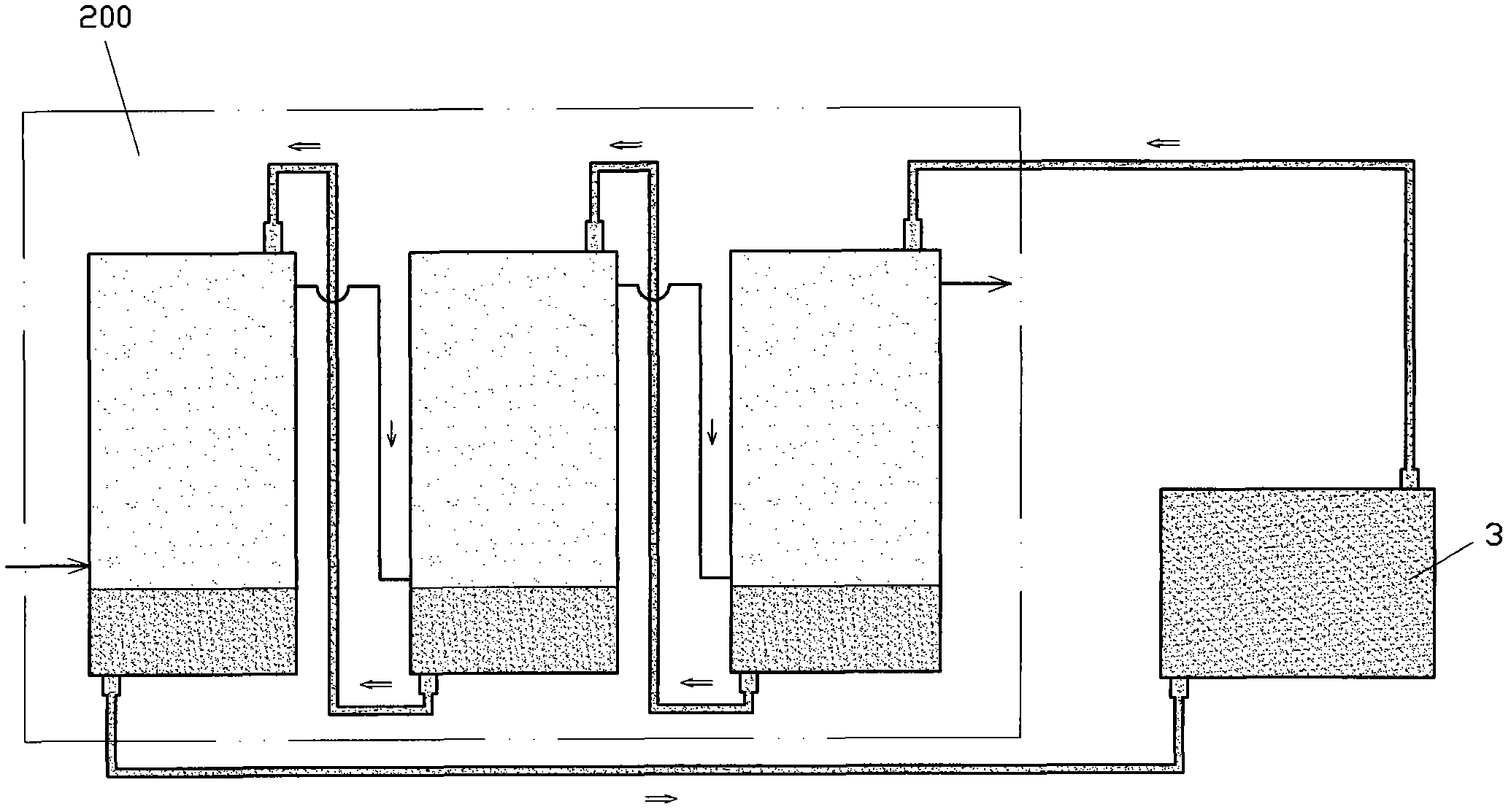

[0022] Such as figure 2 The difference between the exhaust gas high-efficiency cooler shown in Example 1 is that the mixer 2 is set as a multi-stage mixer 200 composed of two or more mixers 2 arranged in series in air flow and liquid flow in series.

Embodiment 3

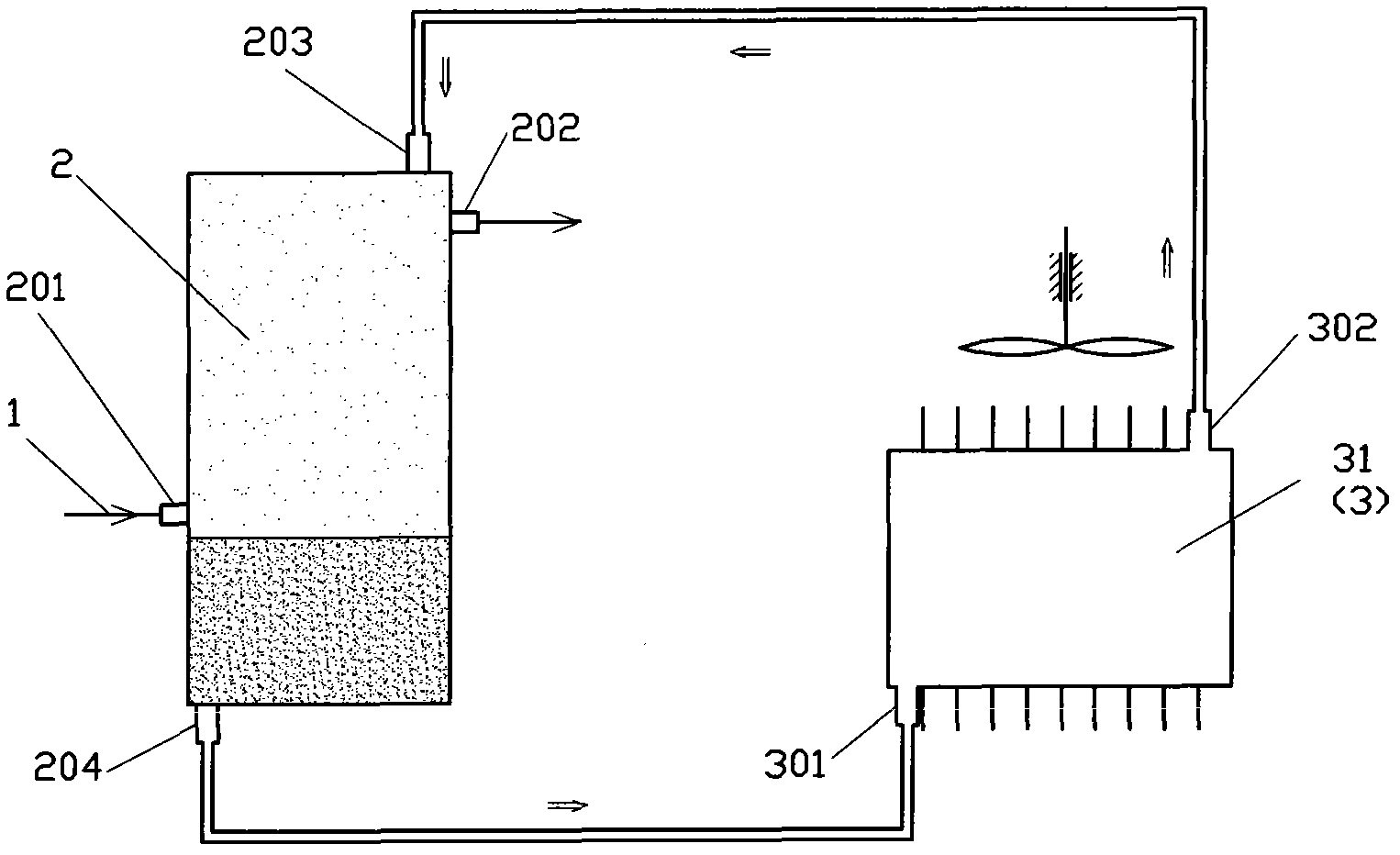

[0024] Such as image 3 The difference between the exhaust gas high-efficiency cooler shown in Embodiment 1 is that the radiator 3 is set as a radiator 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com