Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Efficient liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

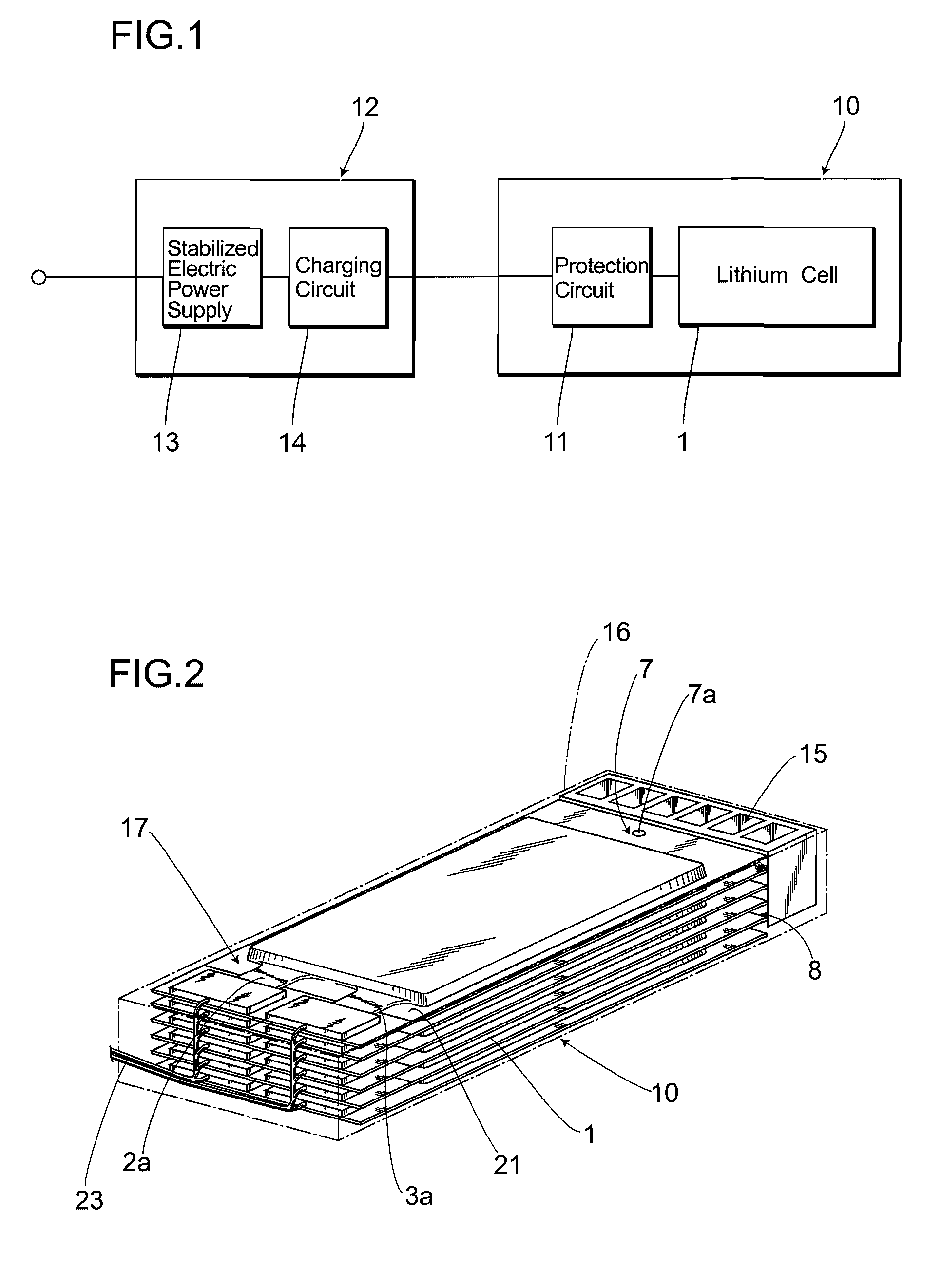

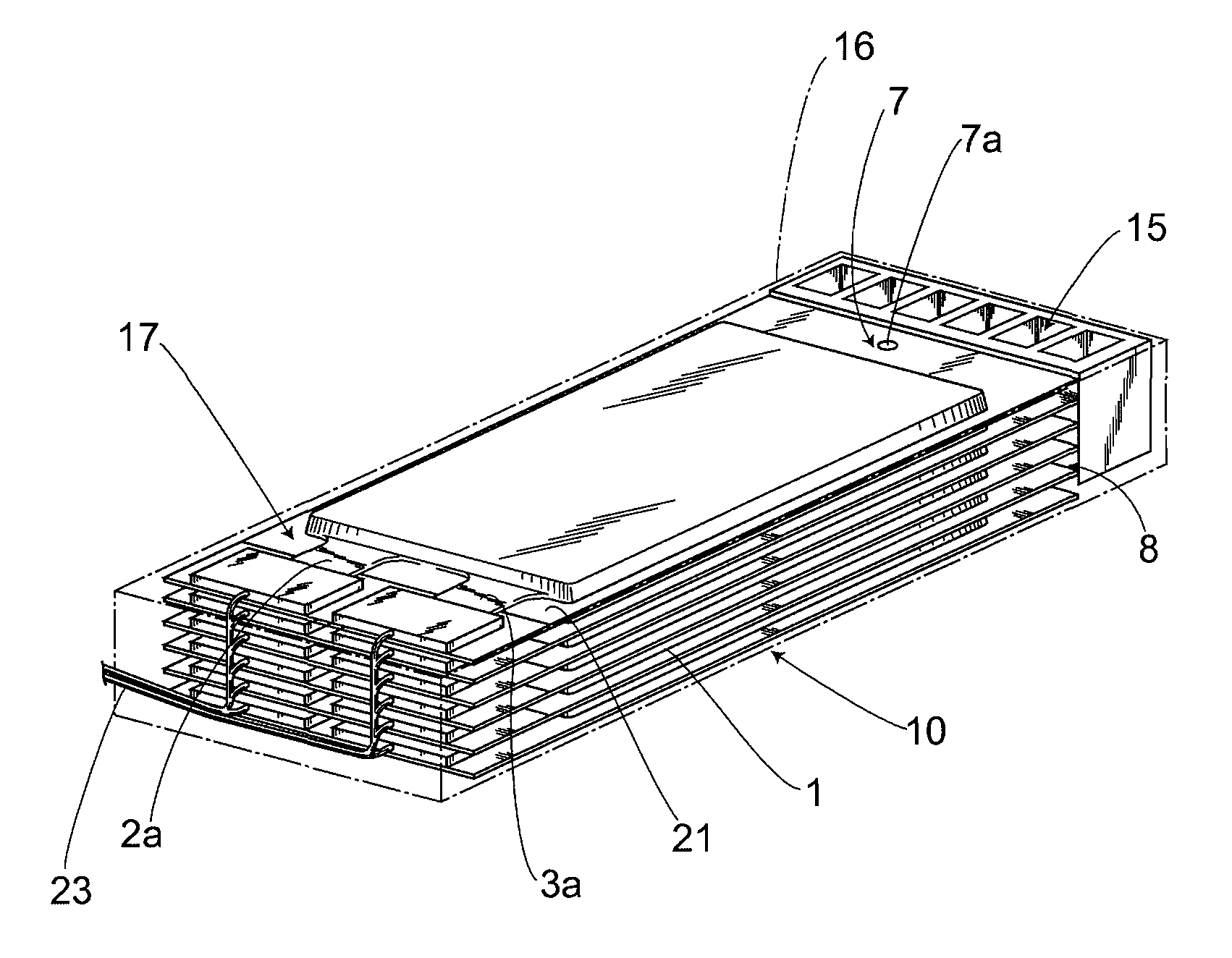

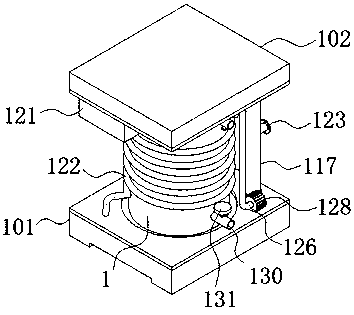

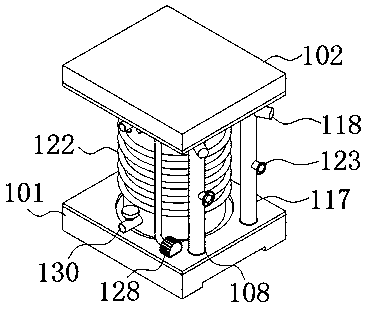

Battery pack

InactiveUS20090220851A1Easy to useFree from riskBattery isolationVent arrangementsOvervoltageBattery cell

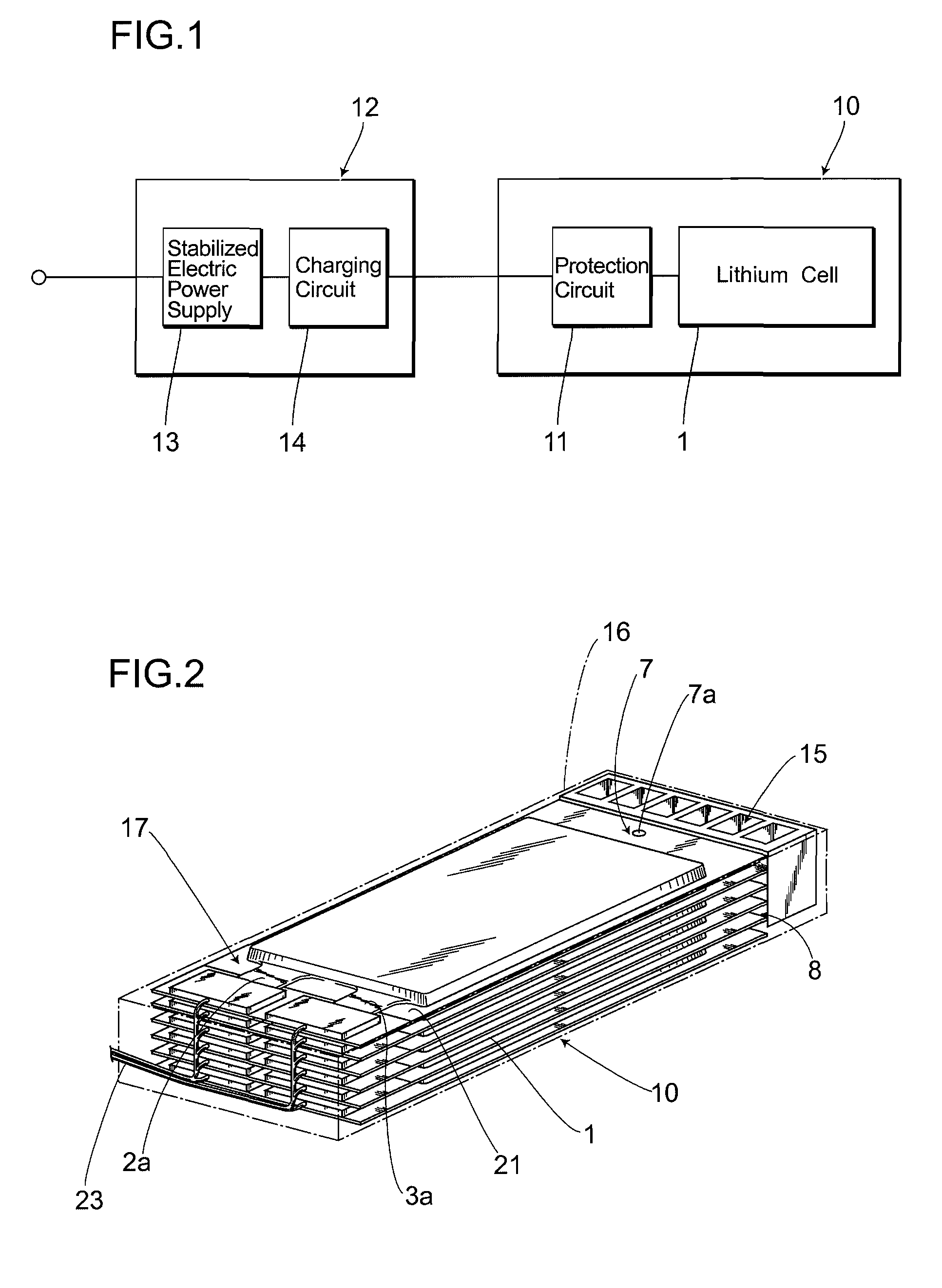

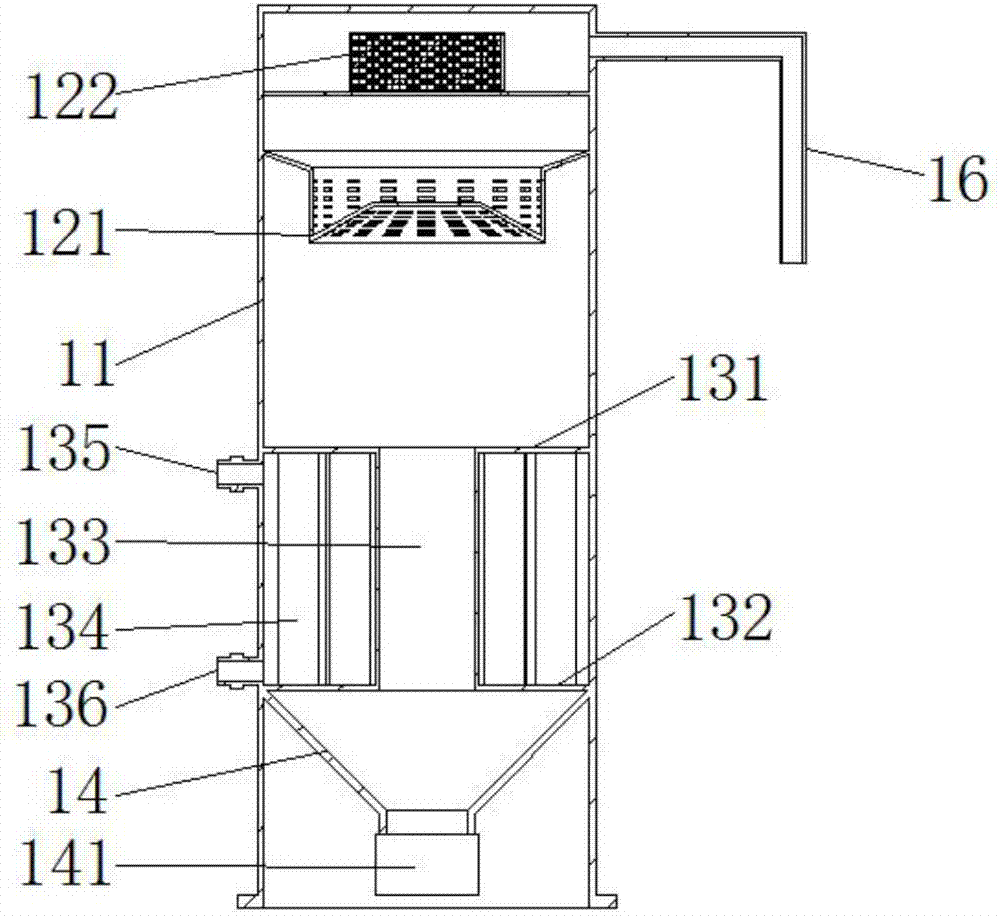

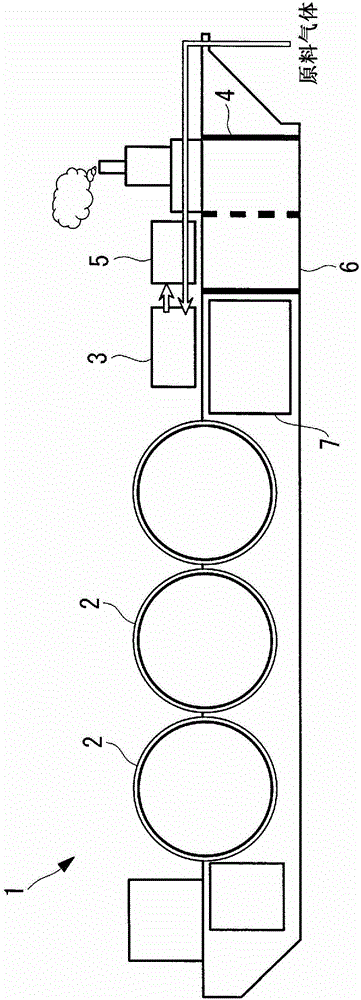

There is provided a risk-free and easy-to-use battery pack using battery cells 1 as a secondary battery, in which internal gases evaporated by applying overvoltage or the like thereto are processed inside a case to be prevented from leaking to the outside of the case and thereby even if the case has been led to rise in pressure due to a thermorunaway of the battery, the case is free from breaking. To realize this performance, the battery pack 10 is provided with a battery cell housing 17 for housing lithium cells 1 and a gas processor 15 for liquefying the internal gases g generated from the lithium cells 1.

Owner:TDK LAMBDA CORP

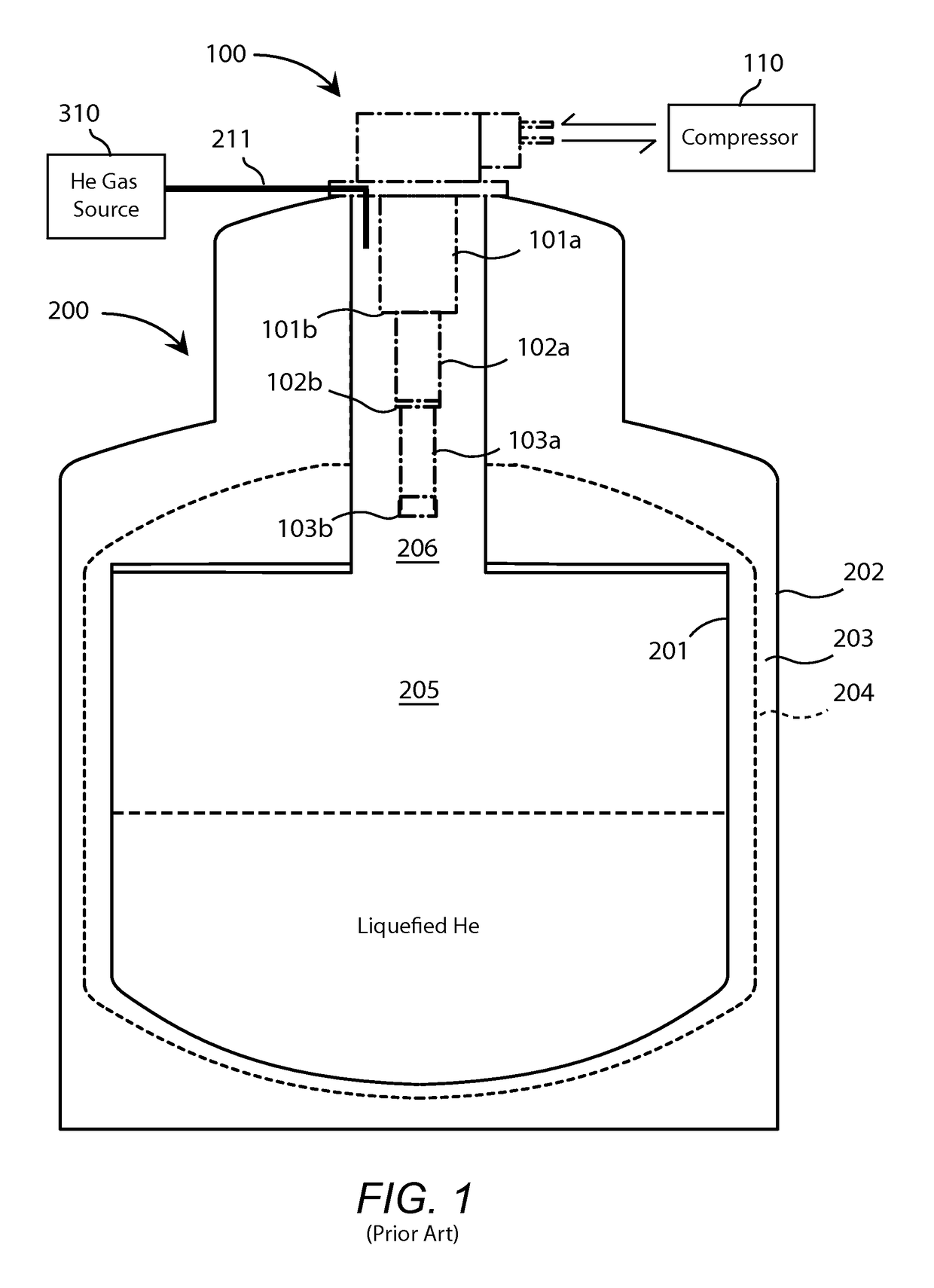

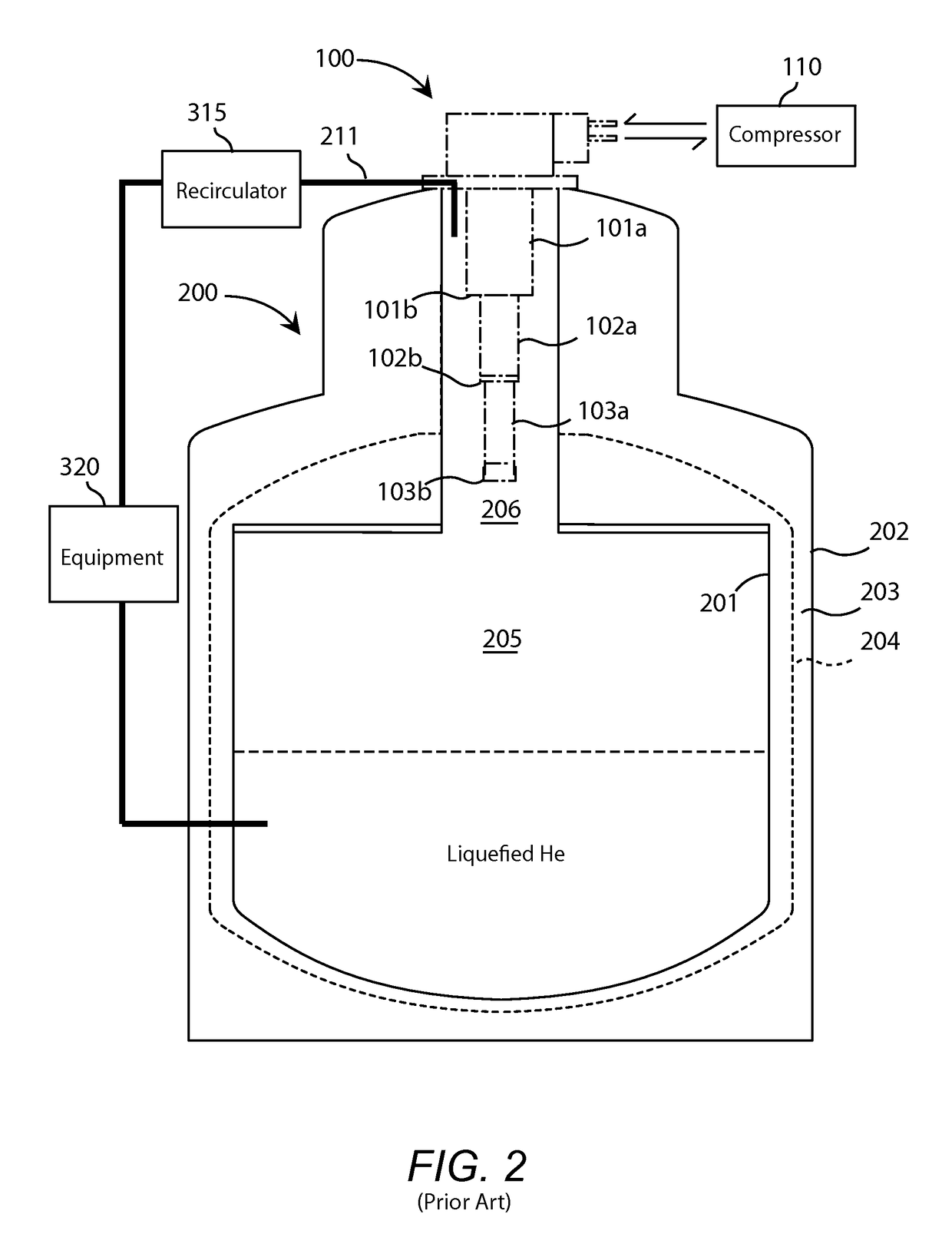

Liquefier with pressure-controlled liquefaction chamber

ActiveUS20130014517A1Improve liquefaction efficiencyIncrease cooling powerVessel mounting detailsSolidificationCounter flowEngineering

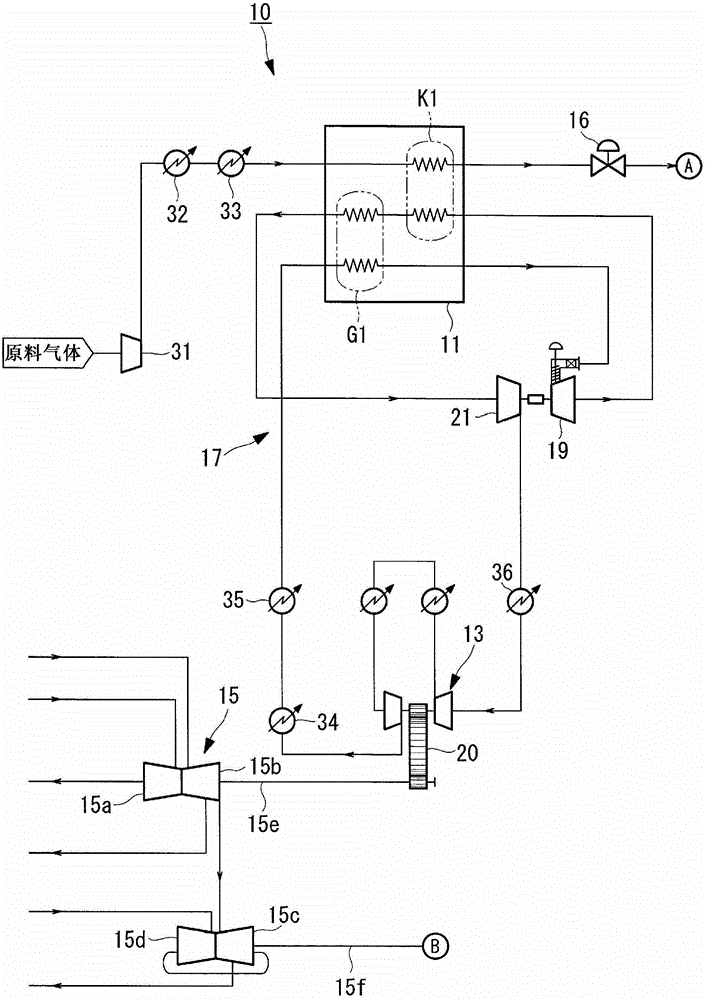

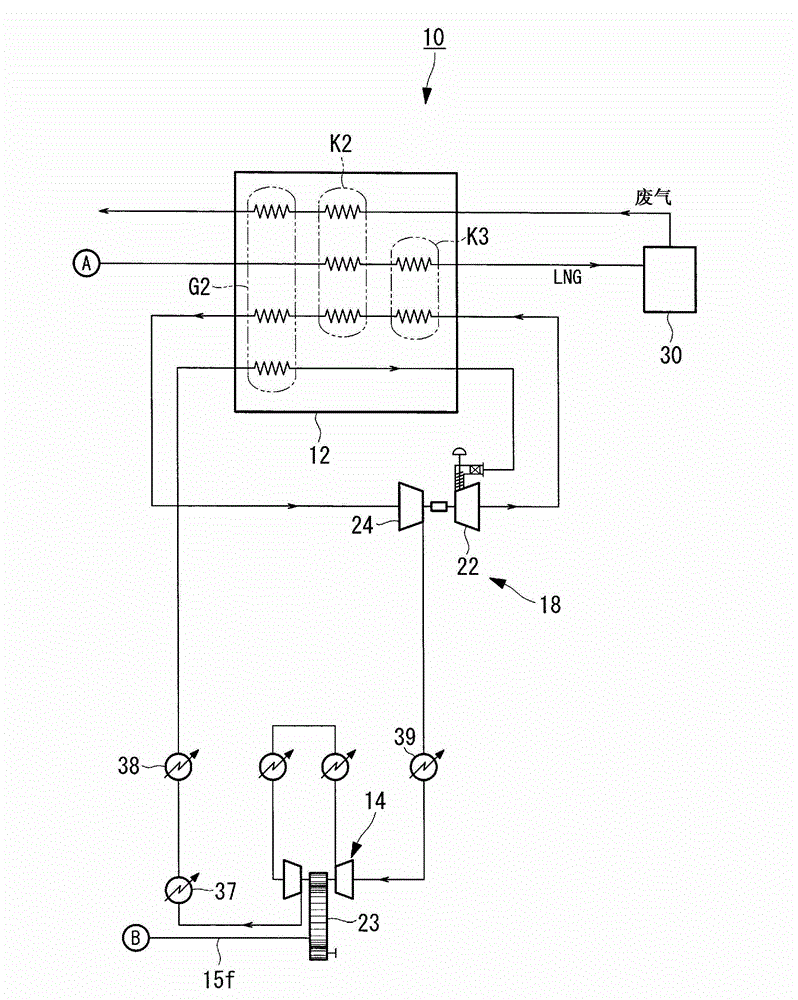

A liquefier includes a Dewar having a storage portion and a neck portion extending therefrom. A hermetically isolated liquefaction chamber is disposed within the neck of the Dewar. One or more control components including a temperature and pressure sensor are coupled to a CPU and disposed within the liquefaction chamber for dynamic control of liquefaction conditions. A gas flow control is coupled to the CPU for regulating an input gas flow into the liquefaction chamber. A volume surrounding the liquefaction chamber may be adapted to provide a counter-flow heat exchange. These and other features provide improved liquefaction efficiency among other benefits.

Owner:QUANTUM DESIGN

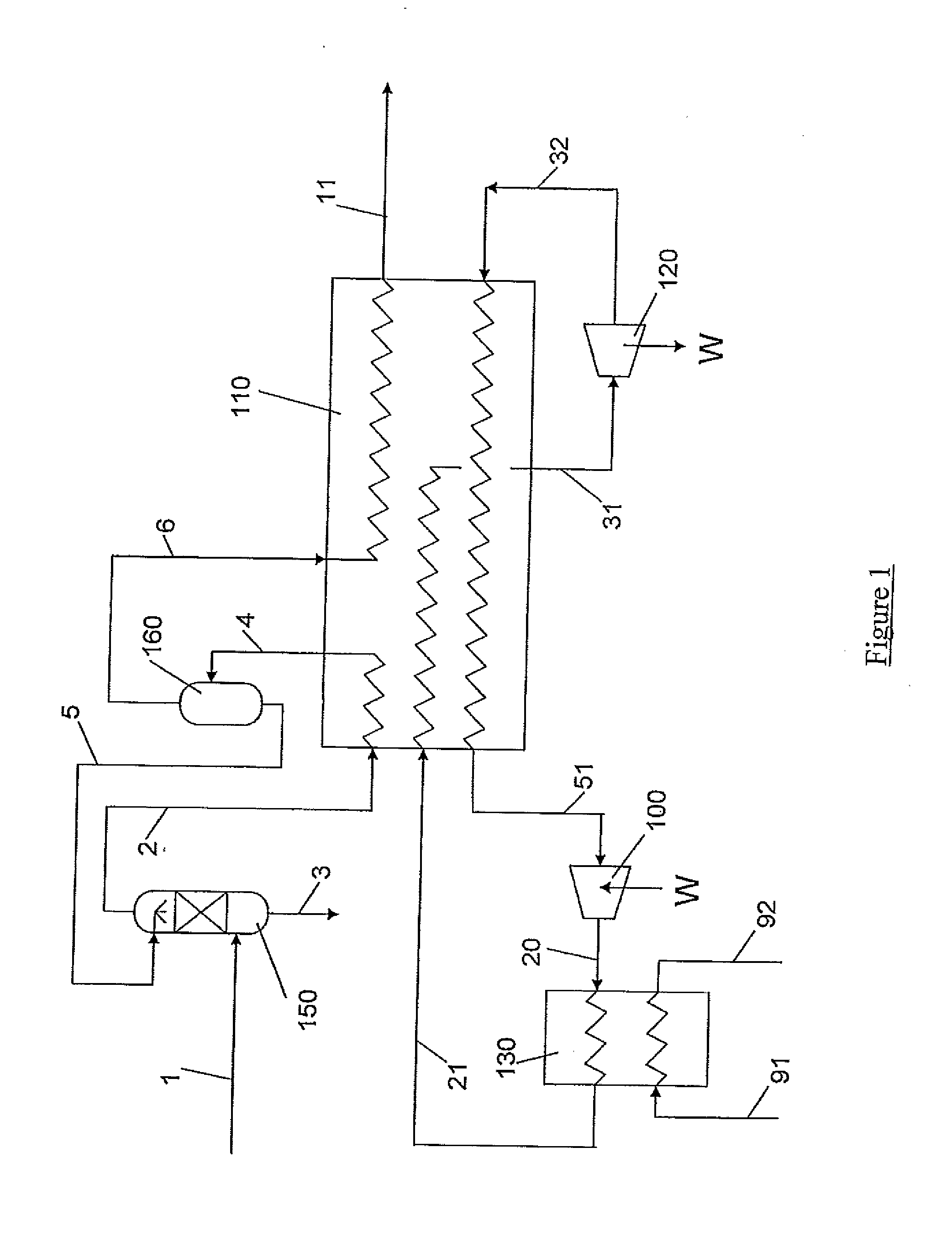

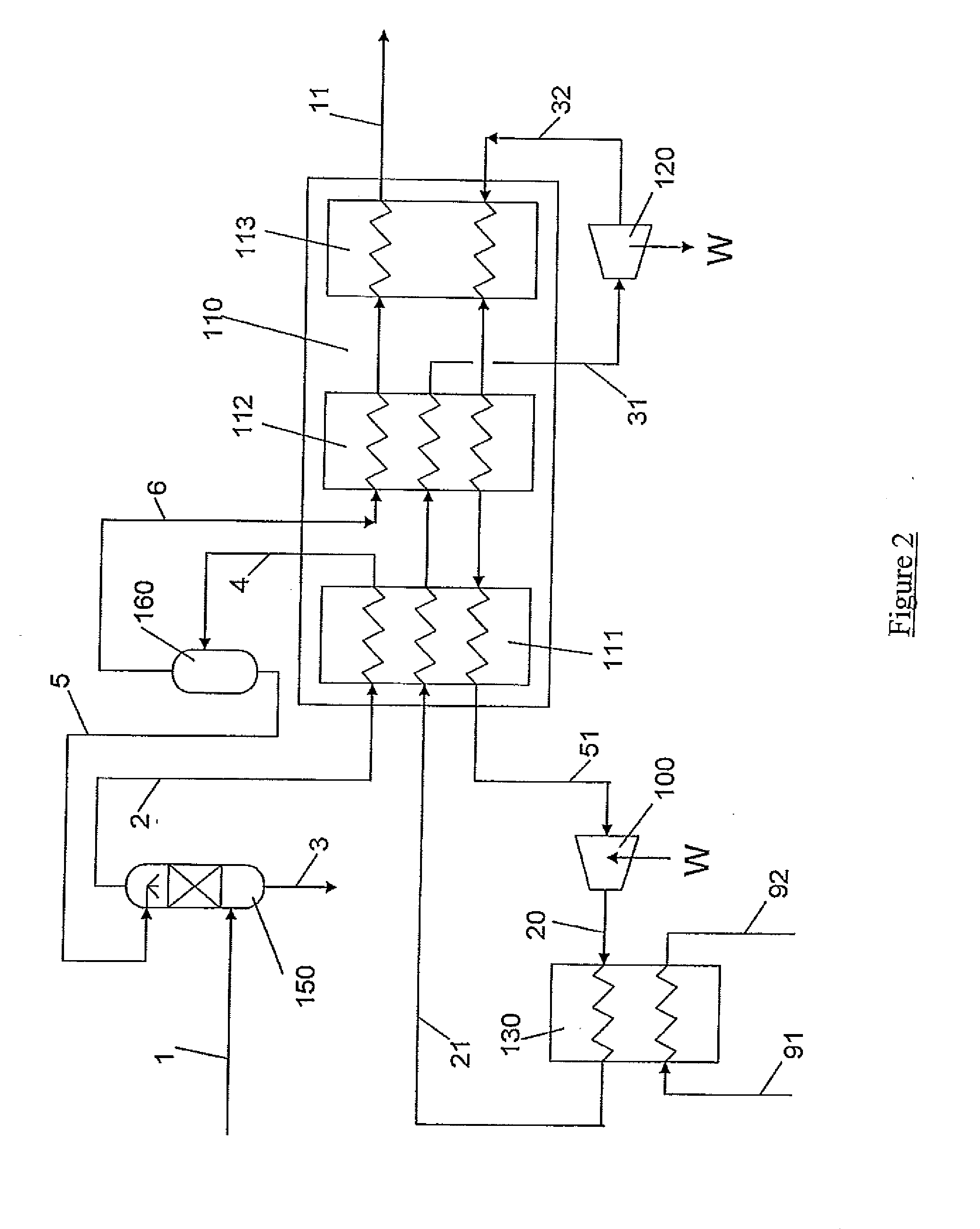

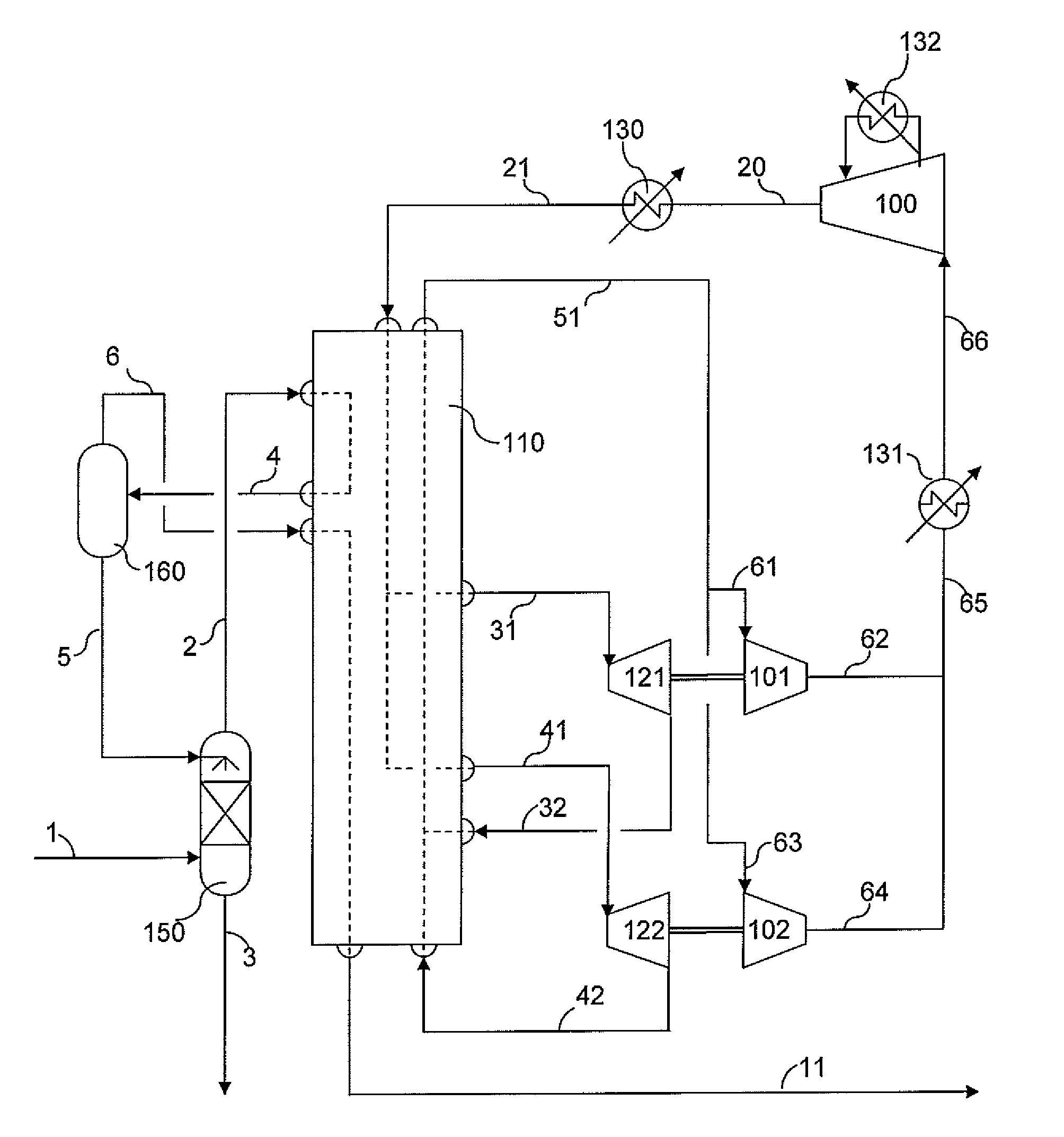

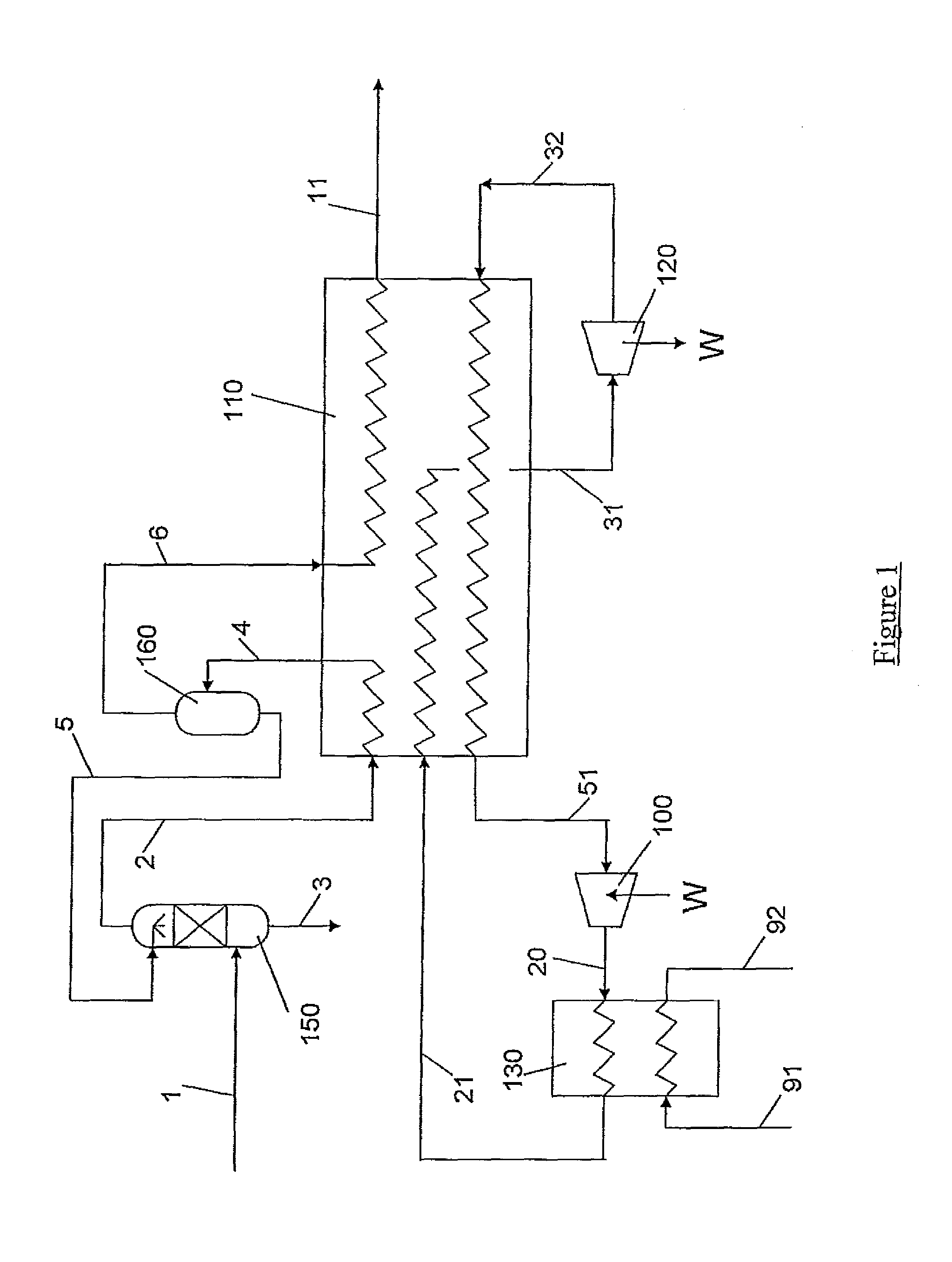

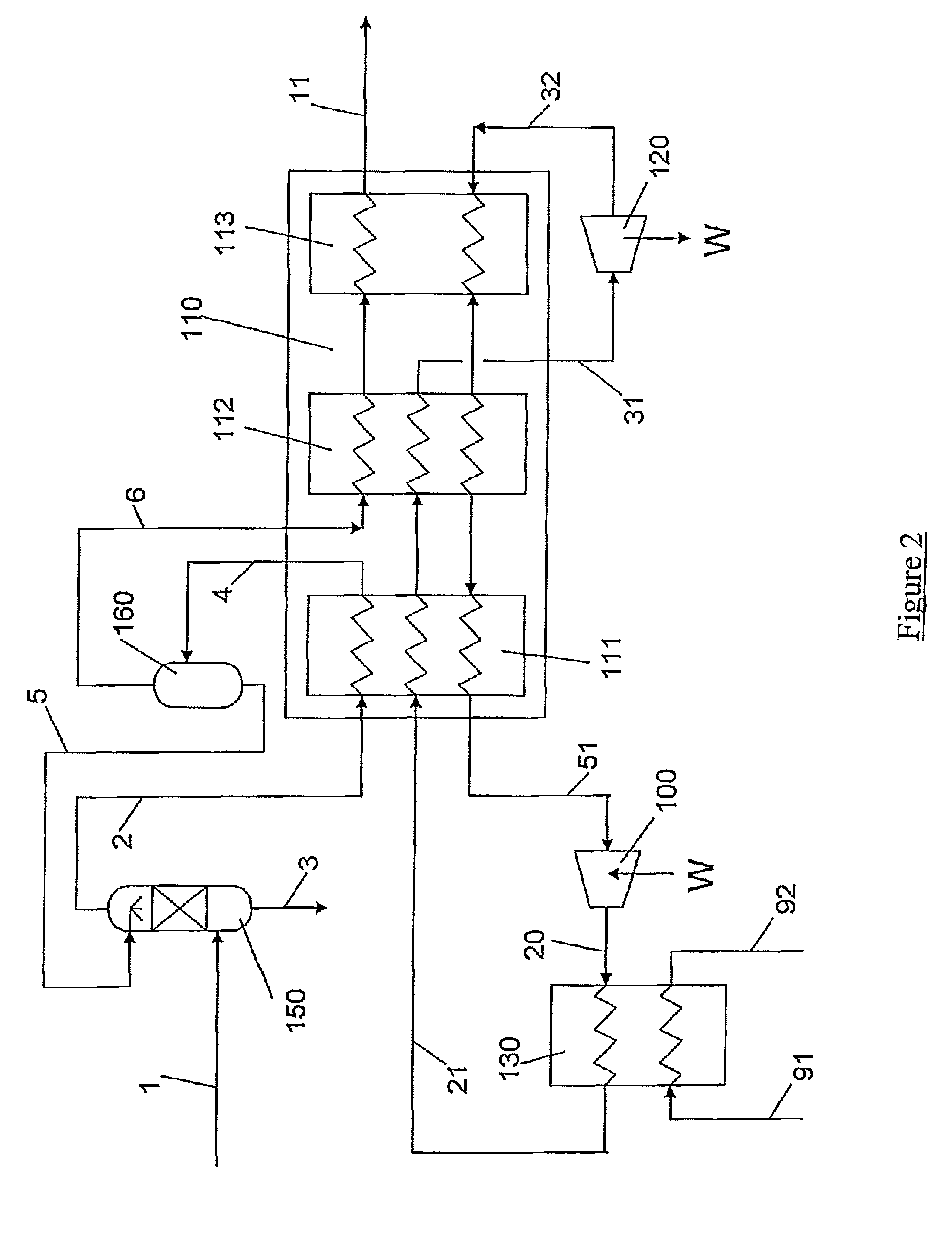

Method and system for producing liquefied natural gas (LNG)

ActiveUS20100154470A1Broaden applicationRobust and simple processSolidificationLiquefactionRefluxFractionation

A method and system for optimizing the efficiency of an LNG liquification system of the gas expansion type, wherein an incoming feed gas is first separated in a fractionation column by counter current contact with a cold reflux fluid, and a gaseous stream introduced into the heat exchanger system at a reduced temperature such that an intermediate pinch point is created in the warm composite curve.

Owner:ARAGON AS

Battery pack

InactiveUS7964300B2Efficient liquefactionAvoid residueBattery isolationVent arrangementsOvervoltageEngineering

There is provided a risk-free and easy-to-use battery pack using battery cells 1 as a secondary battery, in which internal gases evaporated by applying overvoltage or the like thereto are processed inside a case to be prevented from leaking to the outside of the case and thereby even if the case has been led to rise in pressure due to a thermorunaway of the battery, the case is free from breaking. To realize this performance, the battery pack 10 is provided with a battery cell housing 17 for housing lithium cells 1 and a gas processor 15 for liquefying the internal gases g generated from the lithium cells 1.

Owner:TDK LAMBDA CORP

Process for producing aqueous pigment liquid dispersion and ink-jet recording ink

InactiveUS20090326118A1Good dispersionImprove adsorption capacityInksOrganic dyesLiquid stateAqueous medium

The applicants provide a process for producing an aqueous pigment liquid dispersion that is formed by mixing a solid kneaded mixture containing a pigment (a) containing mainly an azo-type pigment, a styrene-acrylic acid copolymer (b), a basic compound (c), and a wetting agent (d1), with an aqueous medium, the process including a liquefaction step of adding water (e) and a wetting agent (d2) while continuing the kneading of the solid kneaded mixture, thereby generating a liquid state, wherein the total quantity of the wetting agent (d2) added in the liquefaction step is within a range from 0.5 to 40 mass % of the solid kneaded mixture at the point of initiation of the liquefaction step.

Owner:DAINIPPON INK & CHEM INC

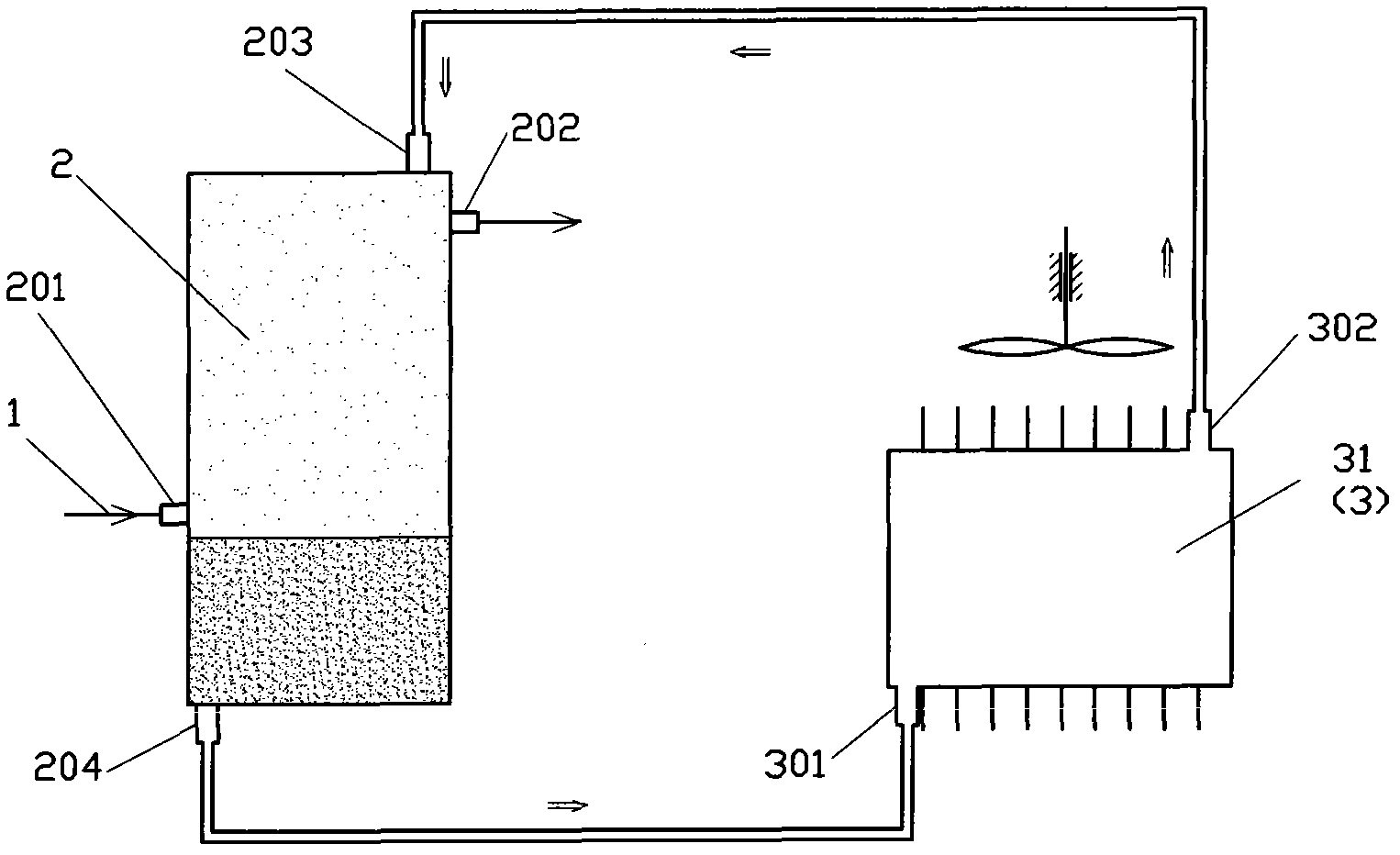

Parallel-connected condenser and cooling device using the same

InactiveUS20190078846A1Increase flow rateSatisfactory cooling performance of coolingSemiconductor/solid-state device detailsStationary conduit assembliesEvaporatorEngineering

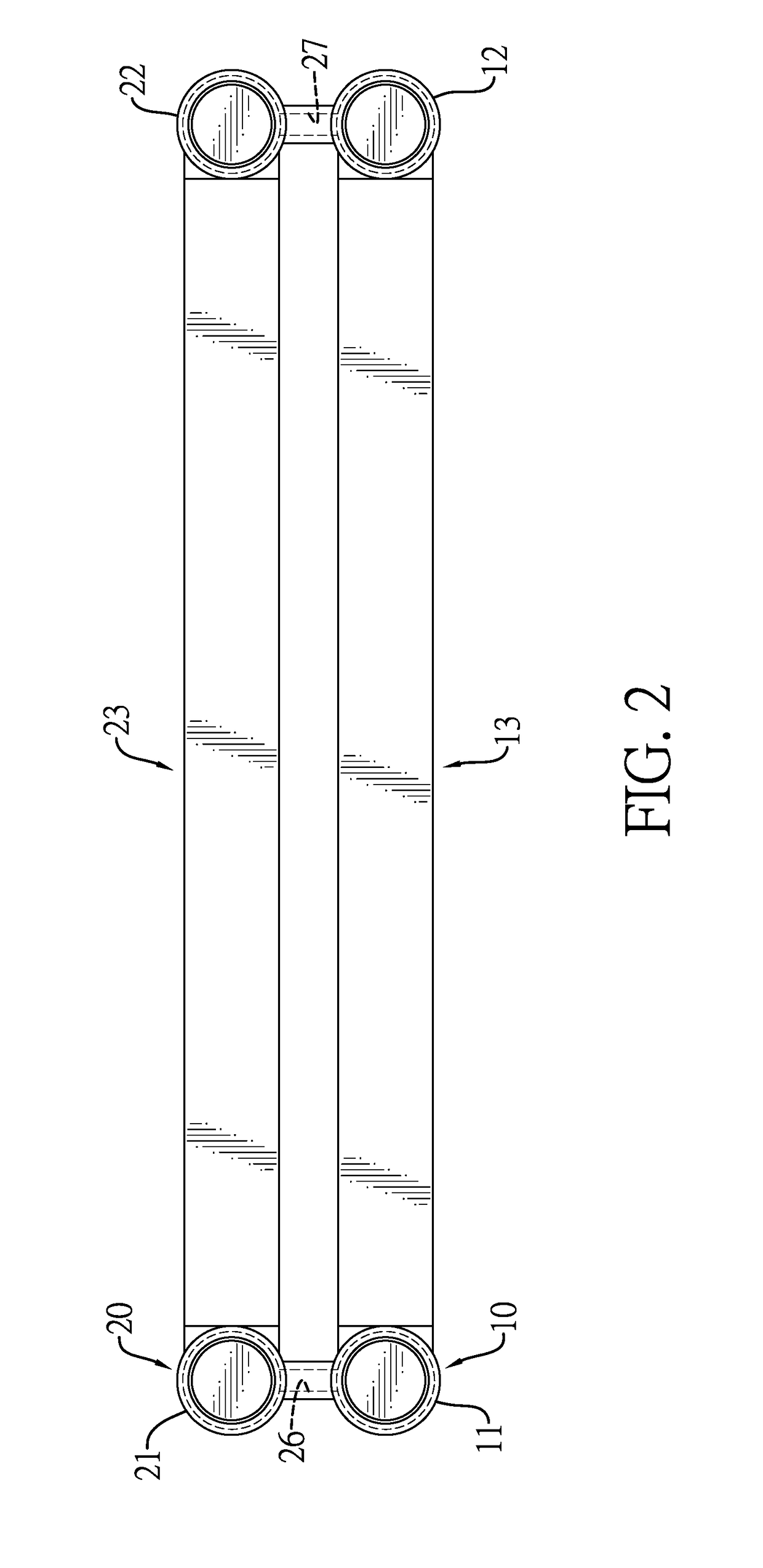

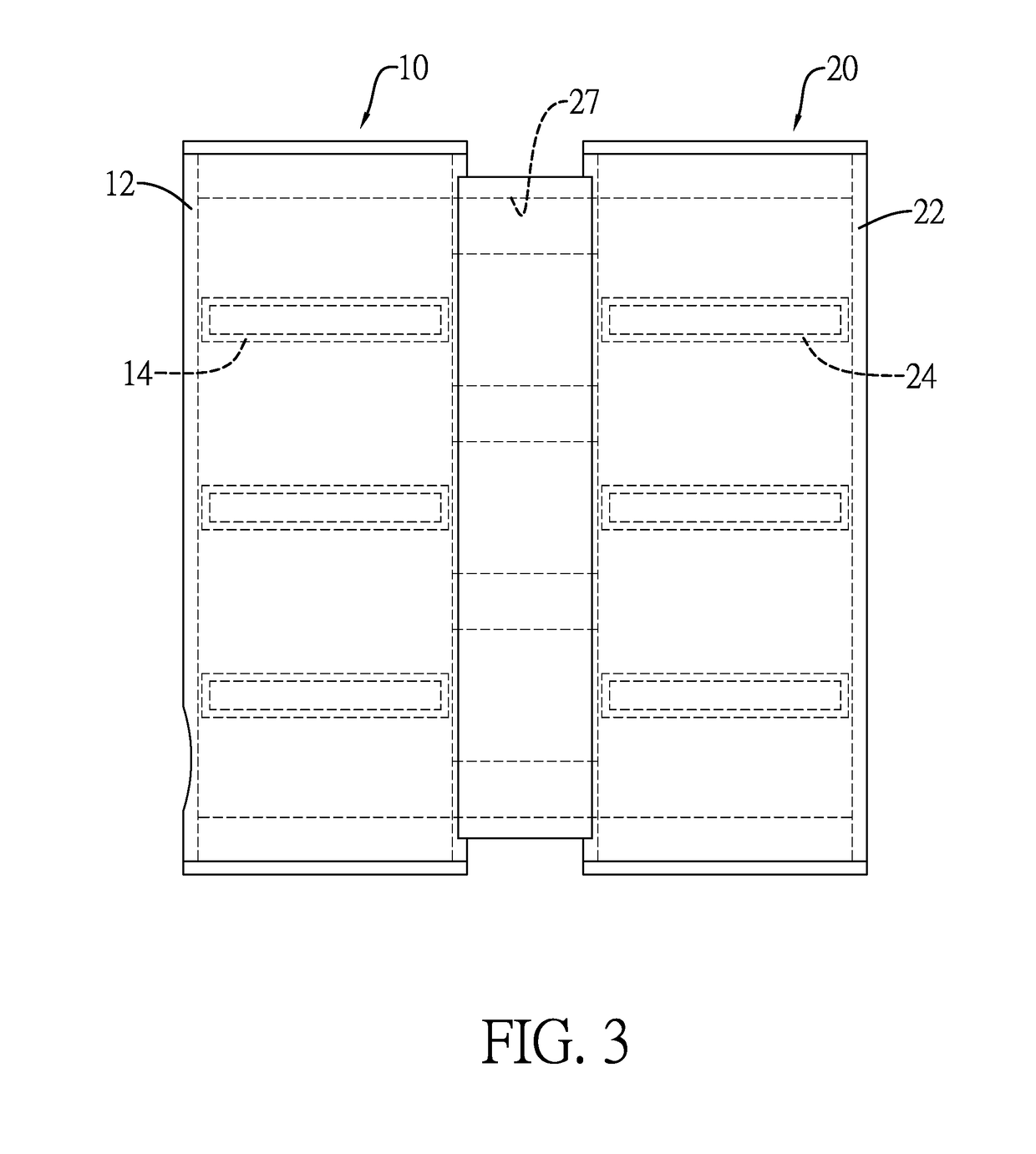

A cooling device includes a parallel-connected condenser and an evaporator assembly. The parallel-connected condenser has a primary condenser assembly and at least one auxiliary condenser assembly. The evaporator assembly includes an evaporator, a coolant input pipe and a coolant output pipe. Two ends of the coolant input pipe are respectively connected to the evaporator and a first primary condenser tube. Two ends of the coolant output pipe are respectively connected to the evaporator and a second primary condenser tube for the parallel-connected condenser and the evaporator assembly to form a closed coolant circulation loop with coolant filled therein. By virtue of the primary condenser assembly and the auxiliary condenser assembly parallelly connected, gaseous coolant can be circulated through different paths and liquefied to effectively enhance cooling and liquefaction efficiency of coolant when the coolant is circulated through the cooling device.

Owner:MAN ZAI IND

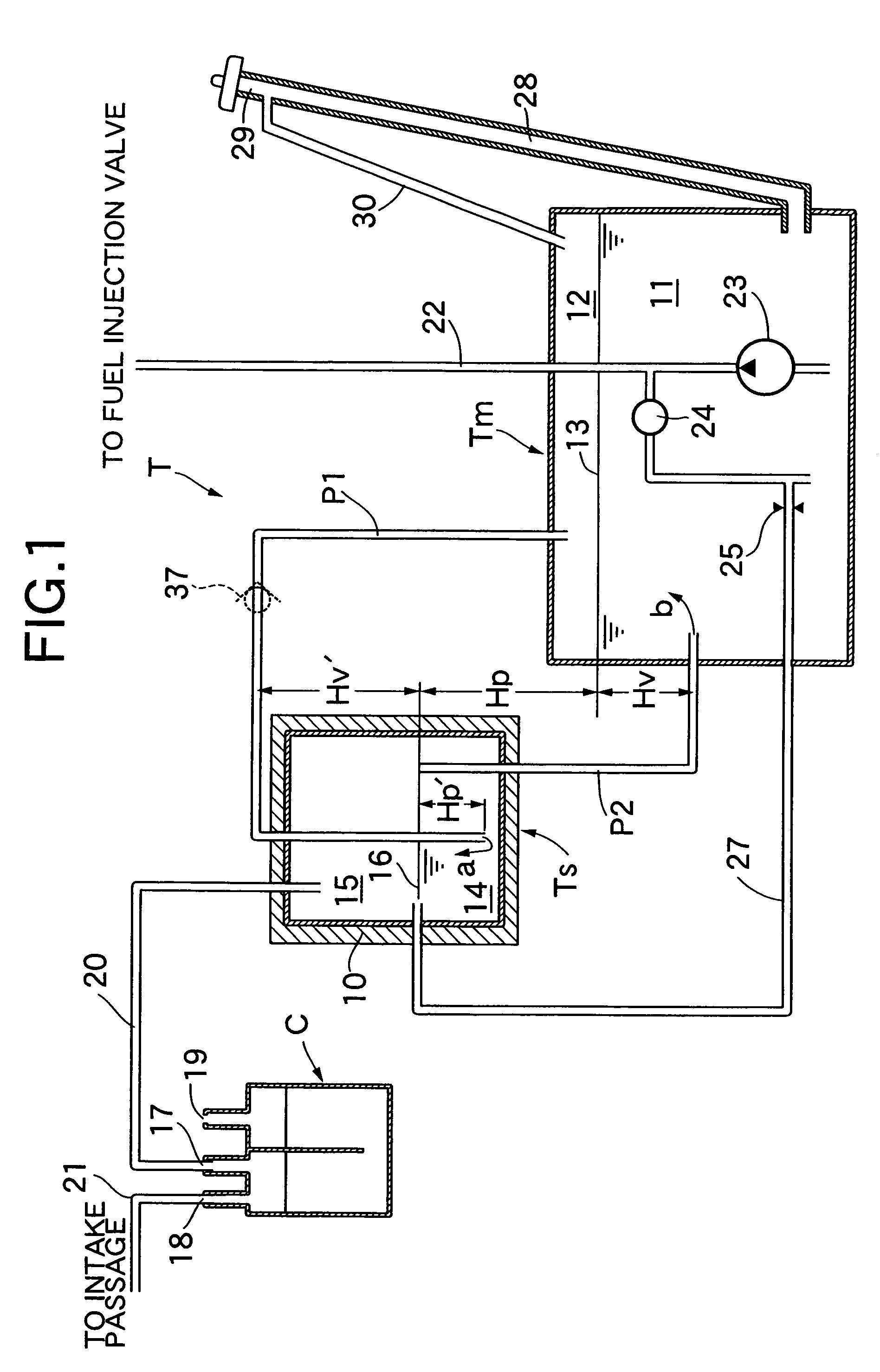

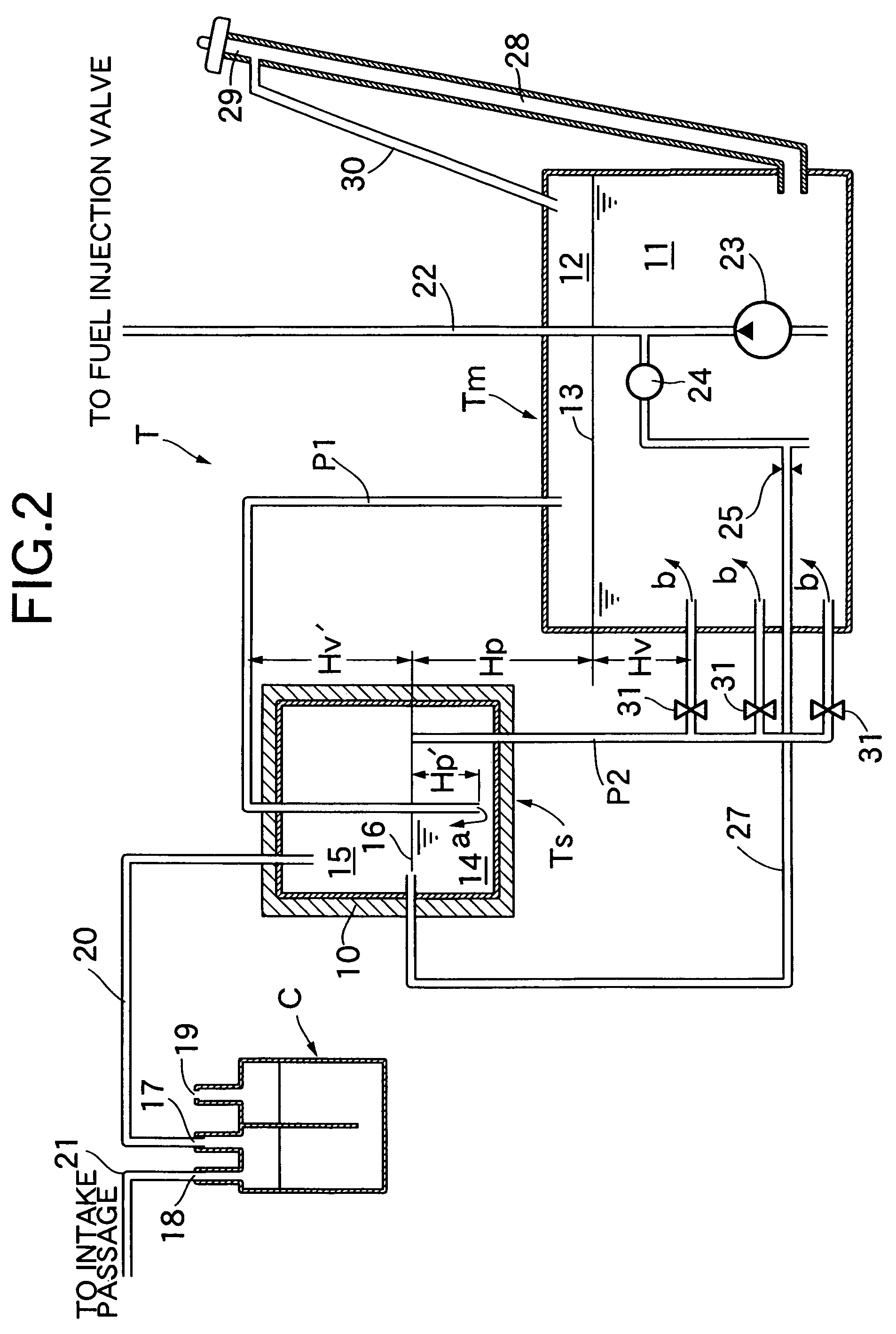

Fuel vapor release suppression system for fuel tank

InactiveUS7380543B2Efficient liquefactionNon-fuel substance addition to fuelPipeline systemsPressure decreaseEngineering

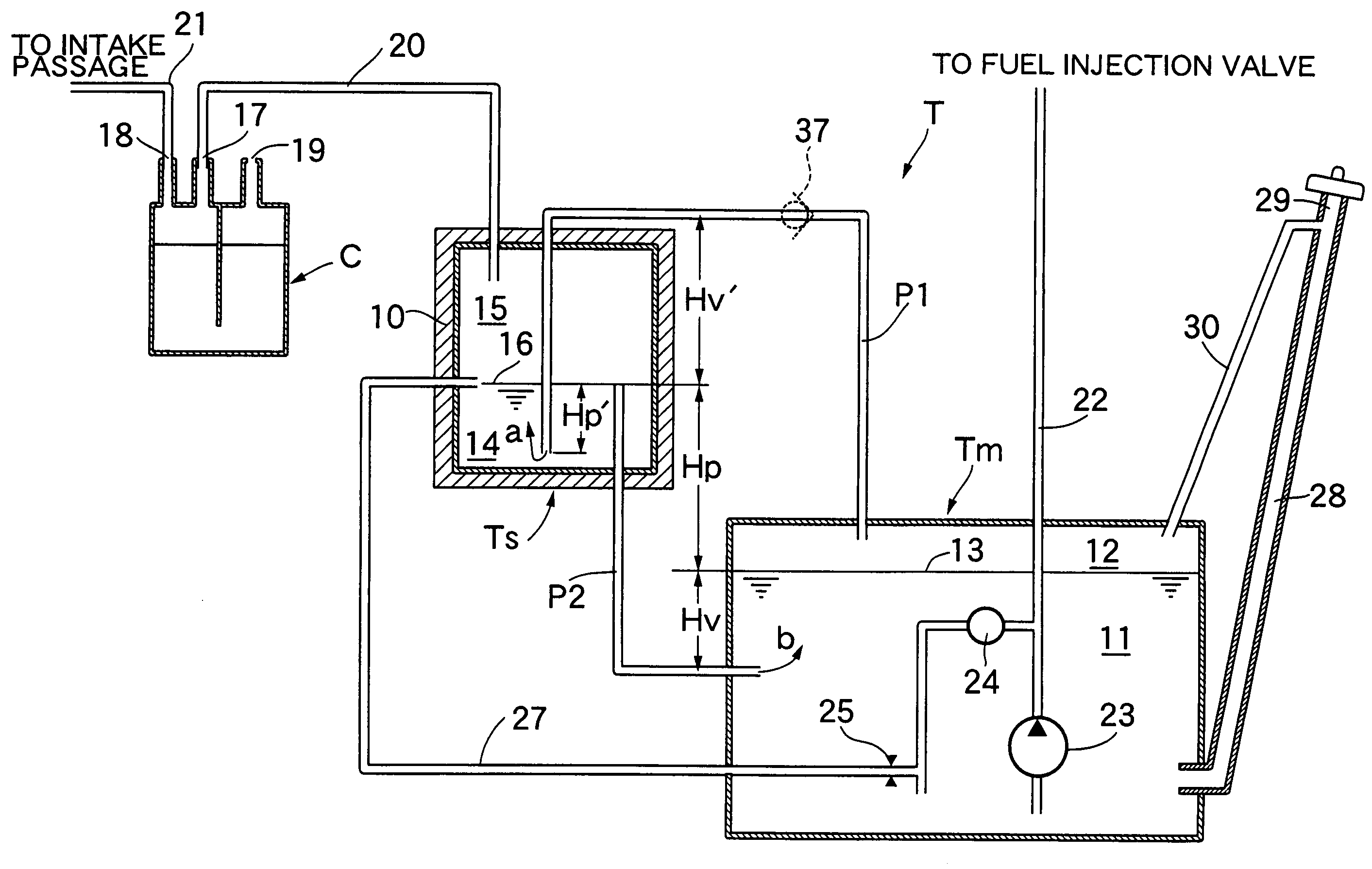

In a fuel vapor release suppression system for a fuel tank, a main tank and a sub tank communicate with each other, and the sub tank and a canister communicate with each other. When the main tank has a higher temperature, fuel vapor of the main tank is supplied to the sub tank where the fuel vapor is liquefied. When the main tank has a lower temperature, fuel vapor of the sub tank is supplied to the main tank. At this time, low concentration fuel vapor is supplied from the canister to the main tank, thereby accelerating generation of fuel vapor corresponding to sub tank fuel vapor pressure, so that the sub tank fuel vapor pressure decreases. Therefore, liquefaction is accelerated in the sub tank when the main tank temperature increases. Thus, fuel vapor generated in a fuel tank is effectively liquified irrespective of ambient air temperature.

Owner:HONDA MOTOR CO LTD

Method of recovering ammonia and method of recycling ammonia by using the same

ActiveUS20130312456A1Improve purification effectPromote recoverySolidificationLiquefactionHydrogenNitrogen

There are provided methods capable of easily and efficiently recovering and recycling ammonia from exhaust gas containing a small amount of ammonia, the exhaust gas being exhausted from a production process of a gallium nitride compound semiconductor. The method of recovering ammonia includes filtering exhaust gas containing ammonia, hydrogen, nitrogen, and a solid compound with a filter to remove the solid compound from the exhaust gas; pressurizing and cooling the filtered exhaust gas with a heat pump to liquefy ammonia contained in the filtered exhaust gas; and separating liquefied ammonia from hydrogen and nitrogen to recover liquefied ammonia. The method of recycling ammonia includes evaporating recovered liquid ammonia; mixing the evaporated ammonia with another crude ammonia to obtain mixed gas; purifying the mixed gas; and supplying the purified gas to the production process of a gallium nitride compound semiconductor.

Owner:JAPAN PIONICS

Efficient air exhaust cooler

InactiveCN102094697AEfficient coolingReduce volumeExhaust apparatusSilencing apparatusExhaust gasChiller

The invention discloses an efficient air exhaust cooler which comprises an engine air exhaust duct, a mixer and a heat radiator, wherein the mixer is provided with an air exhaust inlet, an air exhaust outlet, a cooling liquid inlet and a cooling liquid outlet; the engine air exhaust duct is communicated with the air exhaust inlet; the cooling liquid outlet is communicated with the cooled liquid inlet of the heat radiator; and the cooled liquid outlet of the heat radiator is communicated with the cooling liquid inlet. According to the invention, the exhaust air in a thermal motive system can be cooled, liquefied and / or solidified efficiently.

Owner:靳北彪

Compression type exhaust gas self cooling system

ActiveCN102213158AImprove cooling effectEfficient liquefactionInternal combustion piston enginesEngine componentsGas phaseGas compressor

The invention discloses a compression type exhaust gas self cooling system. The system comprises a thermal power system, a thermal power system exhaust path, an exhausting thermal power unit, a gas compressor, a first heat exhauster, a second heat exhauster and an expansion unit, wherein the thermal power system exhaust path of the thermal power system is communicated with the gas inlet of the exhausting thermal power unit; the exhaust port of the exhausting thermal power unit is communicated with the cooled gas inlet of the first heat exhauster; the cooled gas outlet of the first heat exhauster is communicated with the gas inlet of the gas compressor; the compressed gas outlet of the gas compressor is communicated with the cooled gas inlet of the second heat exhauster; the cooled gas outlet of the second heat exhauster is communicated with the gas inlet of the expansion unit; and the exhausting thermal power unit outputs power to the gas compressor or outputs power to the gas compressor in a compensatory manner. The system disclosed by the invention has the following beneficial effect: the closed gas phase cycle of the thermal power system can be efficiently realized and the exhaust of the thermal power system to the environment can be reduced or eliminated.

Owner:张家港市乐余科创园投资发展有限公司

Detergents for cold-water cleaning

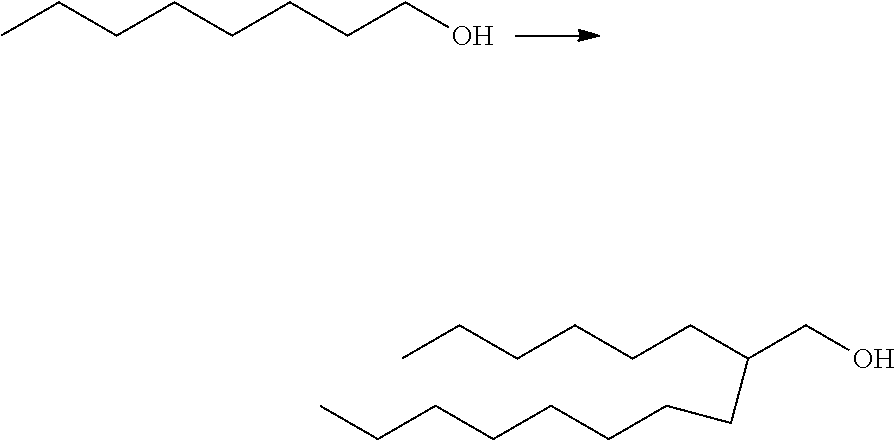

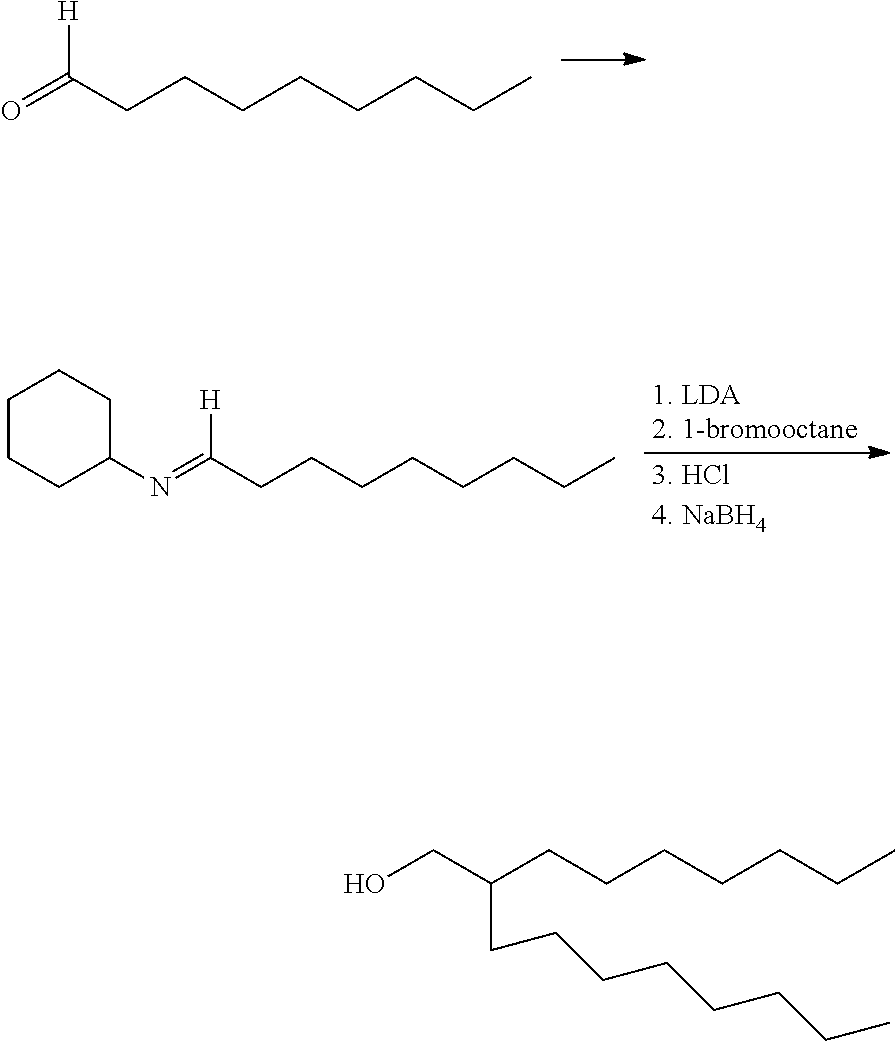

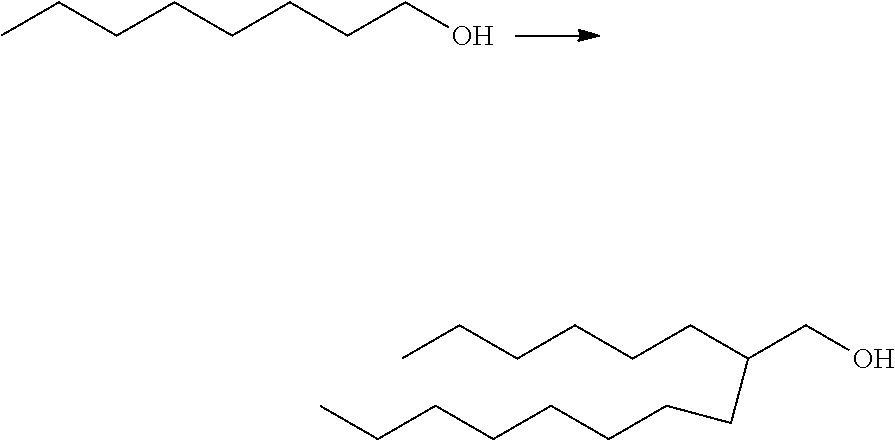

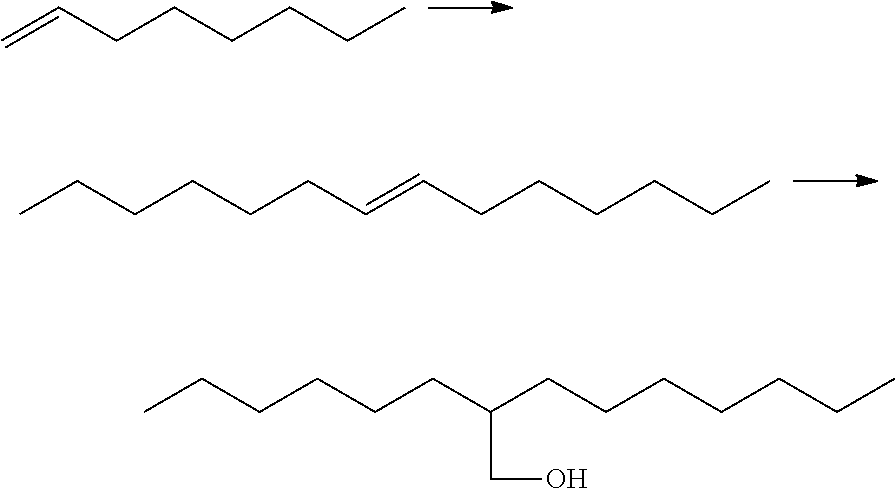

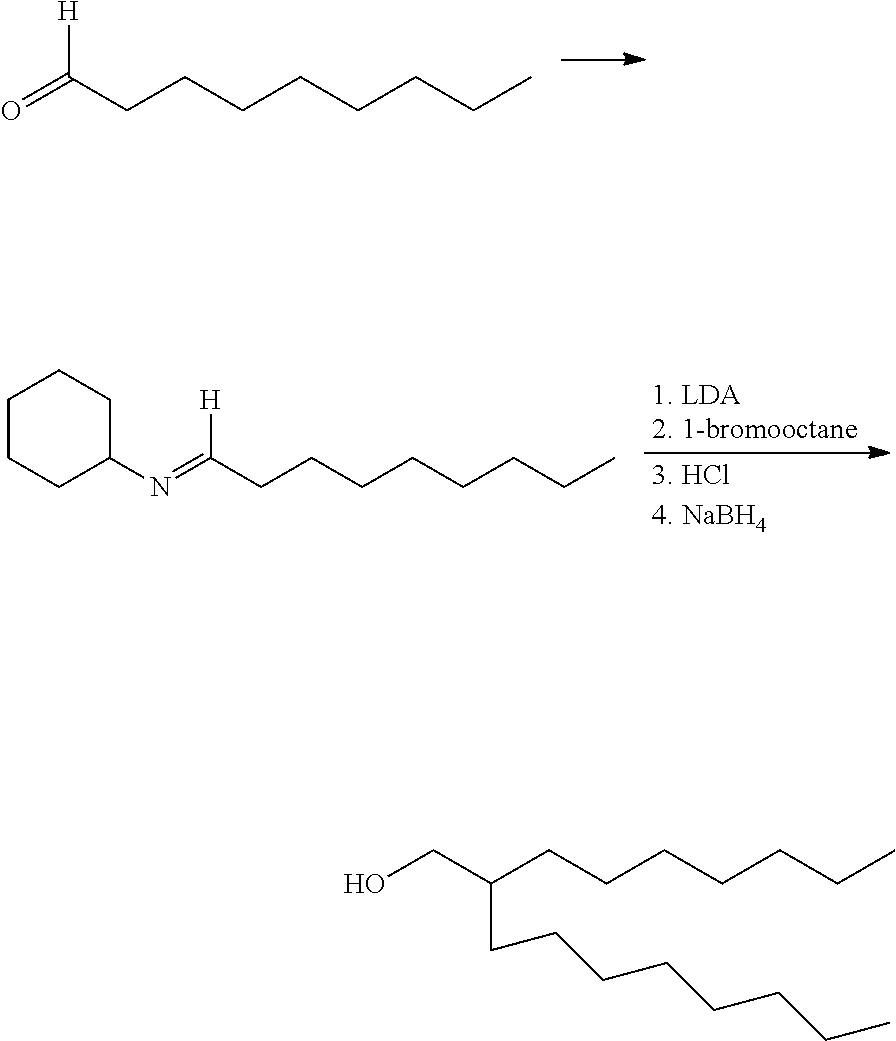

ActiveUS20170066998A1Efficient liquefactionImprove performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsBetainePhosphate

Detergents useful for cold-water cleaning and mid-chain headgroup and alkylene-bridged surfactants useful therein are disclosed. The mid-chain headgroup surfactant has a C14-C30 alkyl chain and a polar group bonded to a central zone carbon of the alkyl chain. The alkylene-bridged surfactant has a C12-C18 alkyl chain, a polar group, and a C1-C2 alkylene group bonded to the polar group and a central zone carbon of the C12-C18 alkyl chain. Preferred surfactants in these classes are alcohol sulfates, alcohol ethoxylates, ether sulfates, sulfonates, arylsulfonates, alcohol phosphates, amine oxides, quaterniums, betaines, and sulfobetaines. Surprisingly, detergents formulated with the surfactants provide outstanding cold-water performance in removing greasy stains such as bacon grease, butter, cooked beef fat, or beef tallow from soiled articles.

Owner:STEPAN COMPANY

Method of recovering ammonia and method of recycling ammonia by using the same

ActiveUS8889090B2Easily and efficiently recovering and recyclingEfficient liquefactionHydrogenSolidificationPhysical chemistryExhaust fumes

There are provided methods capable of easily and efficiently recovering and recycling ammonia from exhaust gas containing a small amount of ammonia, the exhaust gas being exhausted from a production process of a gallium nitride compound semiconductor. The method of recovering ammonia includes filtering exhaust gas containing ammonia, hydrogen, nitrogen, and a solid compound with a filter to remove the solid compound from the exhaust gas; pressurizing and cooling the filtered exhaust gas with a heat pump to liquefy ammonia contained in the filtered exhaust gas; and separating liquefied ammonia from hydrogen and nitrogen to recover liquefied ammonia. The method of recycling ammonia includes evaporating recovered liquid ammonia; mixing the evaporated ammonia with another crude ammonia to obtain mixed gas; purifying the mixed gas; and supplying the purified gas to the production process of a gallium nitride compound semiconductor.

Owner:JAPAN PIONICS

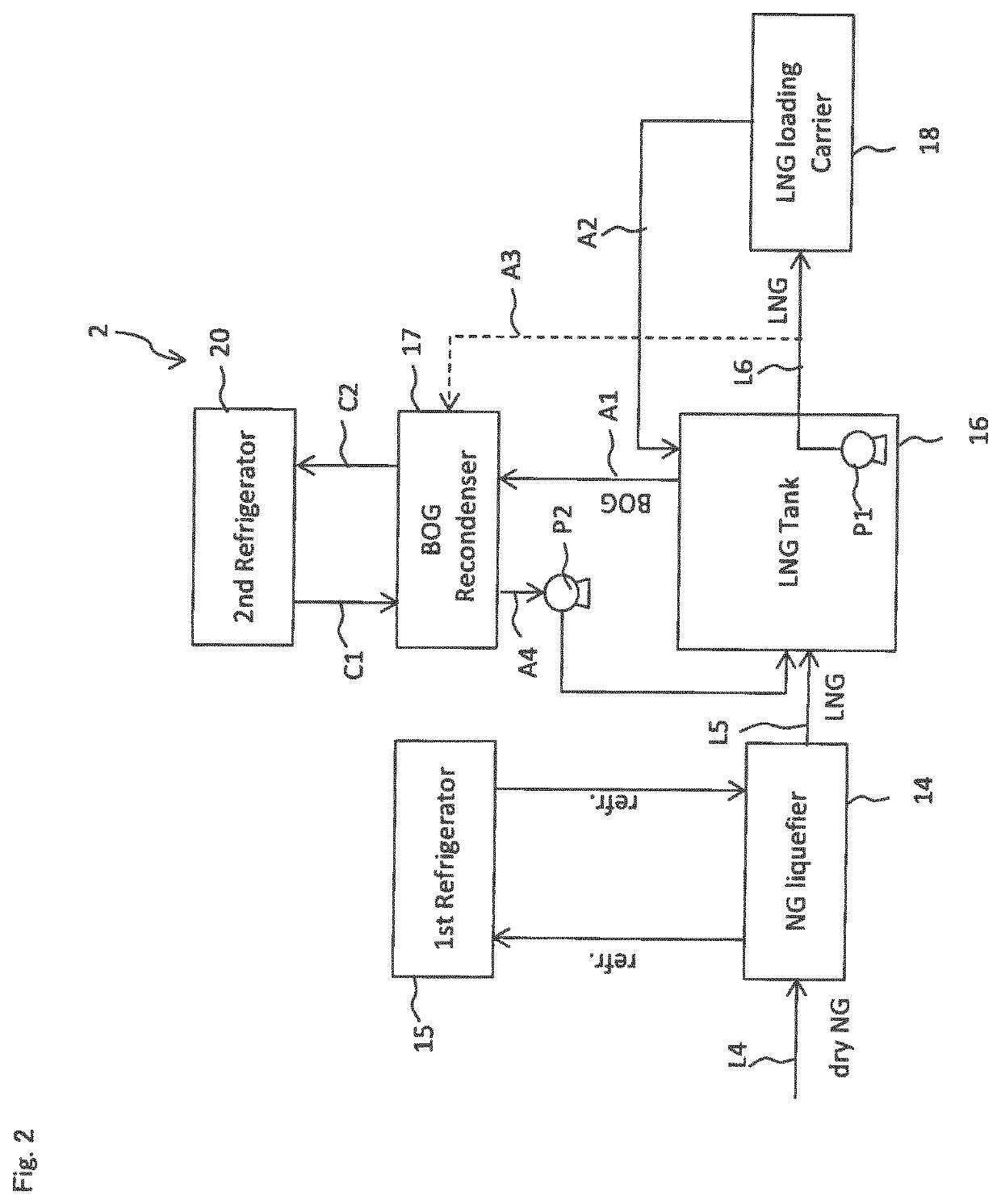

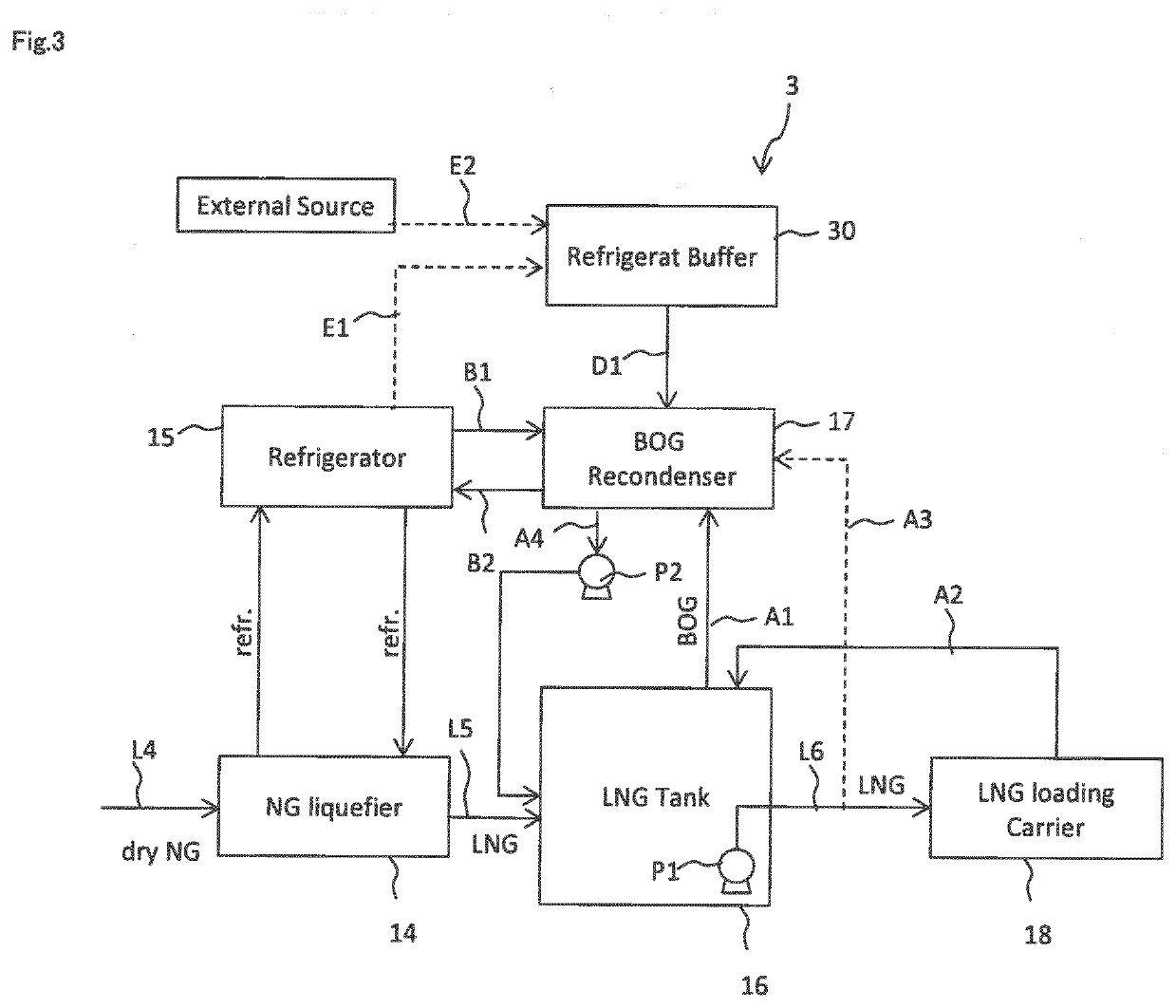

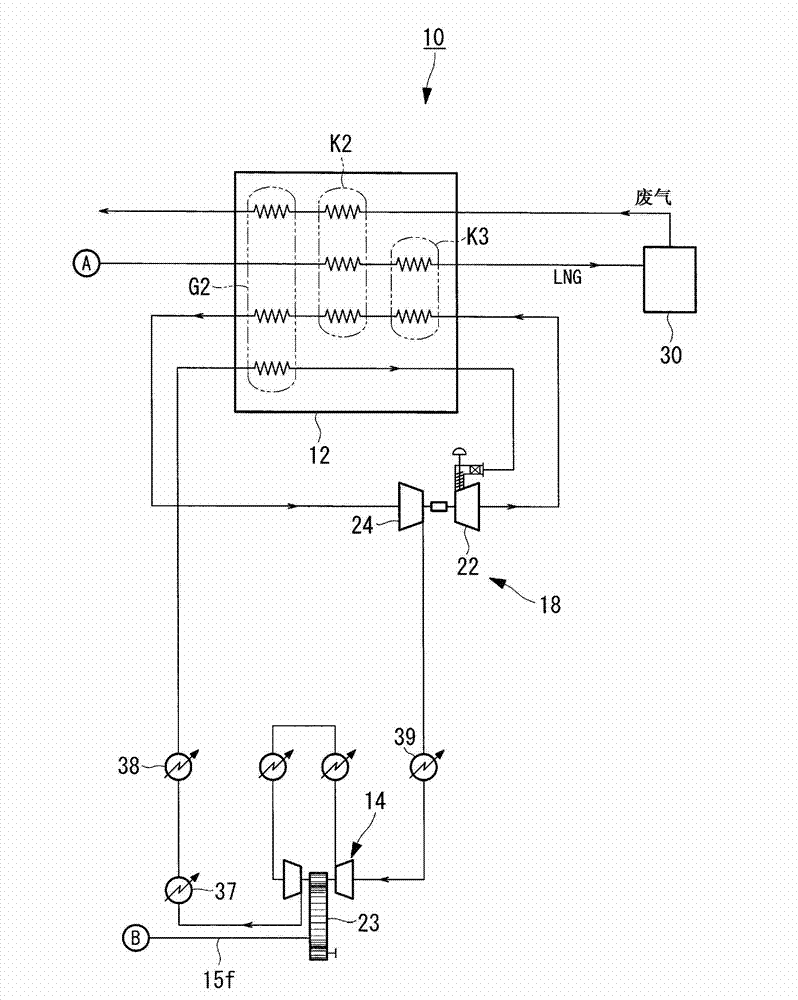

LNG production system equipped with recondenser

InactiveUS20200056837A1Efficient liquefactionSolidificationLiquefactionThermodynamicsPetroleum engineering

An LNG production system including a boil off gas recondenser that can recondense boil off gas without using a BOG compressor and without depending on an LNG liquefaction process is provided.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

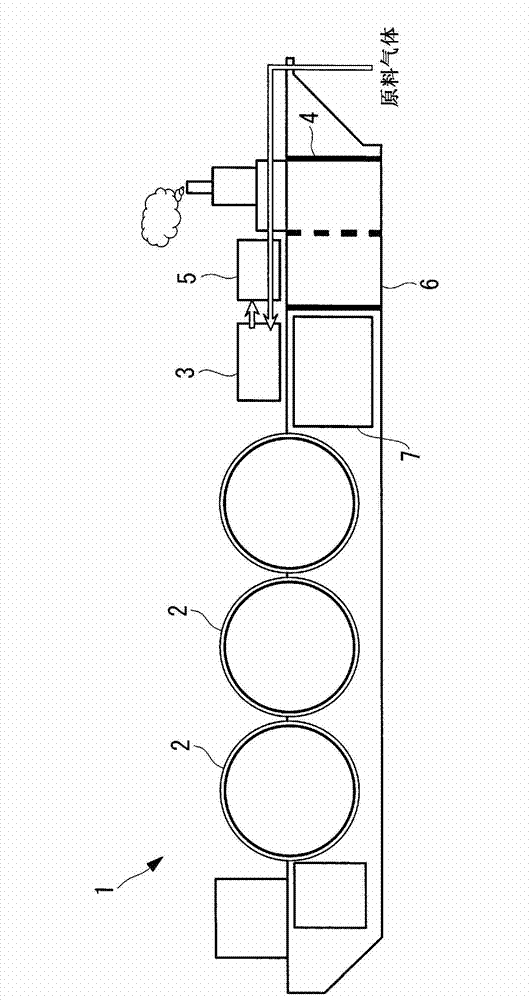

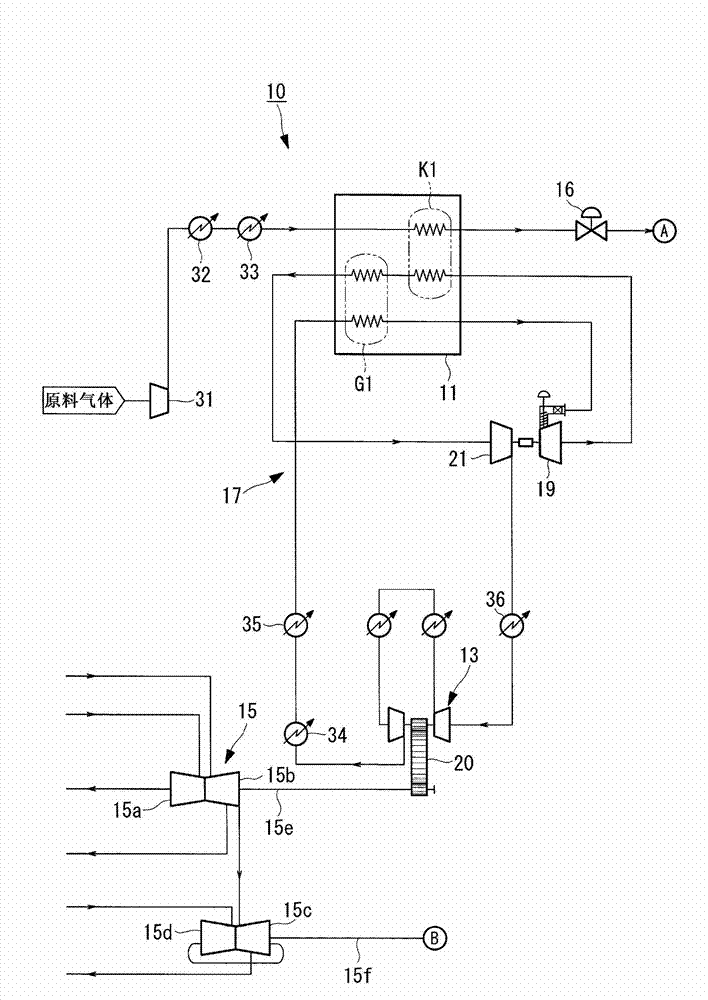

Liquefaction method, liquefaction device, and floating liquefied gas production equipment comprising same

A liquefaction method, a liquefaction device, and floating liquefied gas production equipment comprising the same which are capable of inhibiting reductions in liquefaction efficiency during liquefaction, are safe, and which make it possible to reduce the size of the equipment. The present invention is characterized in that the pressure of a gas that has undergone heat exchange with a single-component high-pressure heat carrier is reduced, and the reduced-pressure gas is liquefied by heat exchange with a low-temperature heat carrier that is of a similar type as the high-pressure heat carrier but has a lower temperature.

Owner:MITSUBISHI SHIPBUILDING CO LTD

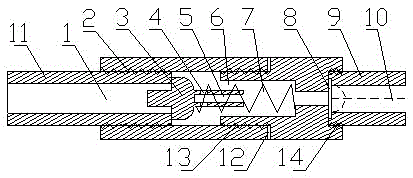

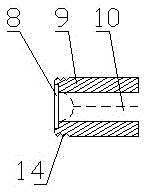

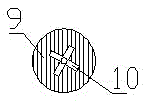

Single-hole cross-shaped jet slurry-making nozzle

A single-hole cross-shaped jet slurry-making nozzle comprises a casing, a non-return valve, a spring and a nozzle, wherein an air chamber and a pipe nipple are arranged in the casing, the pipe nipple is used for being connected with a main air pipe used for supplying air, and an air inlet hole is formed in the pipe nipple; the non-return valve and the spring are mounted in the air chamber, one end of the spring is connected with the casing, the other end of the spring is connected with the non-return valve, the non-return valve is connected with the pipe nipple mounted in the casing, and a tail rod is arranged on the non-return valve and located in the spring; when high-pressure air passes through the air inlet hole, the high-pressure air pushes the non-return valve open and then enters the air chamber; the open / closed state of the non-return valve is controlled by the spring; when no high-pressure air is supplied, the non-return valve is pushed by the spring to a closed state; and the nozzle is mounted on the casing and communicates with the air chamber, a notched rubber gasket is arranged in the nozzle, and a nozzle hole of the nozzle is cross-shaped. Through the single-hole cross-shaped jet slurry-making nozzle, uniform tailings slurry can be prepared fast and efficiently, and the effects of slurry making and blocky tailings hammering are remarkable.

Owner:邓代强 +2

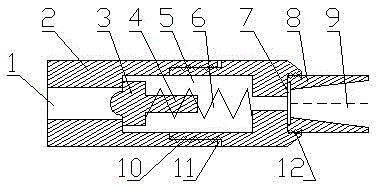

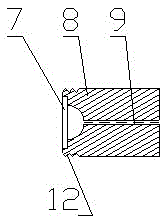

Single-hole linear jet flow mortar making nozzle

InactiveCN105537015AEfficient liquefactionAvoid large areas of sand accumulationSpray nozzlesSpray nozzleEngineering

A single-hole linear jet flow mortar making nozzle comprises a shell, a one-way valve, a spring and a nozzle body. The shell is internally provided with an air inlet hole and an air chamber, the one-way valve and the spring are installed in the air chamber, one end of the spring is connected with the shell, and the other end of the spring is connected with the one-way valve; a tail rod is arranged on the one-way valve, and the tail rod is located in the spring; when high-pressure air passes through the air inlet hole, the high-pressure air pushes open the one-way valve and then enters the air chamber, switching-on and switching-off states of the one-way valve are controlled by the spring, and if the high-pressure air is not supplied, the one-way valve is pushed by the spring to the switching-off state; the nozzle body is installed on the shell and communicated with the air chamber, an incision rubber pad is arranged in the nozzle body, and a nozzle hole of the nozzle body is of a platode structure. By means of the single-hole linear jet flow mortar making nozzle, uniform tail mortar can be prepared rapidly and efficiently, the cleaning effect is significant, processing is convenient, the structure is simple, and the making cost is low.

Owner:邓代强 +2

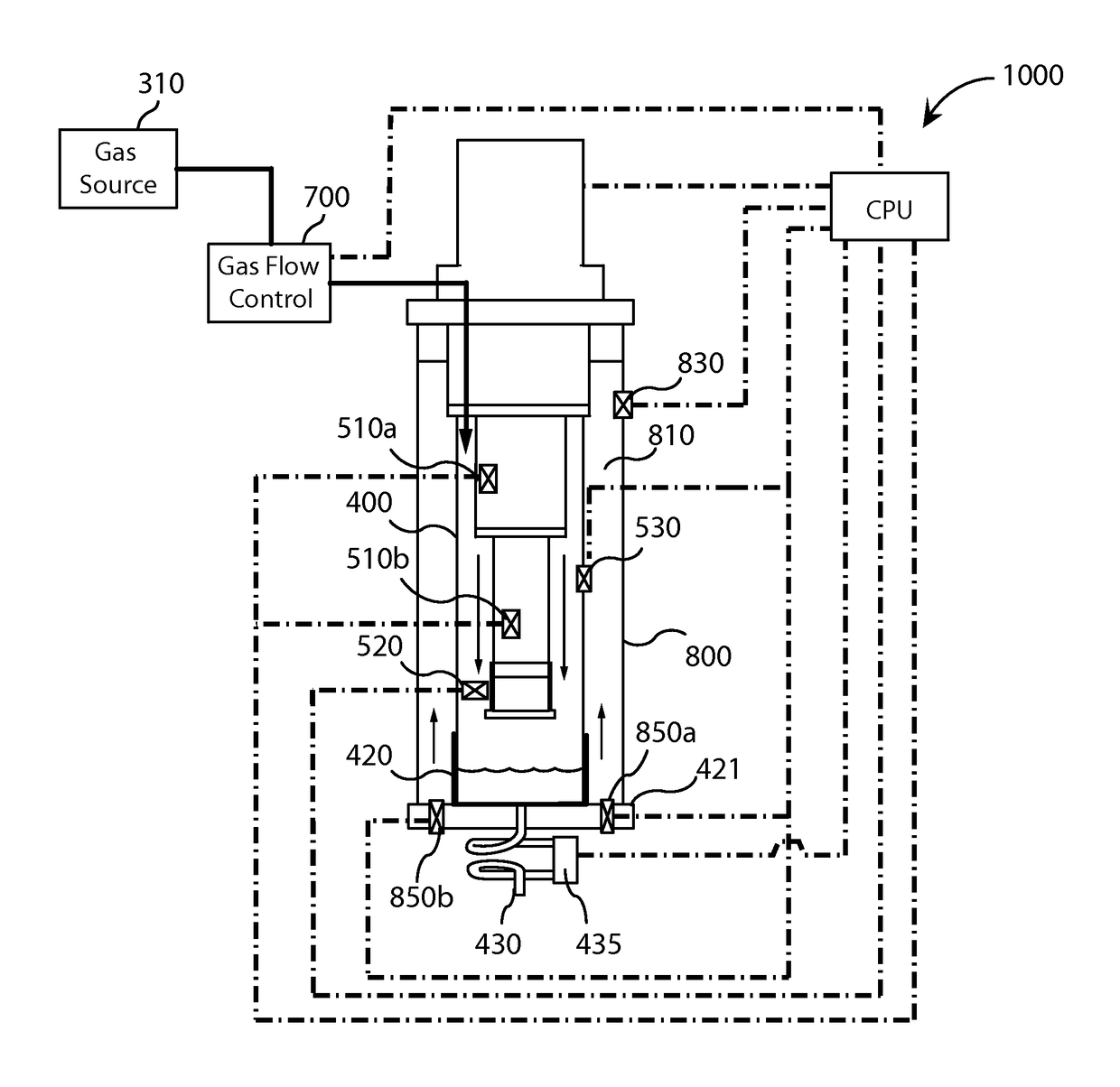

Liquefier with pressure-controlled liquefaction chamber

ActiveUS9671159B2Improve liquefaction efficiencyIncrease cooling powerVessel mounting detailsSolidificationCounter flowEngineering

A liquefier includes a Dewar having a storage portion and a neck portion extending therefrom. A hermetically isolated liquefaction chamber is disposed within the neck of the Dewar. One or more control components including a temperature and pressure sensor are coupled to a CPU and disposed within the liquefaction chamber for dynamic control of liquefaction conditions. A gas flow control is coupled to the CPU for regulating an input gas flow into the liquefaction chamber. A volume surrounding the liquefaction chamber may be adapted to provide a counter-flow heat exchange. These and other features provide improved liquefaction efficiency among other benefits.

Owner:QUANTUM DESIGN

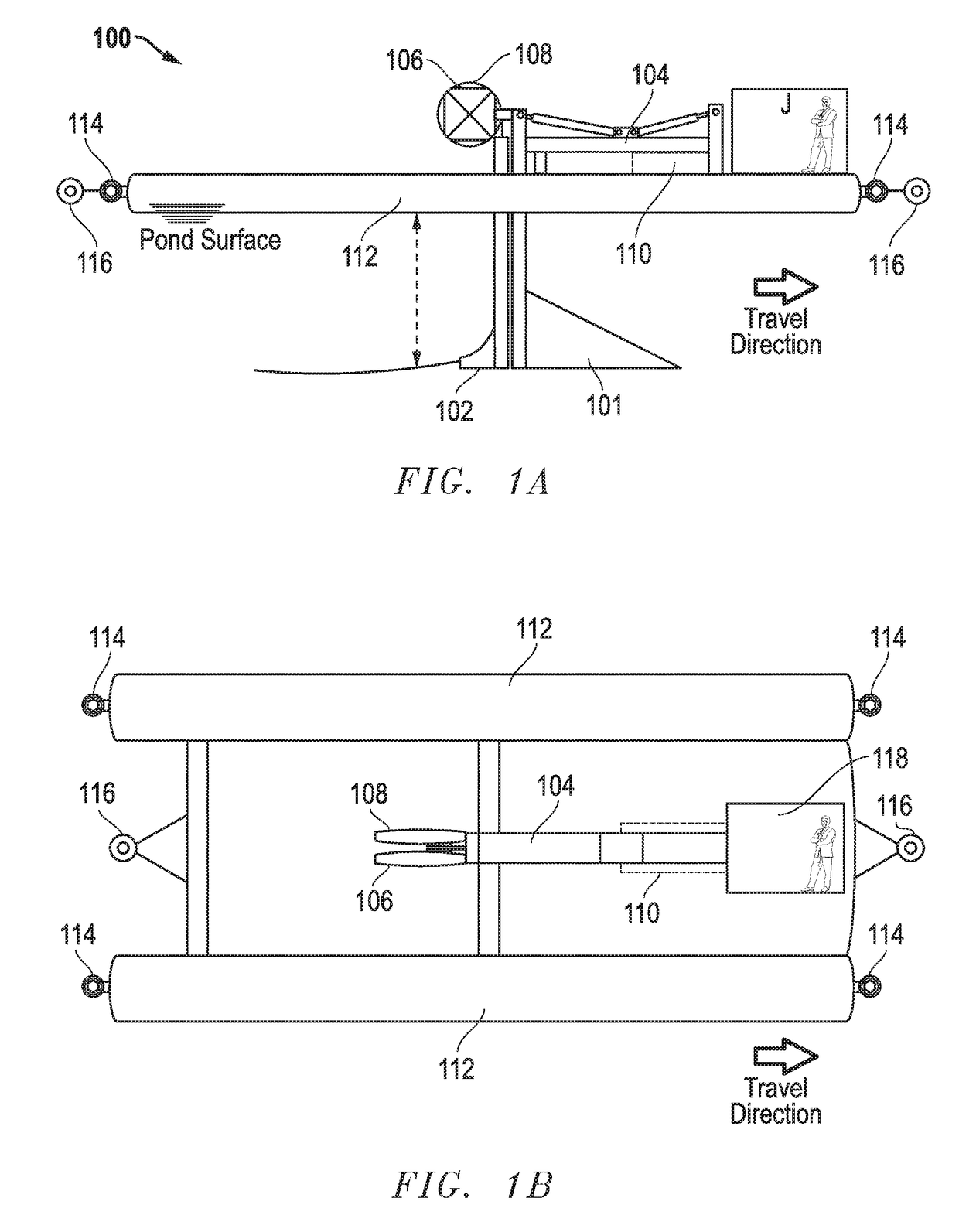

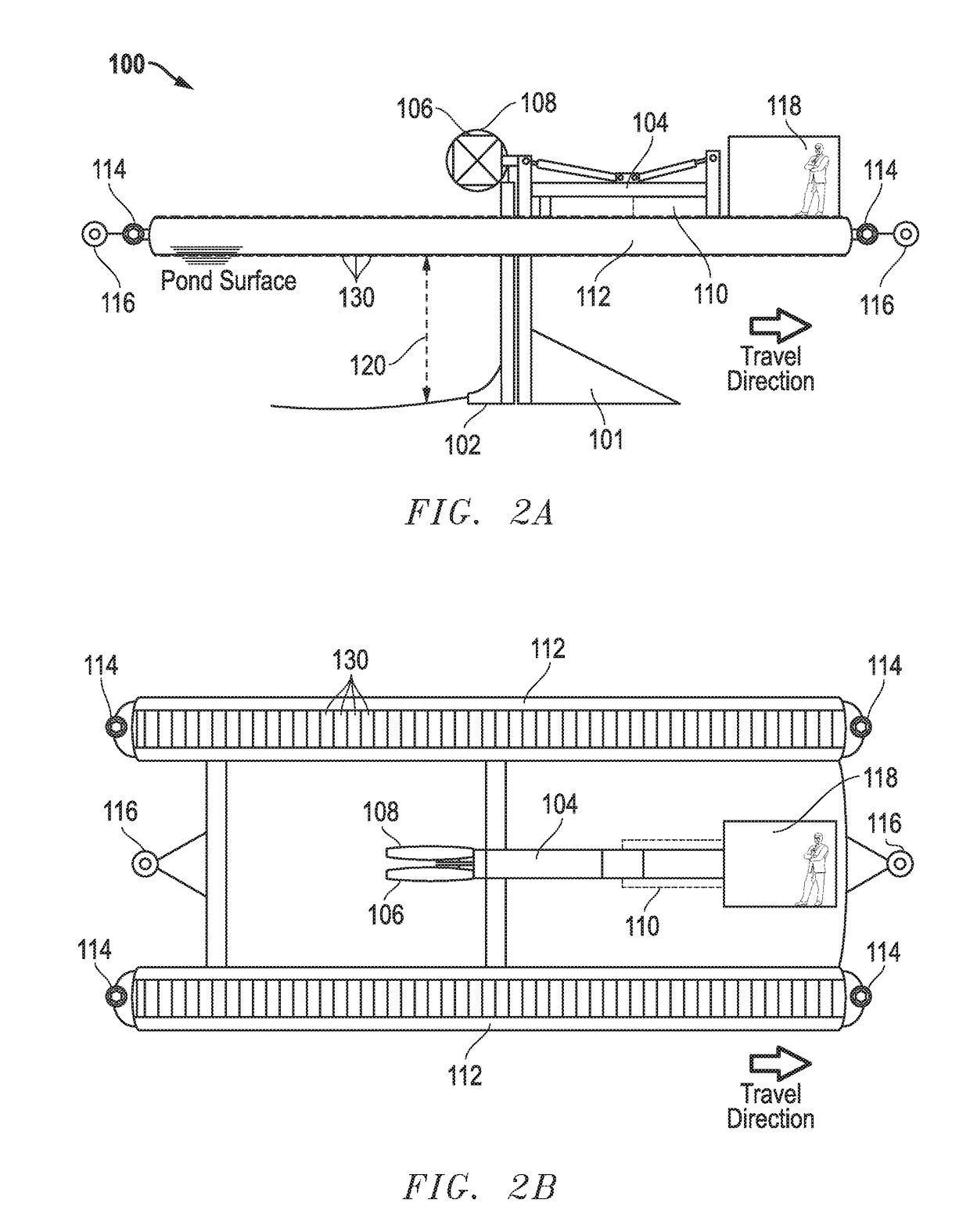

Device for the installation of vacuum consolidation dewatering horizontal drains for dewatering sludge ponds

InactiveUS20180112367A1Effective drainageSufficient protectionSoil drainageSoil-shifting machines/dredgersVacuum consolidationCombustion

A device for installing horizontal drains in a coal combustion residual or other sludge pond consists of a trenching device that extends downwardly to the depth of required installation of the drains and an attachment through which the drains are fed during installation. The trenching device and attachment are mounted onto a carrier for floatation of the required equipment on the surface of a water-filled sludge pond. The carrier can be winched, hauled or driven across the surface of the sludge. A hydraulic system may be used to raise and lower the trenching device and attachment. The trenching device may be equipped with a chain driven blade mechanism or dredging device for the purpose of cutting a trench into the pond sludge, and a vibratory trenching device may be used to effectively liquefy the material to make the trenching device easier to pull or tow through the sludge in the pond.

Owner:AECOM TECHNICAL SERVICES INC

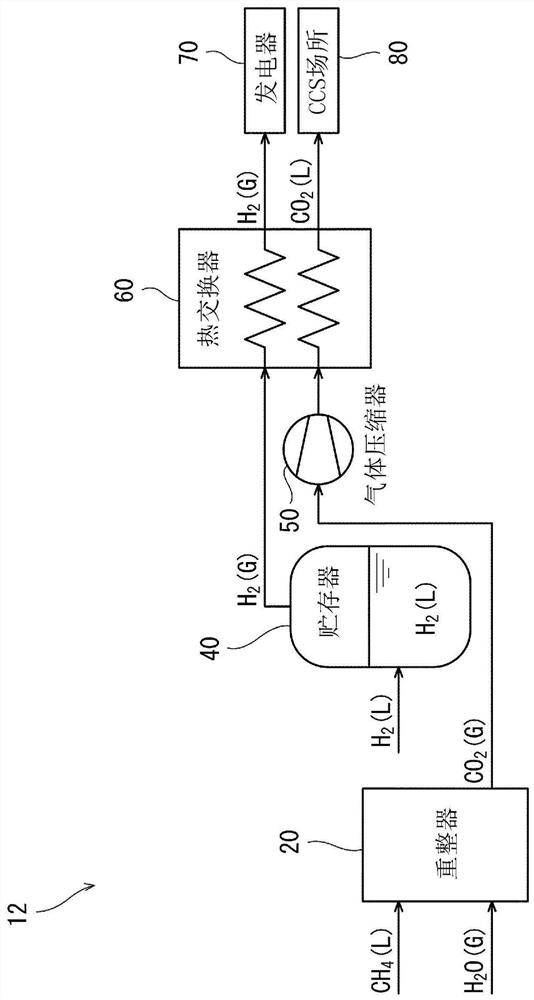

Liquid hydrogen production facility and hydrogen gas production facility

PendingCN111919077AEfficient liquefactionSolidificationLiquefactionProcess engineeringLiquid hydrogen

The present invention is characterized by being equipped with: a reformer for reforming a hydrocarbon to generate hydrogen gas; a hydrogen liquefaction device for liquefying the hydrogen gas to generate liquid hydrogen; a reservoir for storing the liquid hydrogen; and a heat exchanger for carrying out a heat exchange between a boil-off gas produced in the reservoir and carbon dioxide produced in the step in which the hydrogen gas is generated, thereby liquefying the carbon dioxide.

Owner:KAWASAKI HEAVY IND LTD

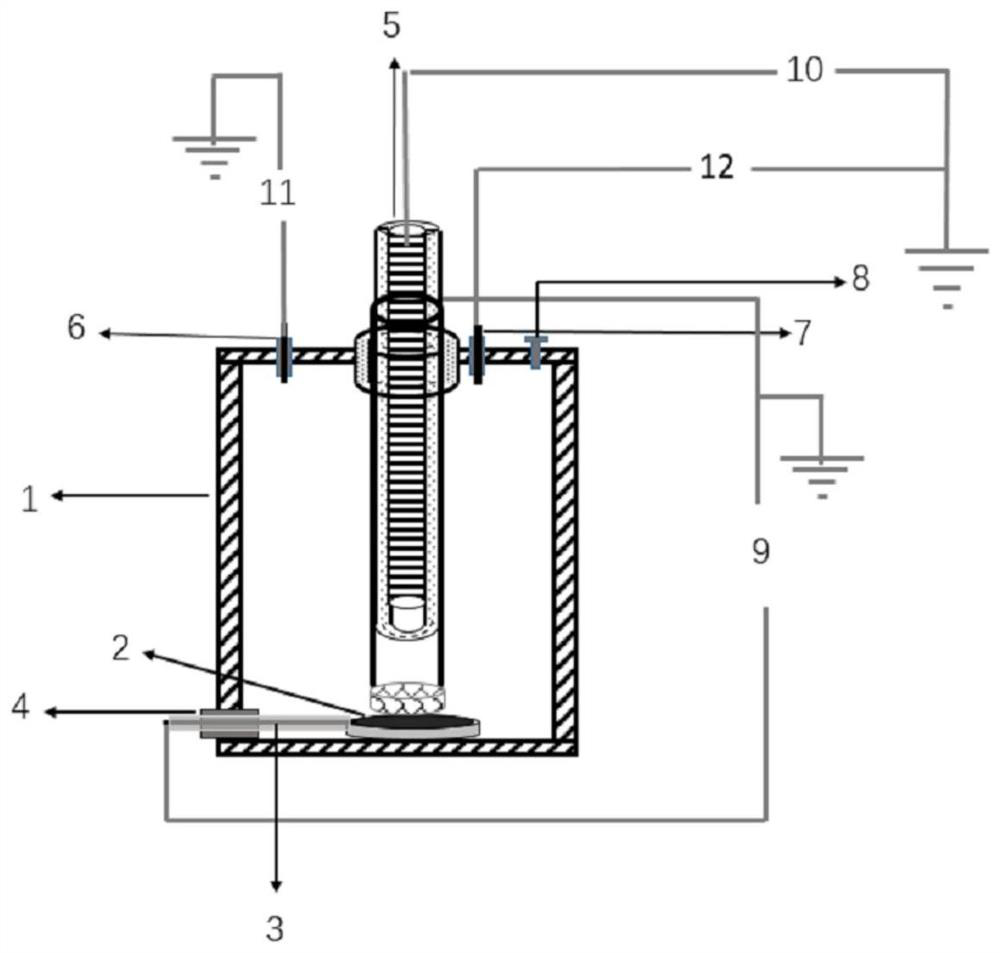

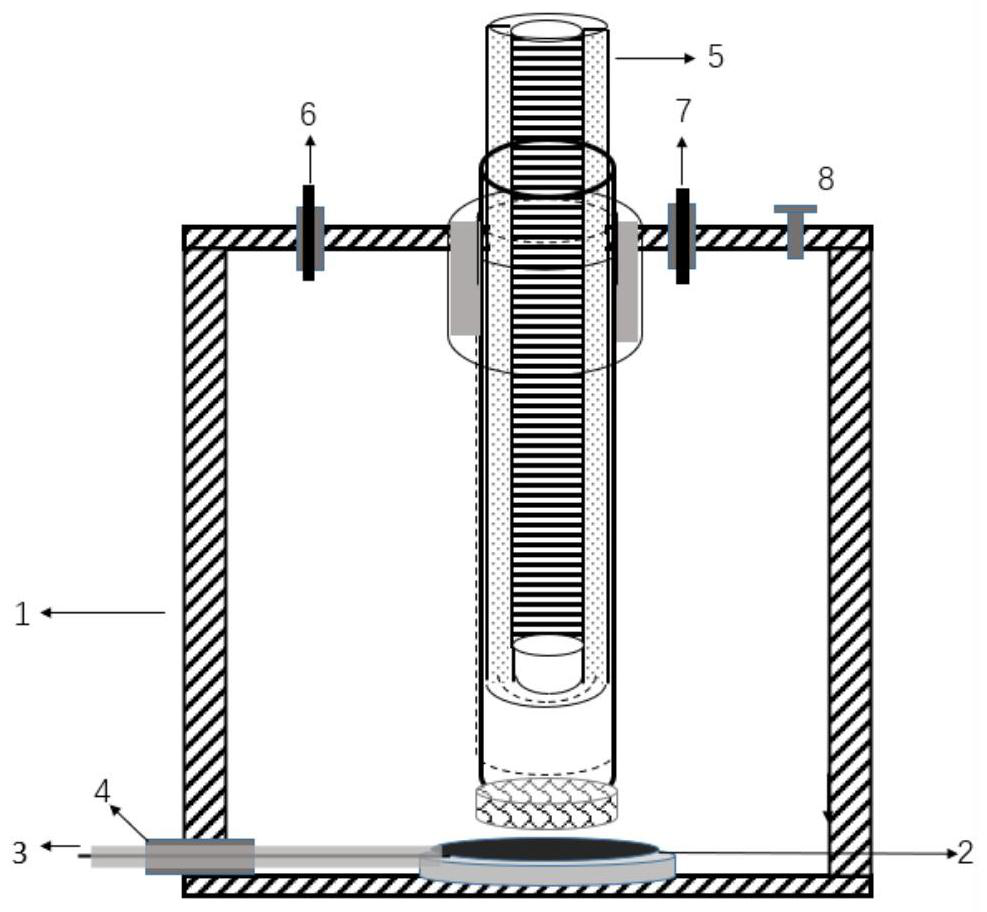

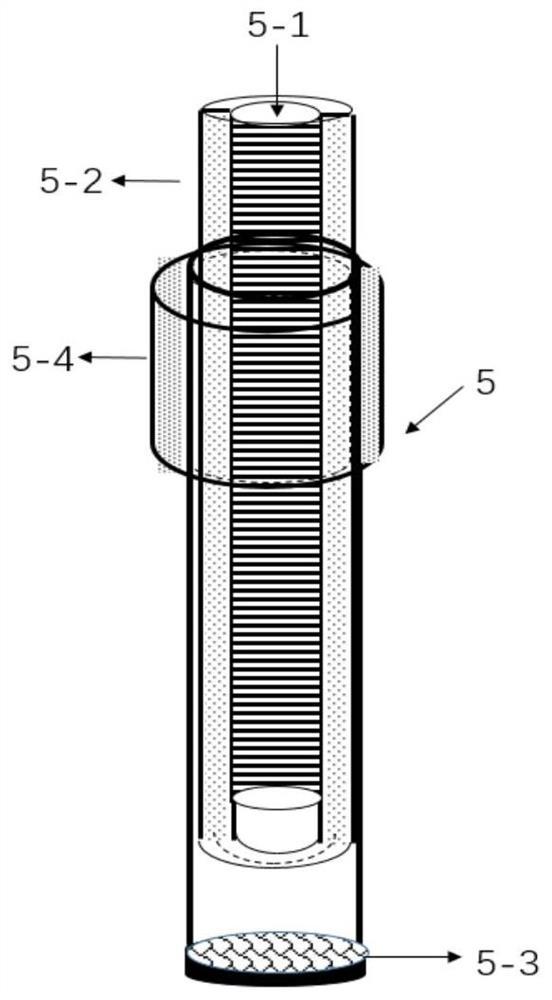

High-pressure reaction kettle and control method thereof

ActiveCN112090371AImprove qualityEfficient liquefactionProcess control/regulationEnergy based chemical/physical/physico-chemical processesCavitation bubbleHigh voltage electrode

The invention provides a high-pressure reaction kettle and a control method thereof, the high-pressure reaction kettle comprises: a high-pressure reaction kettle cavity for accommodating biomass, a solvent and water; an ultrasonic generation device which is used for generating cavitation bubbles from an aqueous solution in thehigh-pressure reaction kettlecavity; and a high-voltage electrode assembly which is used for discharging in the high-voltage reaction kettle cavity to generate plasma; The ultrasonic generation device and the high-voltage electrode assembly have a synergistic effect, thecavitation bubbles are provided by the ultrasonic generation device, and the high-voltage electrode assembly discharges and loads on the cavitation bubbles to realize discharging and generate the plasma, so that the cavitation bubble volume is increased, the solution heating efficiency is improved, and the liquefaction effect of the content of free radicals in the cavitation bubbles is improved.

Owner:XIAMEN UNIV

Storage safety device for volatile liquid

ActiveCN111377157ARealize automatic controlSimple structureLarge containersTank wagonsEngineeringRefrigeration

The invention discloses a storage safety device for volatile liquid, and relates to the technical field of volatile liquid storage. The device comprises a tank body, a base and a fixed seat; a condensation recovery chamber is arranged in the base; a pressure relief chamber is arranged in the fixed seat; a third through hole and a fourth through hole are respectively formed in the bottom of the pressure relief chamber; a peripheral side surface of the third through hole is fixedly connected with a pressure relief pipe; a plurality of breather pipes are mounted close to the top of the peripheralside of the tank body; one end of each breather pipe penetrates through the peripheral side of the pressure relief pipe; a third spring is mounted at one end, away from the tank body, in the breatherpipe; and one end of the third spring is fixedly connected with a sliding block. Through the design of the third spring, the sliding block, the pressure relief pipe and the pressure relief chamber, automatic pressure control can be achieved, the structure is simple, and safety is high; through the design of a refrigeration control box, a spiral condensation pipe and the condensation recovery chamber, gas liquefaction can be achieved, the temperature in a spiral condensation pipe is reduced, the tank body is effectively cooled, liquid volatilization is reduced, and the safety is high.

Owner:义乌市研创工业设计有限公司

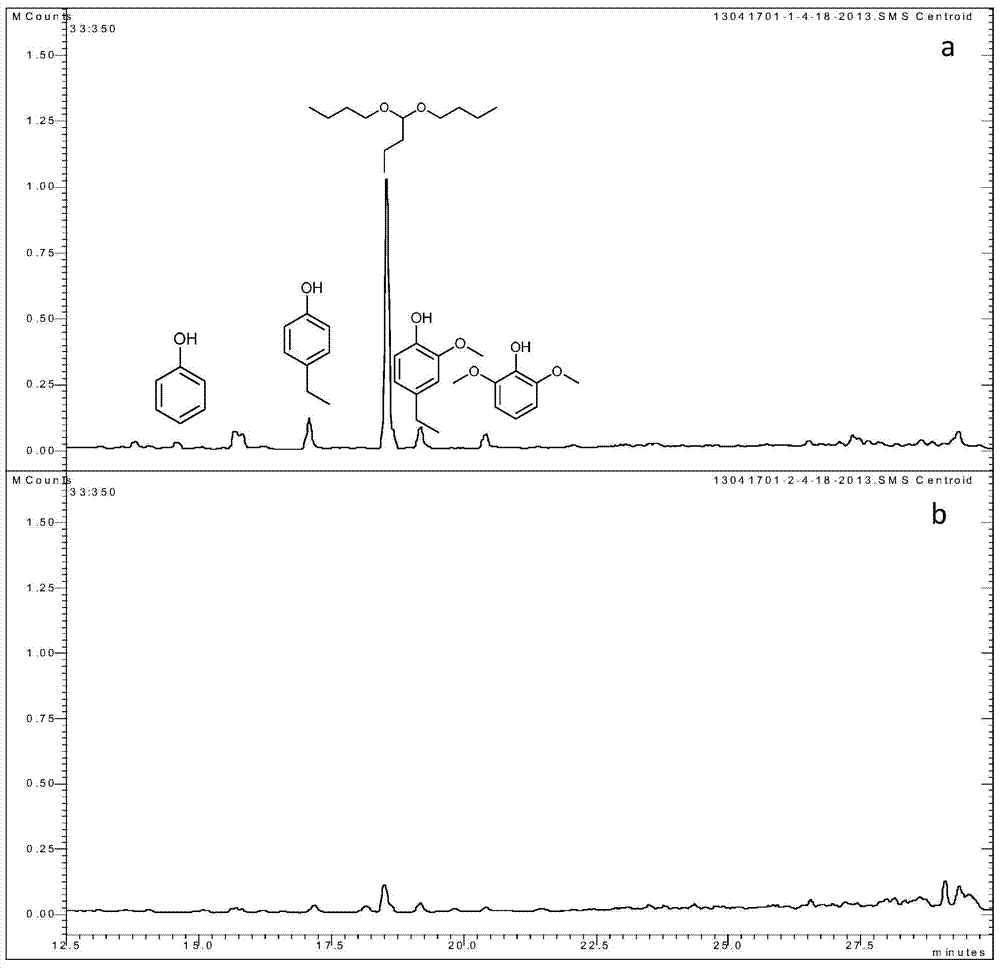

Preparation method of starch-based flame-retardant polyether polyol

The invention discloses a method for preparing flame-retardant polyether polyol by catalytically liquefying pre-gelatinized starch by taking boron phosphate as a catalyst, and belongs to the technicalfield of efficient utilization of chemical material biomass. The preparation method comprises the following steps of: taking pre-gelatinized starch as the raw material, adopting a mixed solvent of diethylene glycol, diethanol amine and glycerol as a liquefying agent and using boron phosphate as the catalyst, and carrying out reaction in a hydrothermal kettle to prepare the flame-retardant polyether polyol. The hydroxyl value of the obtained flame-retardant polyether polyol is 360.5-436.5mgKOH / g, and the liquefaction rate of starch is as high as 96.4%. The limit oxygen index of the foam prepared from the liquefied product reaches 28.9, the heat conductivity coefficient is 0.019 W / m.K, the compression strength is 206.0 kPa, the apparent density is 62.8 kg / m<3>, and the flame retardant property can be self-extinguished when the foam is away from fire. The mechanical properties are equivalent to those of polyurethane rigid foam prepared from petrochemical raw materials, and the indexes meet the requirements of the industrial standard (JG / T314-2012) and the national standard (GB10800-1989, GBT8813-2008 and GBT6343-2009) of polyurethane rigid foam composite insulation boards.

Owner:CHANGCHUN UNIV OF TECH

Additional liquid natural gas plant and method of operating thereof

InactiveUS20200033054A1Efficient processEconomy of scaleSolidificationLiquefactionPetroleum engineeringLiquefaction

The invention relates to a liquid natural gas plant for producing liquefied natural gas. The liquid natural gas plant comprises two or more parallel treatment and liquefaction trains, each train comprising a cooling stage arranged to receive a cleaned natural gas stream from a gas treatment stage, an NGL-extraction unit for extracting natural gas liquids, thereby generating a light natural gas stream. The liquid natural gas plant comprises an additional liquefaction train, comprising an additional cooling stage arranged to receive an additional feed stream for generating additional liquefied natural gas. The additional feed stream comprises two or more side streams taken from the light natural gas taken from the respective light natural gas streams of the one or more parallel treatment and liquefaction trains.

Owner:SHELL OIL CO

Method used for extracting nutrients via pulp refining and enzymatic hydrolysis of enteromorpha, and preparing enteromorpha organic composite fertilizer

PendingCN107324915AHigh retention rateEasy to extractAnimal feeding stuffAmmonium salt fertilisersNutrientChemistry

The invention belongs to the technical field of enteromorpha rapid high efficiency treatment and utilization, and organic fertilizer production, and discloses a method used for extracting nutrients via pulp refining and enzymatic hydrolysis of enteromorpha, and preparing an enteromorpha organic composite fertilizer from the nutrients. The method comprises follow steps: harvested fresh enteromorpha is immersed in fresh water to remove salt and sand, and is smashed using a large-size waterweed pulverizer; physical pulp refining is carried out using a large-size pulping machine; enteromorpha nutrients are extracted; and enteromorpha is subjected to rapid liquefaction so as to obtain enteromorpha slurry; the obtained enteromorpha slurry is subjected to enzymatic hydrolysis and distillation condensation, phosphorylation is carried out with a phosphorylation agent, and combination of inorganic fertilizers is carried out so as to obtain the enteromorpha organic composite fertilizer. According to the method, fresh enteromorpha is subjected to pulp refining and enzymatic hydrolysis so as to extract the nutrients, so that a difficult drying step is avoided; investment cost is low; cost is low; efficiency is high; capacity is large; enteromorpha environment-friendly treatment is realized preferably; and large environment pollution caused by large scale enteromorpha is eliminated.

Owner:RIZHAO XURI COMPOSITE MATERIALS

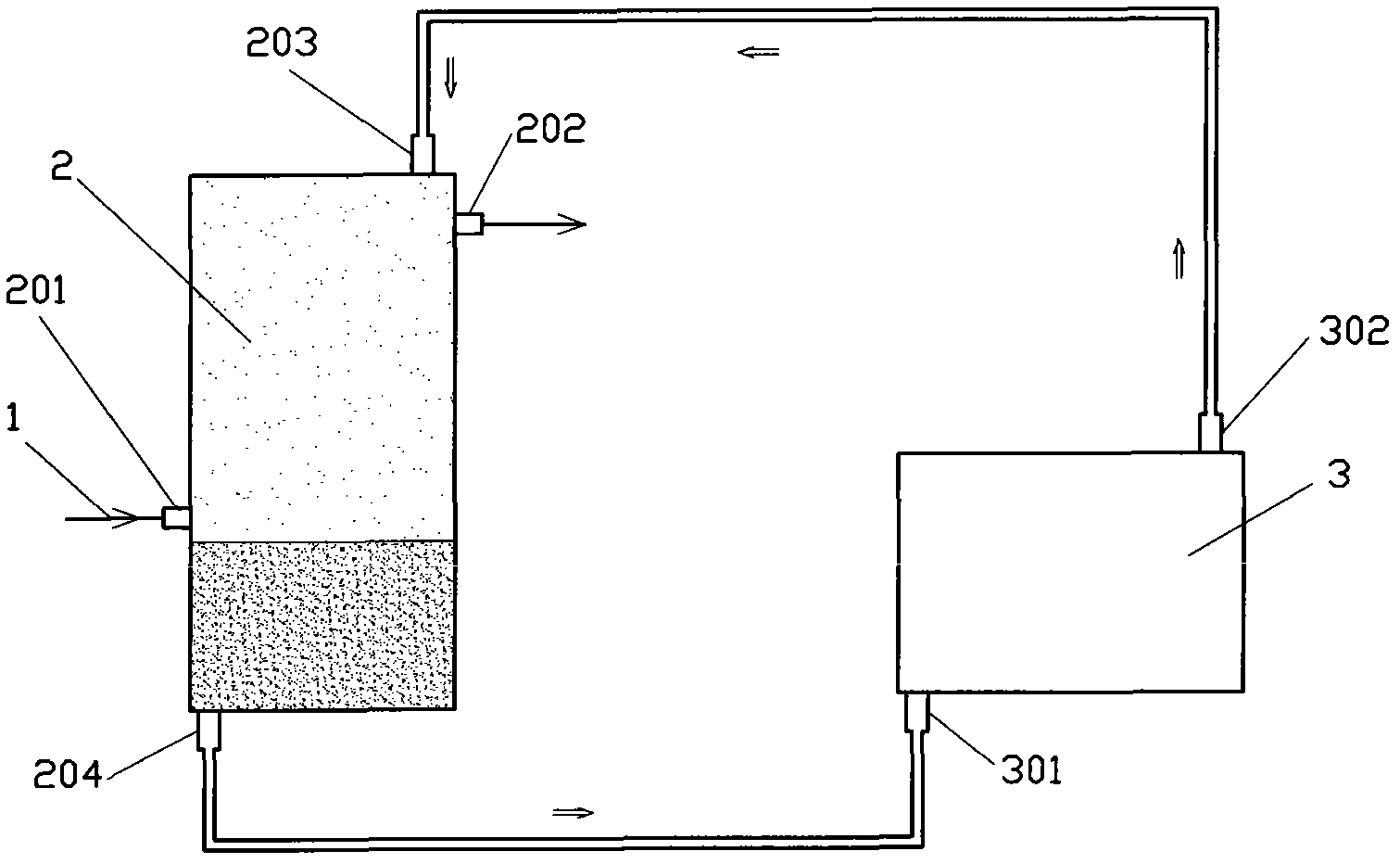

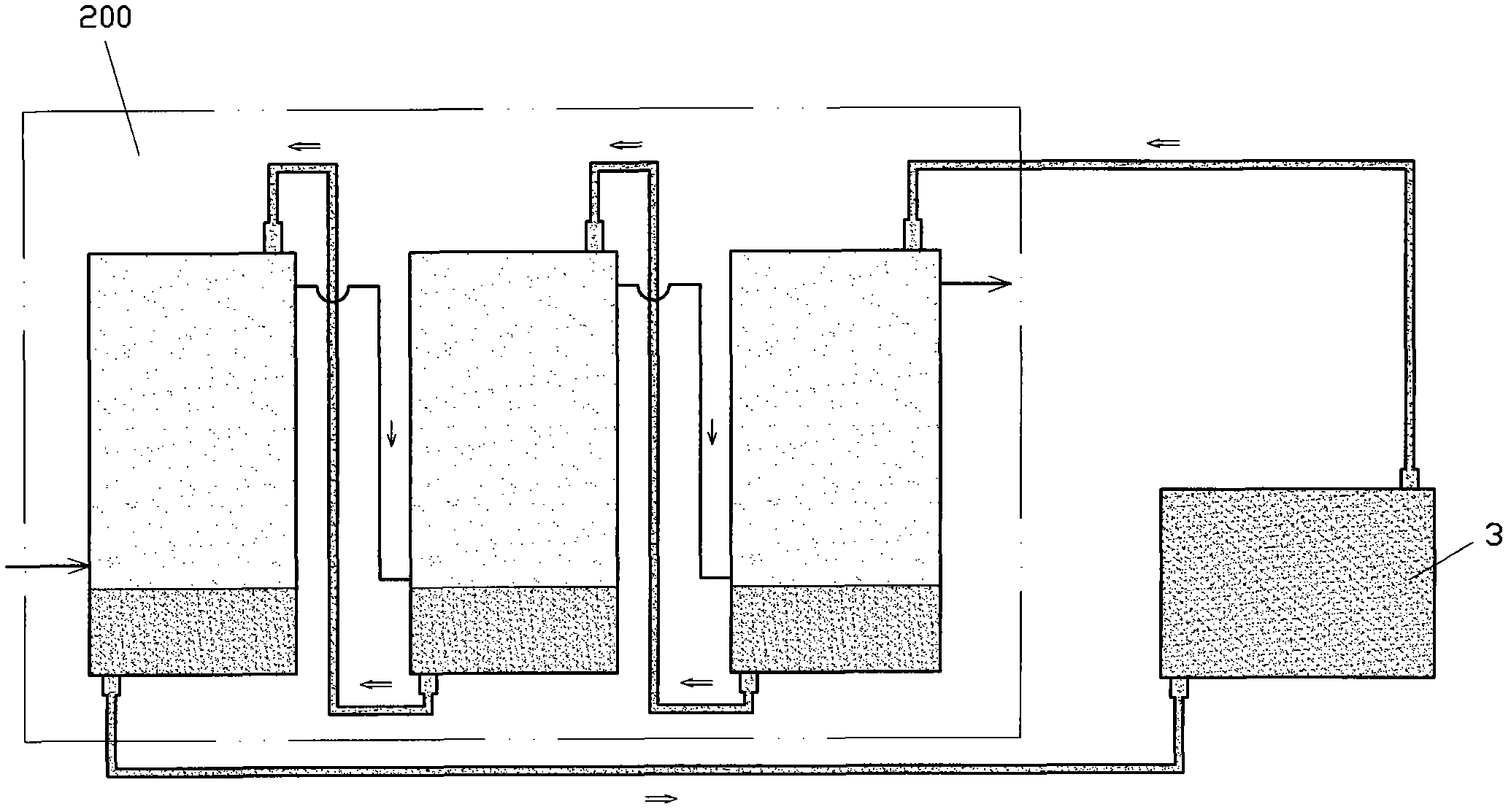

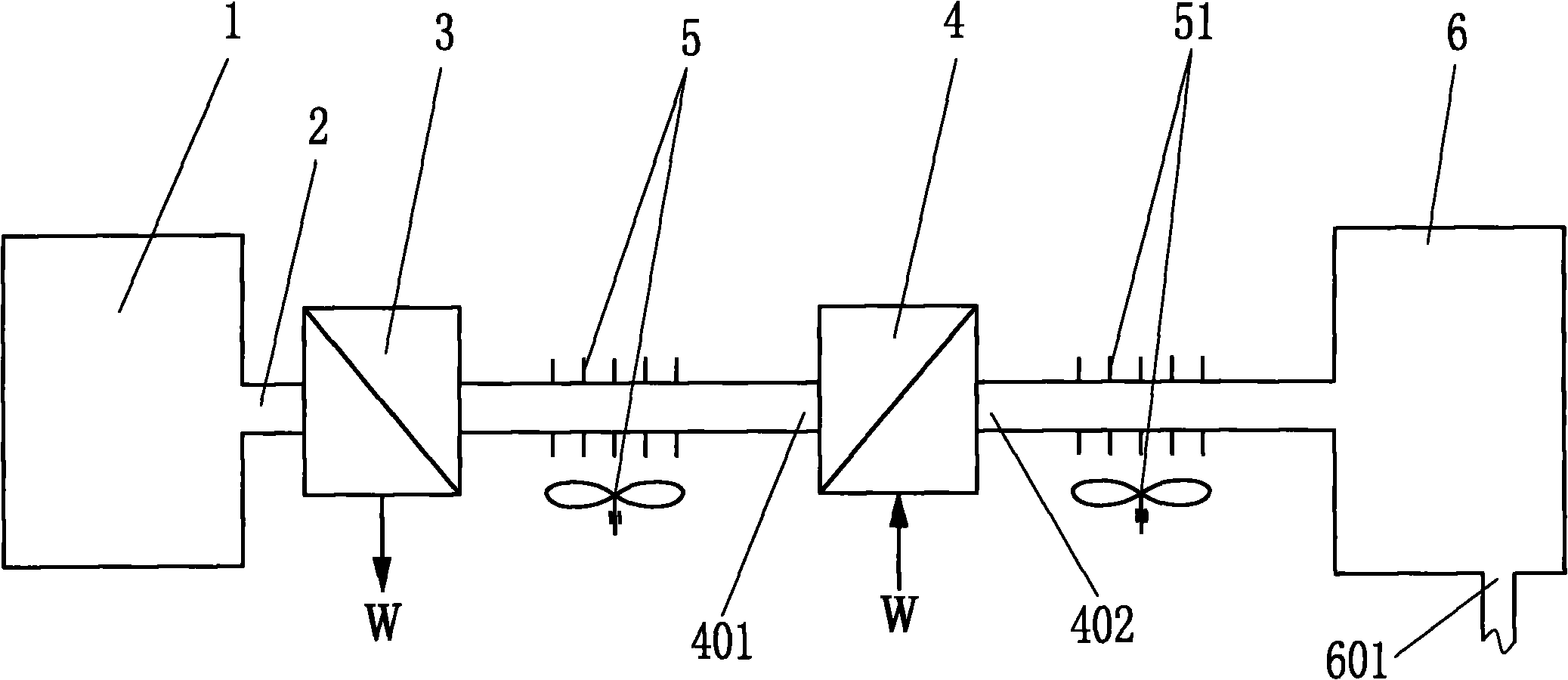

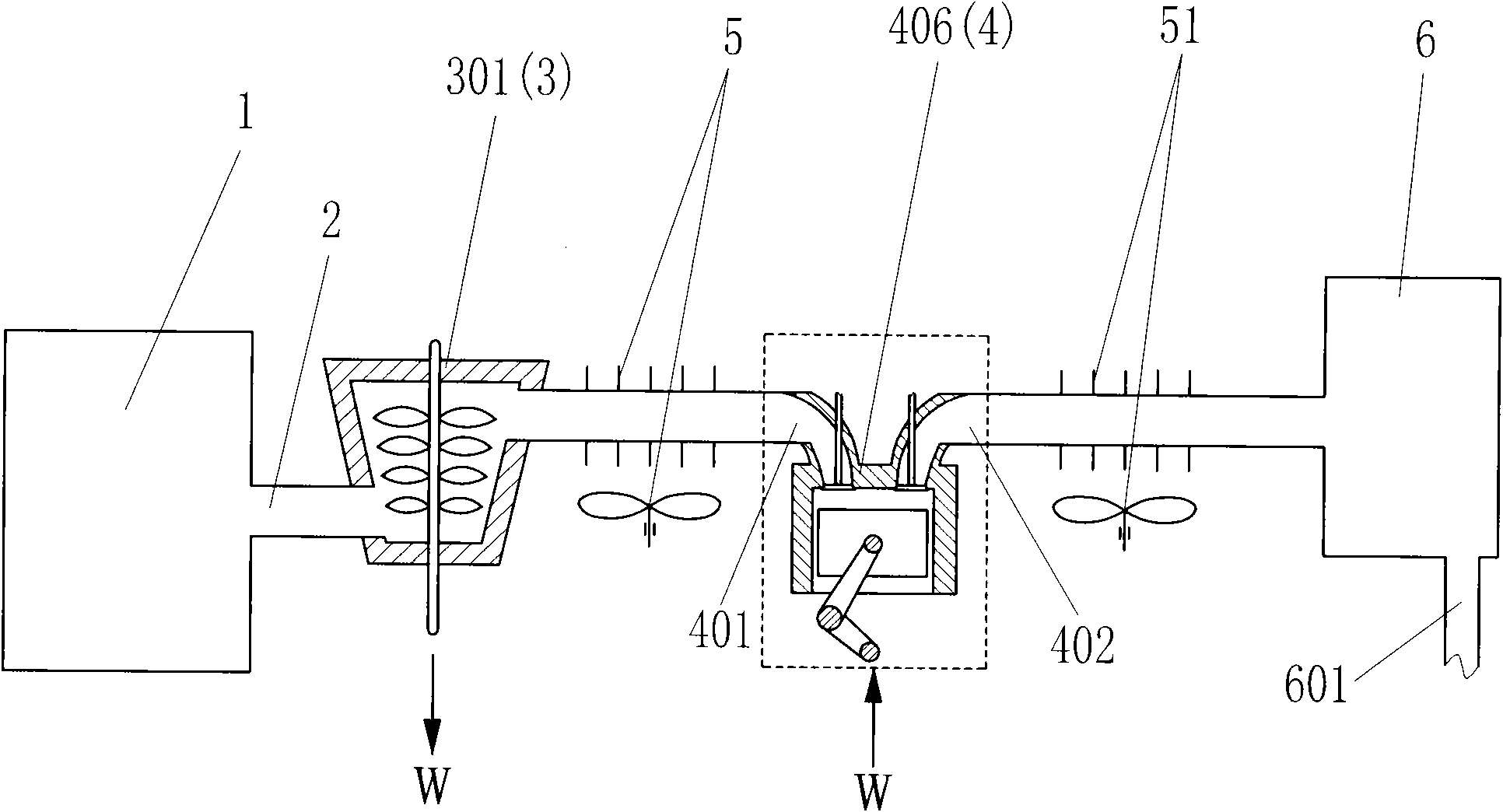

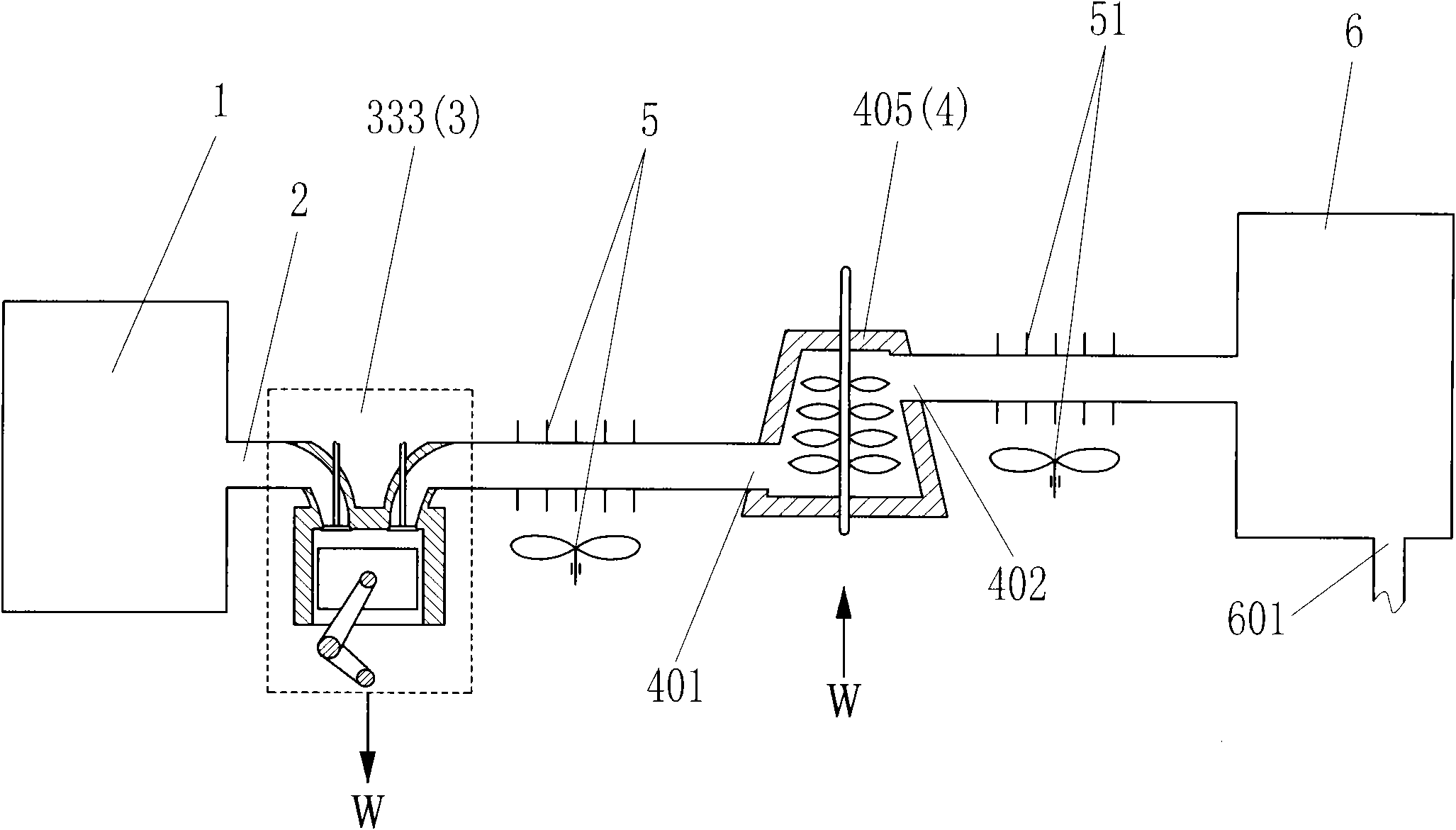

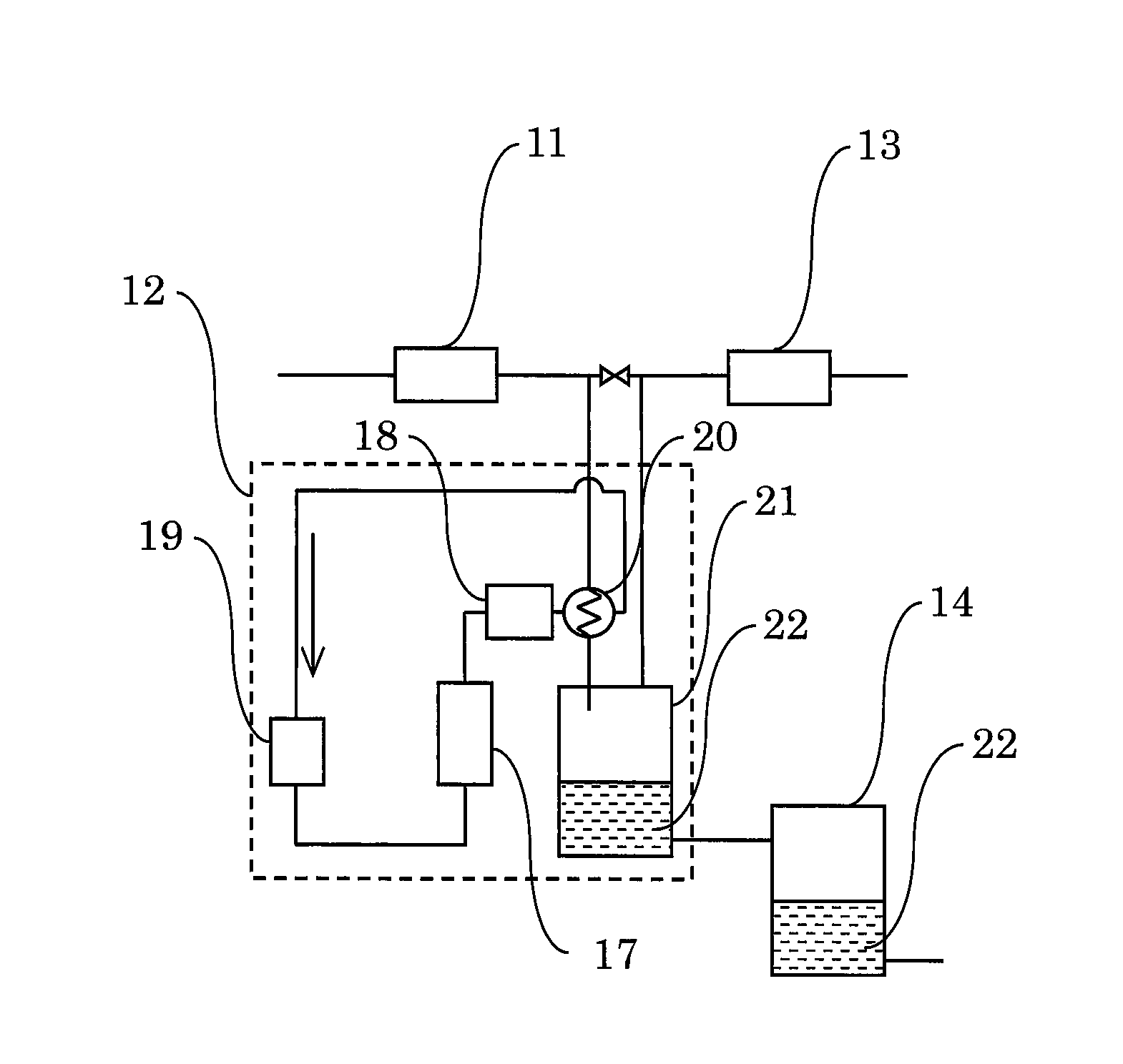

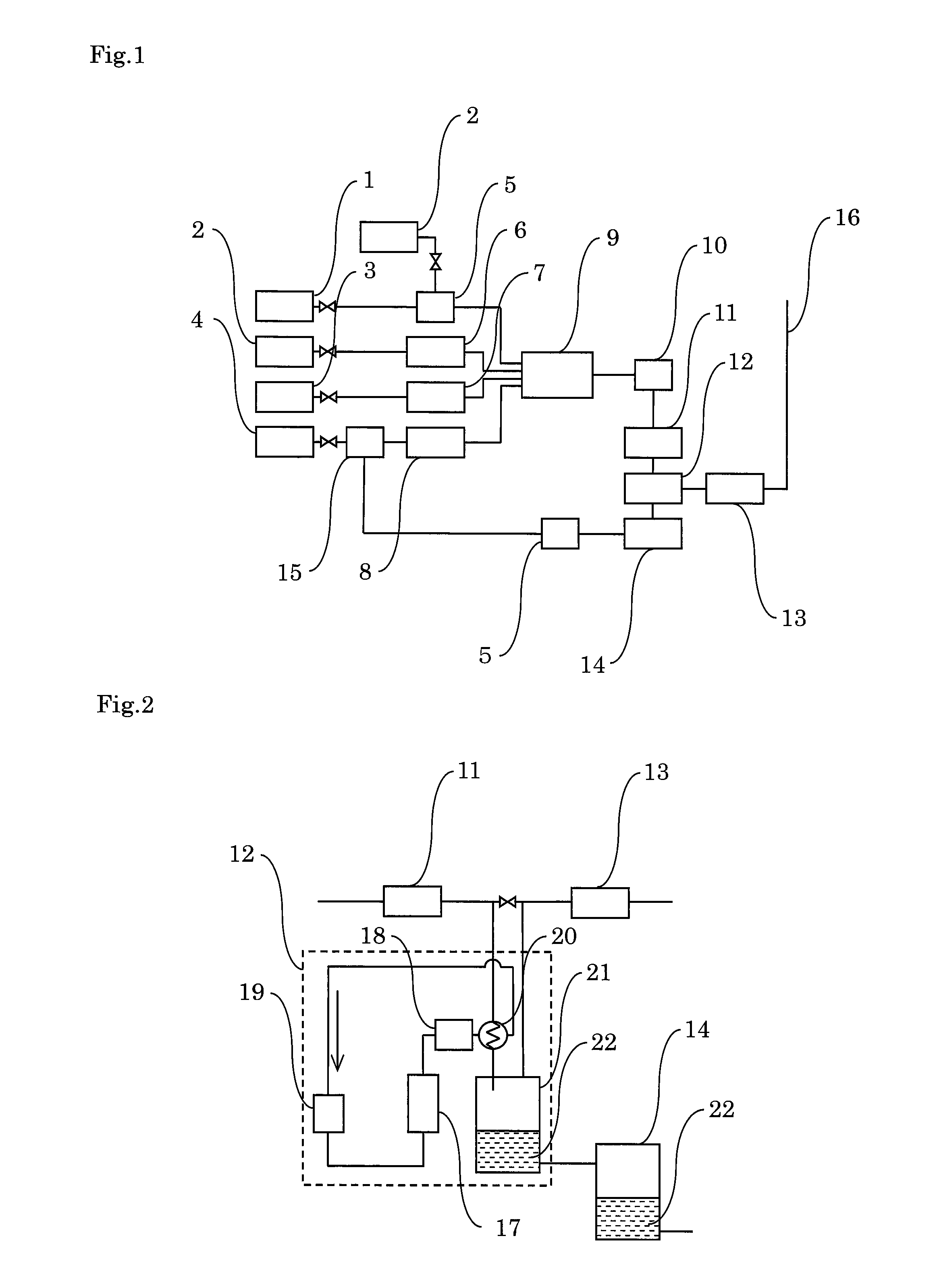

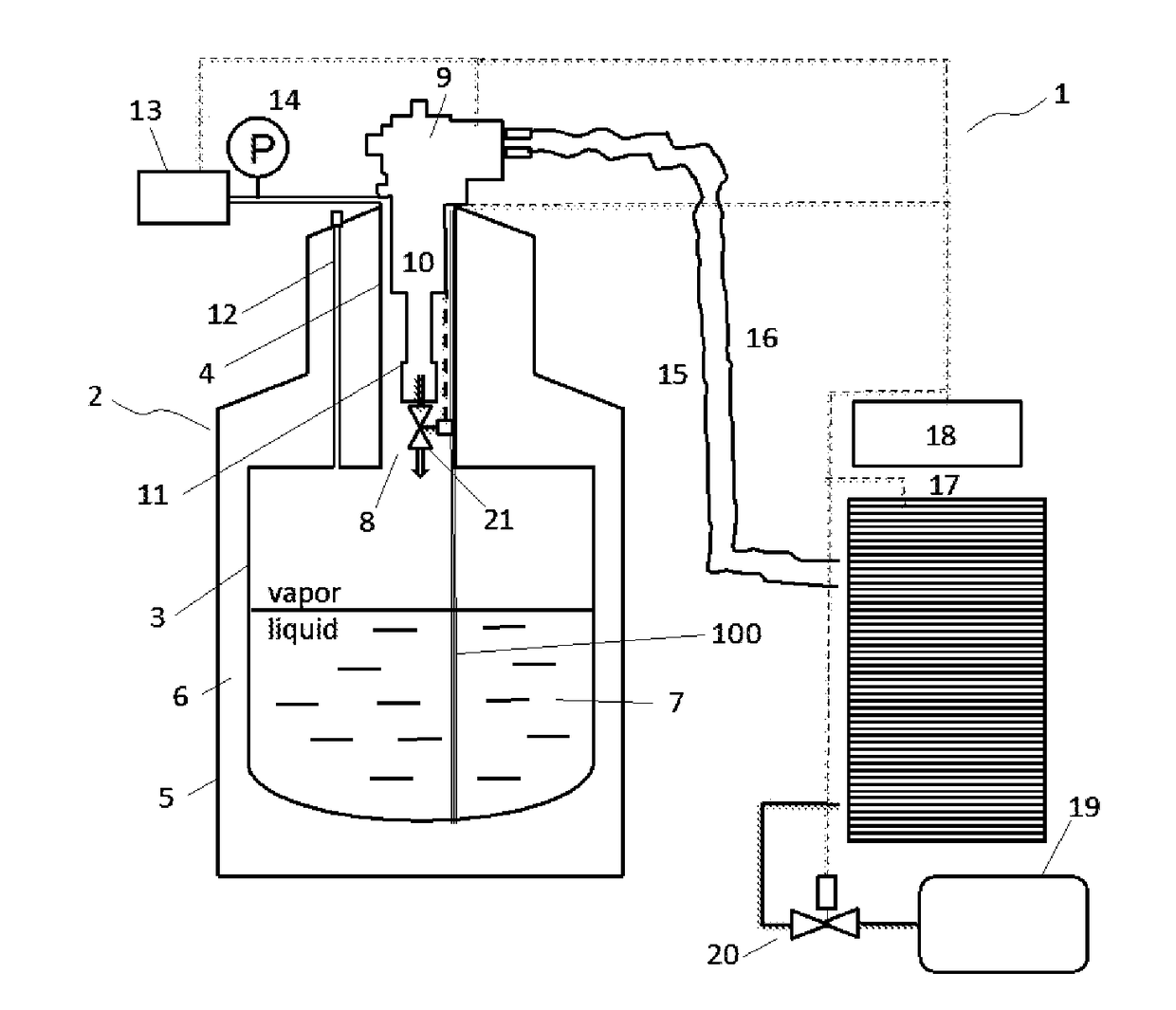

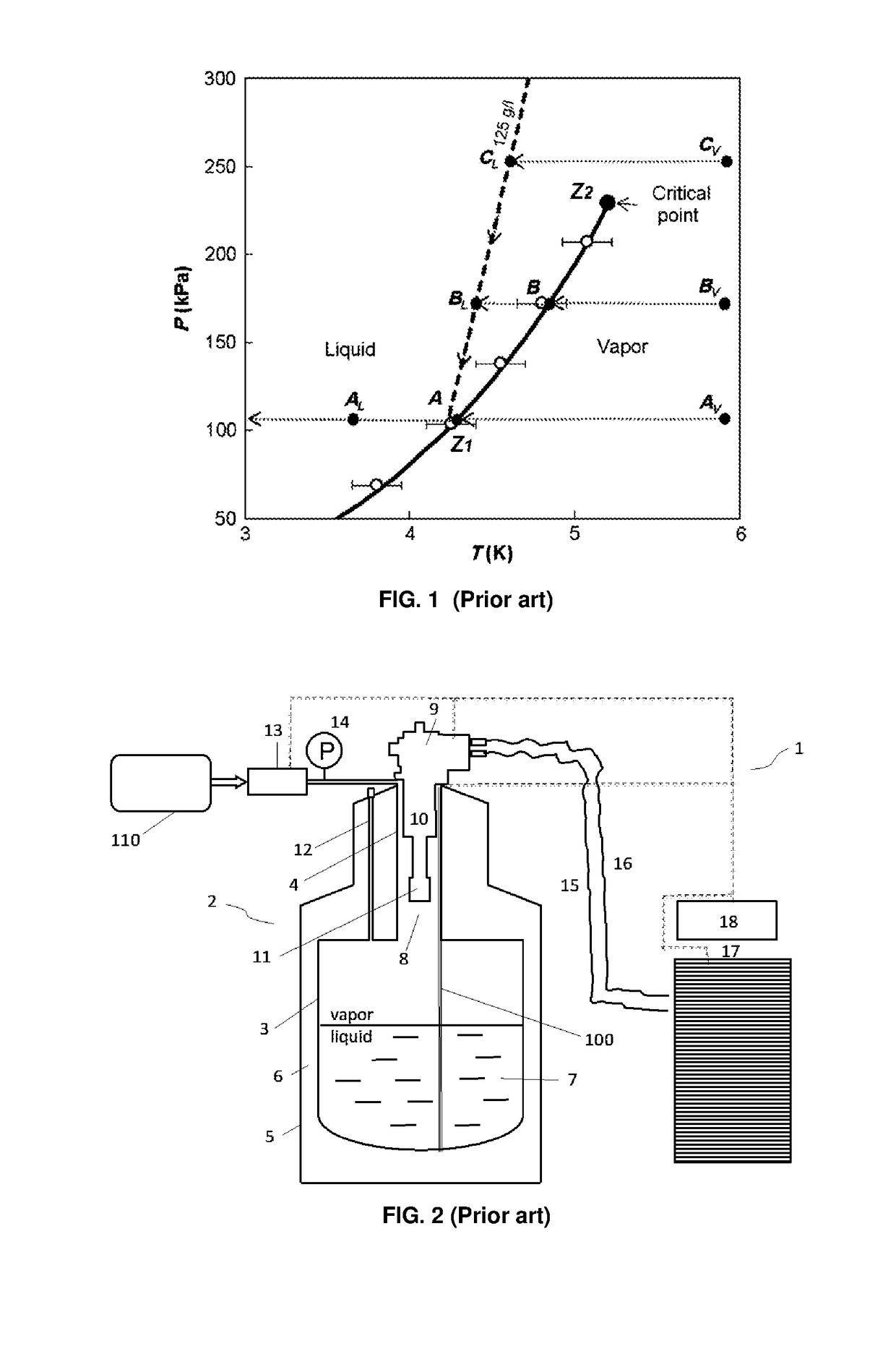

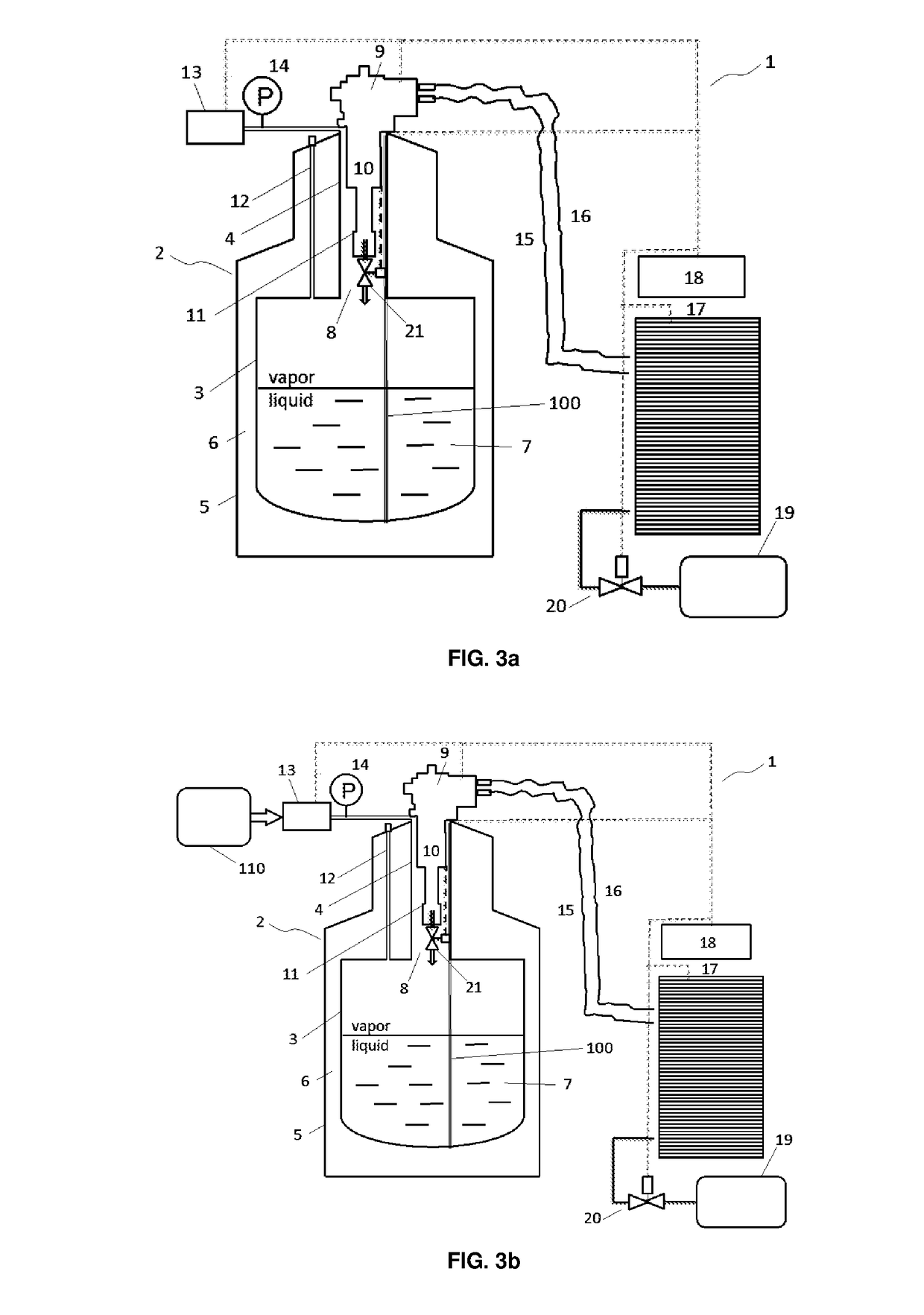

System and method for improving the liquefaction rate in cryocooler-based cryogen gas liquifiers

InactiveUS20170370638A1High efficiencyIncrease cooling powerSolidificationLiquefactionGas constantProcess engineering

The present invention relates to a cryogen-gas liquefaction system (1) and method comprising: a storage container (2) comprising a liquid storage portion (3) and a neck portion (4) with a liquefaction region (8) above said bath (7); a coldhead (9) arranged at the neck portion (4) comprising one or more refrigeration stages (10, 11); a gas intake module (12) containing an amount of gas-phase cryogen for its introduction into the storage container (2); and a pressure control mechanism (13) for controlling the cryogen gas pressure within the liquefaction region (8) of the storage container (2). Advantageously, the coldhead (9) further comprises: a refrigeration compressor (17) for distributing gas-phase cryogen inside the coldhead (9); one or more extraction orifices (22) communicating a gas circulation circuit inside the coldhead (9) with the external region of the refrigeration stages (10, 11), acting as pass-through ports (23); and a gas injection source (19) connected with the gas circulation circuit of said refrigeration compressor (17) through a gas injection valve (20), that maintains a total amount of gas constant in the compressor gas circuit, to compensate for the amount of gas extracted and liquefied through the extraction orifices (22).

Owner:UNIV DE ZARAGOZA +1

Method and system for producing liquefied natural gas (LNG)

ActiveUS9151537B2Improve gas efficiencyIncrease contentSolidificationLiquefactionRefluxFractionation

A method and system for optimizing the efficiency of an LNG liquification system of the gas expansion type, wherein an incoming feed gas is first separated in a fractionation column by counter current contact with a cold reflux fluid, and a gaseous stream introduced into the heat exchanger system at a reduced temperature such that an intermediate pinch point is created in the warm composite curve.

Owner:ARAGON AS

Detergents for cold-water cleaning

ActiveUS10421930B2Efficient liquefactionImprove performanceOrganic detergent compounding agentsNon-ionic surface-active compoundsBetaineAlcohol

Detergents useful for cold-water cleaning and mid-chain headgroup and alkylene-bridged surfactants useful therein are disclosed. The mid-chain headgroup surfactant has a C14-C30 alkyl chain and a polar group bonded to a central zone carbon of the alkyl chain. The alkylene-bridged surfactant has a C12-C18 alkyl chain, a polar group, and a C1-C2 alkylene group bonded to the polar group and a central zone carbon of the C12-C18 alkyl chain. Preferred surfactants in these classes are alcohol sulfates, alcohol ethoxylates, ether sulfates, sulfonates, arylsulfonates, alcohol phosphates, amine oxides, quaterniums, betaines, and sulfobetaines. Surprisingly, detergents formulated with the surfactants provide outstanding cold-water performance in removing greasy stains such as bacon grease, butter, cooked beef fat, or beef tallow from soiled articles.

Owner:STEPAN COMPANY

A microemulsion reactor for catalytic depolymerization of lignin

InactiveCN105126727BIncrease liquefaction rateHigh selectivityOrganic chemistryChemical/physical/physico-chemical stationary reactorsDepolymerizationFiltration

The invention discloses a micro emulsion reactor used for lignin catalytic depolymerization. The micro emulsion reactor is used through following steps: 1) mixing and stirring organically-soluble lignin, sulfonic acid-functionalized acidic ionic liquid, a hydrocarbon compound, a hydrophobic organic solvent and deionized water; 2) performing a hydrothermal reaction at 150-300 DEG C; and 3) after the reaction is carried out for 5-120 min, filtering a reaction liquid, performing liquid separation to obtain an oil phase containing phenols, a water phase containing the ionic liquid and solid residues. The micro emulsion reactor is high in liquefaction rate of lignin and selectivity. After the reaction, because the lignin is reduced in hydrophilicity, the reaction spontaneously forms two phases, so that the solid residues are obtained through filtration and the water phase being rich in the ionic liquid is obtained through the liquid separation. Extra water is removed in a rotary evaporation manner to recycle the ionic liquid for the next reaction directly. The reactor has a significant process strengthening effect on the depolymerization of lignin.

Owner:SOUTH CHINA UNIV OF TECH

Intelligent treatment equipment system for platemaking waste developing liquid

InactiveCN107200371AEfficient separationEfficient evaporationNature of treatment waterWater/sewage treatment by heatingWater vaporVacuum pump

The invention belongs to the technical field of wastewater treatment and specifically relates to an intelligent treatment equipment system for platemaking waste developing liquid. The intelligent treatment equipment system can be used for evaporating, bubble breaking, condensing and collecting moisture in the printing platemaking waste developing liquid. The system comprises a waste developing liquid evaporating treater and a condenser, wherein a bubble breaking mechanism is arranged in the waste developing liquid evaporating treater, and the condenser is connected with the waste developing fluid evaporating treater. The intelligent treatment equipment system has the beneficial effects that by injecting waste developing liquid into the waste developing liquid evaporating treater and continuously heating the waste developing liquid, the moisture in the waste developing liquid can be evaporated, and the moisture in the waste developing liquid can be effectively separated; bubbles generated by steam can be broken and separated by a large bubble breaking layer and a gas-liquid separating layer, pressure and pressure environment in the equipment are guaranteed, and steam can be quickly inflated into the condenser and quickly liquefied in a multi-branch mode. In addition, a double-layer condensate water temporary storage tank with a constant-pressure assembly and a vacuum pump is used for sucking and storing the liquefied condensate water, so that automatic operation and intelligent treatment of the whole equipment are achieved.

Owner:合肥凯宝乐环境科技有限公司

Liquefaction method, liquefaction device, and floating liquefied gas production equipment comprising same

Provided is a liquefaction method, a liquefying apparatus, and a floating liquefied-gas production facility equipped with the same, with which it is possible to suppress a decrease in liquefaction efficiency when gas to be liquefied is liquefied, to ensure safety, and to make the facility compact. Gas to be liquefied that has been subjected to heat exchange with a high-pressure heating medium composed of a single component is reduced in pressure, after which the gas to be liquefied that has been reduced in pressure is made to exchange heat with a low-temperature-side heating medium that is lower in temperature than and of the same type as the high-pressure heating medium.

Owner:MITSUBISHI SHIPBUILDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com