Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Guaranteed crimp quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

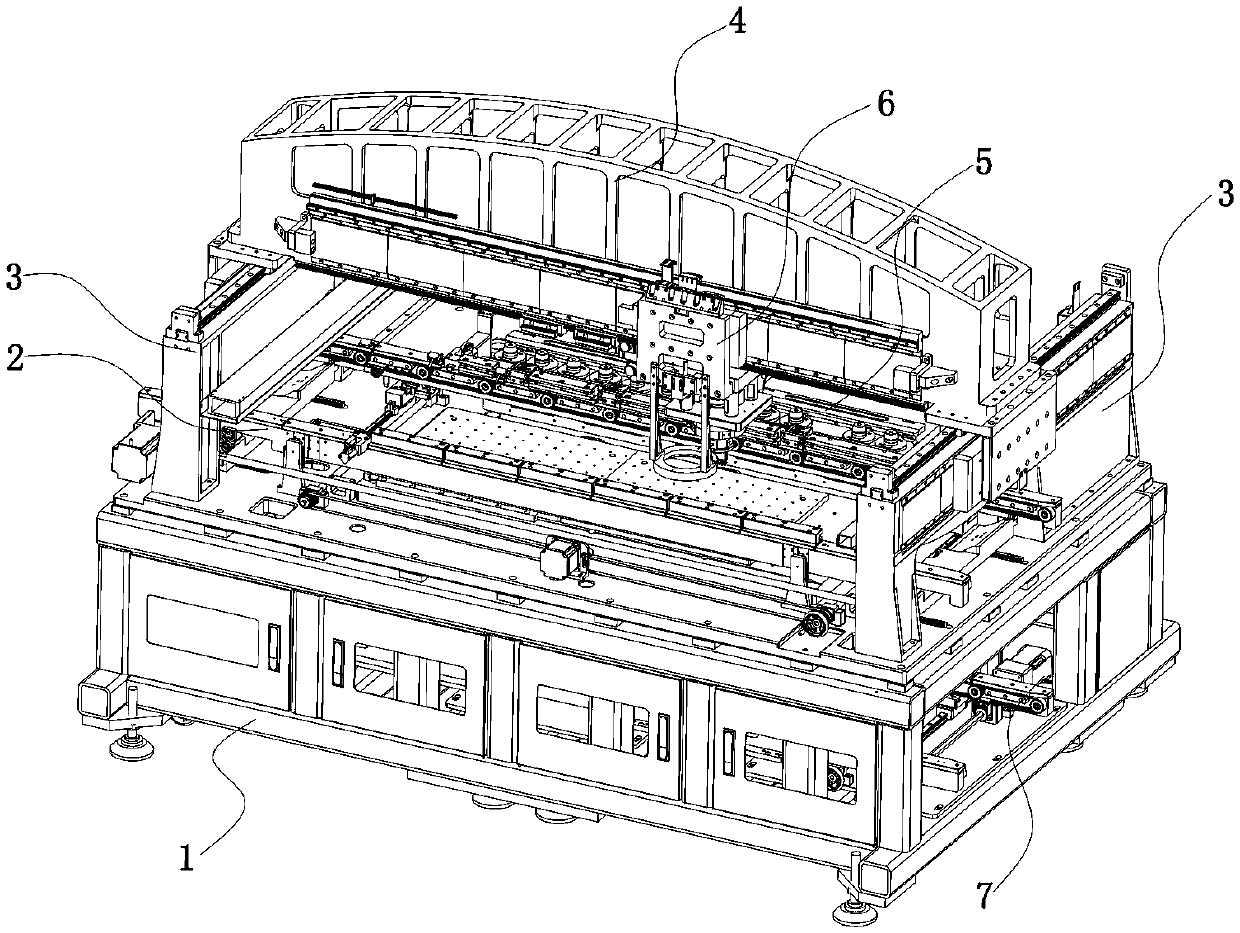

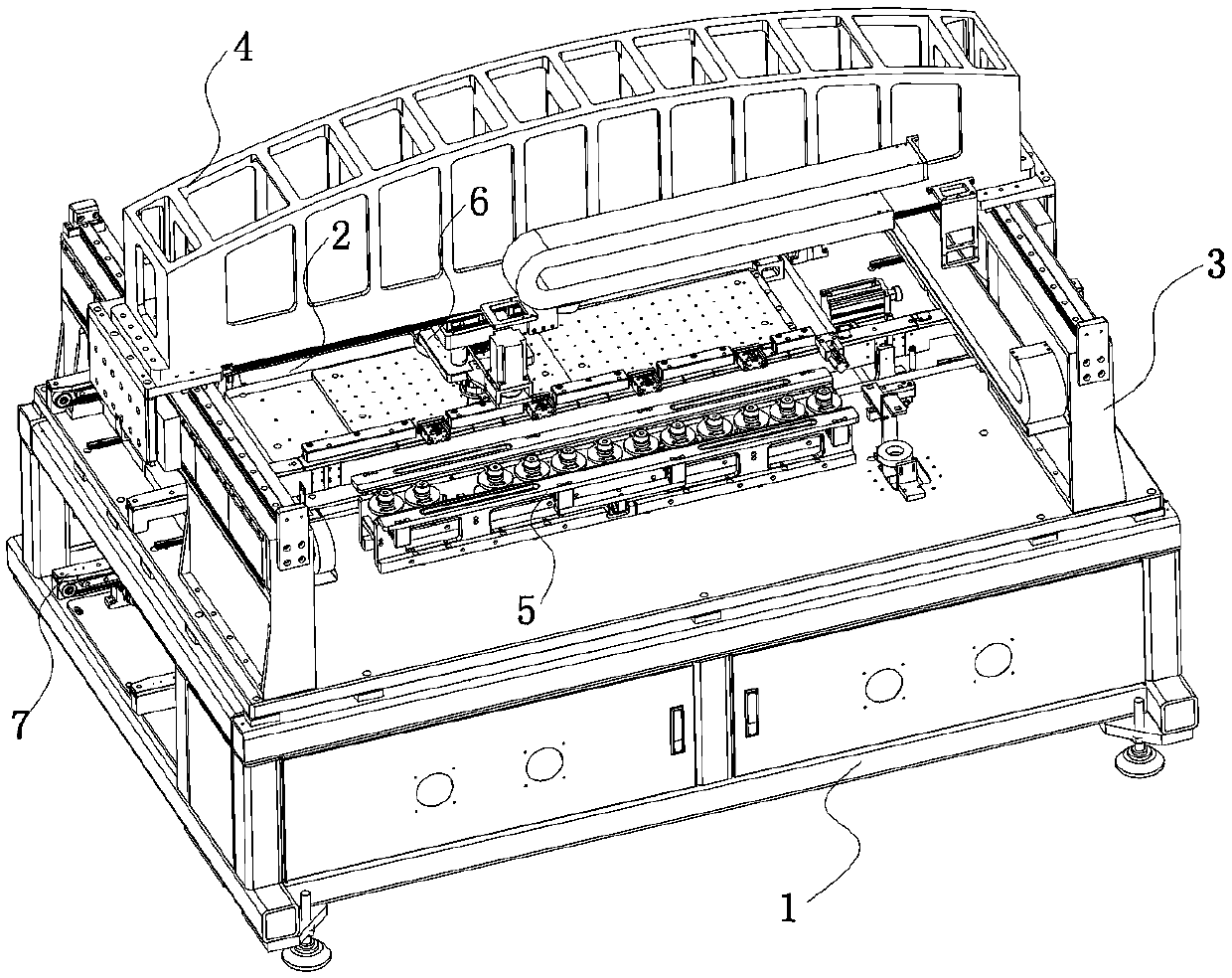

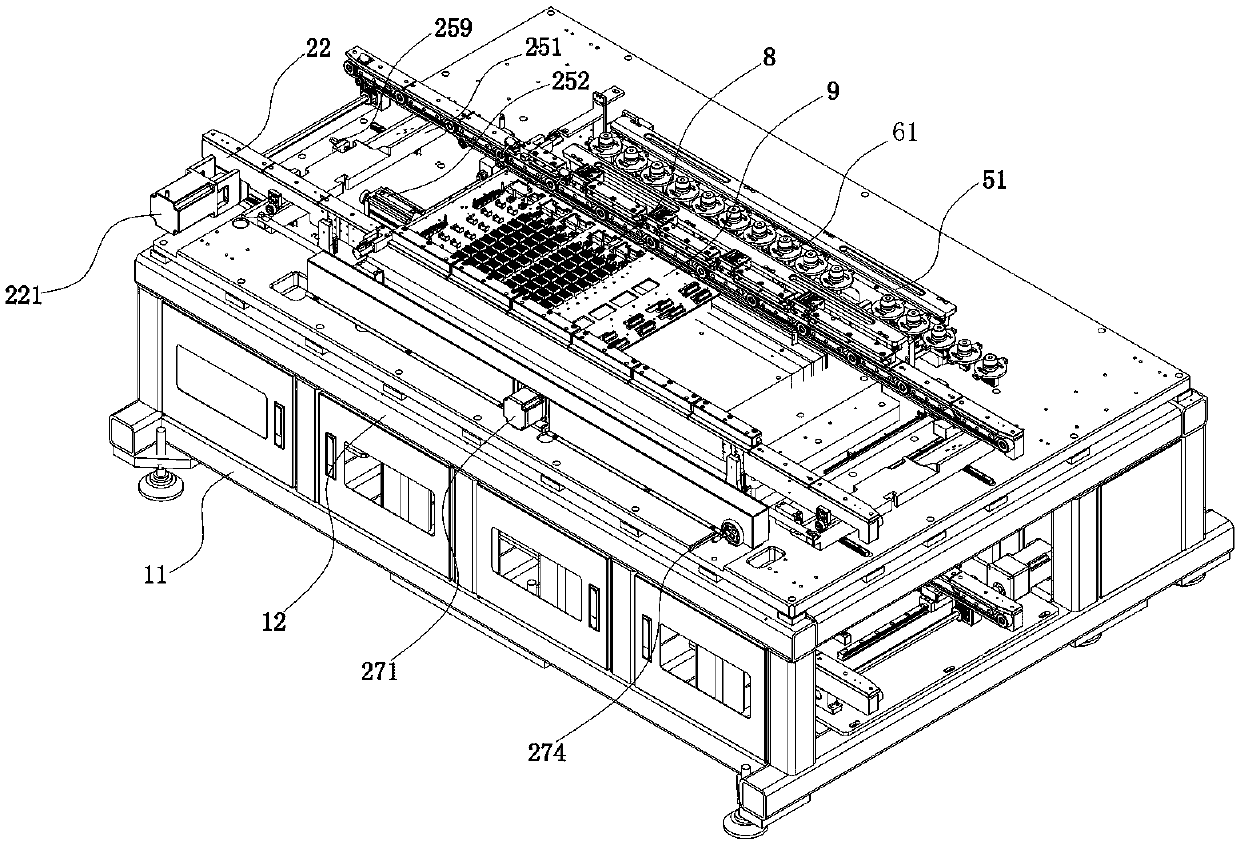

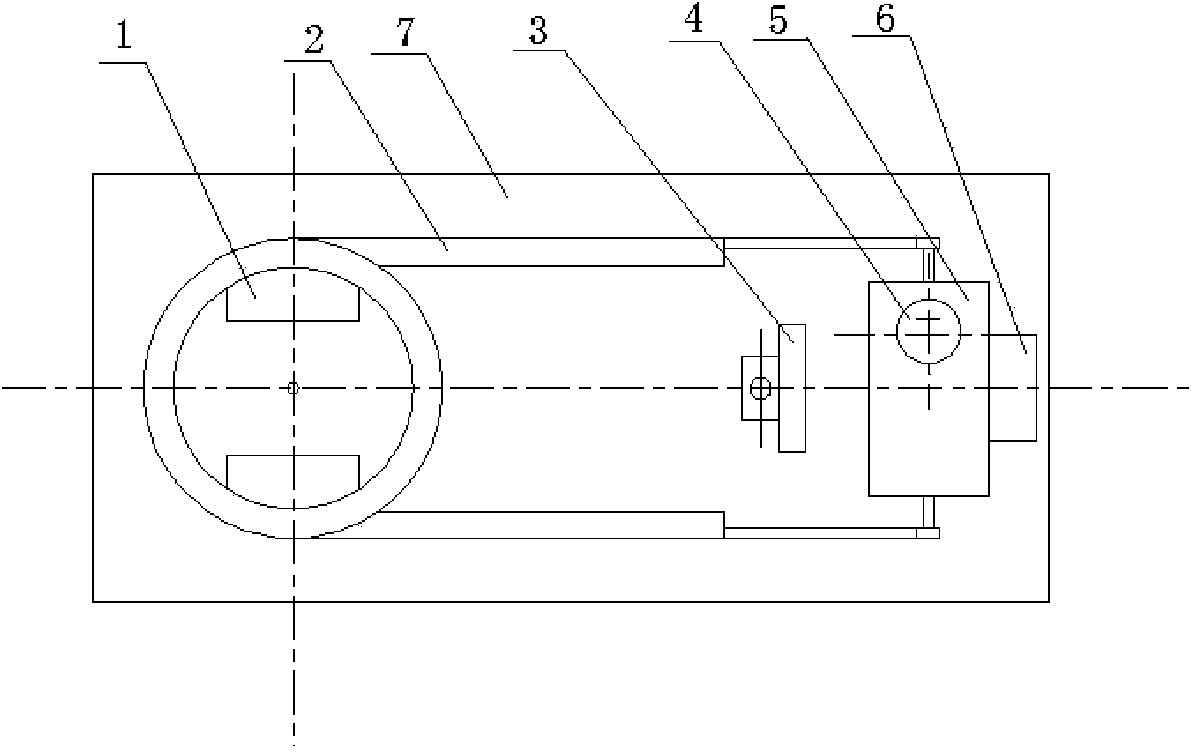

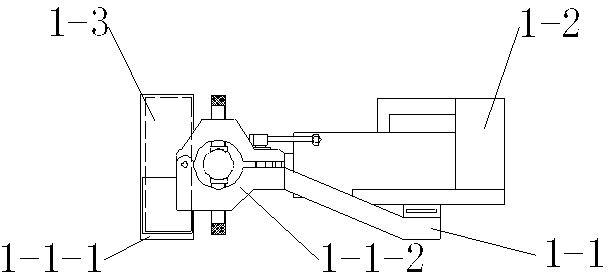

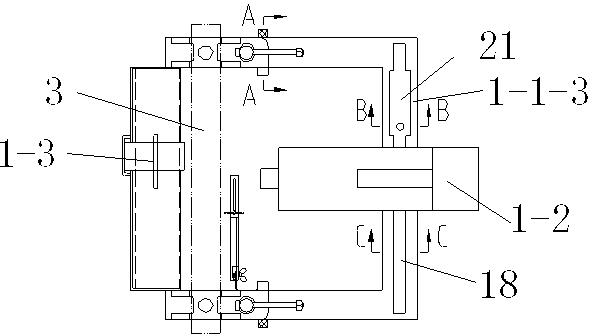

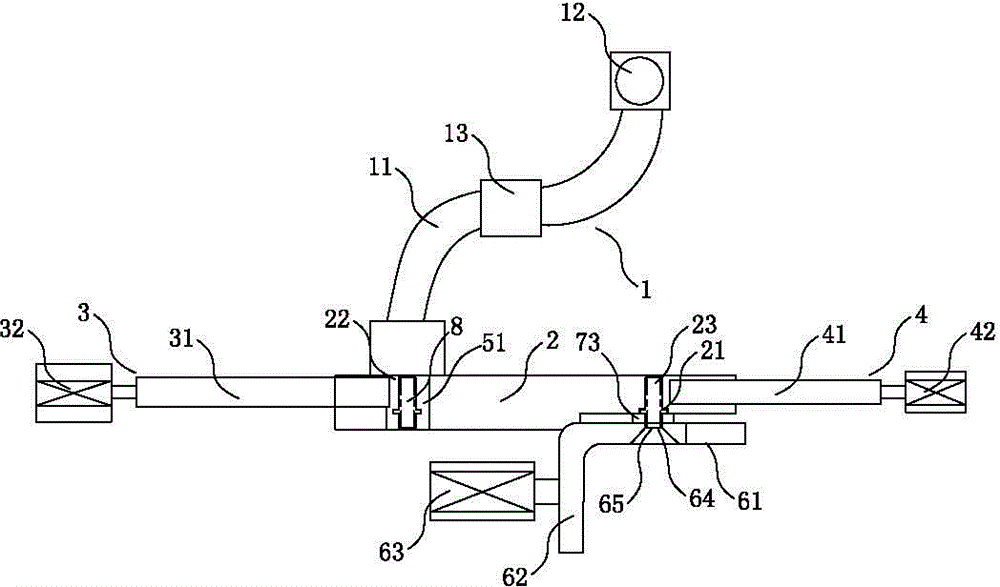

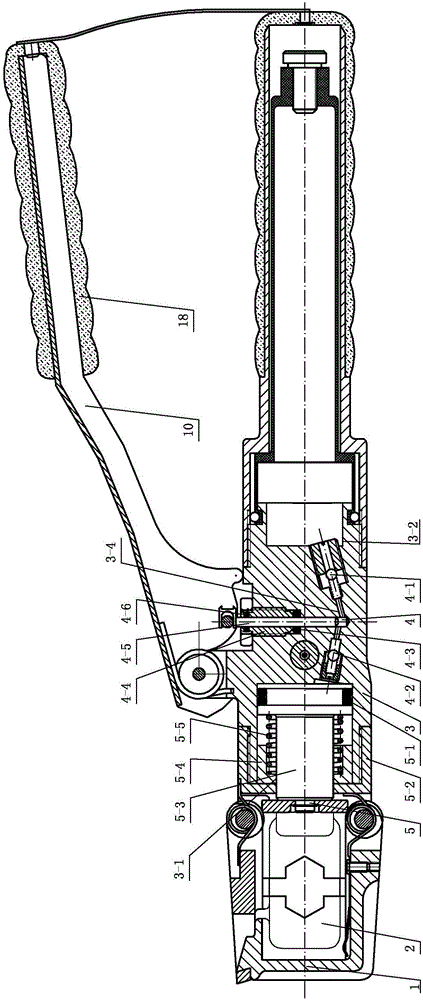

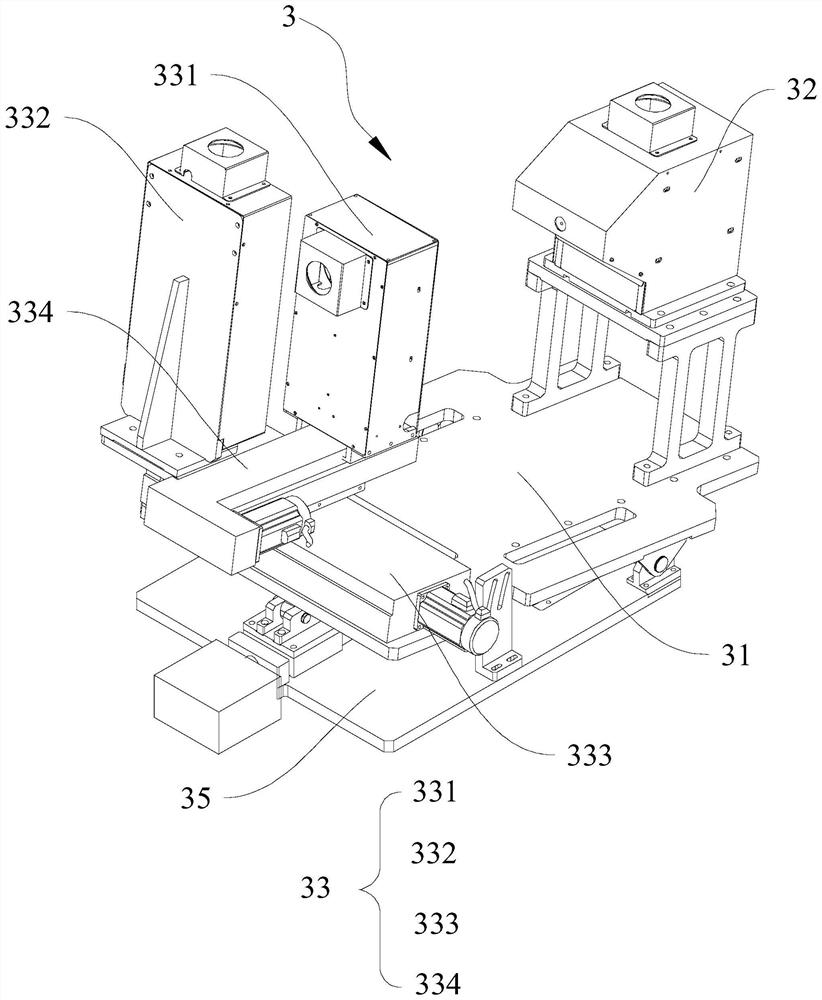

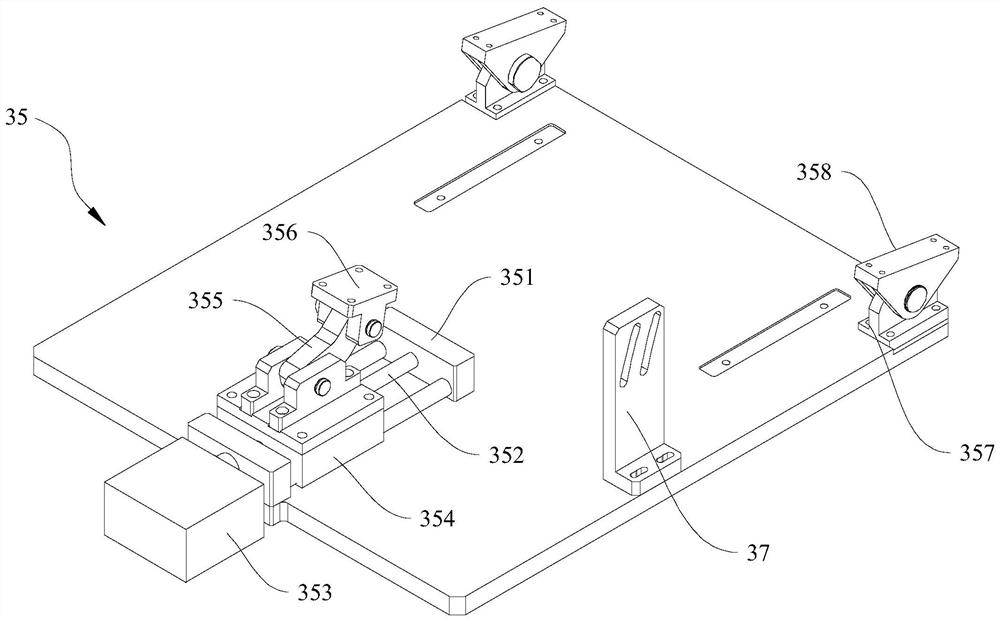

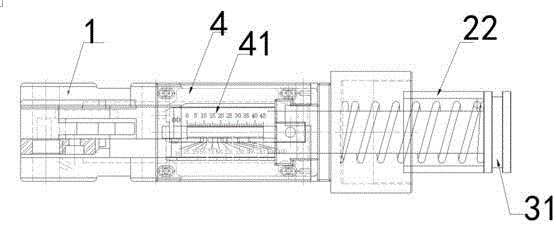

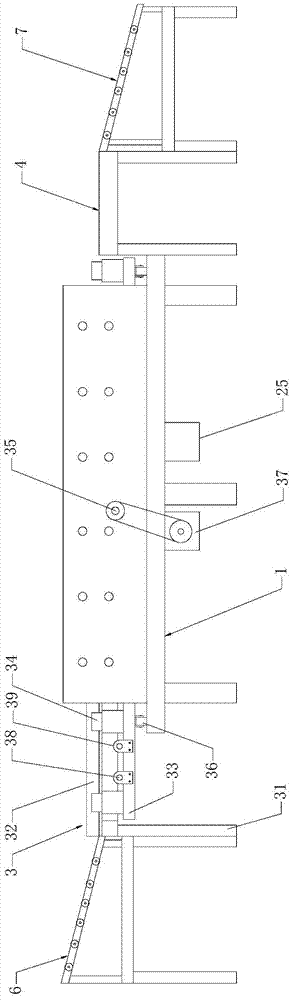

Automatic press-connection machine of connector and press-connection system and press-connection process thereof

ActiveCN105514754ACompact designAccurate crimp positioningLine/current collector detailsFixed connectionsComputer moduleData acquisition

The invention discloses an automatic press-connection machine of a connector and a press-connection system and press-connection process thereof. The automatic press-connection machine comprises a machine body, a portal frame supporting and guiding assembly, a material guiding assembly, a press-connection head replacing assembly and a press-connection assembly; the press-connection system comprises an IPC control chip, a height sensor connected with the IPC control chip, a CCD module, a movement control card, a linear motor and a data acquisition card; the press-connection process comprises a PARS press-connection module, a pressure press-connection module and a distance press-connection module. The automatic press-connection machine of the connector and the press-connection system and press-connection process thereof are applicable to a modern assembly line, fully-automatic material guiding control is adopted, a plurality of press-connection head components are arranged therein, multiple types of press-connection modes are correspondingly matched with the press-connection head components, in the press-connection process, pres-connection heads are replaced automatically, and product press-connection diversity is achieved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Continuous strain section assembly type wiring method for ultrahigh-strength aluminum conductor steel supported wires

InactiveCN102723679AControl loss and wasteGuaranteed crimp qualityApparatus for overhead lines/cablesArchitectural engineeringAluminium

The invention discloses a continuous strain section assembly type wiring method for ultrahigh-strength aluminum conductor steel supported wires. The method includes the steps: 1) calculation of the length of a strain section of a wire; 2) calculation of the manufacturing wire length; 3) utilization of strain hardware; and 4) an assembly type wiring process. By the method, wire loss and waste are effectively controlled, compression quality is guaranteed, and aloft operation is reduced. Further, the method is an accurate, efficient and safe construction method.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +2

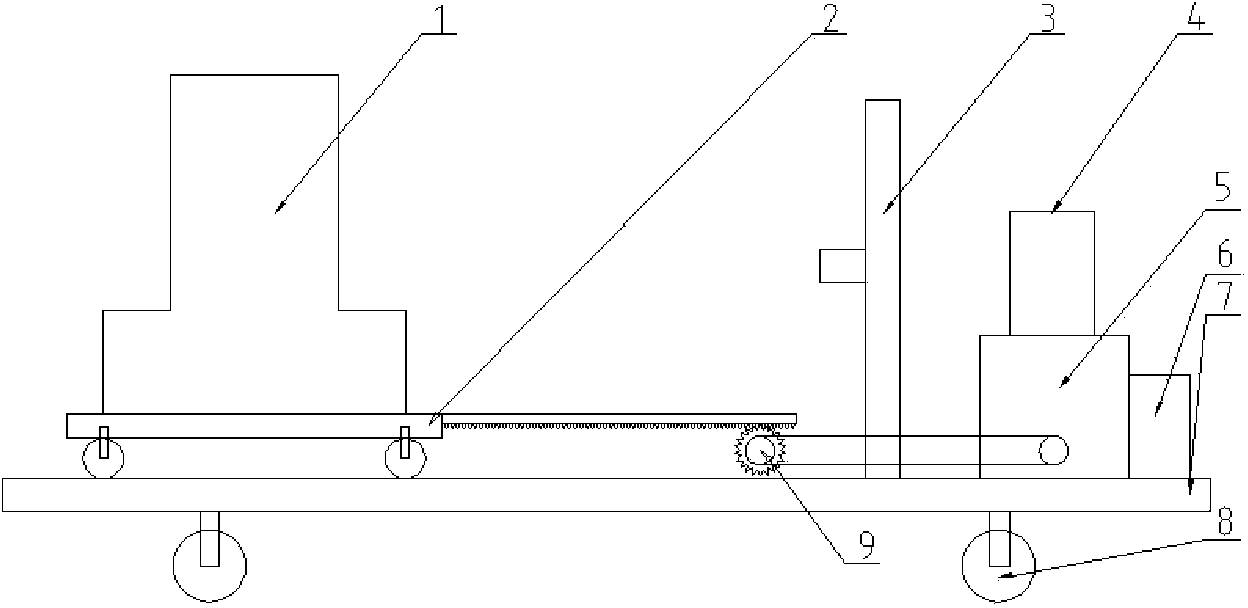

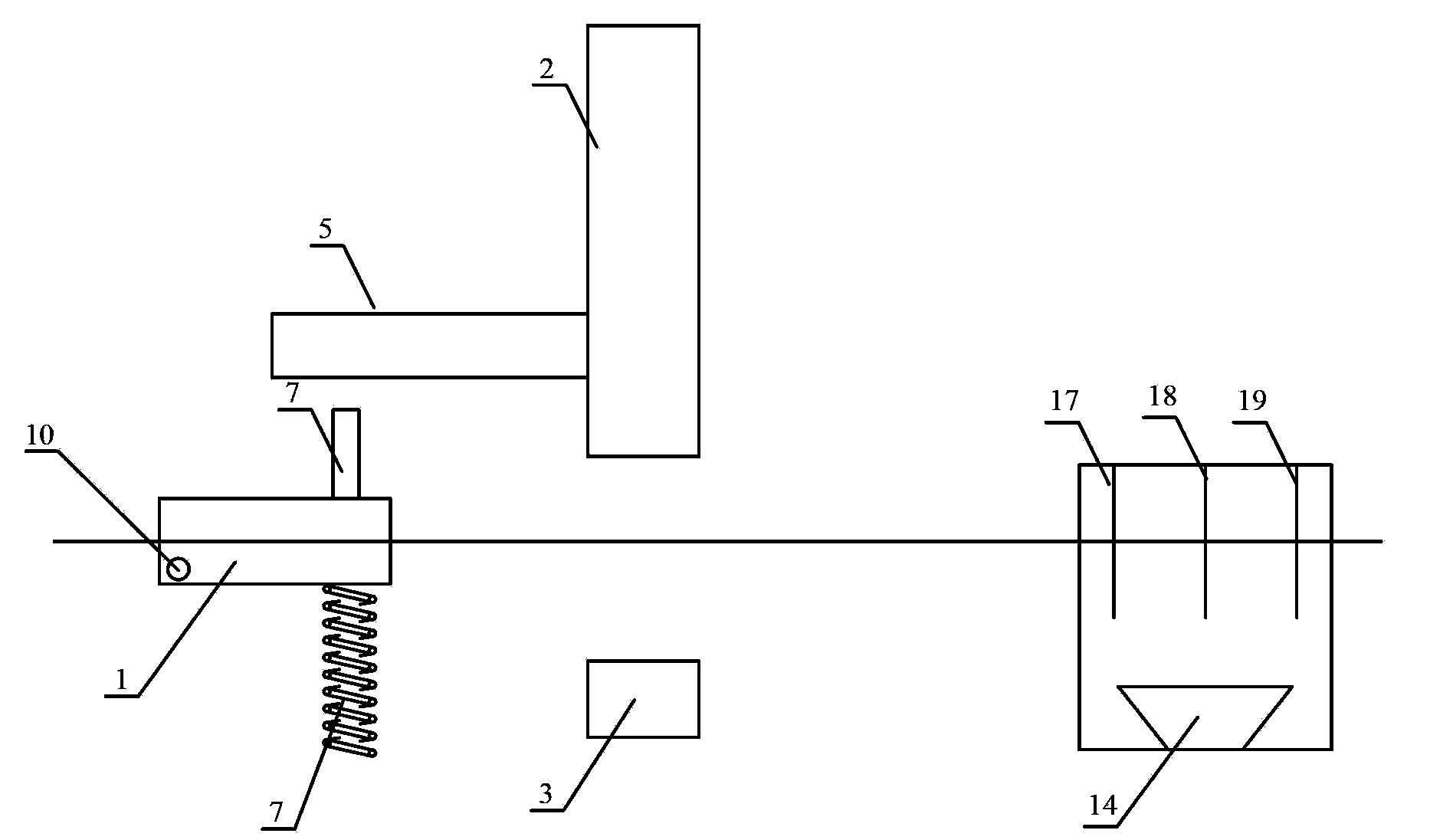

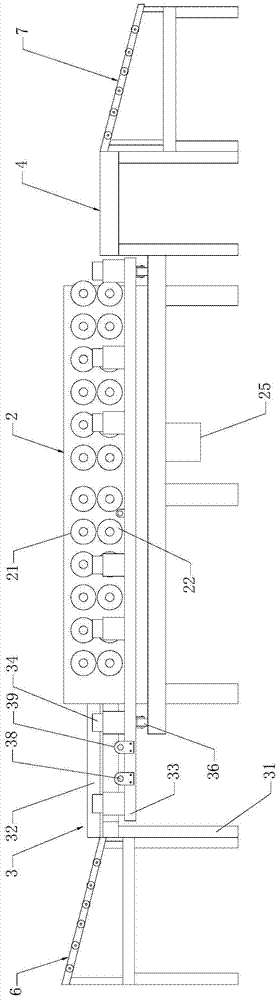

Automatic compression joint device for wires

ActiveCN103986090AMature processing technologyGuarantee processing qualityLine/current collector detailsApparatus for overhead lines/cablesHydraulic pumpUltimate tensile strength

The invention provides an automatic compression joint device for wires. The automatic compression joint device comprises a compression joint mechanism, a fixing mechanism, a motor and a hydraulic pump, wherein the compression joint mechanism, the fixing mechanism, the motor and the hydraulic pump are sequentially and vertically arranged on a support plate in the same axis direction, and the compression joint mechanism is connected with the hydraulic pump through a pipeline. The automatic compression joint device is characterized in that a conveying bracket is arranged between the compression joint mechanism and the support plate, a directed wheel and a flat tooth rail are sequentially arranged at the bottom of the conveying bracket in the arraying direction of the compression joint mechanism and the motor, the flat tooth rail is provided with a transmission gear meshed with the flat tooth rail, and the transmission gear is connected with the motor. Compared with the prior art, the automatic compression joint mode of the hydraulic and mechanical combination is adopted for the automatic compression joint device, the length and the step pitch of compression joint are controlled strictly, compression joint errors are reduced, labor intensity is relieved, compression joint efficiency is improved, and compression joint quality is ensured.

Owner:STATE GRID CORP OF CHINA +1

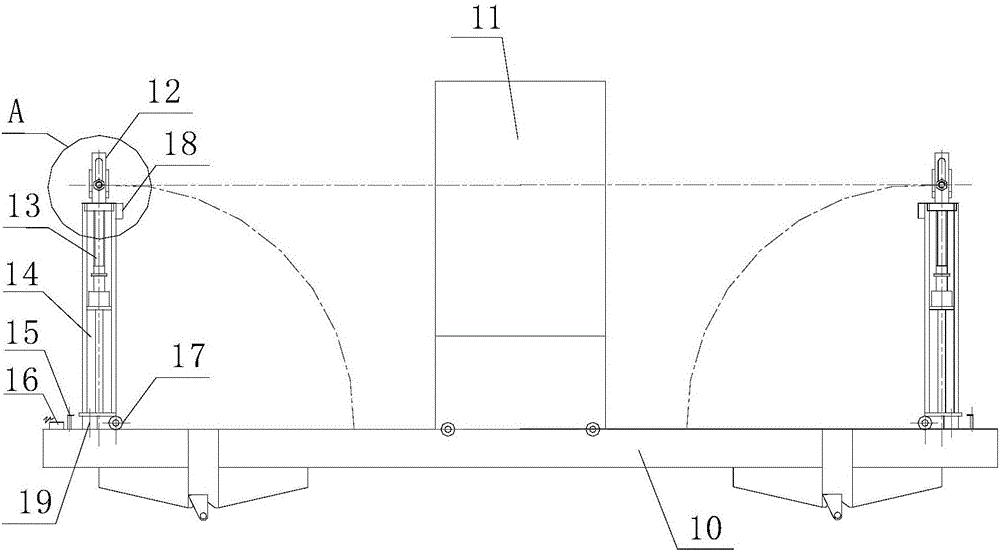

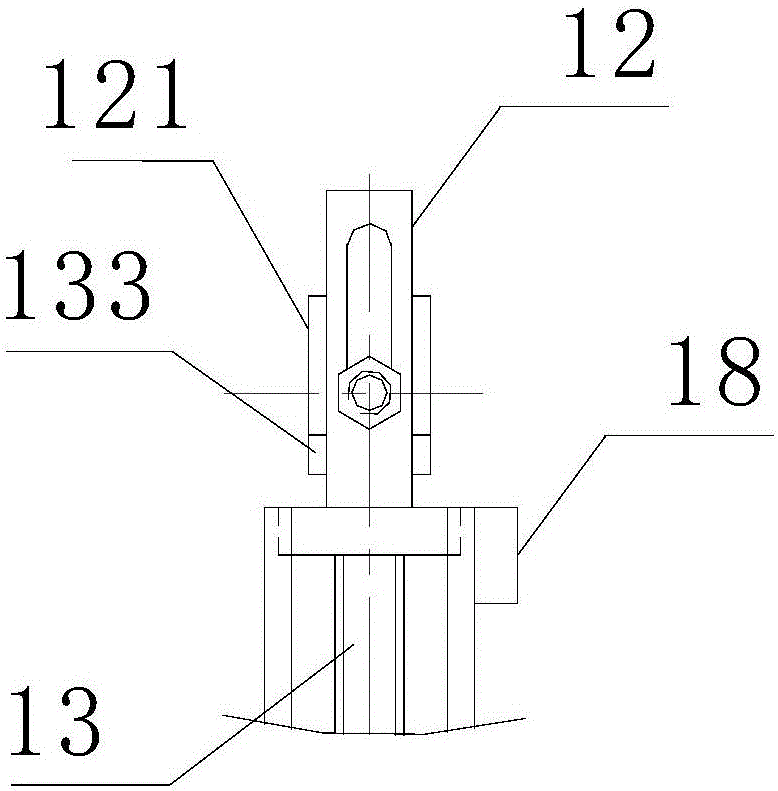

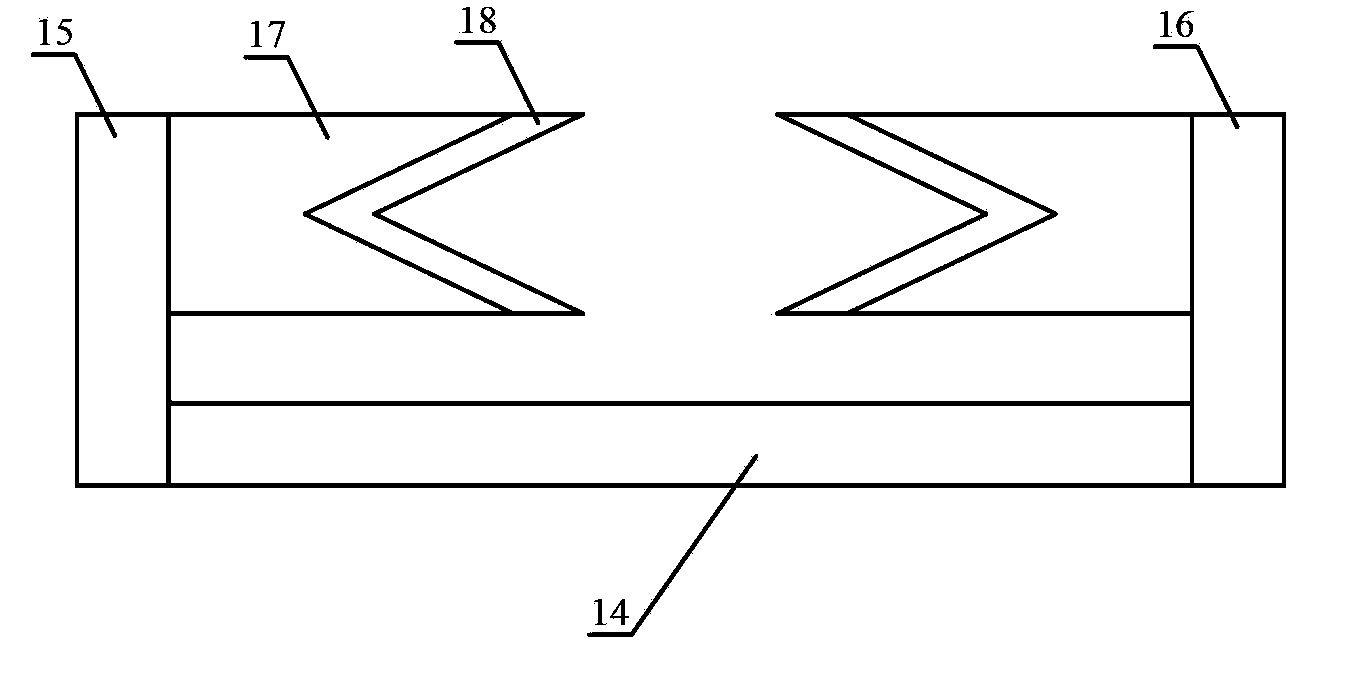

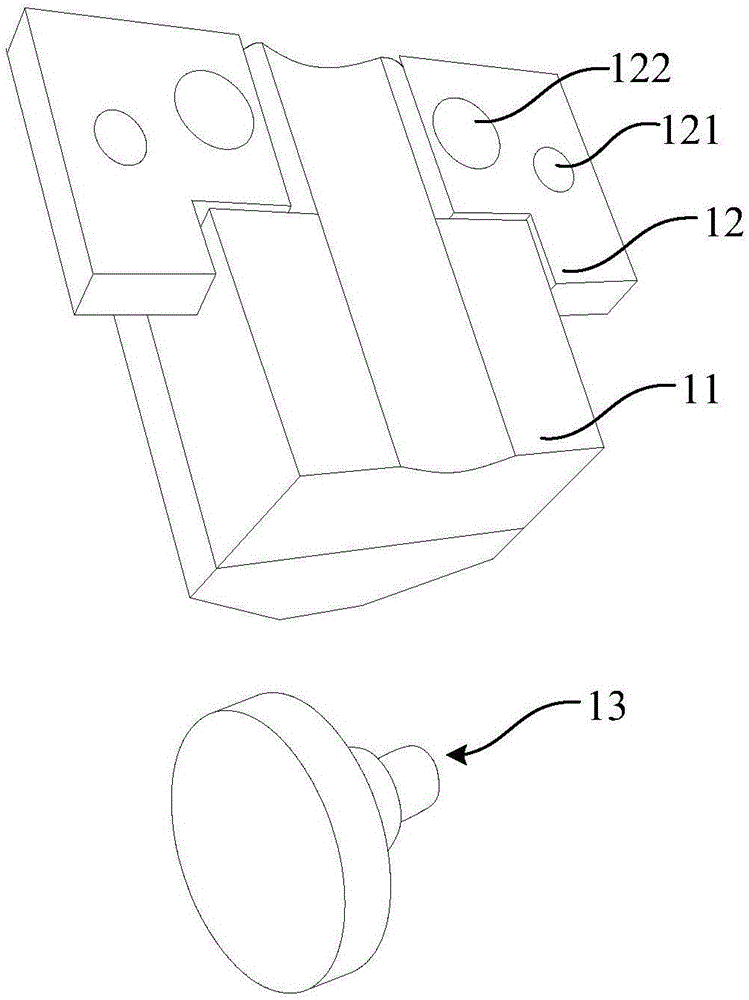

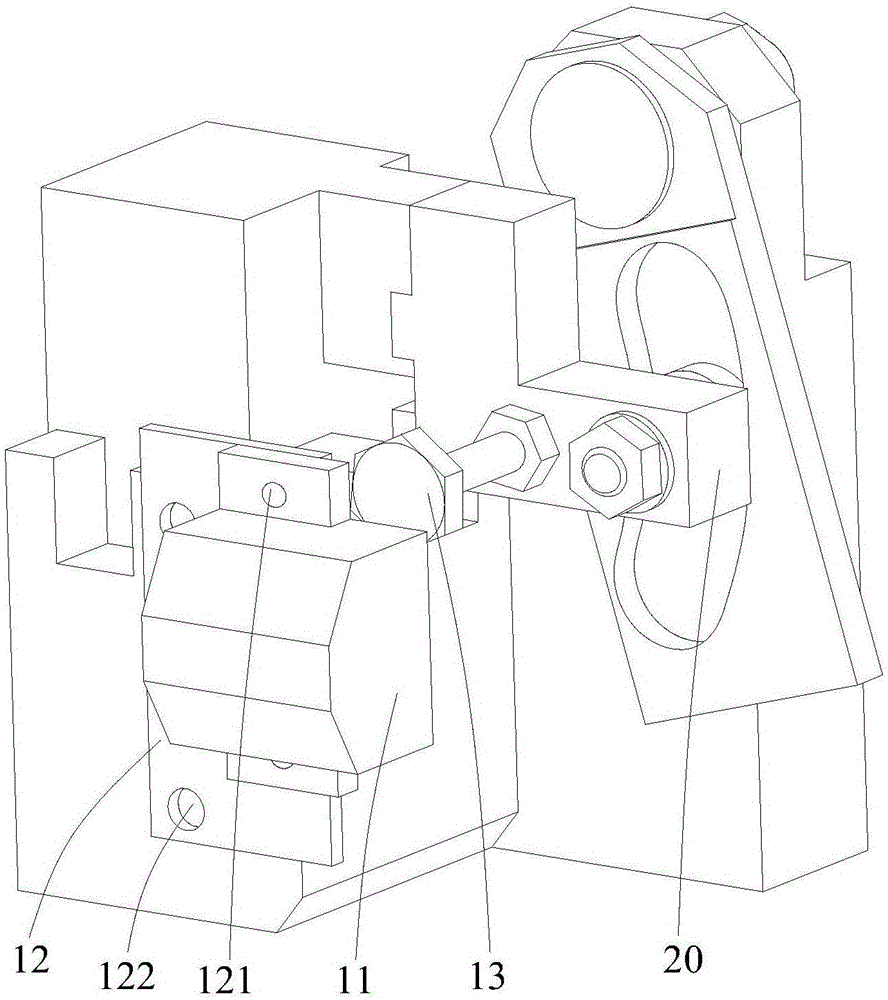

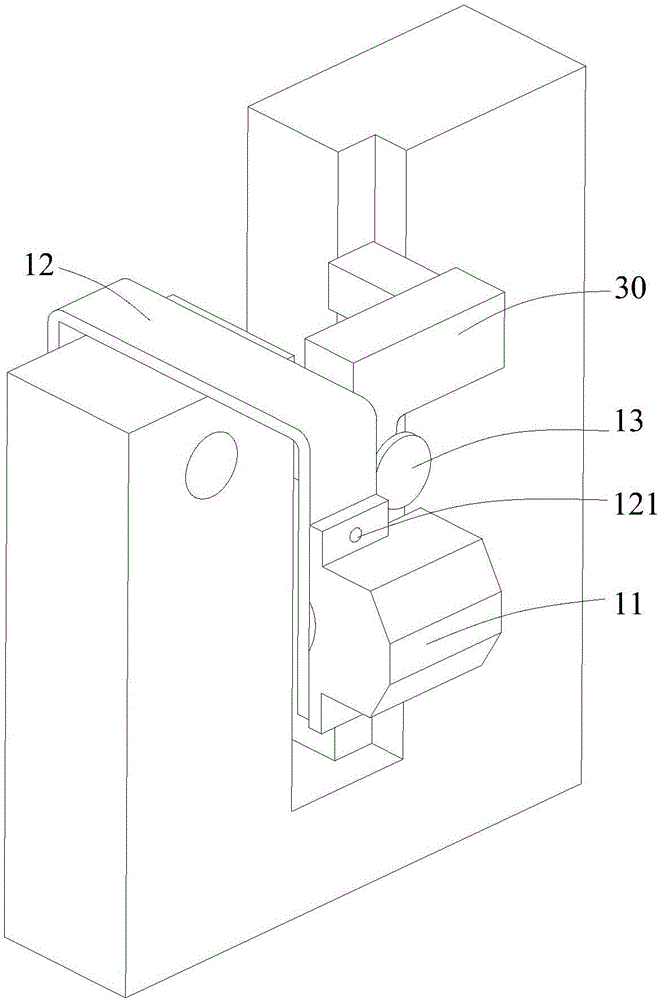

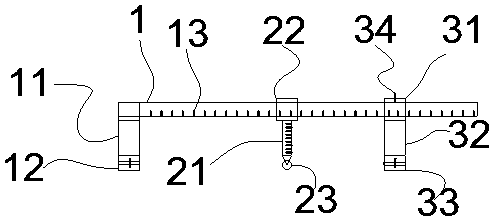

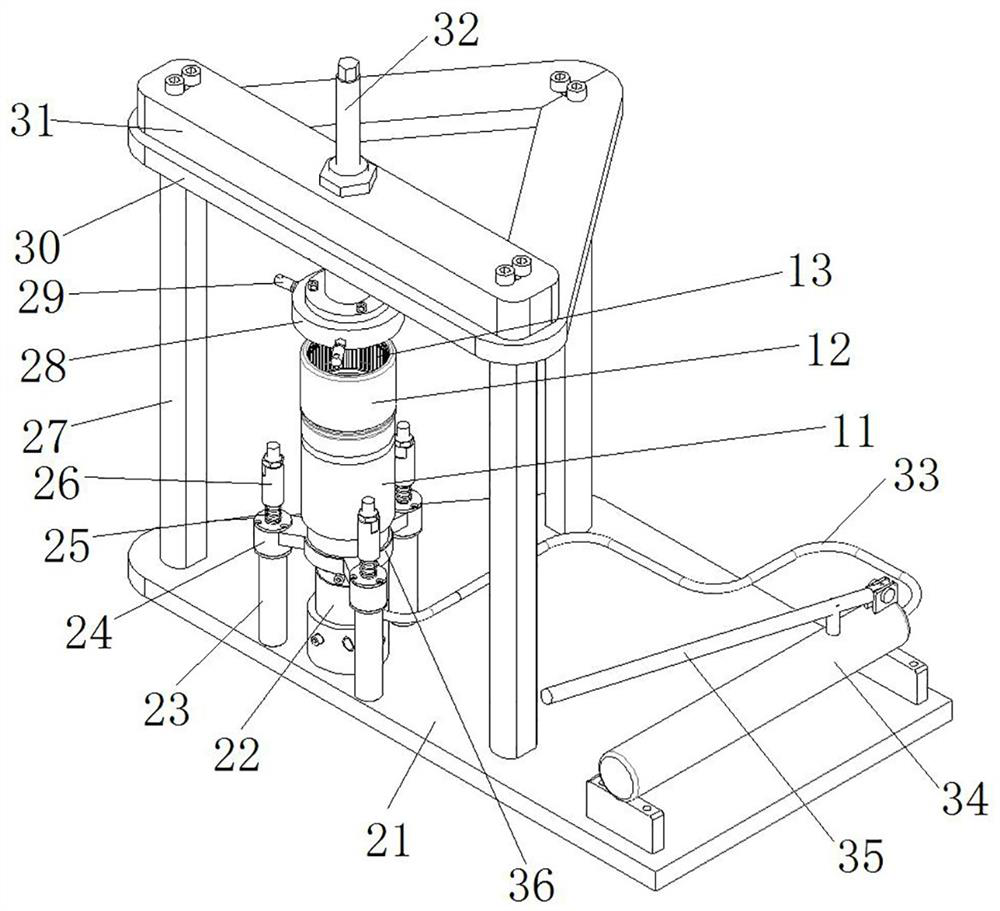

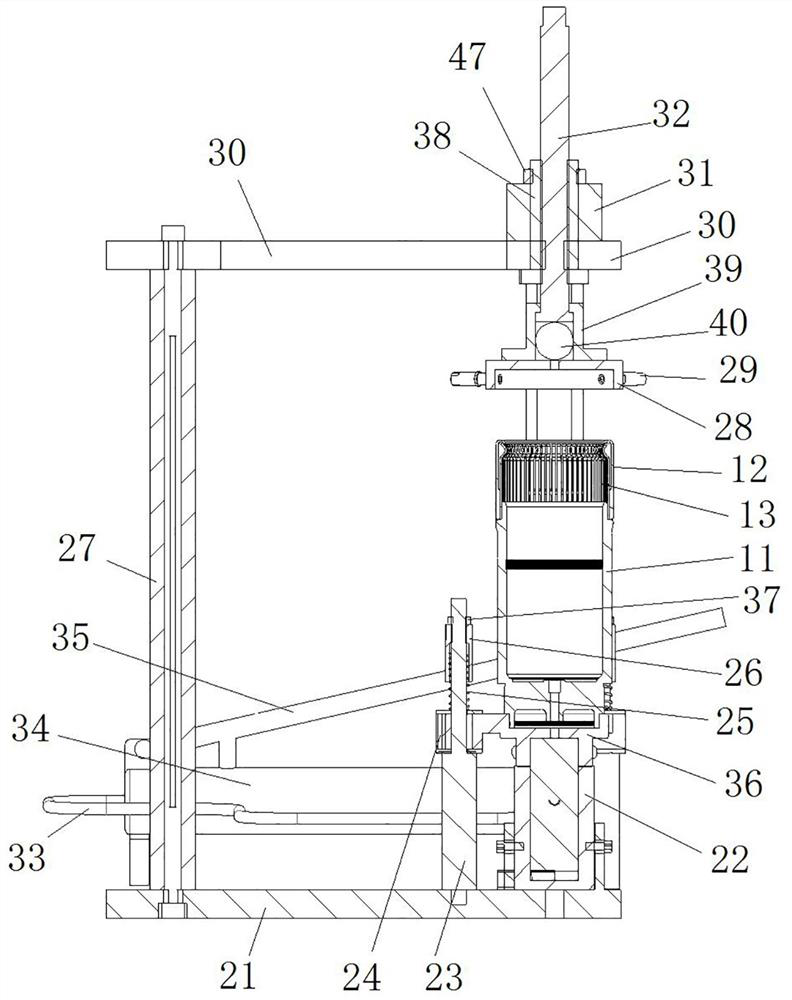

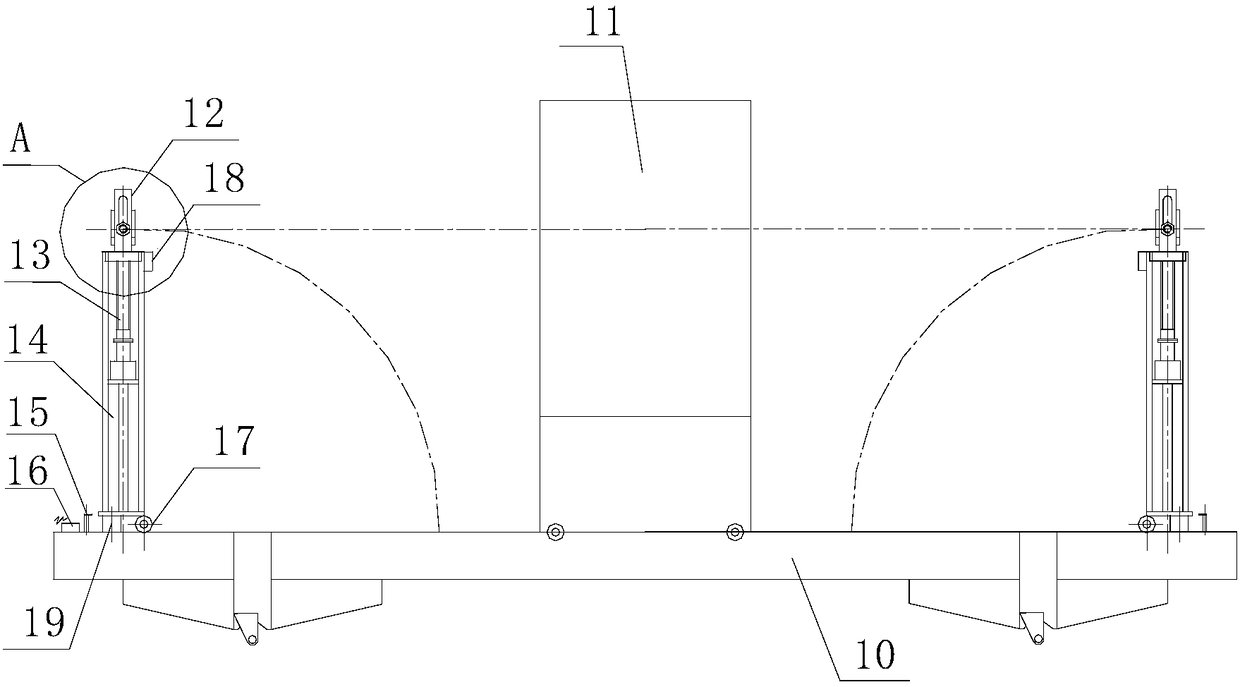

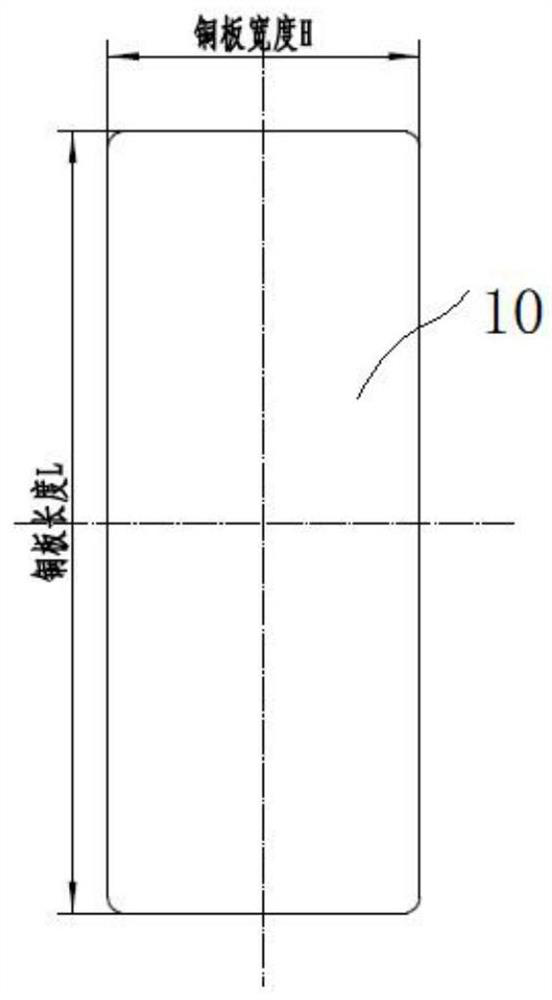

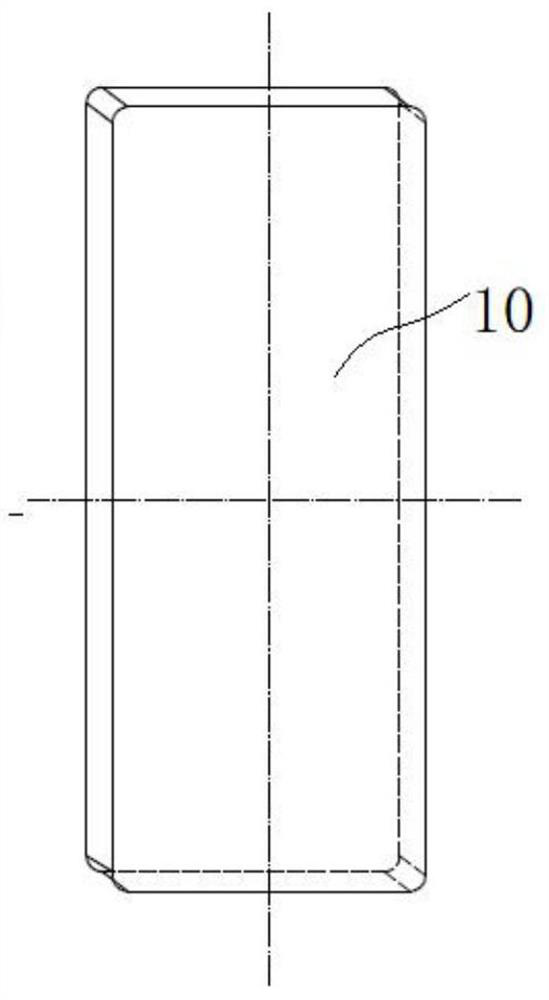

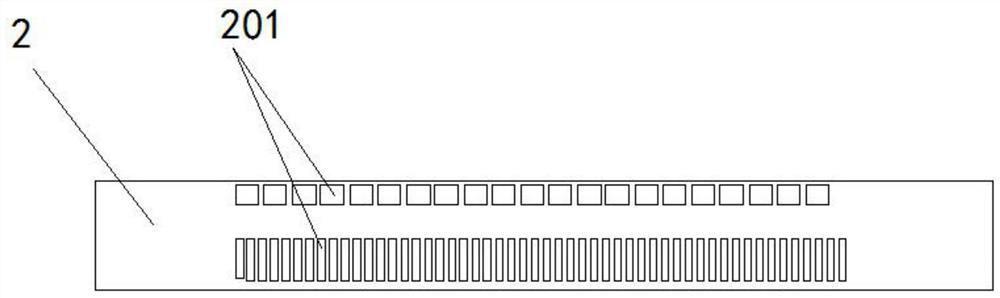

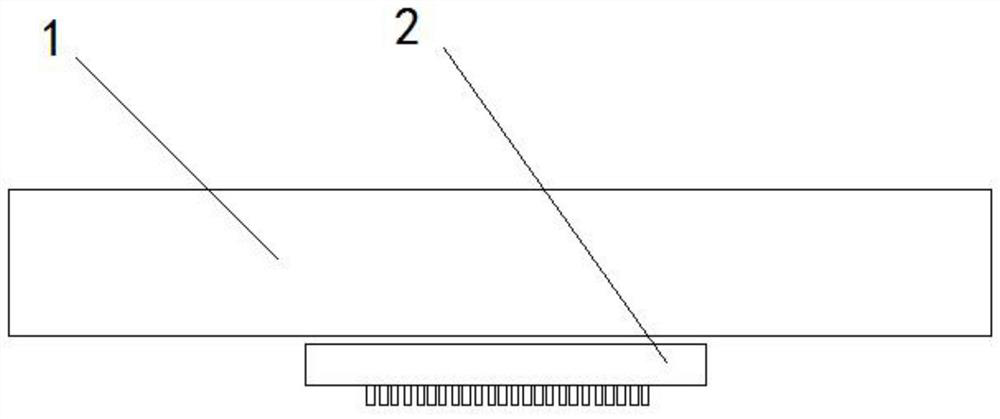

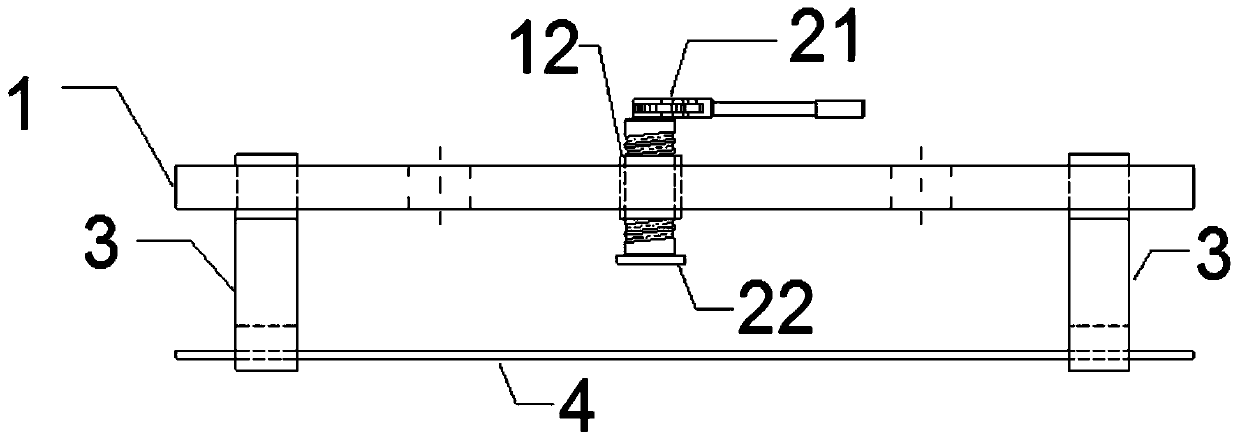

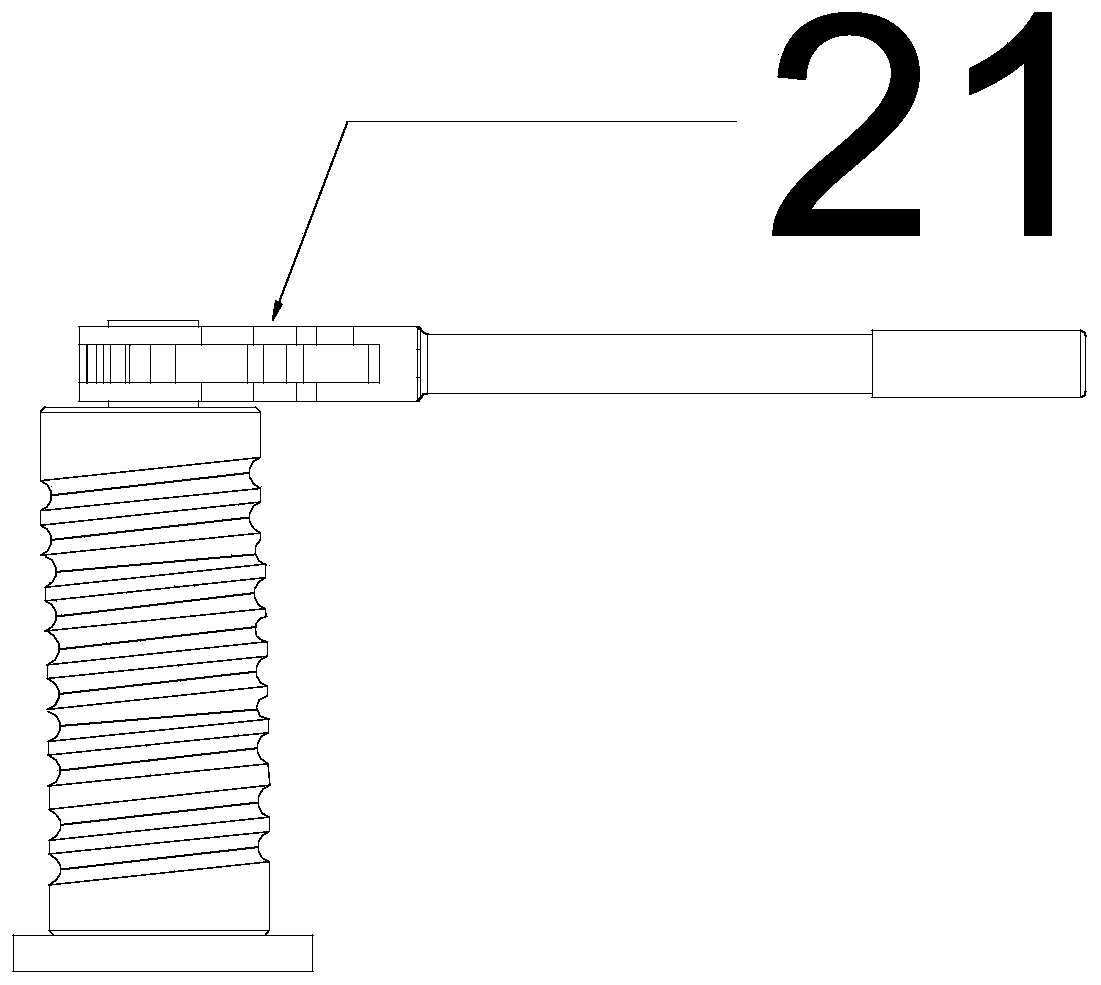

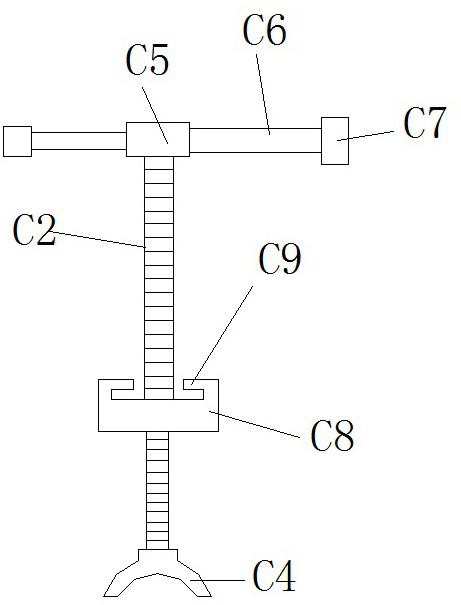

Adjustable lead wire press-connection machine bracket

ActiveCN106451007AGuaranteed crimp qualityEasy to transportLine/current collector detailsConnections effected by permanent deformationEngineeringMechanical engineering

The invention relates to an adjustable lead wire press-connection machine bracket. A press-connection machine (11) is arranged on a press-connection engine (10); stand columns (14) are located on two sides of the press-connection machine (11) respectively and each stand column is of a hollow structure provided with a slide way; a lower adjusting unit (13) is located in the hollow structure of each stand column (14), wherein a screw rod (132) is driven by a driving device (134) to rotate so as to drive a slide block (131) to move along the slide way of each stand column (14); lower adjusting blocks (133) are fixed with the slide blocks (131); each lower adjusting block (133) is of a tapered structure and a groove for containing a lead wire is formed in the upper end of each lower adjusting block (133); an upper adjusting unit (12) is arranged on each stand column (14); an upper bracket (122) acts above each stand column (14); upper adjusting blocks (121) are fixed on the upper brackets (122) through fastening bolts; and a reversed U-shaped groove is formed in each upper adjusting block (121) and and an opening end is inclined outward. By adopting the adjustable lead wire press-connection machine bracket, the straightness of a press-connection finished product can be guaranteed, and the adjustable lead wire press-connection machine bracket is simple in structure and convenient to transport.

Owner:DATONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER

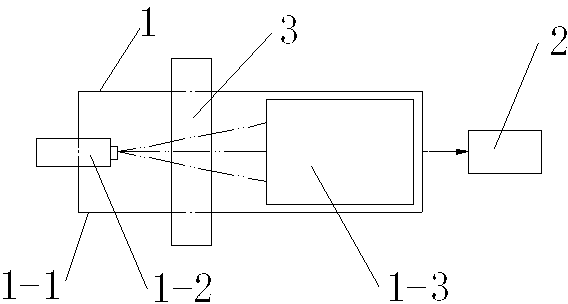

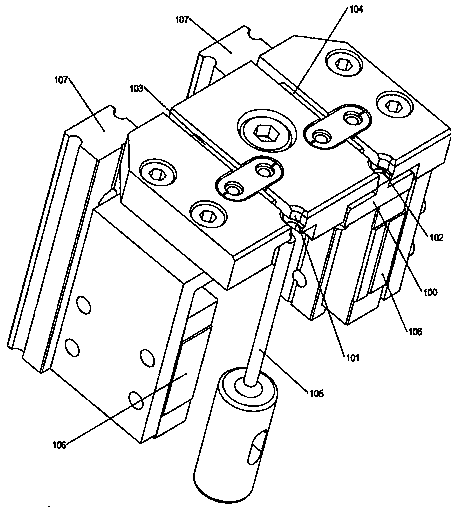

Fitting crimping quality detecting device

ActiveCN103123327AAvoid major accidentsSmall sizeWork holdersStands/trestlesEngineeringAssembly systems

The invention discloses a fitting crimping quality detecting device which comprises a final assembly system and a software imaging system, wherein the final assembly system comprises a clamping appliance, an emission instrument and a receiving instrument, the emission instrument and the receiving instrument are both arranged on the clamping appliance, and the crimping-type fitting needing to be detected is also fixed between the emission instrument and the receiving instrument through the clamping appliance. By utilizing the fitting crimping quality detecting device disclosed by the invention, the problem that the inner crimping quality of the crimping-type fitting cannot be detected in the existing crimping quality detection method can be solved, and the influence of the crimping quality inside the fitting upon the operation quality and safety of the lines can be avoided, so that serious accidents can be avoided.

Owner:QUJING BUREAU OF SUPERVOLTAGE POWER TRANSMISSION CHINA SOUTHERN POWER GRID +1

Pneumatic crimping connector for electric engineering

PendingCN107809046ASimple structureImprove crimp stabilityLine/current collector detailsEngineeringPower engineering

The invention relates to a pneumatic crimping connector for electric engineering. The machine is provided with a base. A cylinder room is fixedly arranged on the upper end of the base. A piston rod isvertically inserted into the upper end of the cylinder room. The lower end of the piston rod passes through the rear end of the cylinder room to be connected with a piston piece. The piston piece ishorizontally arranged in the cylinder room. An air inlet and an air outlet are respectively arranged on the two sides of the cylinder room below the piston piece. A semicircular movable pressing pieceis fixedly arranged on the upper end of the piston rod. Columns are fixedly arranged in positions which are on the upper end of the cylinder room and on the two sides of the semicircular movable pressing piece. A beam is horizontally and fixedly arranged on the upper ends of the columns. A connecting rod is arranged between the columns at the lower end of the beam. A semicircular fixed pressing piece is fixedly arranged at the lower end of the connecting rod and at the upper end of the semicircular movable pressing piece. The pneumatic crimping connector for electric engineering has a simplestructure. Wires are pneumatically crimped at fixed time and at fixed pressure. The overall crimping quality of wires is ensured. The weight of the whole device is reduced. The device is easy to carry. The crimping stability and the crimping efficiency of the crimping connector are improved.

Owner:湖州铭腾电力工程科技有限公司

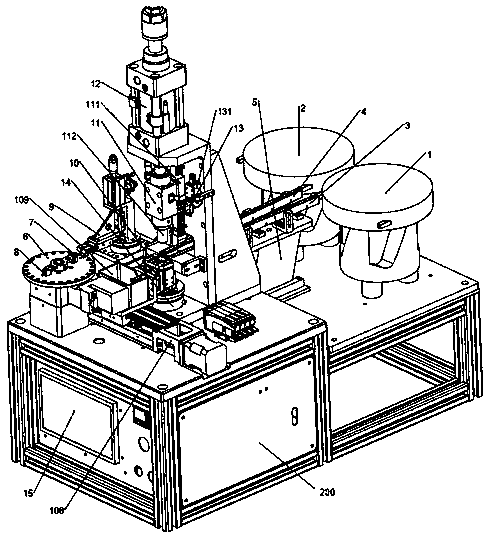

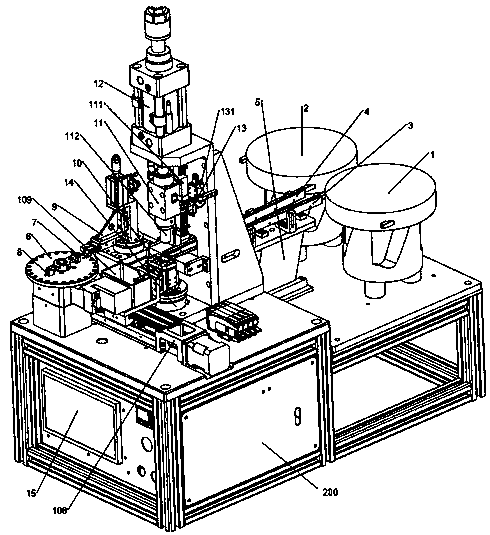

Automatic terminal crimping machine

ActiveCN104319596AFast and efficient crimping processImprove crimping efficiencyLine/current collector detailsElectrical conductorAutomatic testing

The invention relates to an automatic terminal crimping machine which structurally comprises a machine frame and a feeding device, a pushing device, a return material retreating device, a return material blanking device, a clamping device and a crimping device which are arranged on the machine frame. In the crimping process, a terminal enters the feeding position through a feeding pipe of the feeding device, and meanwhile the pushing rod pushes the terminal to the crimping position along a feeding slide. When the direction of the terminal is correct, a conductor of a cable is inserted into the crimping portion of the terminal, then an upper clamping plate and a lower clamping plate clamp the terminal in a fastening mode, and then an upper press die moves downwards to be matched with a lower press die to extrude and deform the crimping portion of the terminal to achieve crimping molding. When the direction of the terminal is wrong, a return material retreating rod pushes the terminal to the return material blanking plate, meanwhile the return material blanking plate moves to enable the terminal to fall into a recycling device below a support. The machine can greatly improve the crimping efficiency, saves time and labor, improves the crimping yield and improves product competitiveness.

Owner:GUANGDONG ZHONGDE CABLE

Novel crimping tool and using method

InactiveCN105479357ALow labor intensity for crimpingCrimp firmlyLine/current collector detailsClampsTransverse grooveEngineering

The invention relates to a novel crimping tool and a using method. The crimping tool mainly comprises a plier body which is provided with an upper plier head and a lower plier head, the upper plier head is fixedly connected with an upper jaw, and the lower plier head is fixedly connected with the lower jaw; the upper jaw is provided with plier protrusions, and the lower jaw is provided with plier concavities used for containing the plier protrusions; each plier protrusion is provided with a circular-arc through groove which is internally provided with an upper protrusion part; transverse grooves are formed in the side faces of the plier protrusions and penetrate through the circular-arc through grooves to form multiple crimping heads. According to the novel crimping tool and the using method, by means of the improvement on the jaw structures, efficient crimping can be conducted on a wire and an insertion hole of an O-shaped inner cavity, positioning can be conducted through a positioning unit, and the insertion hole is not prone to slipping in the crimping process.

Owner:济南无线电十厂有限责任公司

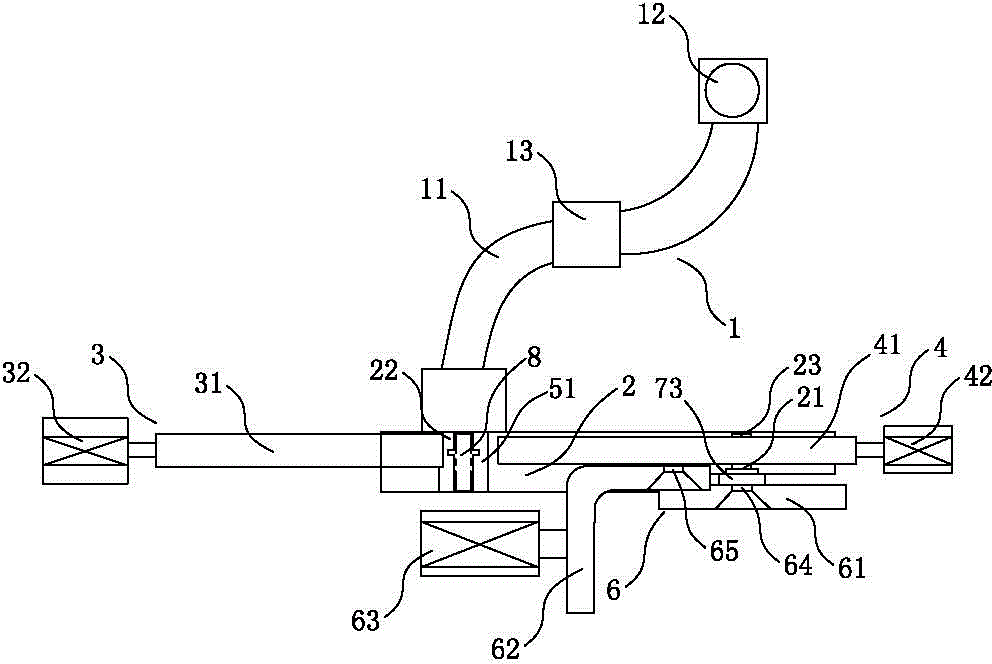

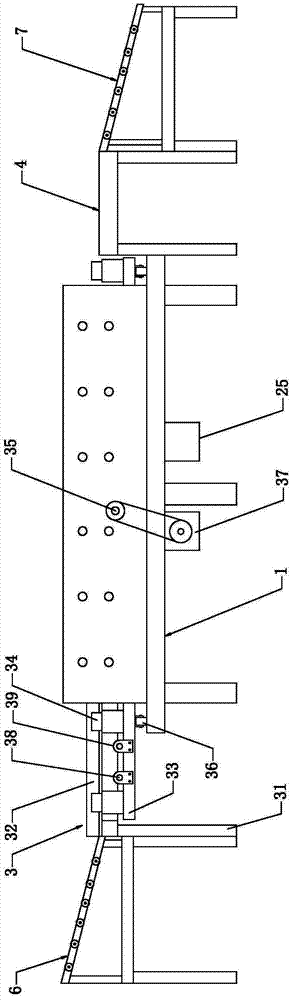

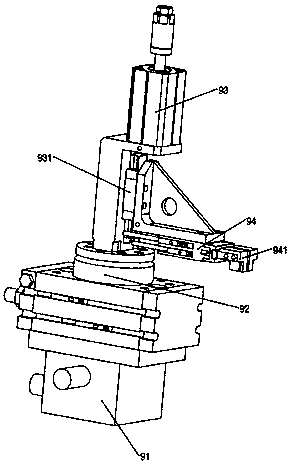

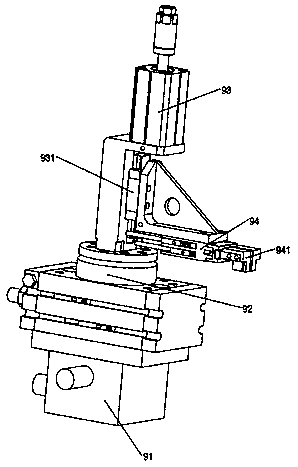

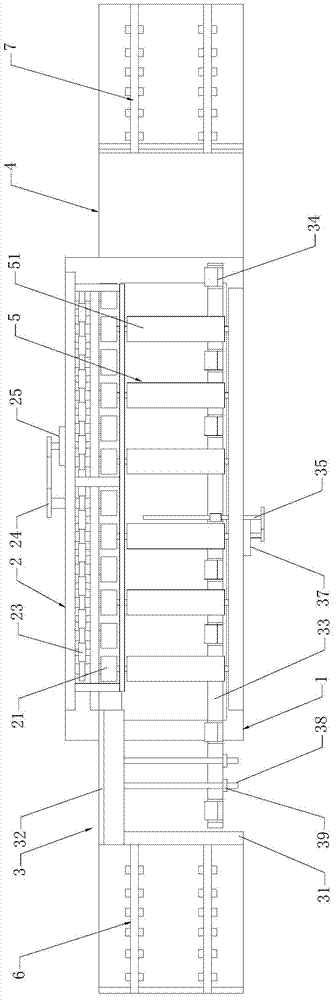

Stripping and crimping machine

InactiveCN103545693APrecise and consistent feeding positionGuaranteed crimp qualityConnection formation by deformationKnife holderEngineering

The invention provides a stripping and crimping machine comprising a crimping device and a cutoff and stripping device. The devices are sequentially disposed in a front-rear direction. The crimping device comprises a frame, a lead guide pipe, a lower punch die and an upper punch die. The lower and upper punch dies fit each other. The cutoff and stripping device comprises a first cutter rest and a second cutter rest both mounted on a slide way; the first and second cutter rests are paired; front strippers, cutters and rear strippers are pairwise disposed on the cutter rests in the wire feeding direction. The stripping and crimping machine has the advantages that the traditional stripping machine and the crimping machine are integrated, wires are fed under mechanical control instead of manual operation during the crimping process, the feeding positions are accurate and uniform, crimping quality is guaranteed, and time and cost are reduced greatly.

Owner:TIANJIN DESHENGYUAN ELECTRONICS

Counting device and counting method of wiring harness terminal crimping die

InactiveCN106295785AImprove work efficiencyEasy to operateCounting mechanisms/objectsEngineeringElectrical and Electronics engineering

Owner:SHANGHAI KUFENG AUTO PARTS

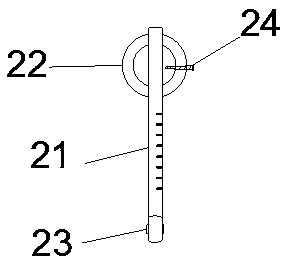

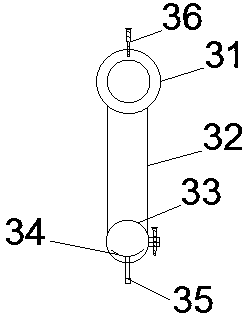

Special-purpose tool for measuring curvature of power transmission line crimping pipe

PendingCN110608655APortable toolReduce weightMechanical counters/curvatures measurementsMeasurement devicePetroleum engineering

The invention, which belongs to the technical field of crimping process control and detection of the power transmission line crimping pipe, relates to a special-purpose tool for measuring the curvature of a power transmission line crimping pipe. The tool comprises a measuring bracket, a bending amount measuring device and a crimping pipe post-crimping length measuring device. The measuring bracketincludes a first supporting part, a first fixed base and a cross beam. The bending amount measuring device includes a telescopic measuring rod, a measuring rod sliding block and a measuring roller. The crimping pipe post-crimping length measuring device includes a first sliding block, a second supporting part and a second fixing base. With the tool, the bending amount of the crimping pipe and thelength of the crimped crimping pipe can be measured at the same time to obtain a bending deformation value. The tool is light can be applied to ground crimping construction control and high-altitudemeasurement; after fixation of a fixing device in the high-altitude measurement, the high-altitude operation personnel can carry out operation conveniently, so that the problem of difficult high-altitude operation is solved. The tool is easy to popularize and apply.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

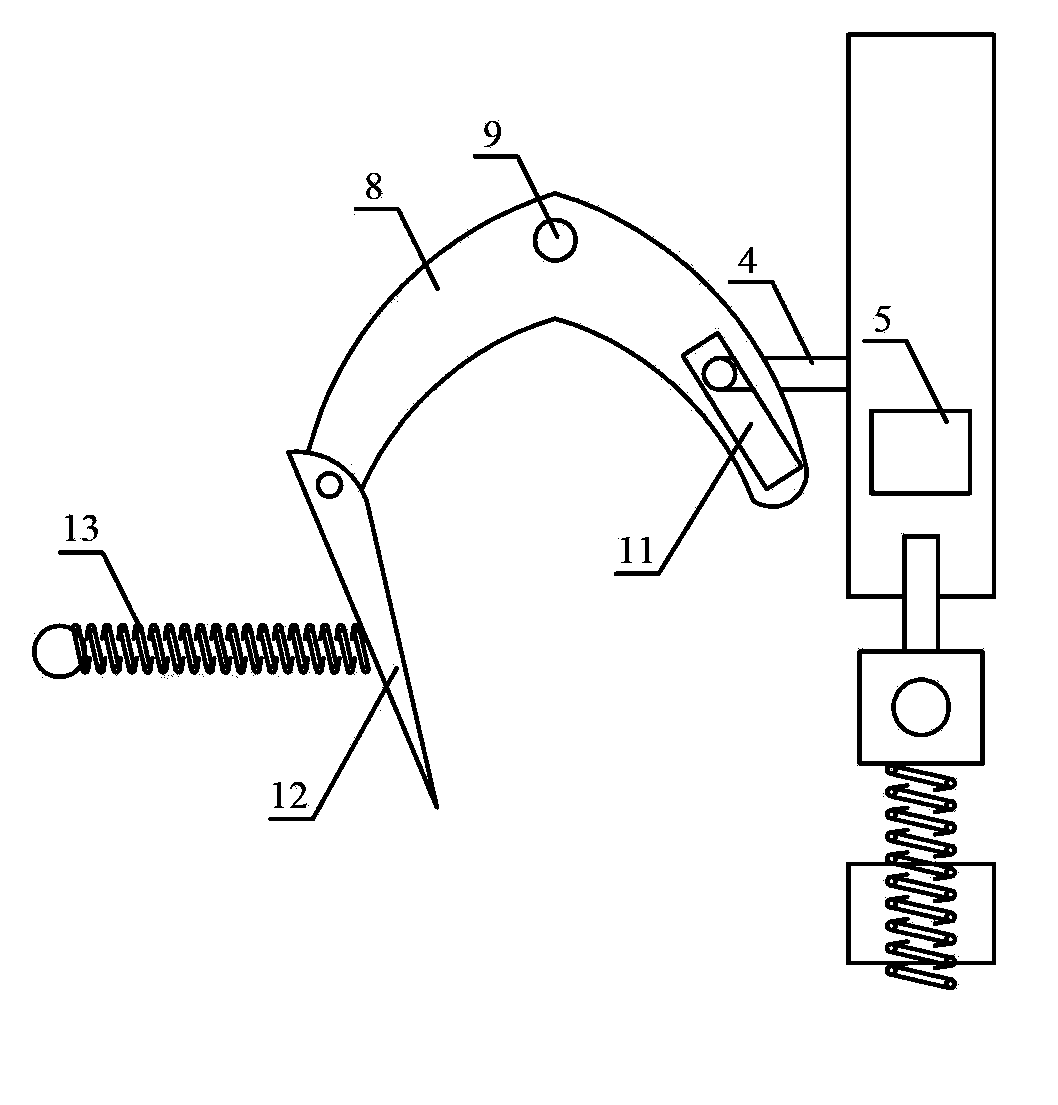

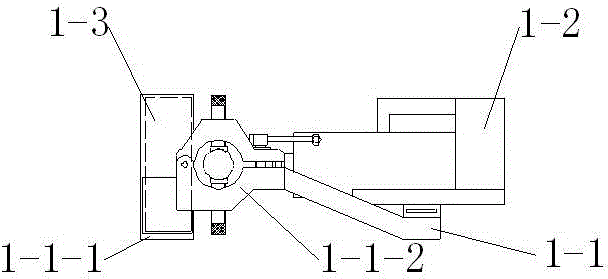

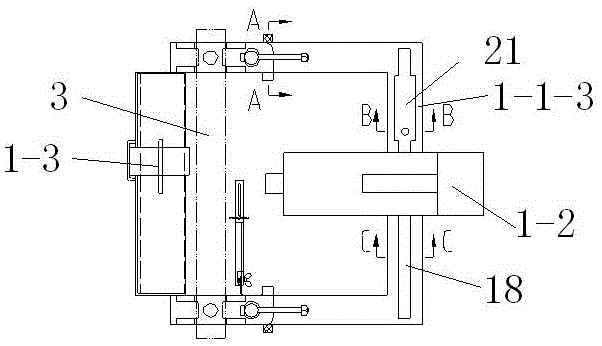

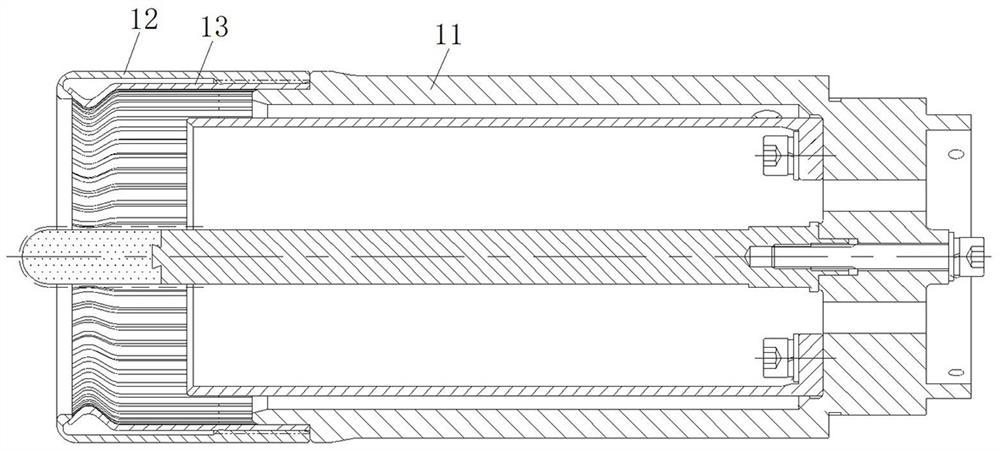

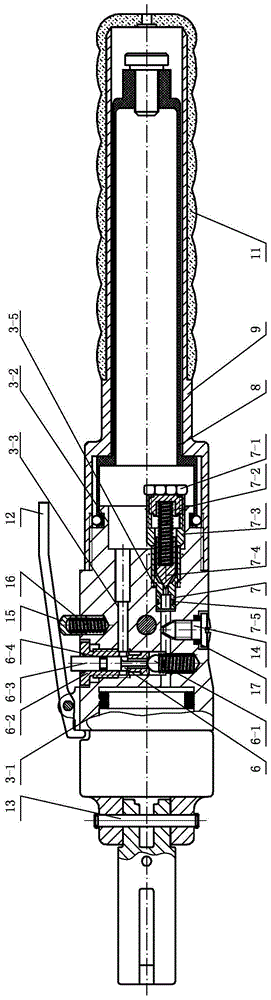

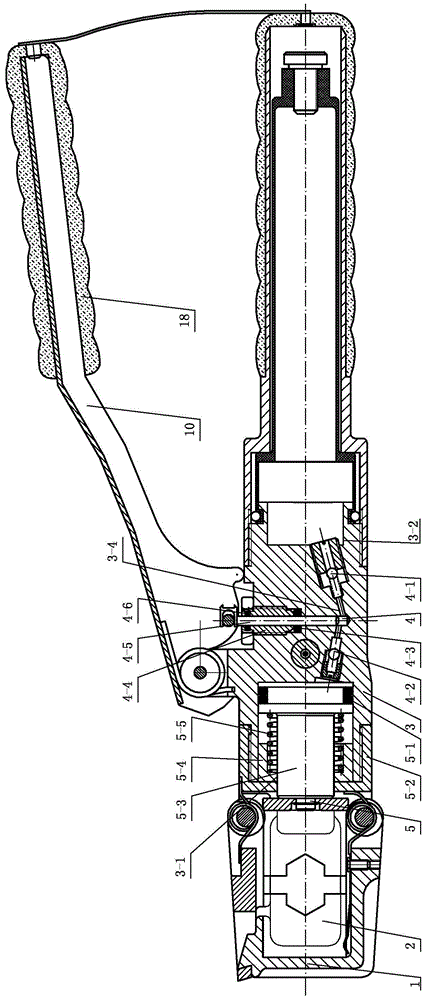

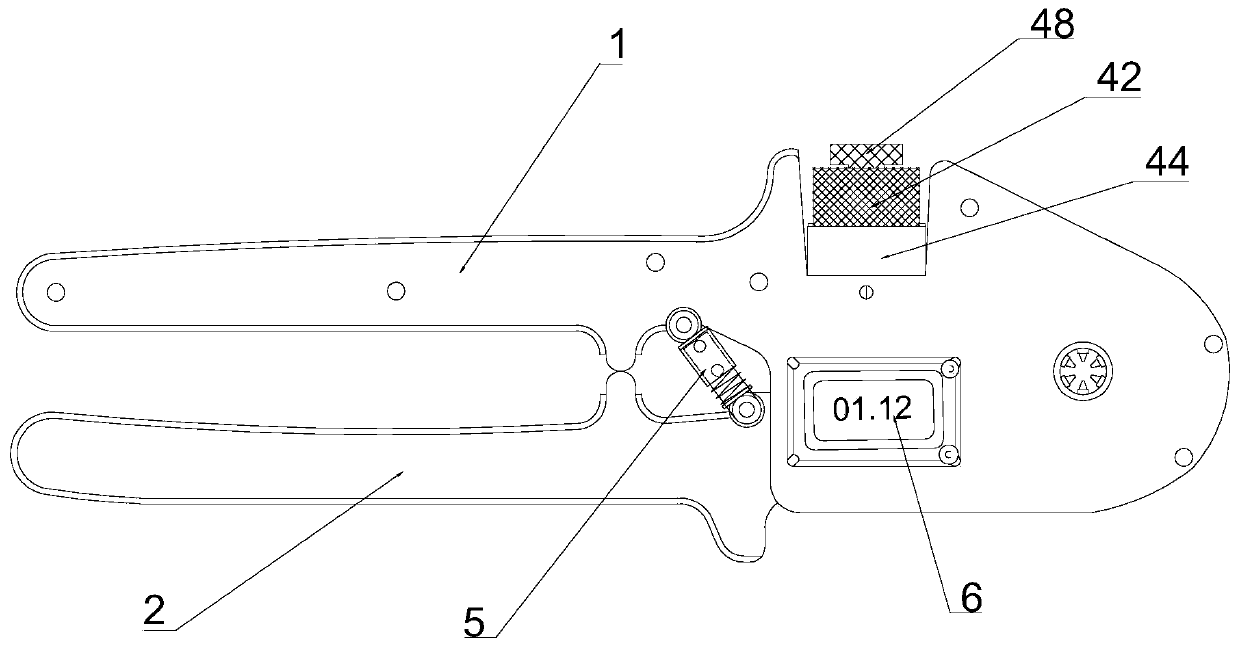

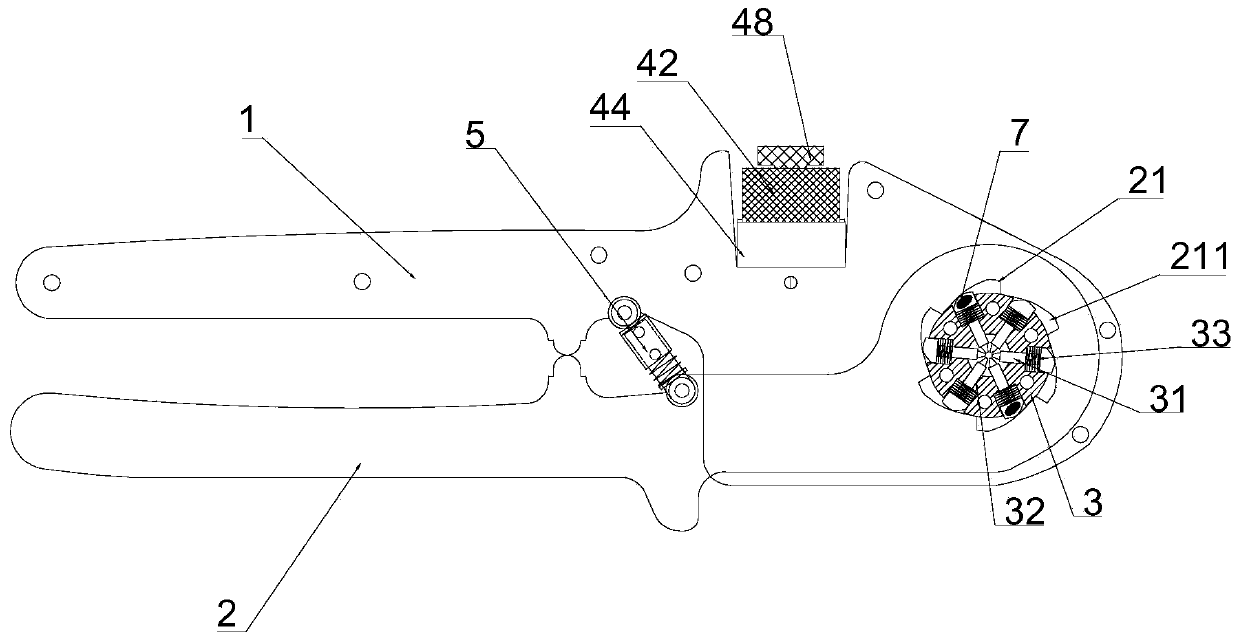

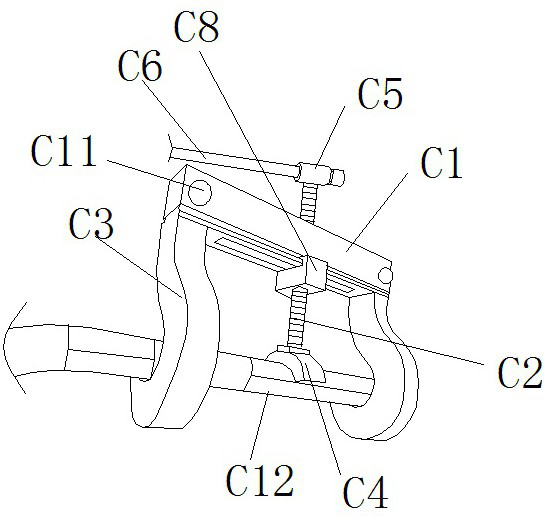

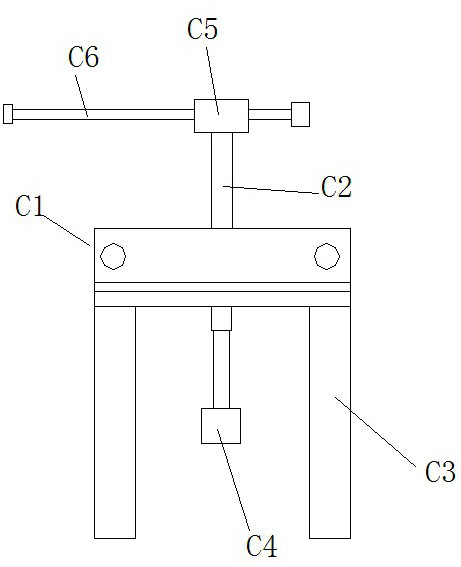

Portable hydraulic pliers for crimping bead string joints

InactiveCN105127939ALabor-saving operationEasy to operatePliersMetal-working hand toolsComputer moduleMechanical engineering

A pair of portable hydraulic pliers for crimping bead string joints relates to a pair of portable hydraulic pliers and aims to solve the problems that no appropriate crimping operation tool is available for conventional crimping of bead string joints, a crimping force cannot be controlled within a reasonable range, and accordingly the connection between a bead string joint and a bead string is not stable. The pair of portable hydraulic pliers comprises a jaw, a pliers pump body, an oil inlet component, a compressing component, an oil draining component, a pressure setting component, an oil receiver, a main handle, a pressurizing moving handle, a pressure unlocking handle, a pressure measuring valve, an elastic load-bearing pin, crimping modules and pin shafts, wherein a first blind hole and a second blind hole are processed in two ends of the pliers pump body respectively; the oil receiver is sleeved with the main handle; the compressing component is mounted on the pliers pump body; the jaw is fixedly mounted on the compressing component; the crimping modules are mounted on the jaw in a sliding way; the pressure setting component is mounted in the second blind hole; the oil inlet component is mounted on the pliers pump body; and the oil draining component is fixedly mounted on the pliers pump body. The pair of portable hydraulic pliers is used in the field of crimping of bead string joints.

Owner:HEILONGJIANG UNIV

Metal crimping quality detection device

ActiveCN103123327BGuaranteed crimp qualityAvoid major accidentsWork holdersStands/trestlesBiomedical engineeringSoftware

The invention discloses a fitting crimping quality detecting device which comprises a final assembly system and a software imaging system, wherein the final assembly system comprises a clamping appliance, an emission instrument and a receiving instrument, the emission instrument and the receiving instrument are both arranged on the clamping appliance, and the crimping-type fitting needing to be detected is also fixed between the emission instrument and the receiving instrument through the clamping appliance. By utilizing the fitting crimping quality detecting device disclosed by the invention, the problem that the inner crimping quality of the crimping-type fitting cannot be detected in the existing crimping quality detection method can be solved, and the influence of the crimping quality inside the fitting upon the operation quality and safety of the lines can be avoided, so that serious accidents can be avoided.

Owner:QUJING BUREAU OF SUPERVOLTAGE POWER TRANSMISSION CHINA SOUTHERN POWER GRID +1

Automatic edge curling device of steel door sheet

The invention discloses an automatic edge curling device of steel door sheet; the automatic edge curling device of steel door sheet comprises a machine frame, a roller group, a feeding platform and a discharging platform; the feeding platform comprises a frame body, a fixed baffle, a movable cross beam, and a movably stop block; the fixed baffle is mounted on the upper end of the frame body; the movably stop block is mounted on the movably cross beam; the distance between the fixed baffle and the movably cross beam can be adjusted by rotating a lead screw; the upper and lower compression rollers in the roller group are both coaxially provided with gears, and the two gears are mutually engaged; a transmission gear is respectively installed among coaxial gears of a plurality of upper compression rollers; an intermediate roller group is installed above the machine frame; the intermediate roller group is used for driving the door sheet to move and used for ensuring the flatness of the door sheet in the edge curling movement process; a gap is arranged between the upper and lower intermediate rollers of the intermediate roller group; each lower intermediate roller is coaxially mounted with a corresponding lower compression roller. The device reduces the wear rate of the upper and lower compression rollers, so as to make the door sheet be uniformly stressed, and make the machining smooth, thereby ensuring the edge curling quality of the door sheet, and saving the machining cost of the enterprises.

Owner:天津华夏防火设备有限公司

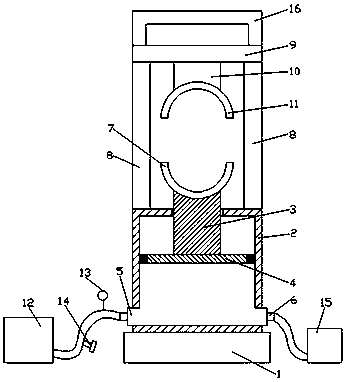

X-ray tank detection device

PendingCN112113984AHigh degree of automationGuaranteed crimp qualityUsing optical meansMaterial analysis by transmitting radiationRobot handEngineering

The X-ray tank body detection device comprises a conveying line used for conveying tank bodies, a bottom plate arranged on the side edge of the conveying line, an X-ray scanning forming device used for detecting tank body edge curling data, a tank body outer size measuring device used for detecting the outer sizes of the tank bodies, a mechanical arm used for clamping and carrying the tank bodiesto be detected, and an industrial personal computer, wherein the X-ray scanning forming device, the tank body outer size measuring device and the mechanical arm are all fixed to the bottom plate, andthe industrial personal computer is electrically connected with the conveying line, the X-ray scanning forming device, the tank body outer size measuring device and the mechanical arm. According to the device, through the arrangement, each can body is sequentially carried to different measuring stations through the mechanical arm on the conveying line, and then under the combination of the multiple measuring devices, the multiple sizes of the outer portions of the can bodies of the two can bodies and multiple data related to can body hemming can be automatically detected and recorded; the automation degree is higher, the measured data is more comprehensive, the hemming quality of the two-piece can is guaranteed, and labor cost is also reduced.

Owner:广东嘉仪仪器集团有限公司

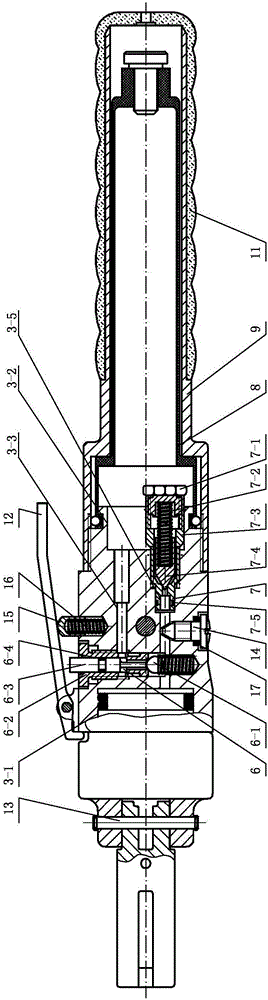

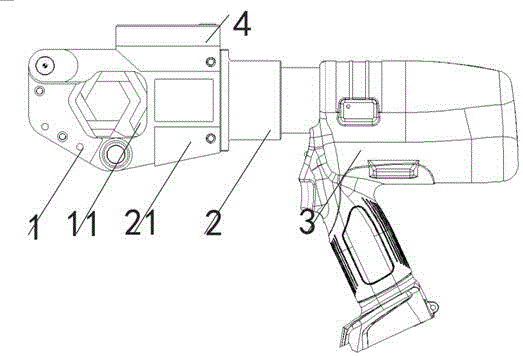

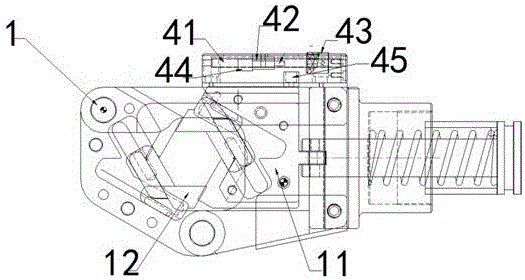

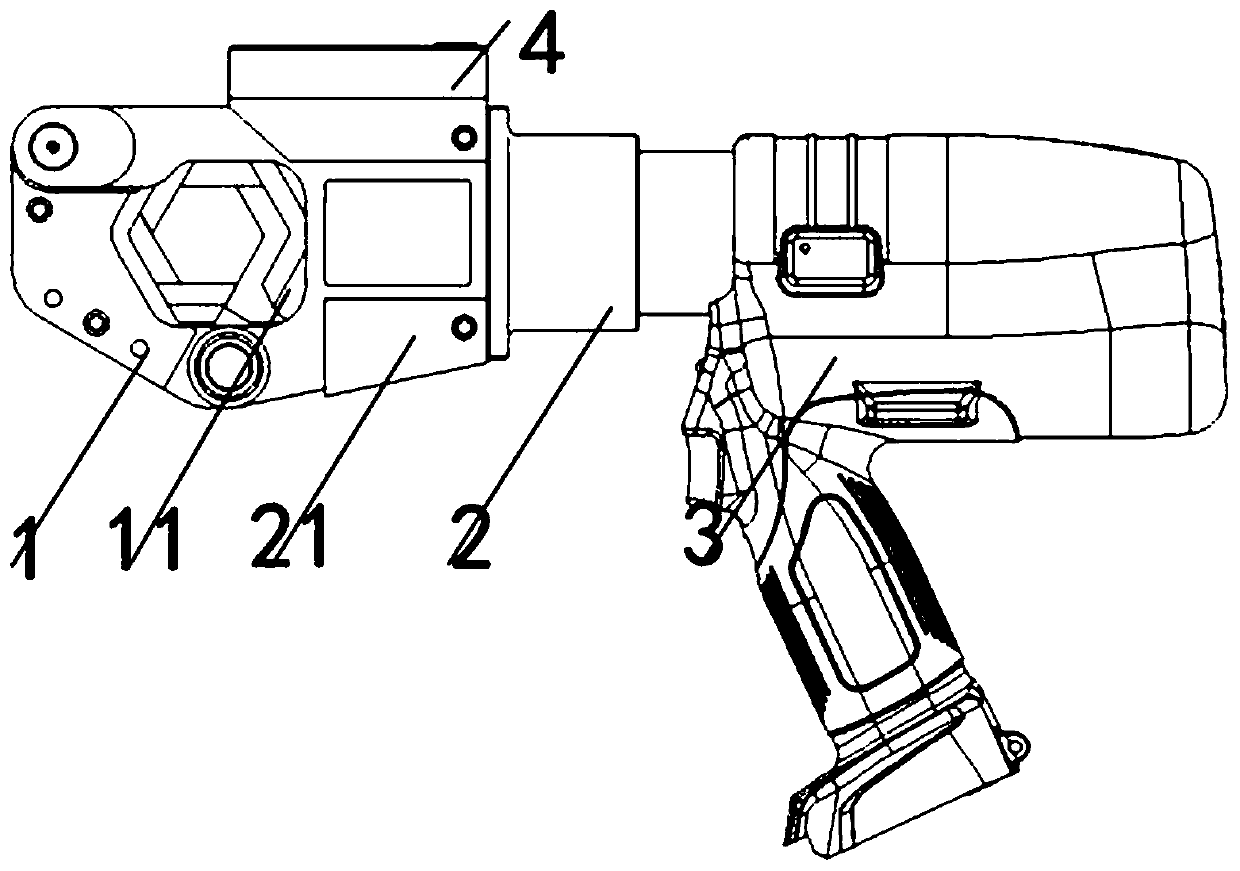

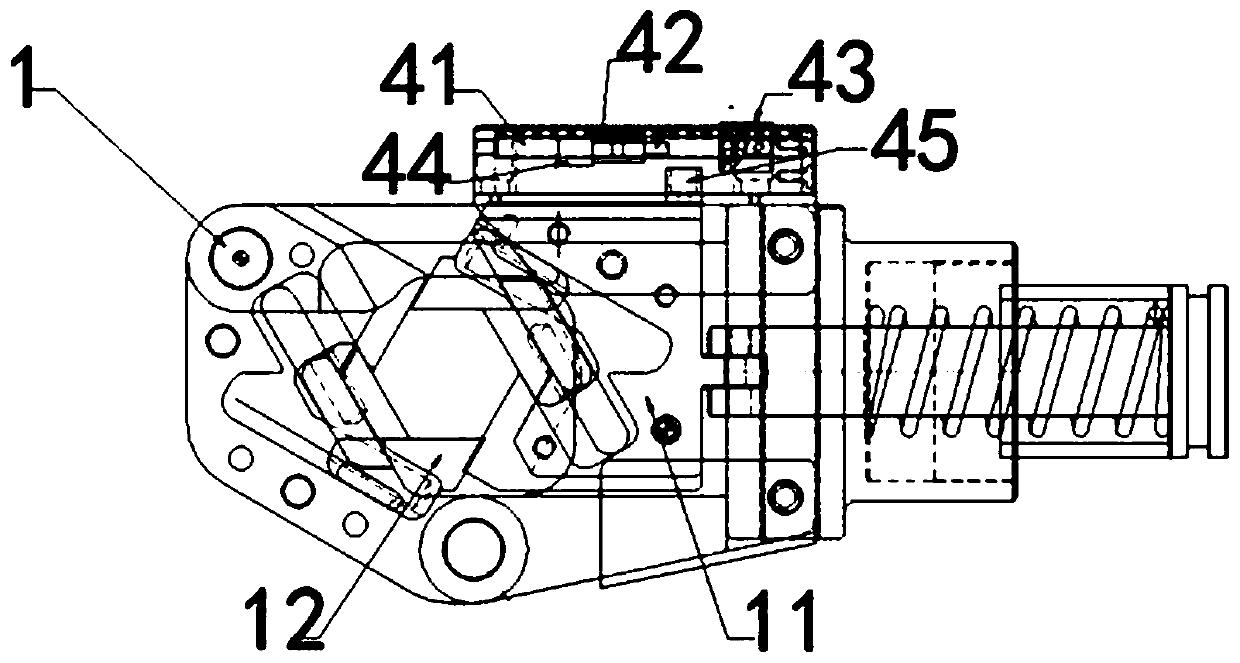

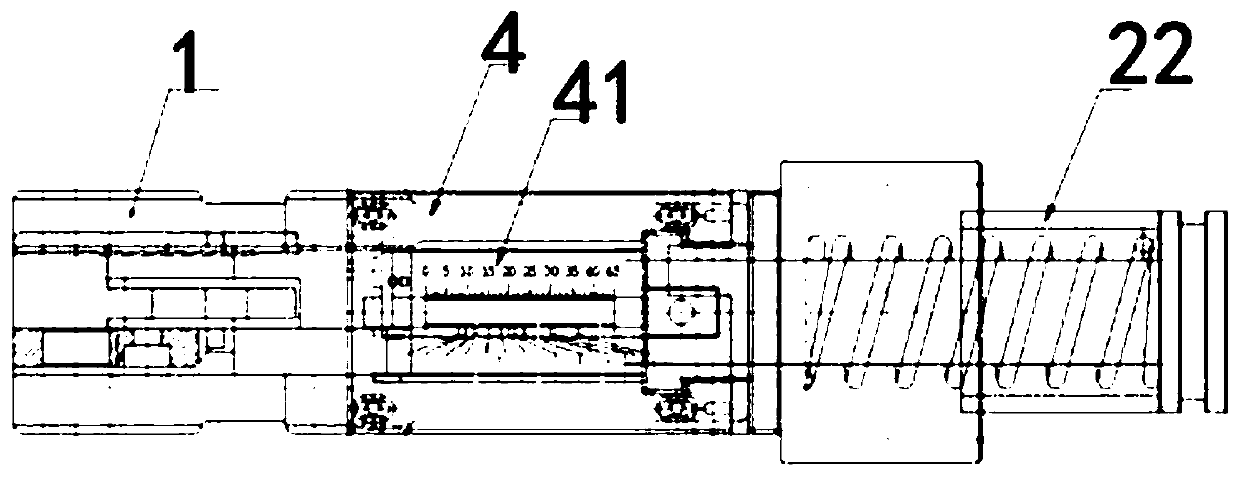

Portable charging regular hexagon die-exchange-free crimping machine for electronic stepless adjustment control copper-aluminum cable terminal and connecting sleeve and operation method

ActiveCN106785781AReduce weightEasy to adjust controlLine/current collector detailsElectricityCoaxial cable

The invention provides a portable charging regular hexagon die-exchange-free crimping machine for an electronic stepless adjustment control copper-aluminum cable terminal and a connecting sleeve and an operation method in the technical field of crimping of electric wires comprising coaxial cables. The portable charging regular hexagon die-exchange-free crimping machine is characterized by comprising a die-exchange-free crimping head, an adapter, a charging hydraulic tool and an electronic stroke control box, wherein the adapter is connected to a hydraulic oil cylinder of the charging hydraulic tool and then the other end is connected with the die-exchange-free crimping head; the electronic stroke control box is arranged at the upper part of the die-exchange-free crimping head; the die-exchange-free crimping head comprises a crimping head and a movable module; the crimping head is fixedly connected to the top end of the adapter; the movable module is arranged in the adapter, one end of the movable module is matched with the crimping head and the other end is connected with a push rod of the hydraulic oil cylinder; an inductor is arranged at the top of the movable module and is matched with an inductor in the electronic stroke control box; and after the two inductors generate signals, the charging hydraulic tool stops supplying electricity to the hydraulic oil cylinder.

Owner:上海科颉贸易有限公司

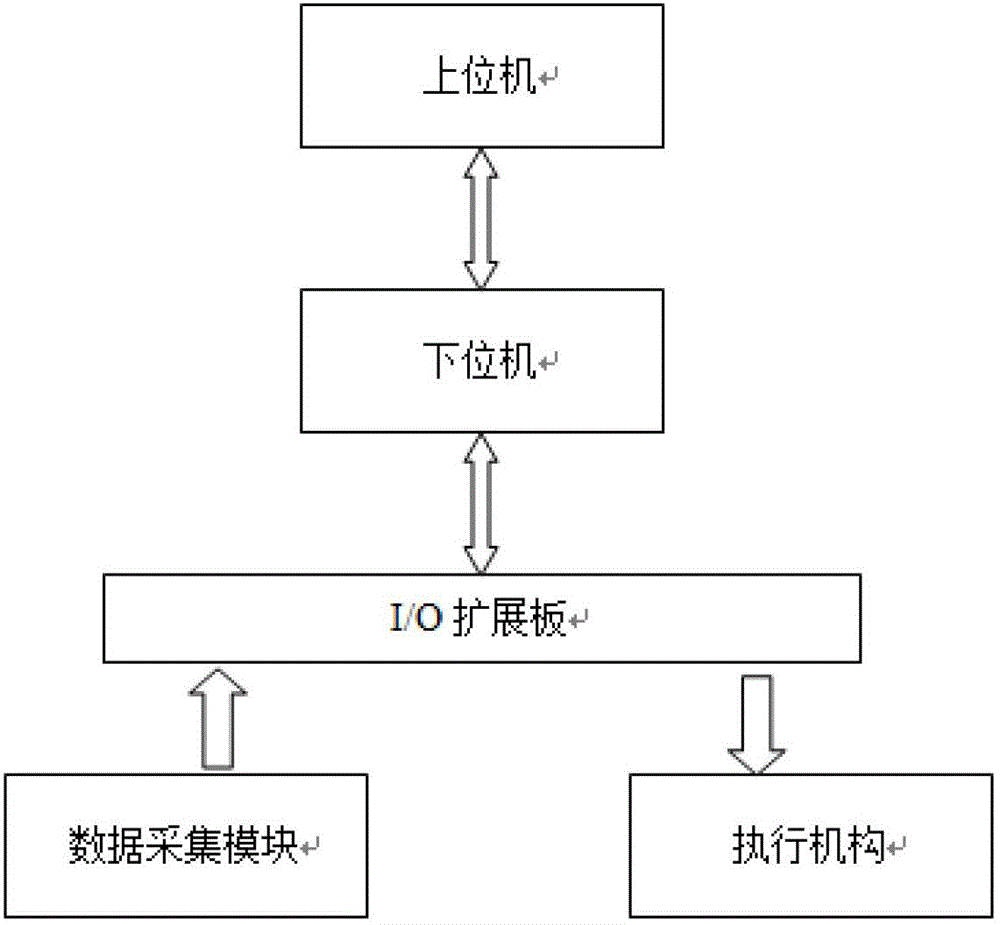

Detecting system for crimping process of stamping parts

InactiveCN103934311ARealize real-time monitoringGuaranteed crimp qualityMetal working apparatusPunchingSwitching signal

The invention discloses a detecting system for the crimping process of stamping parts. The detecting system comprises an upper computer, a lower computer, a data acquisition module, an actuating mechanism and the like, wherein the upper computer is in communication connection with the lower computer; the upper computer is used for human-computer interaction; the lower computer is used for processing data and storing control logic; the lower computer is connected with the data acquisition module and the actuating mechanism; the actuating mechanism controls the action of a punching machine. The detecting system is characterized in that the data acquisition module comprises a sensor, a switch signal source and an I / O expansion board which is used for inputting signals into the lower computer. Through the adoption of the detecting system, parameters can be monitored in a real-time manner, the crimping quality is ensured, the labor productivity is improved, and the manpower and material resources are saved.

Owner:SHANGHAI QIZHONG MECHANICAL & ELECTRICAL EQUIP

Contact seat assembling and crimping tool

ActiveCN112563058AReduce manufacturing costIncrease productivityElectric switchesMechanical engineeringPhysics

Owner:PINGGAO GRP +3

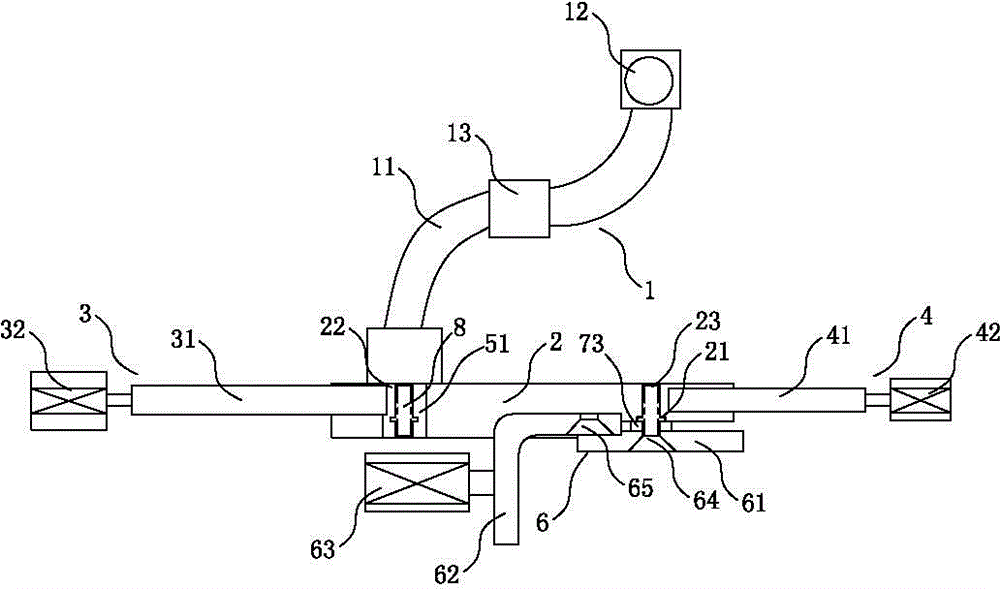

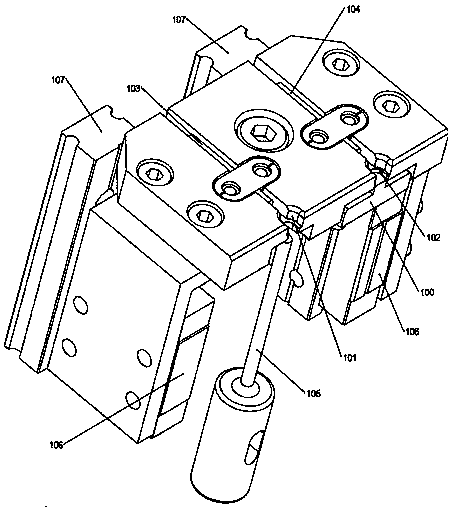

Automatic press-connecting machine for sleeve and guide ring

ActiveCN108436433AReal-time monitoring of pressure valuesImprove labor productivityMetal working apparatusIndustrial engineeringPressure sensor

The invention provides an automatic press-connecting machine for a sleeve and a guide ring. The automatic press-connecting machine for the sleeve and the guide ring comprises a machine table, a feeding and discharging device and a press-connecting device, wherein the feeding and discharging device and the press-connecting device are arranged on the machine table; the press-connecting device comprises a positioning block, a pressing block, a press-connecting cylinder, photoelectric sensors and a pressure sensor, wherein the pressing block is positioned on the positioning block; the press-connecting cylinder is connected with the pressing block; the photoelectric sensors are arranged at the two sides of the pressing block; the pressure sensor is used for detecting the press-connection force;the positioning block is provided with a sleeve positioning hole and a guide ring positioning hole; a sleeve jack-out rod is arranged below the sleeve positioning hole; a guide ring press-connectingjack block is arranged below the guide ring positioning hole; a positioning slide table and a press-connecting slide table are arranged below the positioning block; and the press-connecting slide table is connected with an electric linear guide rail. According to the automatic press-connecting machine provided by the invention, the overall sleeve and guide ring press-connection process is automatically implemented and needs not to be operated step by step separately, so the labor productivity is improved; and meanwhile a press-connection sensor is used for monitoring a pressure value in real time in the overall press-connection process so as to guarantee the press-connection quality.

Owner:JIANGSU ALLRAY

An adjustable wire crimping machine bracket

ActiveCN106451007BGuaranteed crimp qualityEasy to transportLine/current collector detailsConnections effected by permanent deformationEngineeringMechanical engineering

Owner:DATONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER

A portable hydraulic pliers for crimping beaded rope joints

InactiveCN105127939BLabor-saving operationEasy to operatePliersMetal-working hand toolsEngineeringBlind hole

A pair of portable hydraulic pliers for crimping bead string joints relates to a pair of portable hydraulic pliers and aims to solve the problems that no appropriate crimping operation tool is available for conventional crimping of bead string joints, a crimping force cannot be controlled within a reasonable range, and accordingly the connection between a bead string joint and a bead string is not stable. The pair of portable hydraulic pliers comprises a jaw, a pliers pump body, an oil inlet component, a compressing component, an oil draining component, a pressure setting component, an oil receiver, a main handle, a pressurizing moving handle, a pressure unlocking handle, a pressure measuring valve, an elastic load-bearing pin, crimping modules and pin shafts, wherein a first blind hole and a second blind hole are processed in two ends of the pliers pump body respectively; the oil receiver is sleeved with the main handle; the compressing component is mounted on the pliers pump body; the jaw is fixedly mounted on the compressing component; the crimping modules are mounted on the jaw in a sliding way; the pressure setting component is mounted in the second blind hole; the oil inlet component is mounted on the pliers pump body; and the oil draining component is fixedly mounted on the pliers pump body. The pair of portable hydraulic pliers is used in the field of crimping of bead string joints.

Owner:HEILONGJIANG UNIV

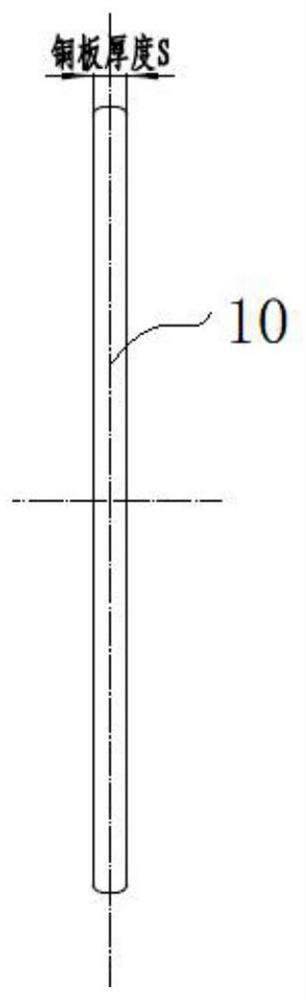

Connecting copper plate for crimping main branch cable conductor in pre-branch cable processing process

PendingCN111710996AAvoid damageGuaranteed crimp qualityConnections effected by permanent deformationConnection formation by deformationElectrical conductorEngineering

The invention discloses a connecting copper plate for crimping a main branch cable conductor in a pre-branch cable processing process. The connecting copper plate is characterized in that the thickness of the connecting copper plate is gradually increased along with the increase of the sum of the sectional areas of the main cable conductor and the branch cable conductor, the width of the connecting copper plate is determined according to the size of the branch cable conductor and is gradually increased along with the increase of the diameter of the main cable conductor, and the length of the connecting copper plate ensures that a gap between two ends of the connecting copper plate in the length direction is within a controllable range after the connecting copper plate coats the main cableconductor and the branch cable conductor; and after the main cable conductor and the branch cable conductor are wrapped by the connecting copper plate, the main cable conductor and the branch cable conductor are crimped through a crimping die. According to the present invention, after the main cable conductor and the branch cable conductor are crimped, the crimping quality and the crimping strength of a product are ensured, and the situation that the crimping quality of the conductor is worse or the conductor is damaged due to the fact that the size of a C-shaped pipe is not matched with the size of the conductor in the past, is avoided.

Owner:GOLD CUP ELECTRIC APP HENGYANG CABLES

Method for calculating COG hot-pressing process parameters

InactiveCN111965868AAvoid breakingGuaranteed crimp qualityNon-linear opticsProcess engineeringTotal thickness

The invention discloses a method for calculating COG hot-pressing process parameters. The method comprises the steps that a COG pressing value expression is constructed according to the IC thickness,the ACF thickness and the glass thickness of a product, a pressing value actually needing to be set by a COG pressing head is calculated according to the expression, and the calculation formula of thepressing value actually needing to be set by the COG pressing head is shown as follows: S = A-(B-(C + D + E)) + F, wherein S is a pressing value actually required to be set by the COG pressing head,A is a Z-axis reference quantity set in the COG pressing head servo system, B is the actual distance between the lower part of the pressing head and the upper part of a back-supporting platform, C isthe total thickness of the IC including Bump, D is the thickness of the glass, E is the ACF thickness obtained according to the specification, and F is an empirical constant. According to the method for calculating COG hot-pressing process parameters, the ACF curing rate reaches the standard after a Bump region is heated and stressed, and empty Bump regions at two ends are not subjected to the pressure action of the pressing head.

Owner:SHENZHEN JINGHUA DISPLAY

Adjustable manual digital crimping pliers

InactiveCN111146665AGuaranteed crimp qualityIncrease the number ofLine/current collector detailsEngineeringMechanical engineering

The invention discloses an adjustable manual digital crimping pliers, and the crimping pliers comprise a fixed handle and a movable handle which are hinged with each other, a crimping head arranged onthe fixed handle in an integrally rotatable manner, and an adjusting assembly for adjusting the relative position between the crimping head and the fixed handle, wherein the movable handle is used for driving the crimping head to perform crimping operation. According to the adjustable manual digital crimping pliers, great convenience is brought to manual operation of the crimping pliers through visual compensation adjustment, and the crimping quality is ensured very accurately; the crimping pliers is simple in structure, is easy to manufacture, and is convenient to use; the crimping pliers are simple in structure and convenient to use, the operation is rapid, the crimping diameter can be checked in real time, the timely compensation calibration can be provided according to the real-time abrasion condition of the crimping head, the crimping quality of the crimping pliers is guaranteed, the number of crimping rods is increased to crimp a wire and a tubular terminal, the crimping is morestable due to the increase of contact points, and the terminal can be effectively prevented from being crushed.

Owner:CHONGQING JIAOTONG UNIVERSITY

Sleeve and guide ring automatic crimping machine

ActiveCN108436433BReal-time monitoring of pressure valuesImprove labor productivityMetal working apparatusEngineeringIndustrial engineering

Owner:JIANGSU ALLRAY

Portable and rechargeable regular hexagonal die-free crimping machine and its operation method

ActiveCN106785781BReduce weightEasy to adjust controlLine/current collector detailsElectricityCoaxial cable

The invention provides a portable charging regular hexagon die-exchange-free crimping machine for an electronic stepless adjustment control copper-aluminum cable terminal and a connecting sleeve and an operation method in the technical field of crimping of electric wires comprising coaxial cables. The portable charging regular hexagon die-exchange-free crimping machine is characterized by comprising a die-exchange-free crimping head, an adapter, a charging hydraulic tool and an electronic stroke control box, wherein the adapter is connected to a hydraulic oil cylinder of the charging hydraulic tool and then the other end is connected with the die-exchange-free crimping head; the electronic stroke control box is arranged at the upper part of the die-exchange-free crimping head; the die-exchange-free crimping head comprises a crimping head and a movable module; the crimping head is fixedly connected to the top end of the adapter; the movable module is arranged in the adapter, one end of the movable module is matched with the crimping head and the other end is connected with a push rod of the hydraulic oil cylinder; an inductor is arranged at the top of the movable module and is matched with an inductor in the electronic stroke control box; and after the two inductors generate signals, the charging hydraulic tool stops supplying electricity to the hydraulic oil cylinder.

Owner:上海科颉贸易有限公司

Adjustable bending straightening tool for power transmission line splicing sleeve

The invention relates to an adjustable bending straightening tool for a power transmission line splicing sleeve and belongs to the technical field of power transmission line splicing sleeve straightening. The tool comprises a straightening cross beam, a straightening force-bearing screw rod, straightening force-bearing hooks and a limiting rod; a plurality of straightening force-bearing hook fixing screw holes are uniformly distributed in the straightening cross beam; a force-bearing screw rod nut is mounted on the straightening cross beam; the straightening force-bearing screw rod comprises aratchet wrench, a force-bearing screw rod and a base; each straightening force-bearing hook comprises a fixing screw rod matched with a straightening force-bearing hook fixing screw hole; each straightening force-bearing hook further comprises a fixing hook; a limiting rod hole matched with the limiting rod in size is formed in each fixing hook; and each fixing hook is provided with a limiting rod locking bolt. The tool is adjustable; the installation position of the straightening force bearing hook can be adjusted, so that the tool can adapt to the straightening of deformed splicing sleeveswith different lengths and different bent parts. The straightening tool is light, universal and easy to operate; and the straightening tool can be used for ground splicing sleeve bending straighteningand can also be used for high-altitude straightening; and the straightening tool is easy to apply and popularize.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

The Method of Fixing Conductor with Compression Tension Clamp

ActiveCN112636249BImprove securityAvoid knockingApparatus for overhead lines/cablesClassical mechanicsStructural engineering

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

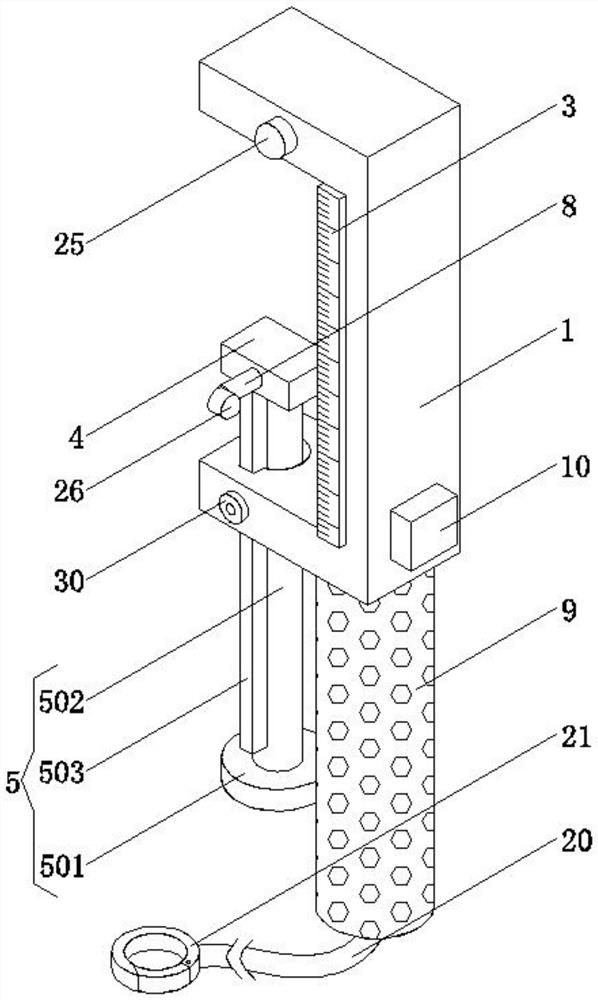

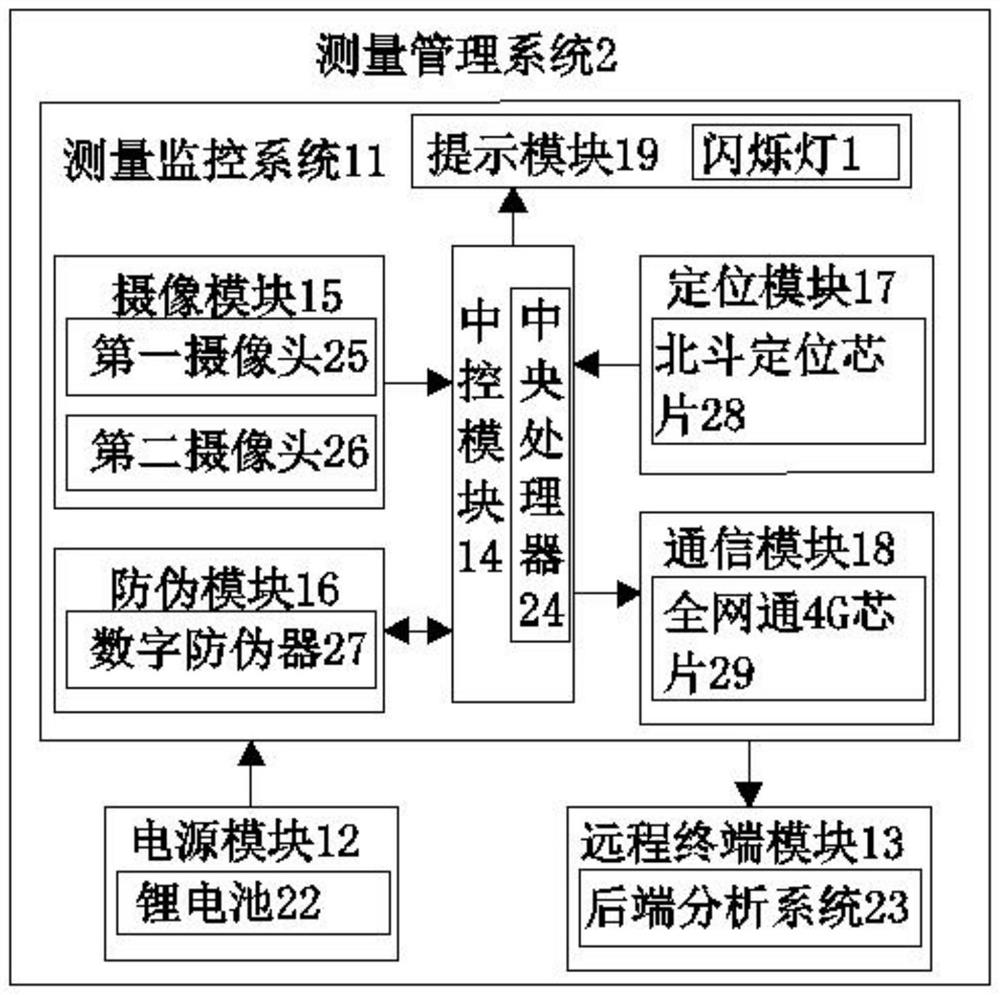

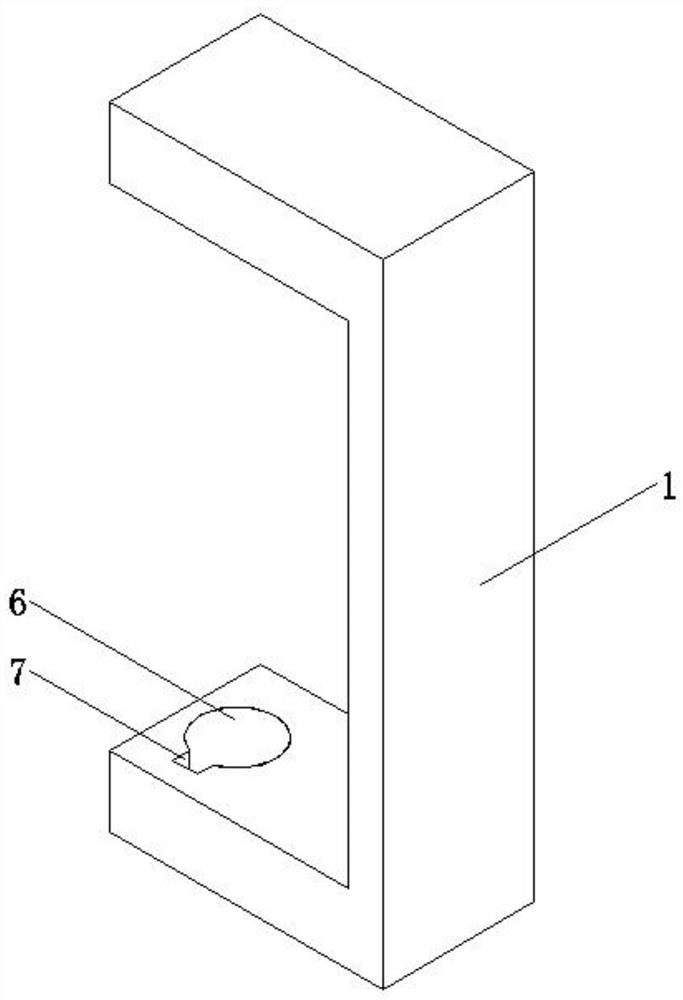

Big data positioning technology-based high anti-counterfeiting remote measurement caliper

InactiveCN113375522AEasy to moveEasy to installOffice automationMechanical measuring arrangementsEngineeringMeasuring ruler

The invention provides a big data positioning technology-based high anti-counterfeiting remote measurement caliper, which comprises a positioning frame and a measurement management system, and is characterized in that the right side of the front side of the positioning frame is fixedly connected with a measurement ruler, the inner cavity of the positioning frame is provided with a clamping plate, and the bottom of the clamping plate is provided with an adjusting mechanism matched with the positioning frame for use; and the bottom of the positioning frame is provided with an opening and a sliding groove which are used in cooperation with the adjusting mechanism, the front side of the clamping plate is fixedly connected with a fixing rod used in cooperation with a measurement management system, and the problem that there is no technical means for guaranteeing the authenticity and accuracy of data for the existing infrastructure project quality is solved.

Owner:马中强

Automatic edge curling device for steel door panels

InactiveCN104511510AStable processingGuaranteed flatnessMetal-working feeding devicesStripping-off devicesGear wheelEngineering

The invention discloses an automatic edge curling device for steel door panels. The automatic edge curling device comprises a frame, a roller group, a loading platform and an unloading platform, wherein the loading platform comprises a rack, a fixed baffle plate, a movable cross beam and a movable stop block; the fixed baffle plate is mounted on the upper end of the rack; the movable stop block is mounted on the movable cross beam; a lead screw is rotated to adjust the space between the fixed baffle plate and the movable cross beam; gears are coaxially mounted on all the upper and lower compression rollers in the roller group and every two gears are engaged with each other; transmission gears are arranged between the coaxial gears of a plurality of upper compression rollers, respectively; a middle roller group for driving a panel to move and guaranteeing the flatness of the panel in the edge curling moving process is arranged above the frame; gaps are formed between the upper and lower middle rollers of the middle roller group; each lower middle roller is coaxially mounted with the corresponding lower compression roller. According to the automatic edge curling device for the steel door panels, the wear rate of the upper and lower compression rollers is reduced so that the stress on the panels can be even, the processing is smooth, the edge curling quality of the panels is guaranteed and the processing cost of an enterprise is saved.

Owner:天津华夏防火设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com