Portable and rechargeable regular hexagonal die-free crimping machine and its operation method

A regular hexagonal, rechargeable technology, applied in the direction of connections, circuits, electrical components, etc., can solve the problems of loose wire structure, high temperature, incomplete crimping, etc., achieve the effects of reducing equipment weight, simple adjustment and control, and avoiding electrical accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

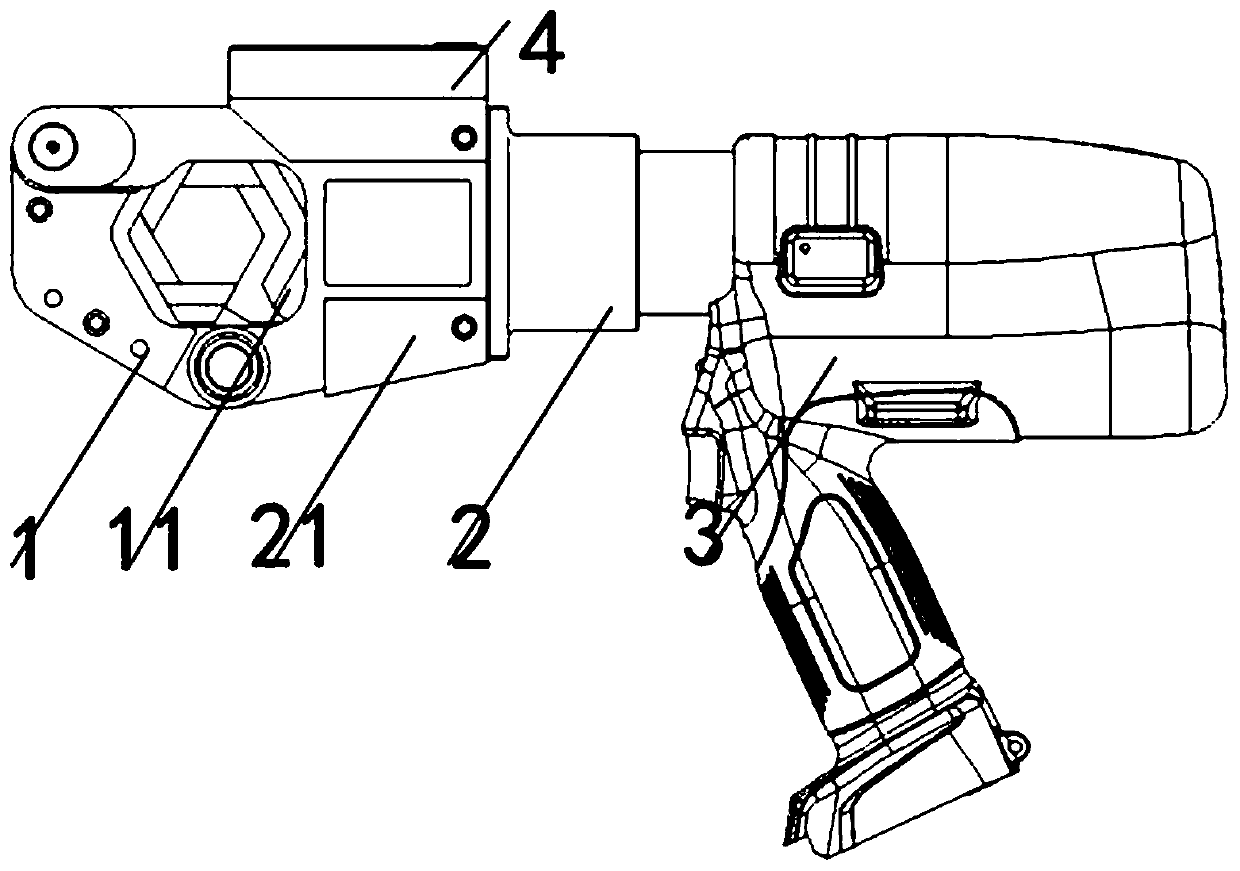

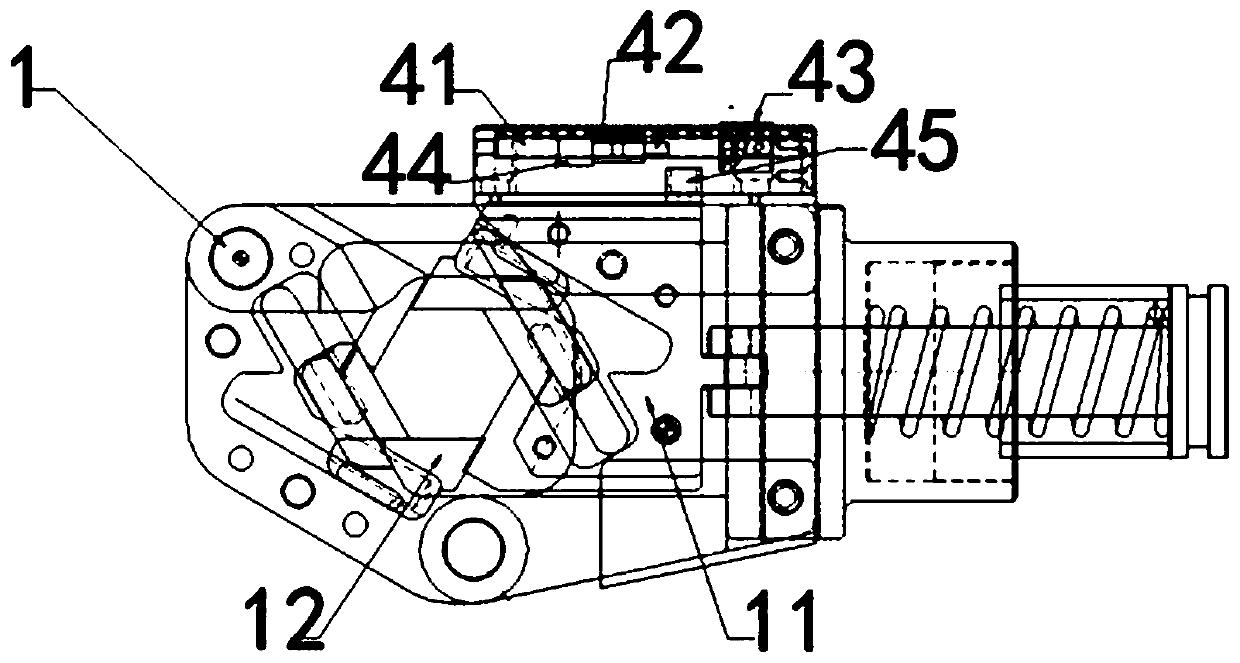

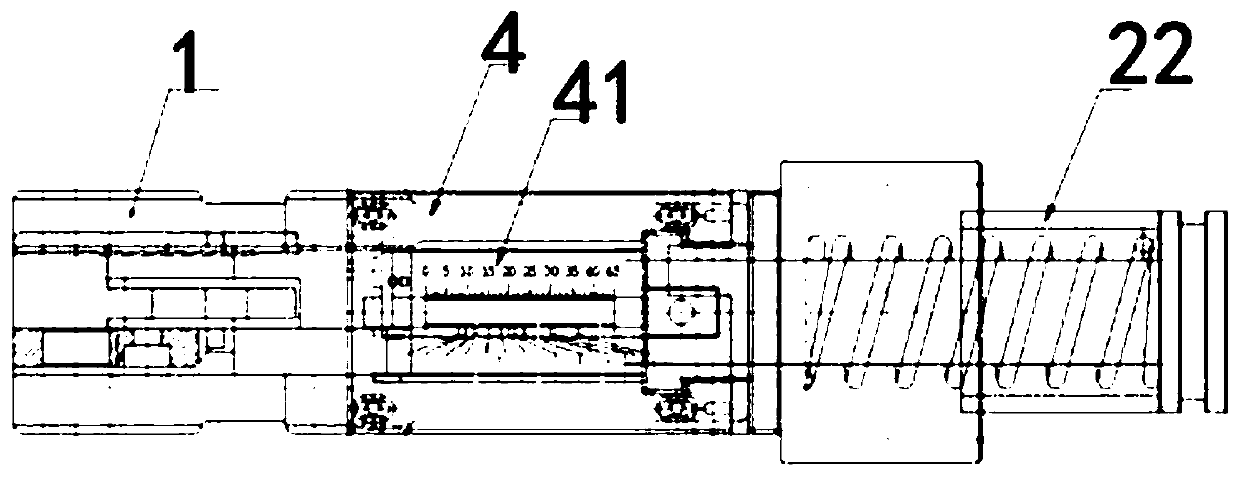

[0035]Portable rechargeable regular hexagonal free-change mold crimping machine, composed of a free-change molded joint 1, an adapter seat 2, a rechargeable hydraulic tool 3 and an electronic stroke control box 4; the adapter seat 2 is connected to the hydraulic cylinder of the rechargeable hydraulic tool 3 , the other end is connected to the free-change molded joint 1; the adapter seat 2 is cylindrical, connected to the cylinder of the hydraulic cylinder, and the ejector pin passes through the cylinder core; the ejector pin is connected to the movable module 11 of the free-change molded joint 1; The compression and release of the crimping head is controlled by jacking up or retracting; the length of the adapter seat 2 is the longest displacement distance required by the piston, and there is a crimping limiter inside it, which is installed on the piston on the top rod. The replacement-free molded joint 1 is composed of a pressing joint 12 and a movable module 11; the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com