Metal crimping quality detection device

A technology of crimping quality and fittings, applied in workpiece clamping devices, manufacturing tools, material analysis using radiation, etc., can solve problems such as the inability to detect the crimping quality of crimping type fittings, and achieve the avoidance of major accidents, small size, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

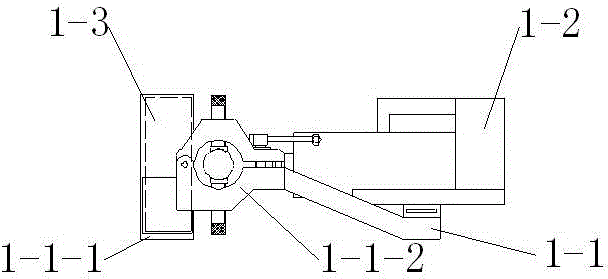

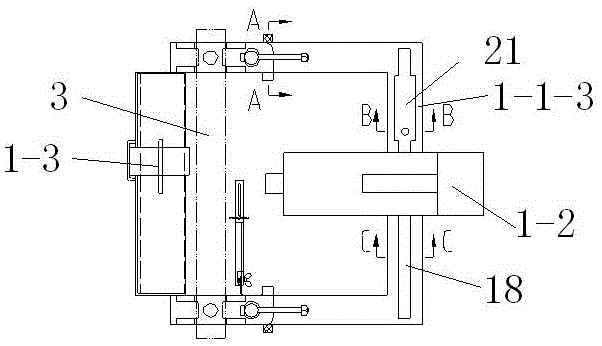

[0026] As shown in the figure, the metal crimping quality inspection device of the present invention includes an assembly system 1 and a software imaging system 2, and the assembly system 1 includes a clamping device 1-1, a transmitter 1-2 and a receiver 1-3 , the transmitter 1-2 and the receiver 1-3 are installed on the clamping device 1-1, and the crimping type fitting 3 to be detected is also fixed on the transmitter by the clamping device 1-1 1-2 and receiver 1-3.

[0027]Wherein, the clamping device 1-1 includes a bracket 1-1-1, a clamping cover part 1-1-2 and a guide rail slider part 1-1-3, which are respectively used to clamp the receiver 1-3, the Detect crimping type fittings 3 and transmitter 1-2, the bracket 1-1-1, clamp cover part 1-1-2 and guide rail slider part 1-1-3 are integrated, and the clamping device 1-1- 1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com