Automatic press-connection machine of connector and press-connection system and press-connection process thereof

A crimping machine and connector technology, applied in the direction of connection, fixed connection, line/collector components, etc., can solve problems such as leakage, affecting crimping efficiency, wasting time and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

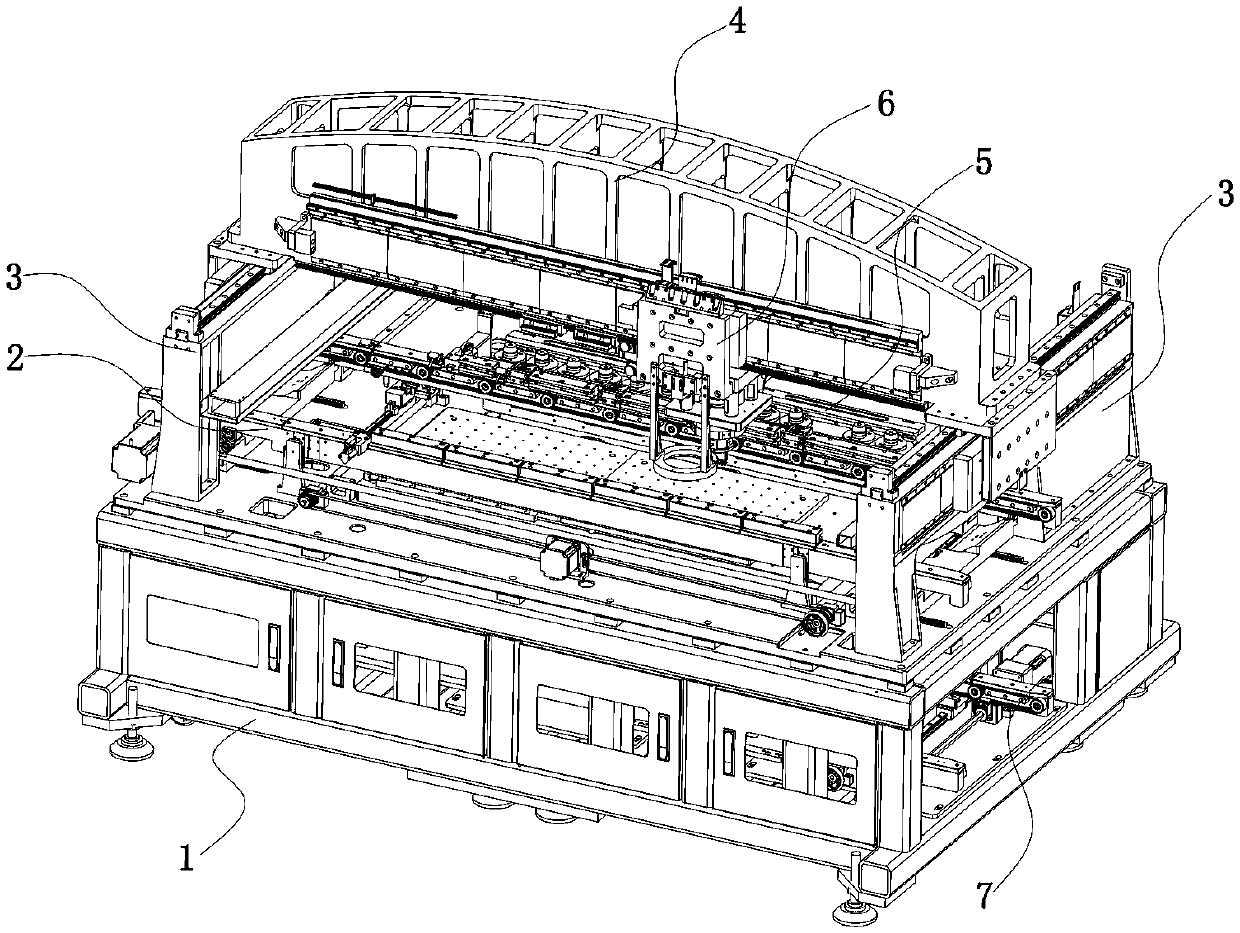

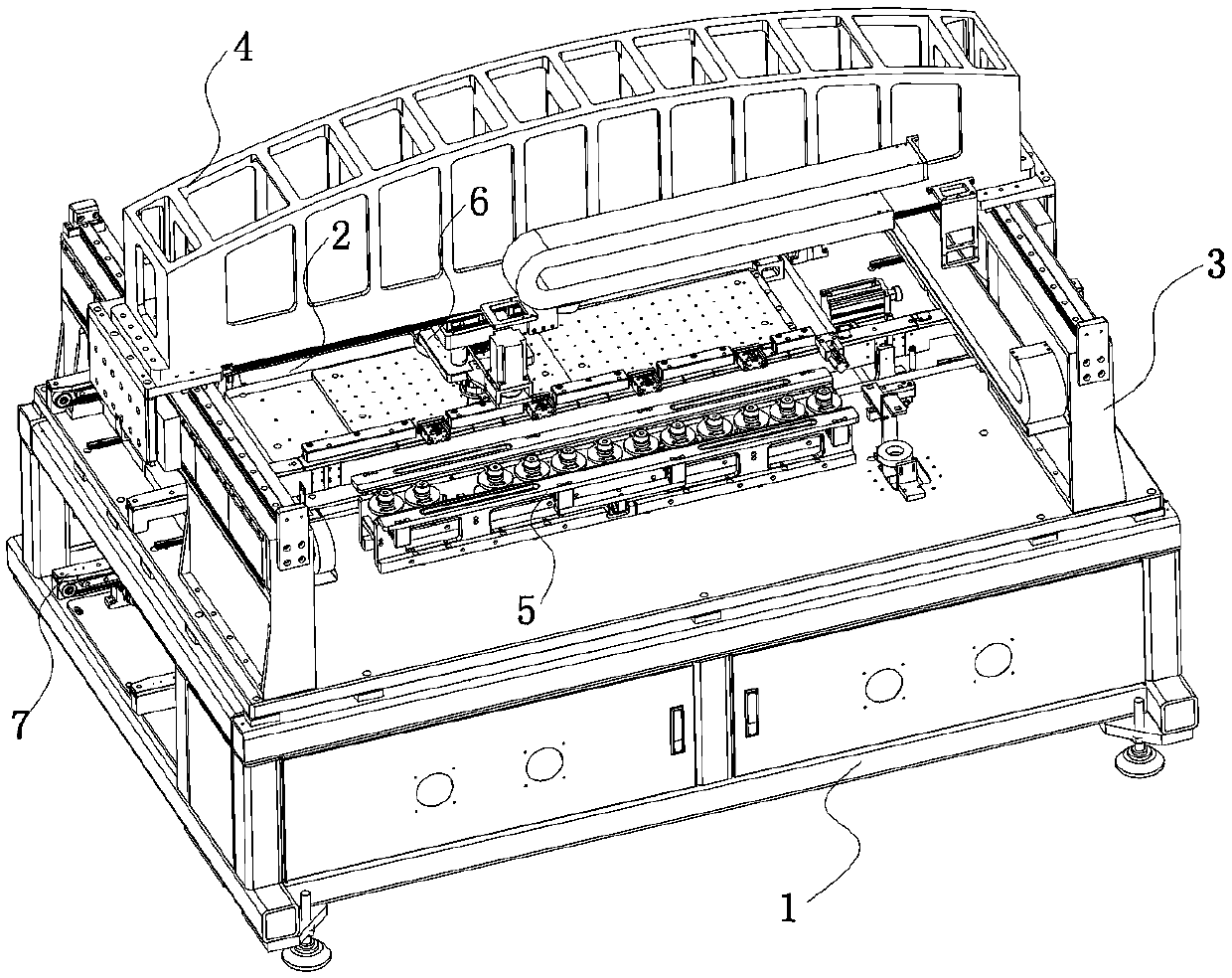

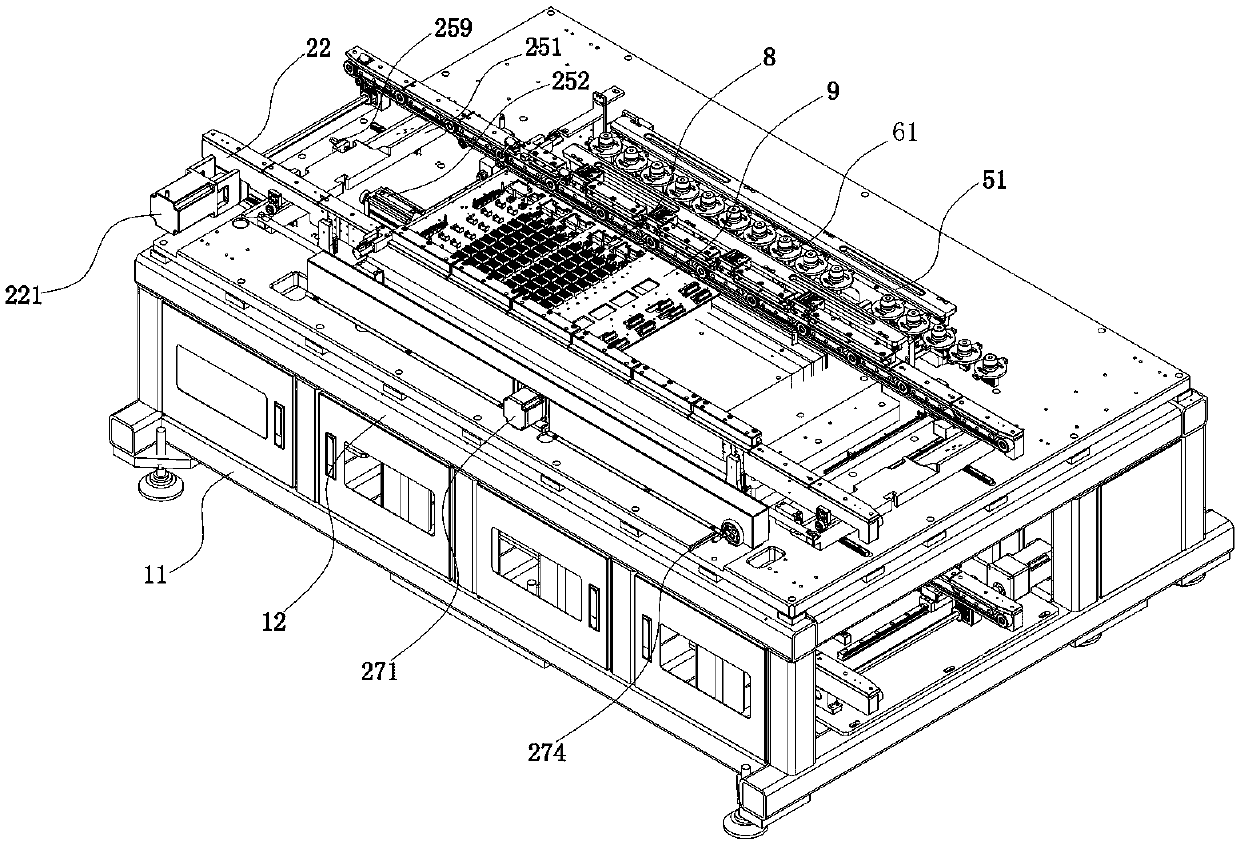

[0091] Embodiment 1: as figure 1 As shown in Figures to 18, the technical solution adopted by the present invention is as follows: an automatic connector crimping machine, including a body 1, a gantry support guide assembly, a material guide assembly 2, a crimping head replacement assembly 5, and a crimping assembly 6. The above-mentioned body 1 is an upper and lower structure, and the material guide assembly 2 is arranged in the upper space of the body 1; the above-mentioned gantry support and guide assembly is fixed on the upper part of the body 1, and the outer cover of the gantry support and guide assembly is provided with an outer cover to form an overall crimping machine structure; The above-mentioned material guide assembly 7 passes through the left and right sides of the crimping machine, guides the PCB board with the connector into the crimping machine, and fixes the limit of the PCB board under the gantry support guide assembly; the above-mentioned crimping head repla...

Embodiment 2

[0112] Embodiment 2: as Figure 20 , 21 , 26, 27, 28, and 29, a crimping process of an automatic connector crimping machine, the crimping process is provided with Z-axis O point, crimping zero point O1 and theoretical zero point O2, wherein, Z-axis O point It is the starting point for the crimping part 61 to move downward in the vertical direction. The height of the crimping zero point O1 is flush with the gasket surface. The theoretical zero point O2 height is the crimping zero point O1 minus the thickness of the PCB board, the thickness of the connector bottom shell and the connection The value after the height of the crimping step surface of the device pin; the movement stroke of the pressure head part 61 through the Z-axis point O point downward crimping process includes no-load stroke, insertion stroke a and crimping stroke b, wherein, the no-load stroke is Z The distance between the axis 0 point and the top surface of the connector, the insertion stroke a is the distanc...

Embodiment 3

[0121] Embodiment 3: as Figure 20 , 21, 30, 31, 32, and 33, a crimping process of an automatic connector crimping machine, the crimping process is provided with Z-axis O point, crimping zero point O1 and theoretical zero point O2, wherein, Z-axis O point It is the starting point for the crimping part 61 to move downward in the vertical direction. The height of the crimping zero point O1 is flush with the gasket surface. The theoretical zero point O2 height is the crimping zero point O1 minus the thickness of the PCB board, the thickness of the connector bottom shell and the connection The value after the height of the crimping step surface of the device pin; the movement stroke of the pressure head part 61 through the Z-axis point O point downward crimping process includes no-load stroke, insertion stroke a and crimping stroke b, wherein, the no-load stroke is Z The distance between the axis 0 point and the top surface of the connector, the insertion stroke a is the distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com