Portable hydraulic pliers for crimping bead string joints

A joint crimping and portable technology, which is applied in the field of hydraulic pliers, can solve problems such as uncontrollable crimping force, no crimping operation tools, unstable connection between beaded rope joints and beaded ropes, etc., to achieve labor-saving operation, good sealing effect, and connection Reliable and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

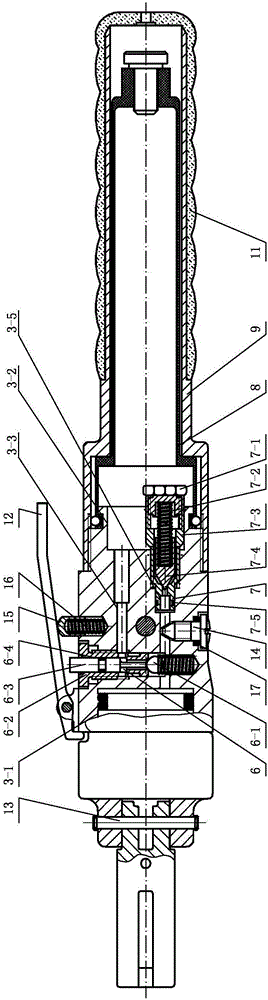

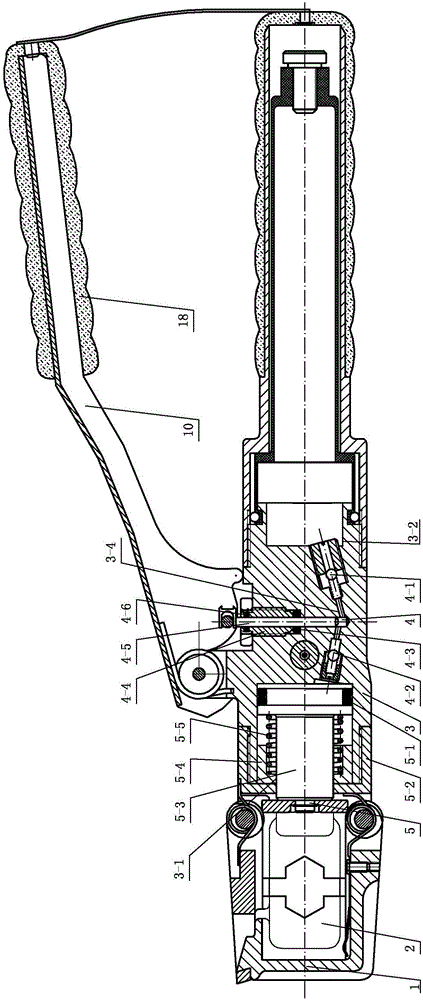

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a portable hydraulic pliers for crimping beaded rope joints described in this embodiment, which includes a jaw 1, a pliers pump body 3, an oil inlet part 4, a pressing part 5, an oil drain part 6, Pressure setting part 7, oil reservoir 8, main handle 9, pressurized moving handle 10, pressure release handle 12, pressure measuring valve 14, elastic load pin 15, two crimping modules 2 and two pin shafts 13; One end of the pressurized mobile handle 10 is processed with a protrusion, the clamp pump body 3 is a cylinder, the two ends of the cylinder are respectively processed with a first blind hole 3-1 and a second blind hole 3-2, and the main handle 9 is circular Barrel body, the main handle 9 is set outside the oil reservoir 8, the pressing part 5 is installed on the pincer pump body 3 at the end of the first blind hole 3-1, the jaw 1 is fixedly installed on the pressing part throug...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, a portable hydraulic pliers for crimping beaded rope joints described in this embodiment, the oil inlet part 4 includes a first one-way valve 4-1 of the oil inlet part, a second one-way valve 4-1 of the oil inlet part Valve 4-2, suction piston first seal ring 4-3, piston guide sleeve 4-4, suction piston 4-5 and suction piston second seal ring 4-6, oil inlet part first unit The direction valve 4-1 and the second one-way valve 4-2 of the oil inlet part are relatively installed on the clamp pump body 3 between the first blind hole 3-1 and the second blind hole 3-2 through threads, and the clamp pump body 3 The side wall of the pump is processed with an oil inlet component installation hole, the suction piston 4-5 is inserted into the piston guide sleeve 4-4, and there is a suction pump between the suction piston 4-5 and the piston guide sleeve 4-4. The second seal ring 4-6 of t...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, a portable hydraulic pliers for crimping beaded rope joints described in this embodiment, the pressing part 5 includes a pressing part sealing ring 5-1, a head cover 5-2, a pressing part piston 5-3. The piston directional ring 5-4 and the piston spring 5-5, the sealing ring 5-1 of the pressing part are set in the first blind hole 3-1, and the piston directional ring 5-4 is embedded in the first blind hole 3 -1 on the inner side wall, the head cover 5-2 is threadedly installed on the outer side wall of the first blind hole 3-1, the jaw 1 is fixedly installed on the head cover 5-2 by two pins 13, and the piston The spring 5-5 is set on one end of the pressing part piston 5-3, and the other end of the pressing part piston 5-3 passes through the piston directional ring 5-4 and the head cover 5-2 in sequence and is fixedly connected with a crimping module 2 , the others are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com