Contact seat assembling and crimping tool

A contact seat and tooling technology, applied in electrical components, electrical switches, circuits, etc., can solve the problem of high production costs, and achieve the effect of ensuring strength, ensuring stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

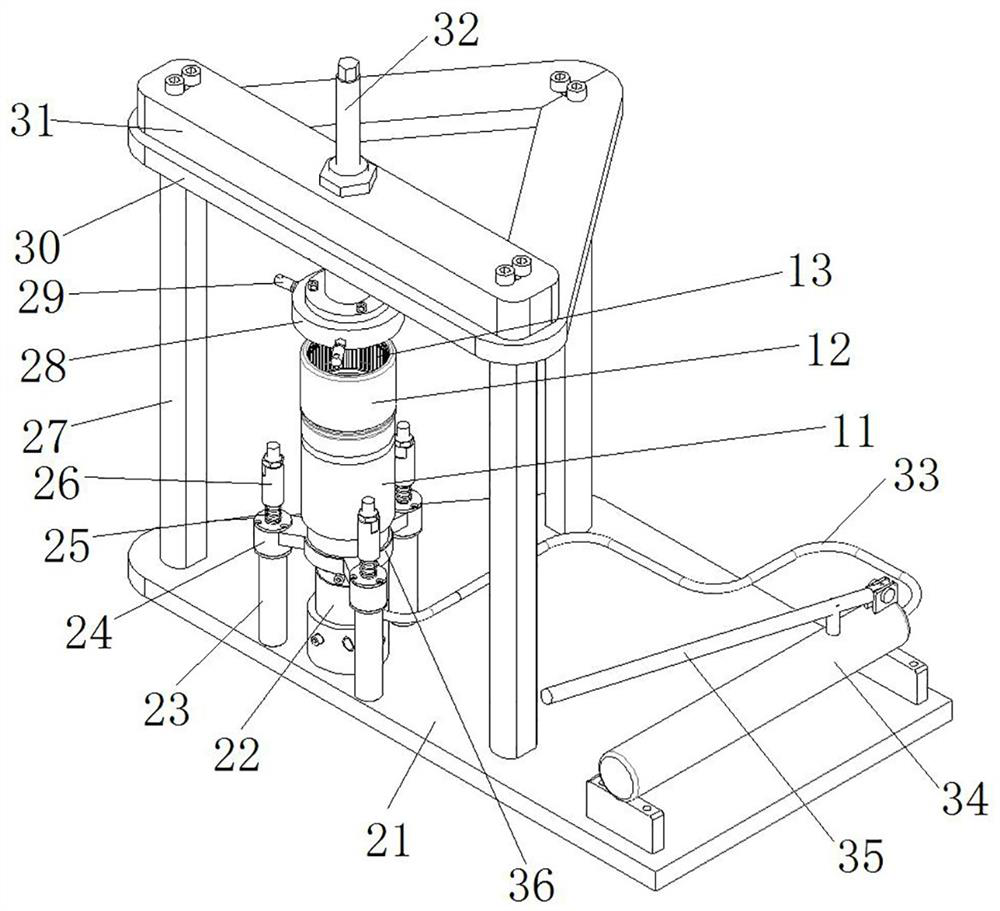

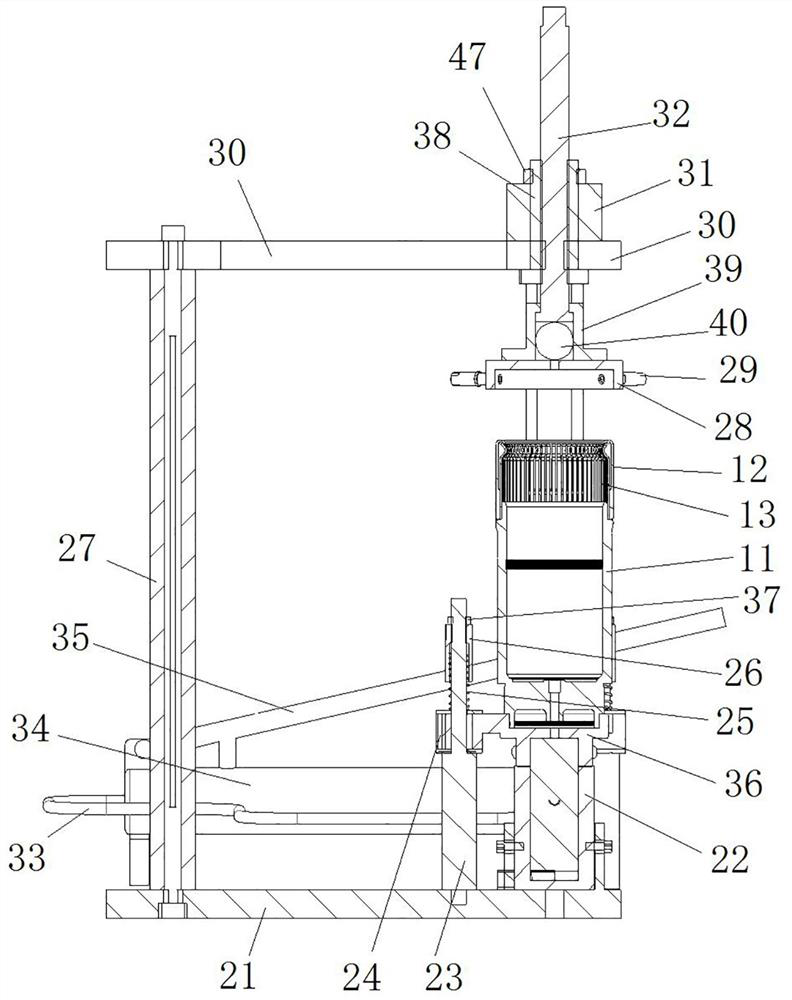

[0059] like figure 2 As shown, the contact seat assembly and crimping tooling includes a frame, and the frame includes a bottom plate 21. Three columns 27 are arranged on the bottom plate 21, and a connecting plate 30 is provided between the upper ends of two adjacent columns 27. The three columns 27 form The triangular structure can ensure the stability of the rack. In other embodiments, only two columns may be arranged on the bottom plate.

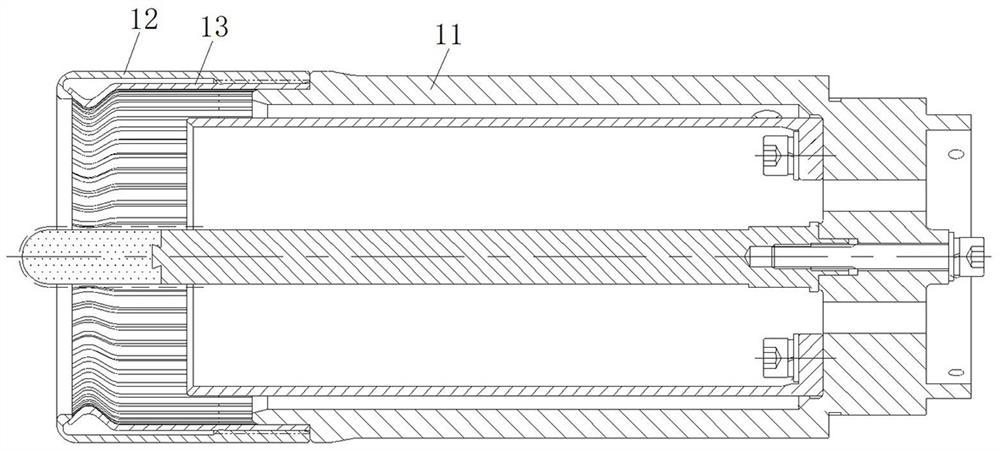

[0060] In this embodiment, the bottom plate 21 is provided with a jack 22, the driving end of the jack 22 is provided with a lower positioning seat 36, the lower positioning seat 36 is used for positioning the static contact seat 11, and the lower positioning seat 36 is driven by the jack 22 to move upwards, that is The jack 22 drives the lower positioning seat 36 to move upward to the positioning seat; because the static contact finger 13 on the static contact seat 11 and the shielding cover 12 are perfectly assembled together, the fo...

Embodiment 2

[0082] like Figure 7 As shown, in this embodiment, the contact seat assembly crimping tool is used for crimping the moving contact seat assembly, and the moving contact seat assembly includes a moving contact seat 52 and an arc strike ring 51 . On the basis of Embodiment 1, the contact seat assembly and crimping tooling also includes an arc pilot ring positioning seat 50 and a moving contact seat positioning seat 53. The arc pilot ring positioning seat 50 is provided with a positioning protrusion and an upper step hole. The contact seat positioning seat 53 is provided with a positioning groove and a lower stepped hole. like Figure 4 and Figure 5 As shown, the groove bottom of the upper positioning groove 48 is provided with an upper threaded hole 49, the groove bottom of the lower positioning groove 45 is provided with a lower threaded hole 46, and the arc pilot ring positioning seat 50 is fixed on the groove bottom of the upper positioning groove 48 by screws. The movin...

Embodiment 3

[0084] In Embodiment 1, the bottom plate 21 of the frame is provided with a guide rod 23, and the guide rod 23 extends vertically, and the lower positioning seat 36 is provided with a guide sleeve 24, and the lower positioning seat 36 is guided by the guide rod 23 and the guide sleeve 24 Fits with guides to mount on the rack. In this embodiment, a guide rod is provided on the bottom plate of the frame, and a guide groove is provided on the guide rod, and the guide groove extends vertically. The guides are mounted on the frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com