Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2971results about "Clamps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

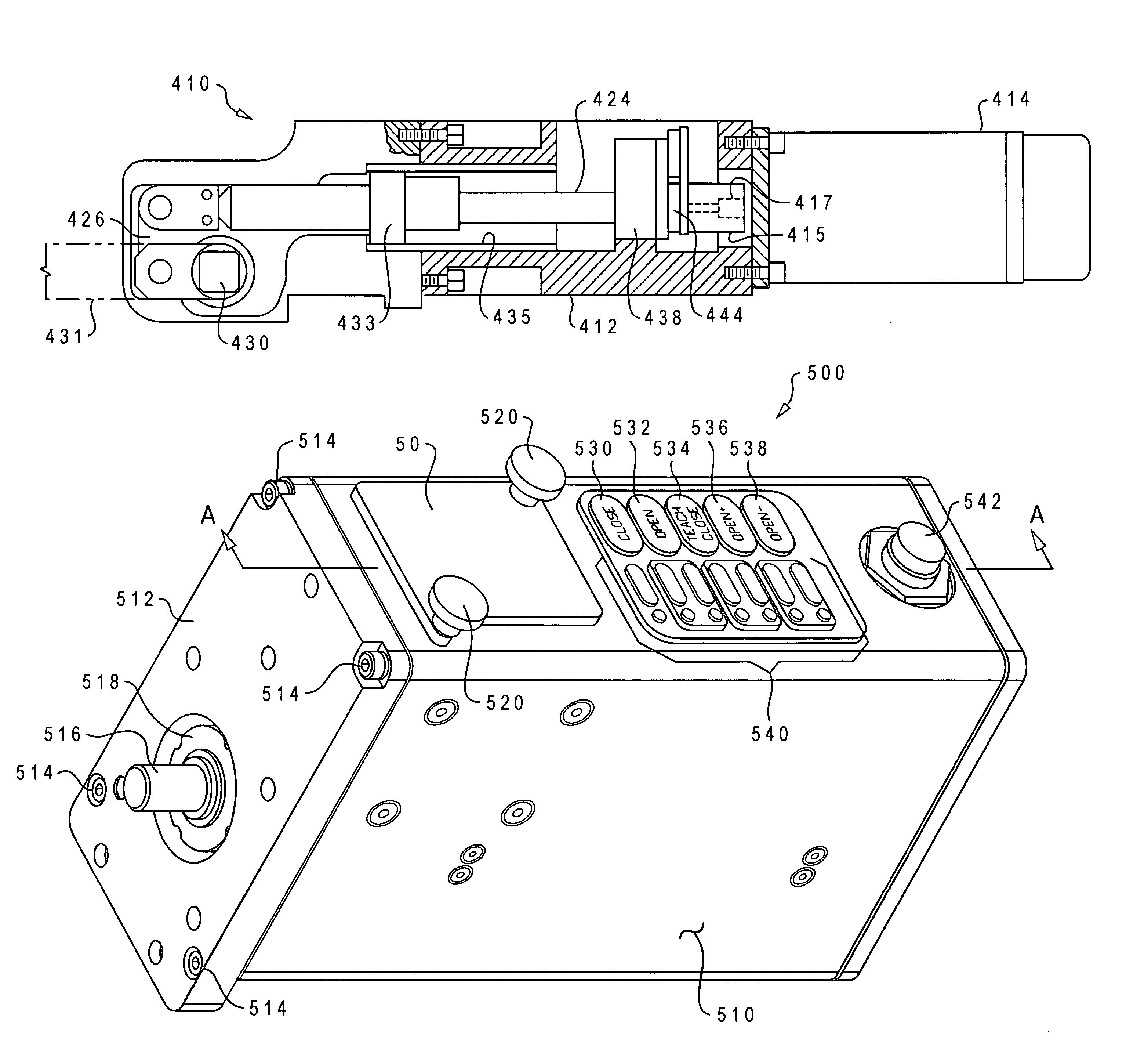

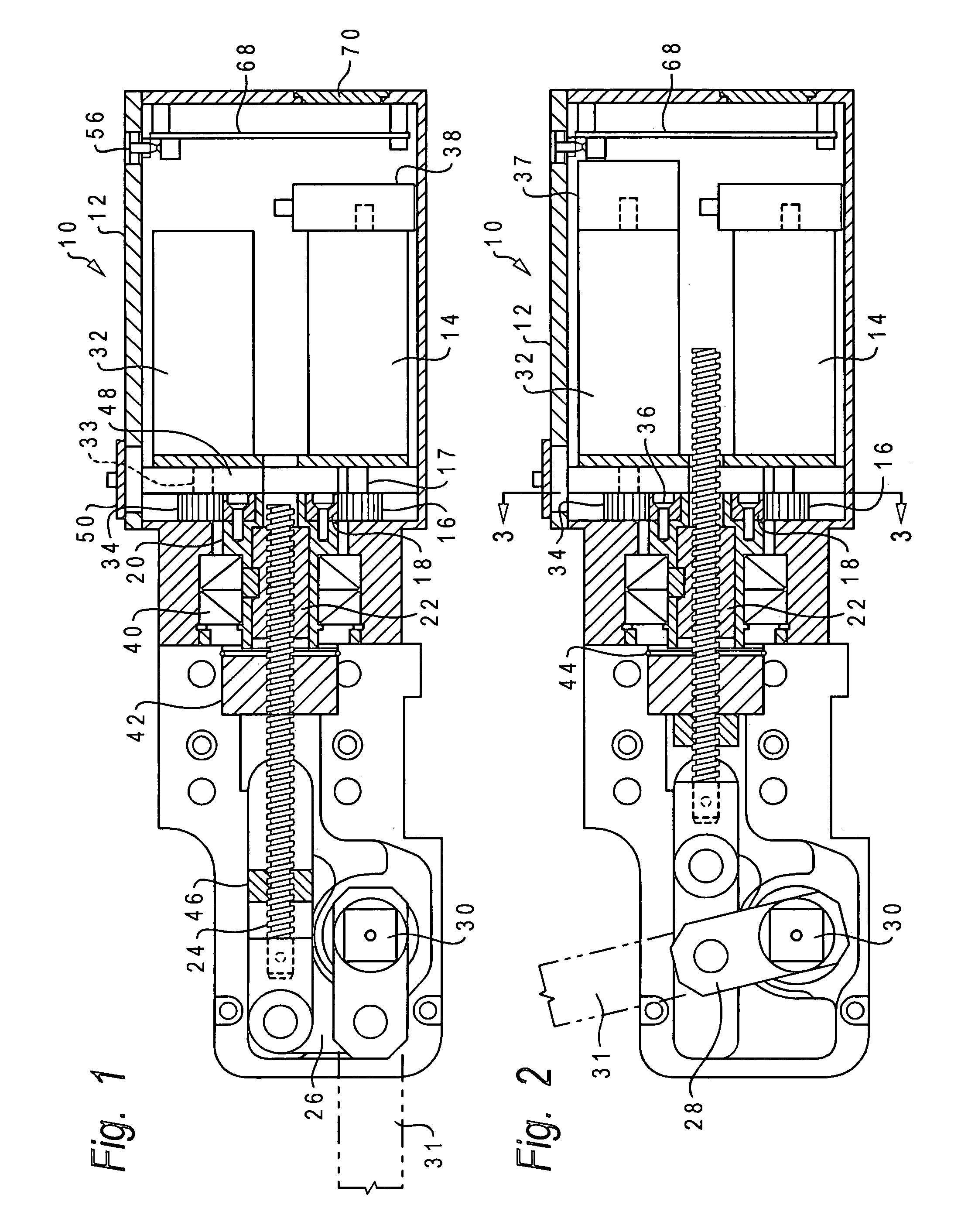

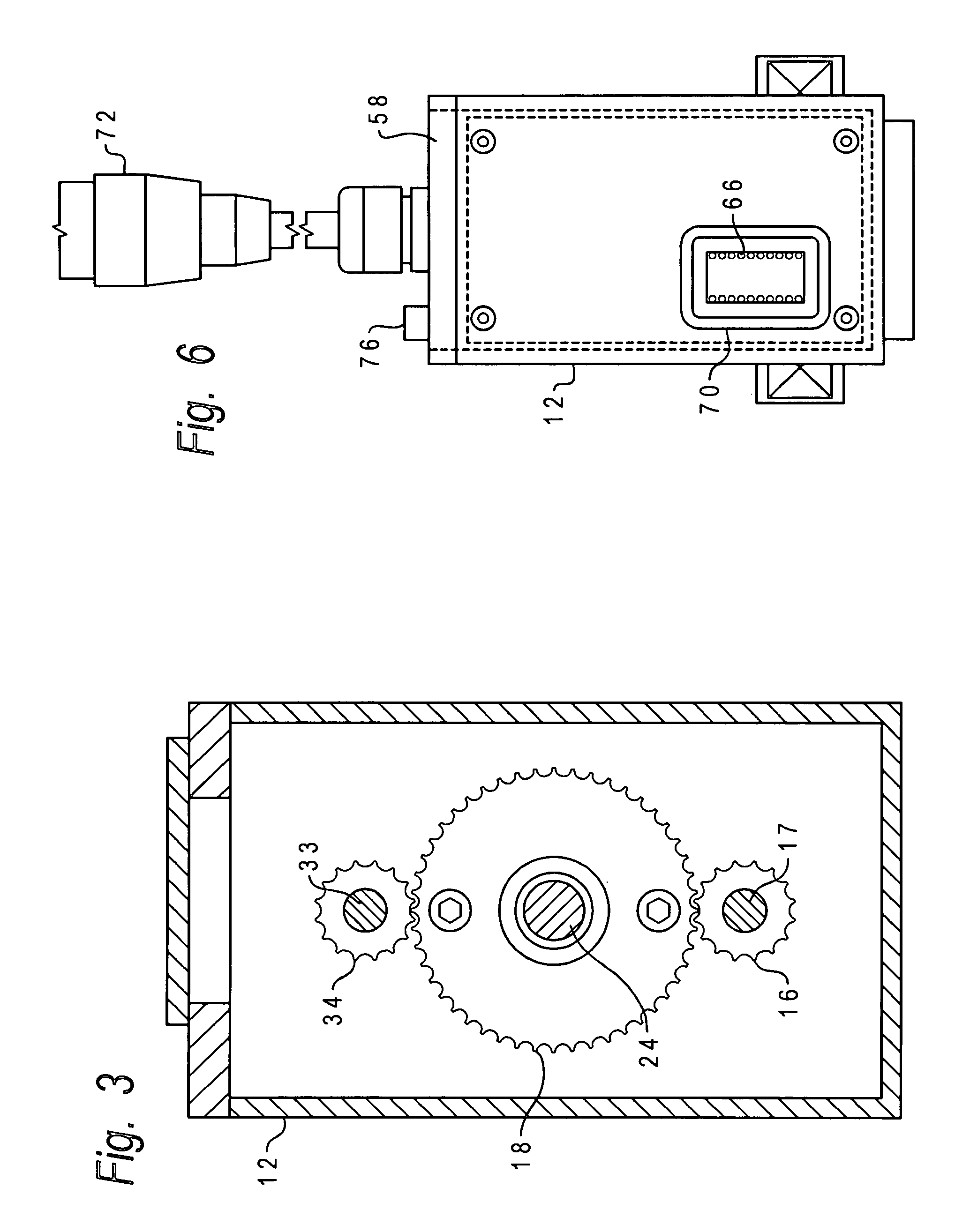

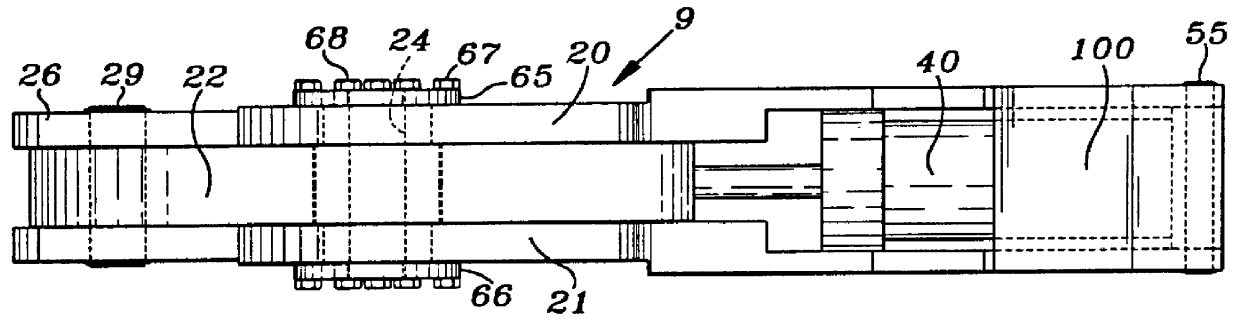

Motor pack for automated machinery

A motor pack for an electrically driven tool includes at least one electric motor and a linearly displaceable member coupled to the electric motor such that the linearly displaceable member is displaced axially by operation of the at least one electric motor. The motor pack further includes a housing enclosing the electric motor and at least partially enclosing the linearly displaceable member. The housing includes a front plate to which a tool head may be removably coupled. The front plate has an aperture formed therein through which the linearly displaceable element can be coupled to a moveable element in the tool head. The motor pack also includes tool control circuitry enclosed within the housing and electrically coupled to the electric motor to control operation thereof.

Owner:DELAWARE CAPITAL FORMATION INC +1

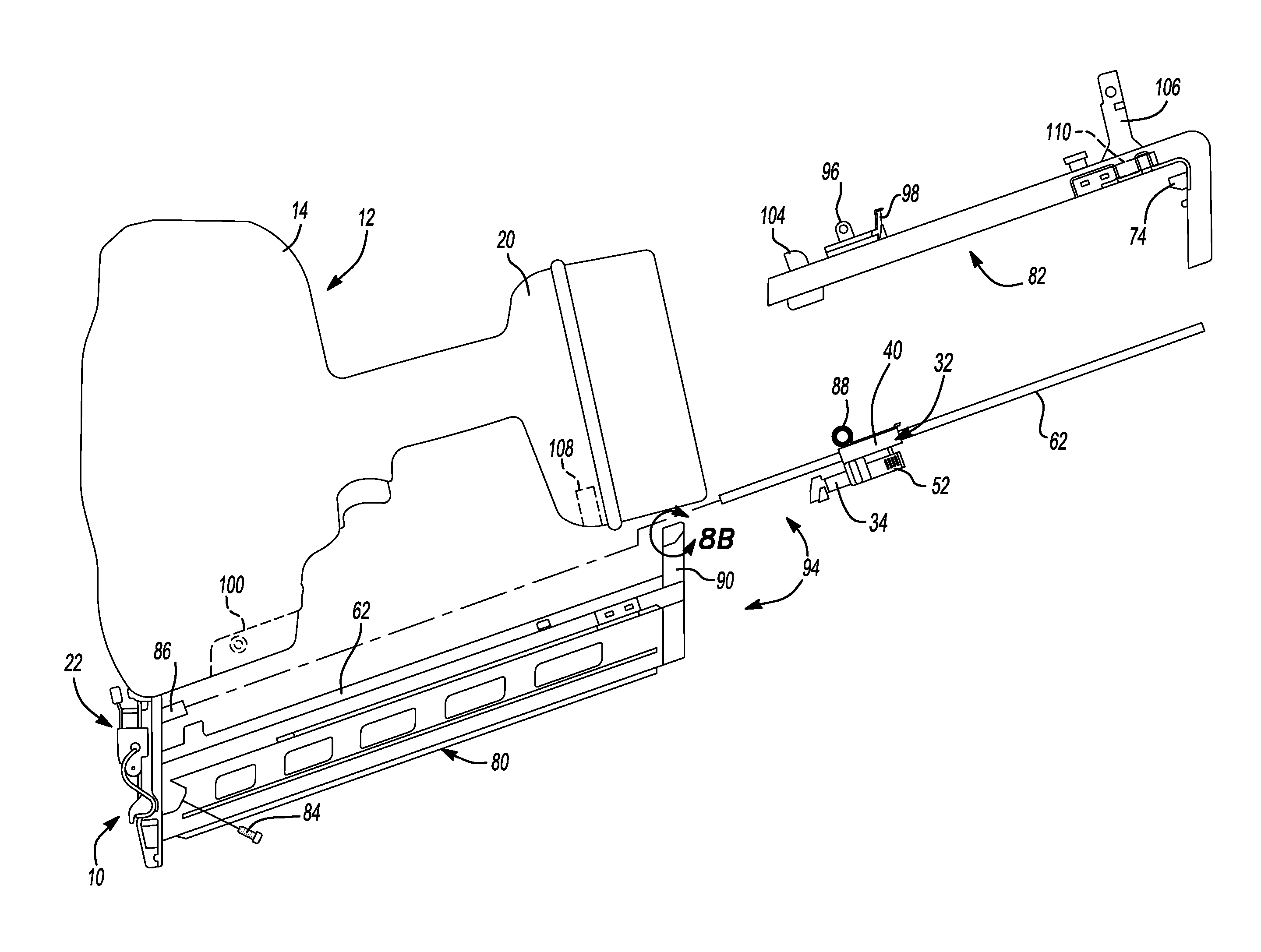

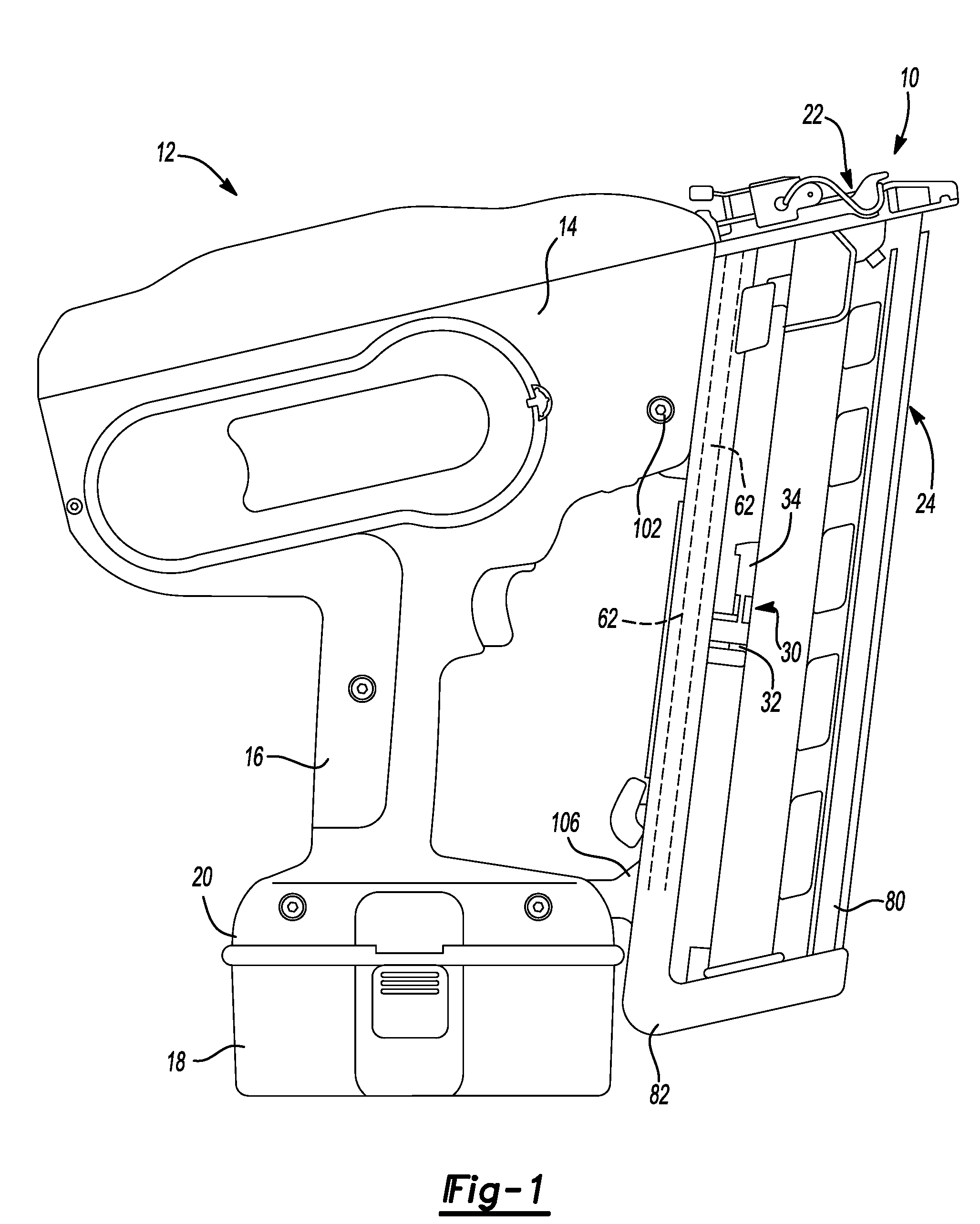

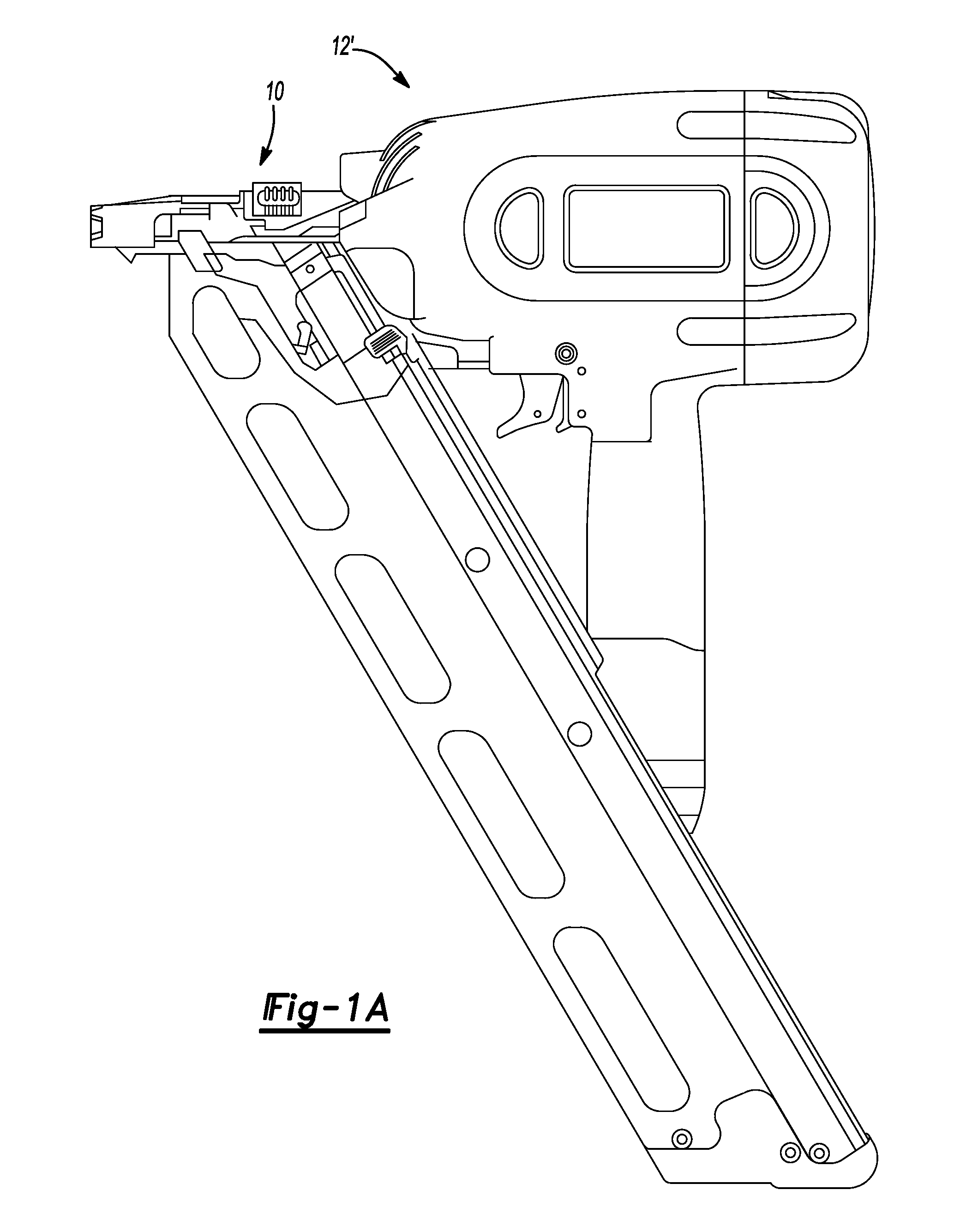

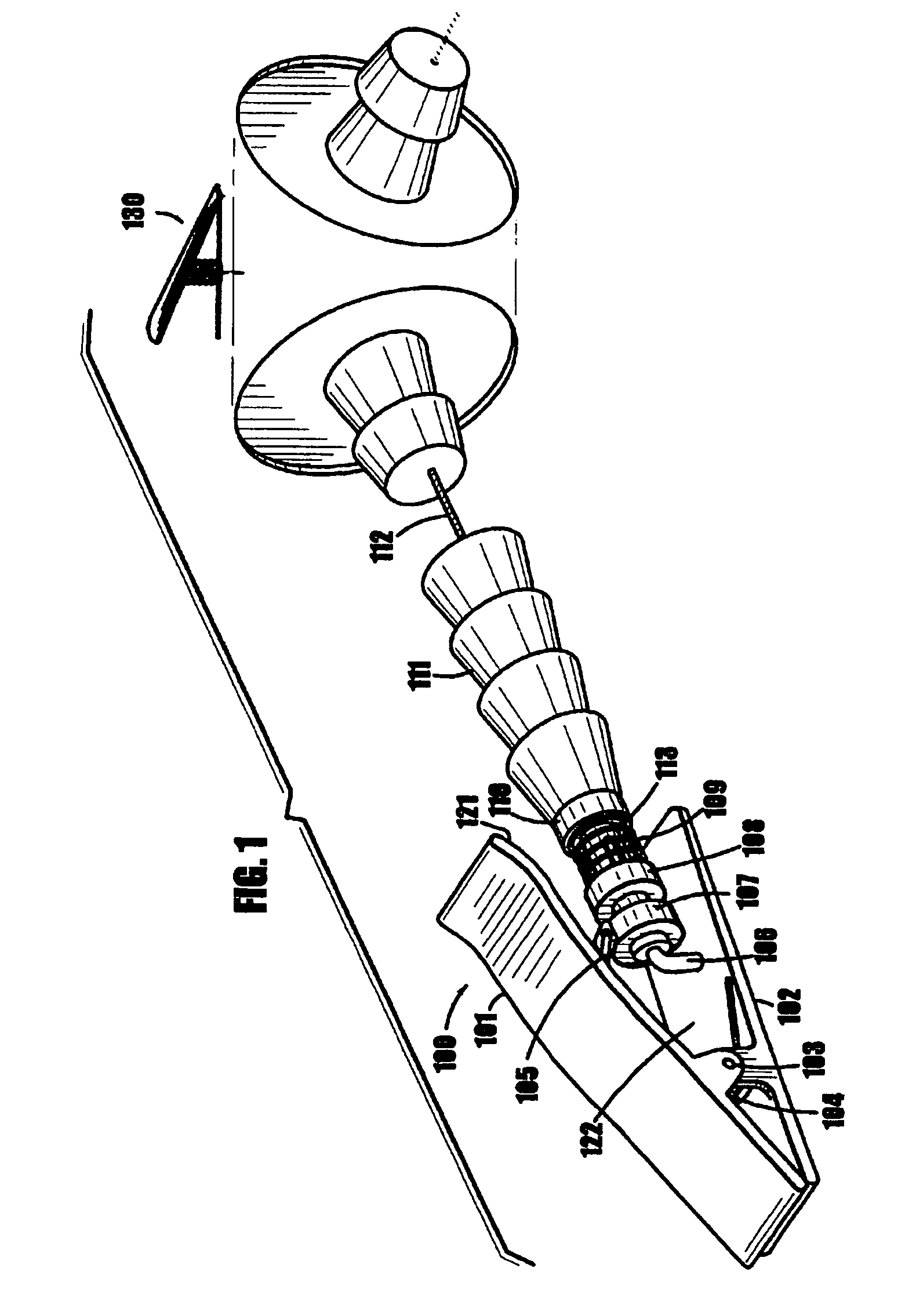

Magazine assembly for nailer

ActiveUS8899460B2Reduce wearSimplified and efficient constructionStapling toolsDispensing apparatusEngineeringMechanical engineering

A cordless nailer is provided having a magazine assembly with improved features. A pusher assembly is provided having a simplified and efficient construction. A pusher retention feature is provided that prevents the driver blade from impacting a nail pusher. A nail retention feature is provided to allow easy loading and unloading of nails into the nailer. Finally, a method of assembling the magazine assembly is provided.

Owner:BLACK & DECKER INC

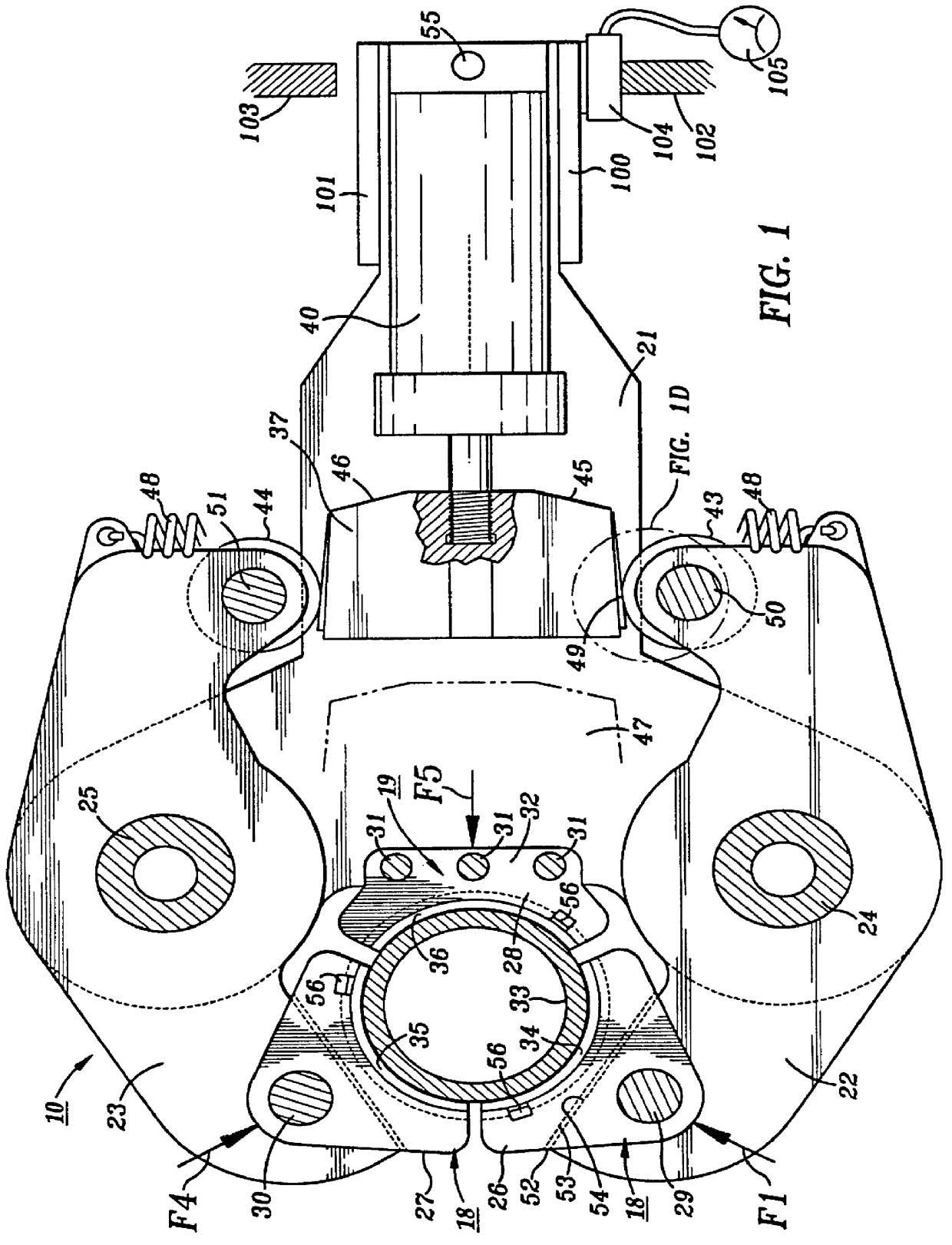

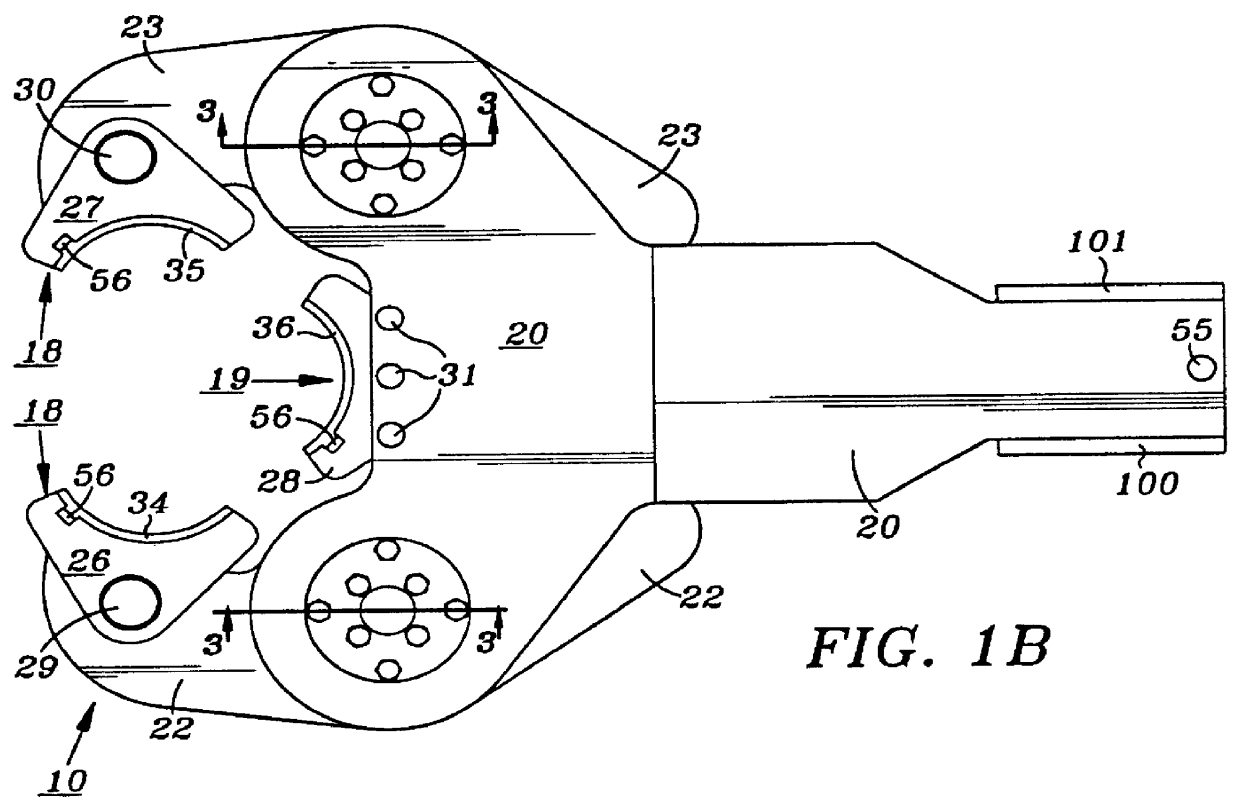

Gripping apparatus for power tongs and backup tools

Apparatus for gripping tubular members including self aligning gripping jaws with high coefficient of friction for resisting force applied to the elongated member to prevent rotation either clockwise or counterclockwise. Linear cams and cam rollers actuated by a fluid cylinder bring the gripping jaws to an elongated member, applying predetermined gripping force and retract the jaws for removal of the elongated member.

Owner:WESCH JR WILLIAM E

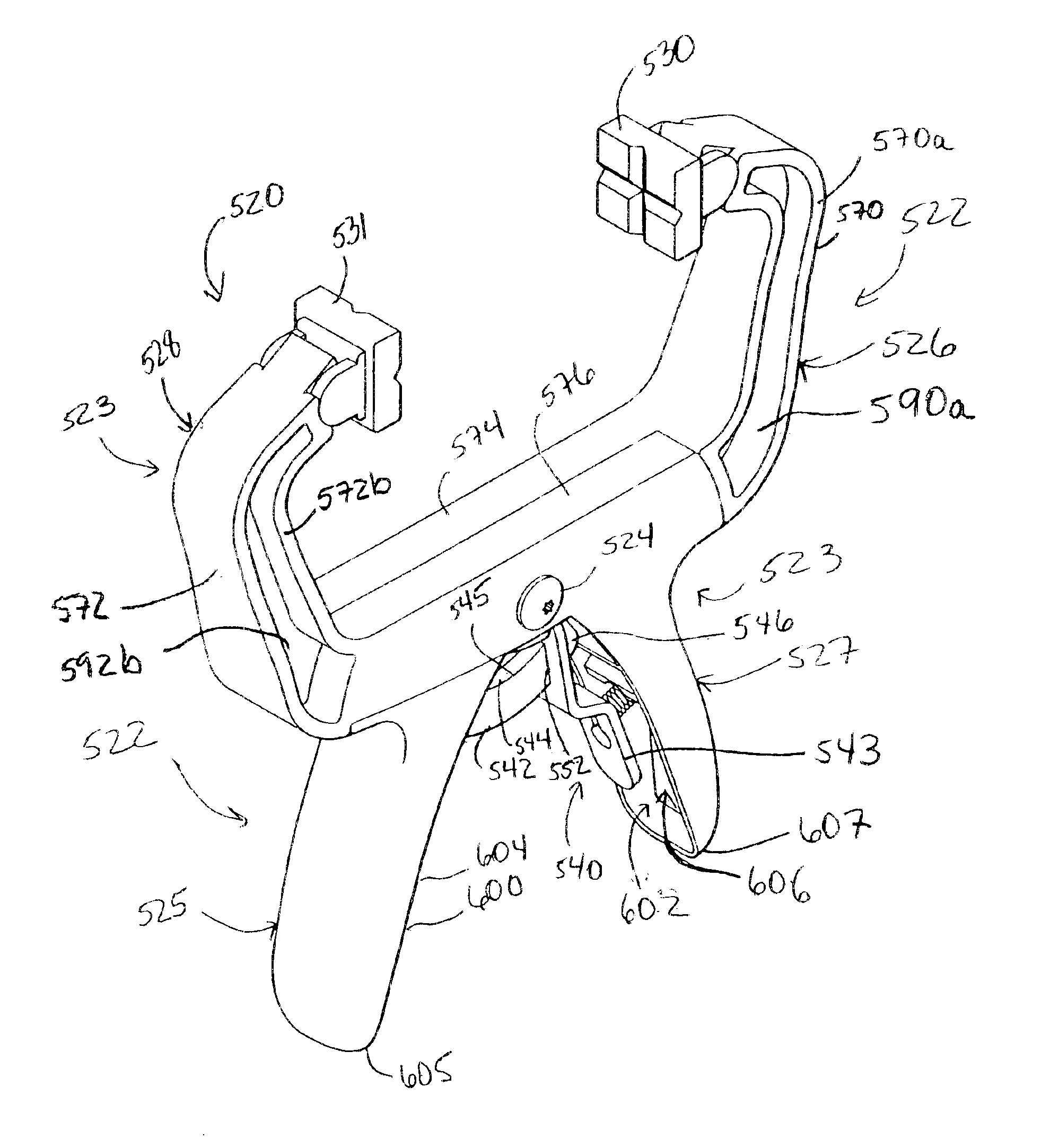

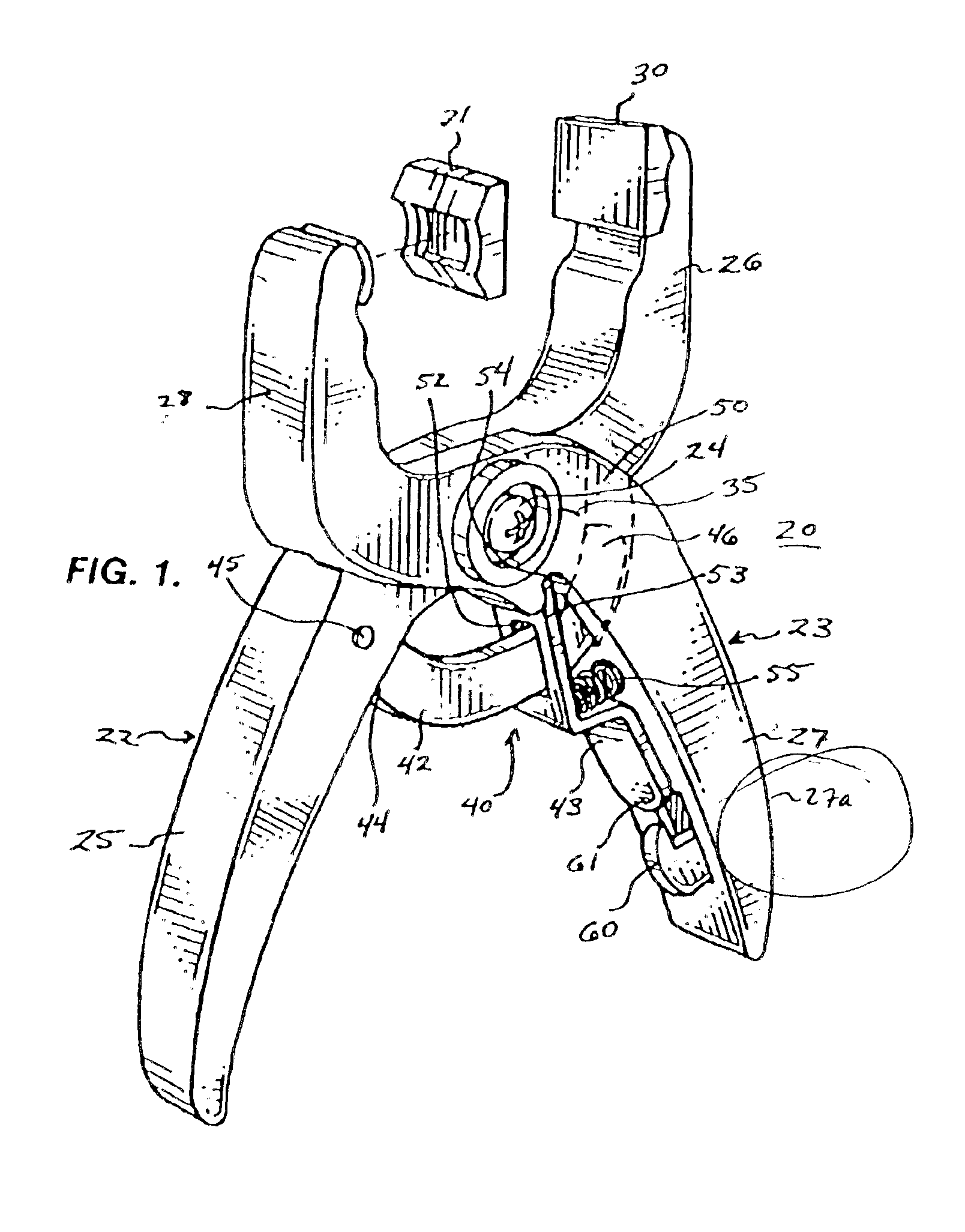

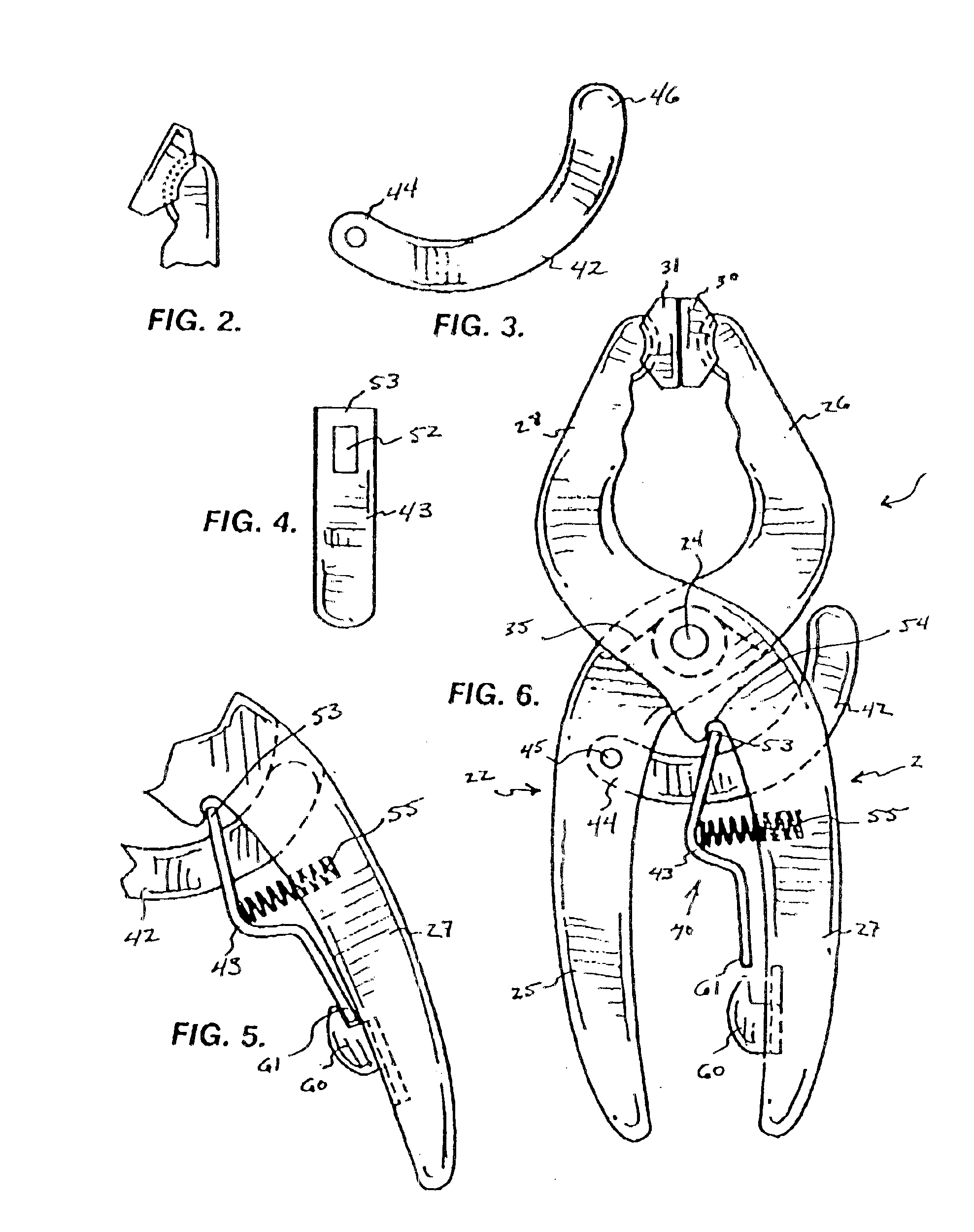

Clamp device

A clamp device is disclosed having a first member having a handle portion and a jaw portion. A second member has a handle portion and a jaw portion. The handle portion and jaw portion of the second member define a notch extending from an inner surface of the handle portion of the second member at least partially into the jaw portion of the second member, the second member being formed as a single piece. A pivot is pivotally coupling the first member and the second member intermediate their respective handle portion and jaw portion for opposed pivotal motion. An arcuate clamp bar has a first end coupled to the first member and a second end, an arc of the arcuate clamp bar being concentric with the pivot. A brake lever has an end pivotally coupled to the second member at the notch. The end contacts the jaw portion of the second member. The brake lever has an aperture with the arcuate clamp bar extending therethrough. The brake lever is movable laterally between a frictionally engaged position, frictionally engaging the arcuate clamp bar and a disengaged position.

Owner:BLACK & DECKER INC

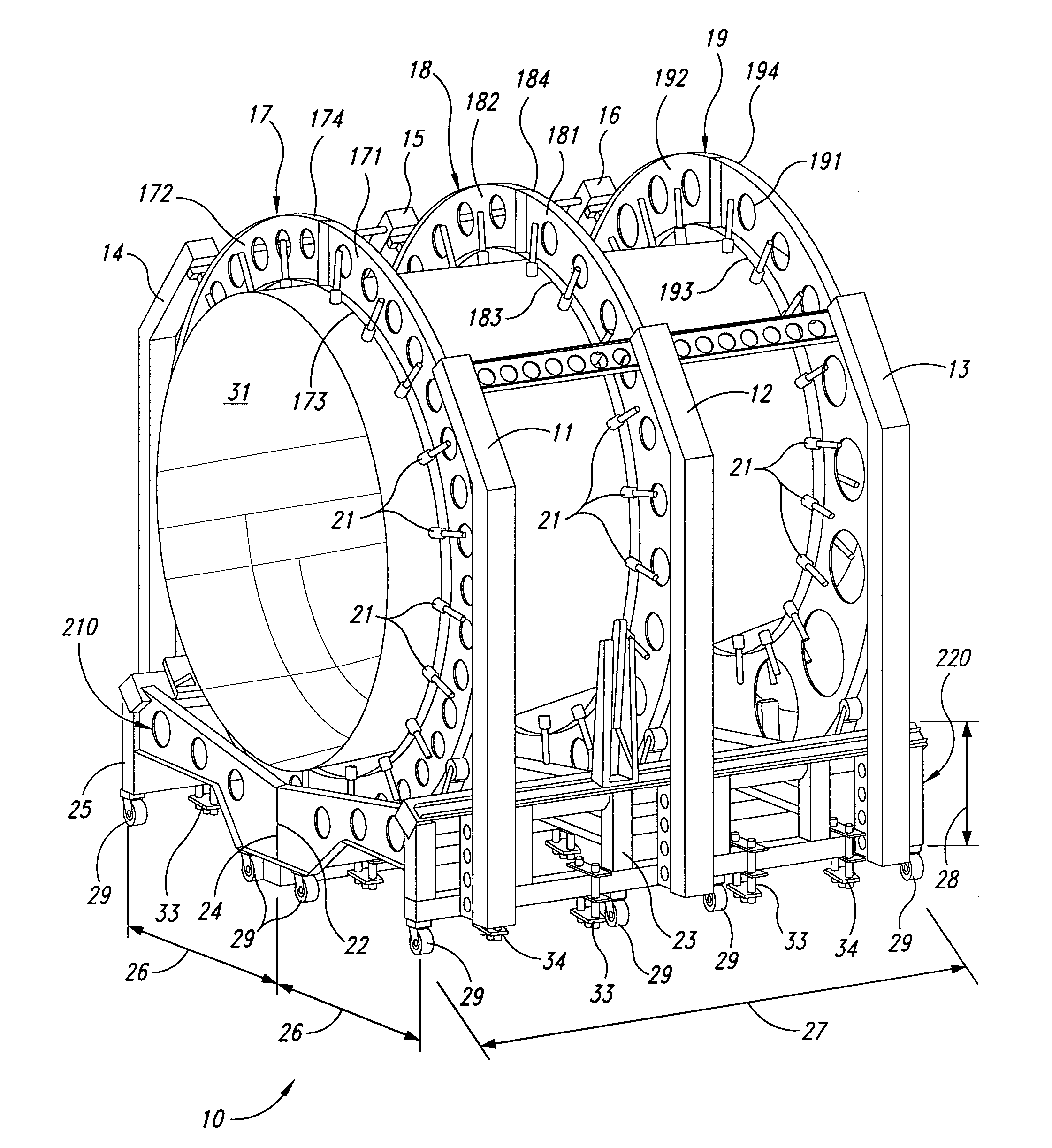

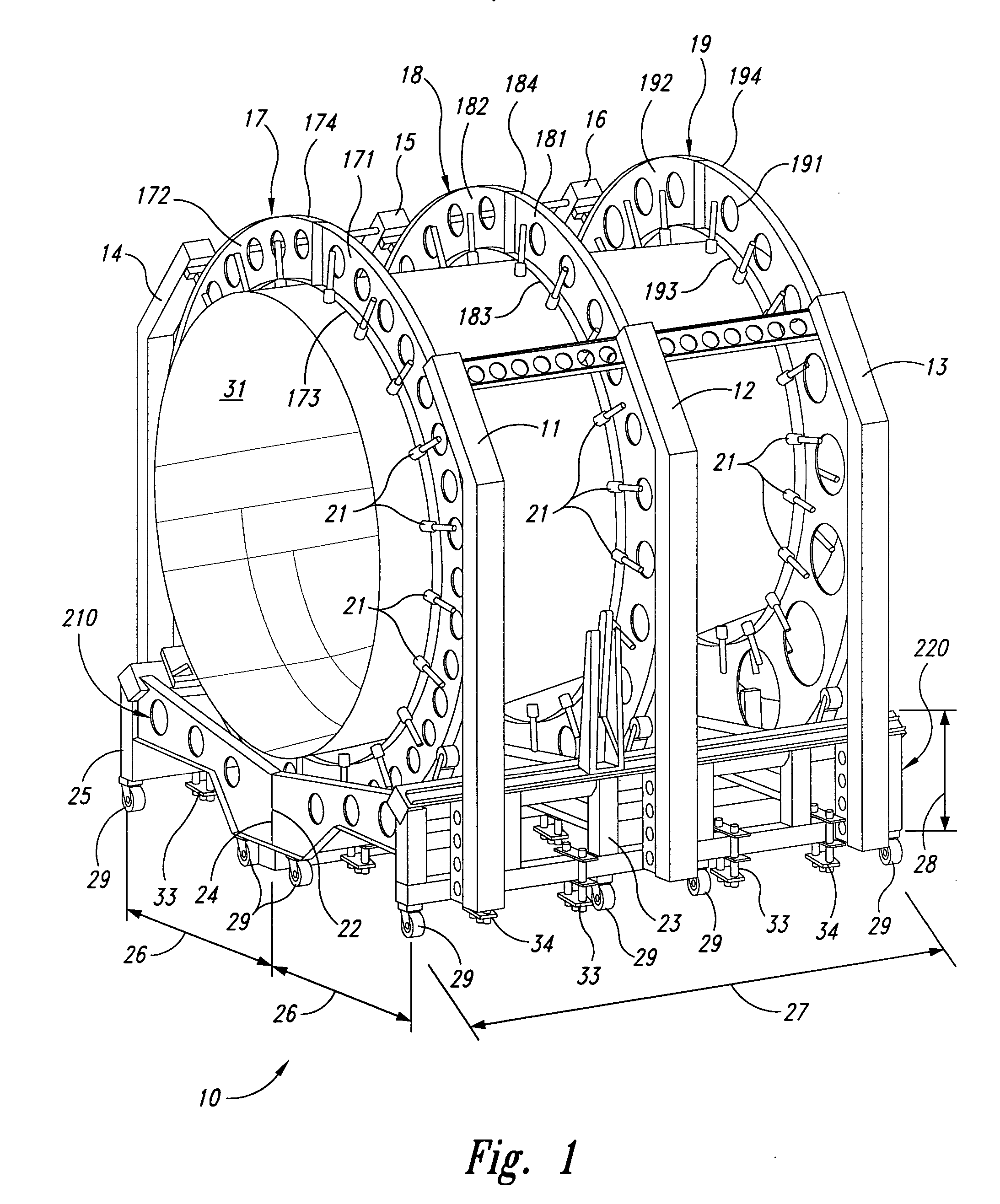

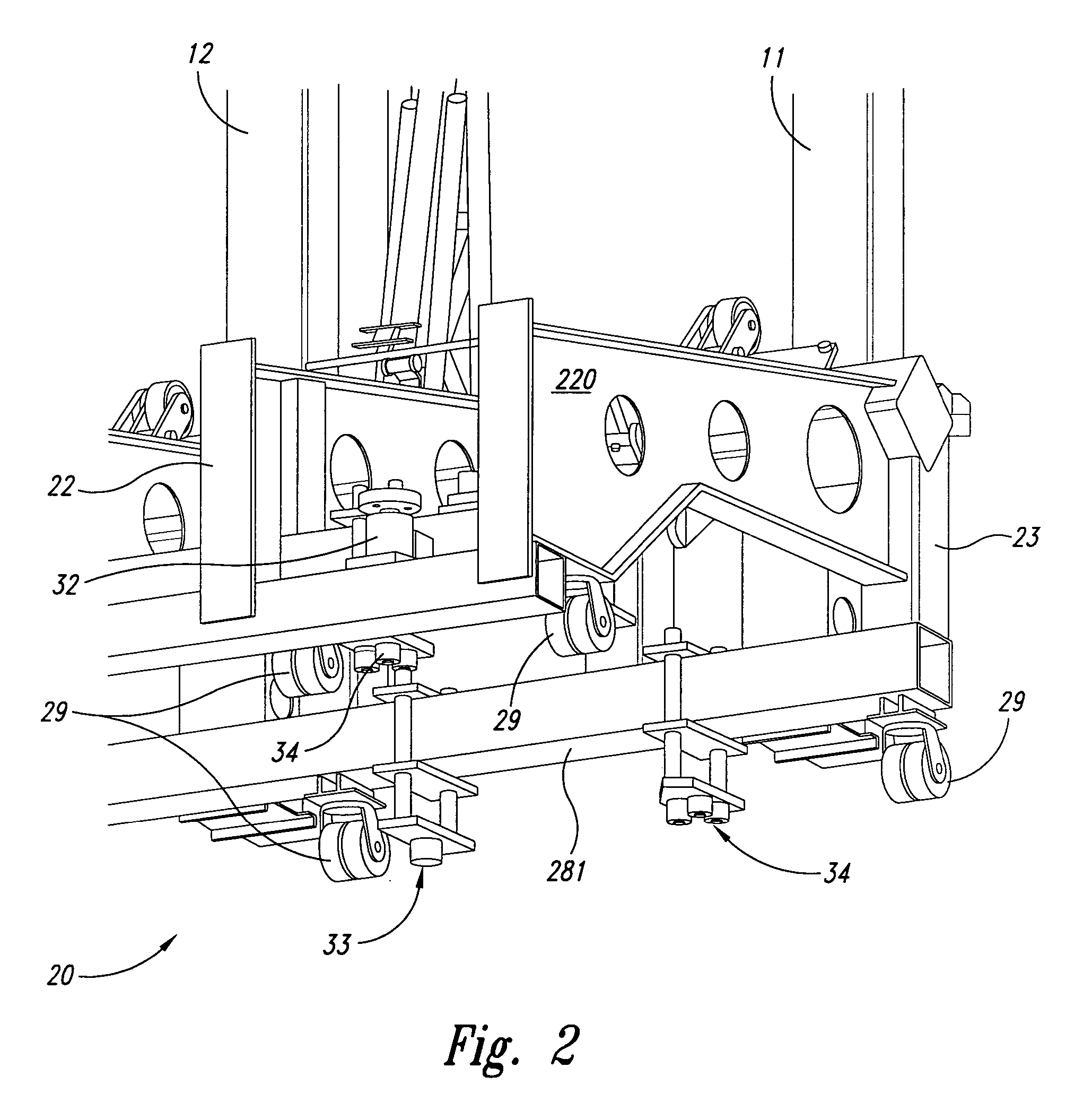

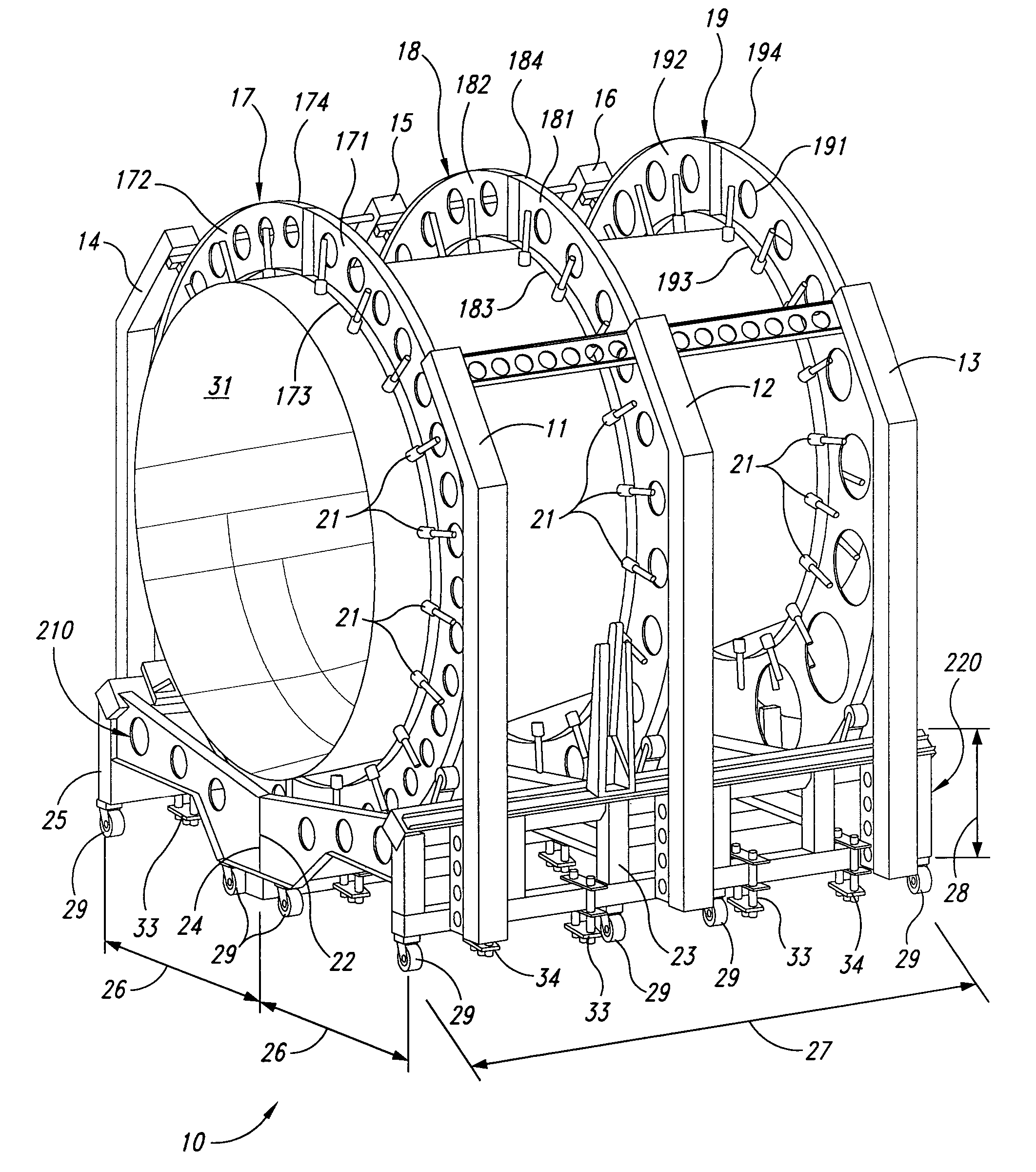

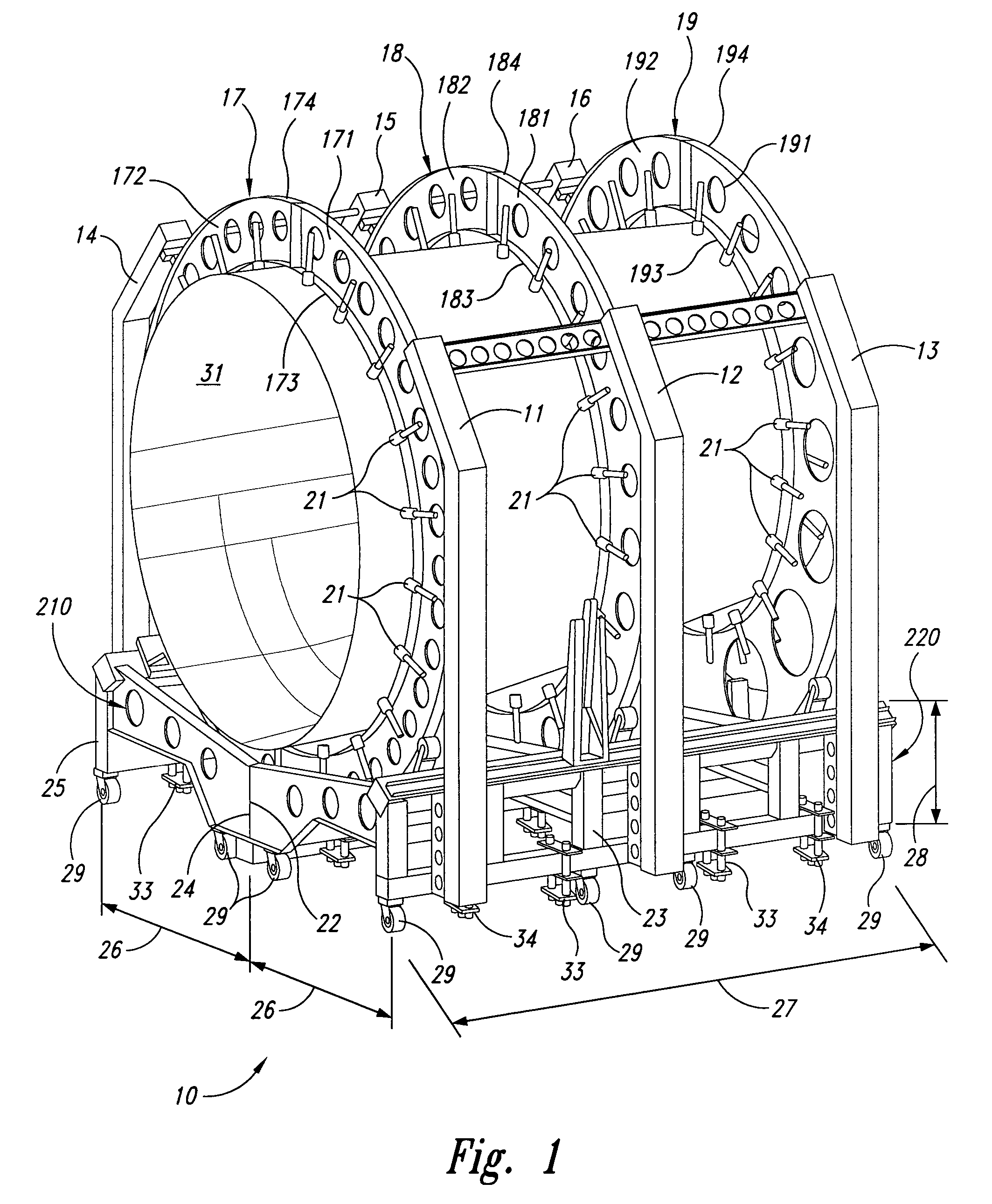

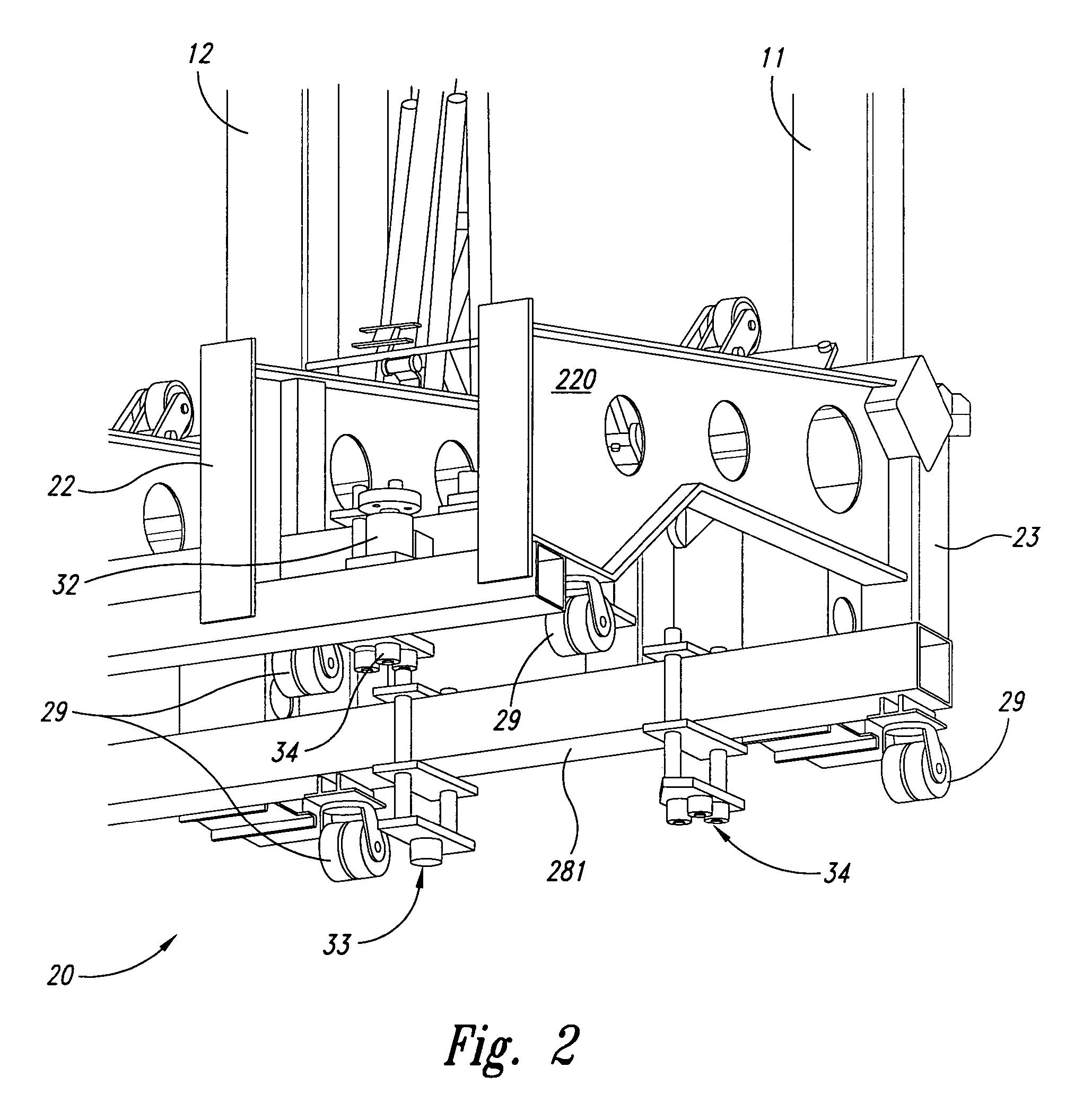

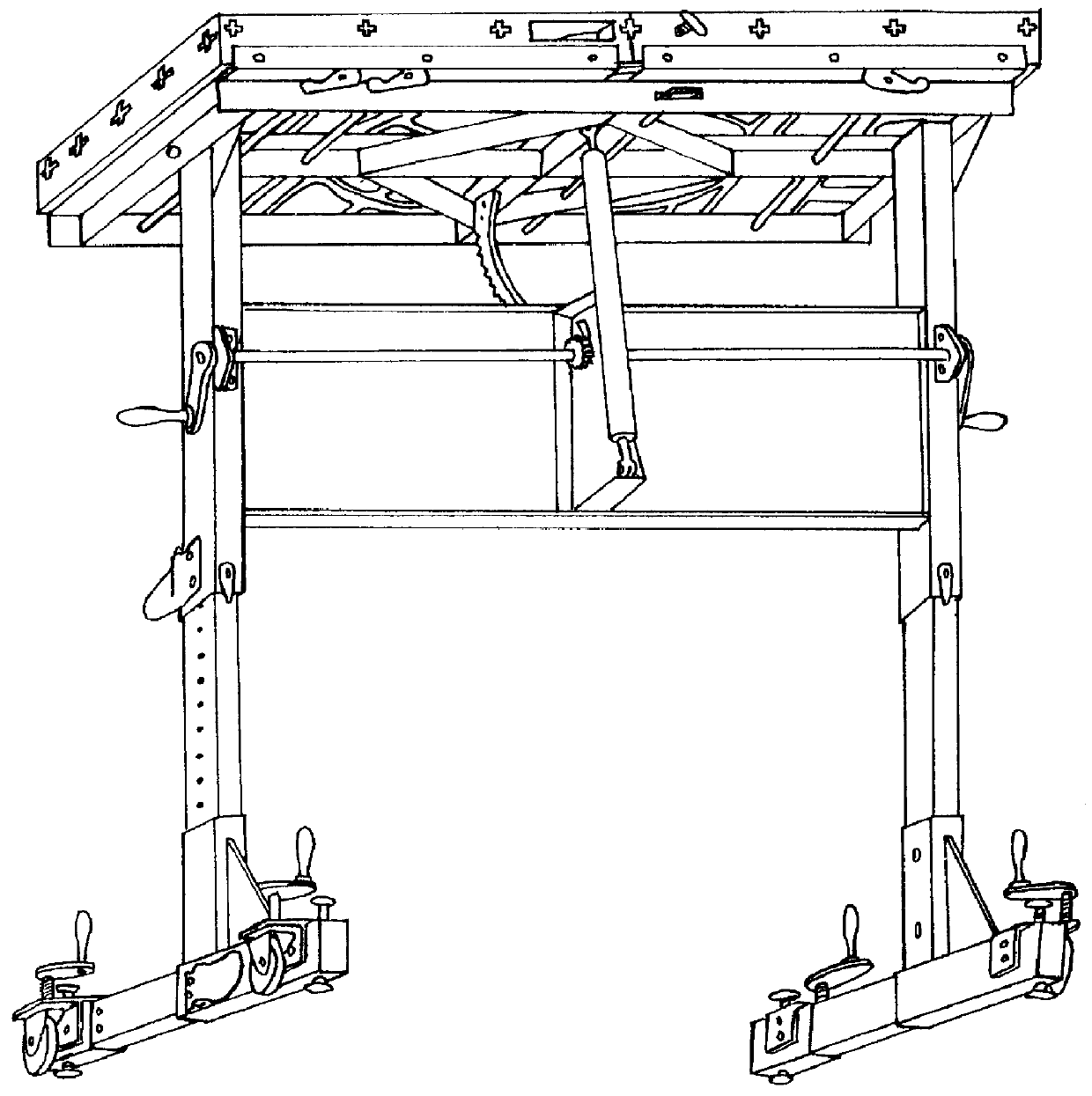

One-piece barrel assembly cart

A one-piece barrel assembly cart includes a right assembly cart base connected with a left assembly cart base and at least three stabilizer rings that are attached to the assembly cart base. The one-piece barrel assembly cart may be used to stabilize a tapered cured composite barrel, for example the large fuselage barrel of the aft section of a large new generation aircraft, such as a 7E7 Boeing airplane. A modular assembly cart includes at least two identical modules. Each of these modules includes a cart base and a stabilizer ring. The diameter of the inner surface of the stabilizer ring may vary as needed. Other modules including a fuselage support may be added. By providing modular assembly carts any shape and size of a one-piece composite barrel may be stabilized after curing of the composite material.

Owner:THE BOEING CO

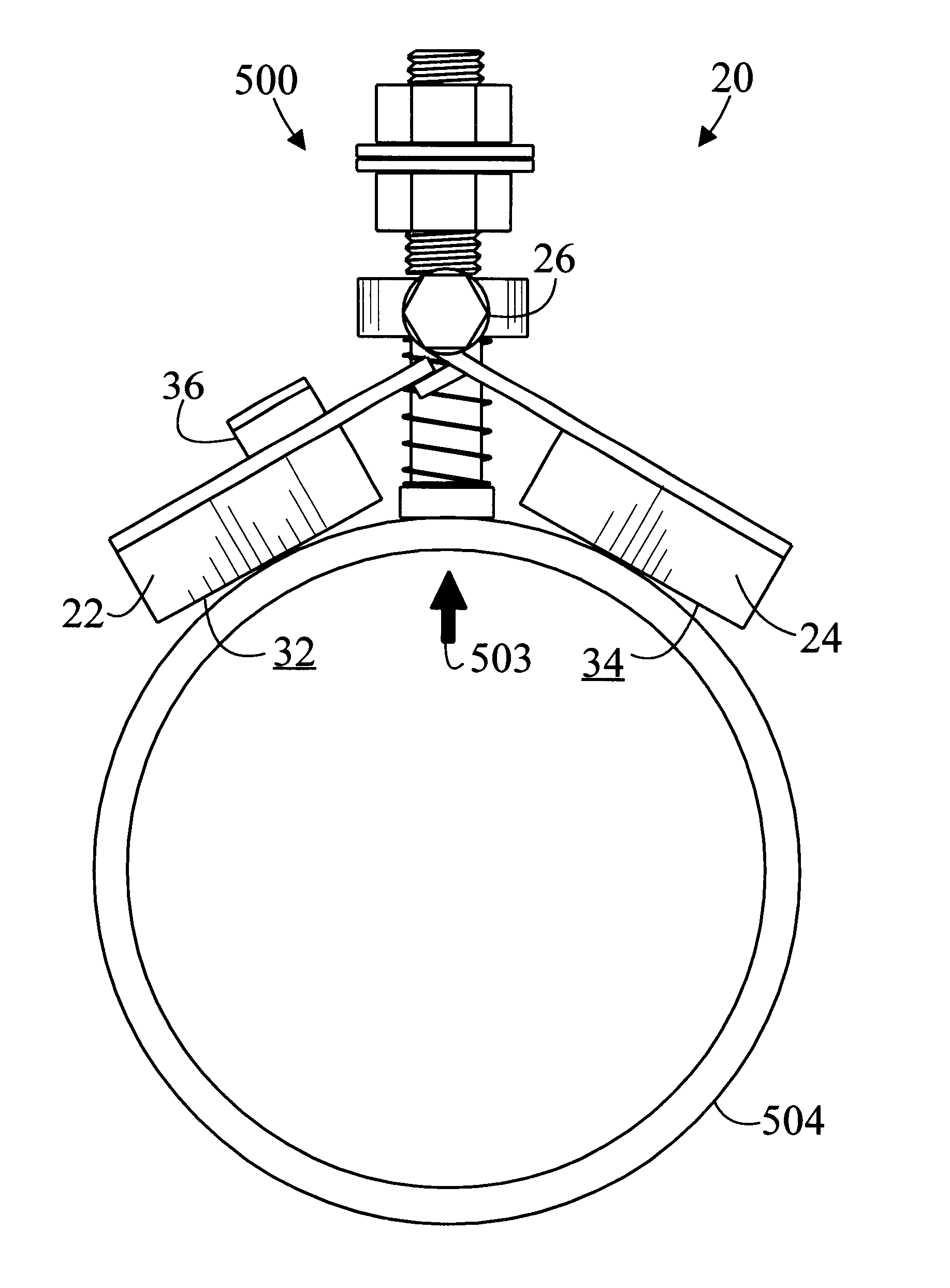

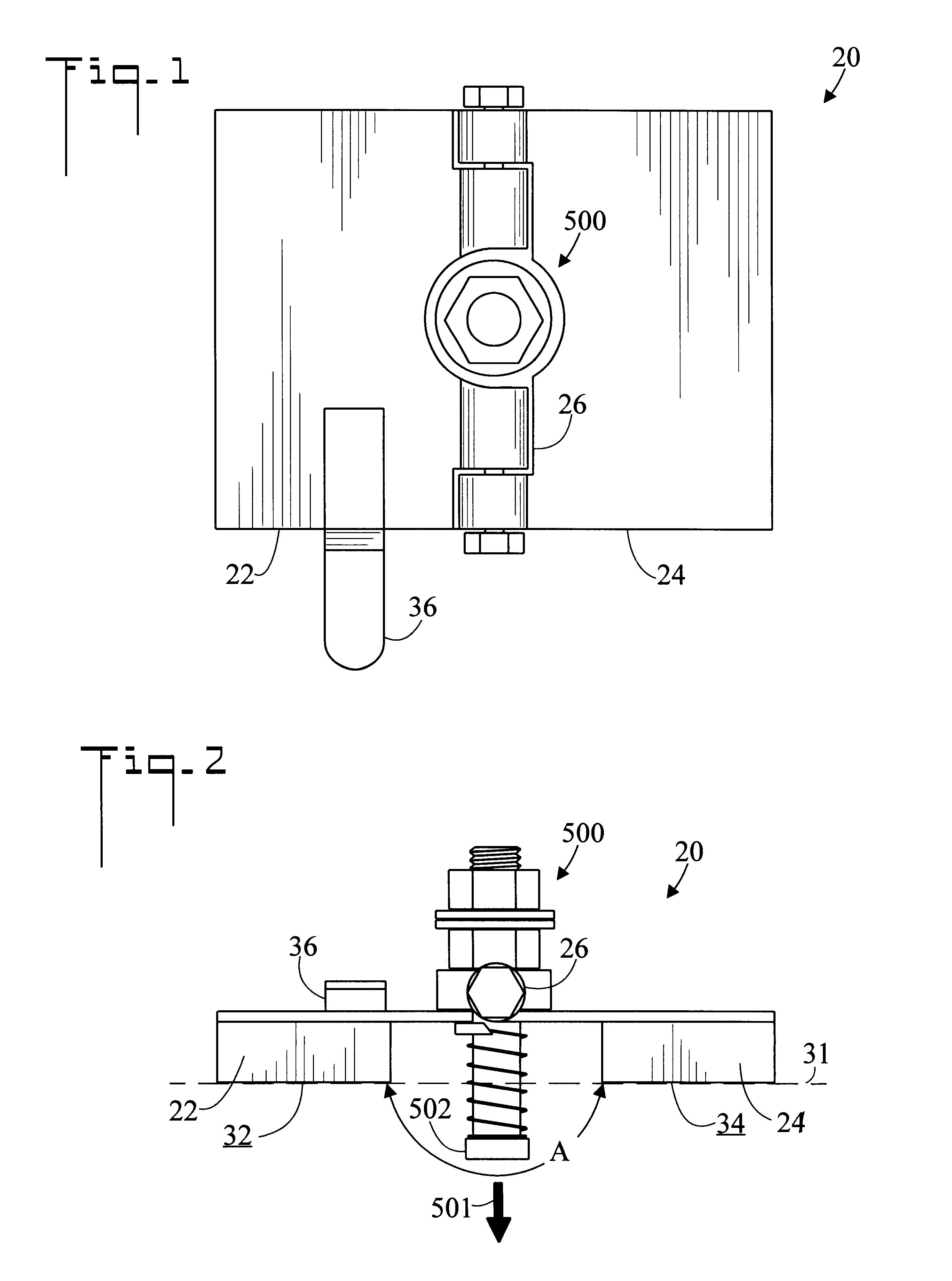

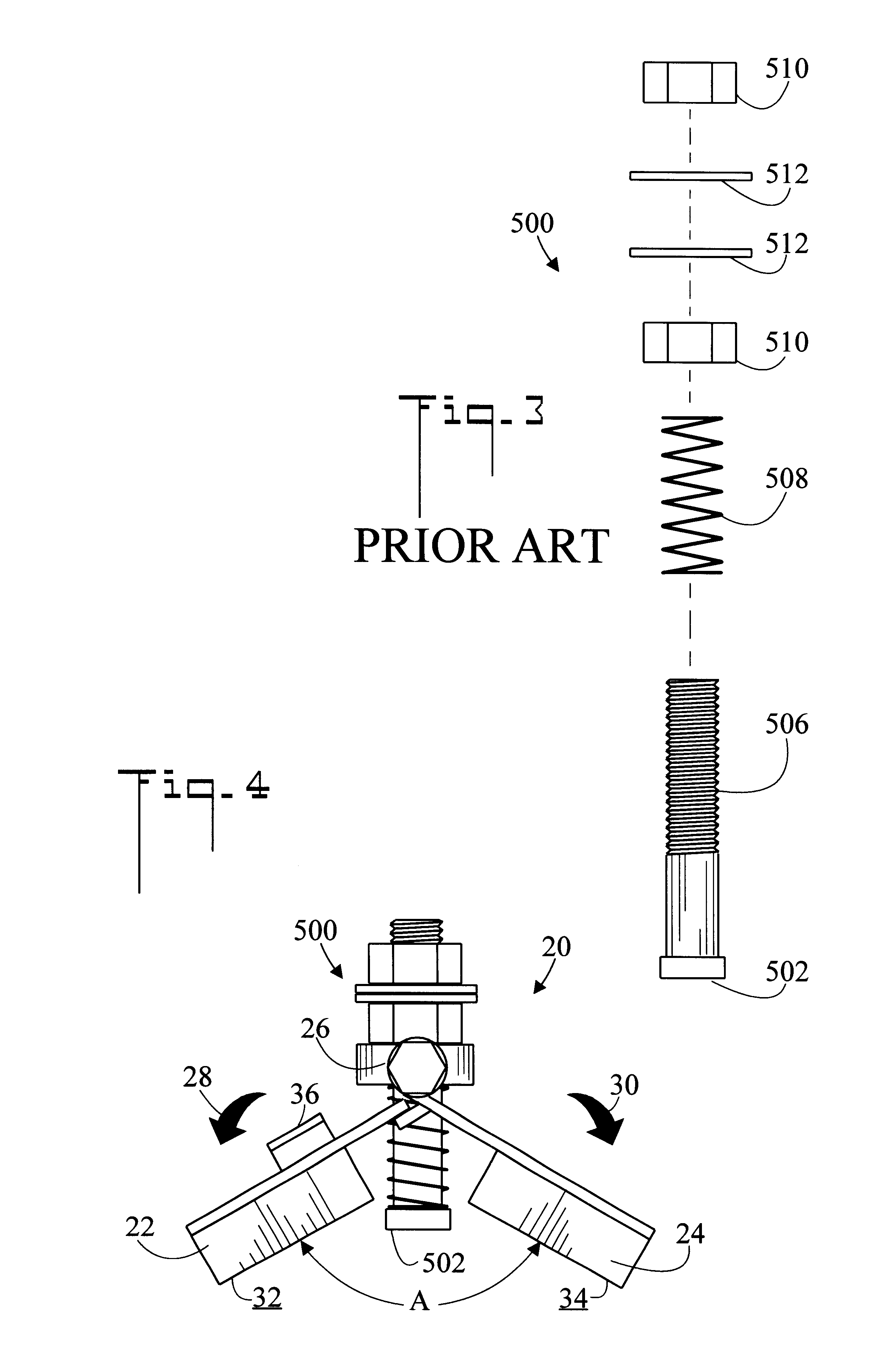

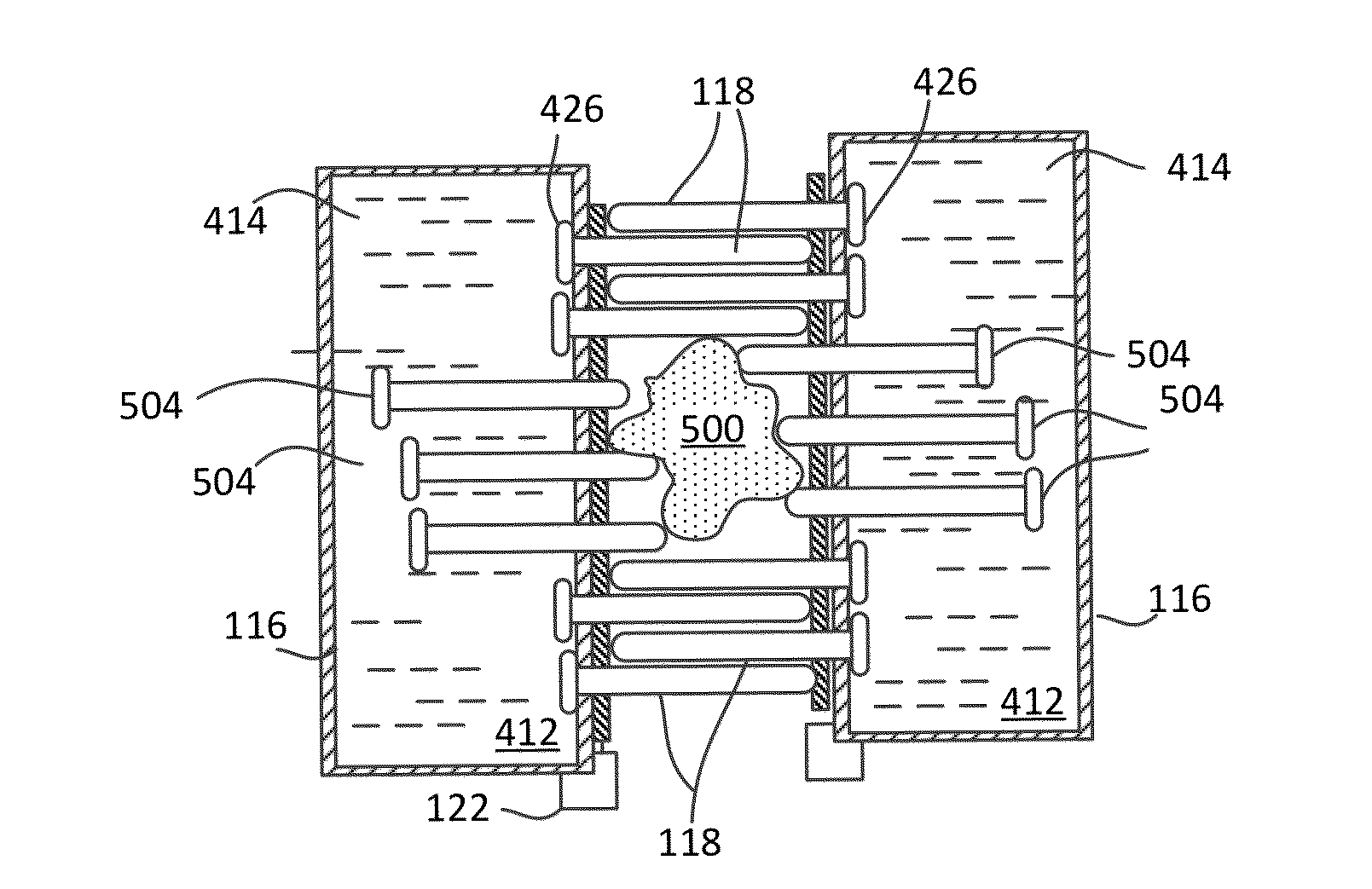

Magnetic clamp for welding magnetic objects

InactiveUS6279885B1Easily be twisted off of pipeImprove gripWorkpiece holdersWelding/cutting auxillary devicesEngineeringHinge angle

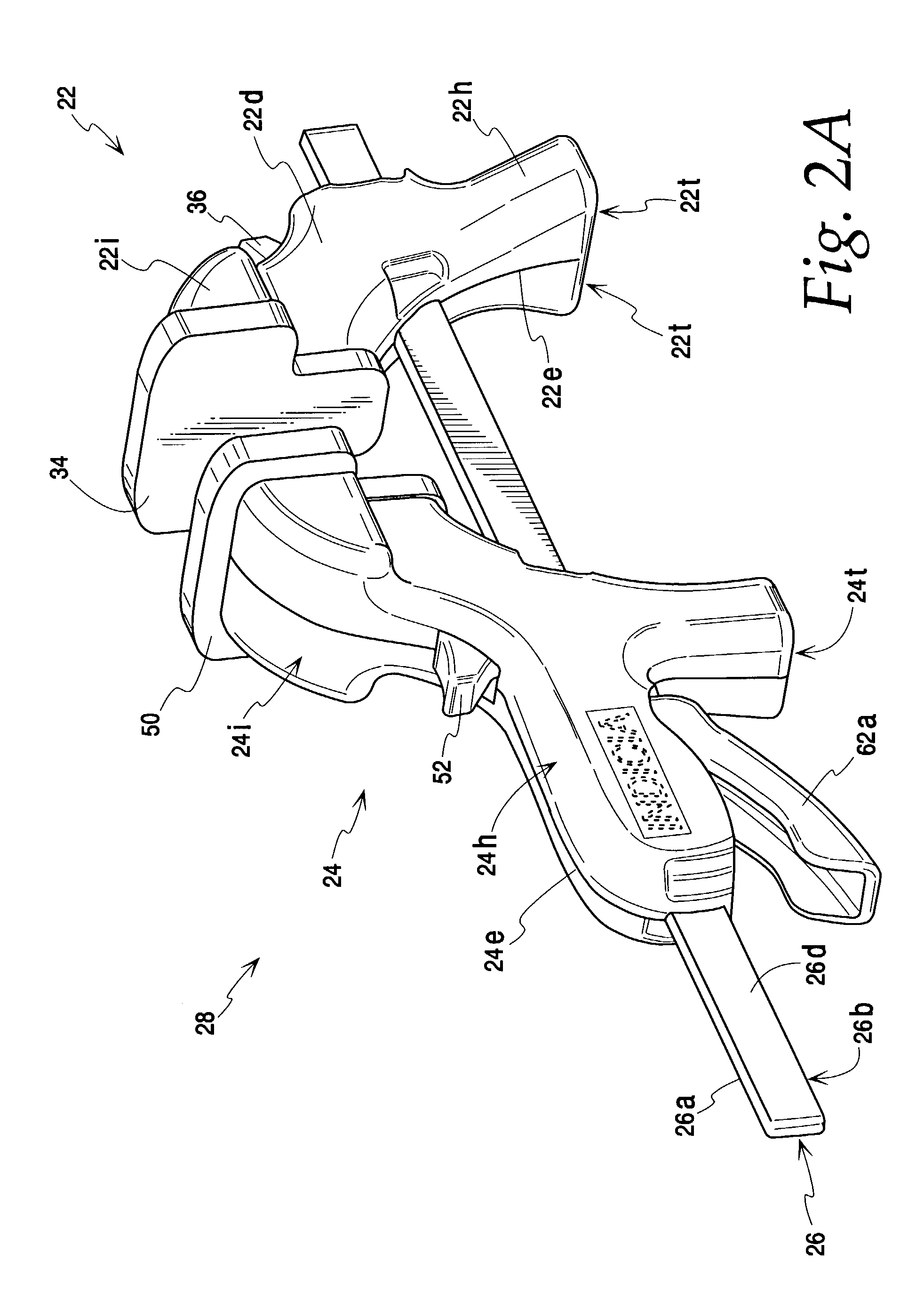

A magnetic clamp (20) for welding a magnetic object (504), includes a first magnetic member (22) and a second magnetic member (24). A hinge (26) connects magnetic members (22) and (24) so that an angle formed by magnetic members (22) and (24) may be changed. A spring loaded terminal (500) having a contact end (502) is disposed between first magnetic member (22) and second magnetic member (24). Magnetic clamp (20) may be attached to magnetic object (504) so that first magnetic member (22), second magnetic member (24), and contact end (502) all abut magnetic object (504). In a preferred embodiment, a removal tab (36) is connected to magnetic clamp (20) to assist in removing magnetic clamp (20) from magnetic object (504).

Owner:LEON JR RAYMOND

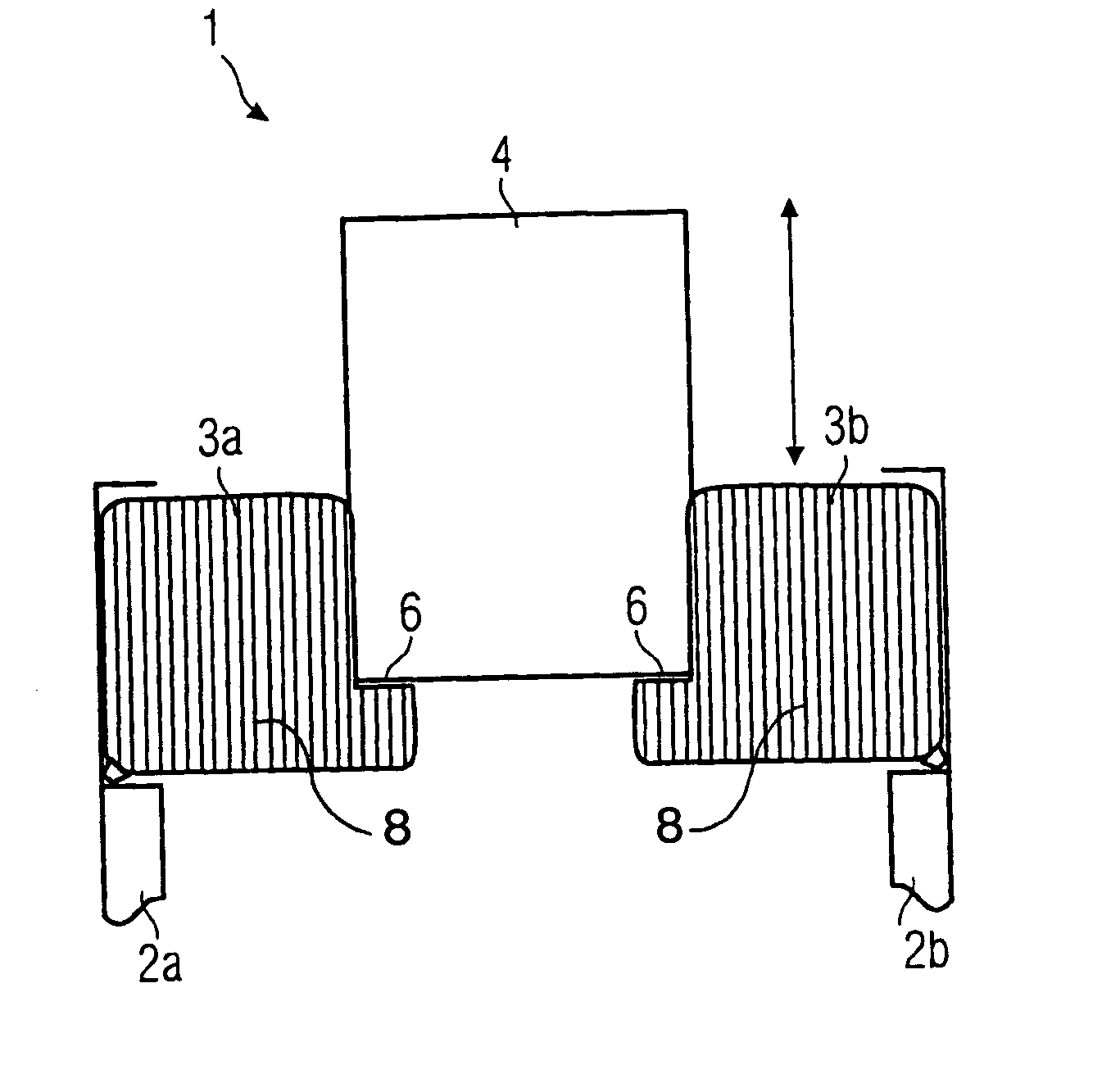

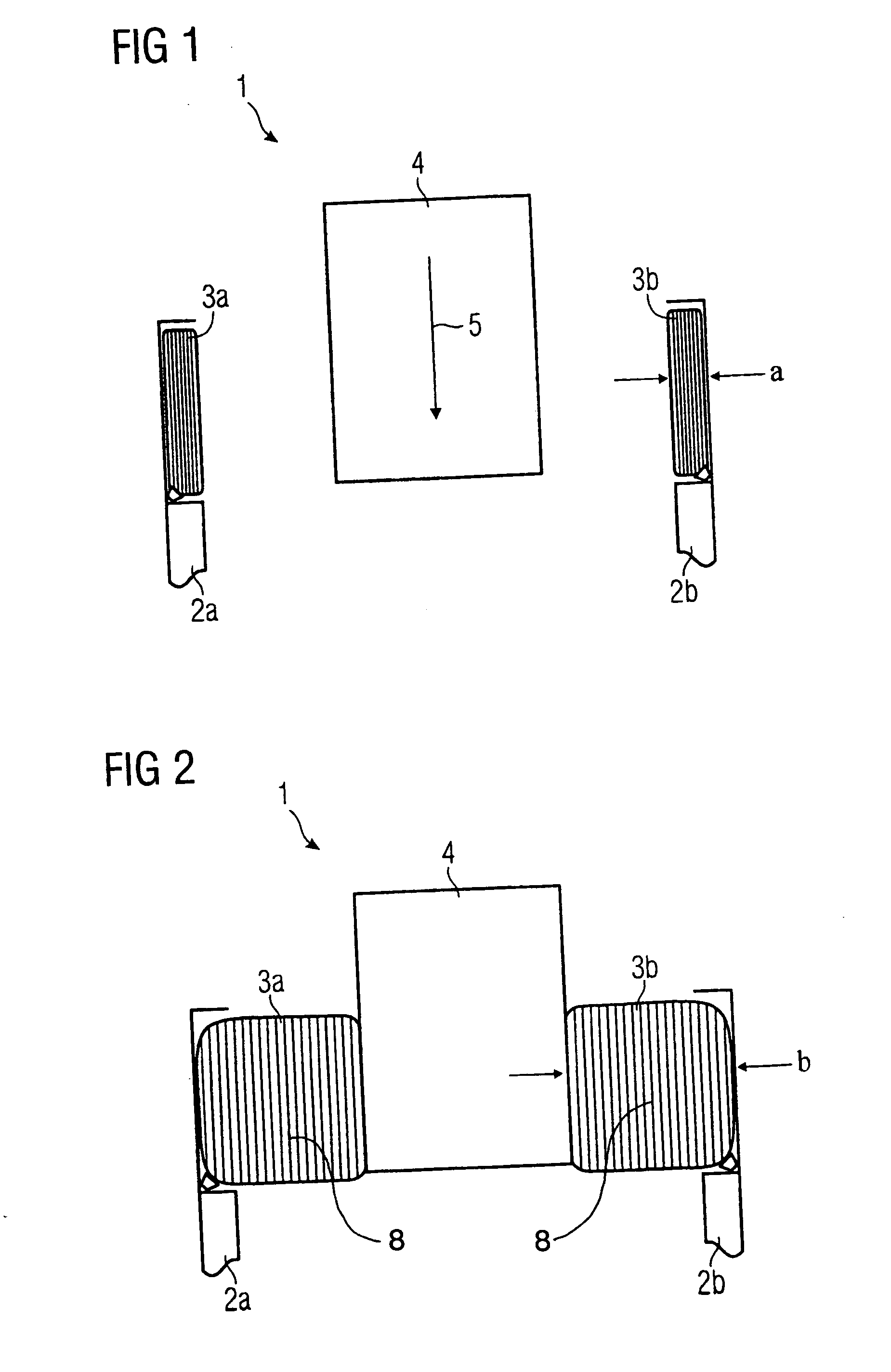

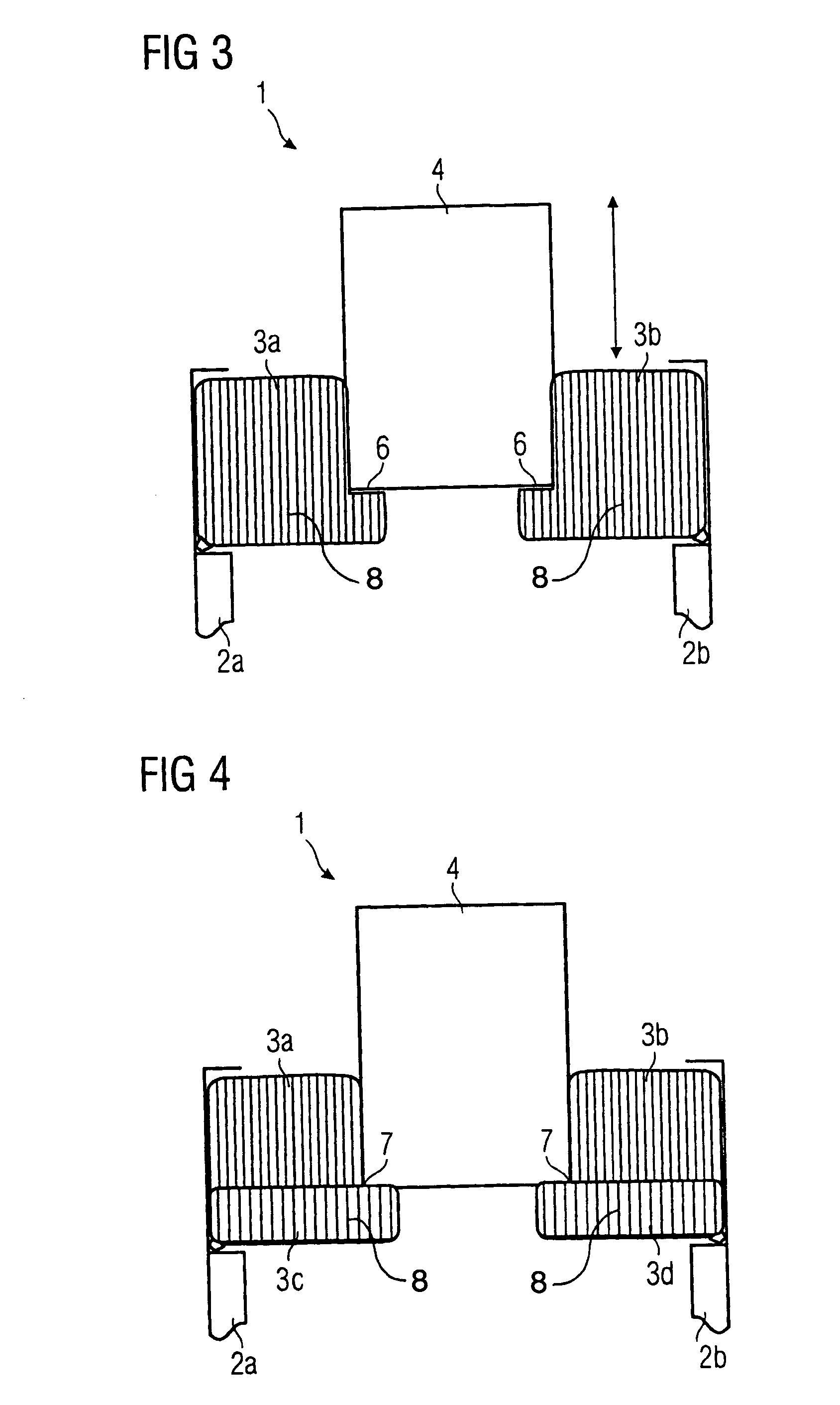

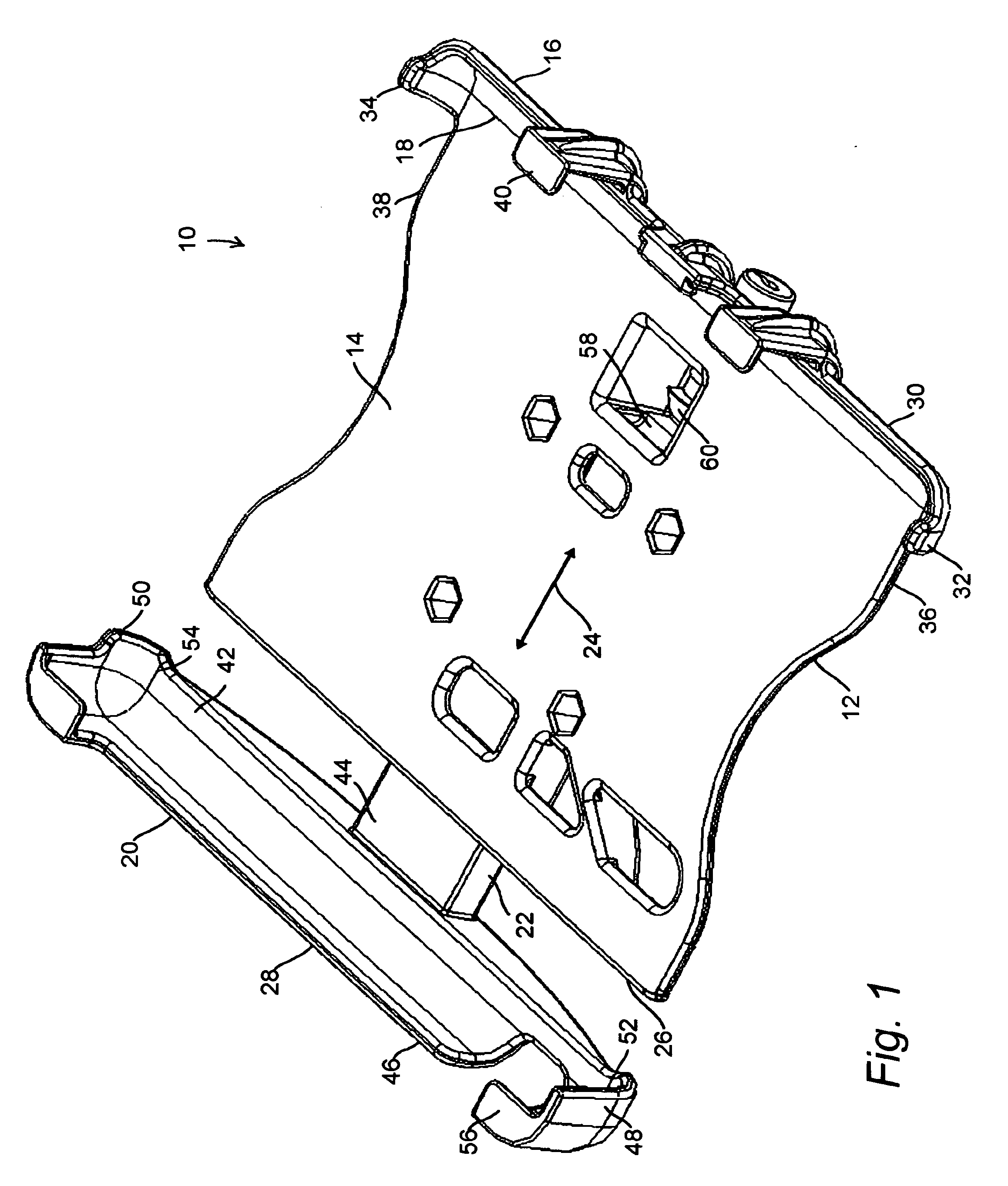

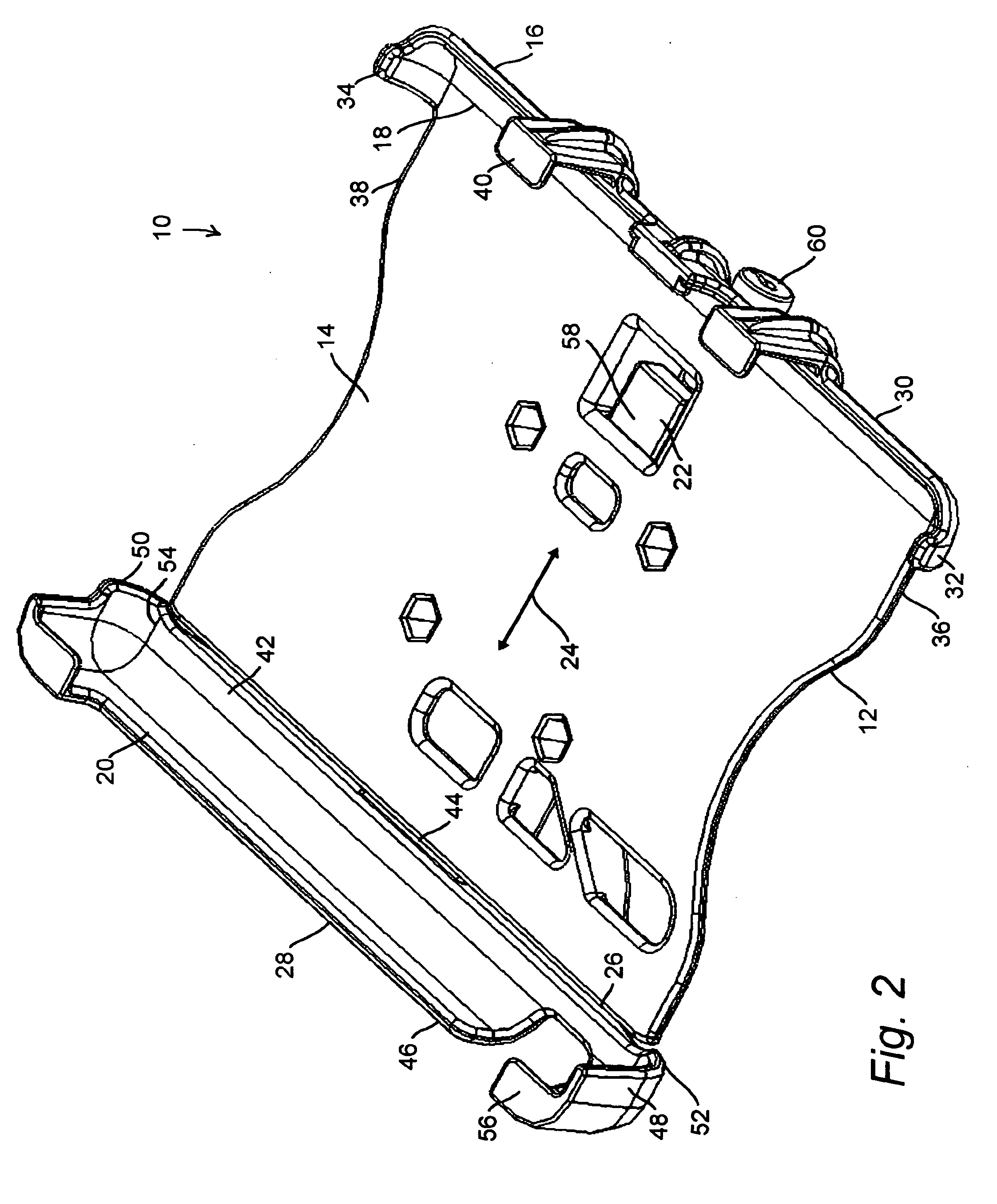

Clamping device for holding and clamping components

ActiveUS8720876B2Avoid that disruptive contoursHigh mechanical strengthMetal-working feeding devicesGripping headsMechanical engineering

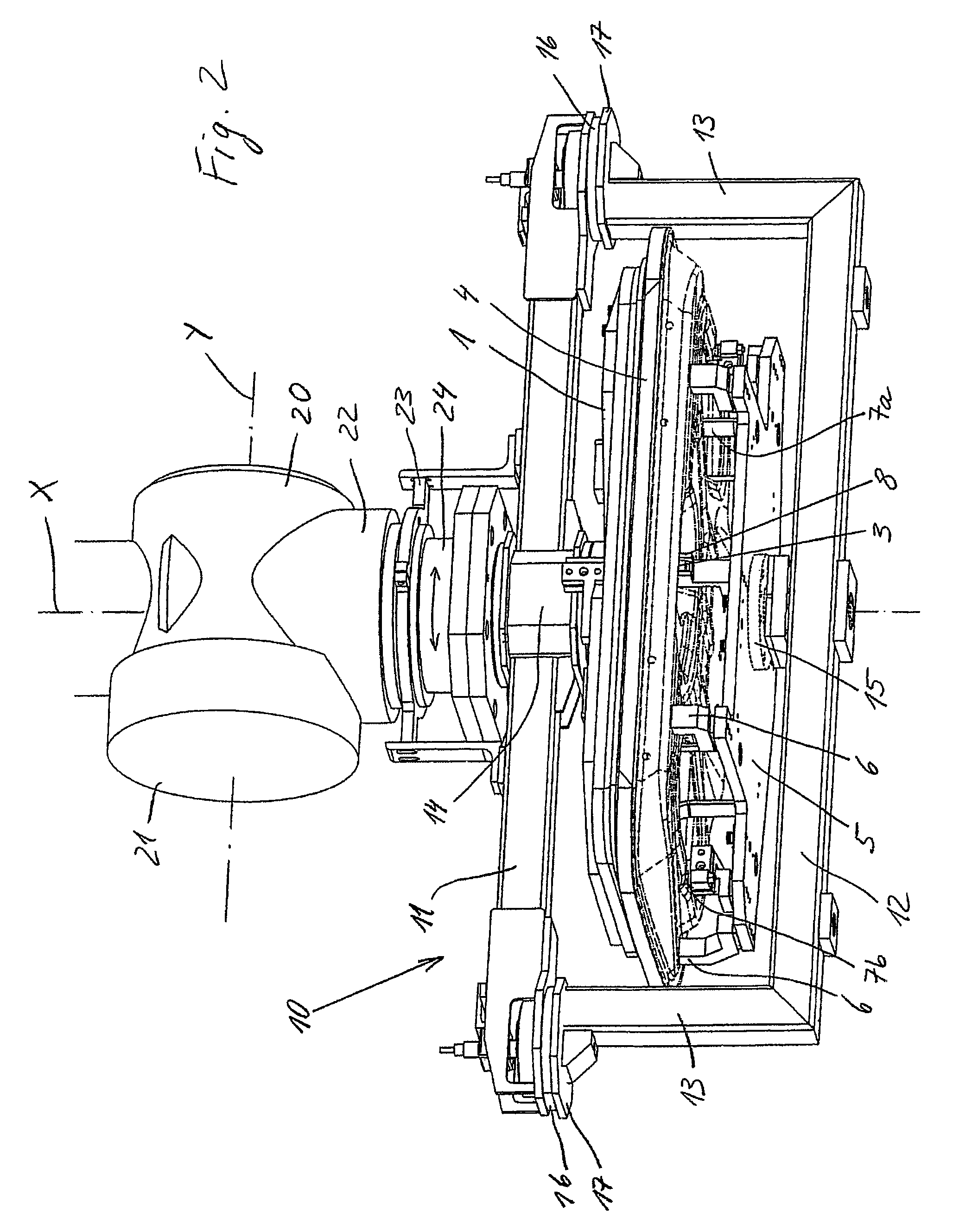

A clamping device for components to be joined, which clamping device comprises: a first component holder for a first component, a second component holder for a second component, and a clamping structure which secures the component holders relative to one another in a joining position, and when the component holders are in the joining position, the clamping structure extends from an external face of the first component holder to an external face of the second component holder facing away from the external face of the first component holder and extends respectively around a peripheral edge of the component holders.

Owner:FFT PRODIONSSYST

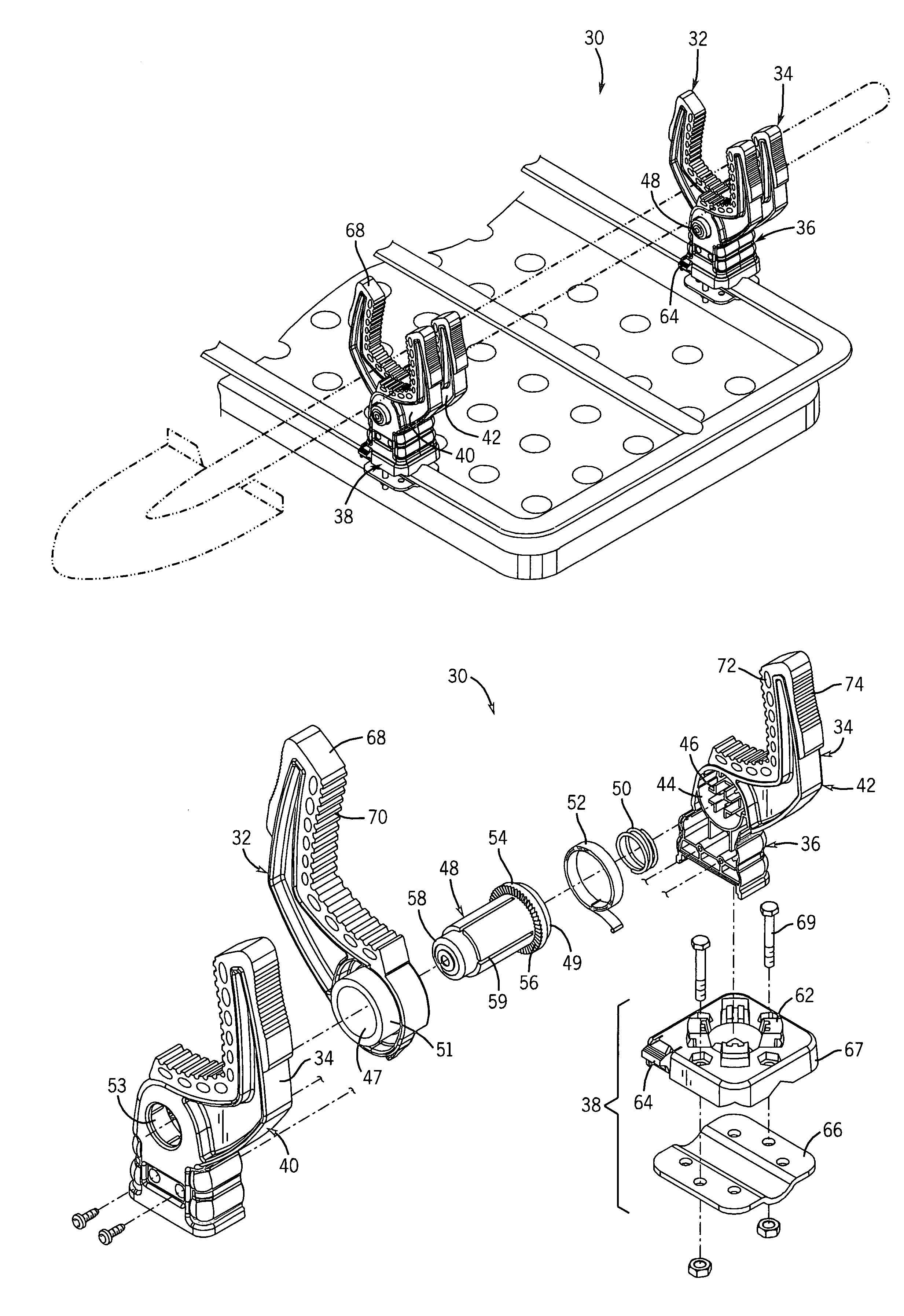

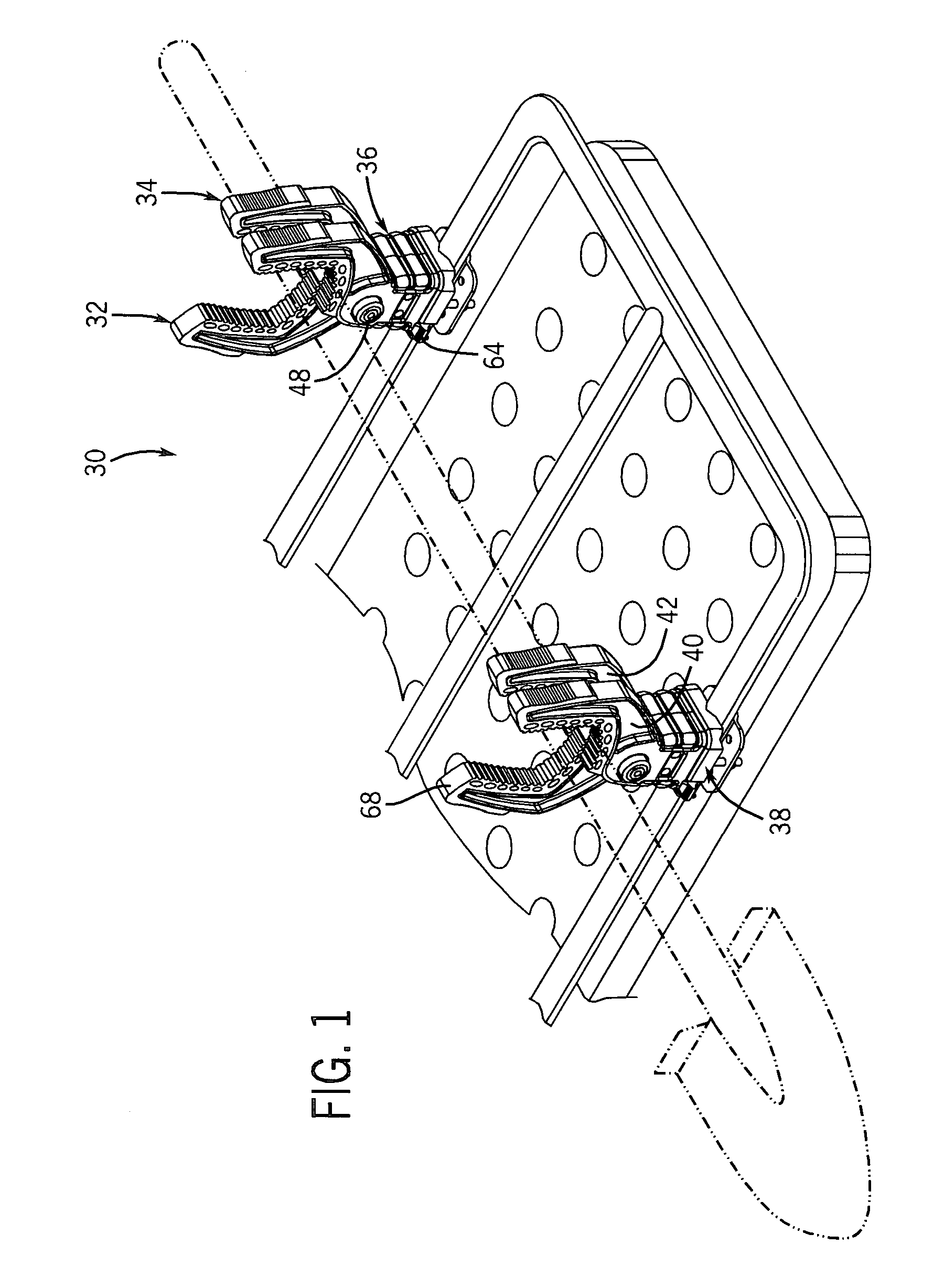

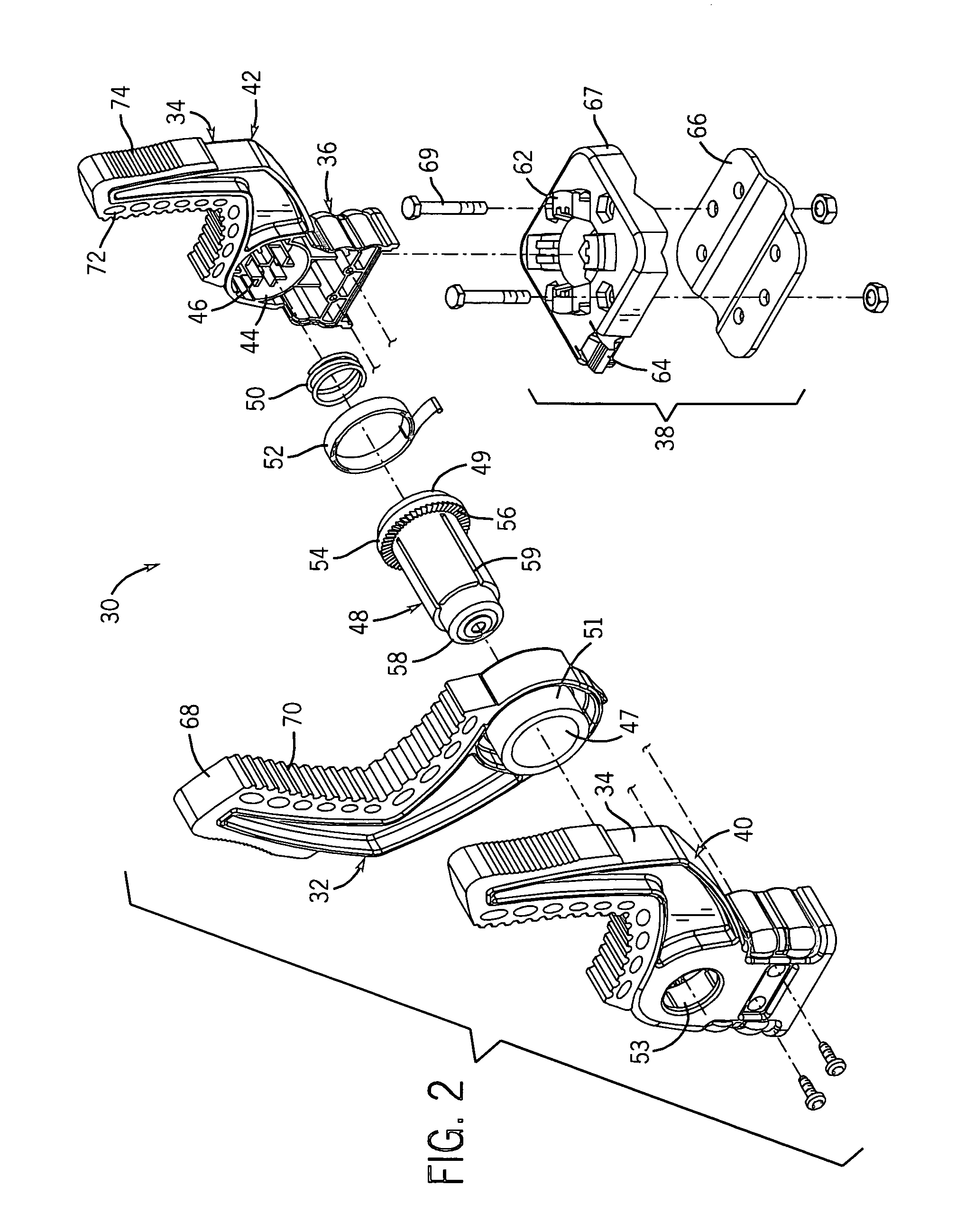

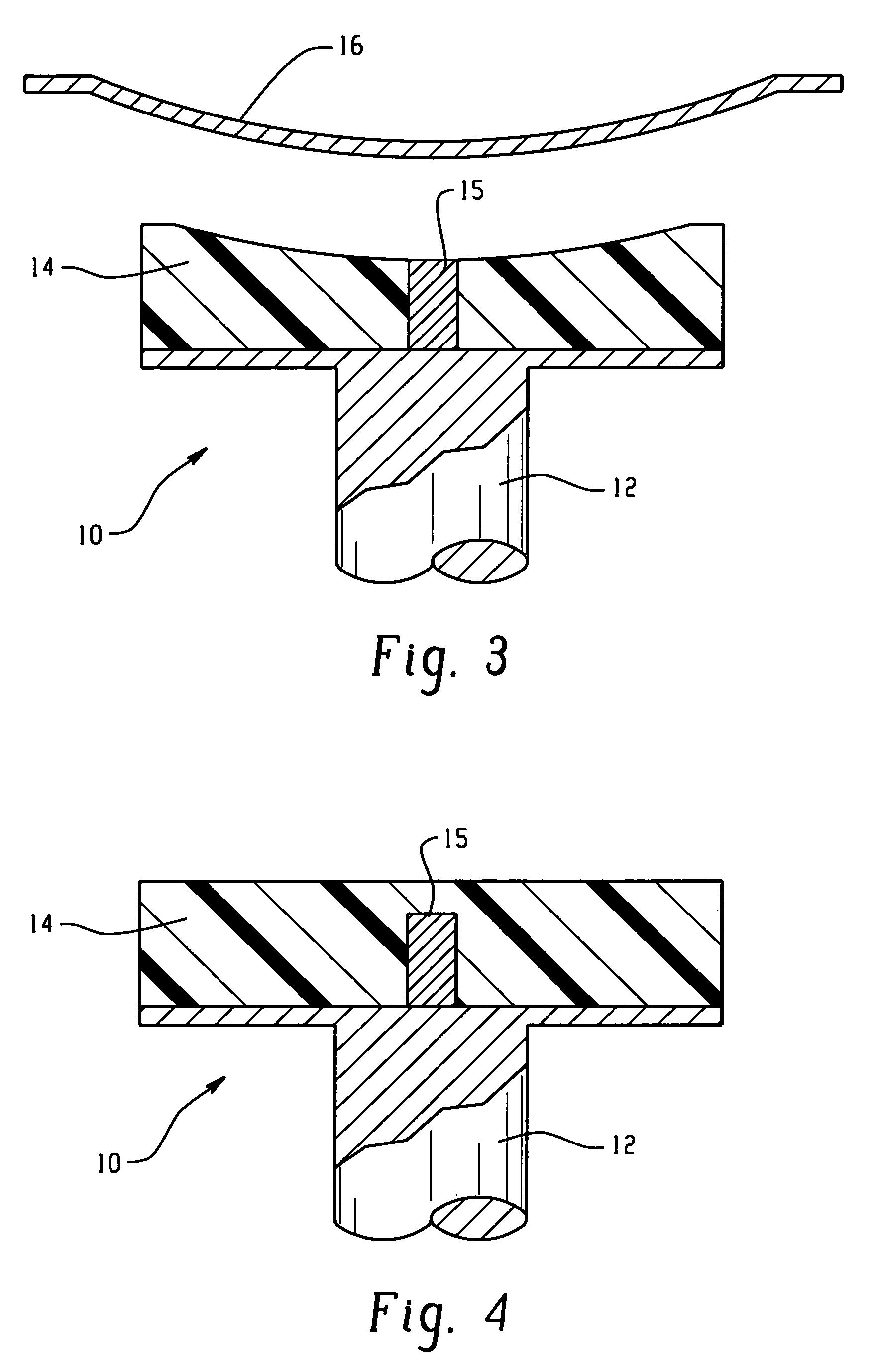

System, method and apparatus for clamping

A number of racks which are configured to allow a number of devices to couple thereto are provided. In some embodiments, the racks are for use with a number of medical devices. Devices may be coupled to a rack by clamps. The racks may include a number of connectors which provide power and / or a network connection to devices coupled thereto. The racks may include a clamp which allows the racks to couple to a supporting structure such as a pole.

Owner:DEKA PROD LLP

Clamping device with flexible arm

One embodiment of the present invention is directed to a clamping device with an attached arm in which the act of opening the clamp makes the arm flexible and the act of closing the clamp makes the arm rigid. By operating in this manner, the present invention may allow a worker to position the arm (while flexible) in any number of different and easily attainable positions while also allowing the worker to secure a workpiece and immobilize the arm in a single step. In another embodiment of the present invention the arm can be made flexible independently of opening the clamp.

Owner:LA MENDOLA CHRISTOPHER LOUIS

One-piece barrel assembly cart

A one-piece barrel assembly cart includes a right assembly cart base connected with a left assembly cart base and at least three stabilizer rings that are attached to the assembly cart base. The one-piece barrel assembly cart may be used to stabilize a tapered cured composite barrel, for example the large fuselage barrel of the aft section of a large new generation aircraft, such as a 7E7 Boeing airplane. A modular assembly cart includes at least two identical modules. Each of these modules includes a cart base and a stabilizer ring. The diameter of the inner surface of the stabilizer ring may vary as needed. Other modules including a fuselage support may be added. By providing modular assembly carts any shape and size of a one-piece composite barrel may be stabilized after curing of the composite material.

Owner:THE BOEING CO

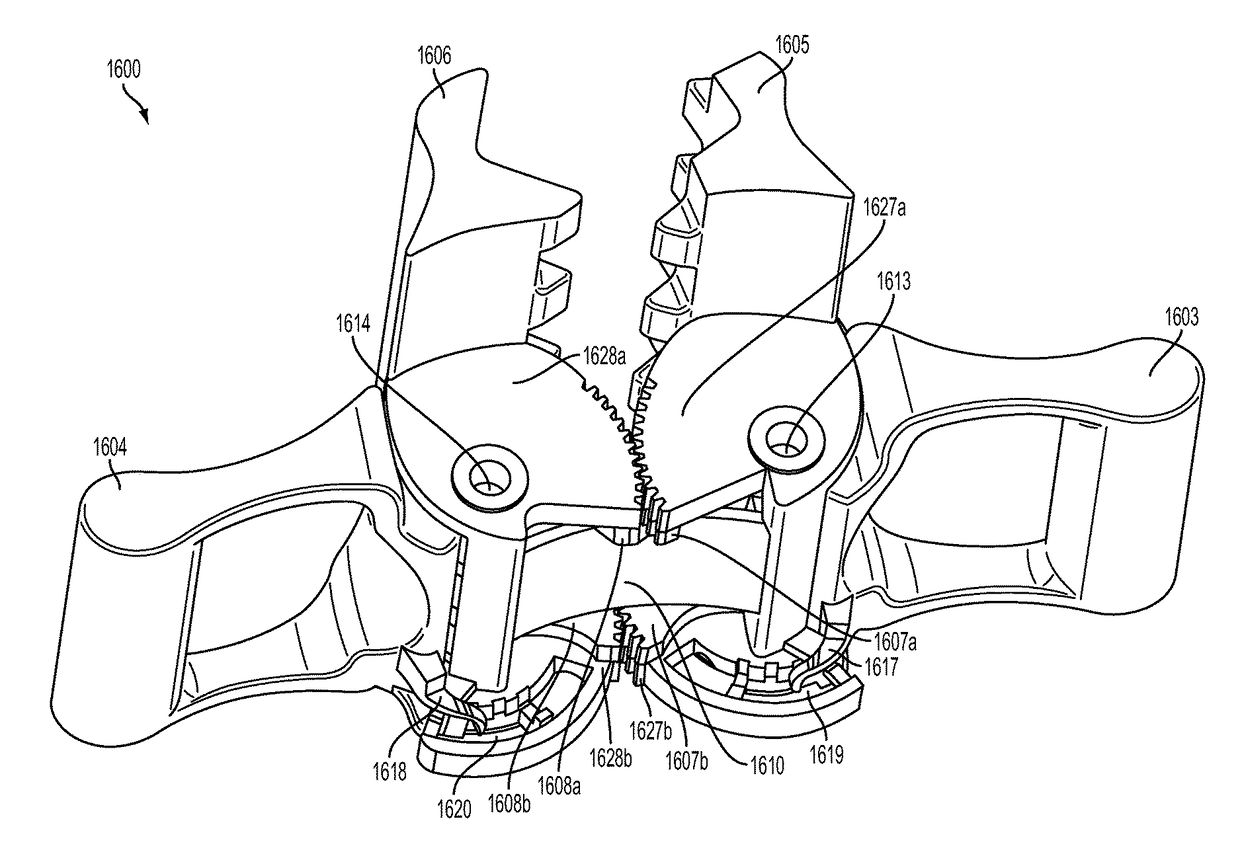

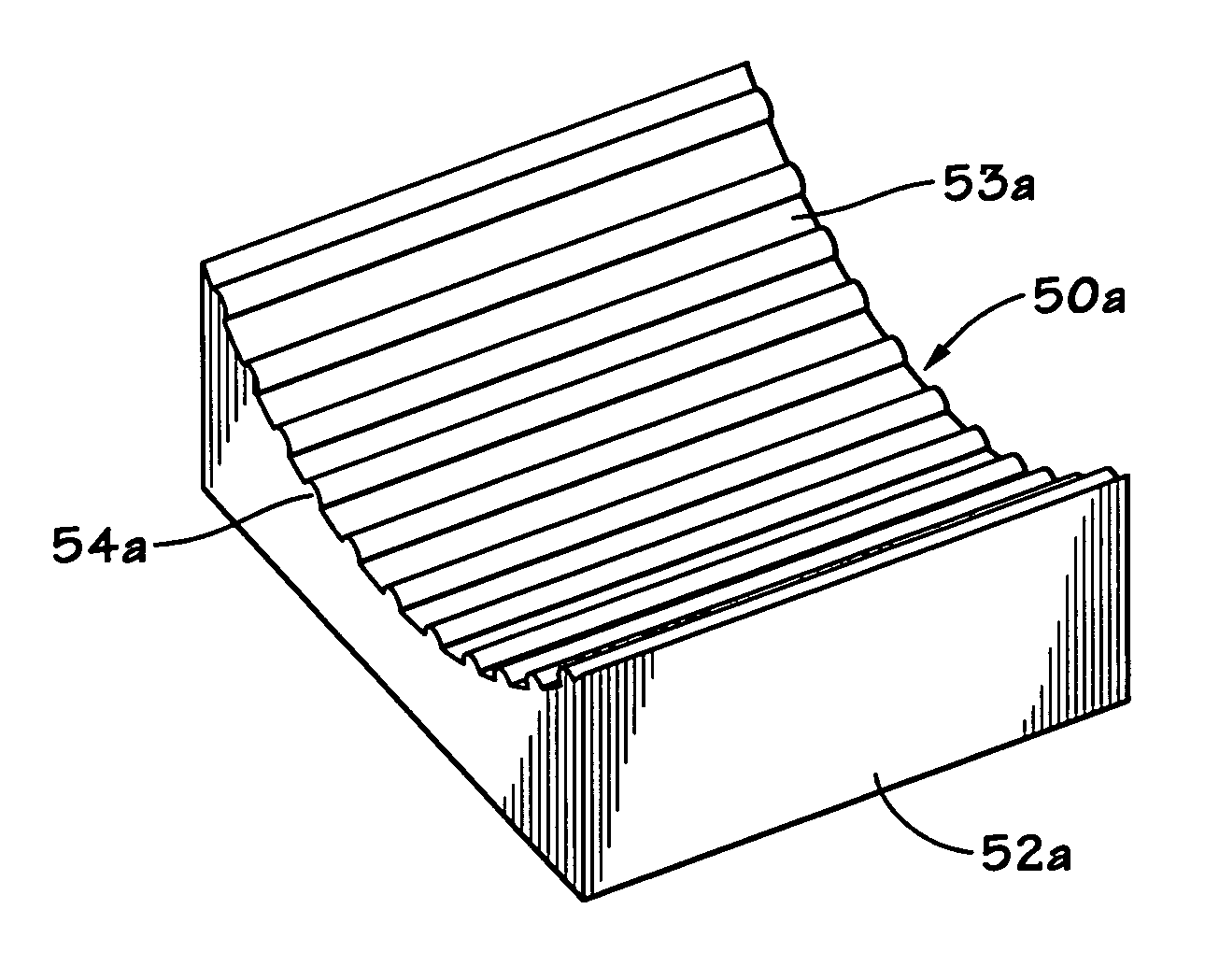

Curvature conformable gripping dies

A gripper is disclosed for gripping a tubular, e.g. to facilitate rotation of the tubular, the gripper including a body, the body having conformable material having an initial body shape, and the conformable material able to change the initial body shape upon contacting a tubular with the body, the tubular having a tubular shape, the conformable material able to conform to the tubular shape of the tubular to facilitate gripping of the tubular with the gripper. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

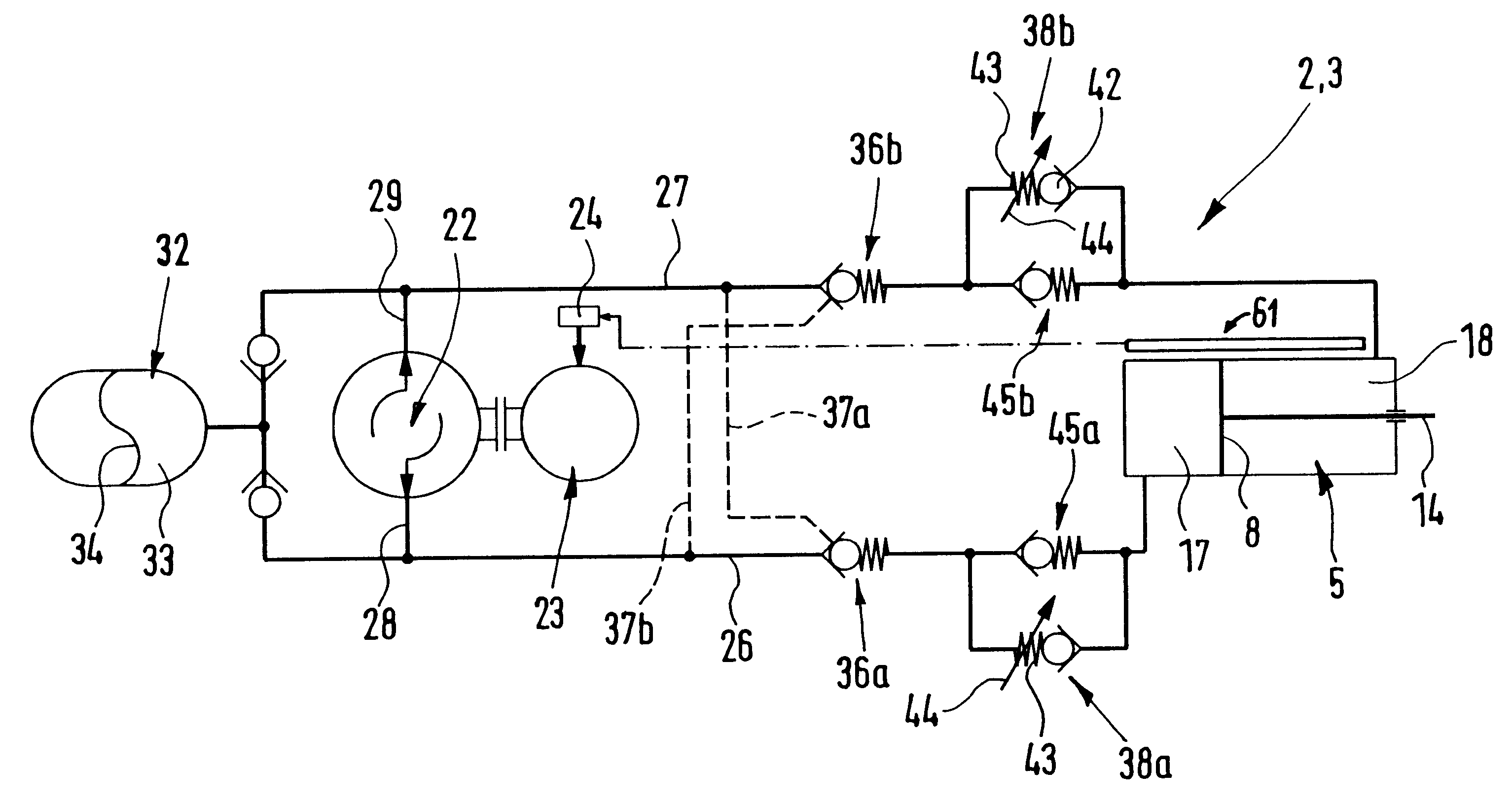

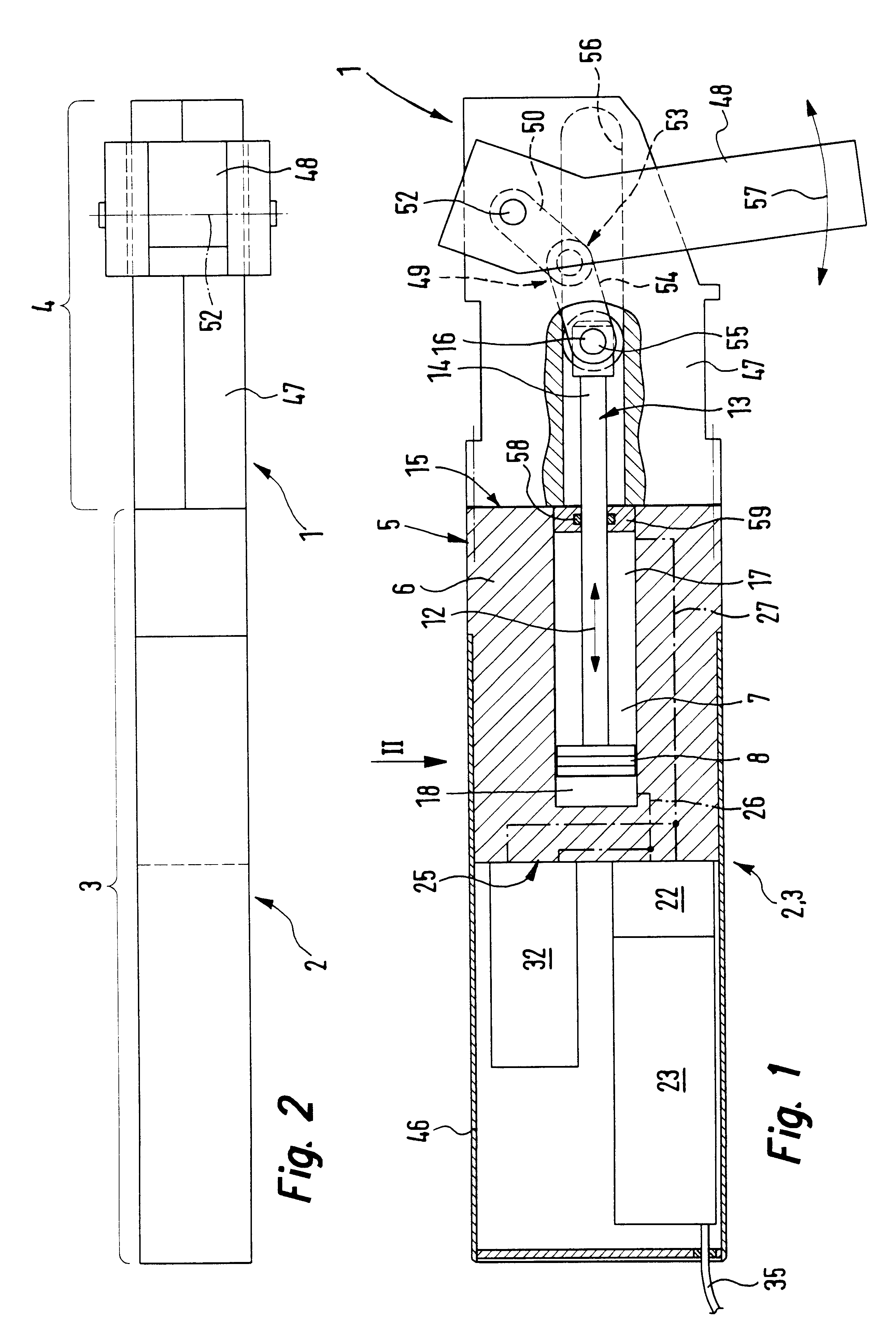

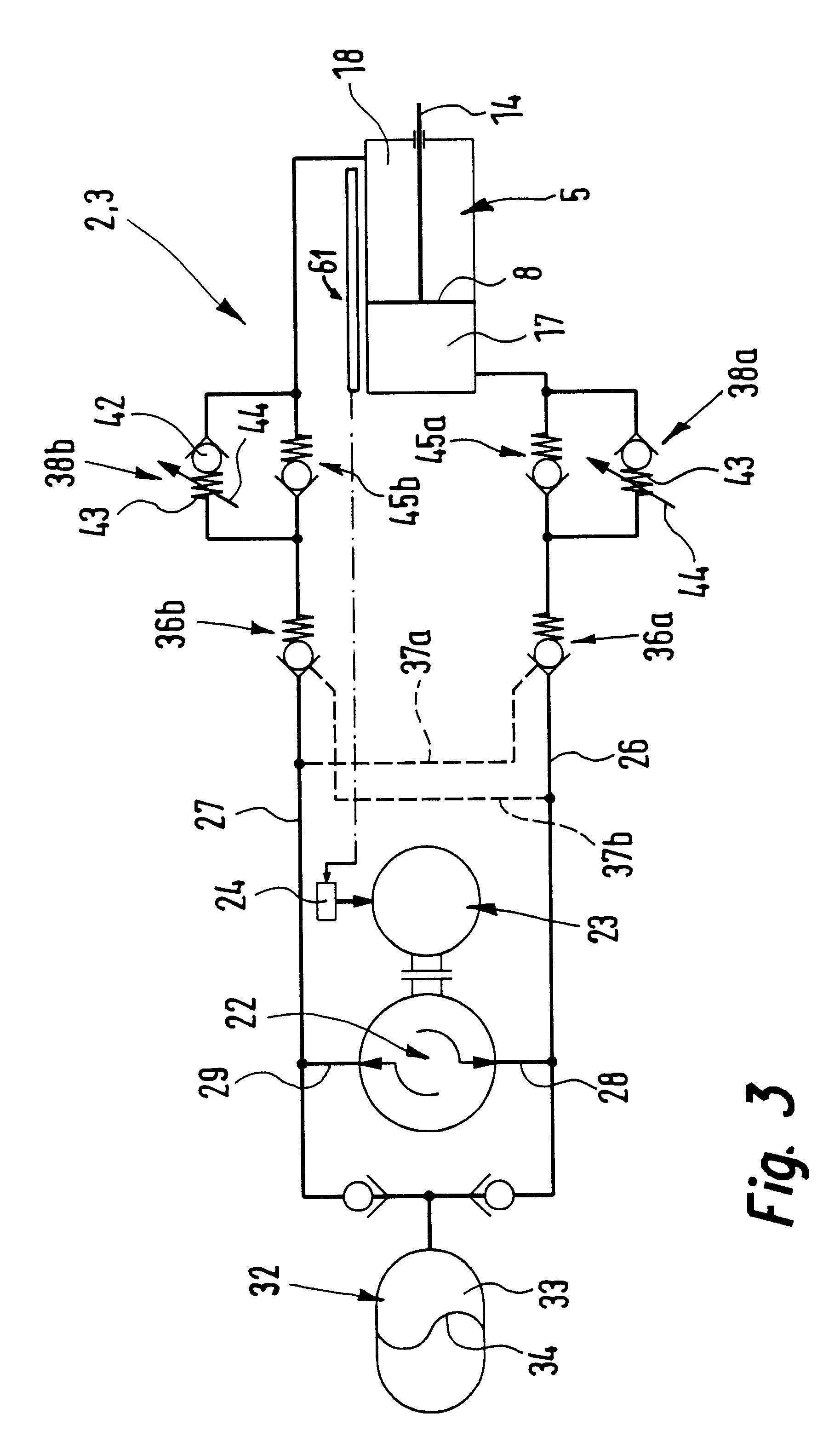

Drive device

InactiveUS6543223B2Easy to driveReduce needFluid couplingsServomotor componentsHydraulic pumpHydraulic circuit

A drive device comprising a closed hydraulic circuit which has a hydraulic drive adapted to be actuated by hydraulic medium and has a hydraulic pump responsible for the supply and removal of the hydraulic medium to and from the hydraulic drive. For the operation of the hydraulic pump an electric motor is provided. The activation of the hydraulic drive is controlled by the operational state of the hydraulic pump.

Owner:FESTO AG & CO KG

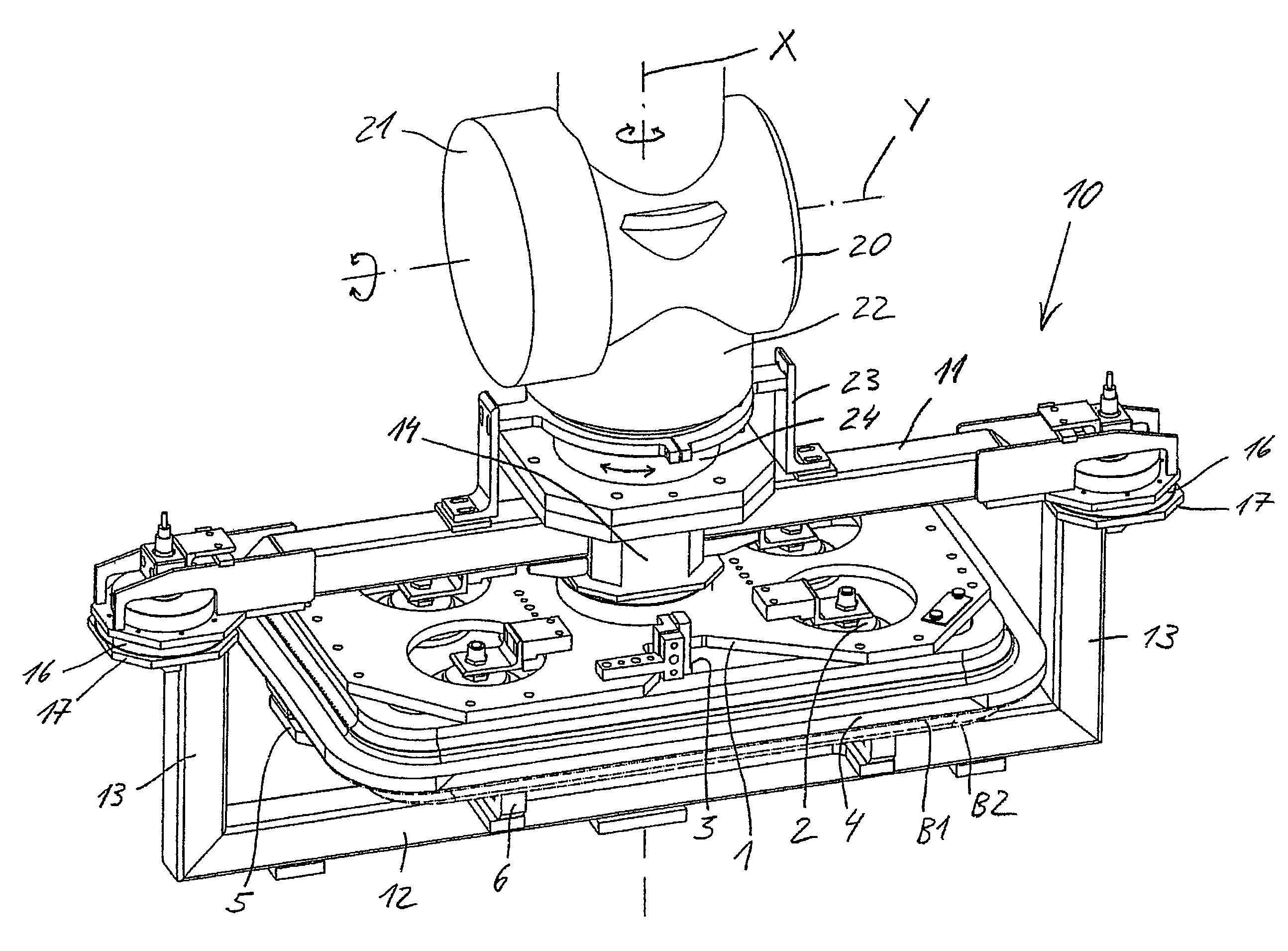

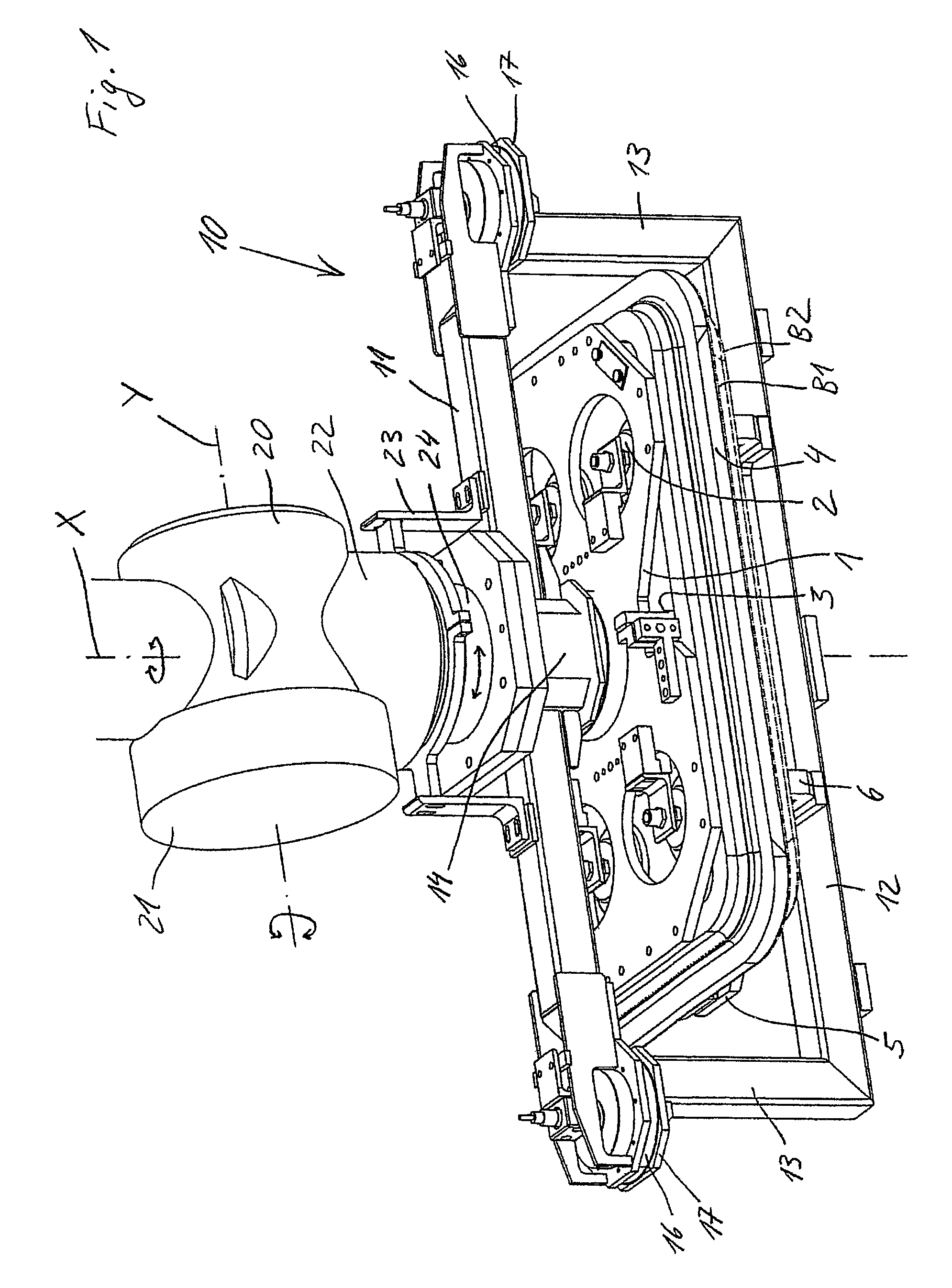

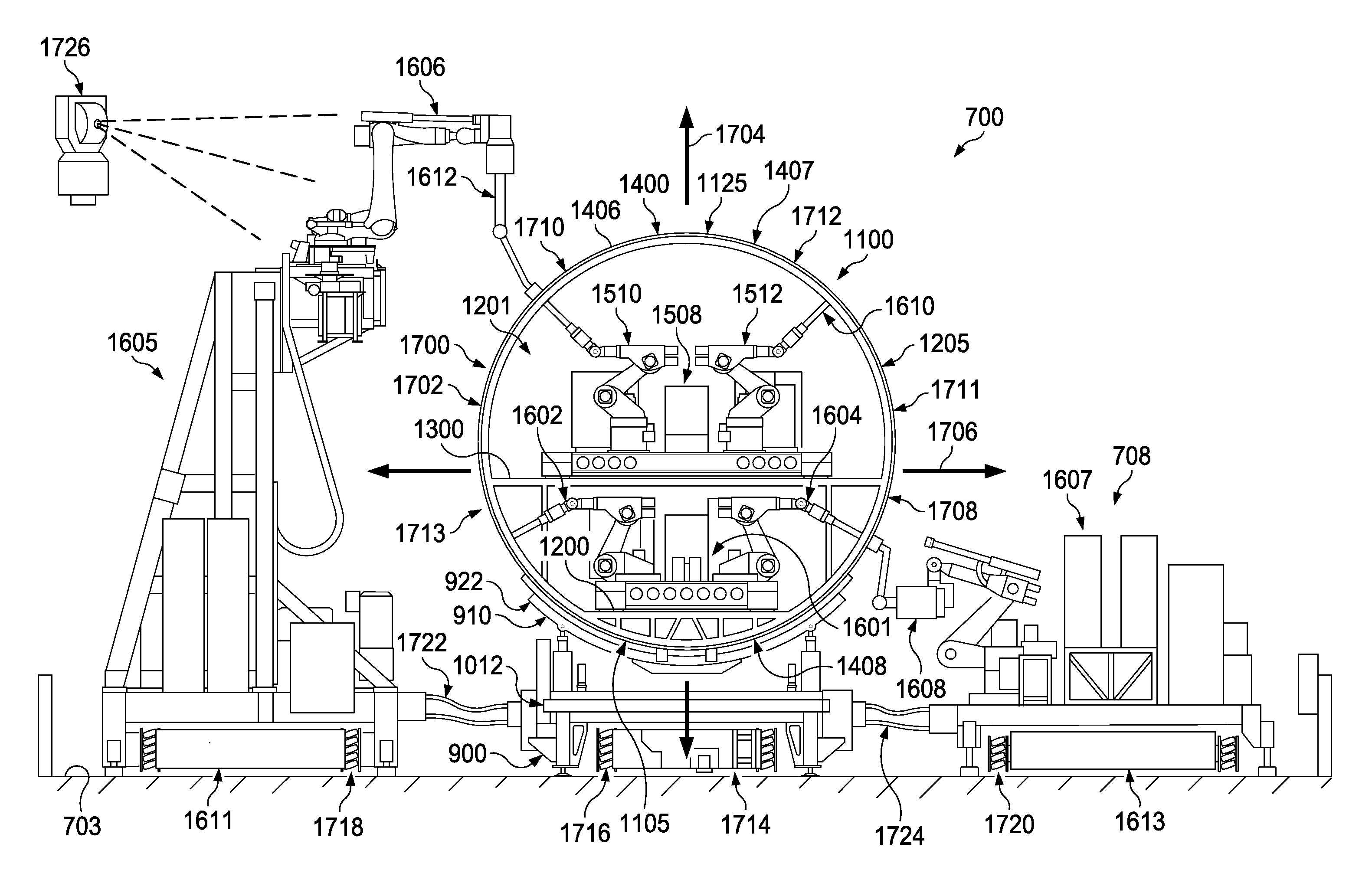

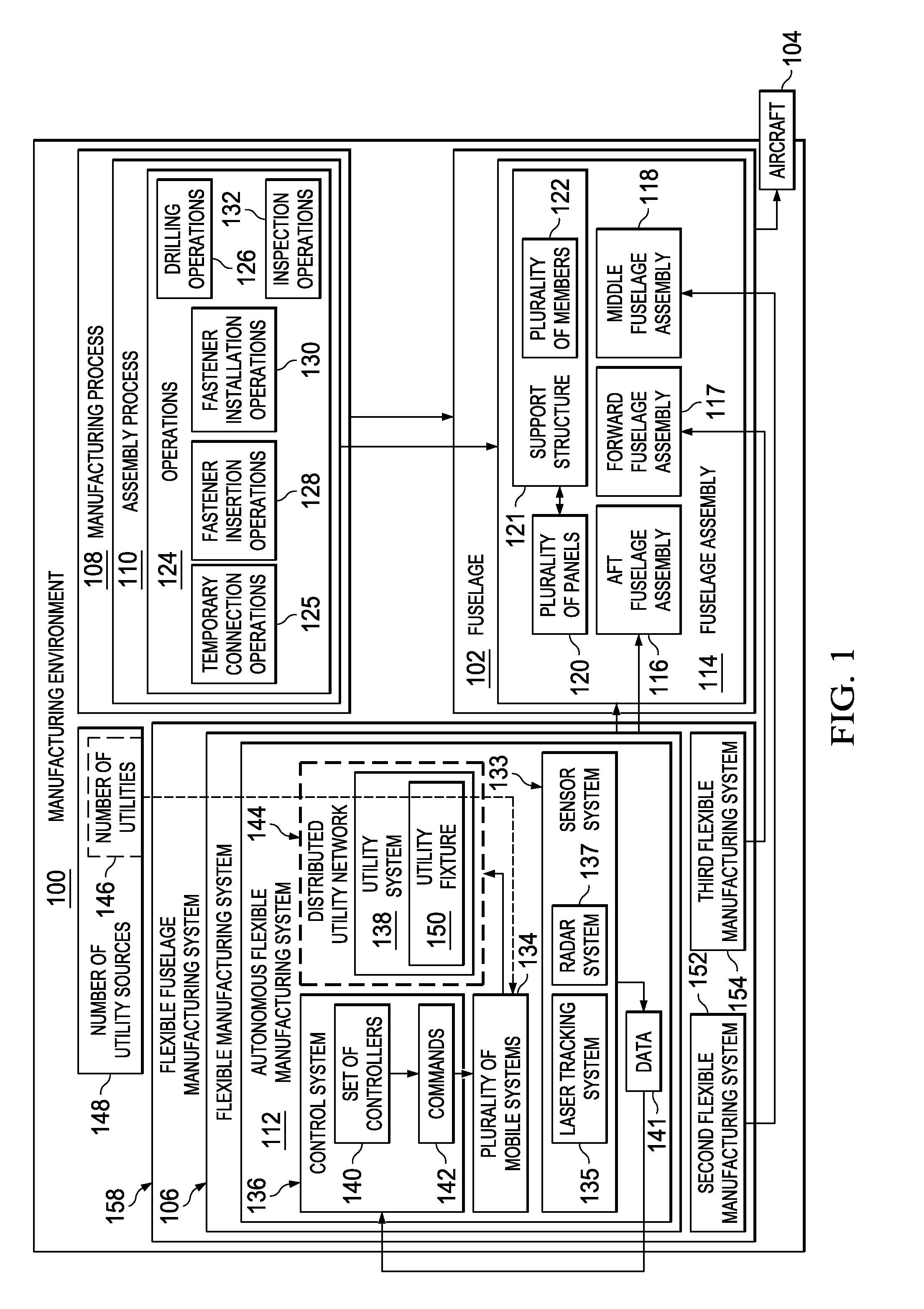

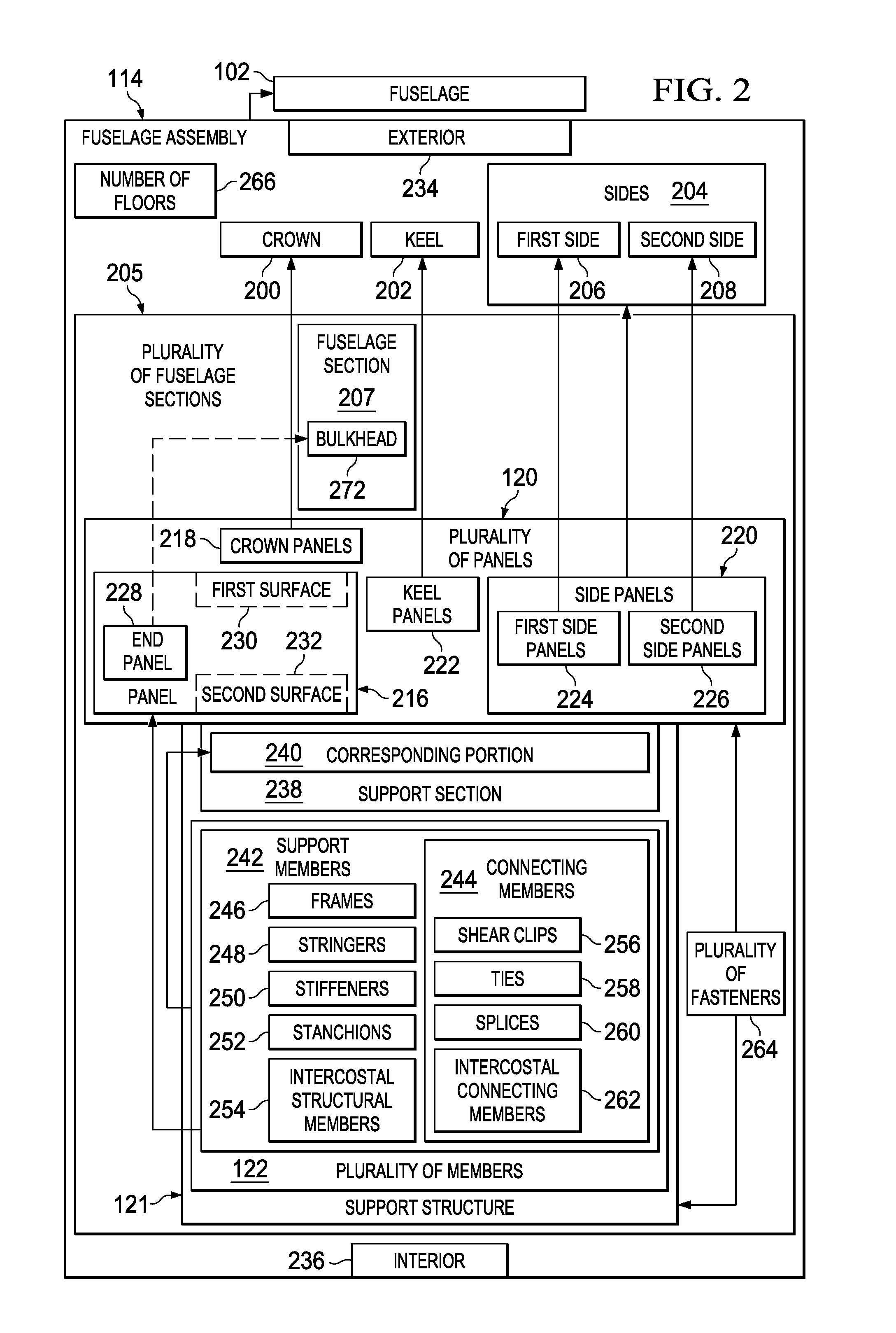

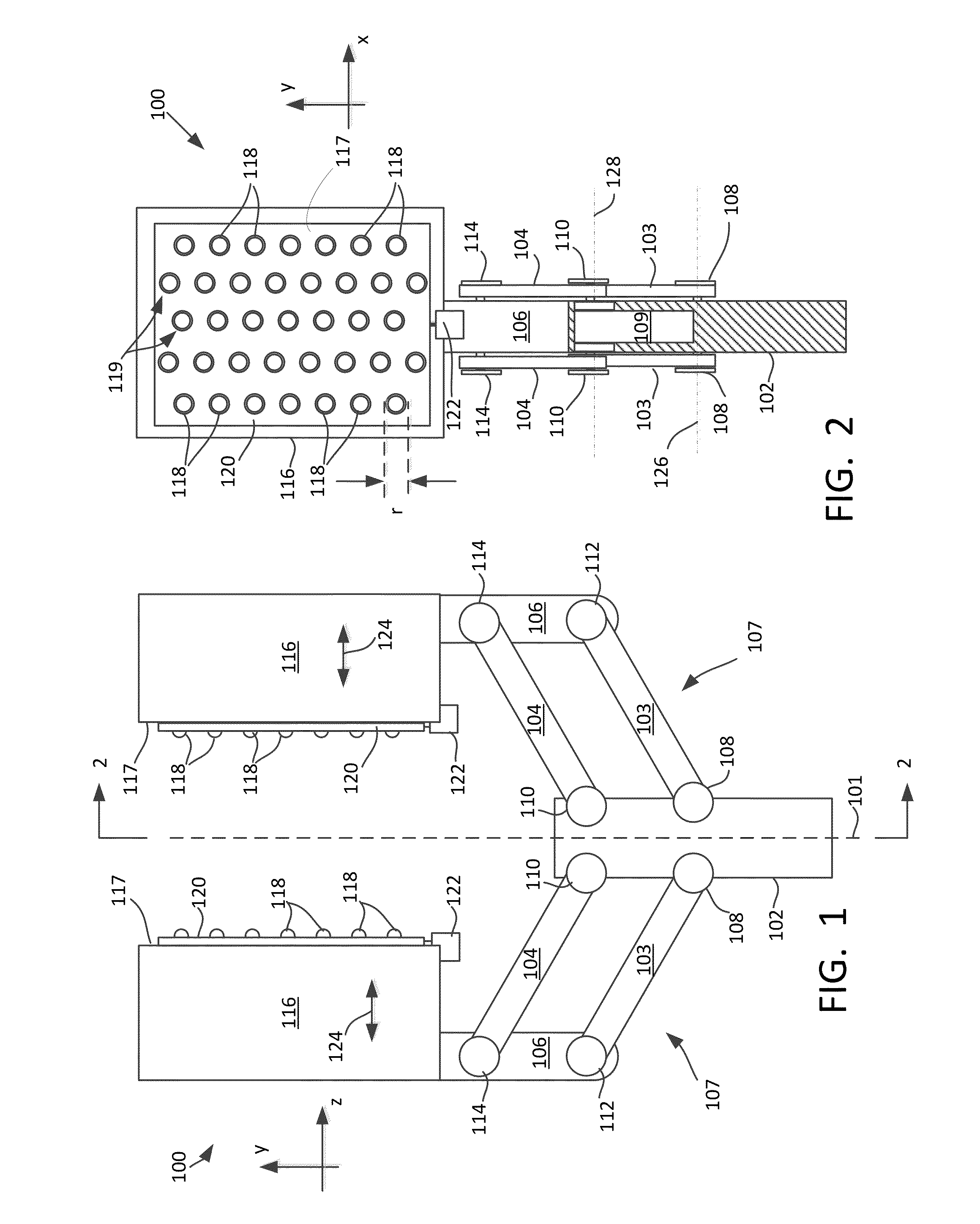

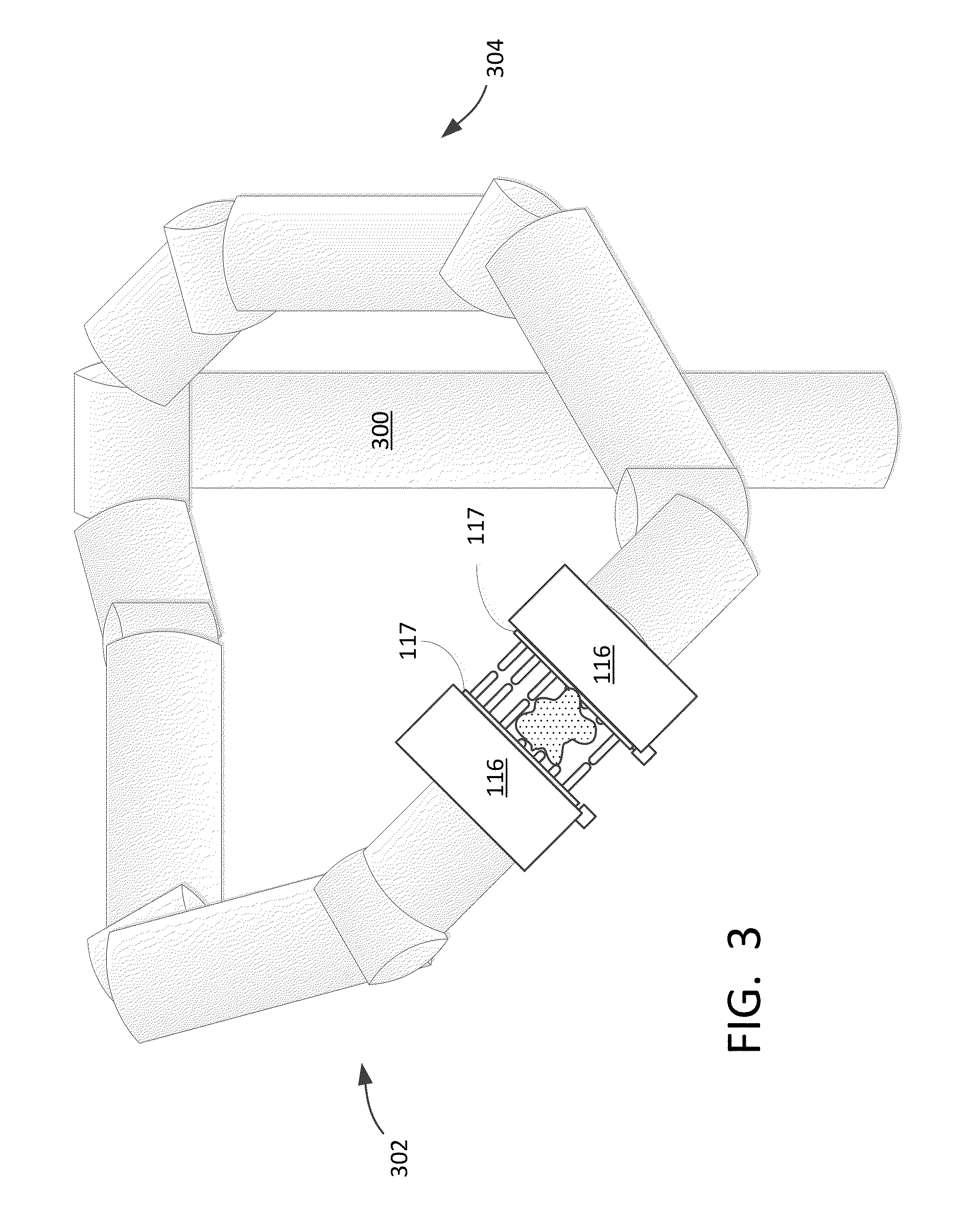

Mobile Platforms for Performing Operations Along an Exterior of a Fuselage Assembly

A method and apparatus for performing an assembly operation. A tool may be macro-positioned relative to an exterior of a fuselage assembly. The tool may be micro-positioned relative to a particular location on the exterior of the fuselage assembly. An assembly operation may be performed at the particular location on the panel using the tool.

Owner:THE BOEING CO

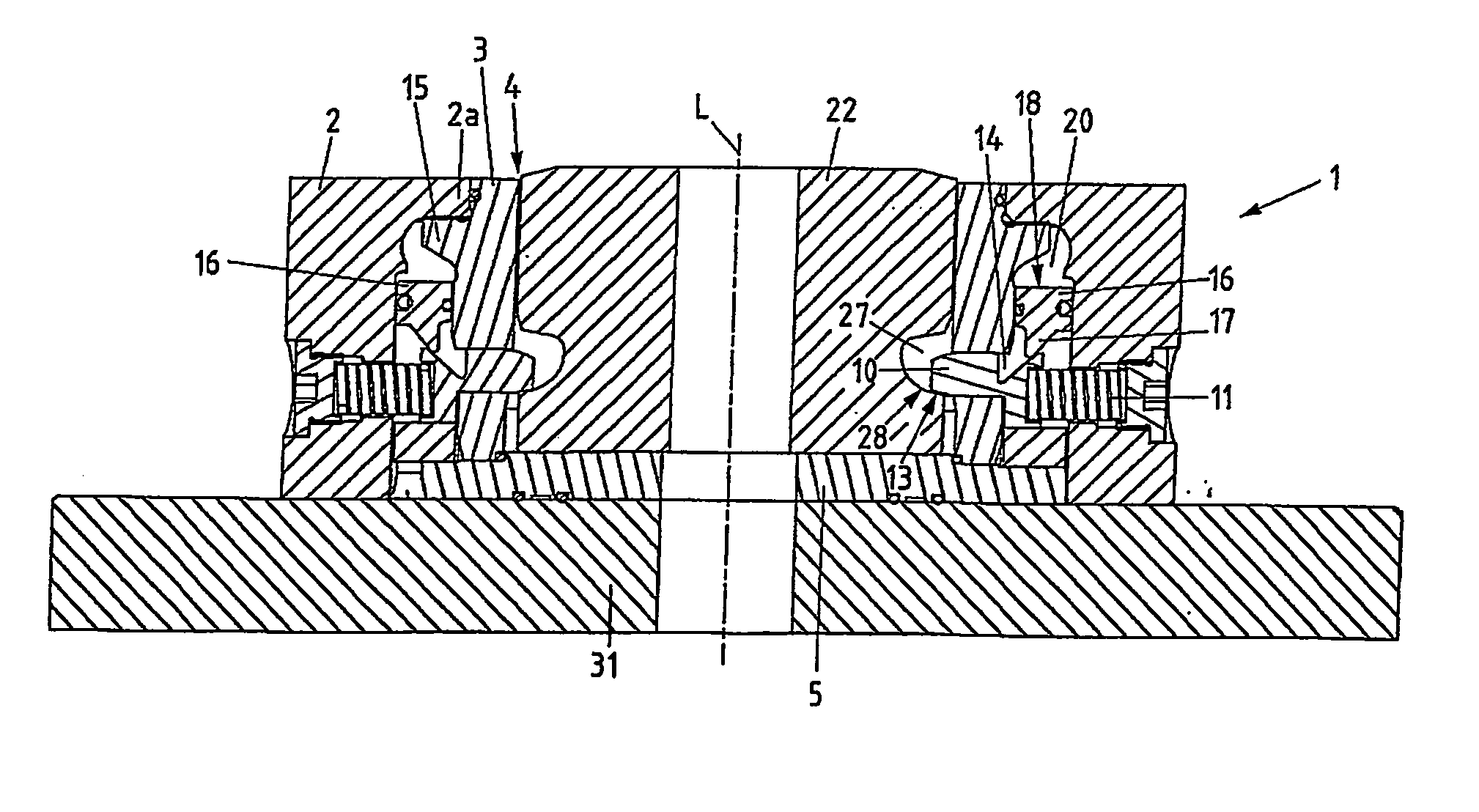

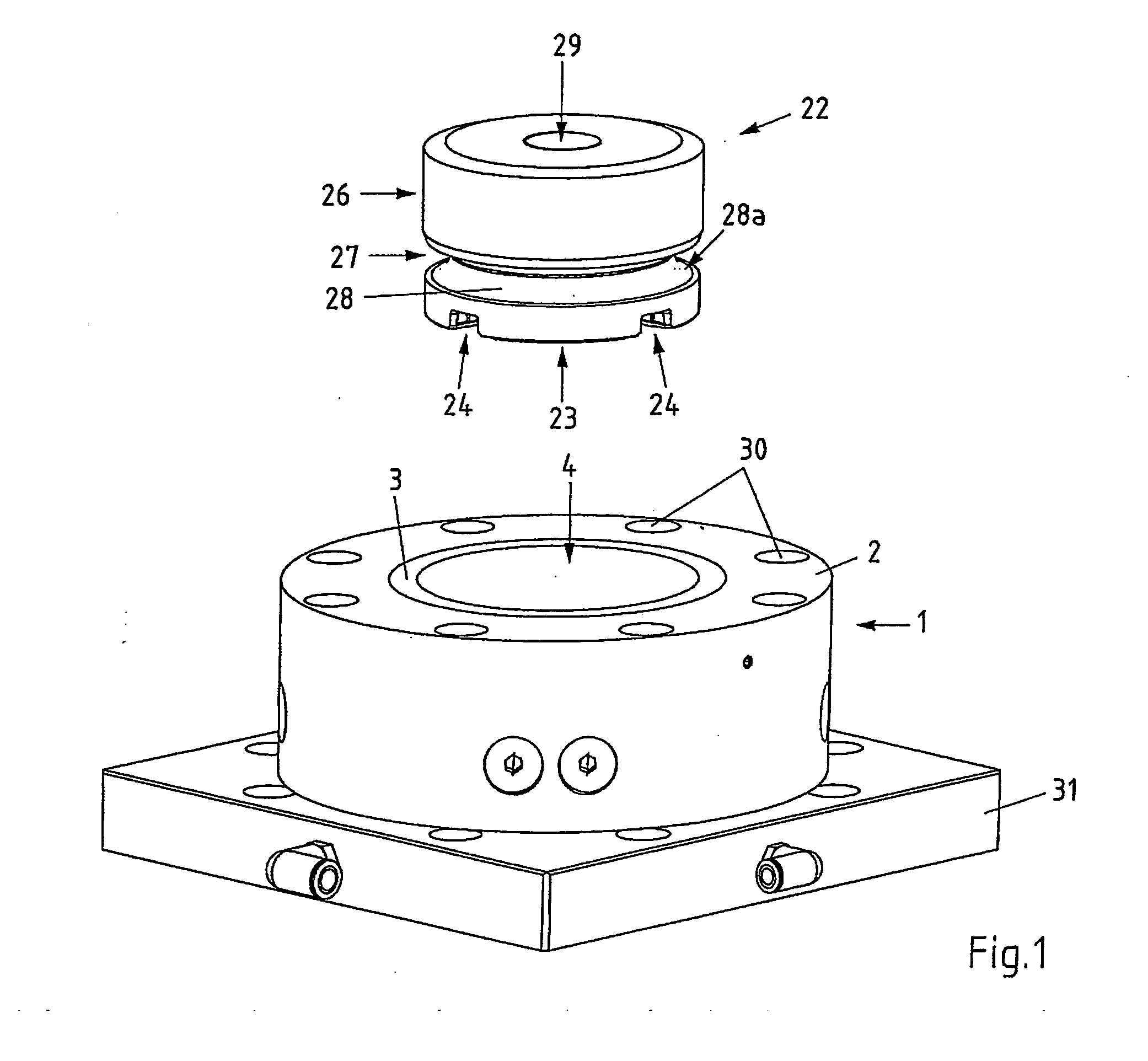

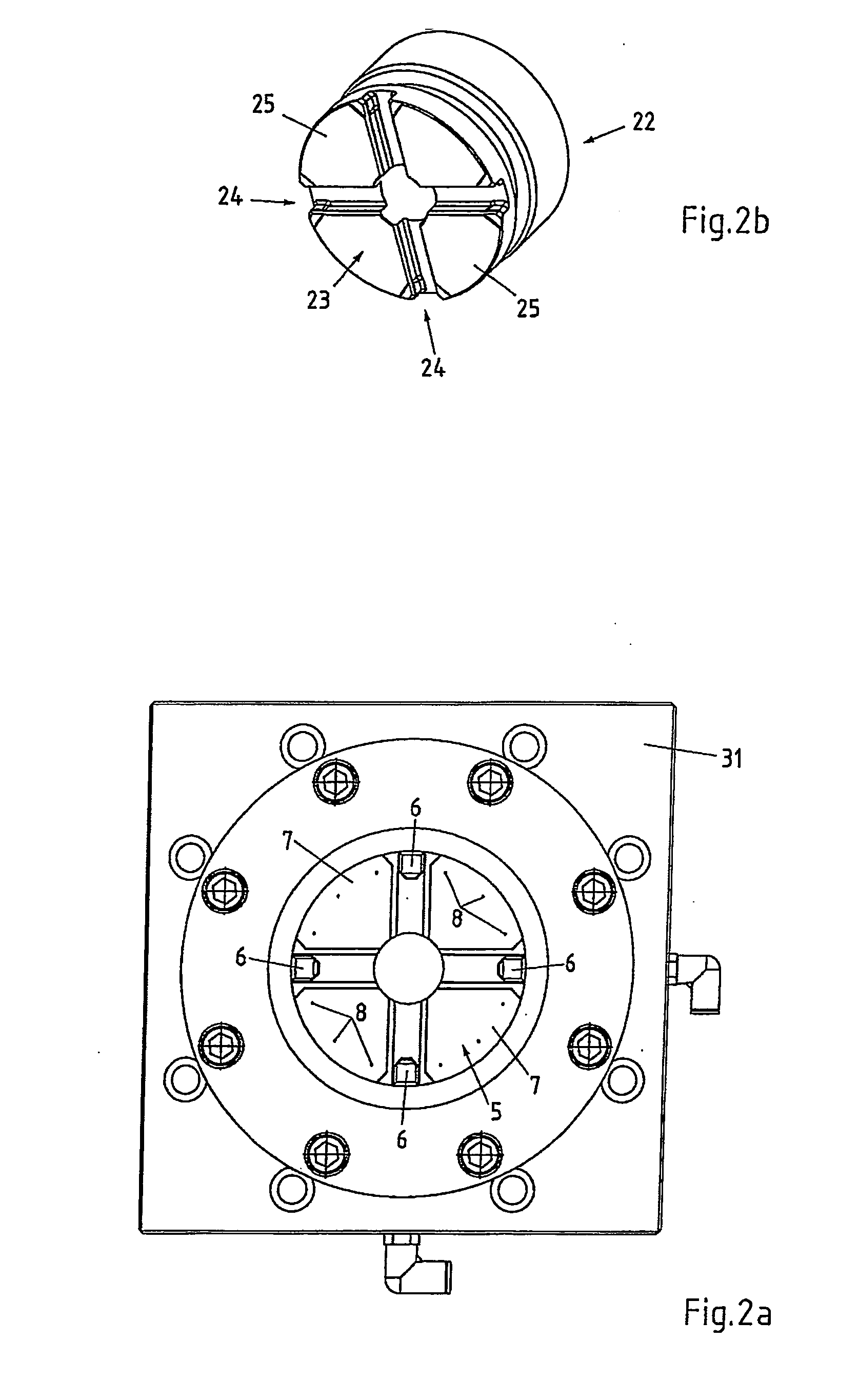

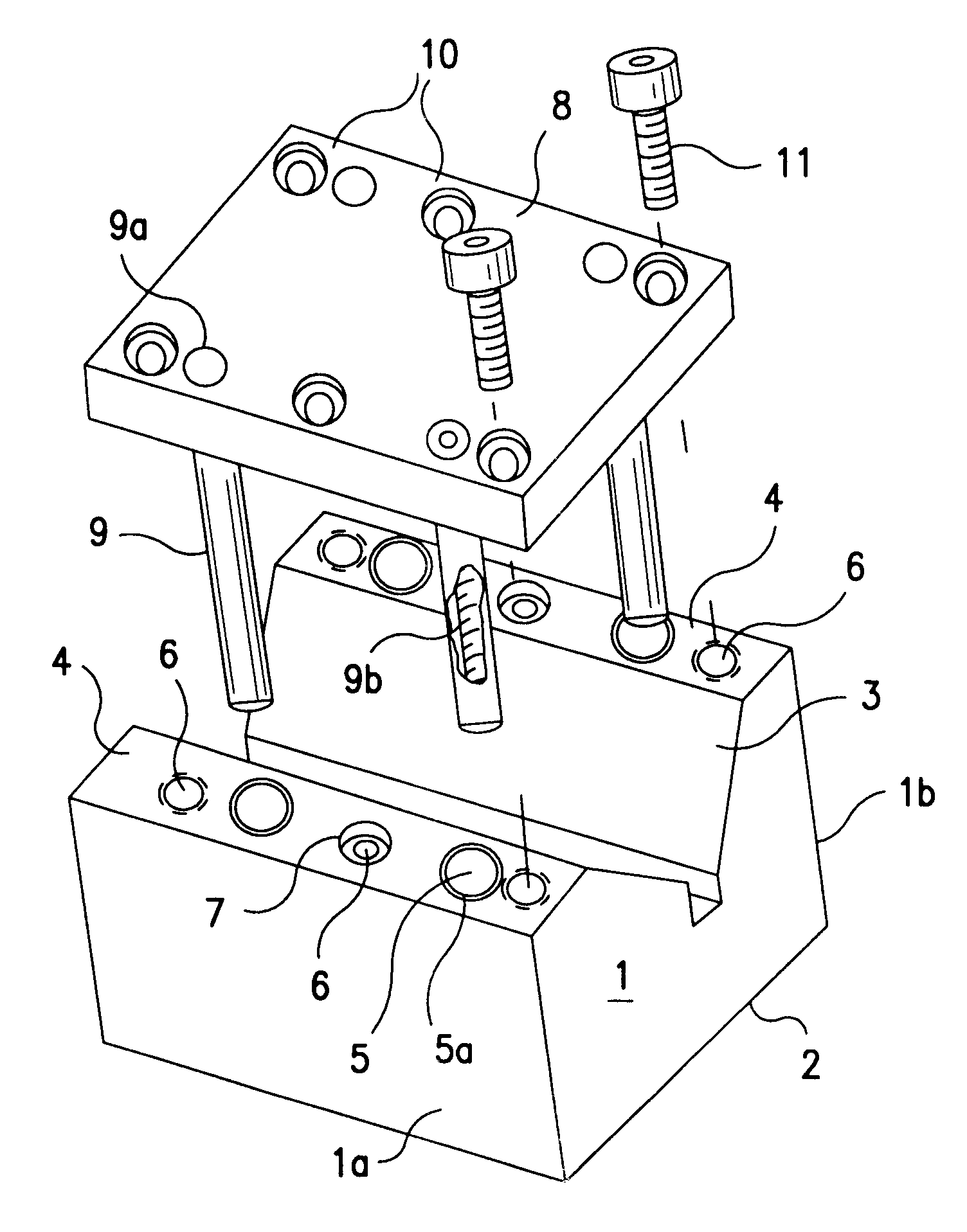

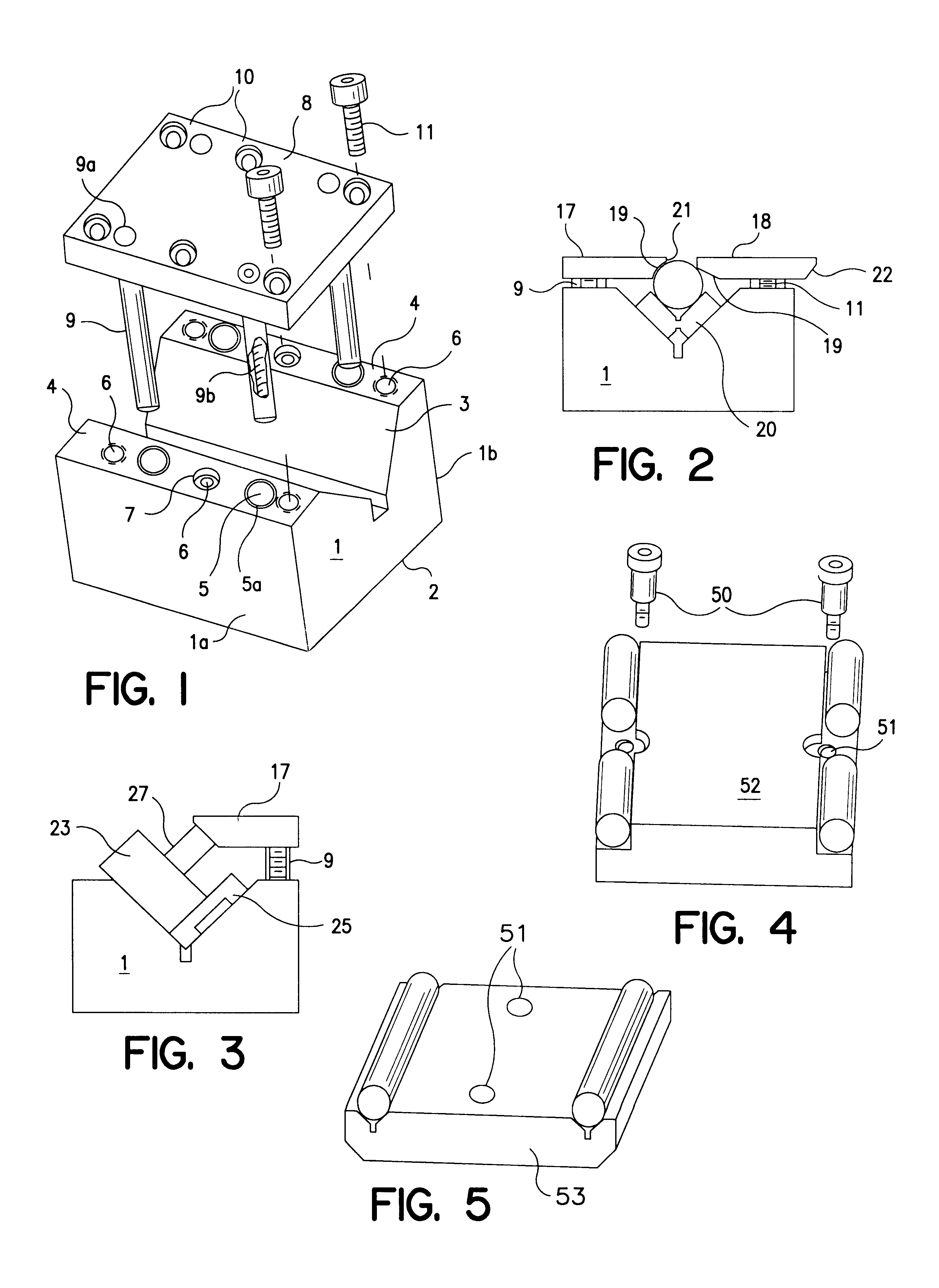

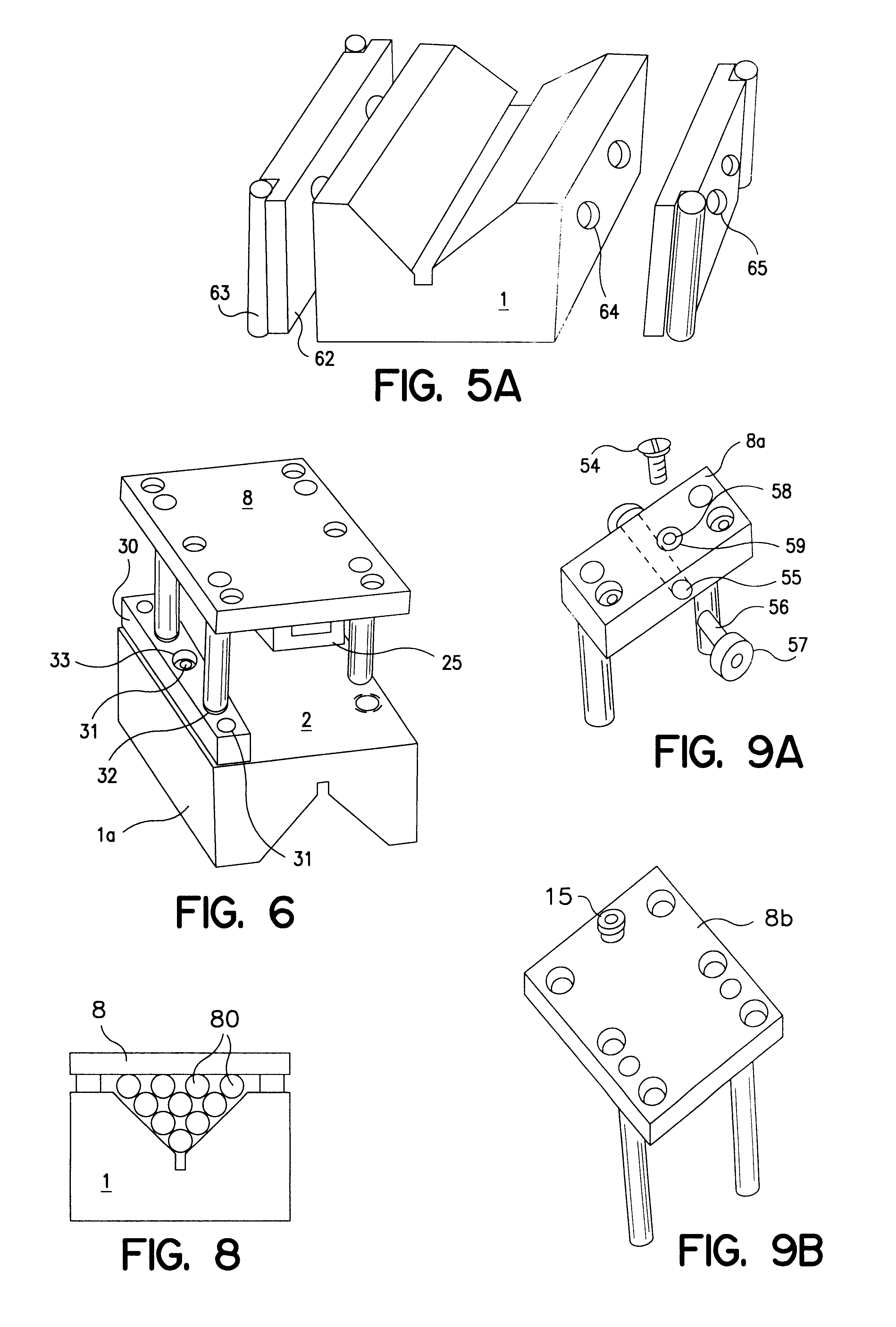

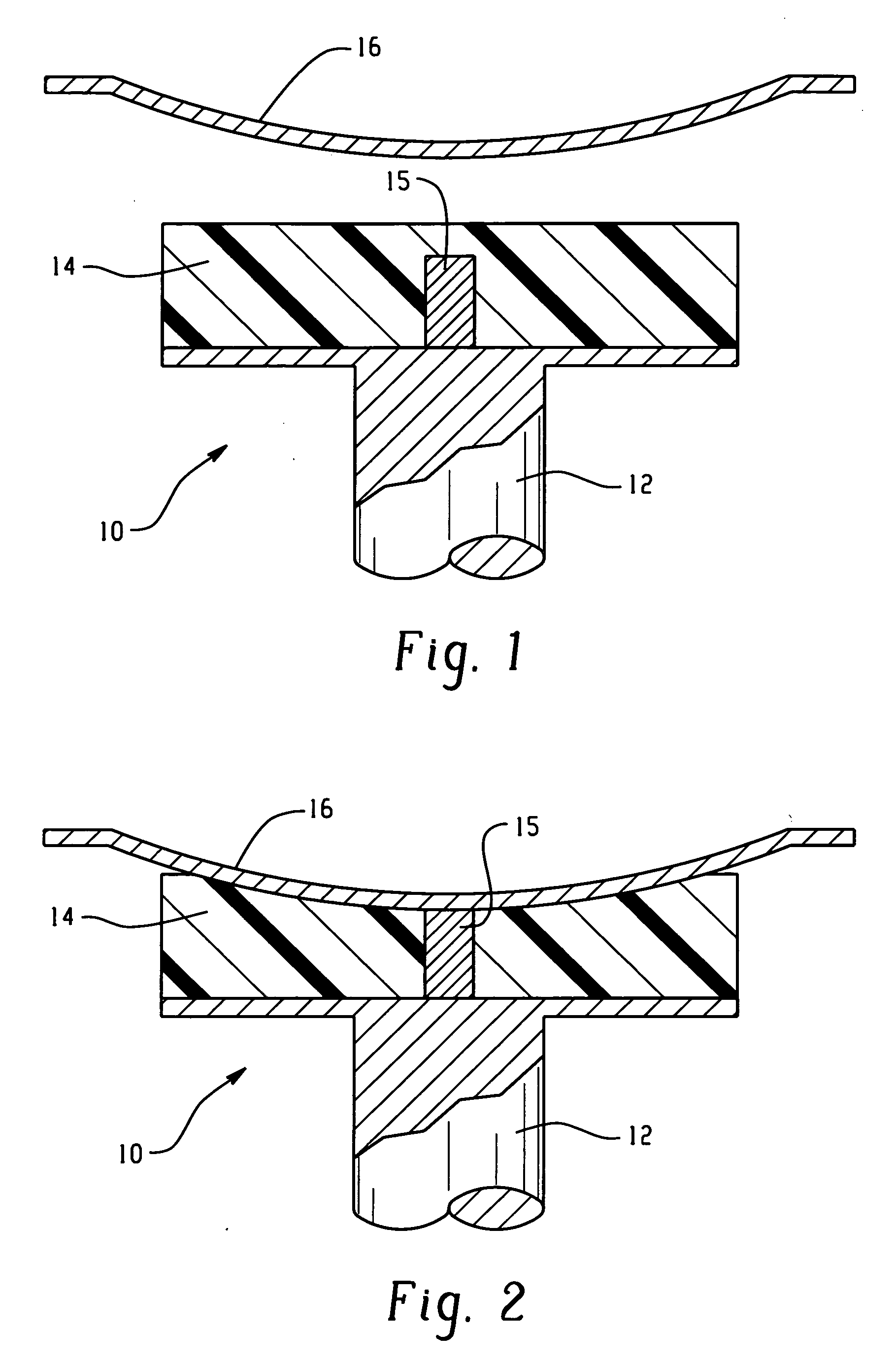

Clamping fixture including a chuck and a workpiece pallet releasably located thereon

ActiveUS20090051094A1Increase the tensile loadHandle high tensile loadRotary cutting toolsLarge fixed membersEngineeringPlunger

A clamping fixture comprises a chuck (1) and a workpiece pallet (22) releasably located thereon. The chuck (1) is provided with a clamping mechanism for locating the workpiece pallet (22). The clamping mechanism comprises a plurality of clamping members configured as plungers (10). The workpiece pallet (22) comprises a clamping surface (28a) running essentially along its shell surface (26) for surface contacting the plungers (10) by its front part (12) provided with a compression surface (13) during clamping.

Owner:EROWA

Load-lifting device for handling items

InactiveUS20060033350A1Rapidly and reliably and securely gripGripping headsMetal-working hand toolsCartonEngineering

The invention relates to a load-lifting device for handling items, comprising two spaced-apart, mutually opposite gripper arms which are equipped on the mutually facing sides with flexibly inflatable gas chambers that can be filled and emptied and between which the item is held when the gas chambers are in the inflated state. In order to be able to quickly, reliably and securely grip items, including cartons and loads with irregular contours or nonplanar gripping faces and / or those with significantly different dimensions, the gas chambers are constructed as collapsible cushions or bellows whose inflated thickness, measured in the direction of action, corresponds in each case to a multiple of the thickness of the bellows or cushions in the deflated state.

Owner:SIEMENS AG

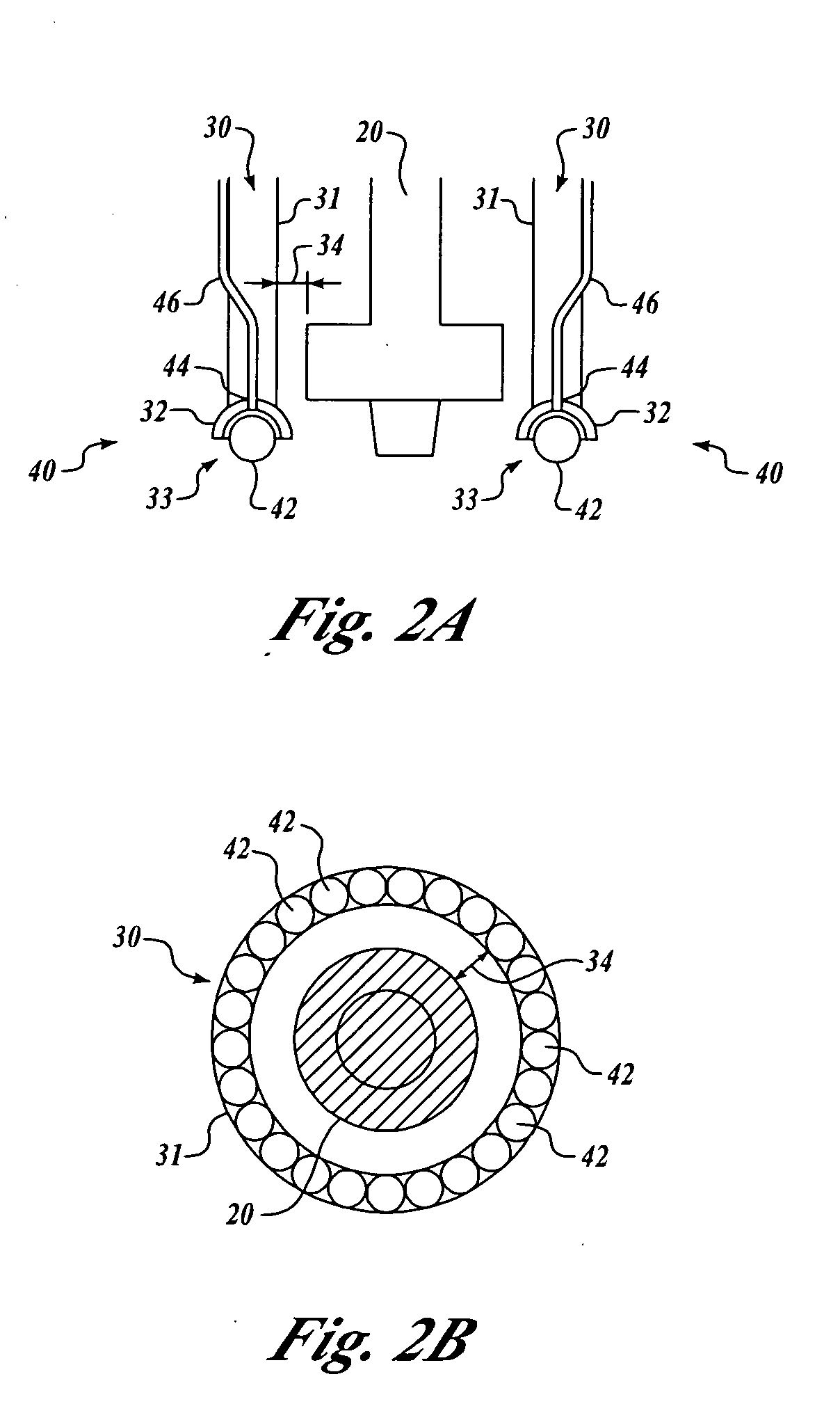

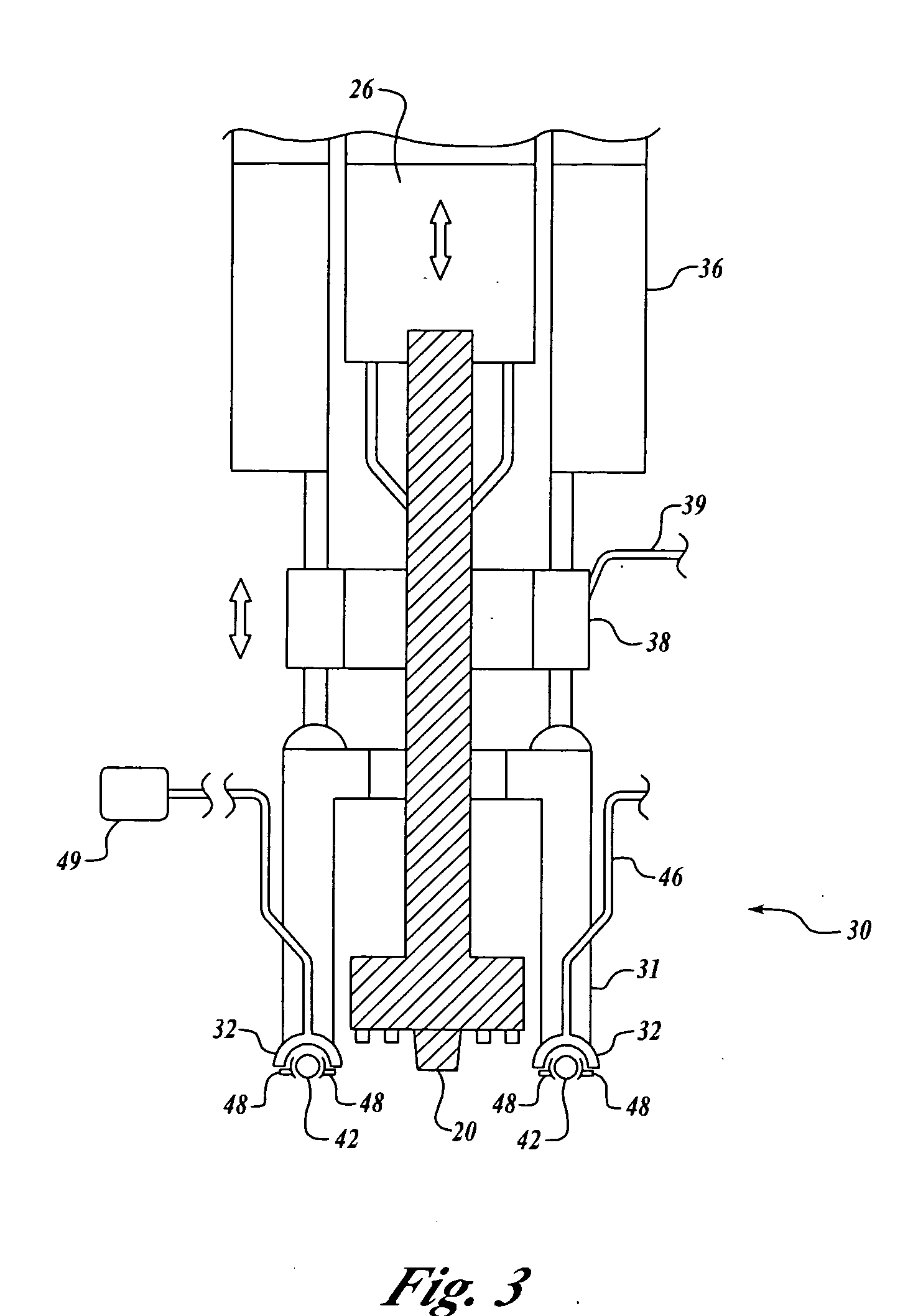

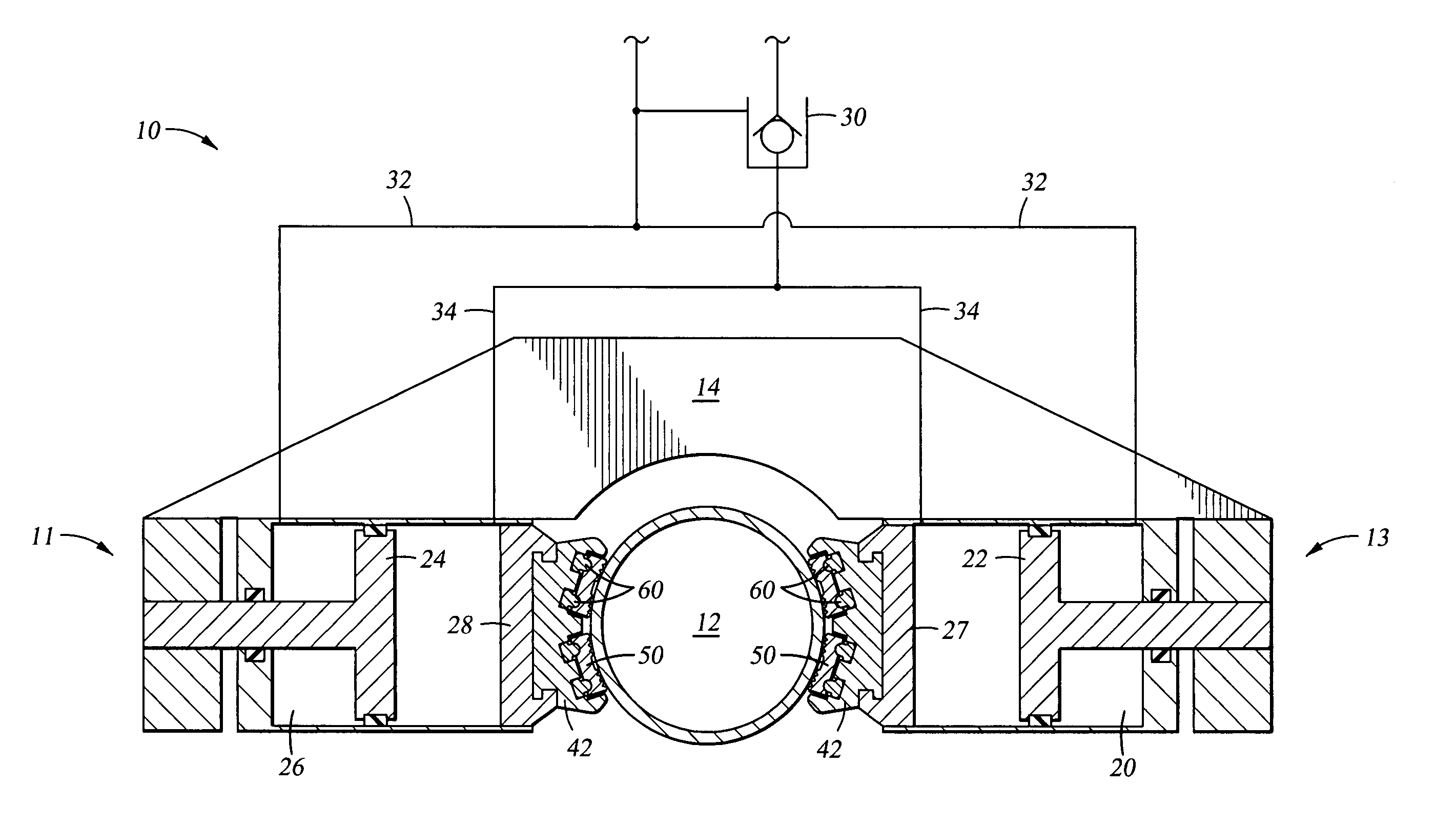

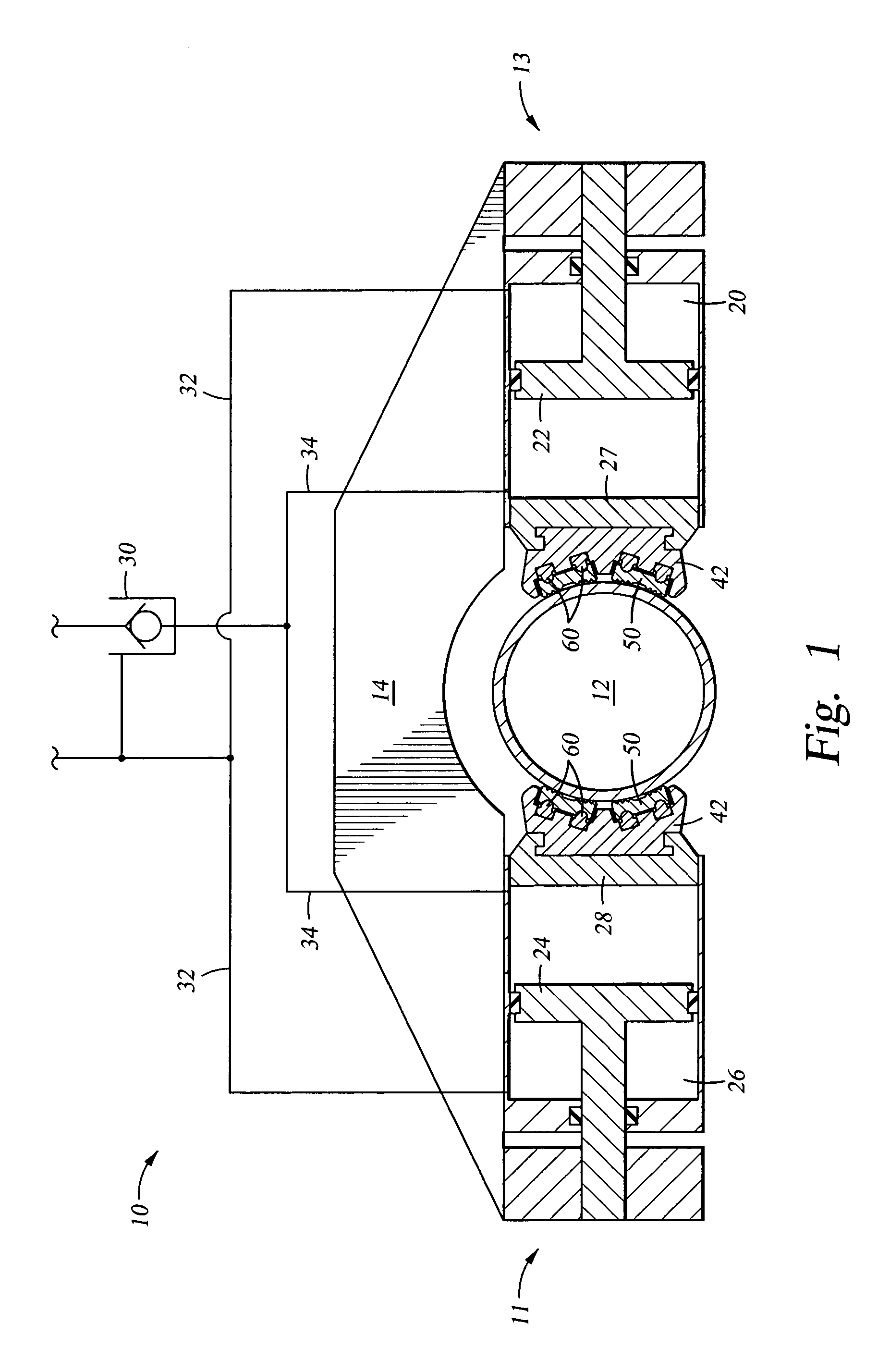

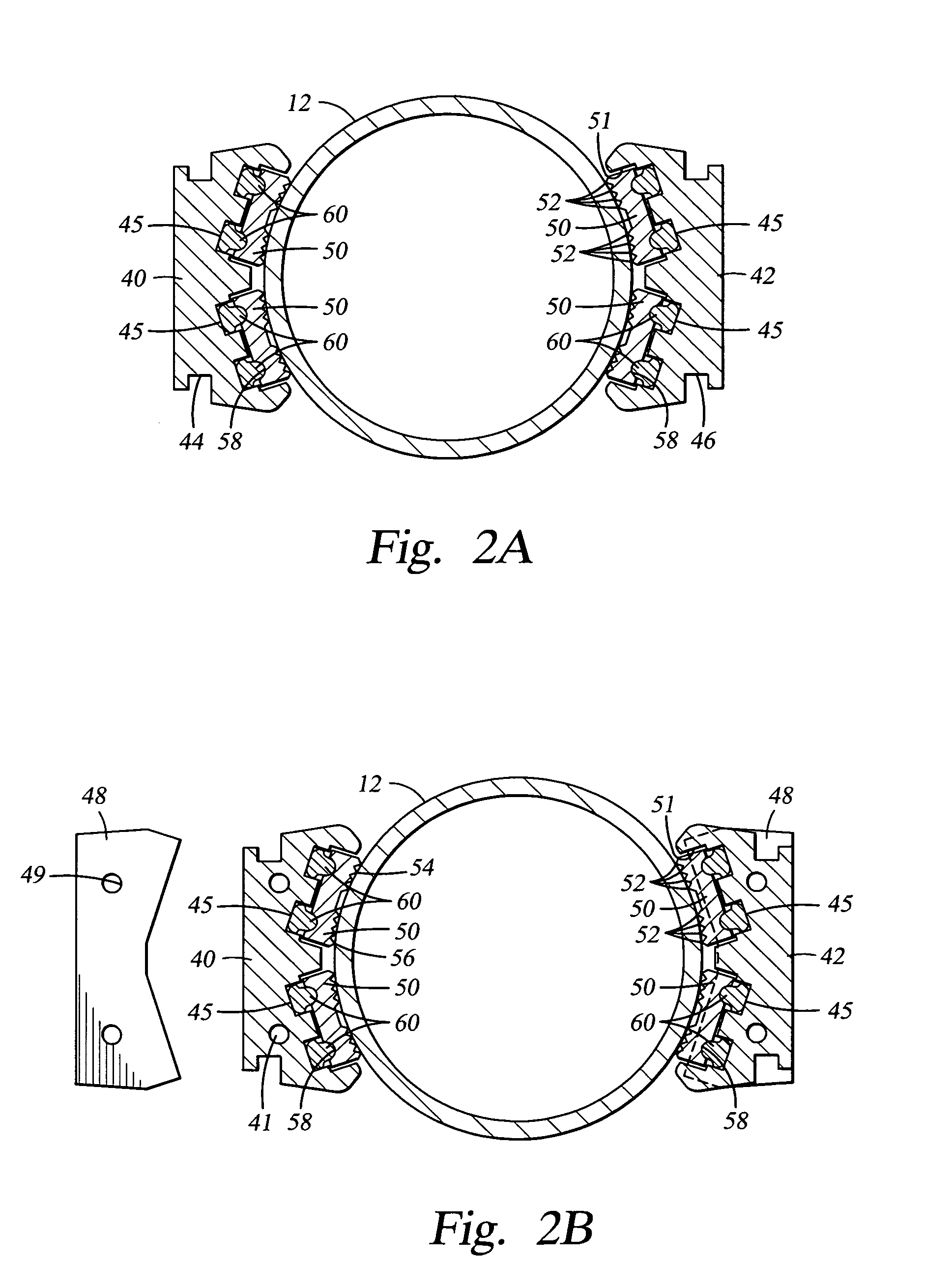

Clamping apparatus and methods for manufacturing

InactiveUS20050092817A1Welding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The present invention is directed to apparatus and methods for clamping around a manufacturing tool engaging a work piece. In one embodiment, a clamp includes a moveable support arranged to at least partially surround a circumference defining a work area. A friction reducing element is attached to the support to apply pressure to the surface when the clamp is engaged with the work piece, and to allow the clamp to be moved with the manufacturing tool. In accordance with other aspects of the invention, the clamp co-annularly or partially surrounds the manufacturing tool. In another embodiment, the manufacturing tool is a friction stir welding tool.

Owner:THE BOEING CO

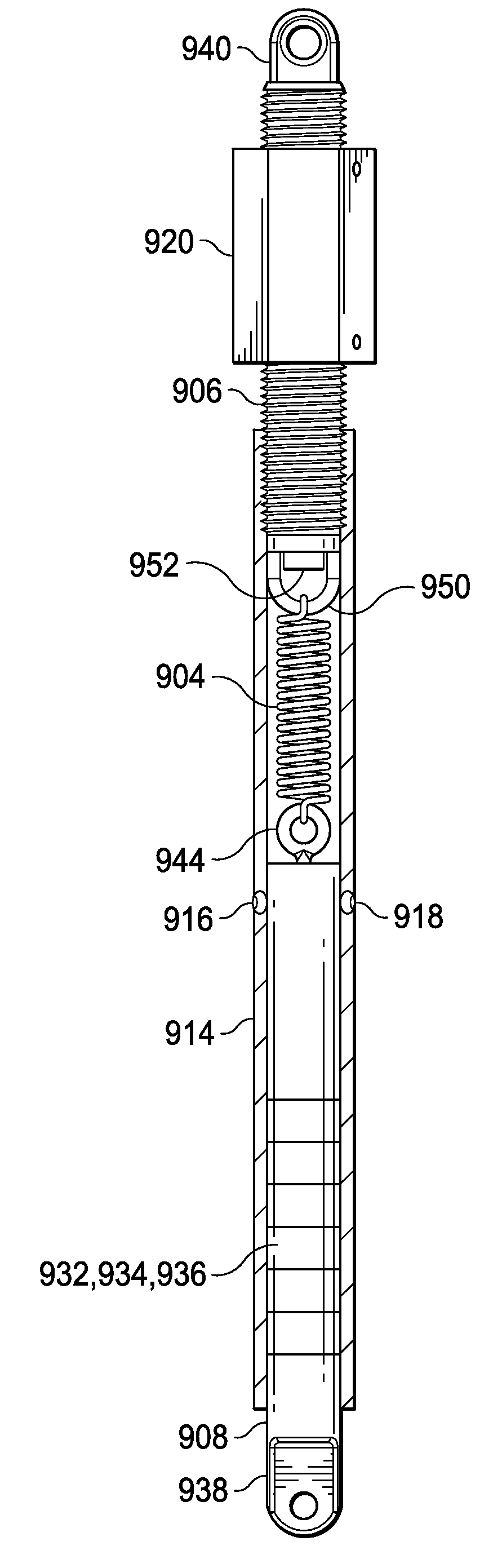

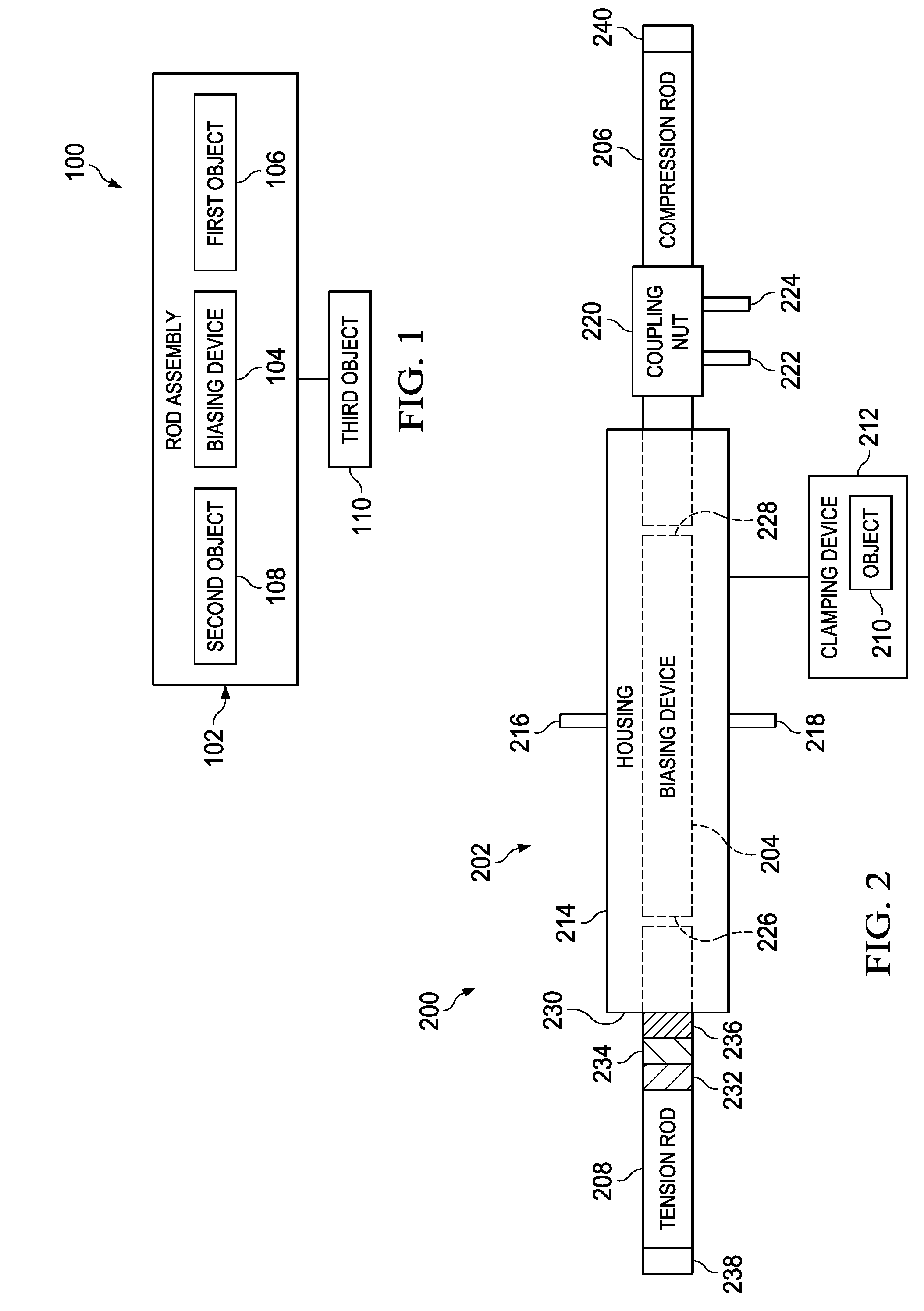

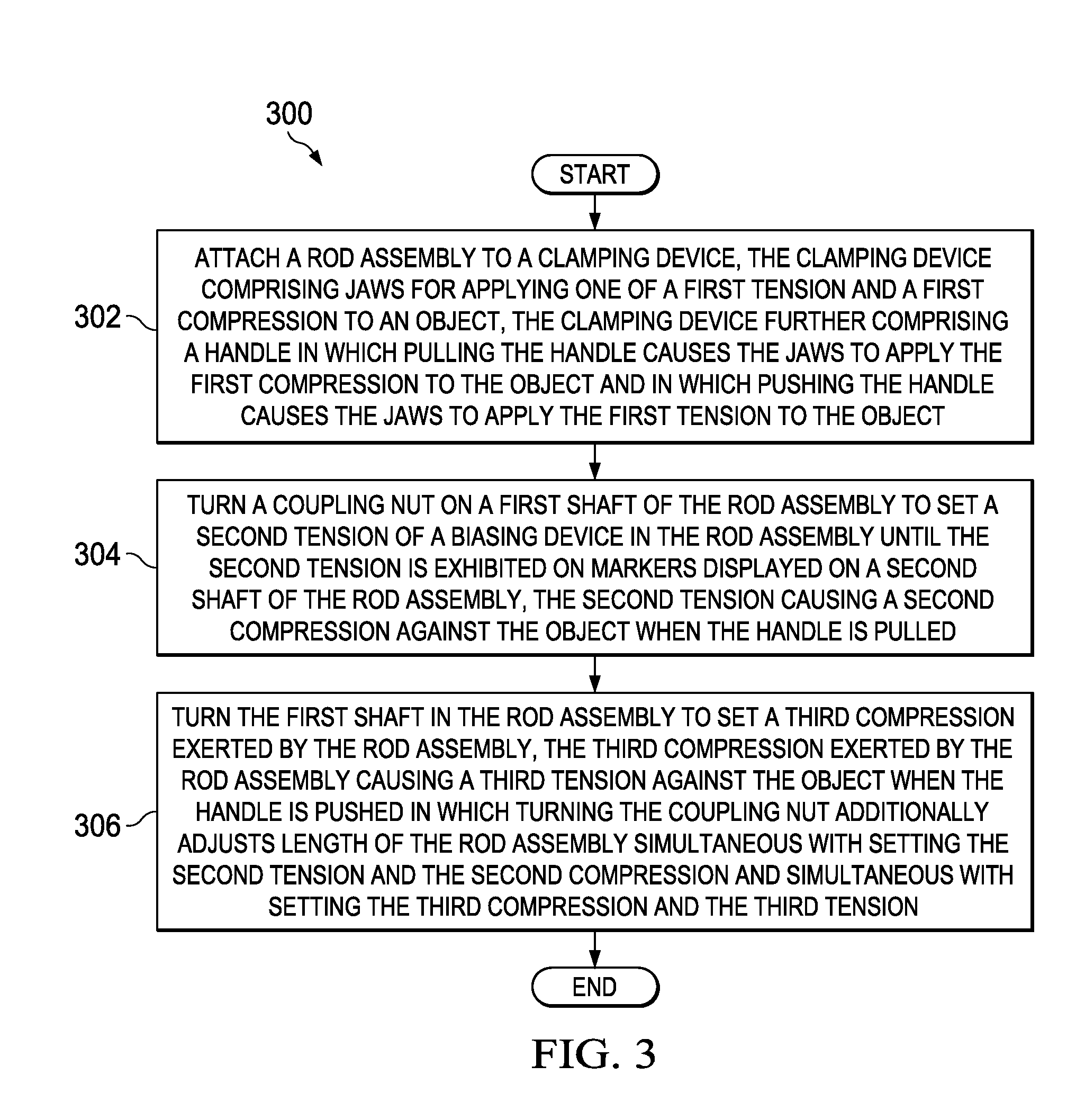

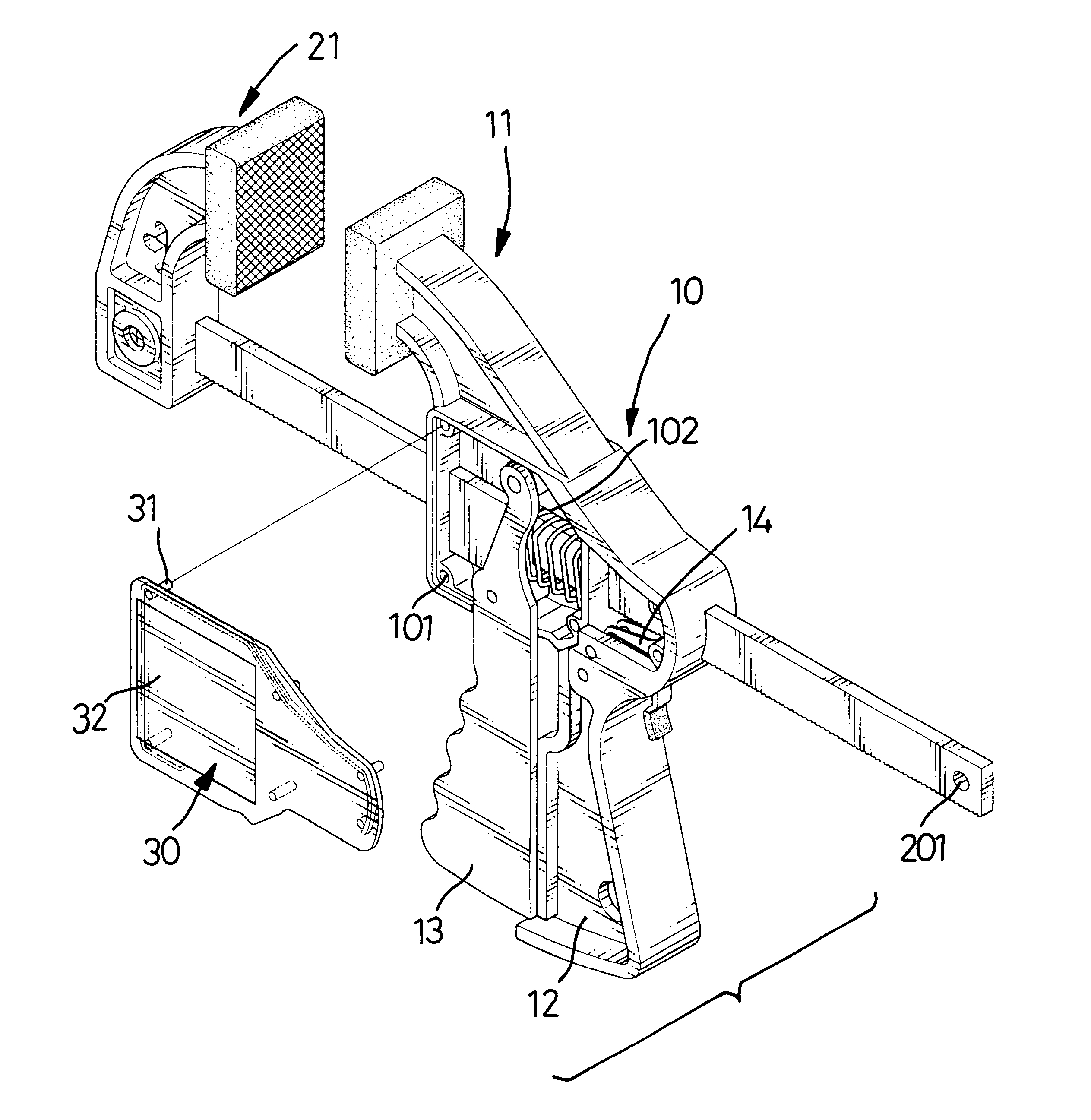

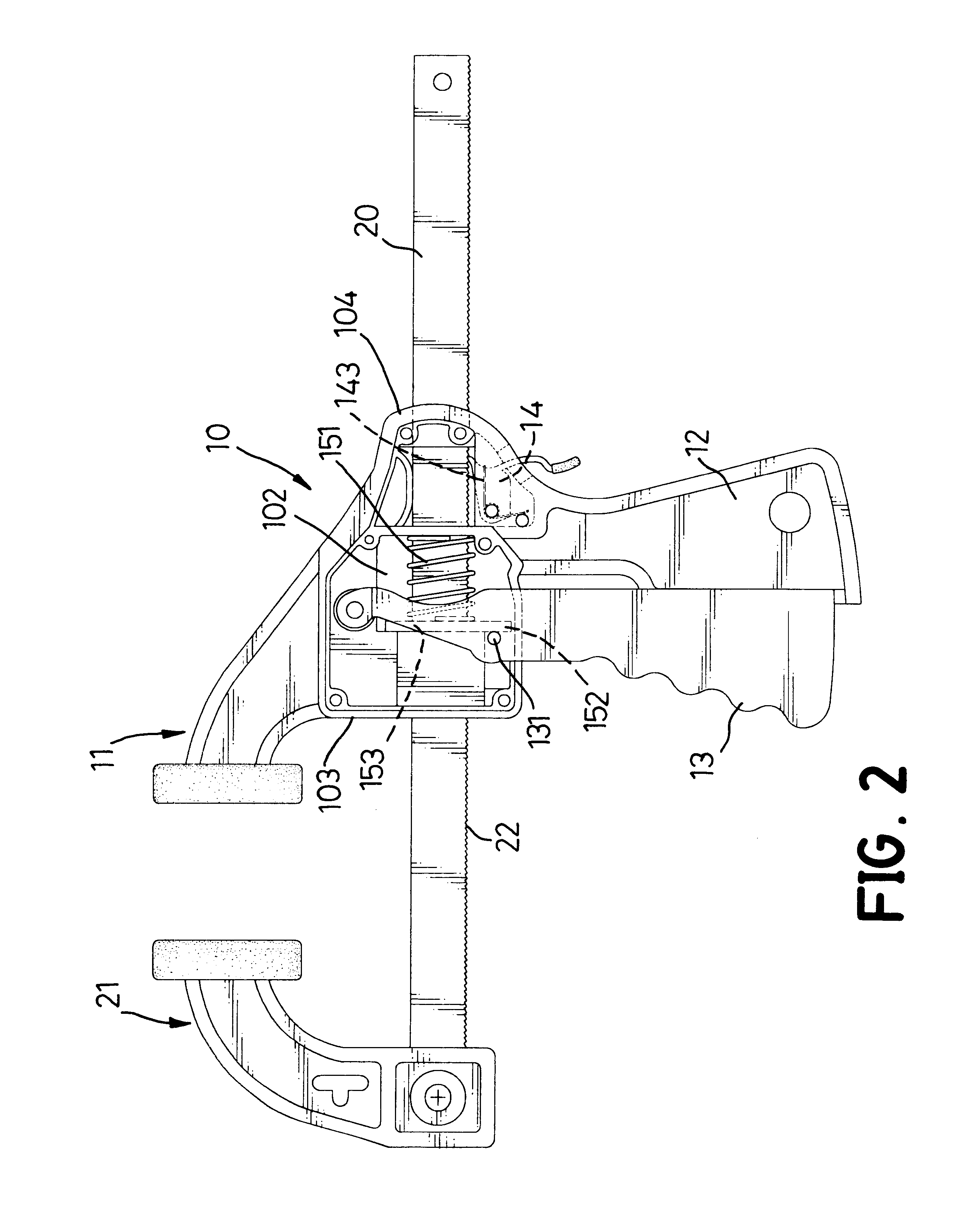

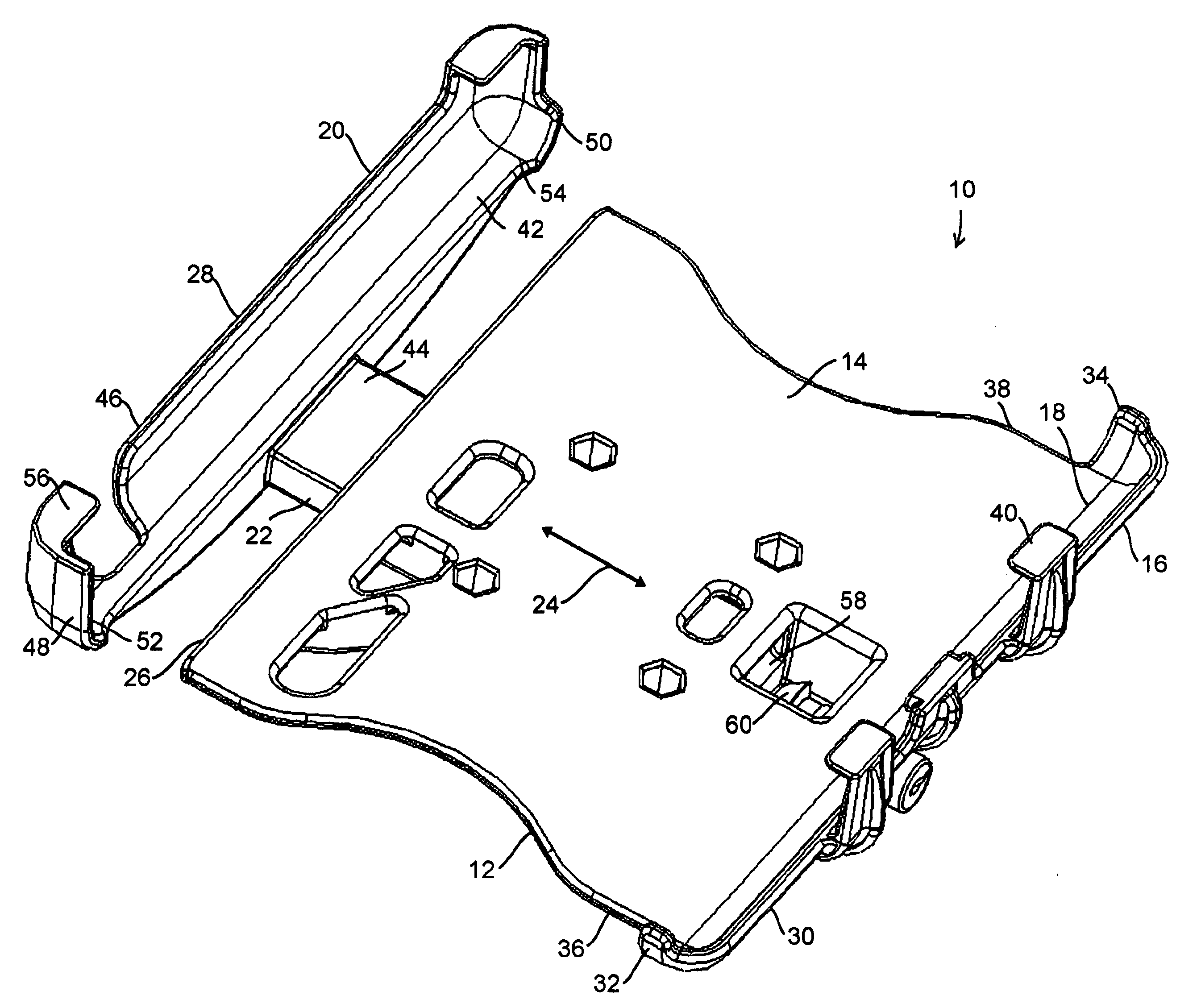

Adjustable Compression, Adjustable Tension Rod Indicator, and Adjustable Extension Rod

A biasing device that returns to a rest position when the biasing device is subjected to one of a first compression by a first object and a first tension by a second object in which the first tension causes a second compression of a third object, in which the first compression causes a second tension of the third object, in which elongation of the rod assembly simultaneously occurs with the first tension and the second compression, and in which elongation of the rod assembly simultaneously occurs with the second tension and the first compression.

Owner:THE BOEING CO

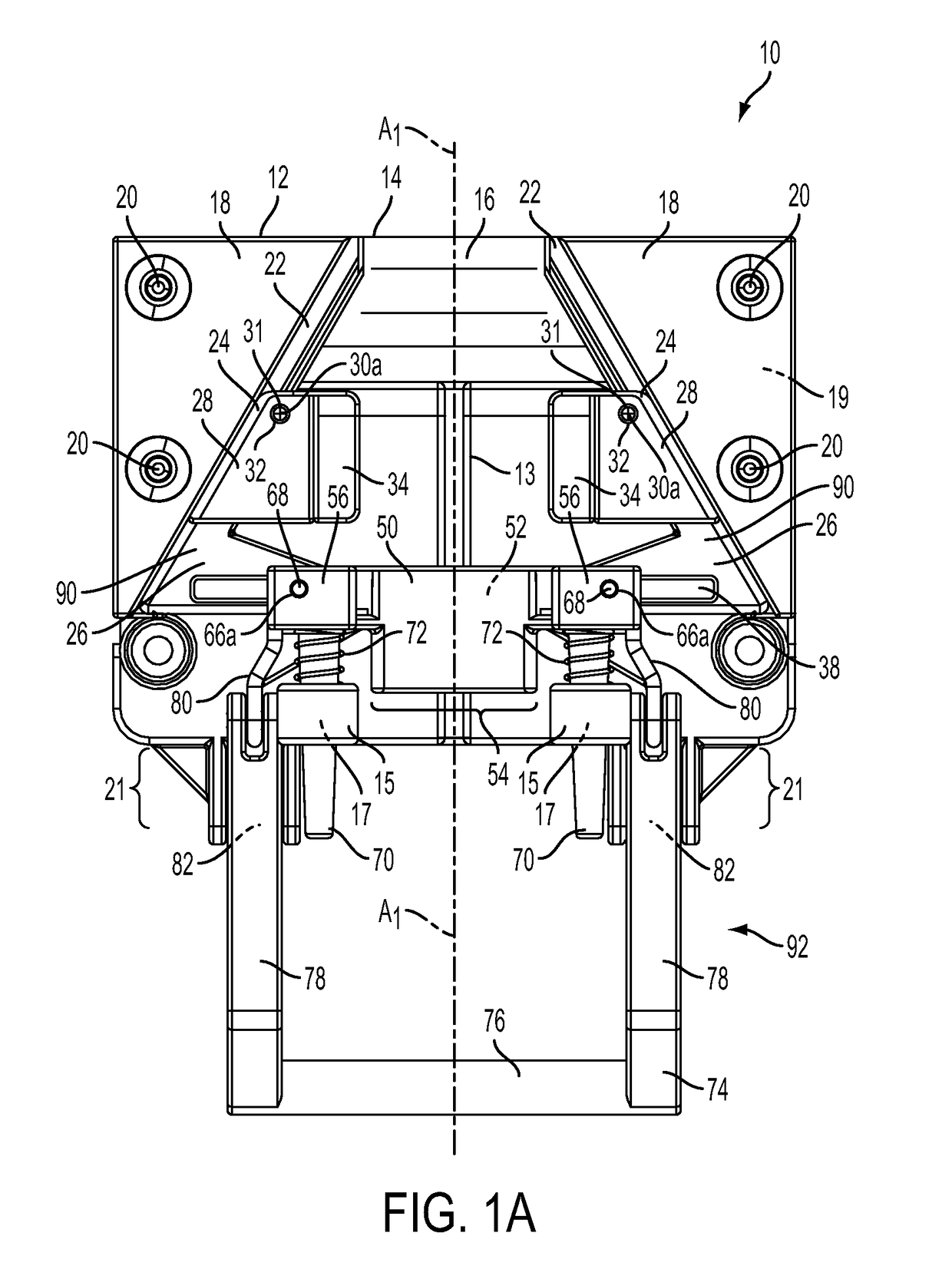

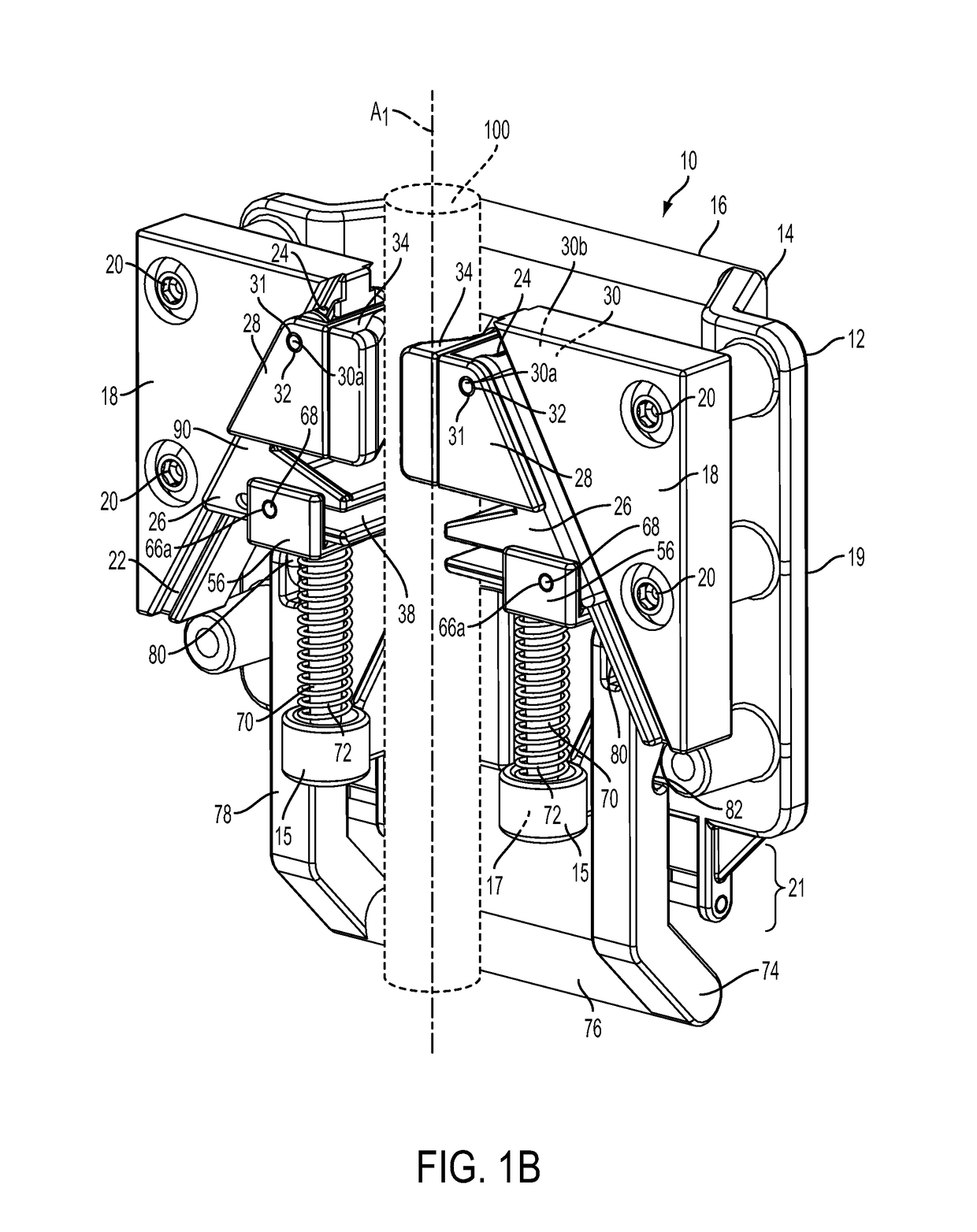

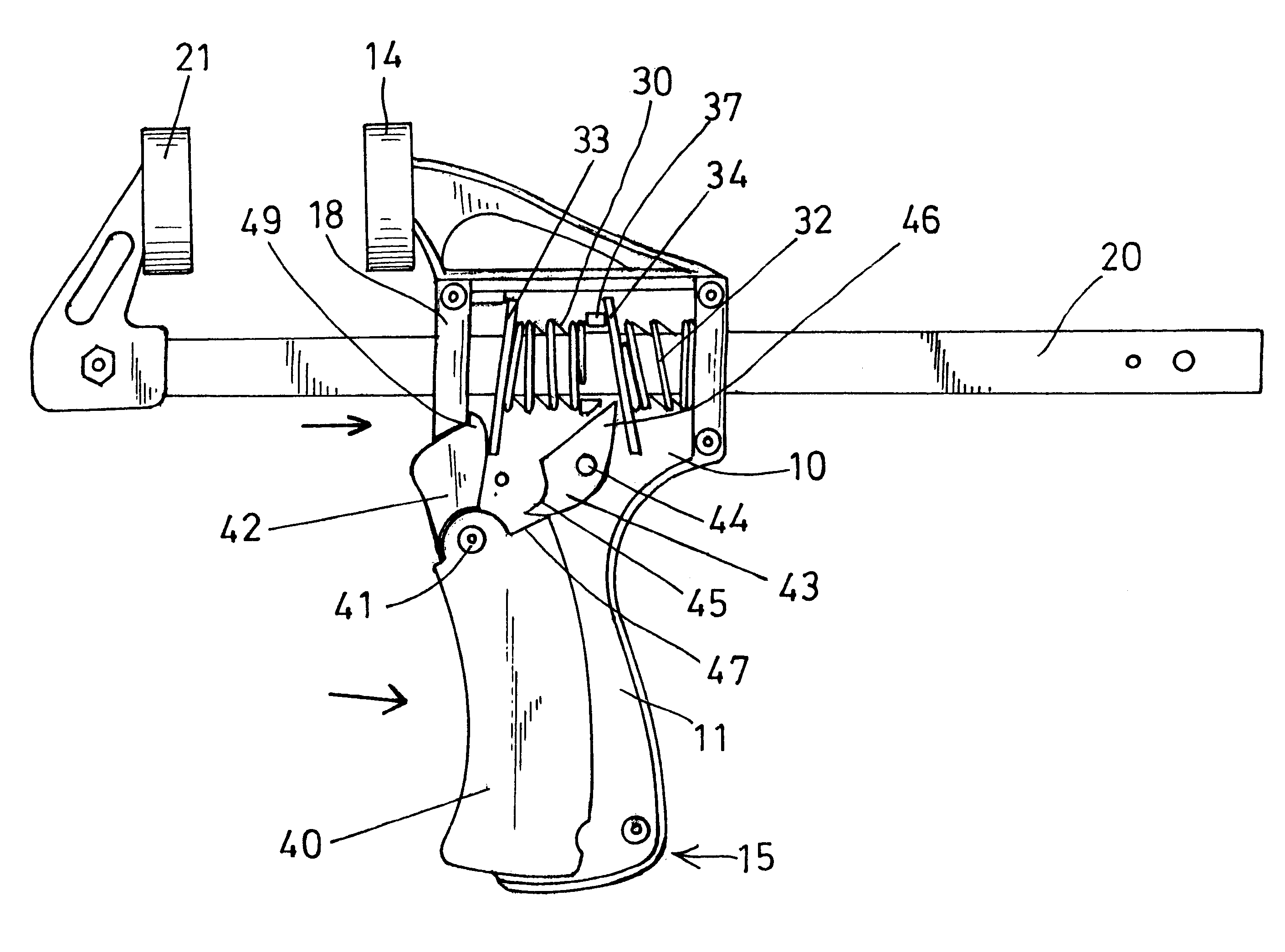

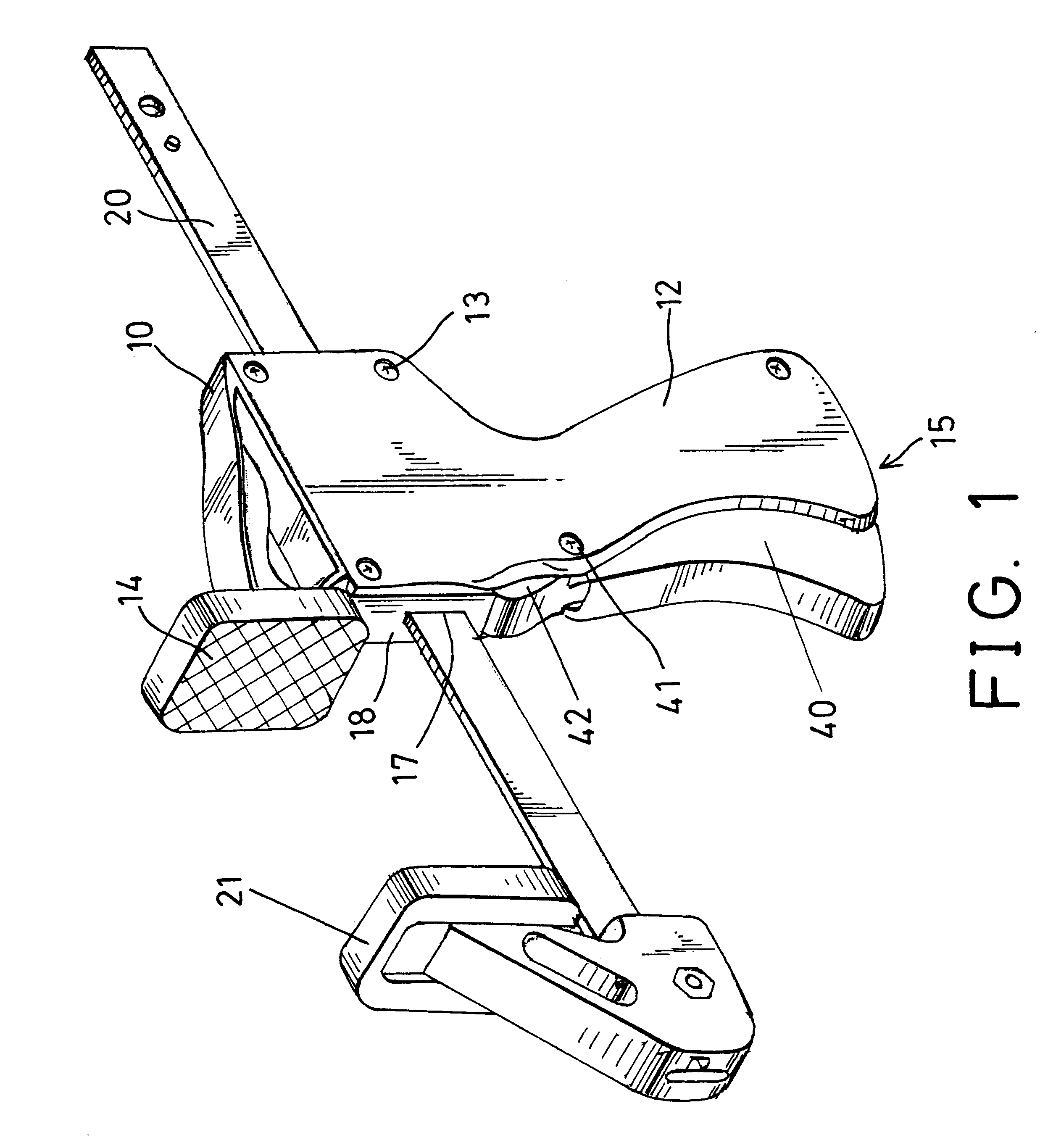

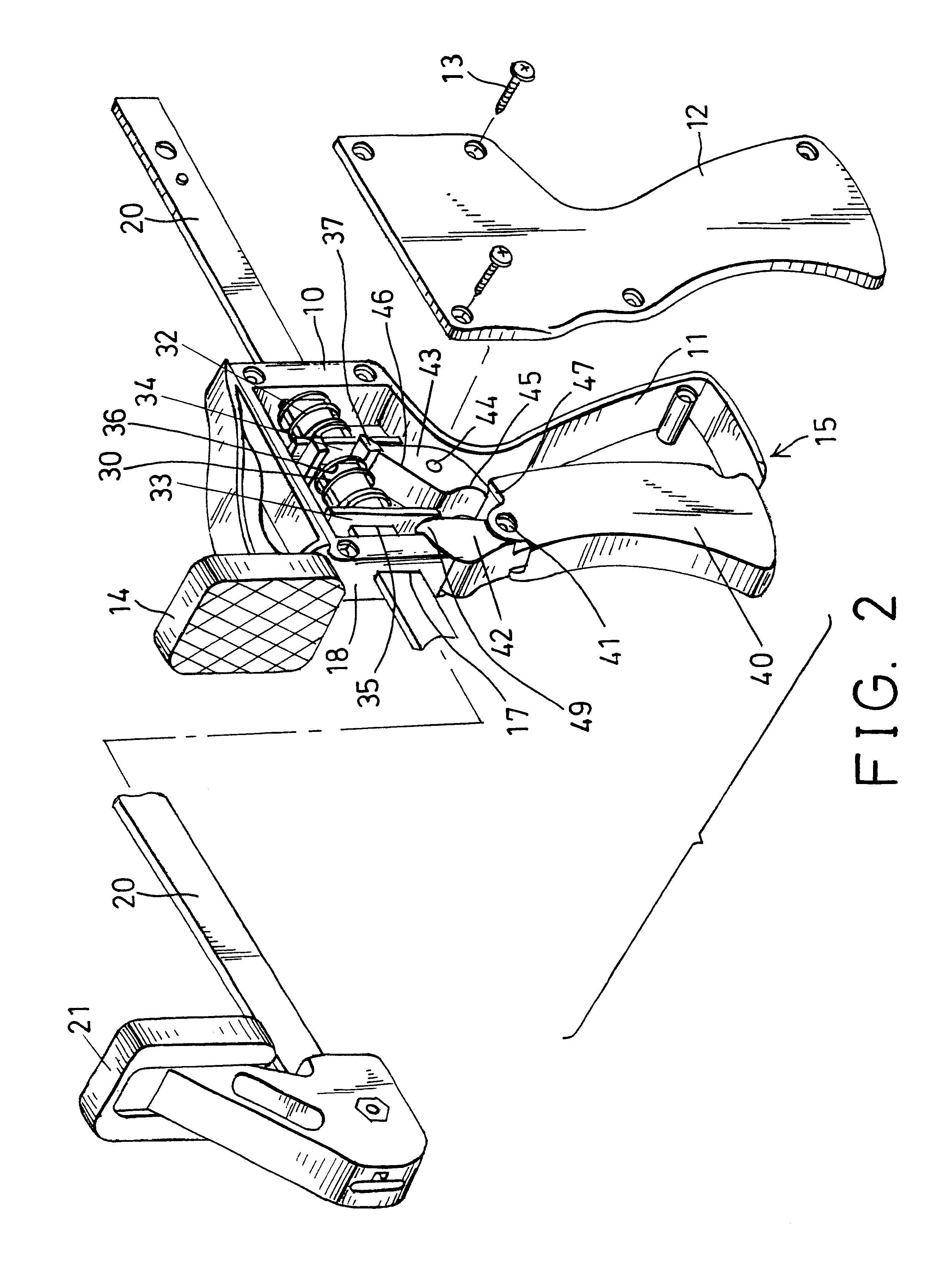

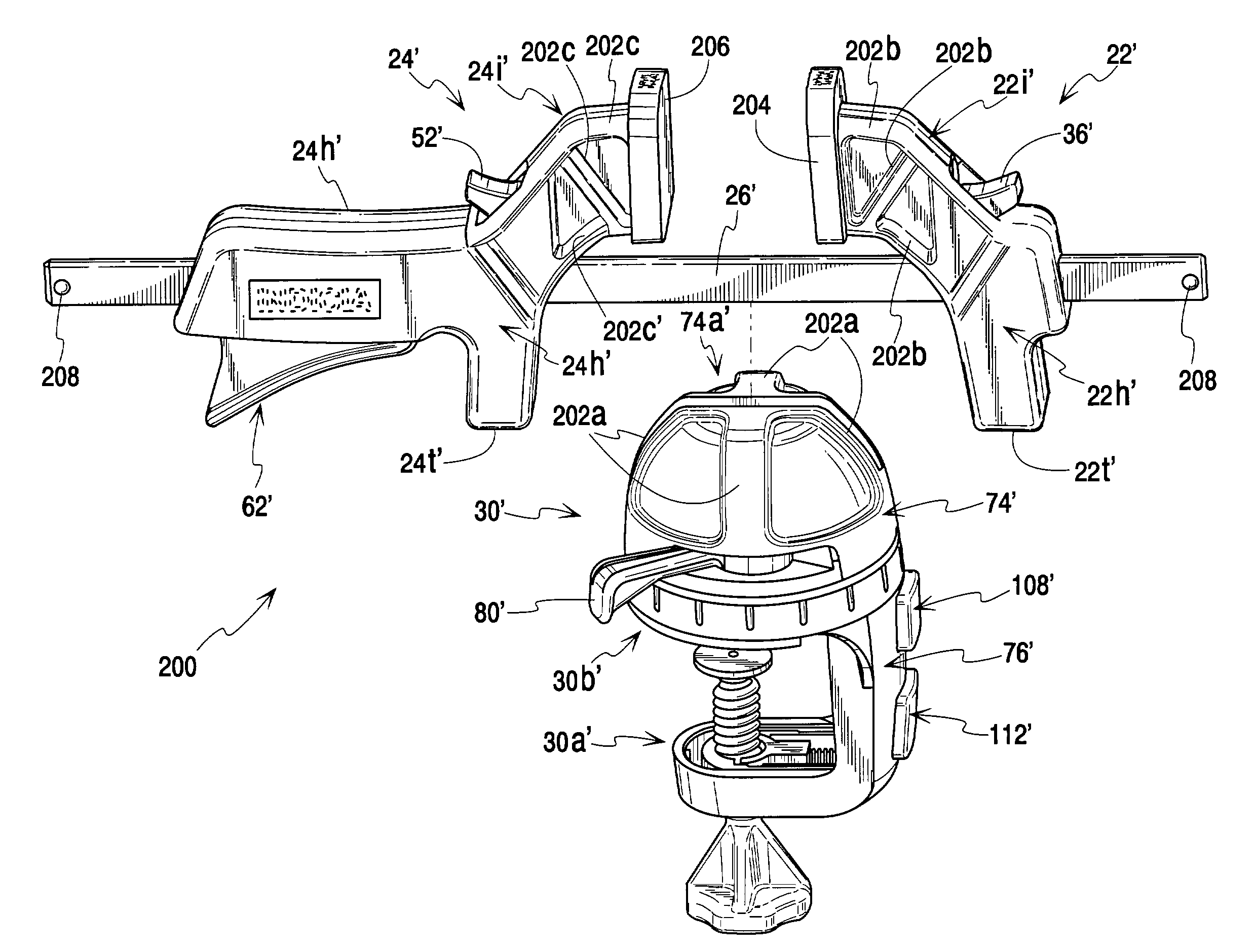

Quick-action bar clamp

A quick-action bar clamp comprises a body, a slide bar, clamp mechanism, a drive assembly and a pawl assembly. The slide bar has a series of teeth along one edge and is movably mounted in the body. The clamp mechanism includes a stationary jaw mounted on the body and a movable jaw opposing the stationary jaw connected to one end of the slide bar. The drive assembly includes a trigger, a drive lever and a spring. A push pin mounted in the trigger presses the drive lever and moves the slide bar when the trigger is squeezed. The pawl assembly includes a pawl, a release tab, a biasing element and a plastic tag. The pawl engages the teeth on the slide bar to positively hold the slide bar in position when the trigger is released.

Owner:LI TSUNG HSIANG

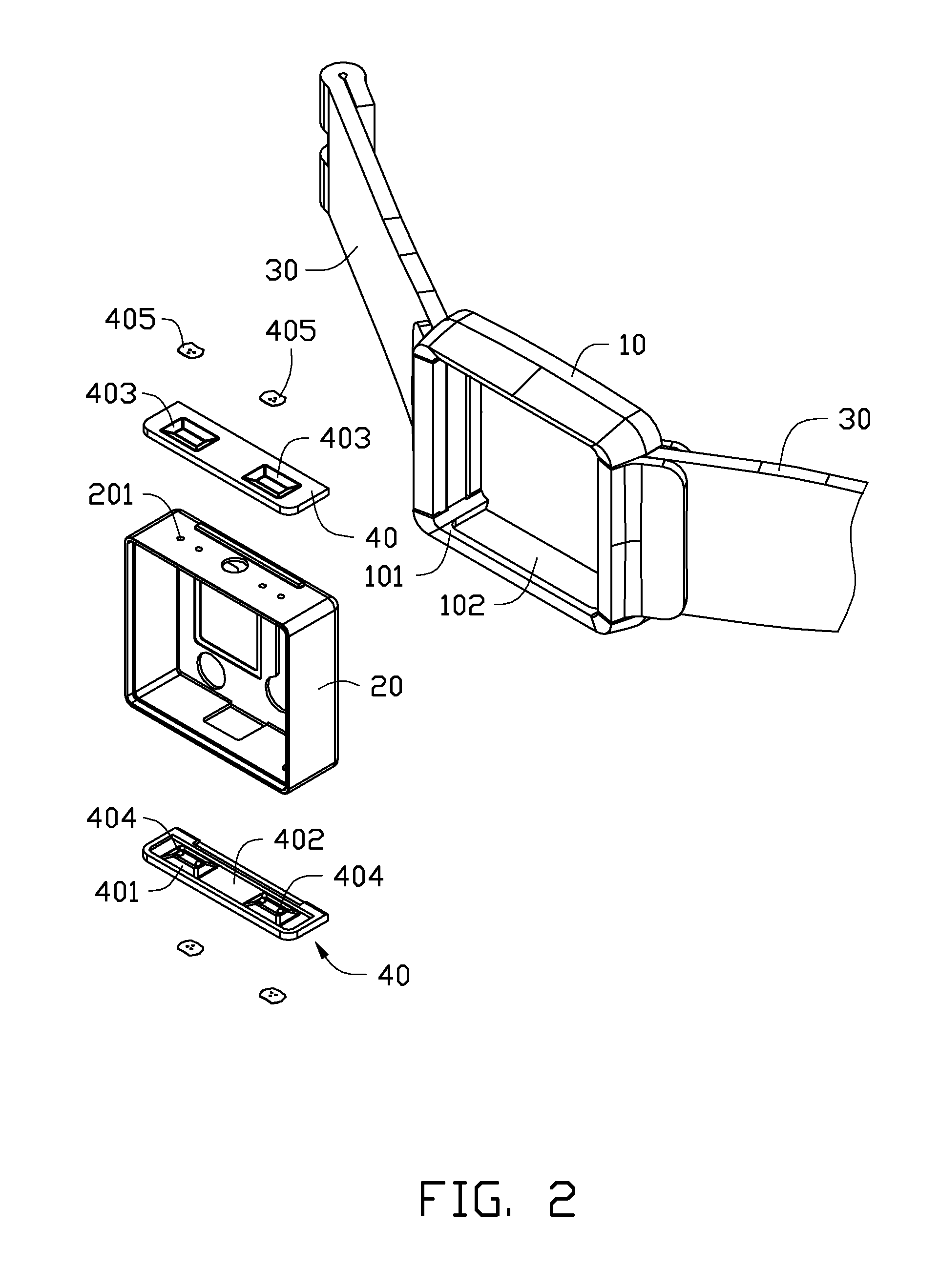

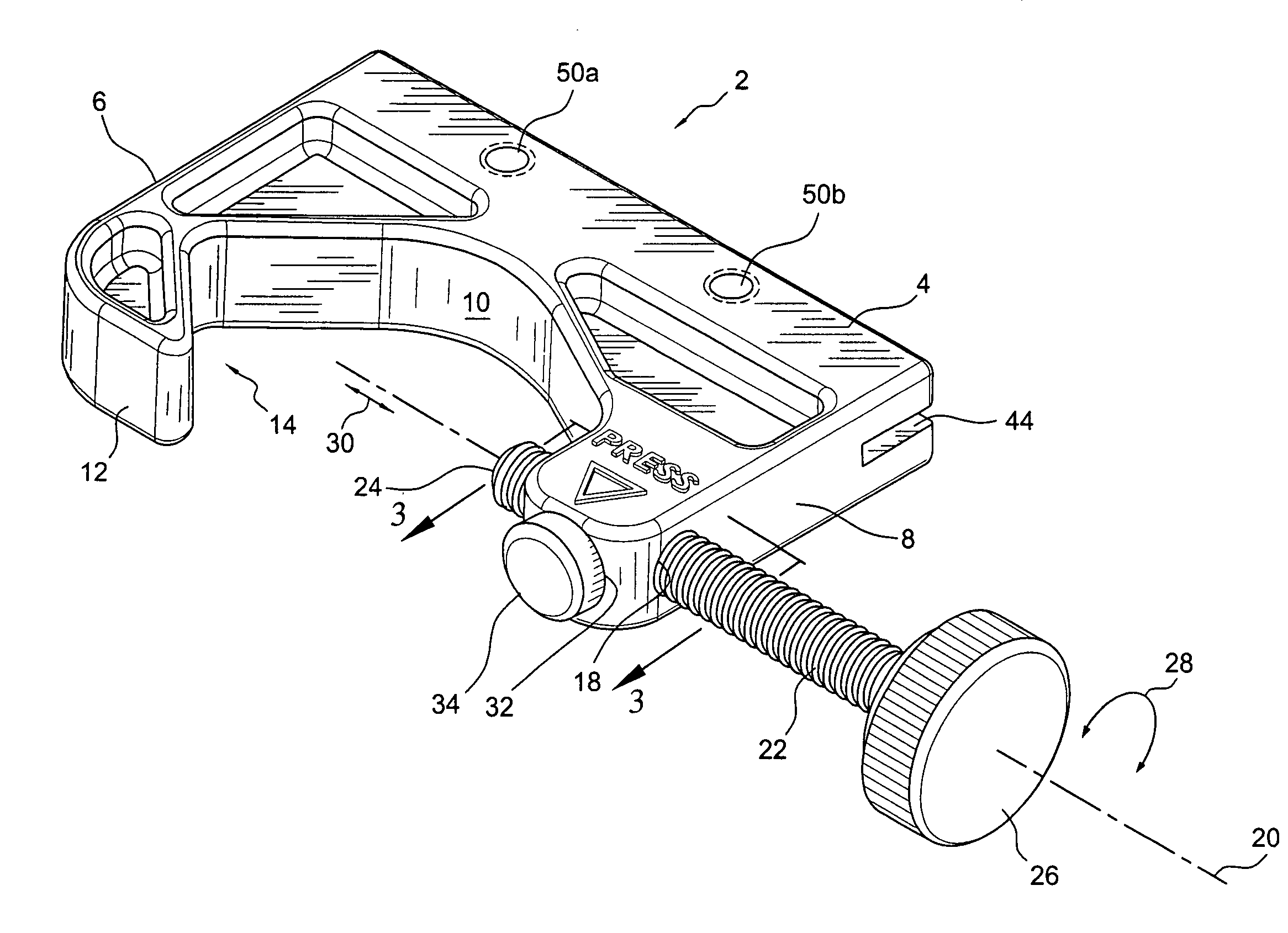

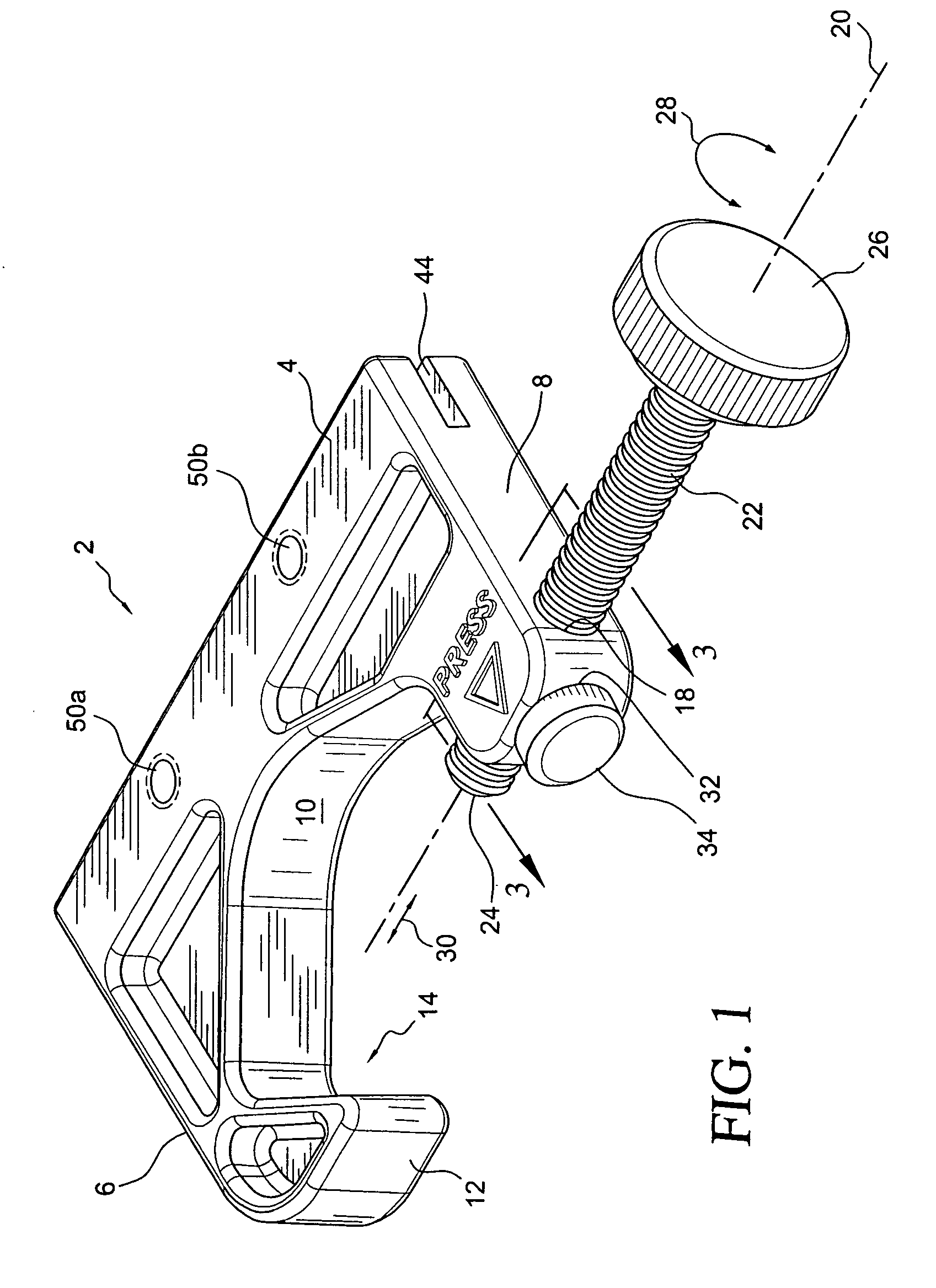

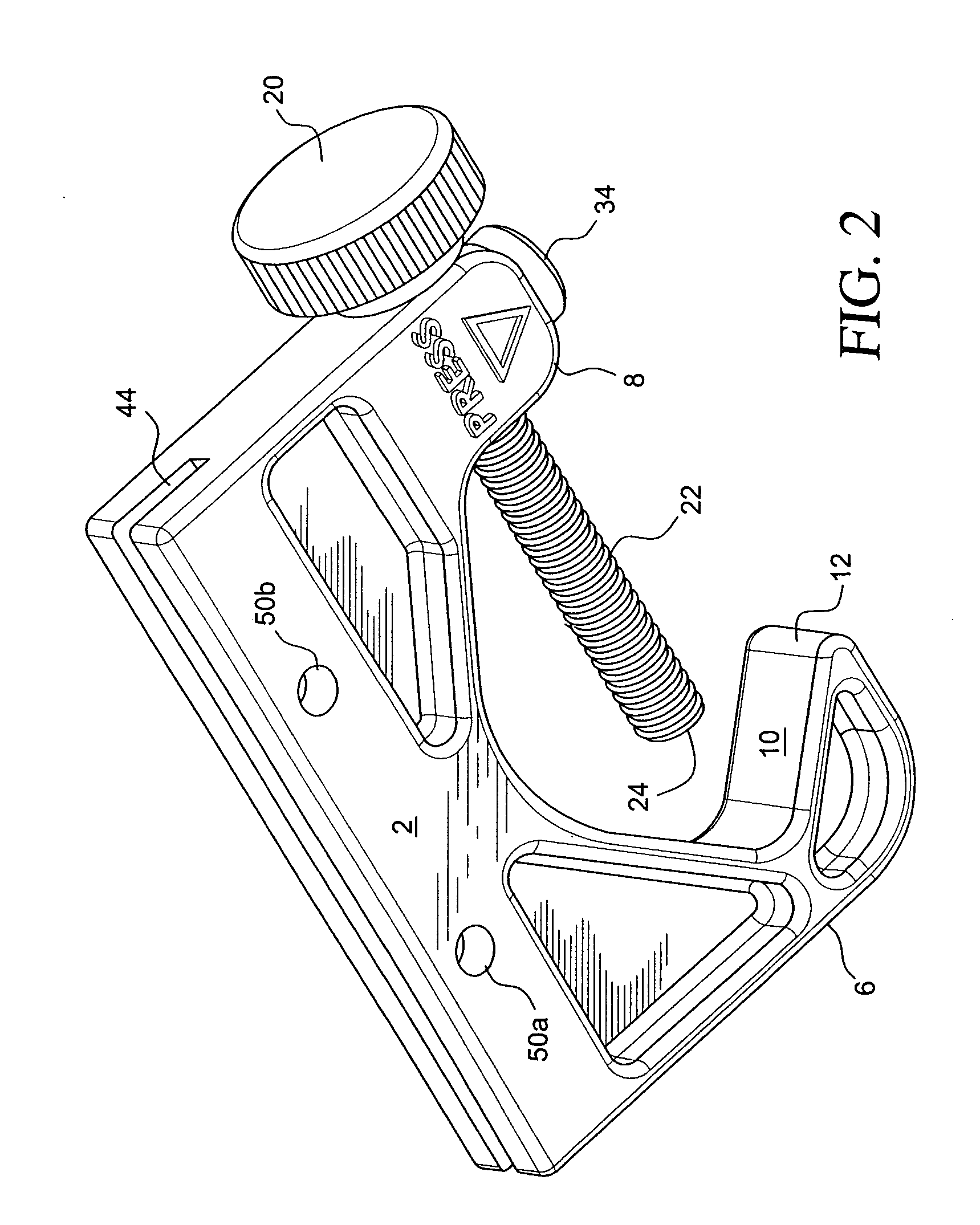

Quick release electronics platform

Owner:CARNEVALI JEFFREY D

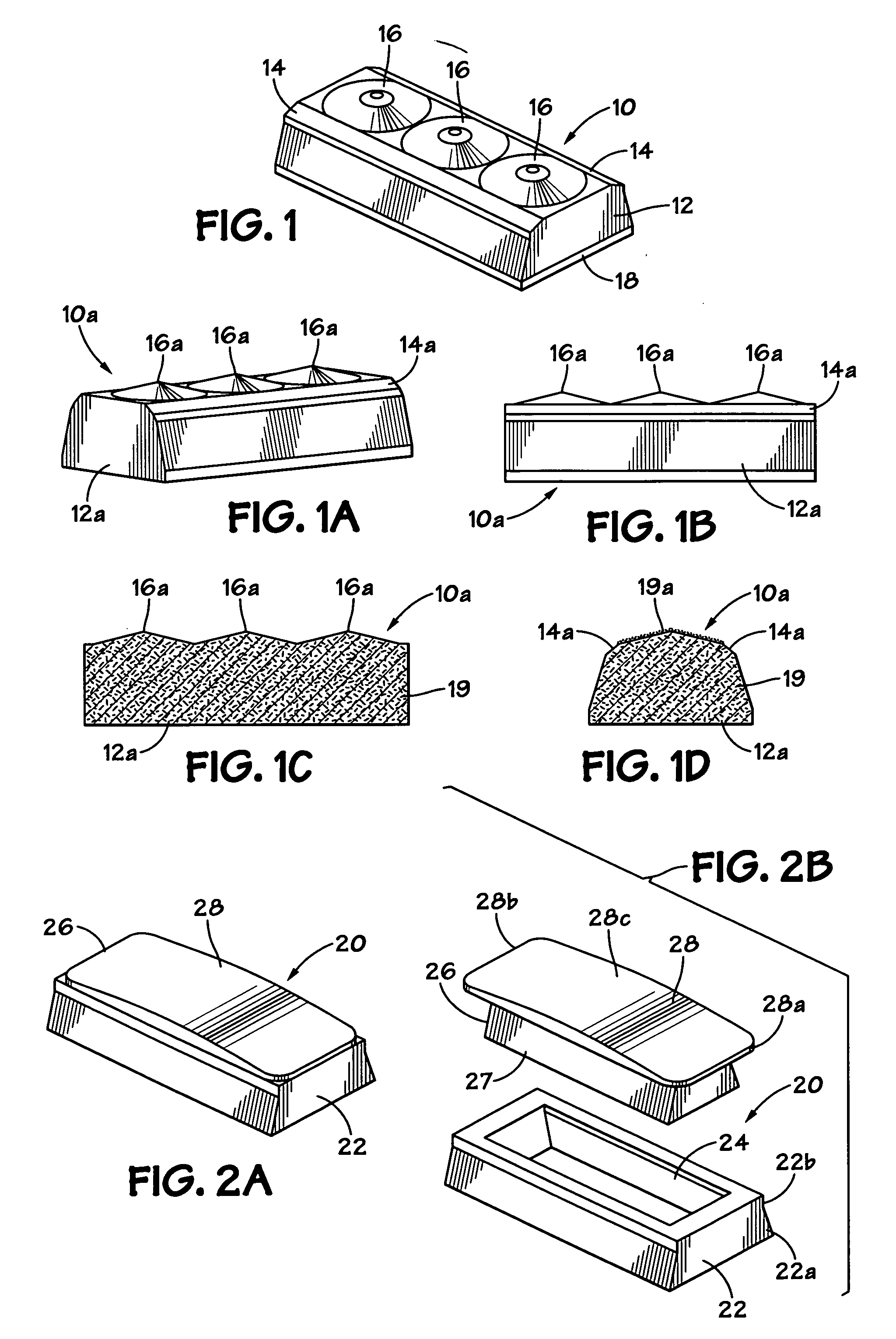

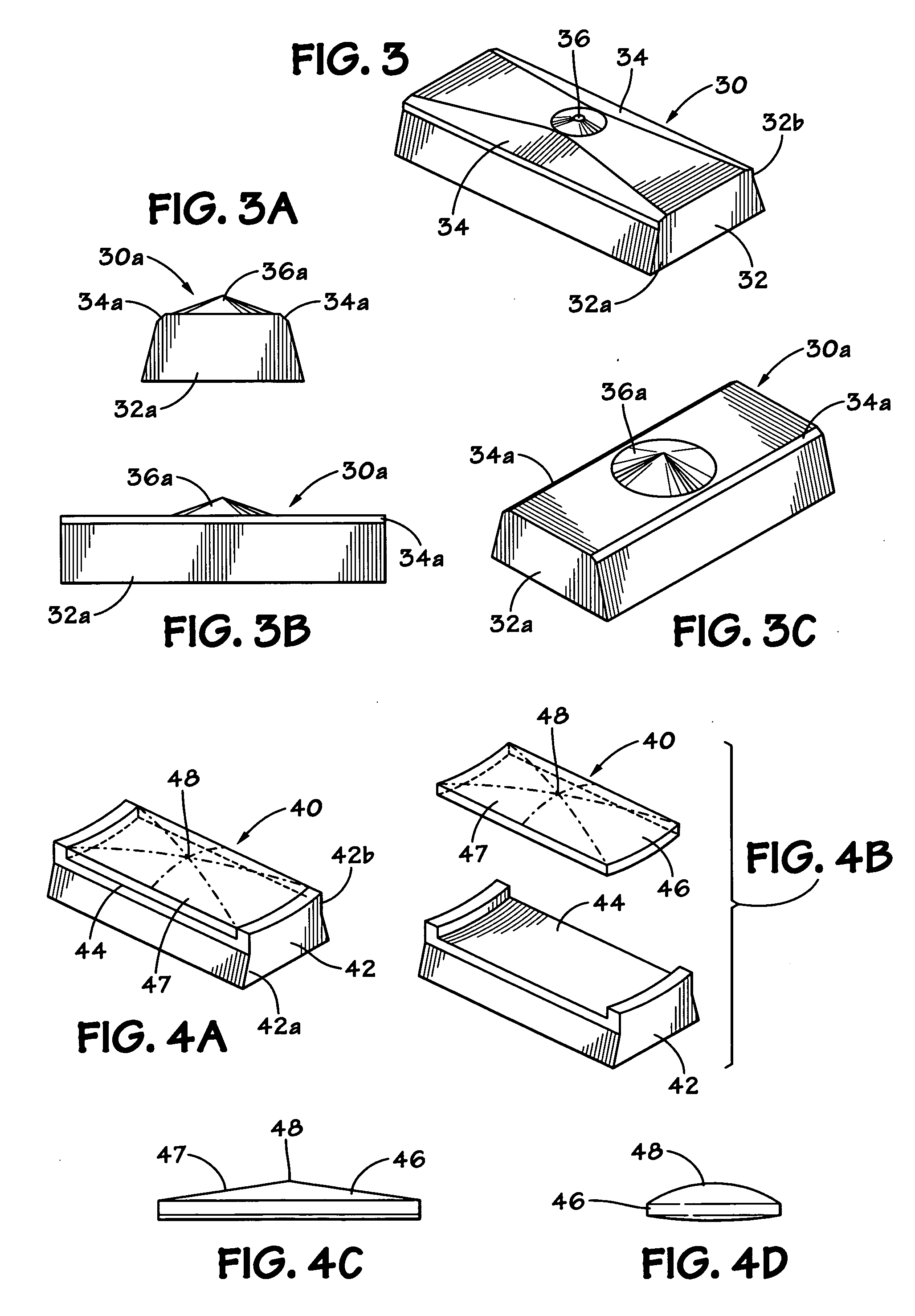

Jaw insert for gripping a cylindrical member and method of manufacture

InactiveUS6971283B2Easy to manufactureSleeve/socket jointsDrilling rodsEngineeringMechanical engineering

An insert for use in a gripping assembly is disclosed. The insert includes a base member having a plurality of gripping teeth. The teeth are arranged in at least two substantially adjacent rows, where at least one row of teeth is offset or staggered longitudinally from an immediately adjacent row of teeth. When the teeth engage a cylindrical member, a resistance profile is created that is substantially continuous and does not oscillate over a length of the insert approaching 100% of the length of the entire insert.

Owner:NAT OILWELL DHT

Gripping device

ActiveUS7337934B2Improve gripLuggage carriersSupplementary fittingsEngineeringMechanical engineering

Owner:POLARIS IND INC

Universal workholding V fixture convertable to other applications

Owner:ANDRONICA RANDALL C

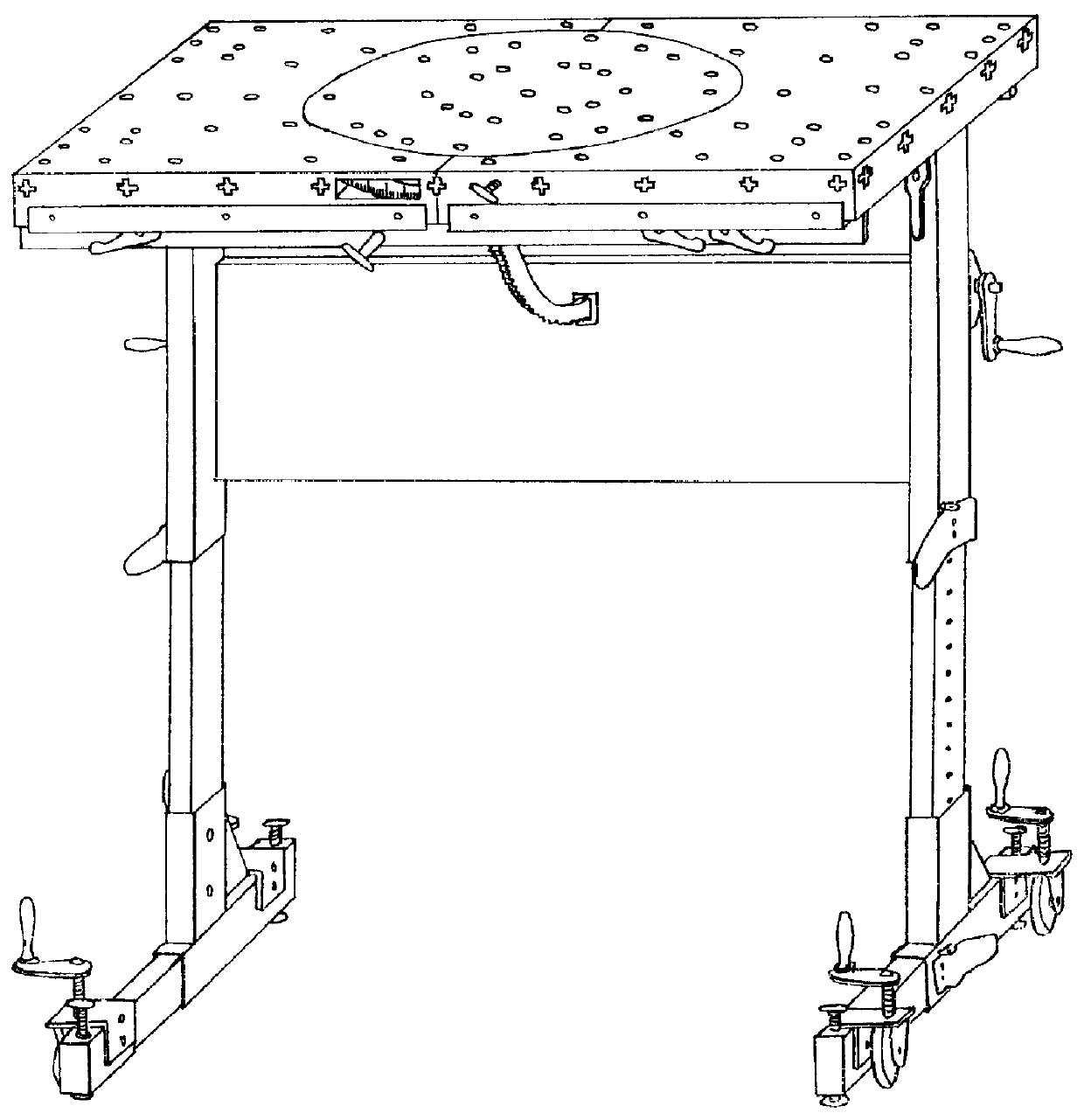

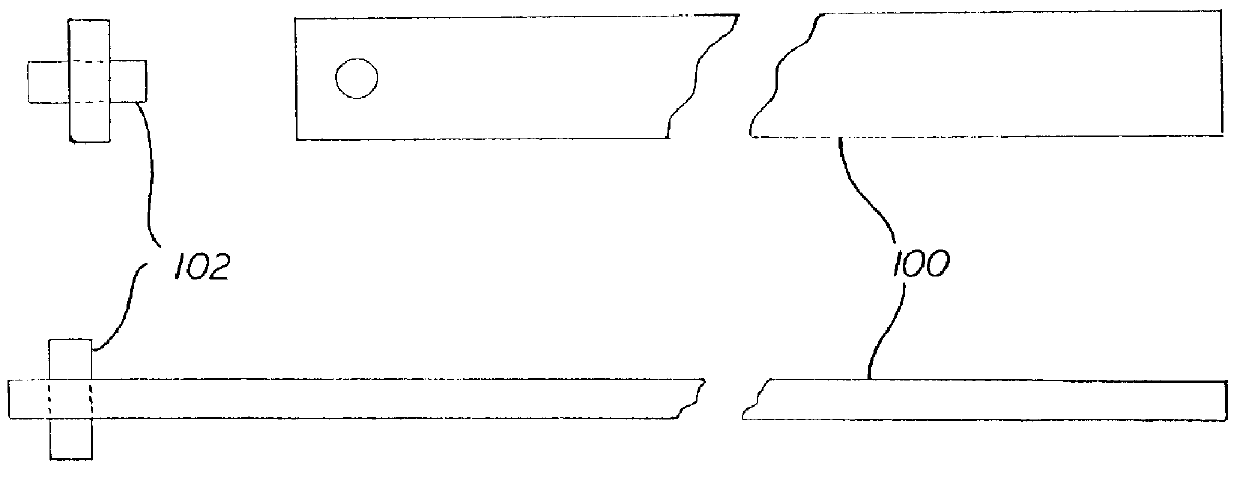

Clamping/securing/connecting system

This is a system / method of clamping or securing or connecting one or more objects together in a wide variety of ways with the main means being a specifically designed bar and mated slot combination. While the main embodiment is the "Handy Table" project, there are many other ramifications of this invention. The bar and slot design can be altered to perform many other tasks where some way of attaching one or more objects to another need be accomplished. The main embodiment is, in my estimation, the most advanced type of work or project surface. The combination of a tri-sectional work surface, adjustable in a variety of ways, in size, in tilting, in multi-angle clamping capability, in precision height adjustment, and in the ability to transport the object being worked on easily, plus the addition of accessaries that enhance the overall capabilities of the "Handy Table", make it useable by many different professions and by the average project worker, be it man or woman, young or old.

Owner:CHAVEZ JR ALEX BENJAMIN

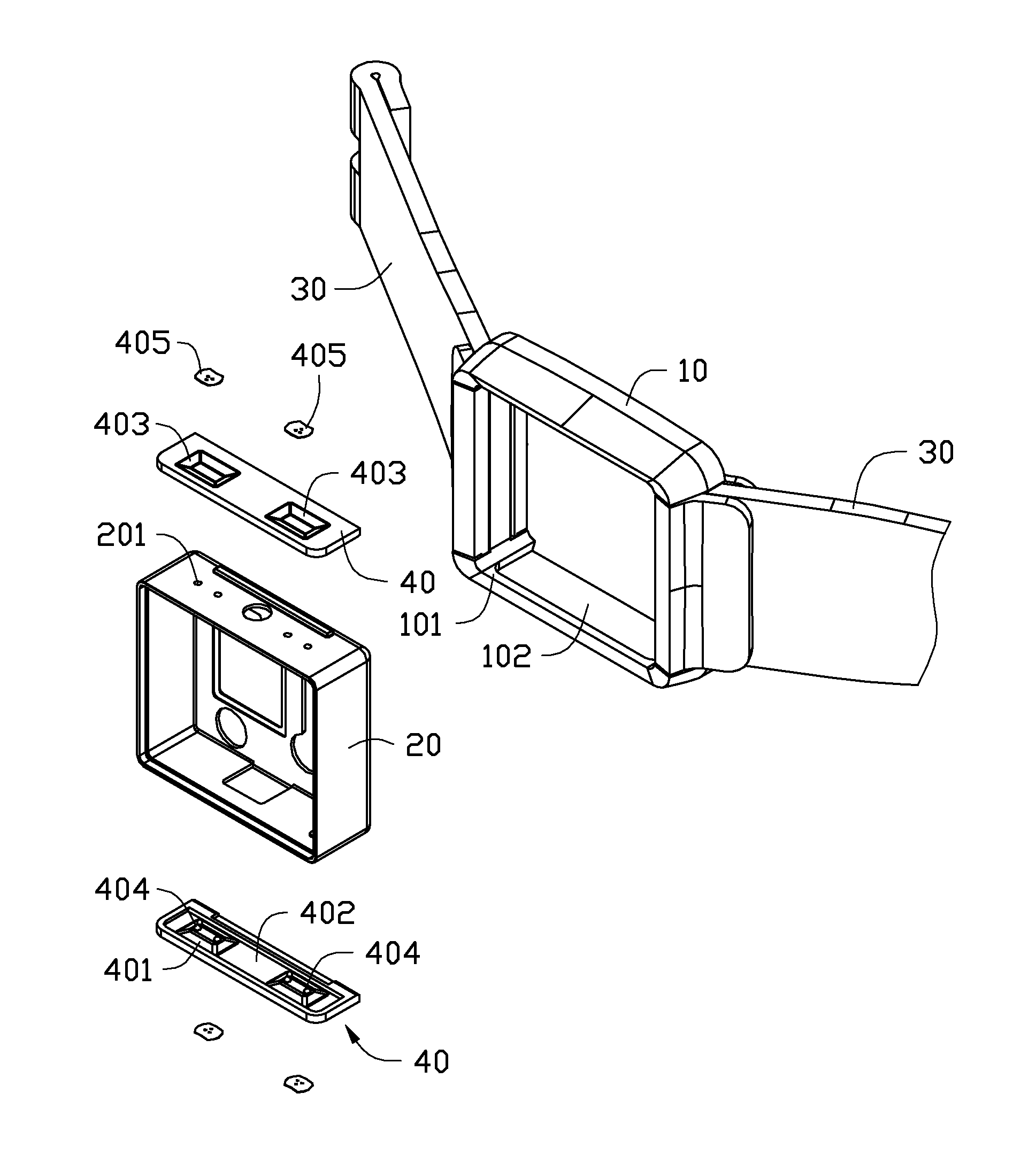

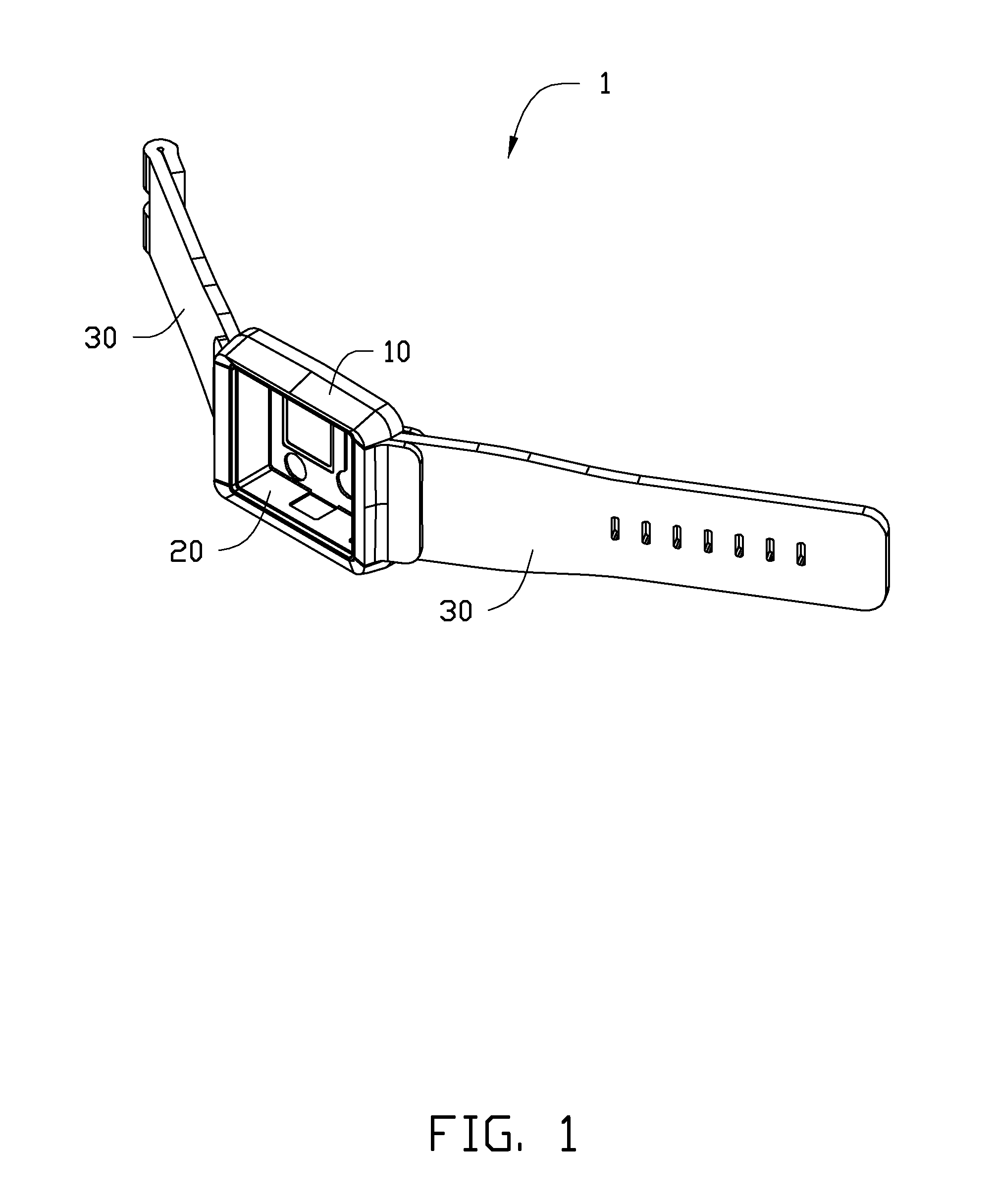

Wearable device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Clamping device having indirect driving mechanism

Owner:LEE YUNG JEN

Pole Clamp

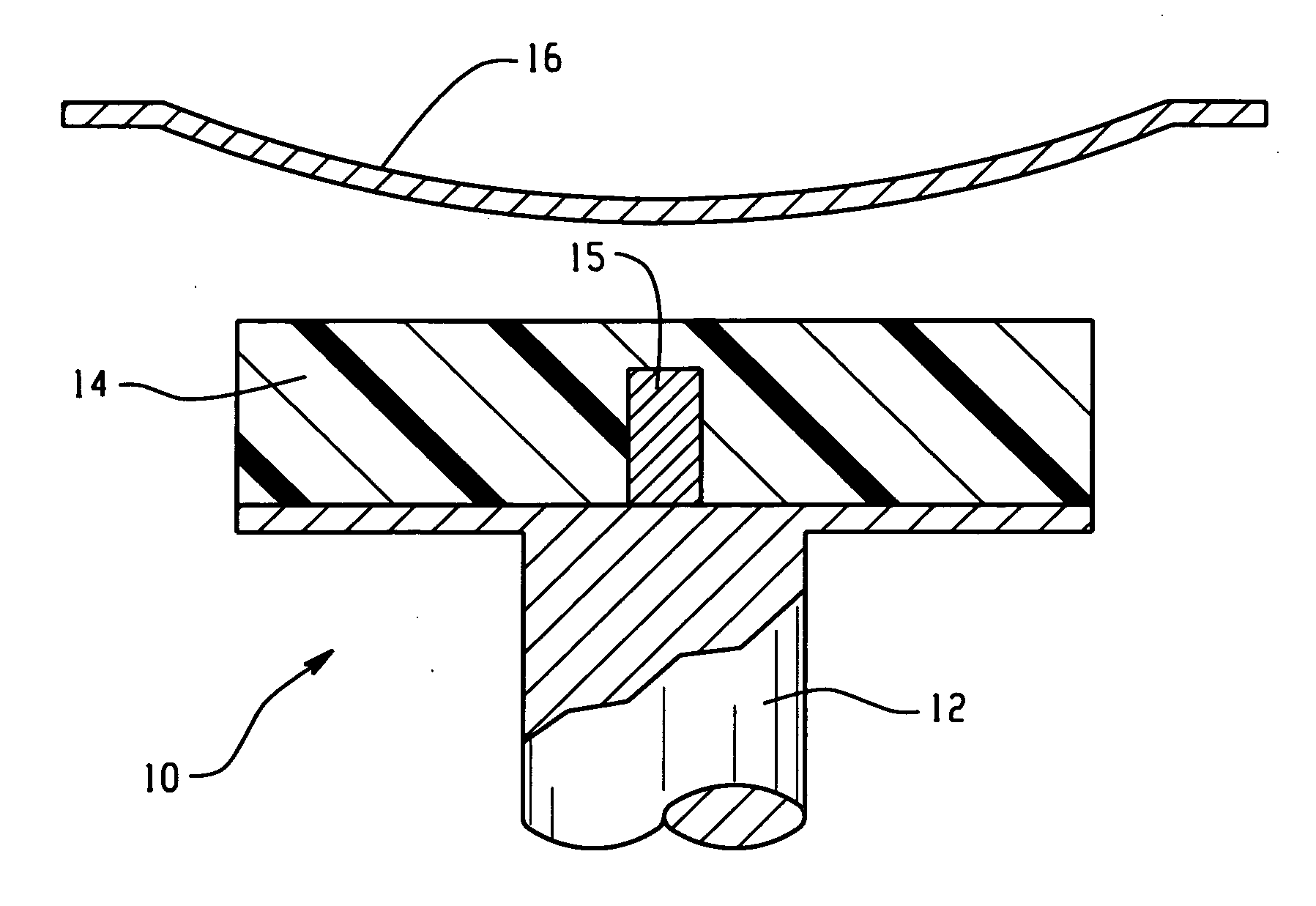

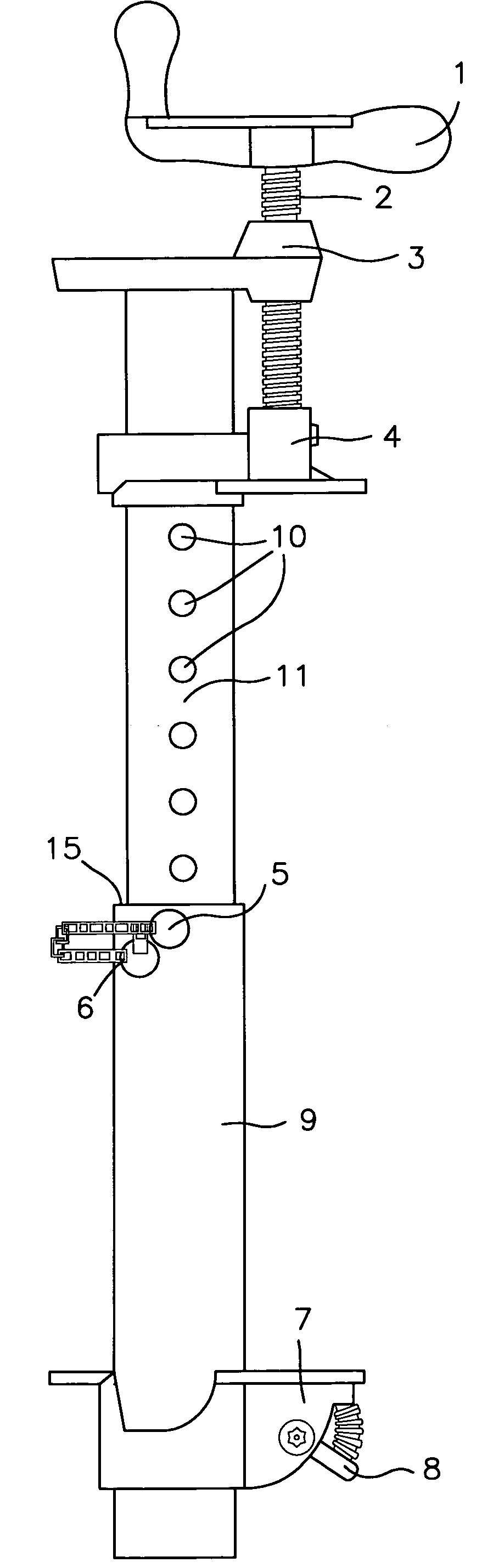

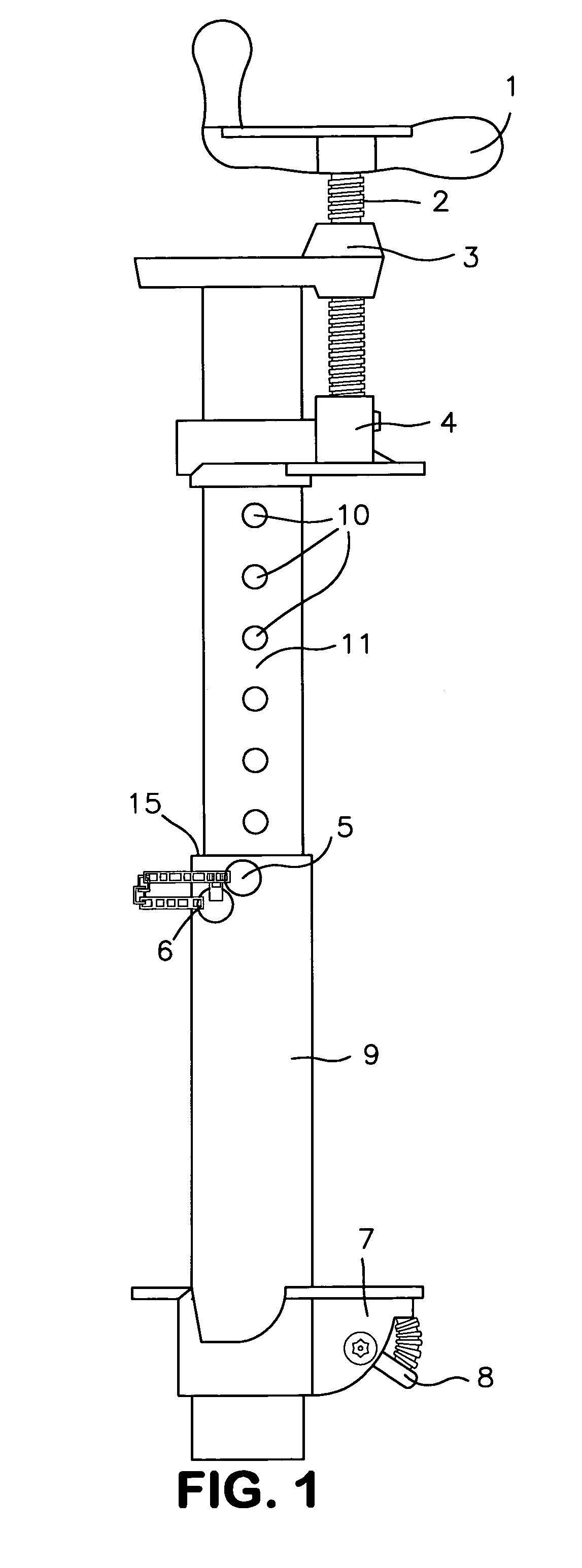

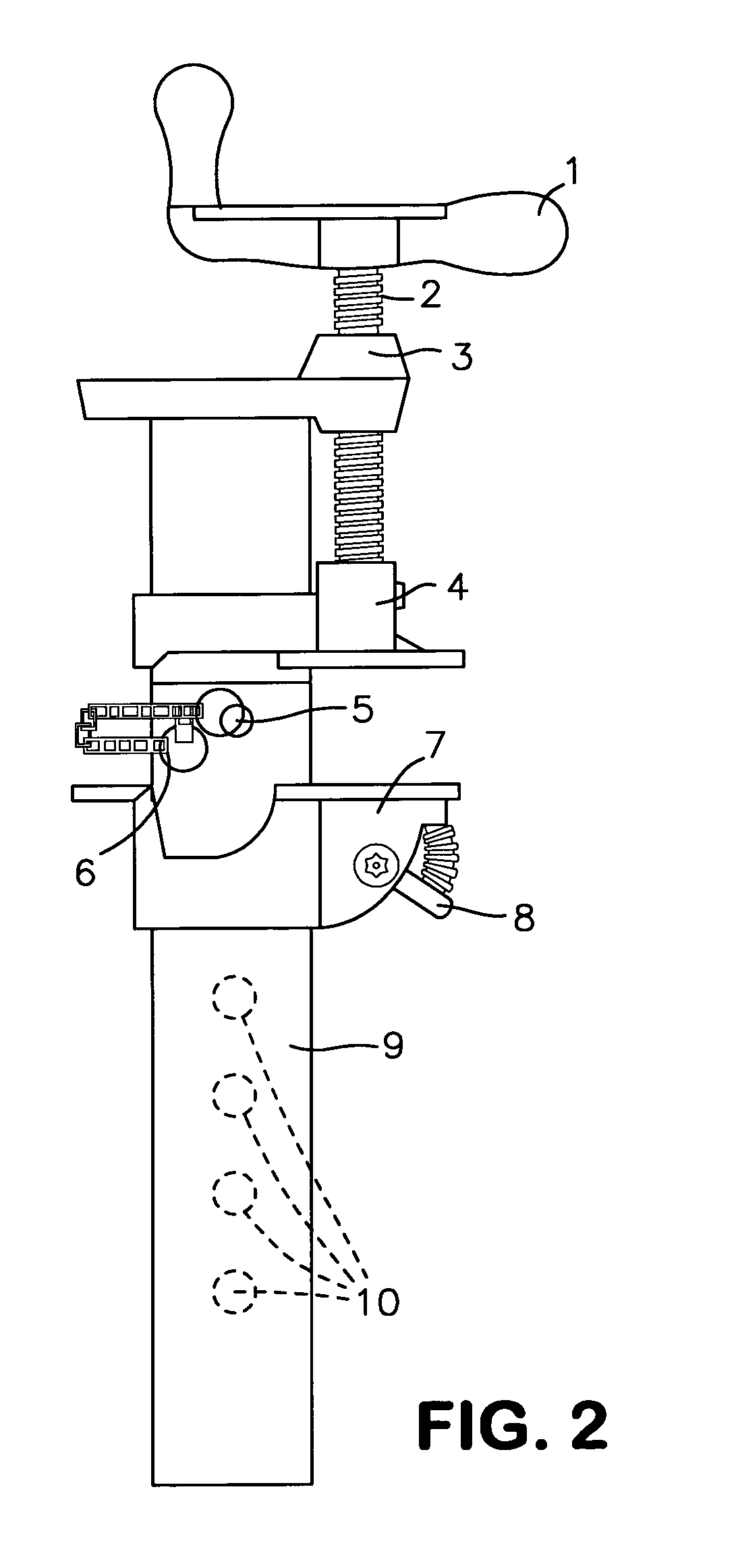

InactiveUS20100314517A1Easy for to turn shaftEasy to processOperating tablesNutsPush and pullWide gap

A pole clamp has two legs wherebetween poles of different diameters may be positioned. One of the legs is configured to grip one side surface of the pole. The other leg of the clamp member has a channel through which a threaded shaft is movable along a longitudinal axis toward the one leg. Also formed in the other leg is a bore orthogonally to the channel. A guide that may be in the form of a half nut is movable within the bore, with the threaded surface of the half nut being in a threaded relationship with the threads of the shaft, when the guide is in a first position, so that the shaft is movable along the axis when it is turned. The guide is movable to a second position to disengage its threaded surface from the shaft. When thus disengaged, the shaft is movable bidirectionally along the axis by simple push and pull movements. A second embodiment of the pole clamp utilizes a yoke slider guide having two arms with a narrow gap and a wider gap between the two arms.

Owner:SMITHS MEDICAL ASD INC

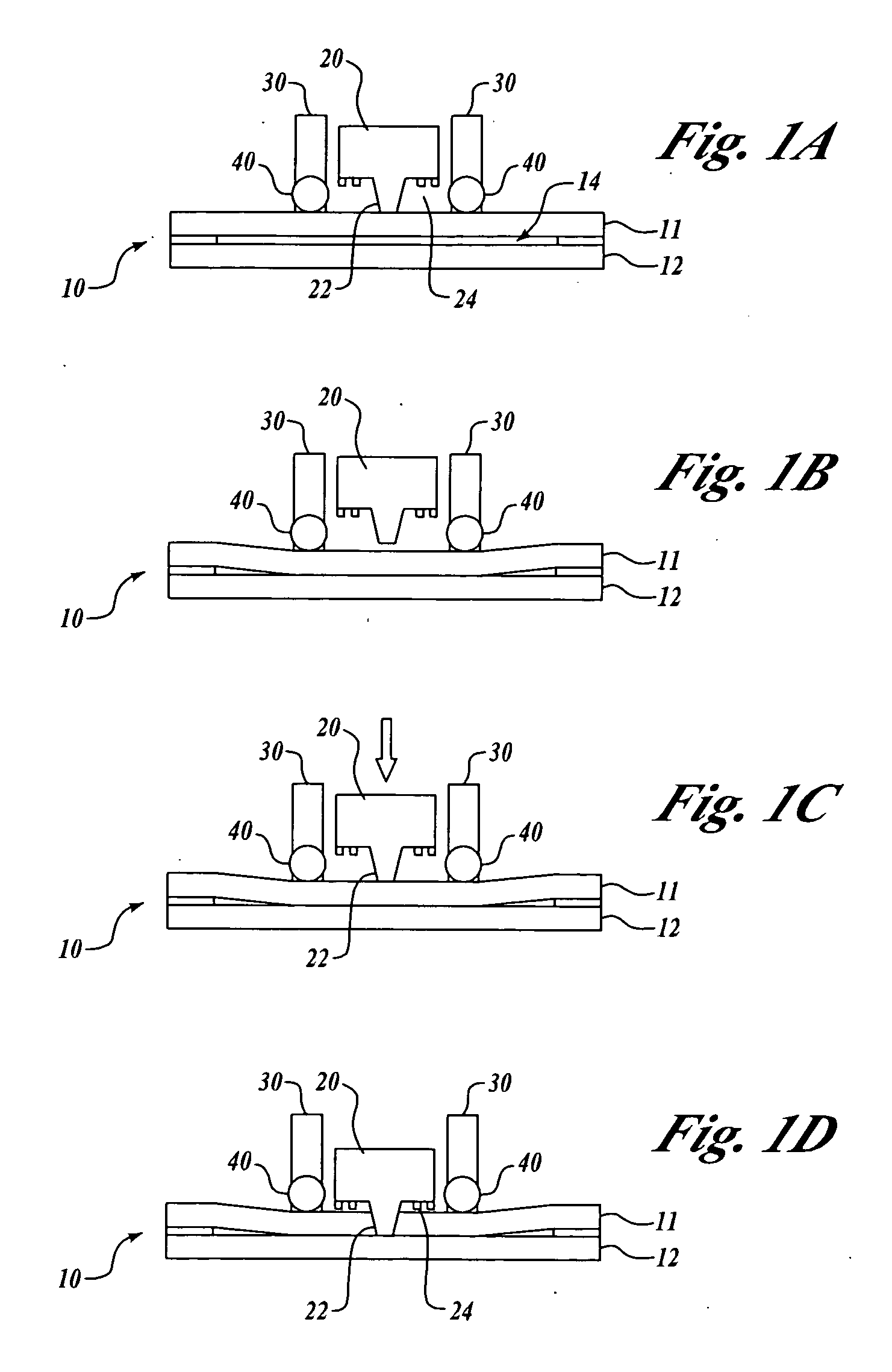

Reconfigurable fixture device and methods of use

ActiveUS20060156785A1Efficient executionShaping toolsMeasurement/indication equipmentsActuatorBiological activation

A reconfigurable fixture device system, including: a base member; a reconfigurable pad disposed on the base member, wherein the reconfigurable pad comprises a shape memory material configured to selectively conform to a surface contour of a workpiece; an activation device in operative communication with the shape memory material; a controller in operable communication with at least one of the reconfigurable pad, the activation device, and the base member; a plurality of sensors for sensing a parameter associated with at least one of the reconfigurable pad, the base member, the fixture device, and the workpiece, wherein the plurality of sensors is in operable communication with the controller; and an actuator in operable communication with the controller and the at least one of the reconfigurable pad, the base member, the fixture device, and the workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Apparatus for securing a workpiece

An apparatus for securing a workpiece comprising first and second clamp members, and a transportable elongate member to which the clamp members are mounted and are operable for being shifted between work engaging and work releasing positions. In one form, the apparatus may be configured with clamp members capable of being fully removed from the elongate member and placed back thereon while maintaining the operability of the clamp members. At least one of the clamp members may be capable of being mounted on the elongate member in a plurality of directions, or may include jaw assemblies which are removable from and / or rotatable with respect to the elongate member. In addition, the apparatus may include a base for securing the base to a work surface and a catch for securing the elongate member to the base. In another form, the base may be configured to receive and secure the elongate member in a plurality of directions.

Owner:JPW IND

Extendable aluminum bar clamp

A bar clamp including a first bar member and a second bar member with the second bar member telescoping out from the first bar member. A securing mechanism, such as a pin in the first member, releasably secures the members together at a preferred telescoping position. The second bar member has a jaw member that can be advanced or retracted by means of a linear actuator and the first bar member has a jaw member that can be adjusted by positioning the cam-action locking mechanism in one of the notches disposed along the length of the first bar member. As a result of the telescoping relationship of the bar members, workpieces of varying sizes may be clamped between the jaw members without the need of multiple bar clamps of varying lengths.

Owner:HARBOR FREIGHT TOOLS USA

Adaptive robotic gripper

Owner:HARRIS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com