Patents

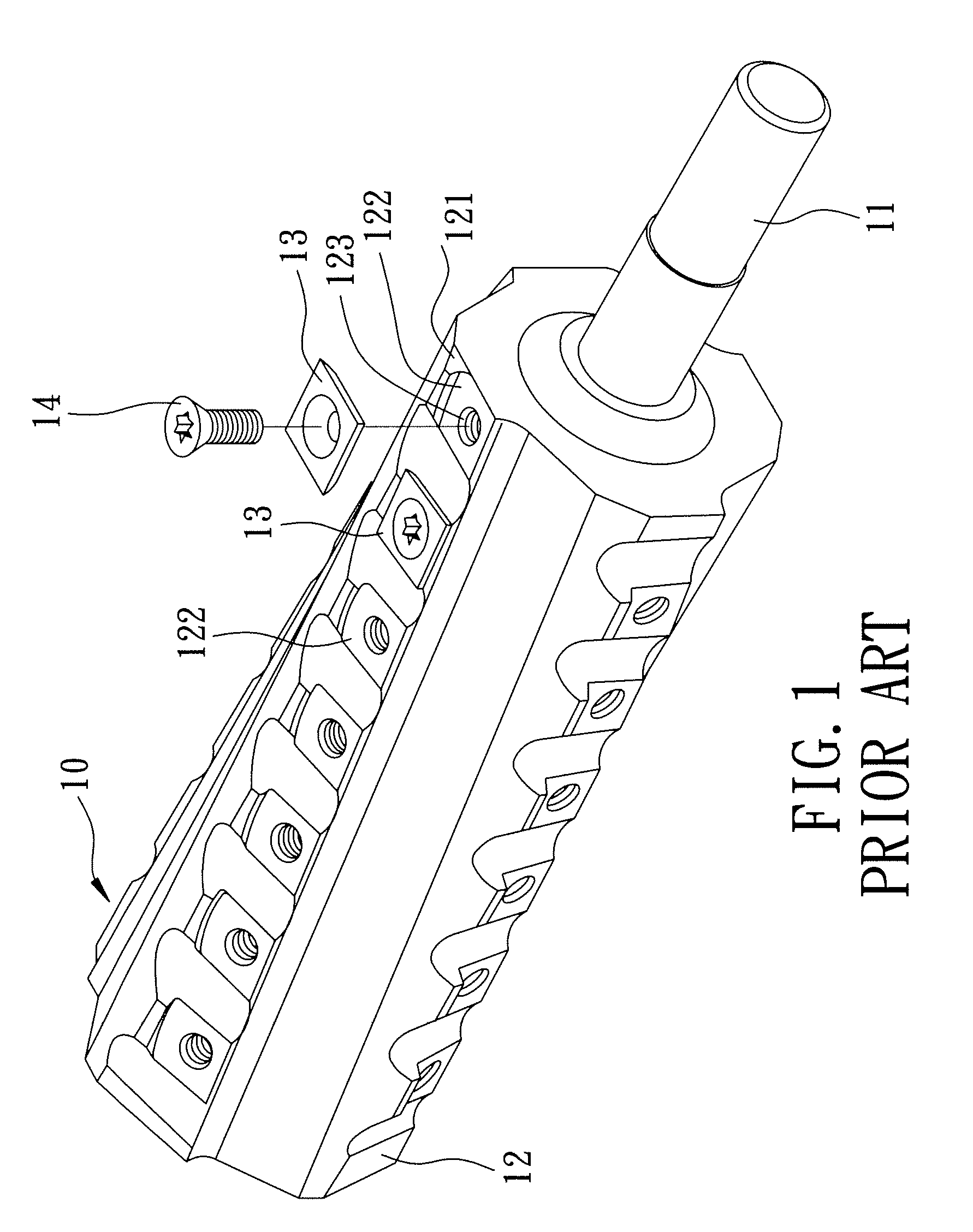

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

505results about "Rotary cutting tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

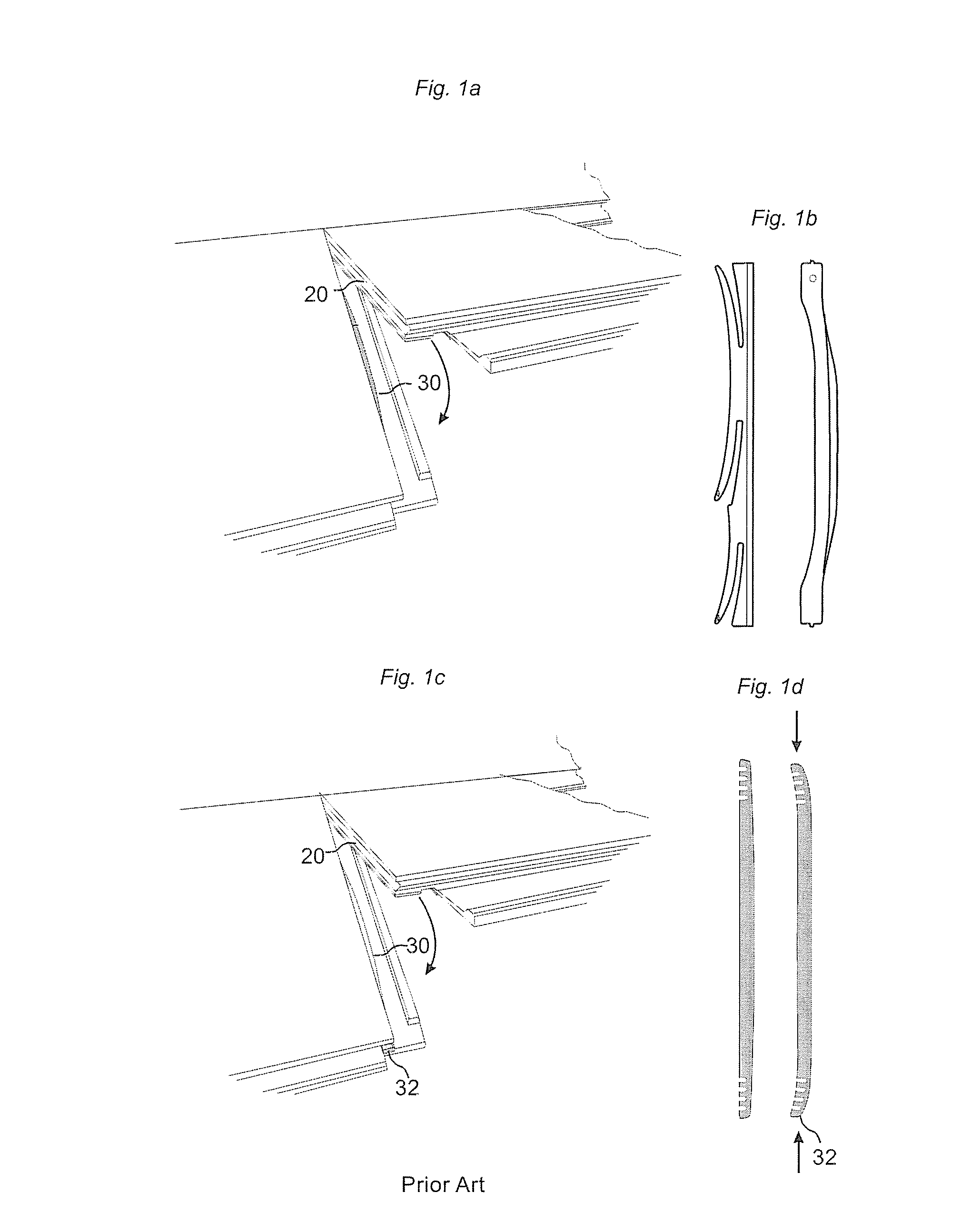

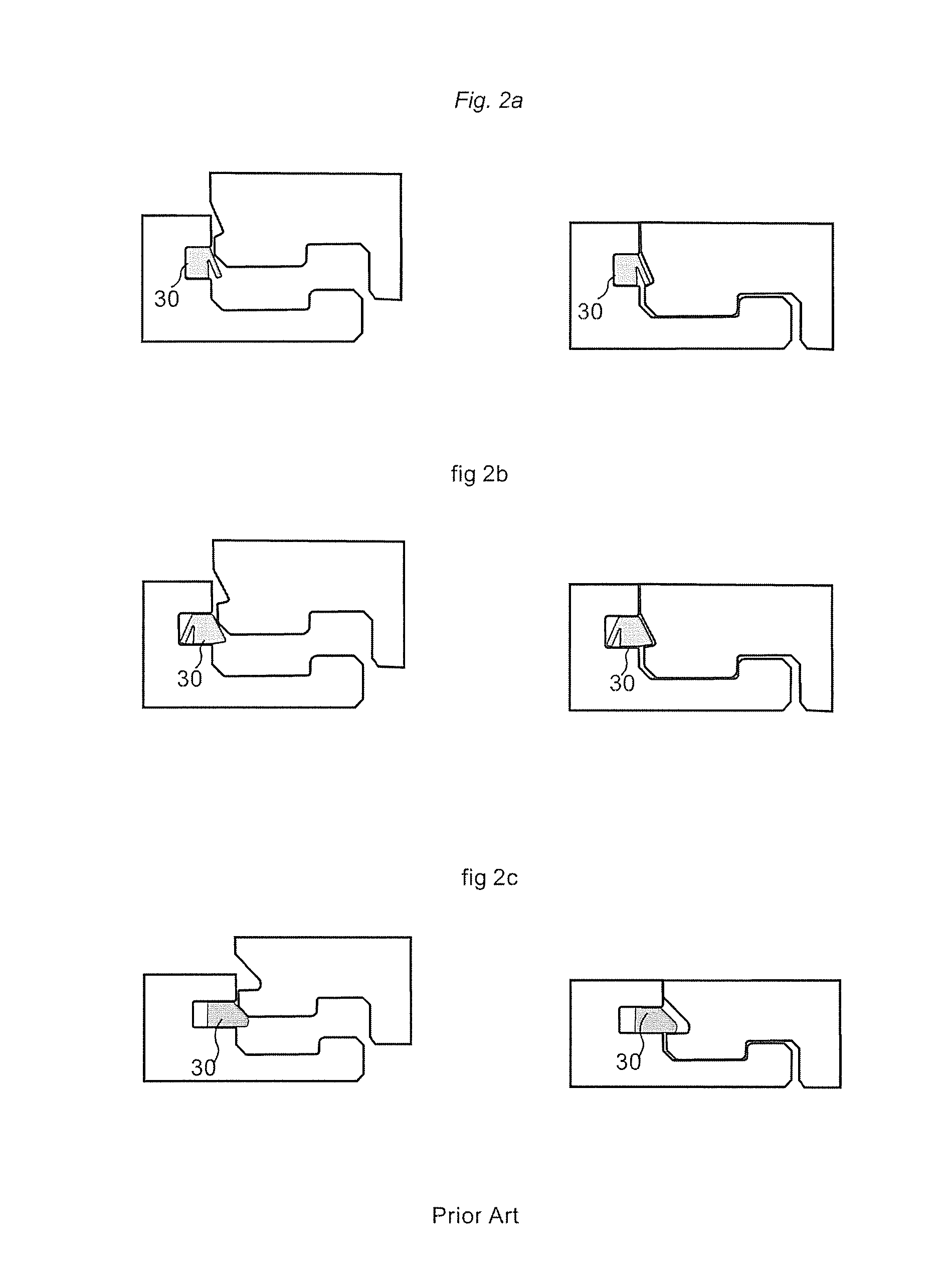

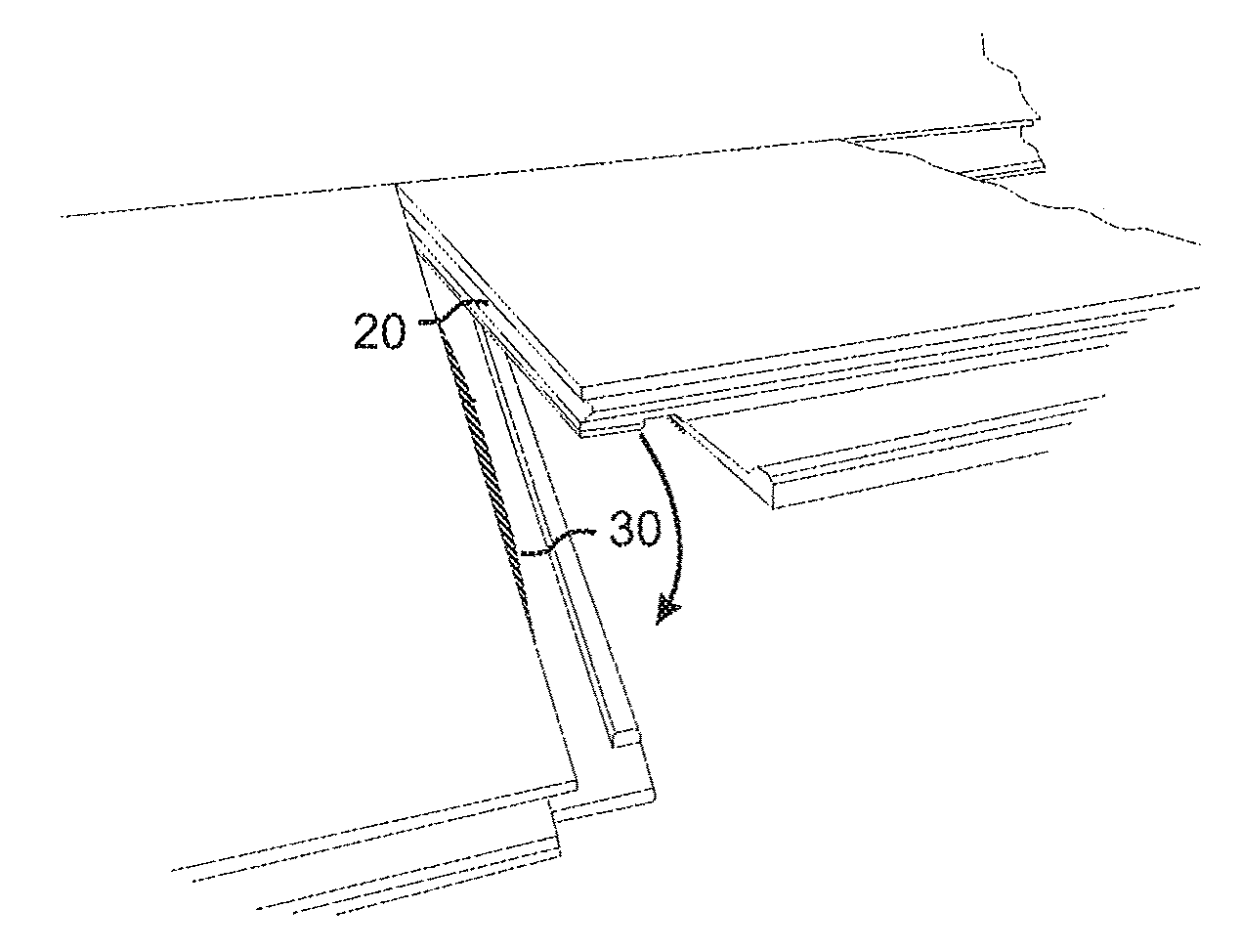

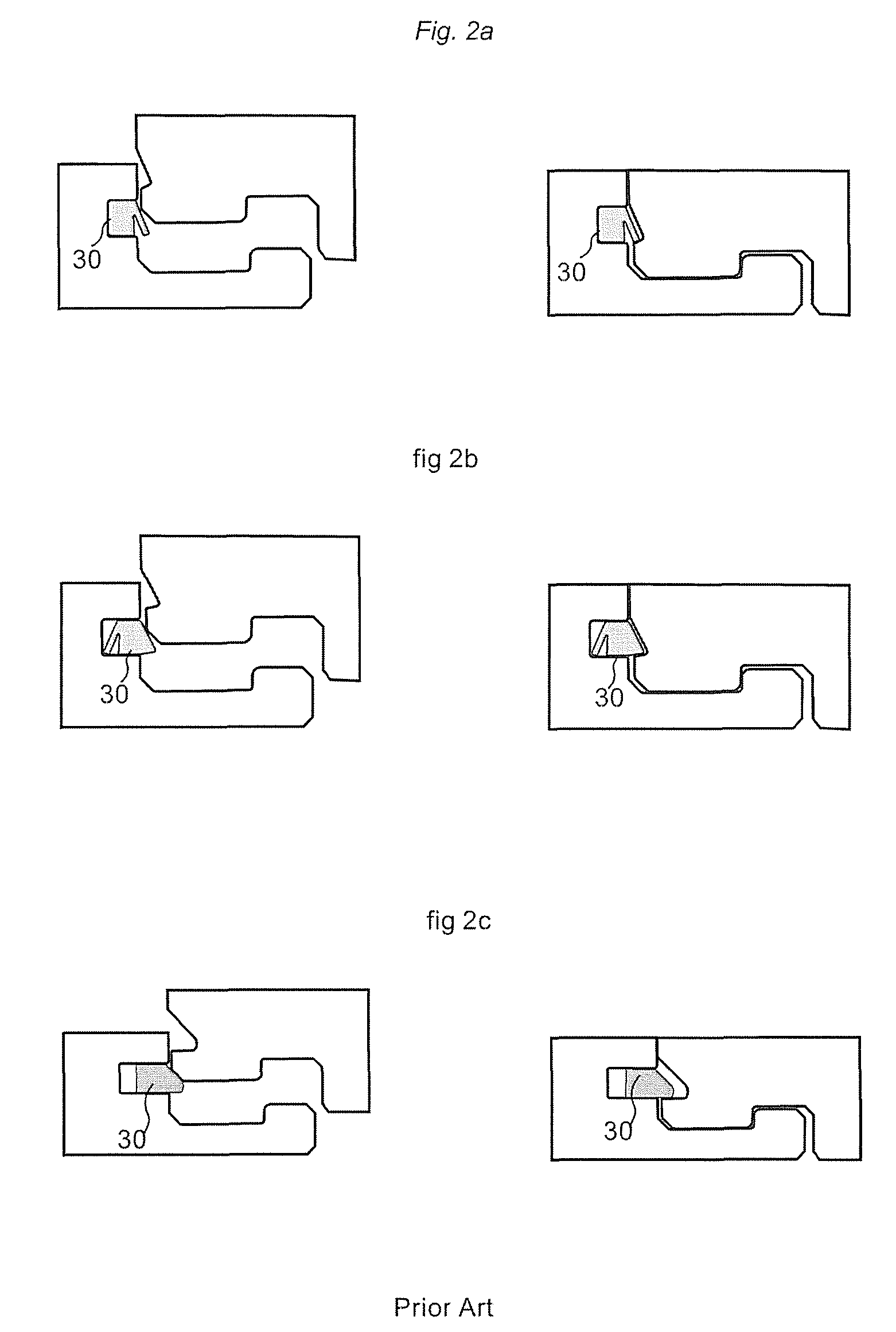

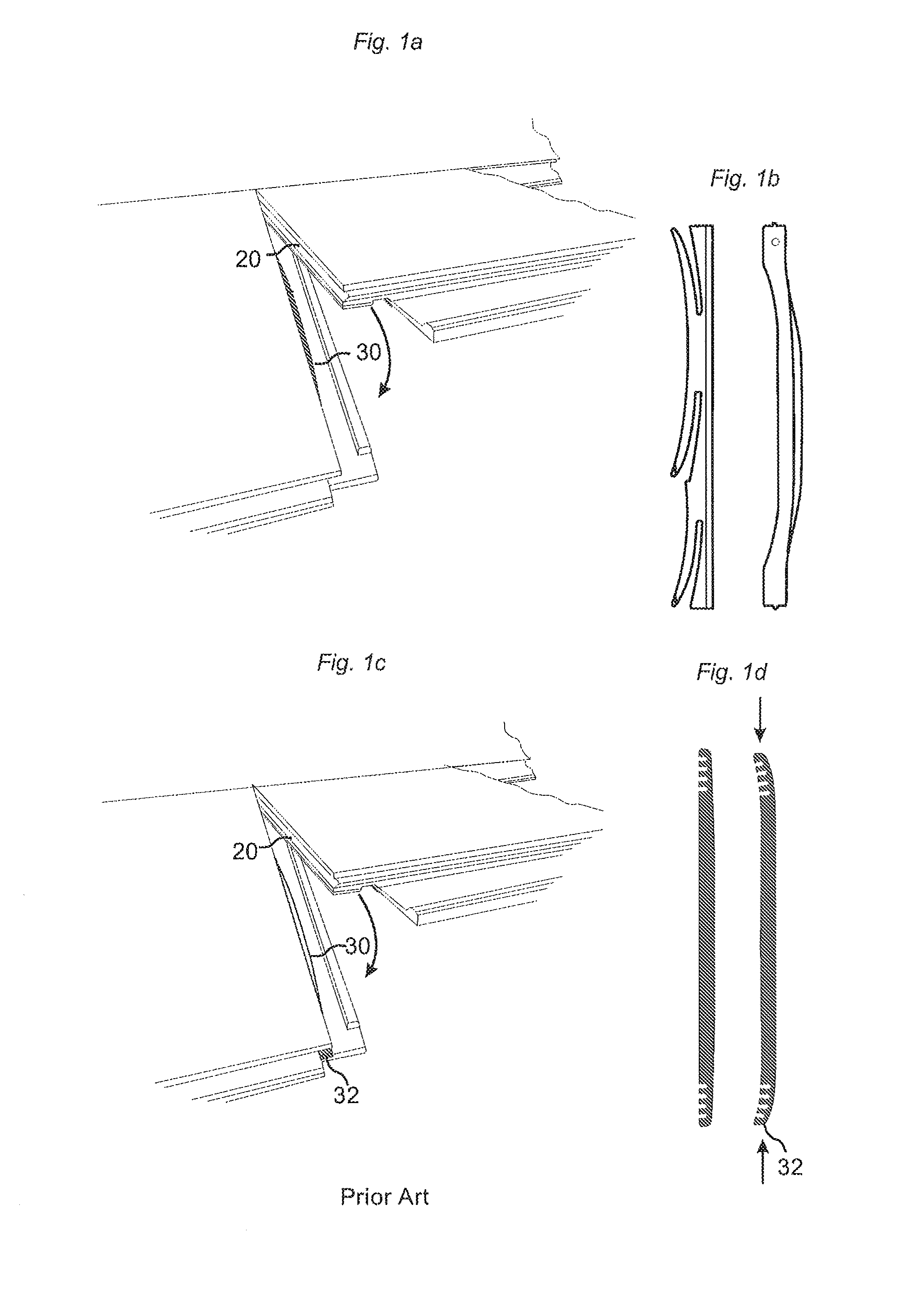

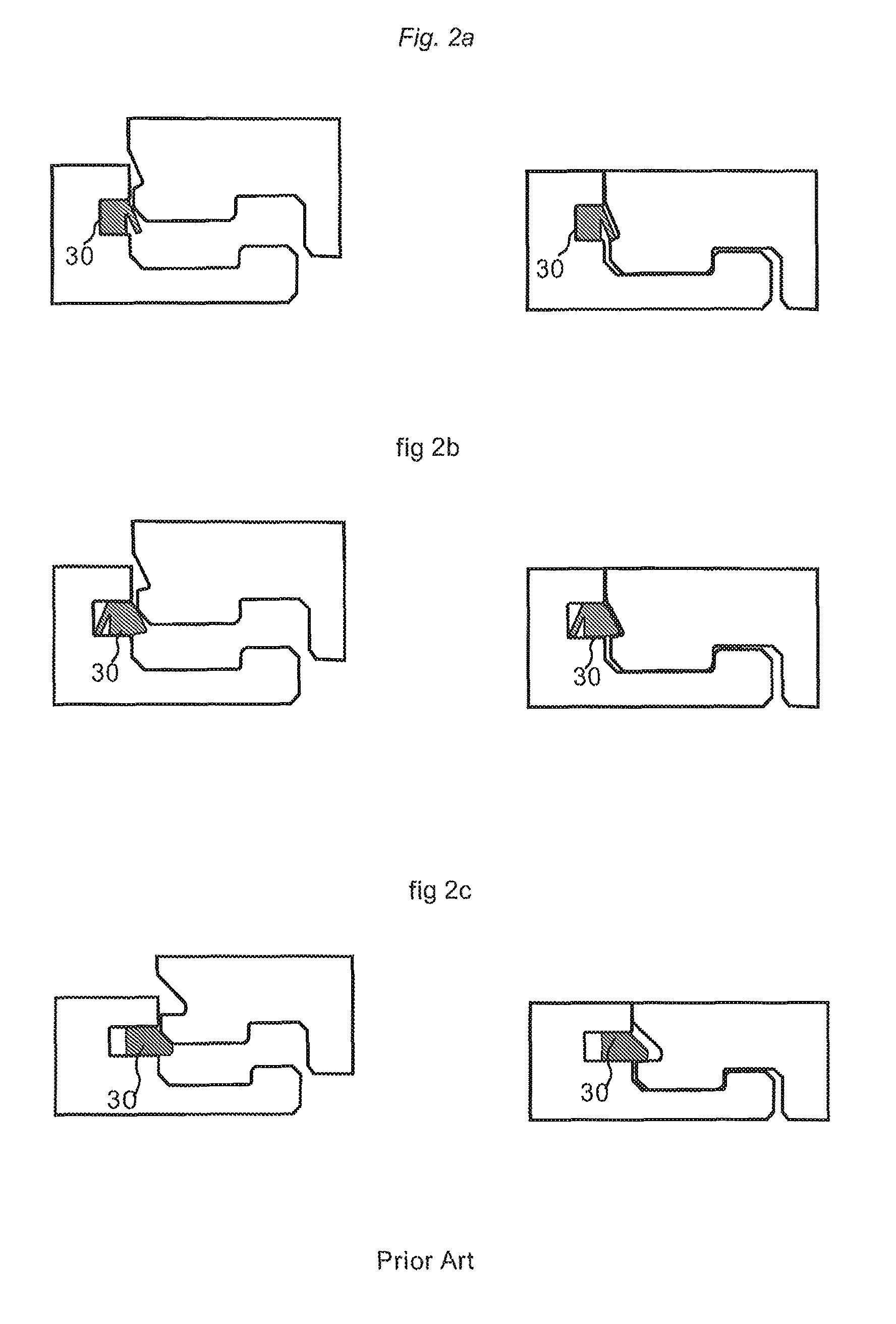

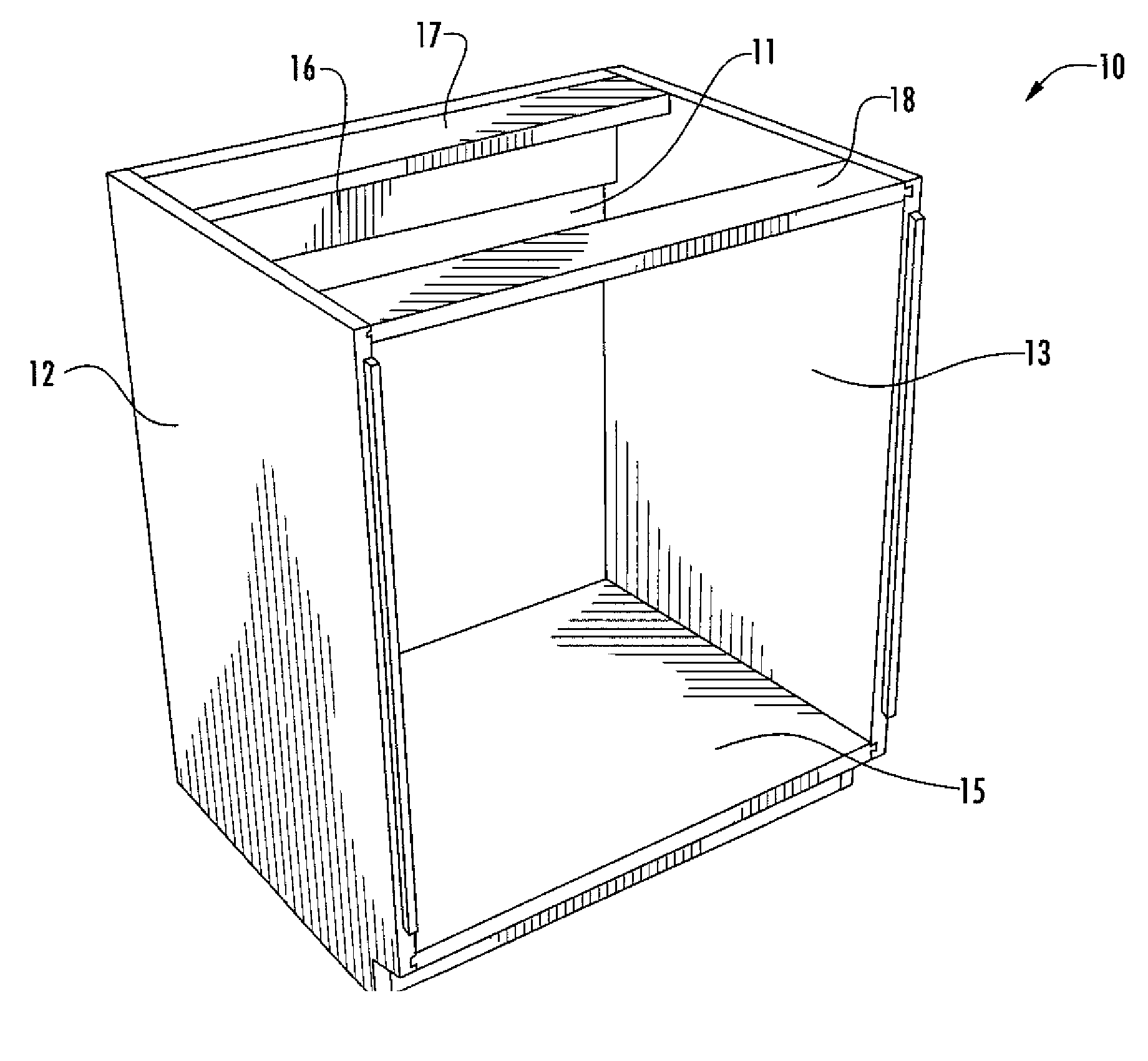

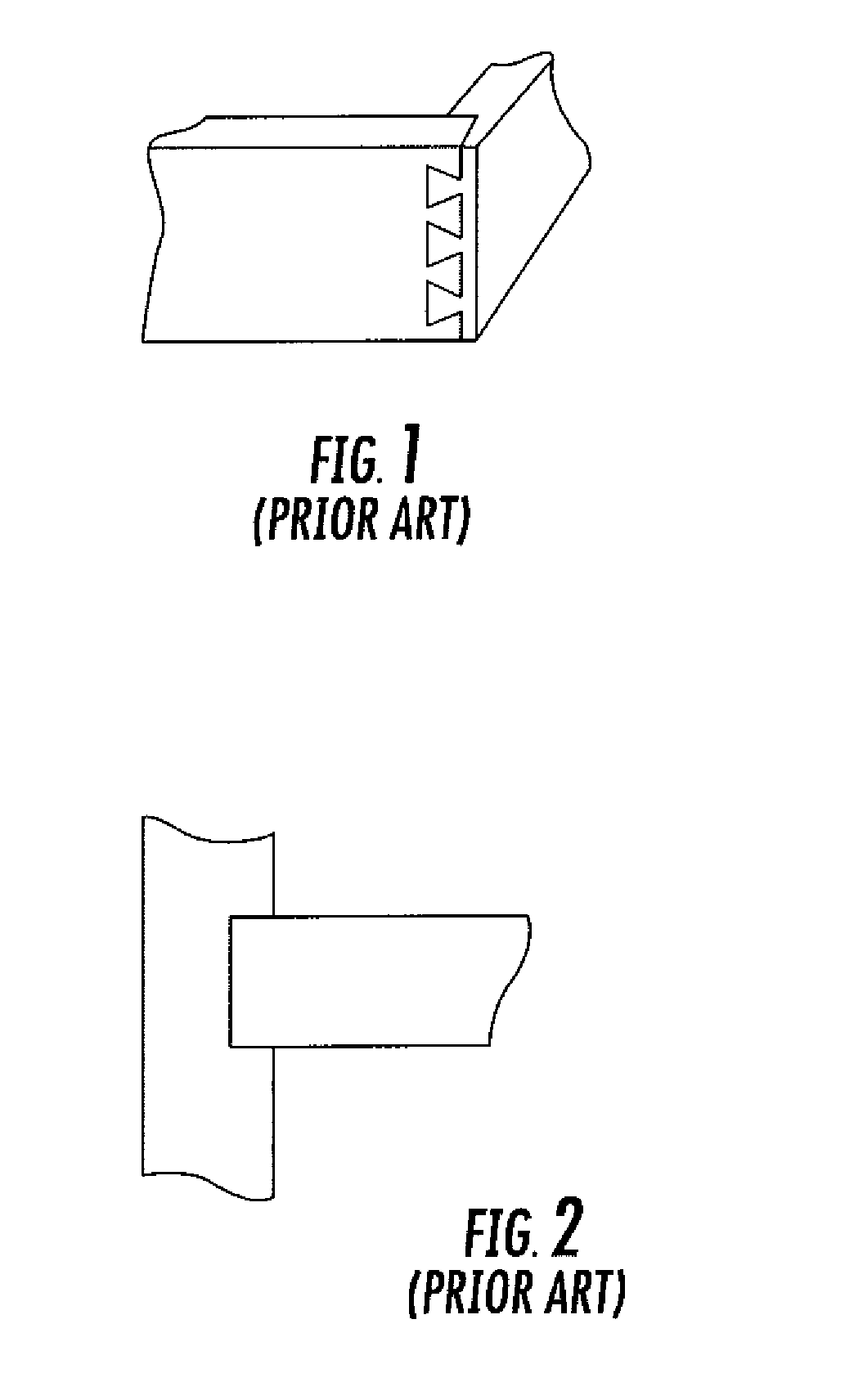

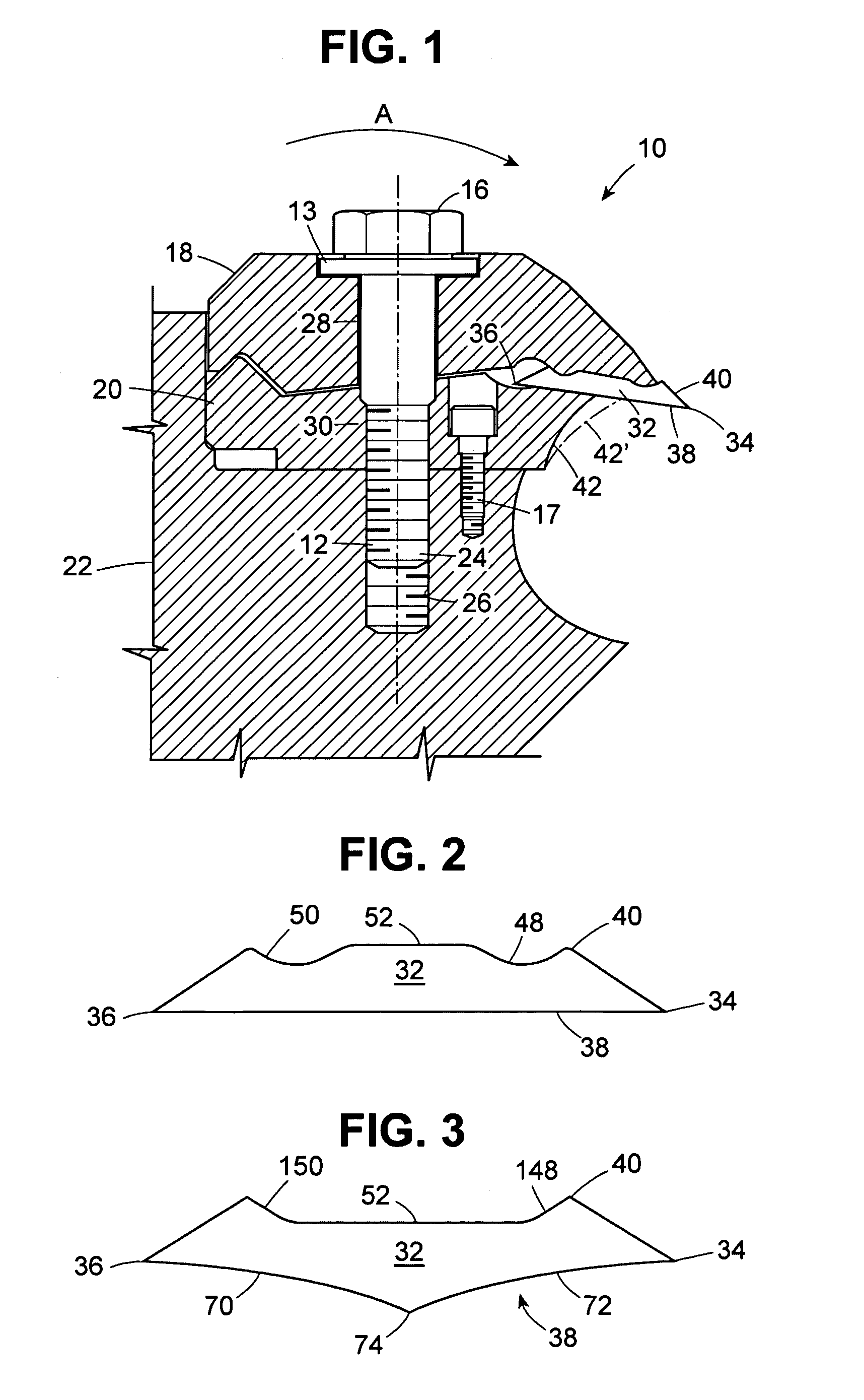

Mechanical locking of floor panels

ActiveUS20090193748A1Avoid vertical displacementReduce vertical frictionTongue/grooves making apparatusWallsEngineeringTongue and groove

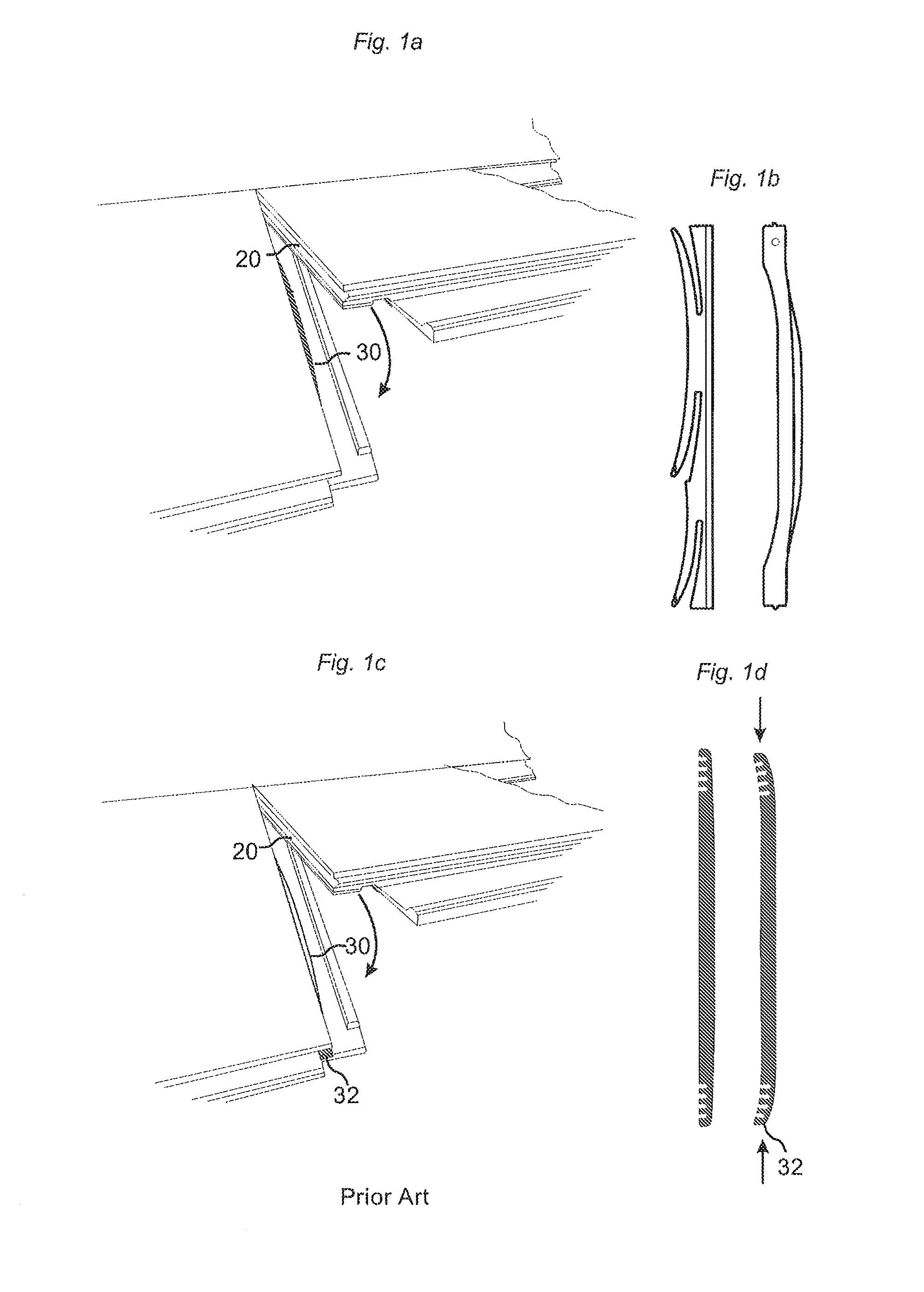

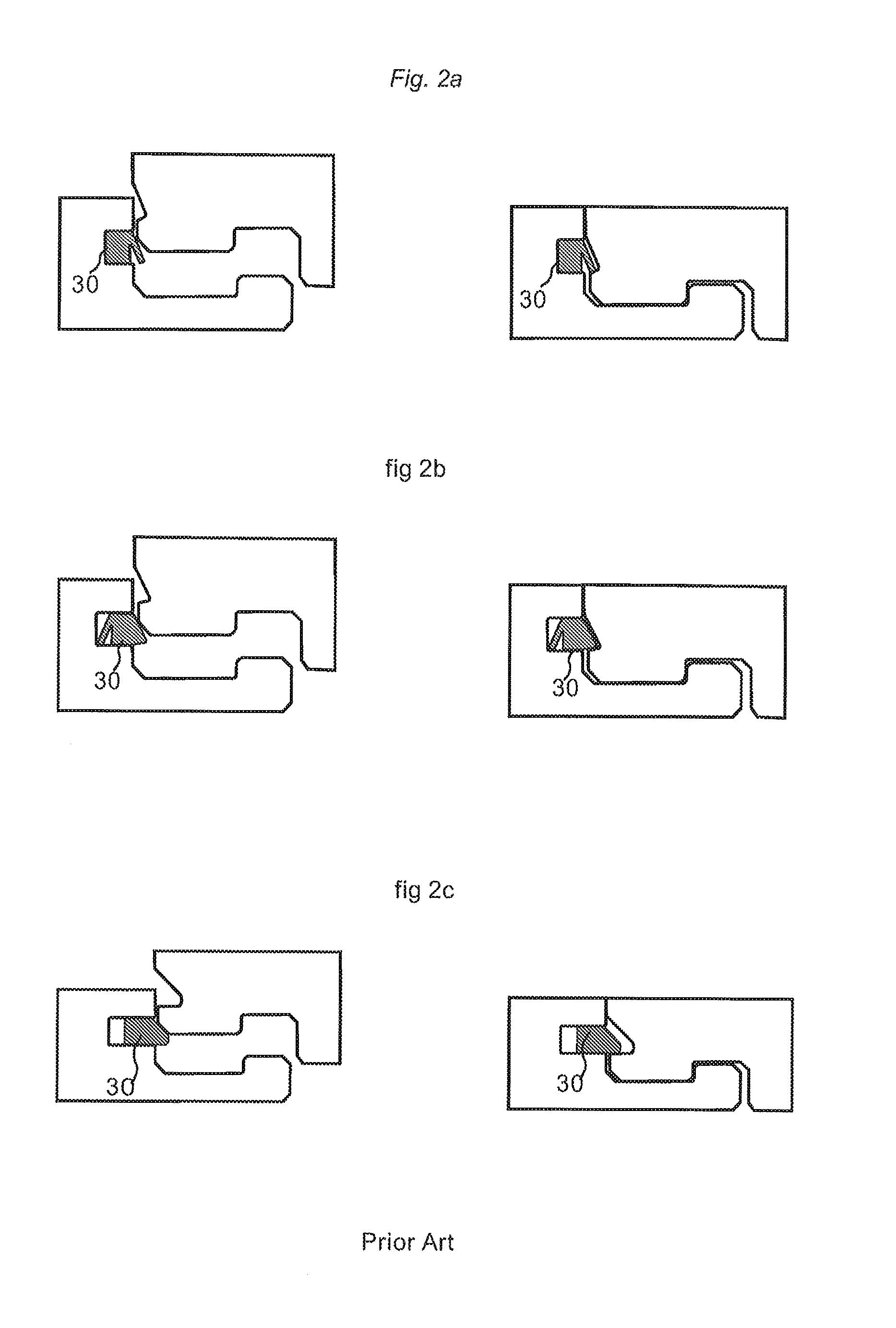

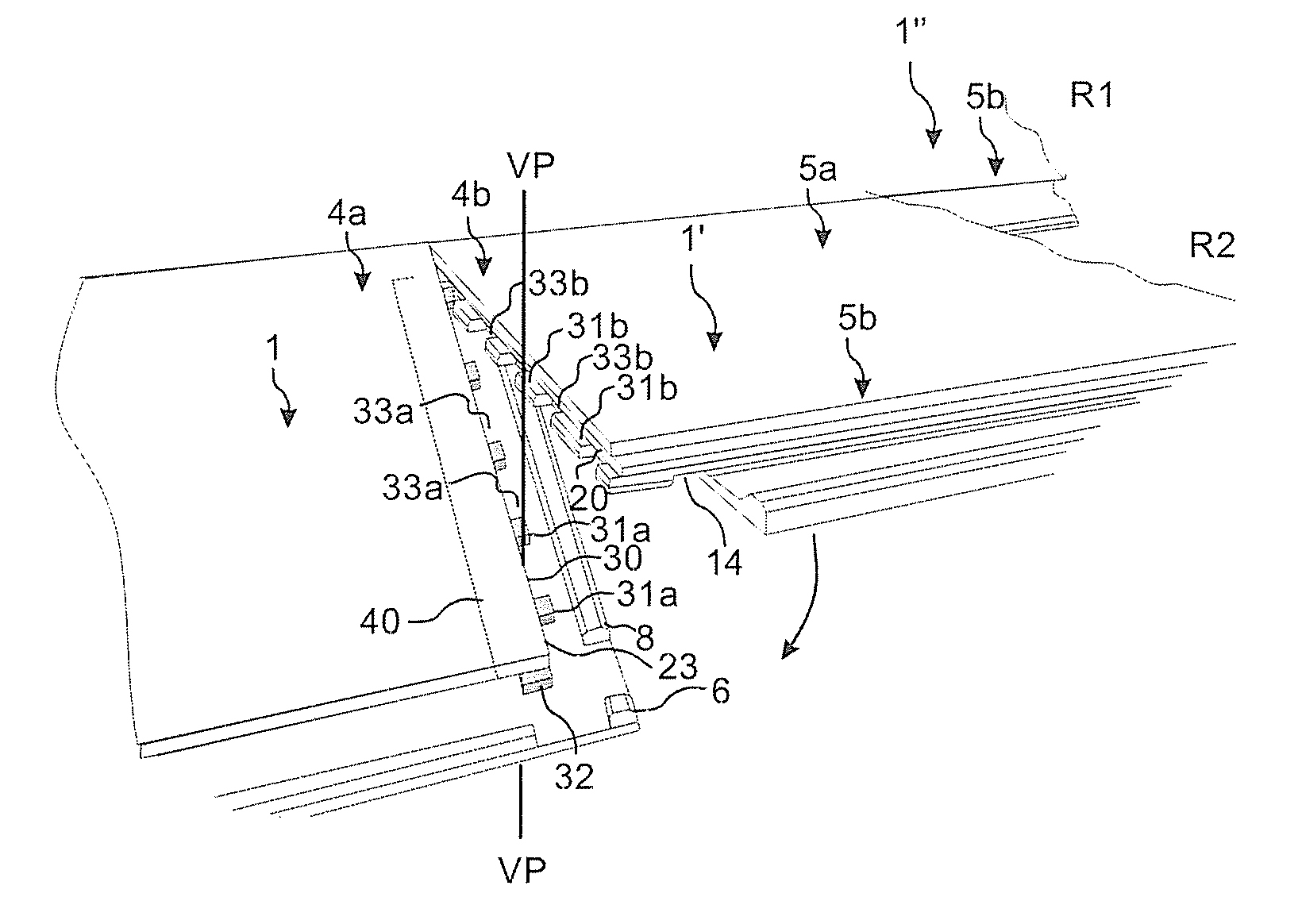

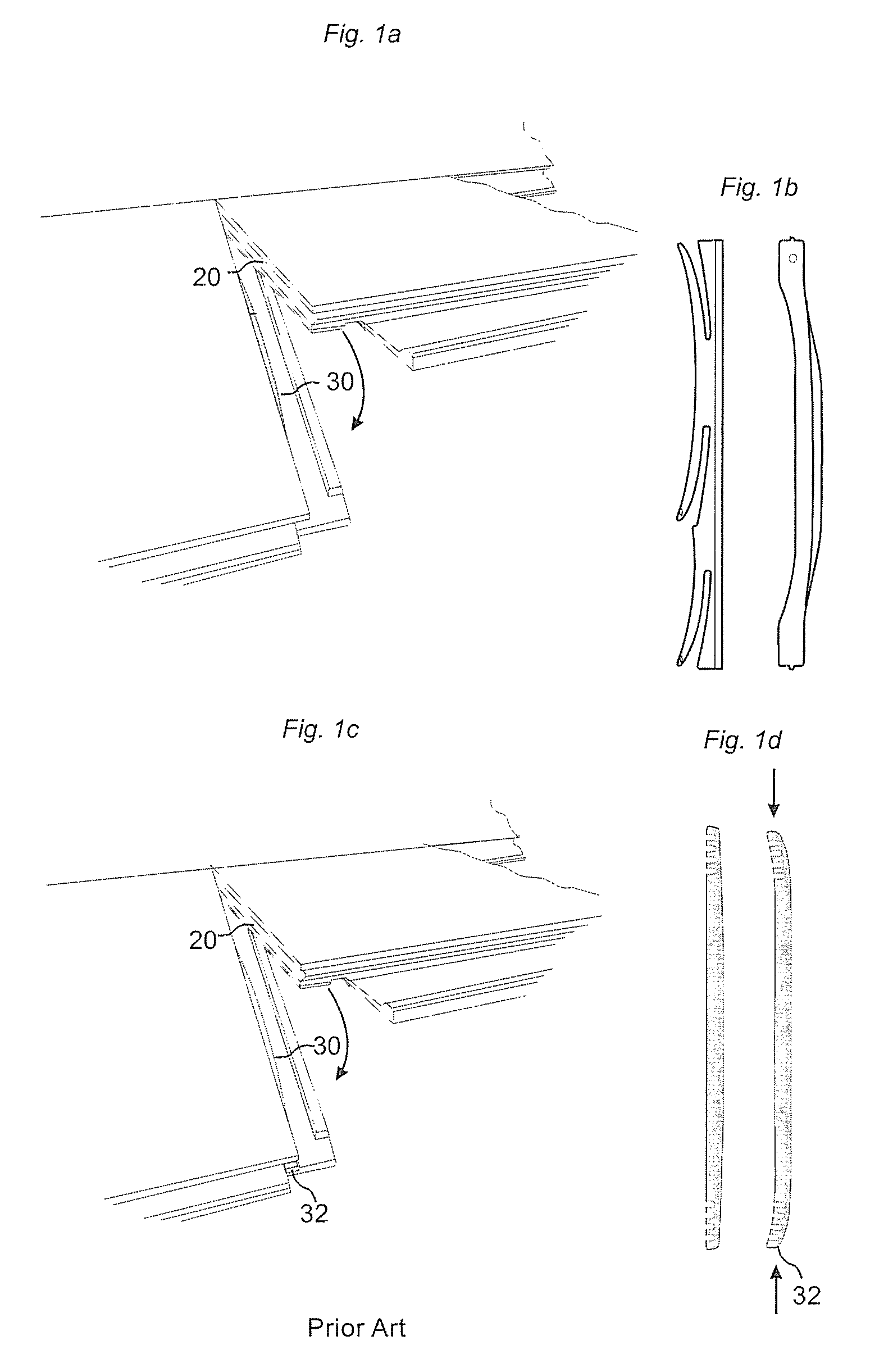

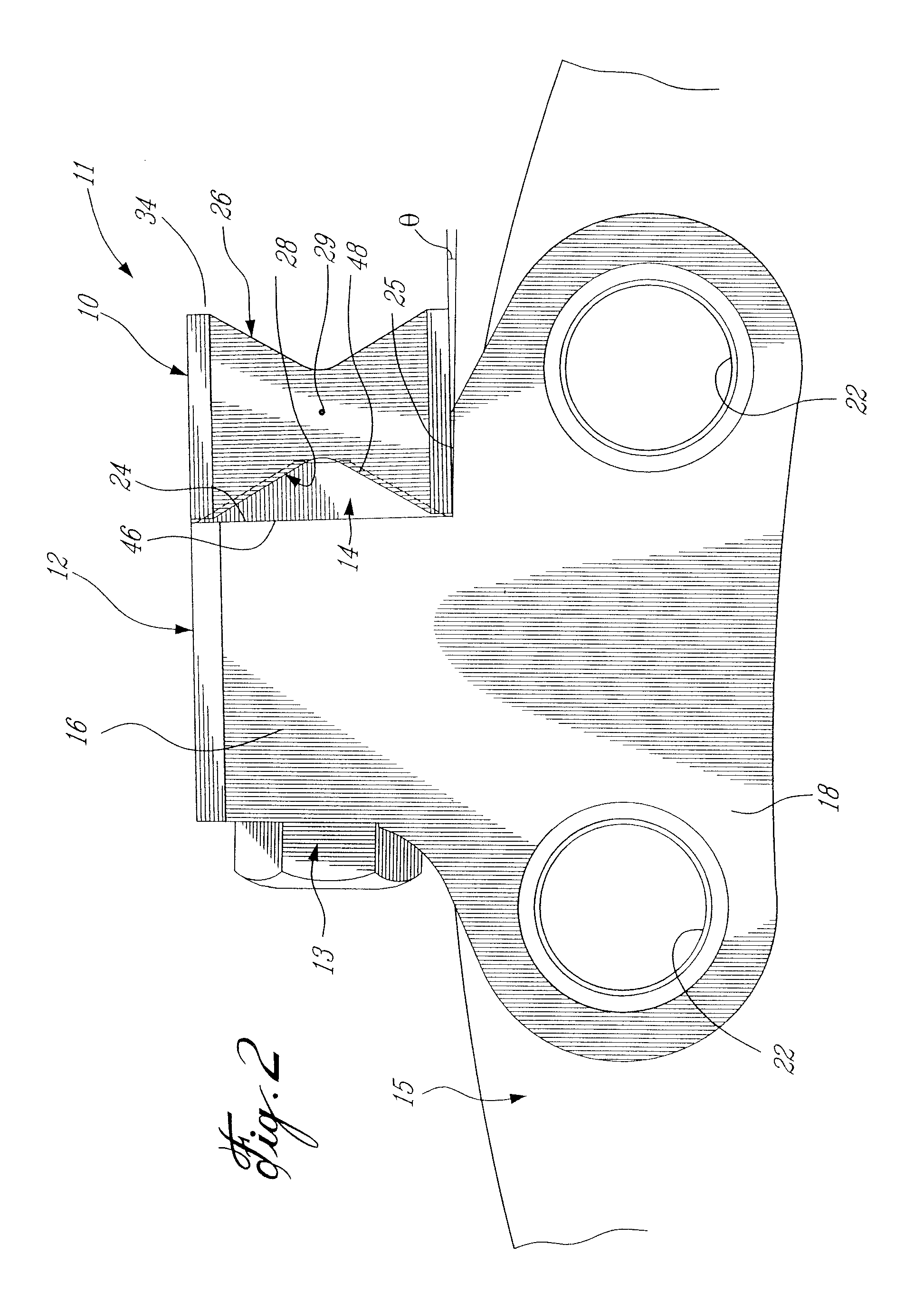

Floor panels are shown, which are provided with a mechanical locking system having tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

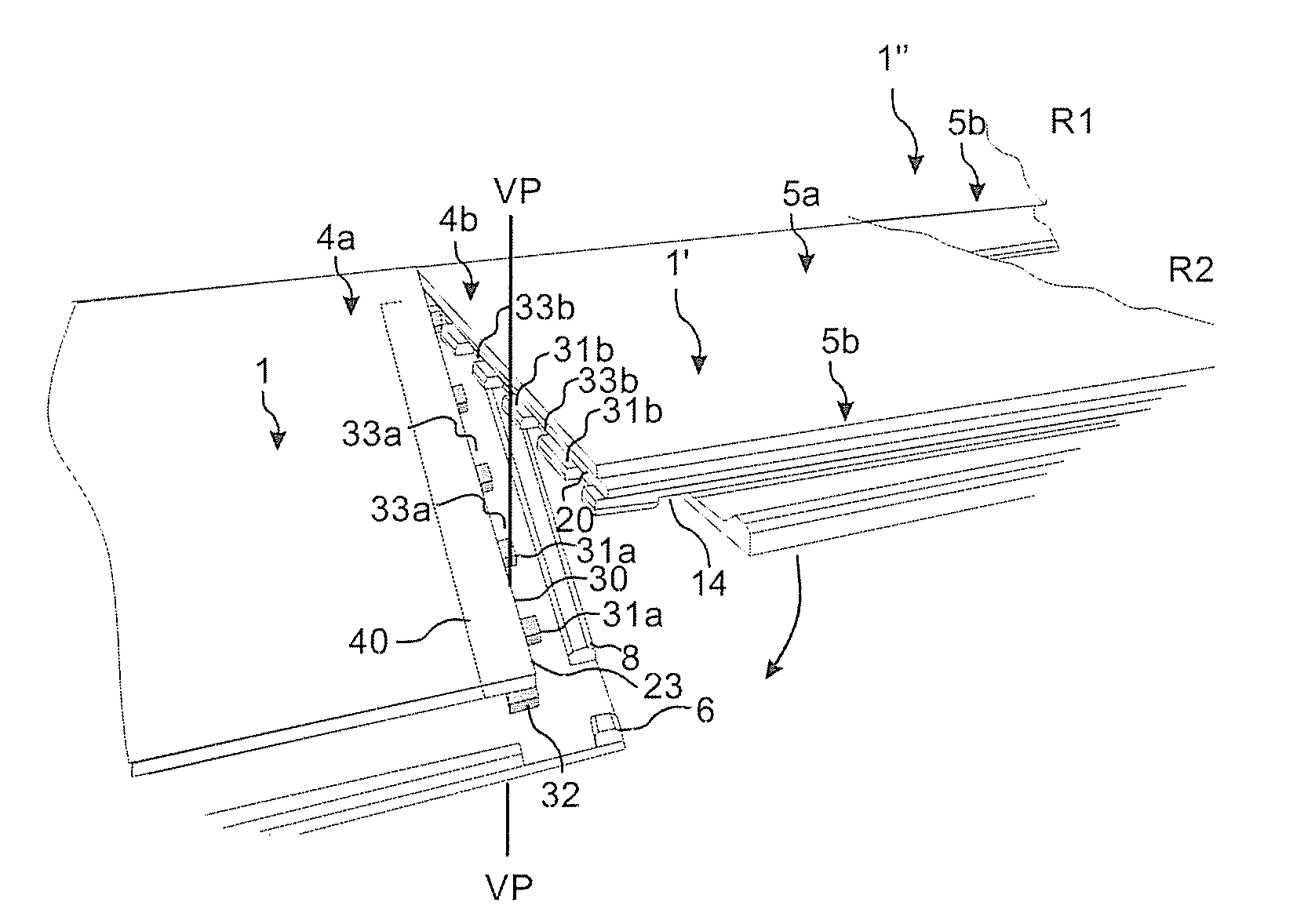

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels

ActiveUS8505257B2Easy to installImprove installation and strength and quality and production costTongue/grooves making apparatusWallsTongue and grooveEngineering

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

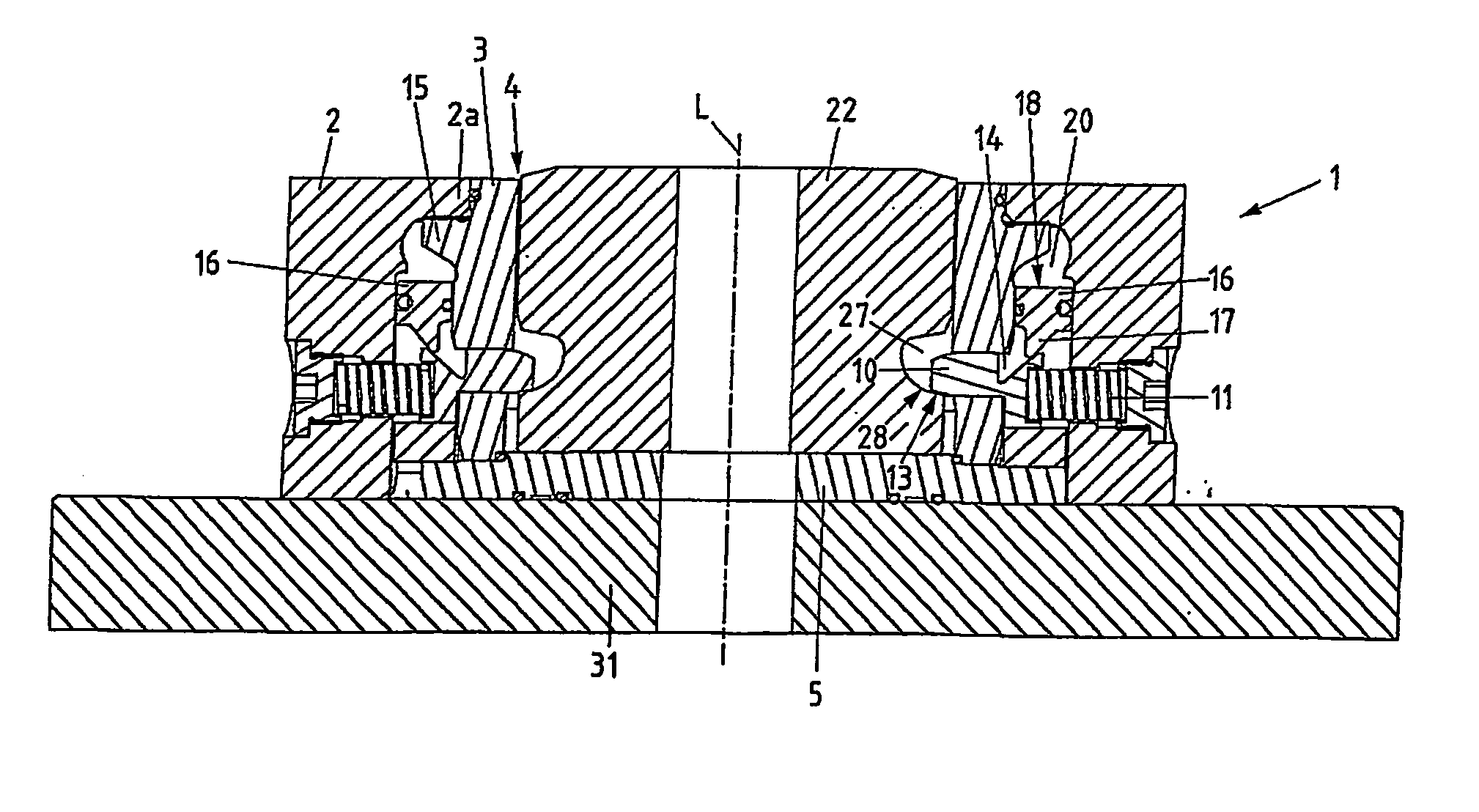

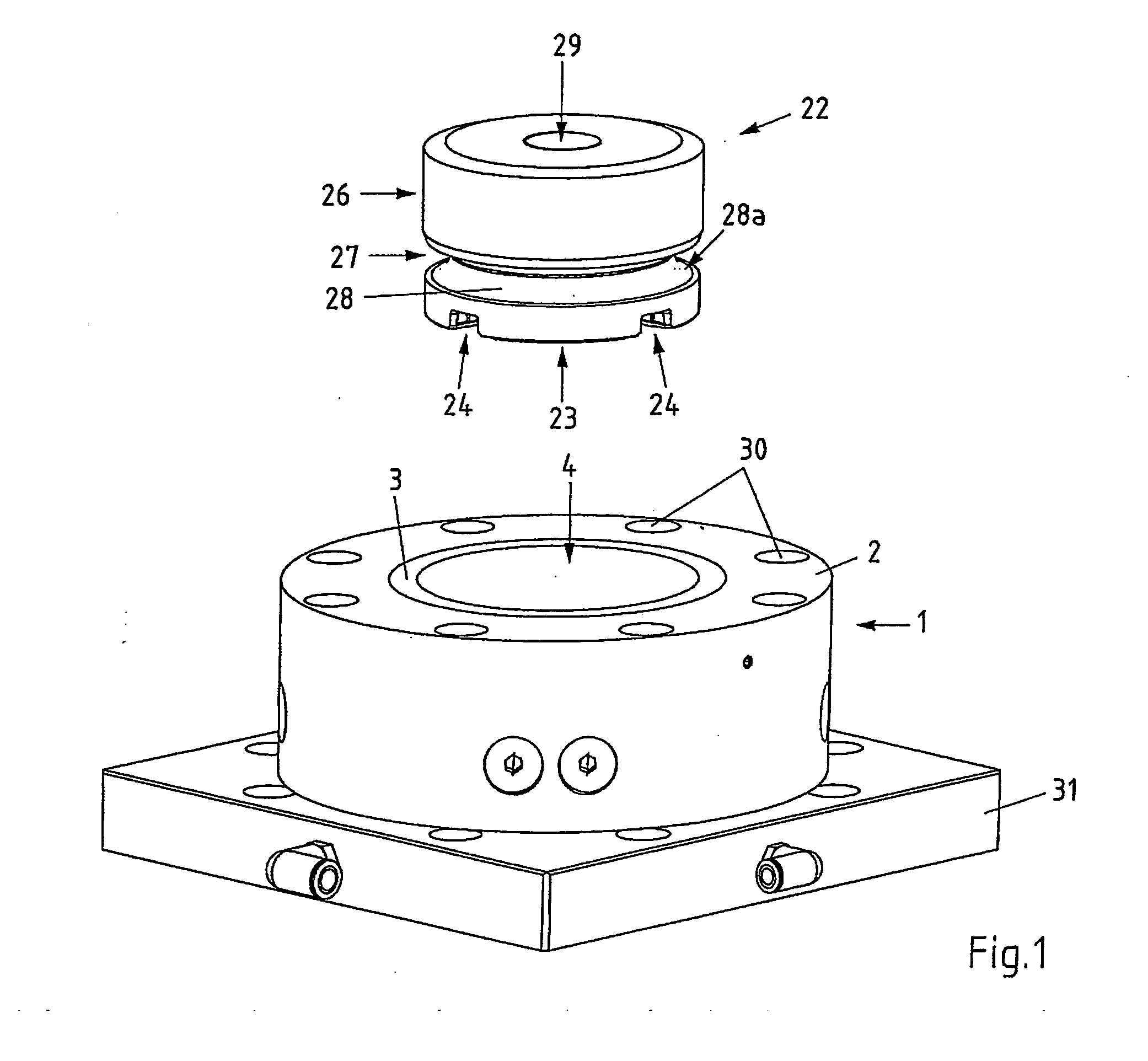

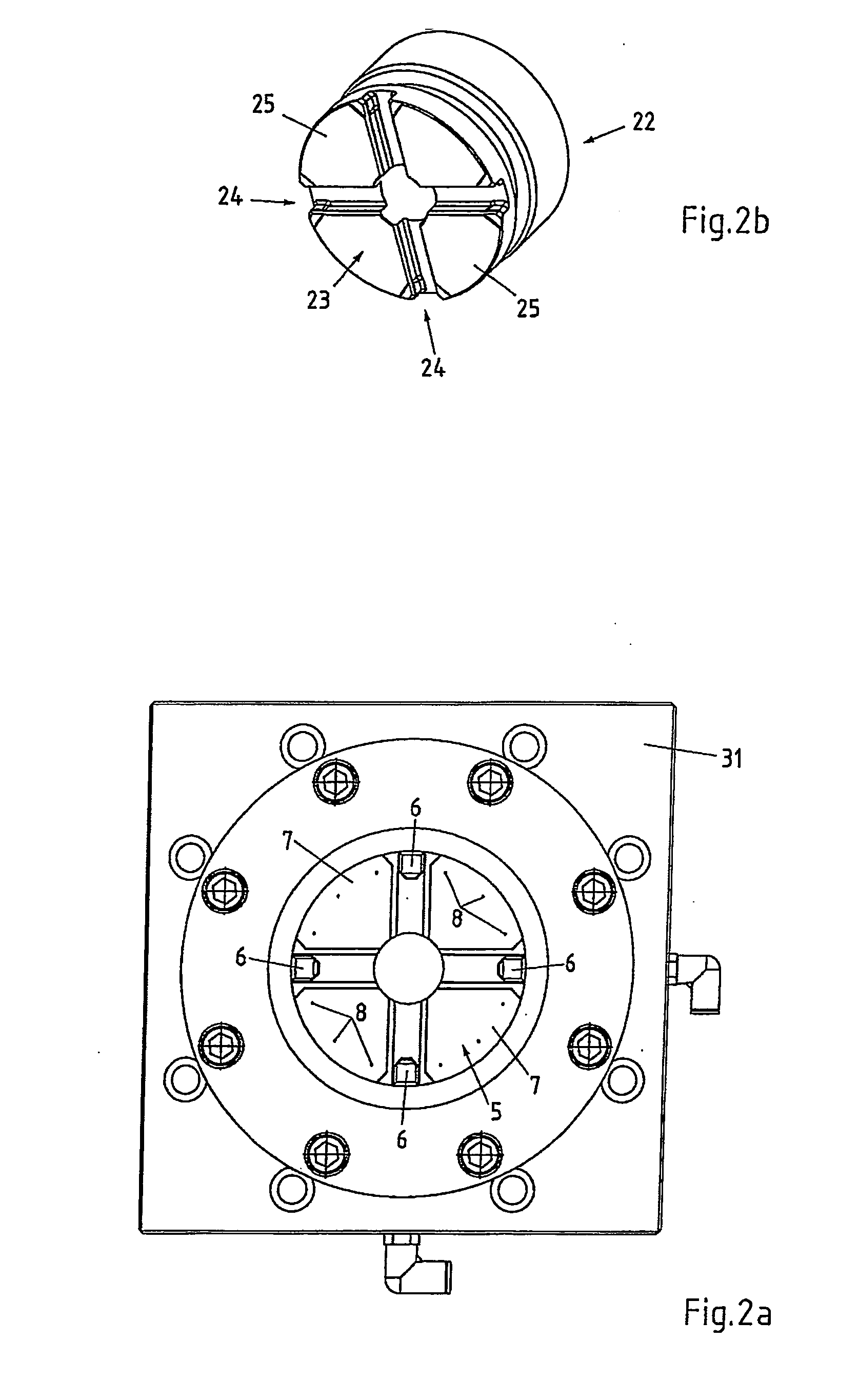

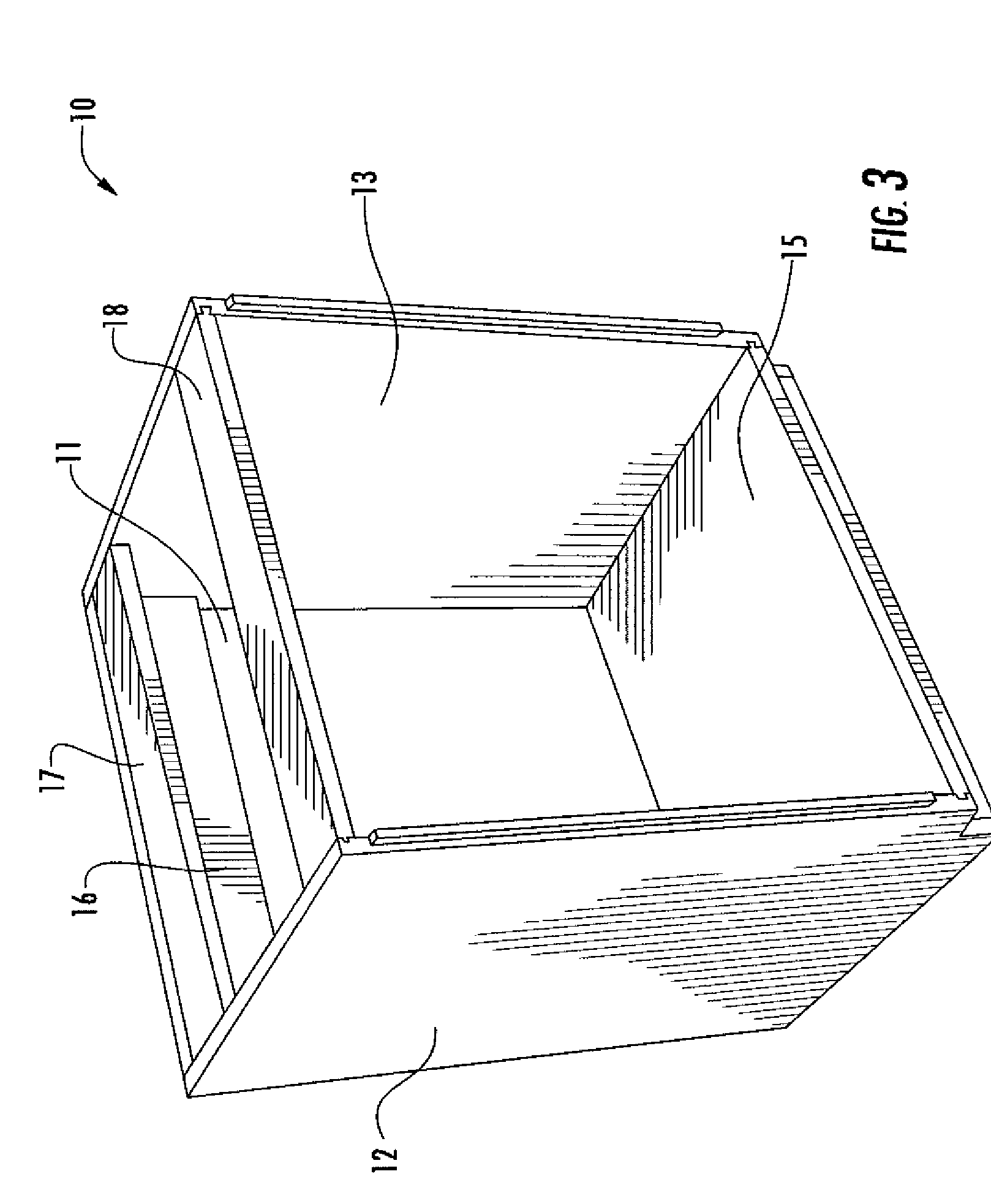

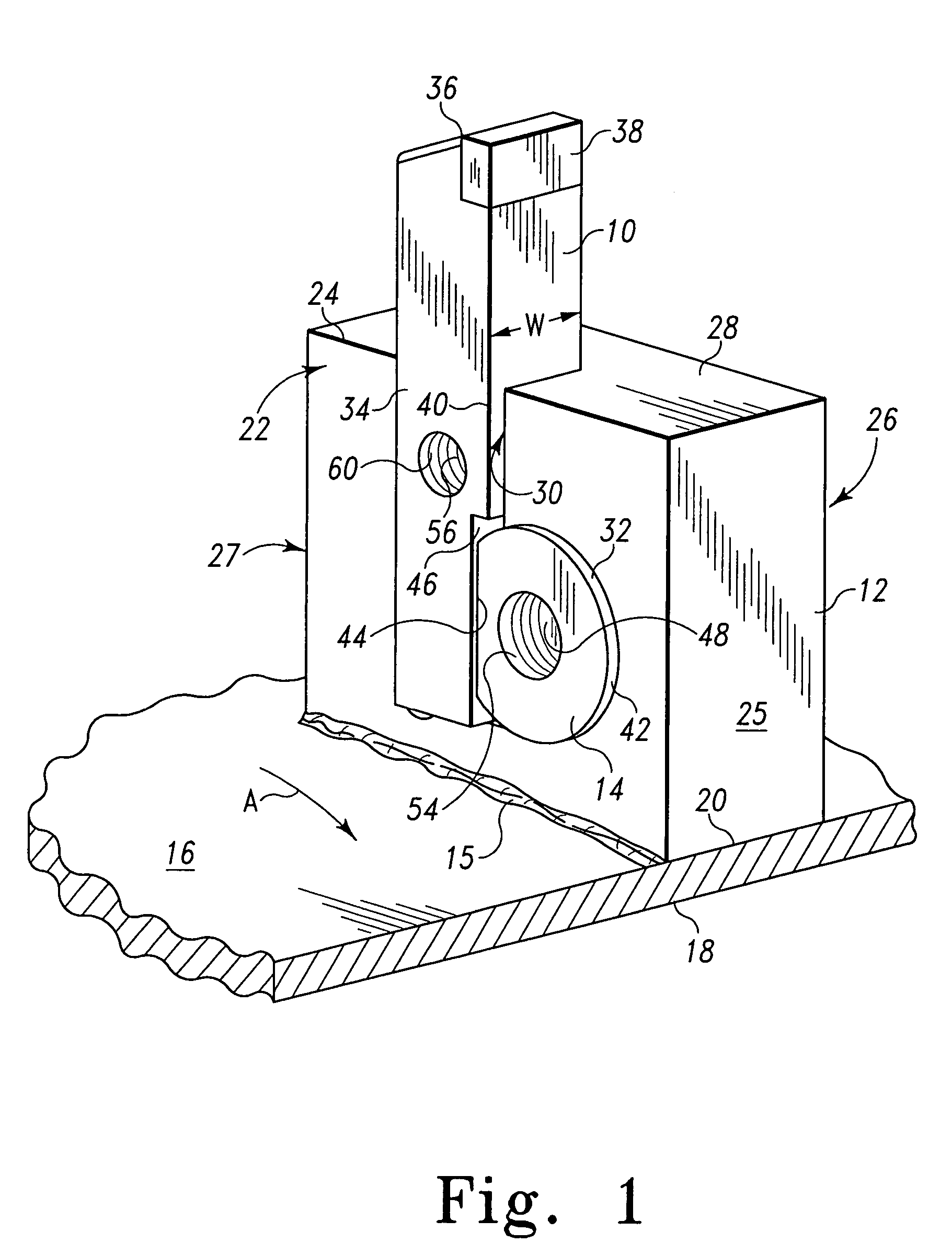

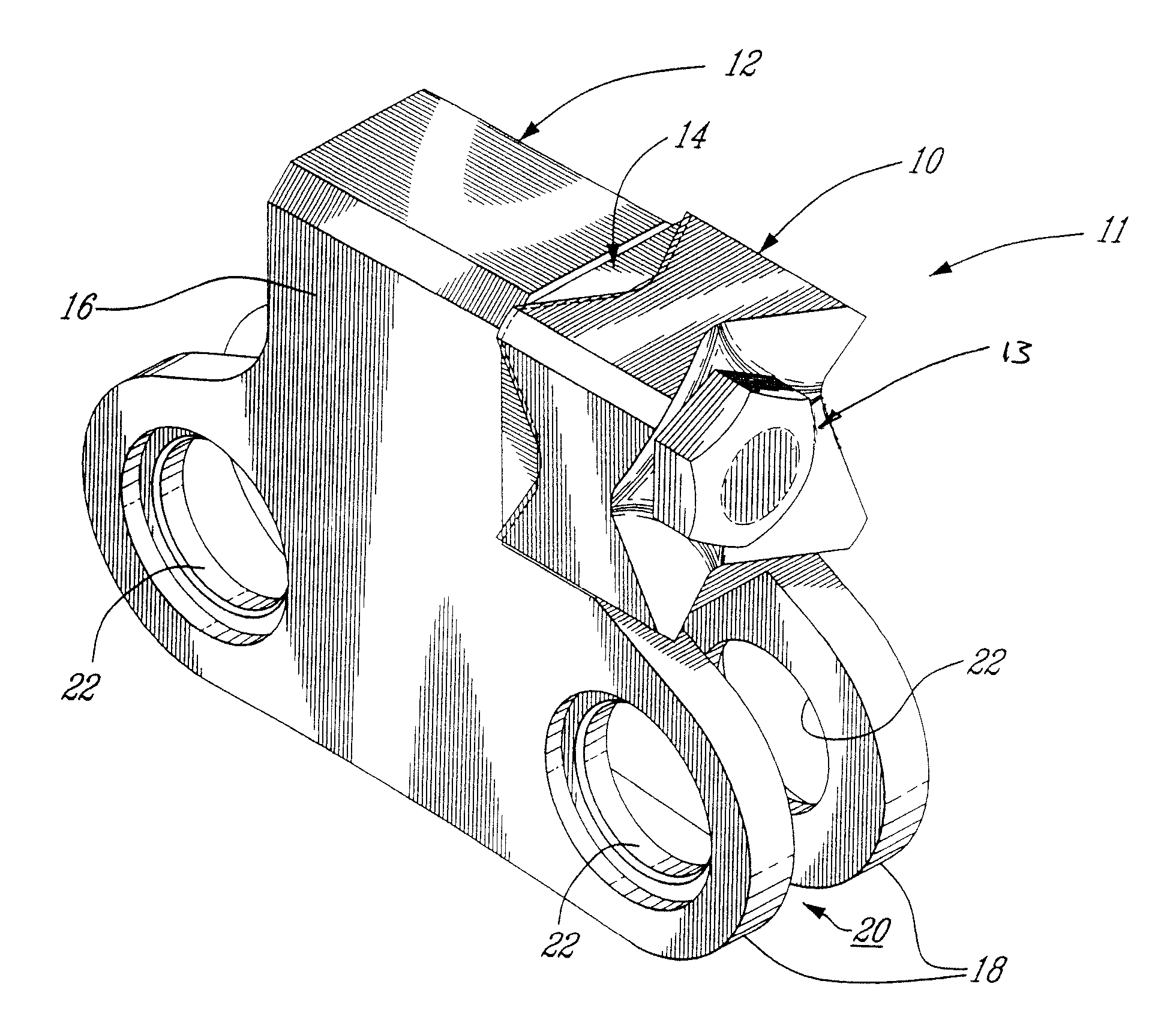

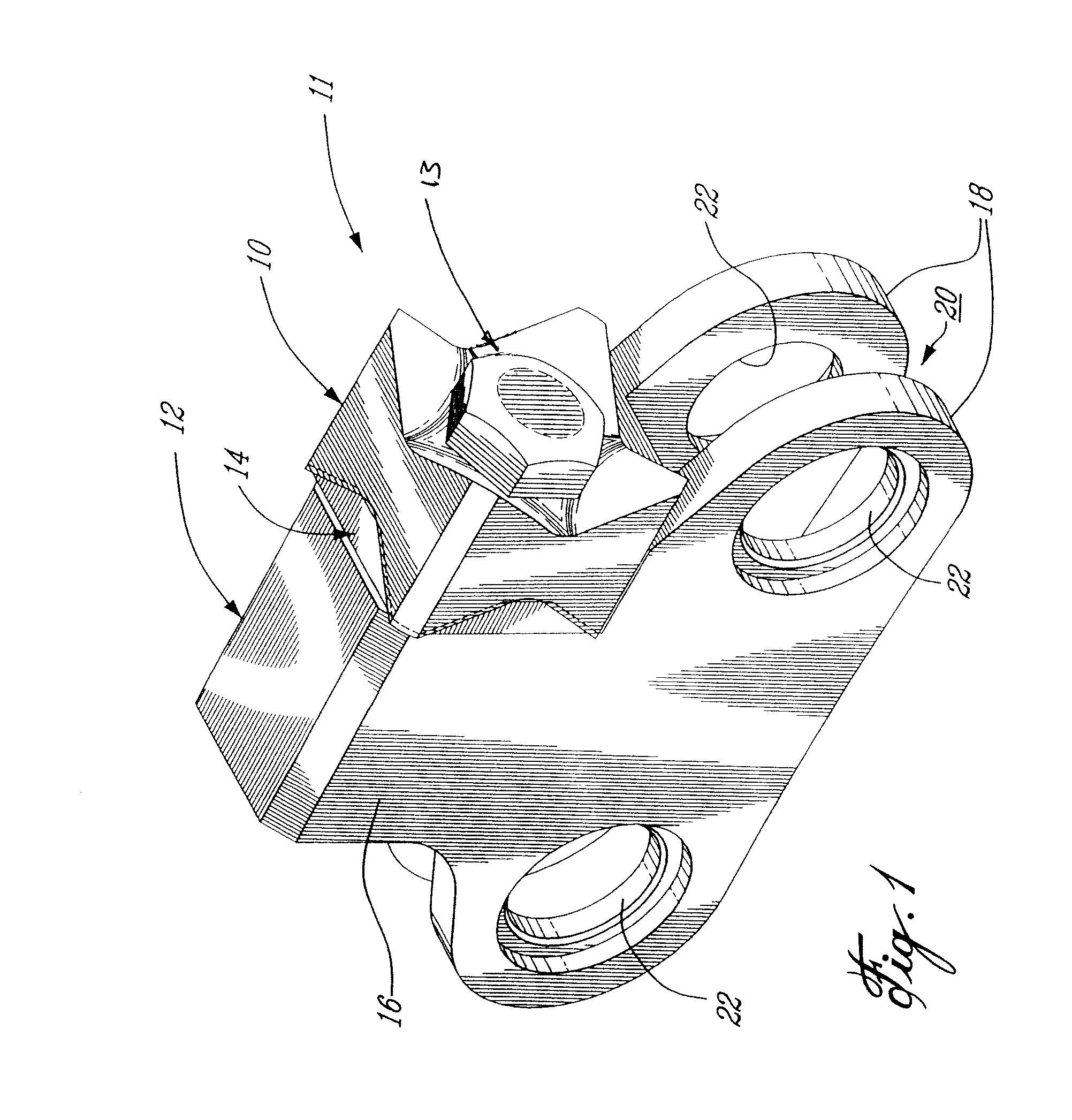

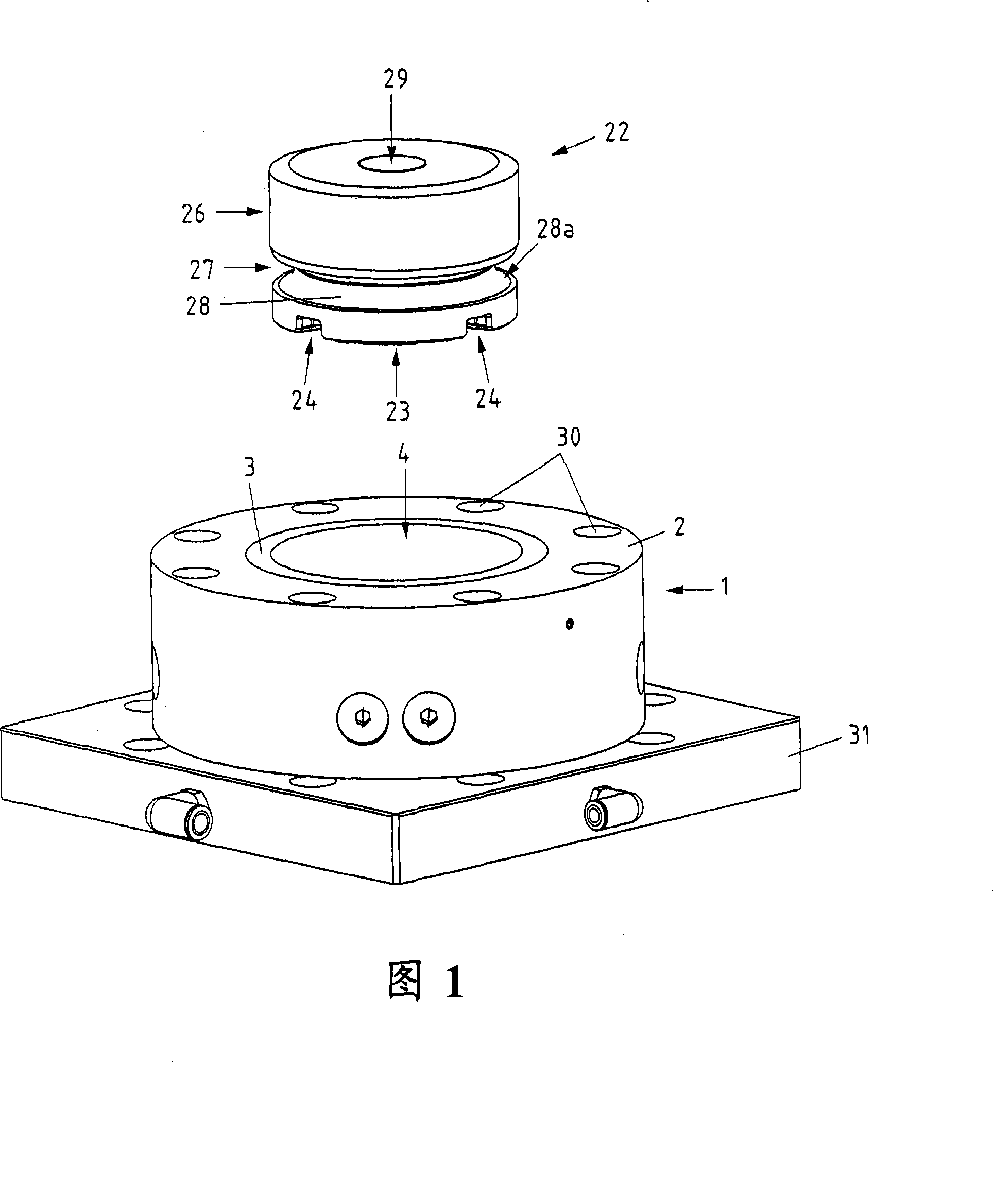

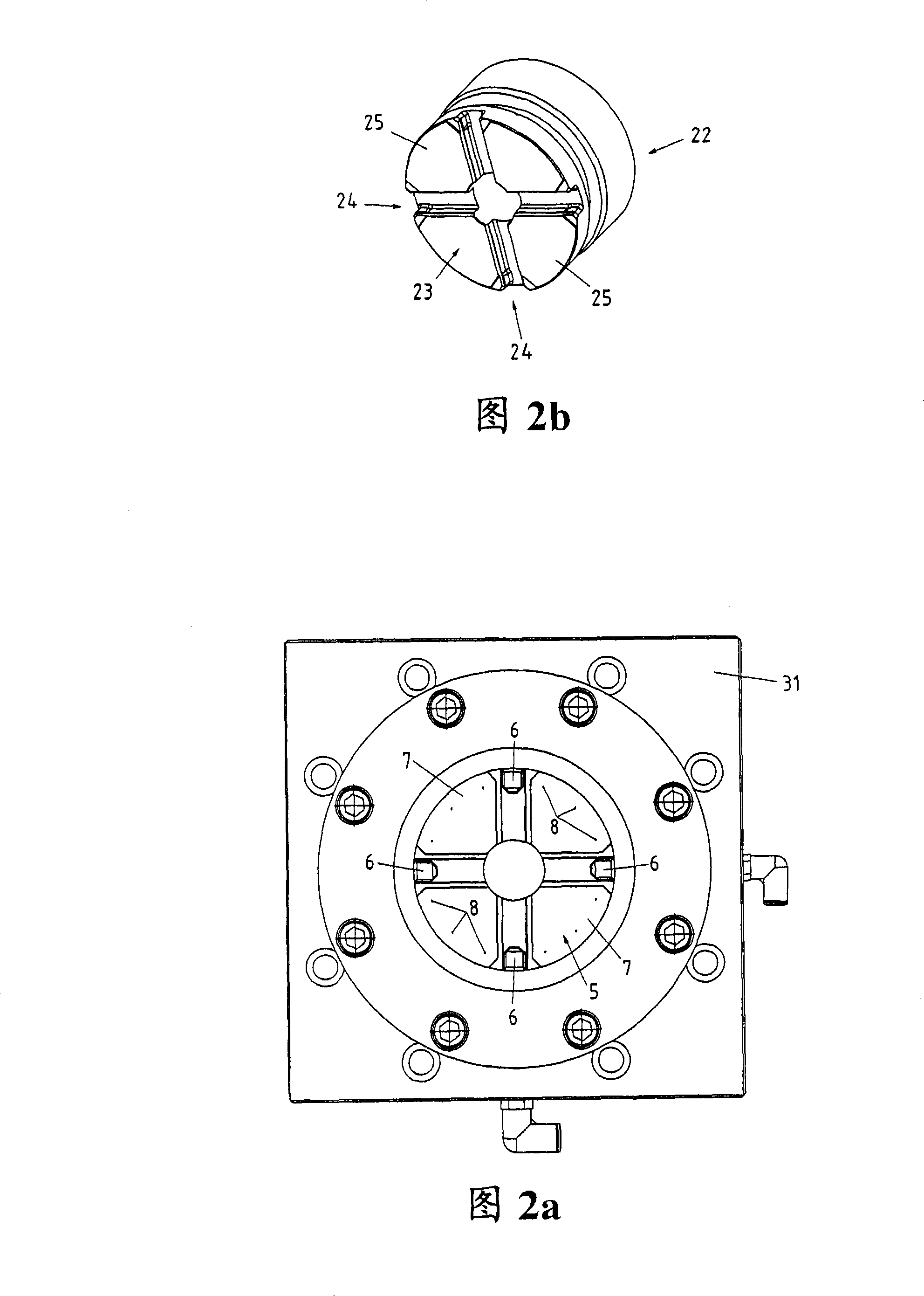

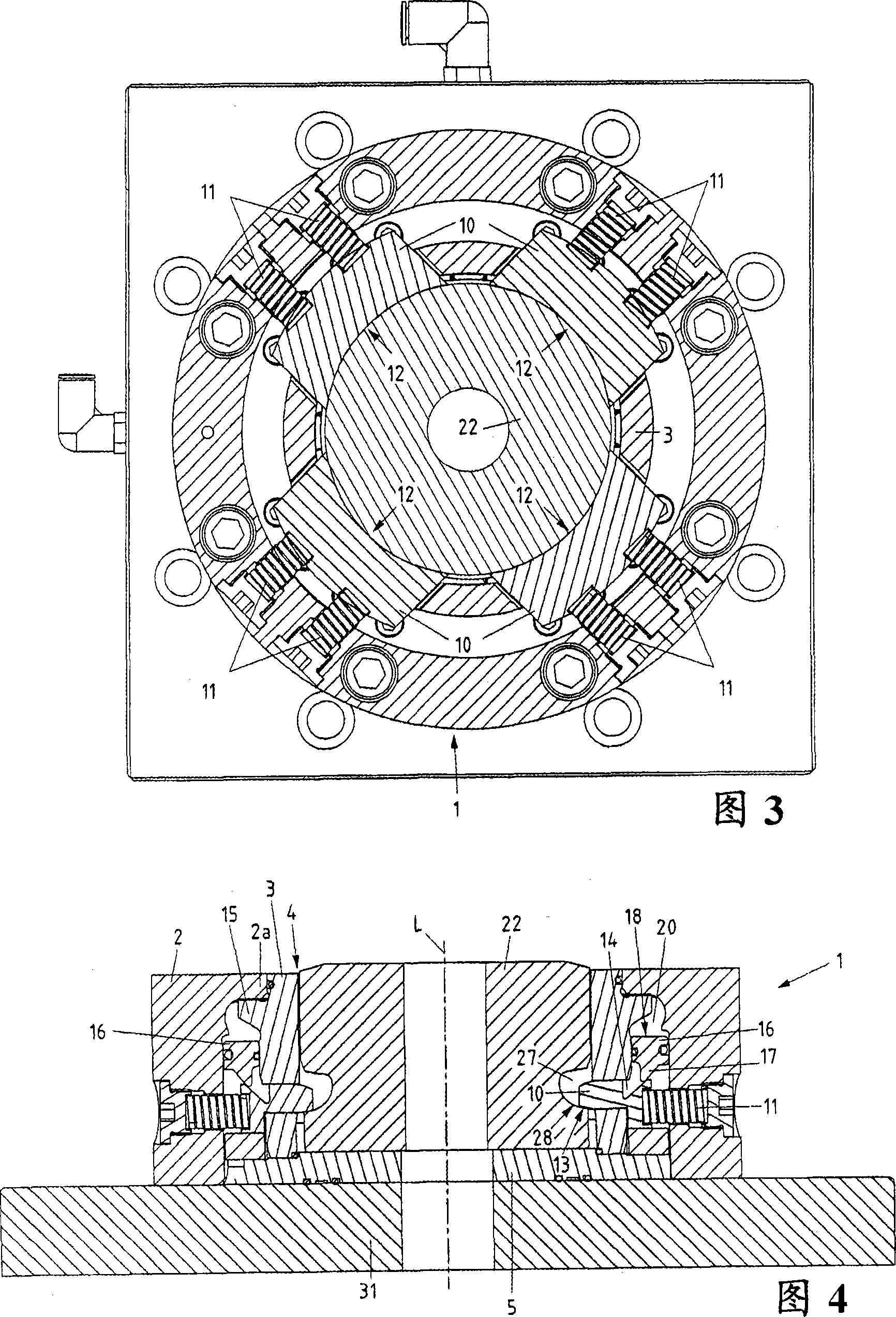

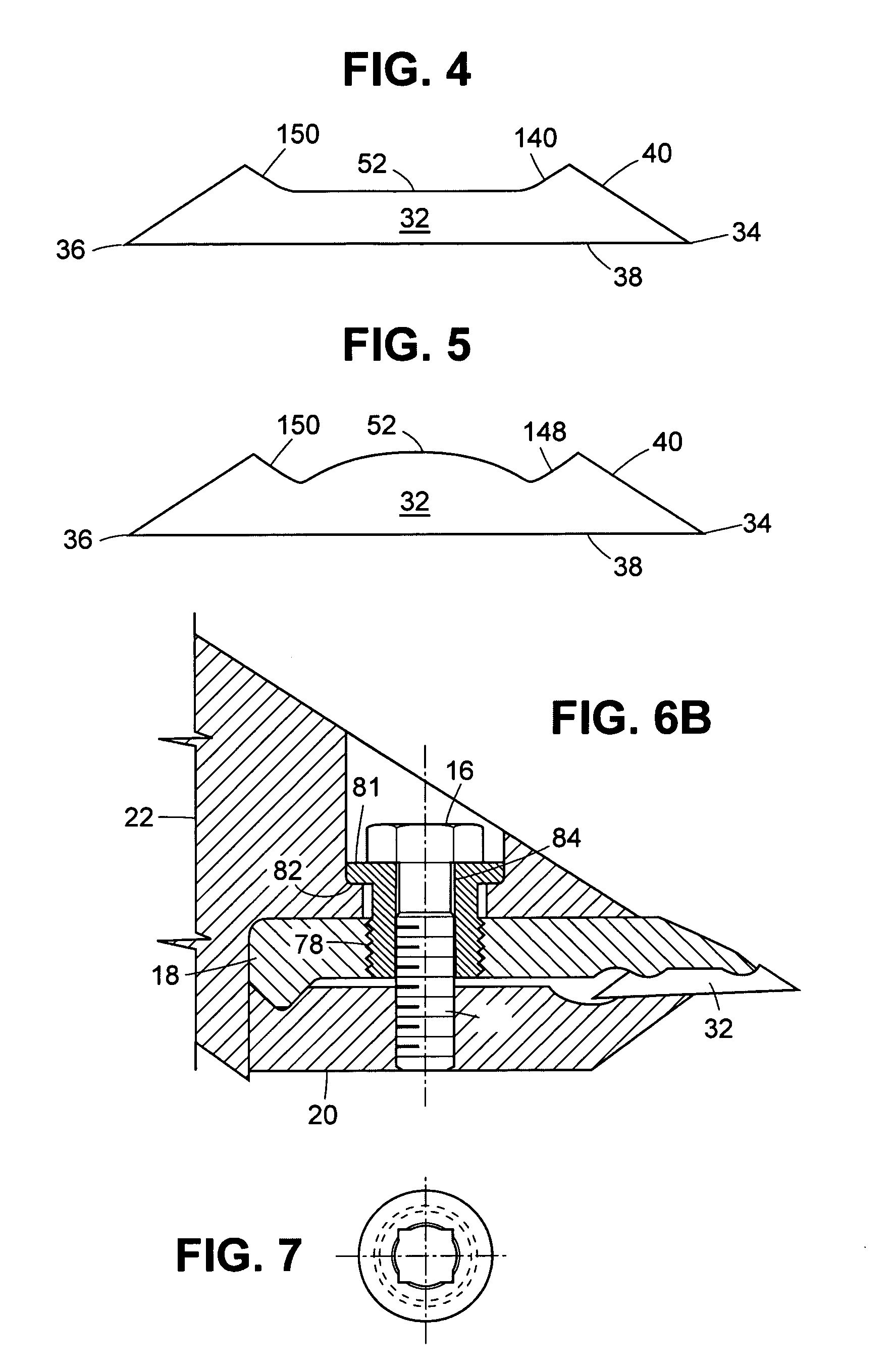

Clamping fixture including a chuck and a workpiece pallet releasably located thereon

ActiveUS20090051094A1Increase the tensile loadHandle high tensile loadRotary cutting toolsLarge fixed membersEngineeringPlunger

A clamping fixture comprises a chuck (1) and a workpiece pallet (22) releasably located thereon. The chuck (1) is provided with a clamping mechanism for locating the workpiece pallet (22). The clamping mechanism comprises a plurality of clamping members configured as plungers (10). The workpiece pallet (22) comprises a clamping surface (28a) running essentially along its shell surface (26) for surface contacting the plungers (10) by its front part (12) provided with a compression surface (13) during clamping.

Owner:EROWA

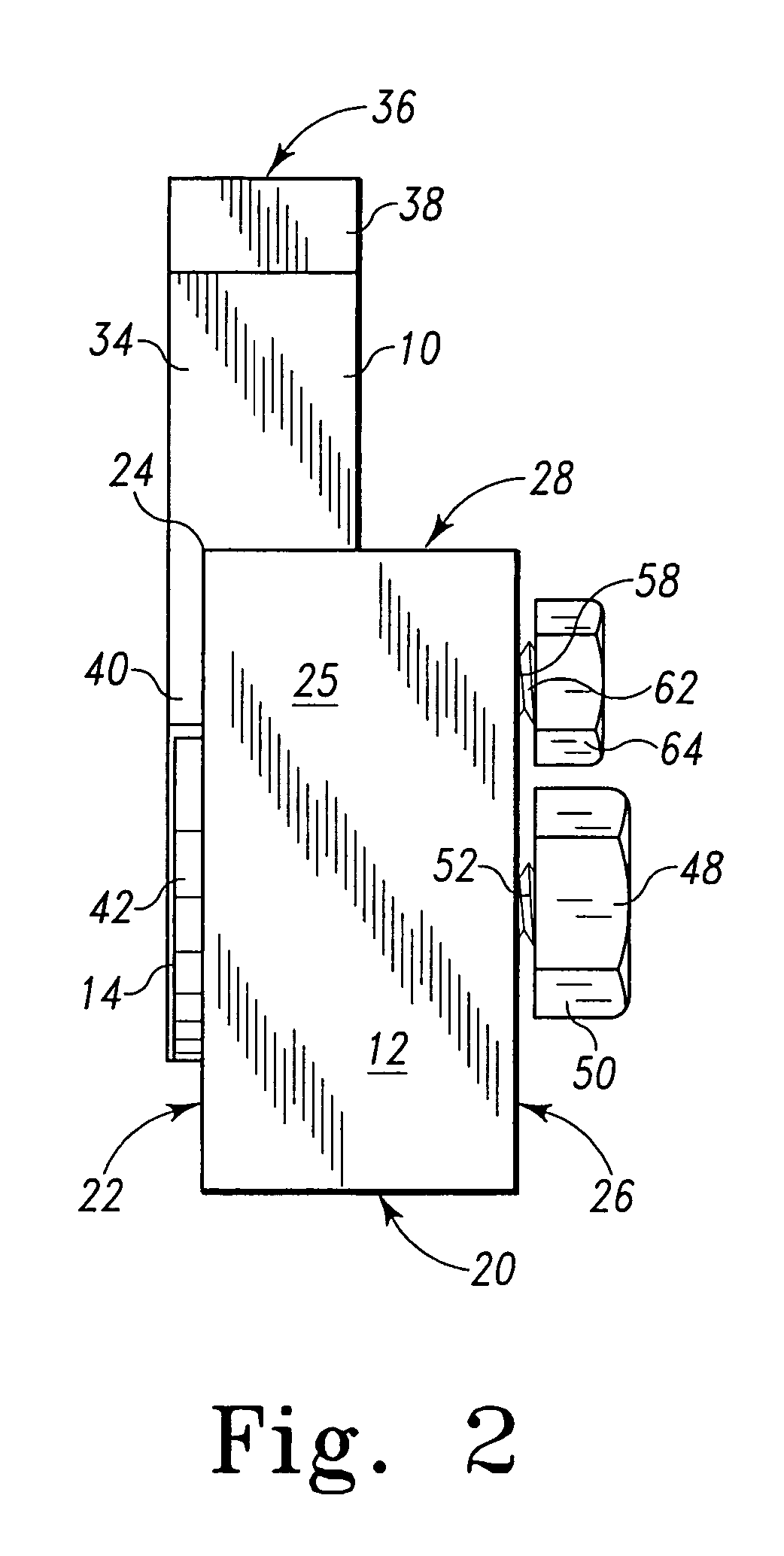

Joint for connecting workpieces

InactiveUS20060273085A1Improve productivityEliminating adhesive curing timeRotary cutting toolsCouplings for rigid shaftsEngineeringMechanical engineering

Owner:CASTO DANIEL A

Method for Joining Workpieces Together and Product Made Thereby

A method of forming a joint between first and second workpieces generally consisting of forming a recess in one of such workpieces, provided with at least one side wall having a serrated cross-sectional configuration with inwardly projecting, distortable segments; providing a portion in the other of such workpieces, insertable into such recess, having a cross-sectional configuration sufficient to engage and distort such segments as such portion is inserted into such recess; and inserting such portion of the other workpiece into such recess, causing the segments to distort and thus provide an interference fit between such workpieces.

Owner:THERMWOOD CORPORATION

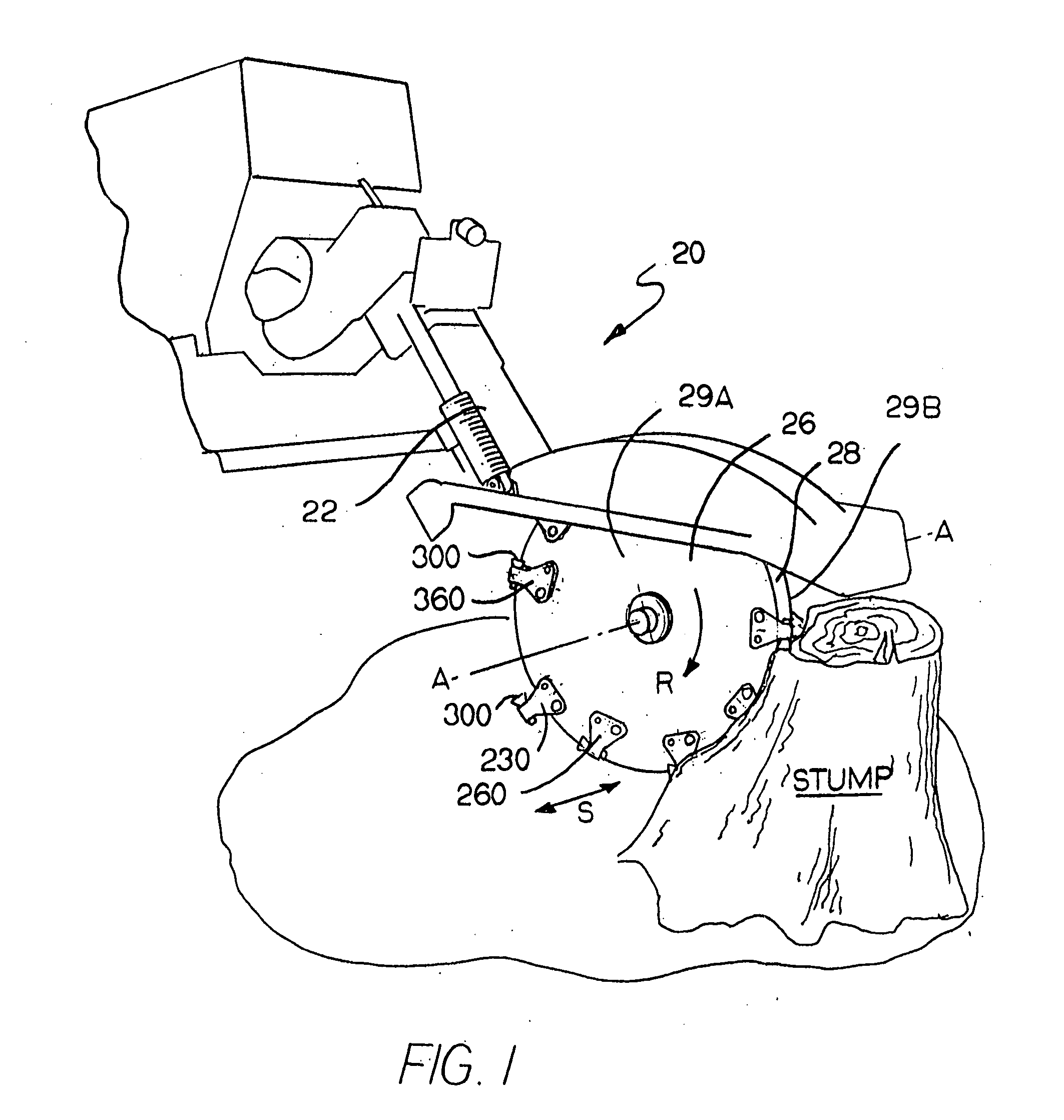

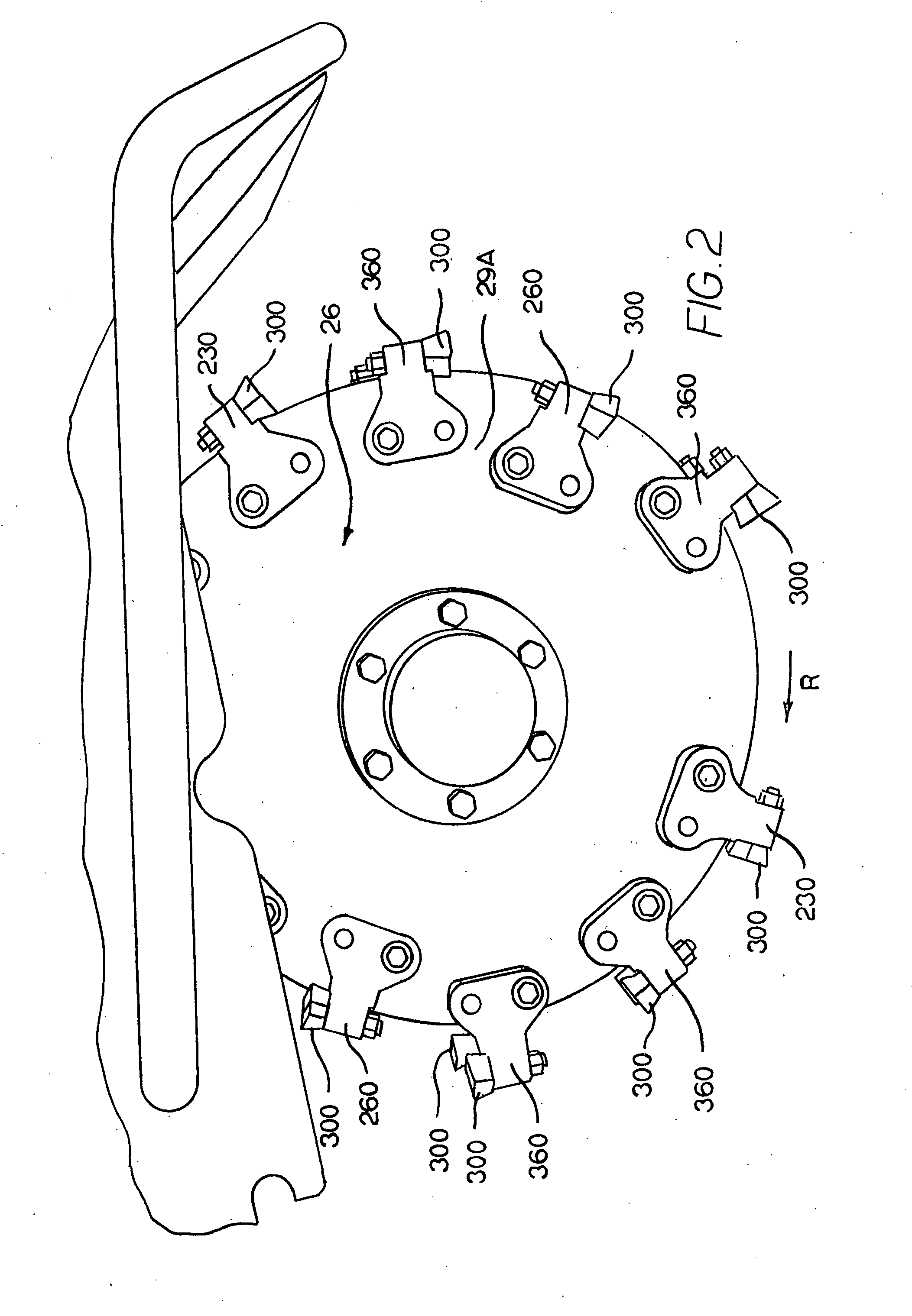

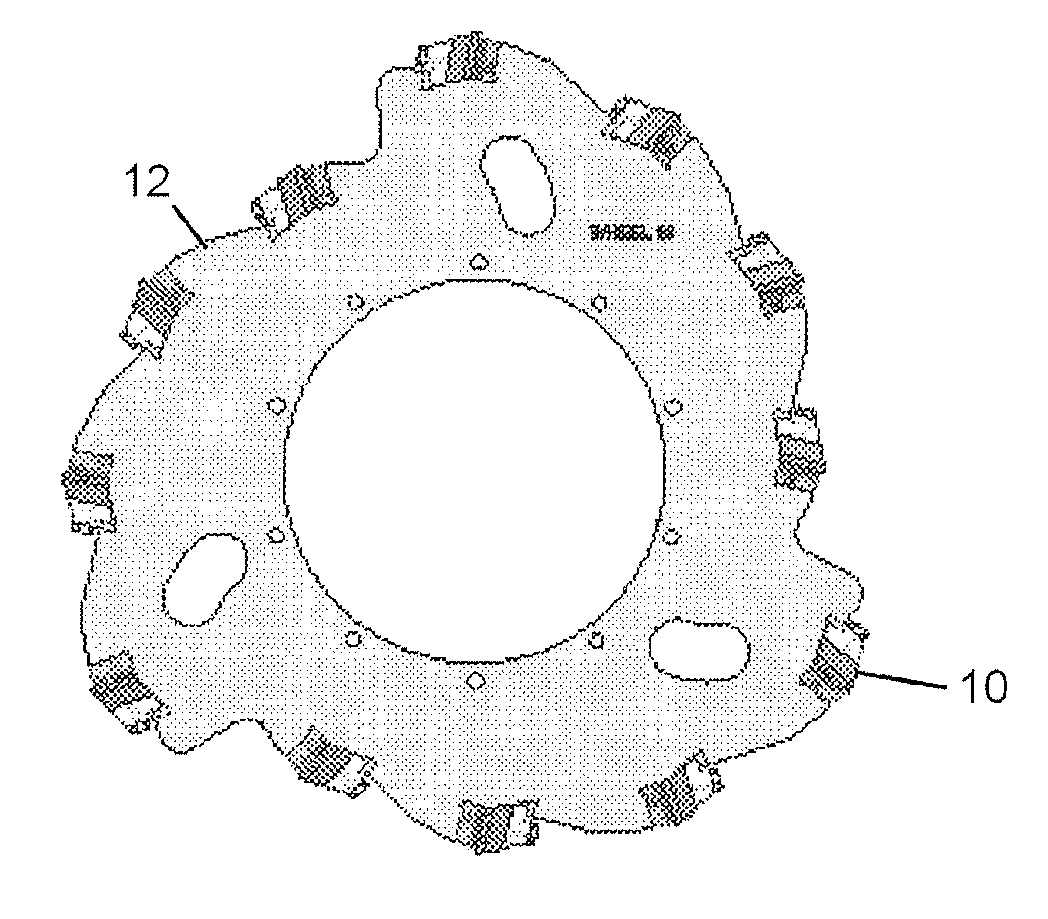

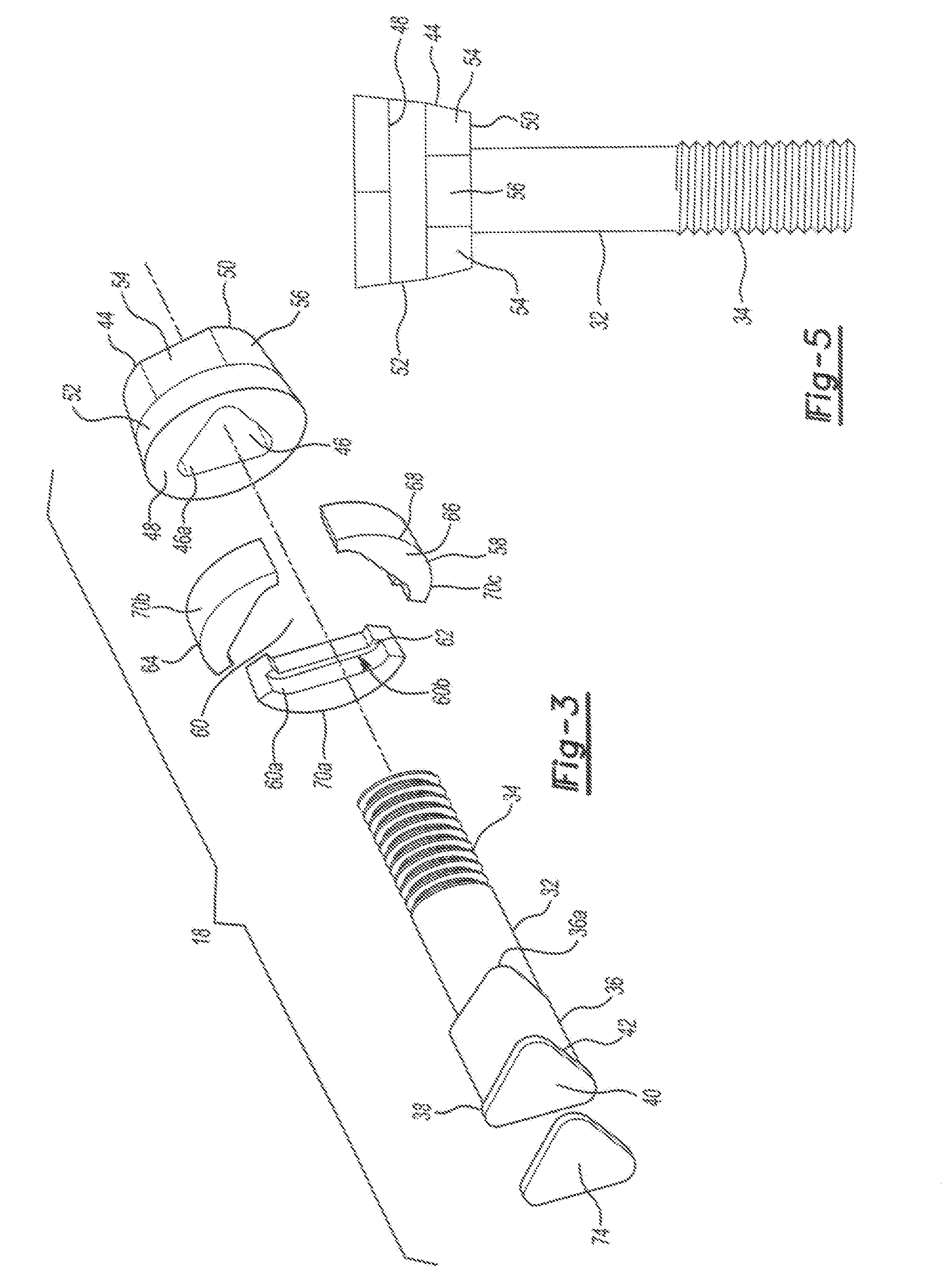

Indexable stump cutter tooth

ActiveUS20080149224A1Prevent rotationMulti-purpose machinesProfiling/shaping machinesDrive wheelEngineering

A stump cutter tooth held by a pocket member, which has first and second edge, and the pocket member being operatively attached to a driven wheel, which has opposite first and second side surfaces. The stump cutter tooth includes an elongate tooth body that has an axial forward end. A first hard region is at the axial forward end of the tooth body and defines at least one distinct cutting edge that has an orientation to engage the stump during operation. A second hard region is at the axial forward end of the tooth body and is distinct from the first hard region. The second hard region provides protection to at least a portion of the pocket member.

Owner:KENNAMETAL INC +1

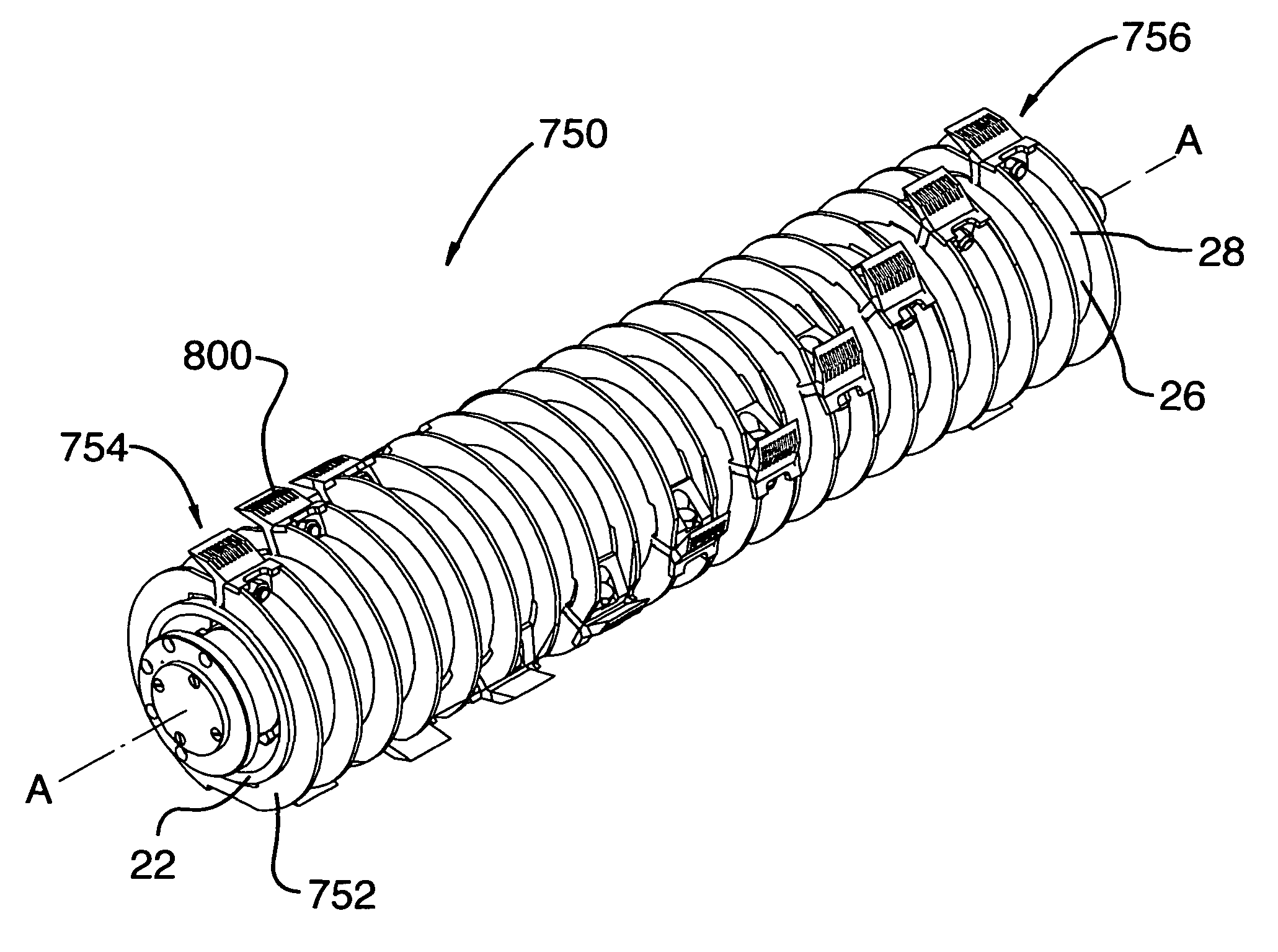

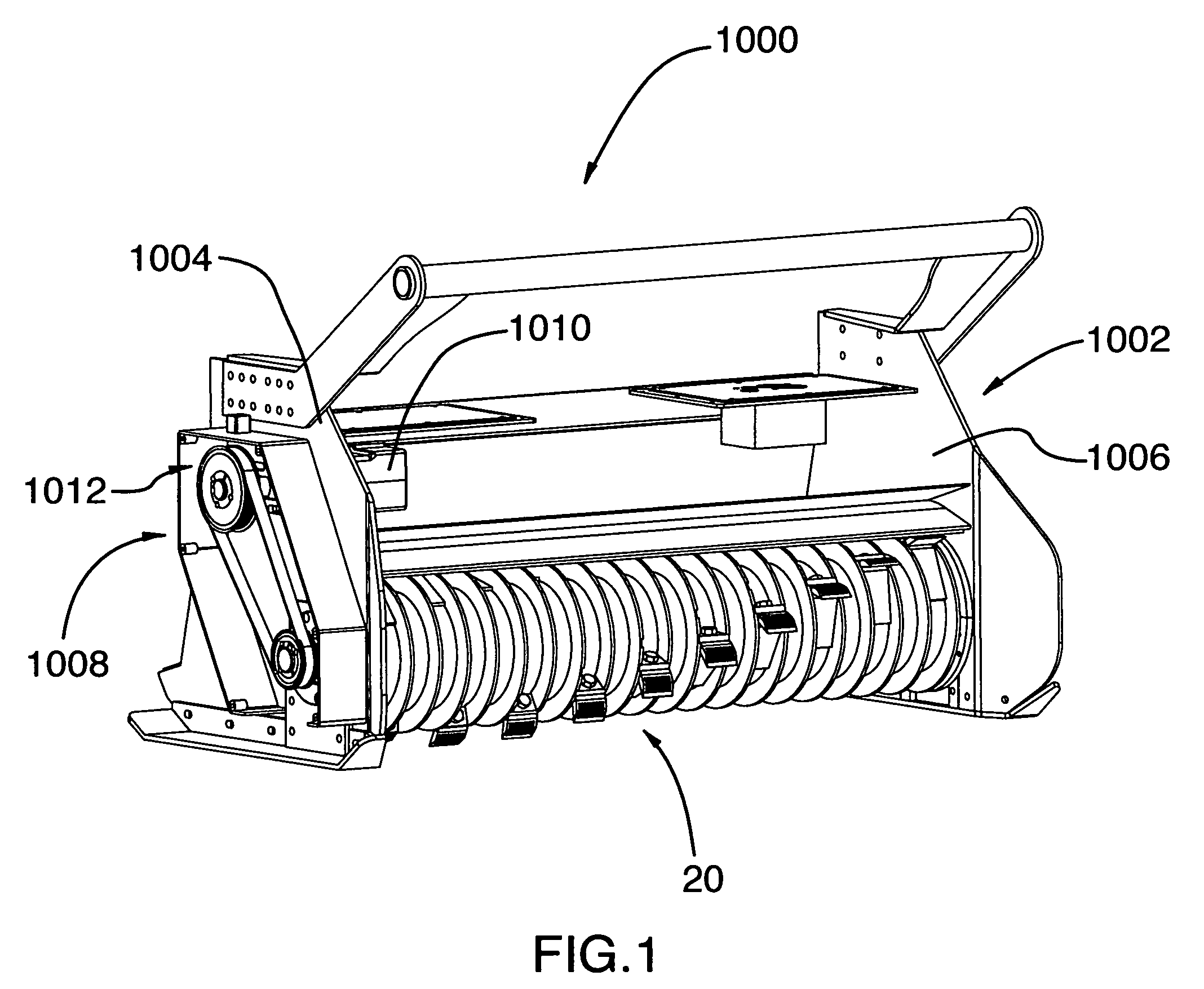

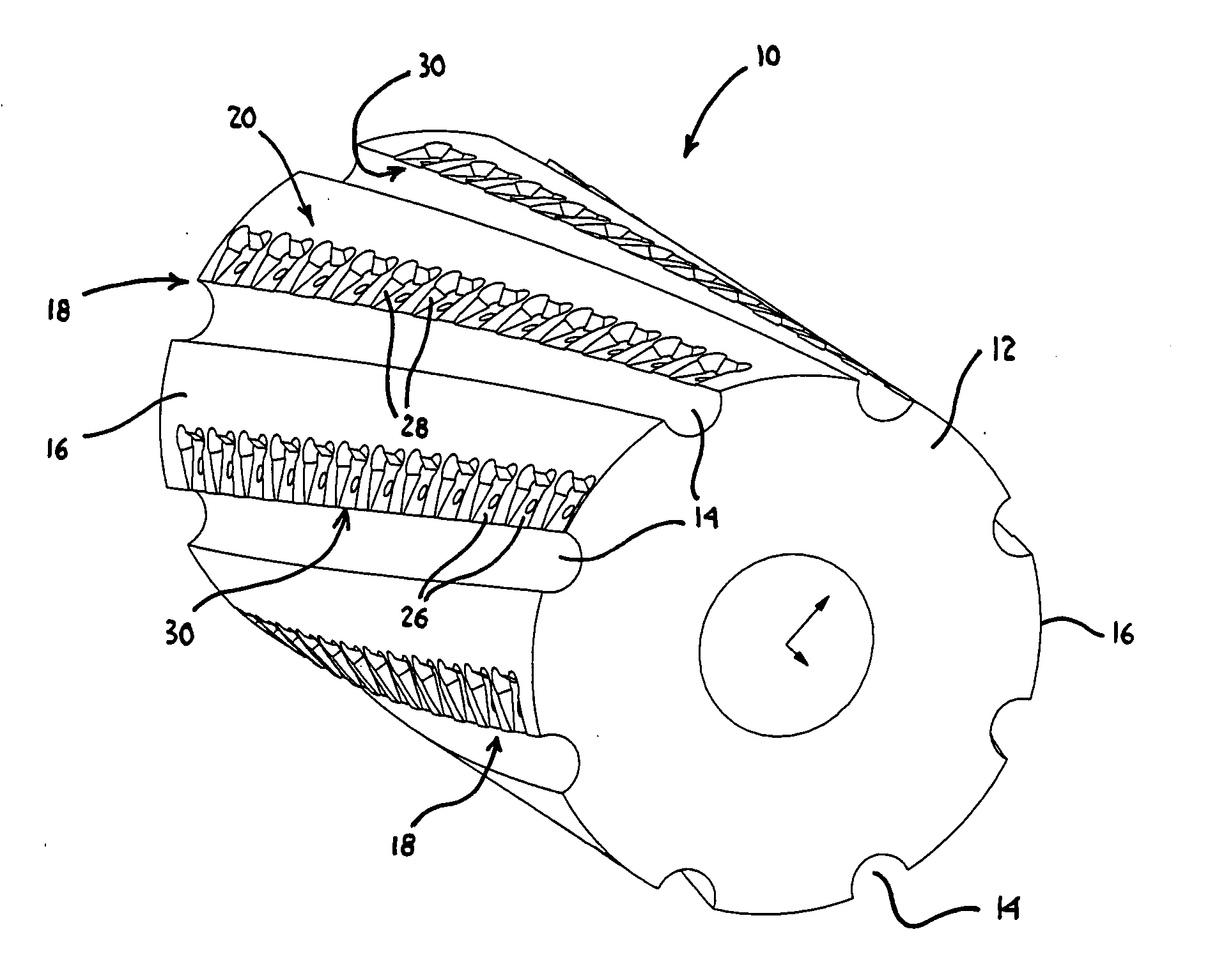

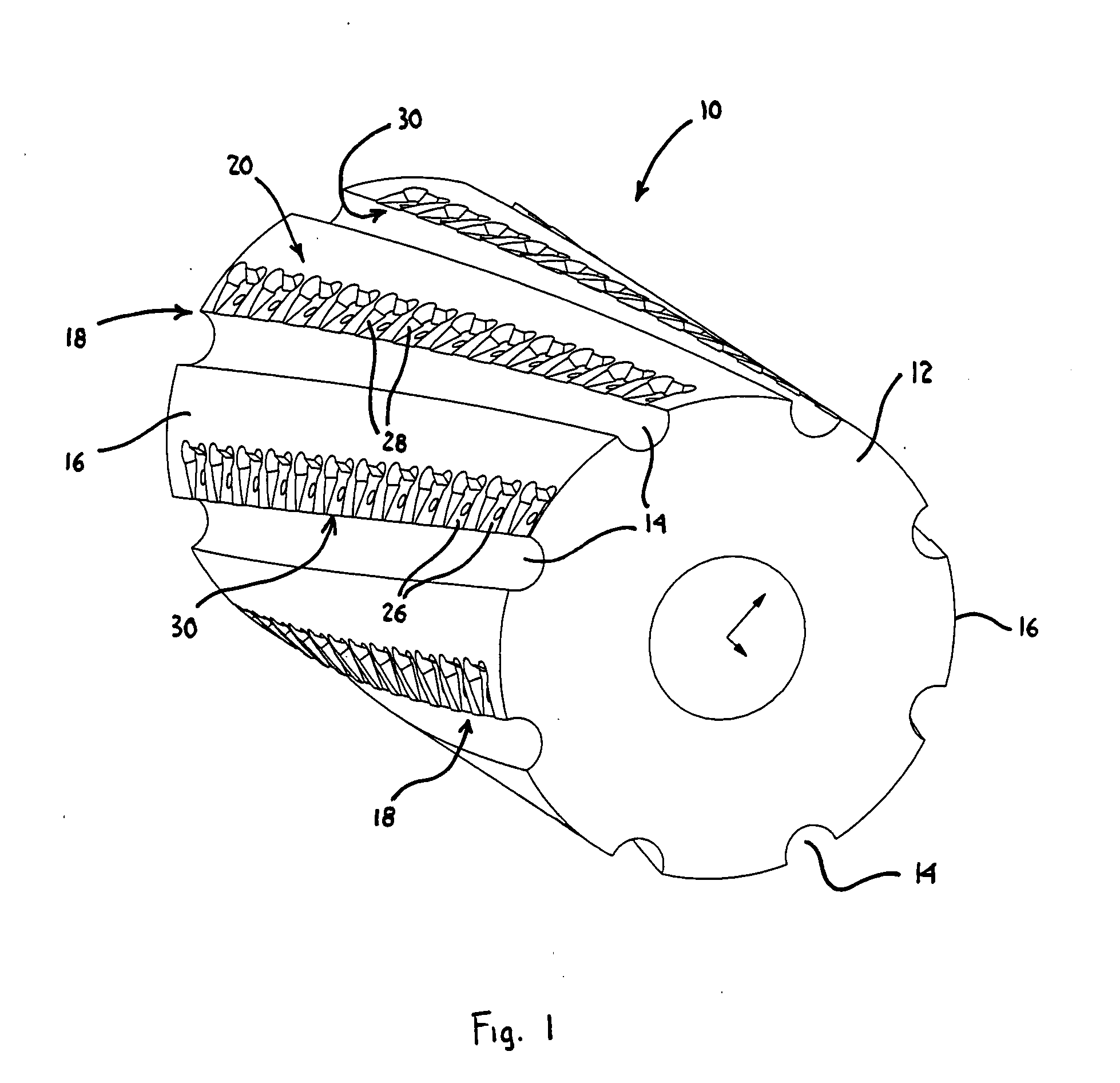

Brush cutting head

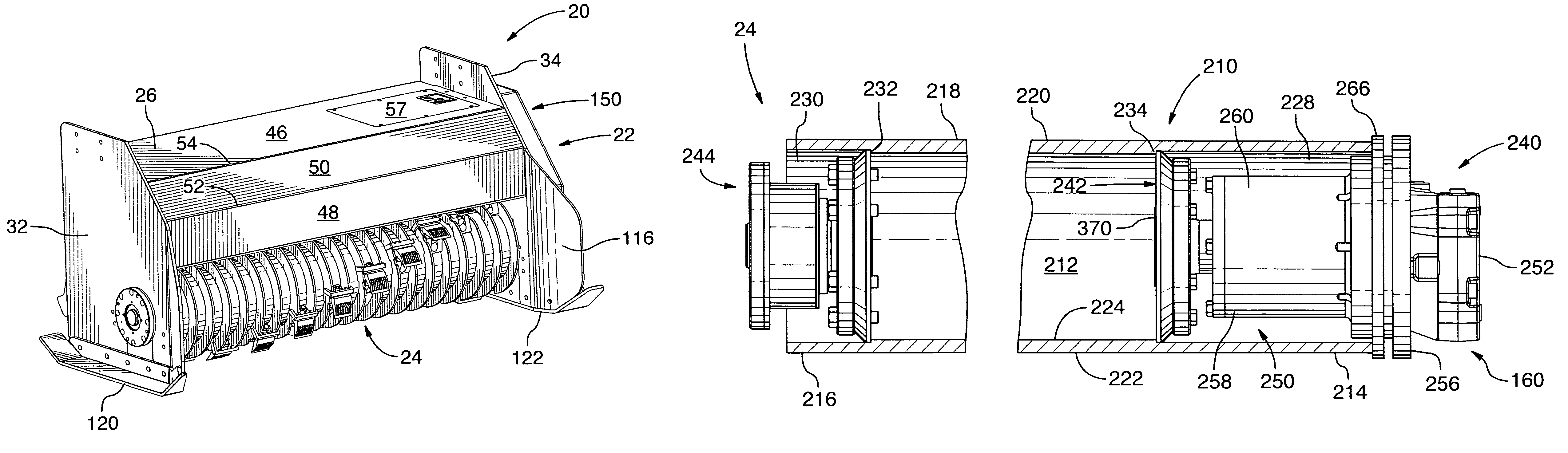

The present invention relates to a brush cutting head for a brush cutter. The brush cutter head includes a cylindrical support body that has a first end, an opposed second end and an intermediate portion extending therebetween. The intermediate portion has a curved surface that defines the circular cross-section of the cylindrical support body. A plurality of collars is mounted to the cylindrical support body at spaced intervals along the intermediate portion. Each collar extends radially from the curved surface of the cylindrical support body. Additionally, each collar cooperates with an adjacent collar to define a mounting station between the adjacent collars. The brush cutter head further includes a plurality of cutting tooth assemblies carried on the outer surface of the cylindrical support body. Each cutting tooth assembly has a cutting tooth for placement within the mounting station and a mounting assembly engageable with the adjacent collars to secure the cutting tooth in the mounting station.

Owner:GYRO TRAC +1

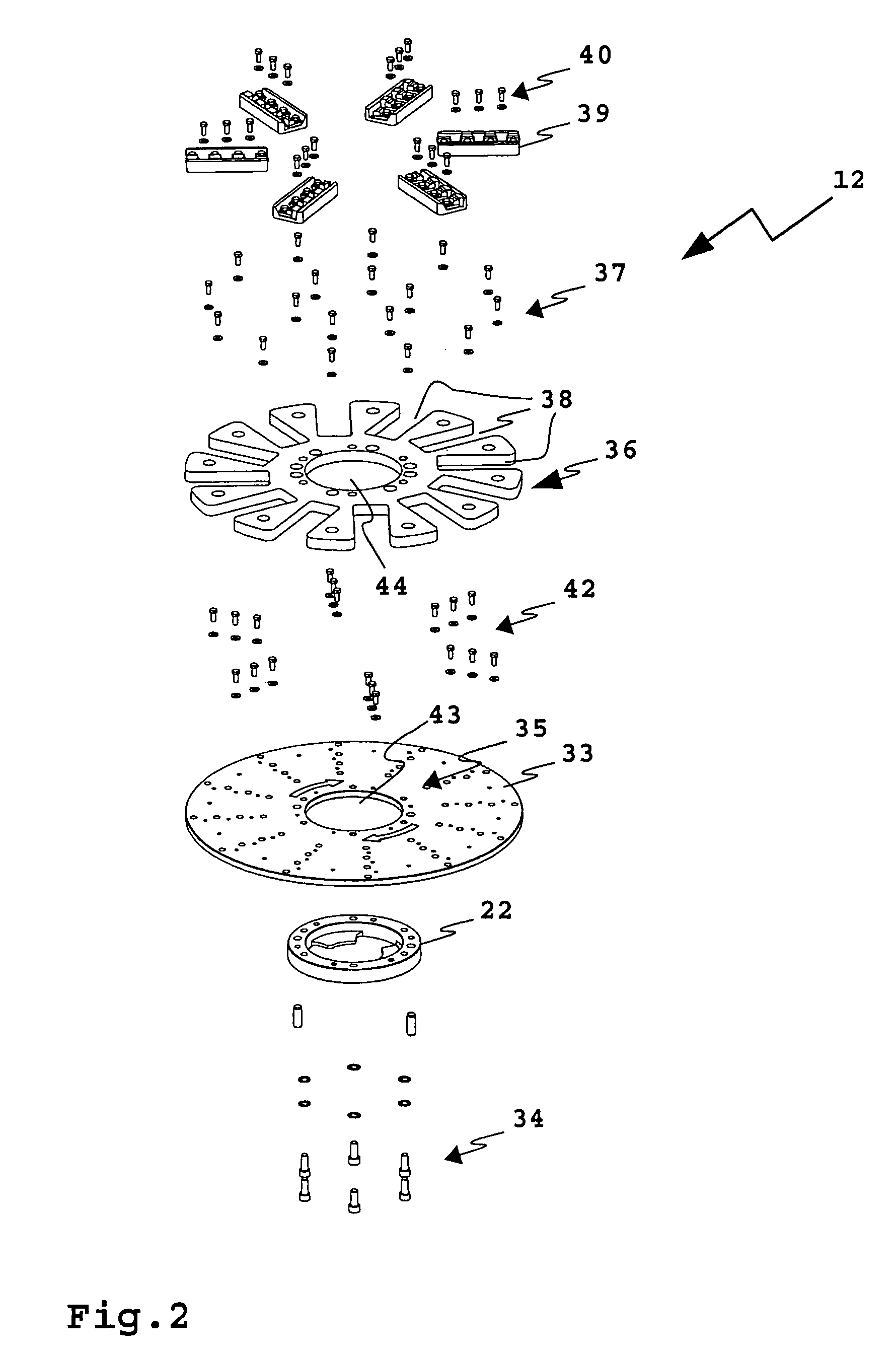

Split wheel stump cutter with replaceable tooth blocks and cutting teeth

InactiveUS6877535B1Multi-purpose machinesProfiling/shaping machinesEngineeringMechanical engineering

A stump grinding apparatus having a split cutting wheel includes several replaceable cutter blocks secured to the periphery of the wheel. One or more replacement teeth are removably anchored in holes in each block and may also be mounted on holes in the side of the split wheel as well. The teeth are typically provided with a hardened cutting face, and are reinforced with an extension projecting back from the face. Each tooth includes a shank which fits into one of the holes. The shank contains a groove which receives a spring clip or a spring pin for securing the tooth in the hole. The wheel periphery contains individual recesses that are shaped to receive the cutter blocks. Each block includes means for insuring alignment of the block in the corresponding recess. The block is wedged tightly into its recess to reduce the likelihood of accidental removal.

Owner:BENNINGTON JOHN W

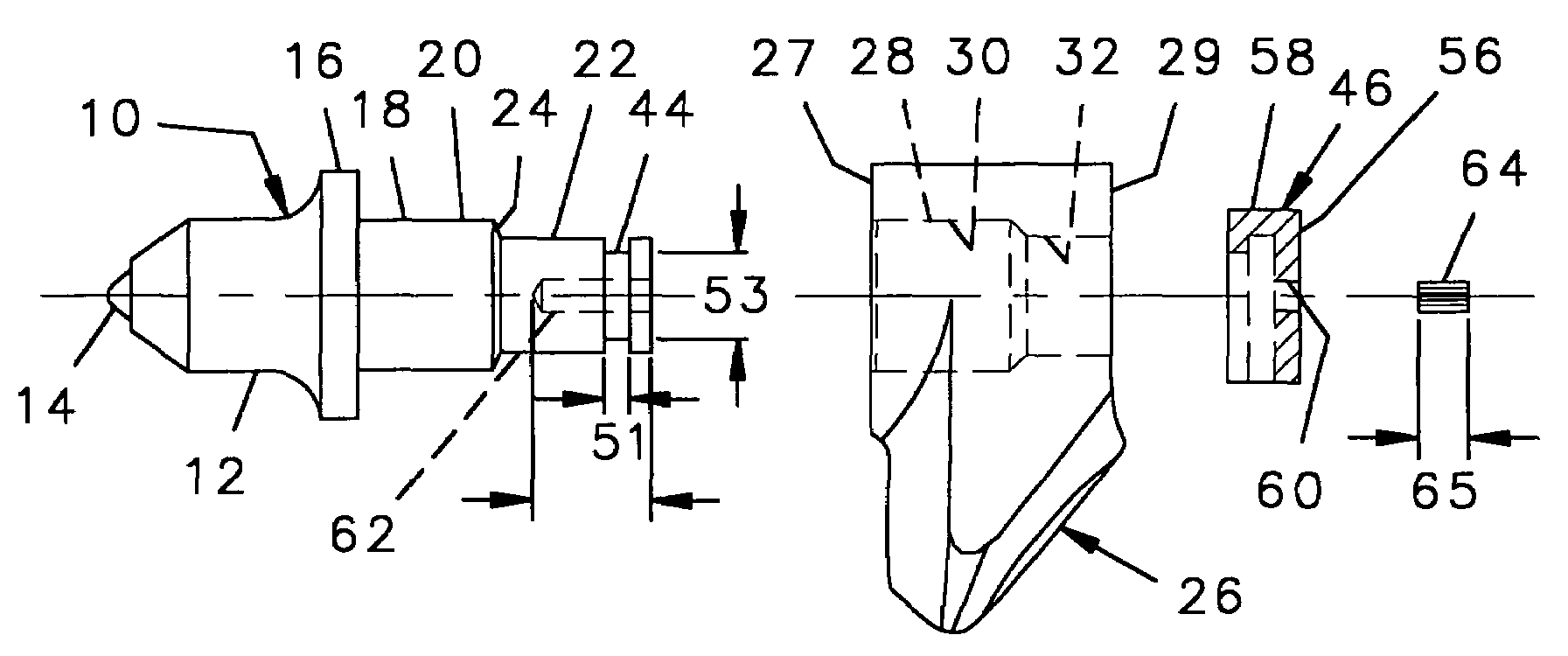

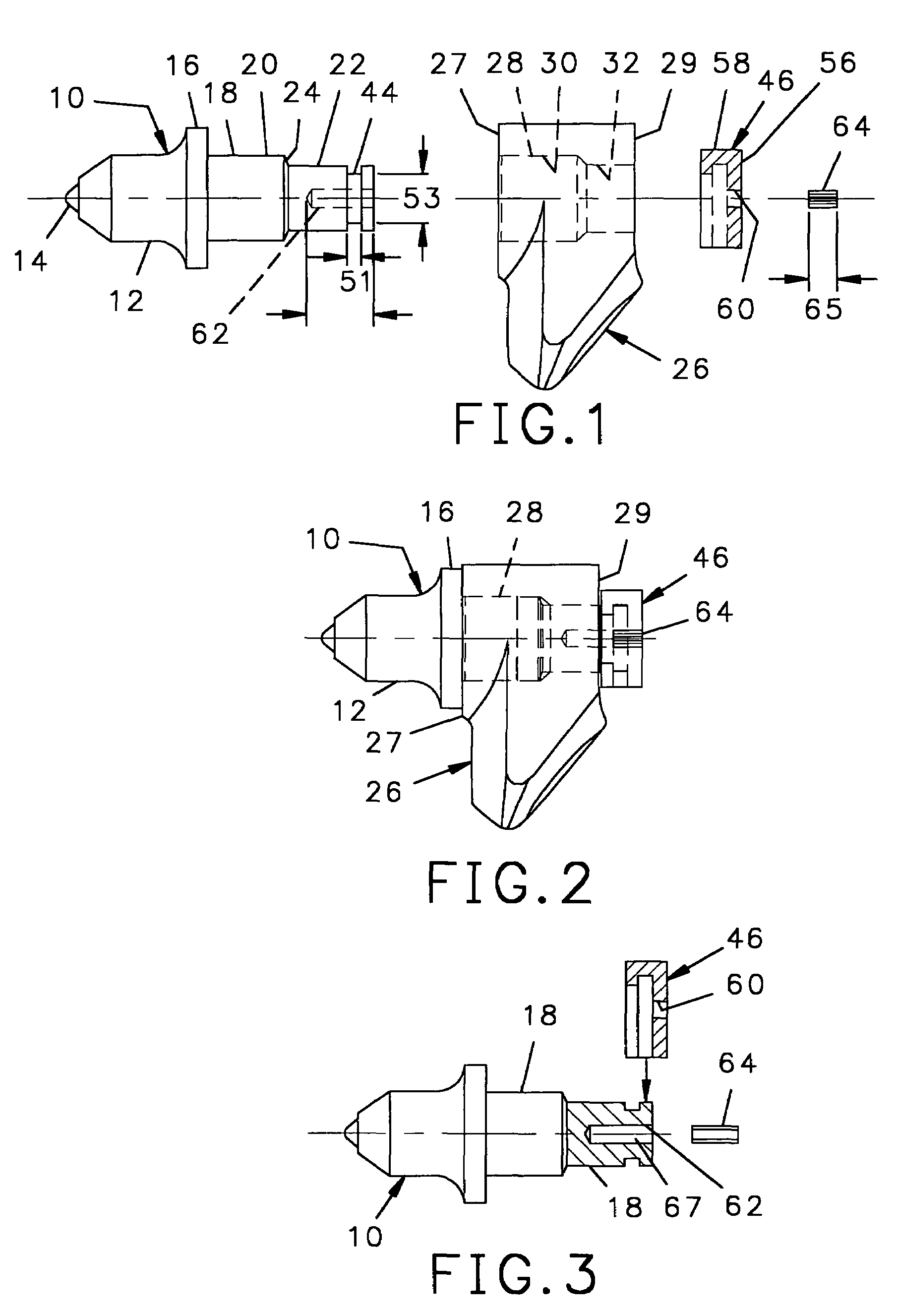

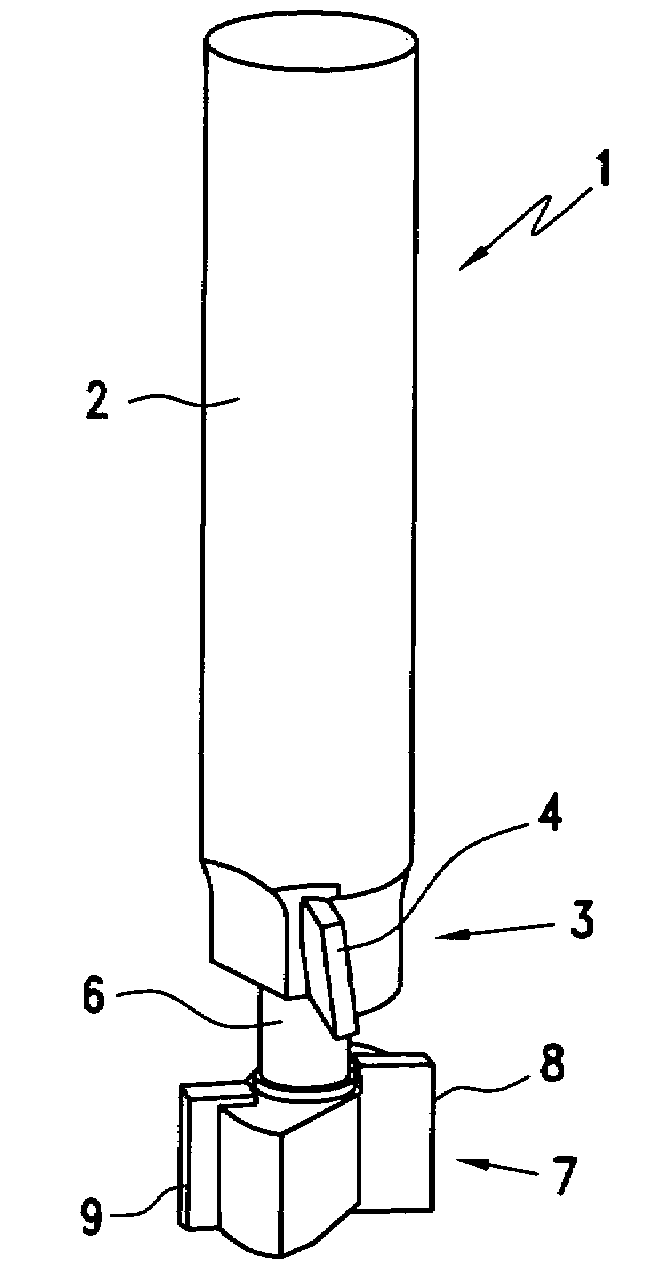

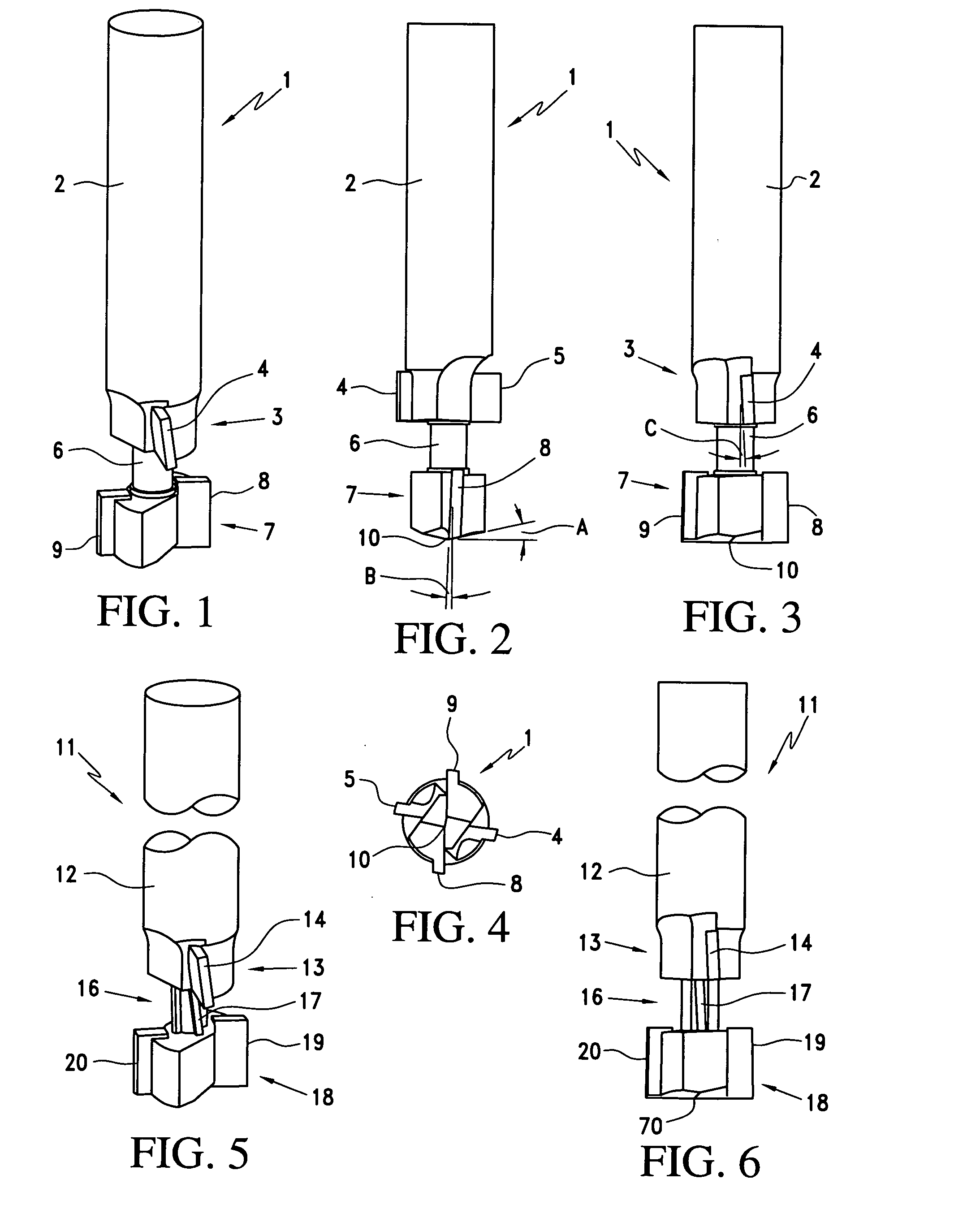

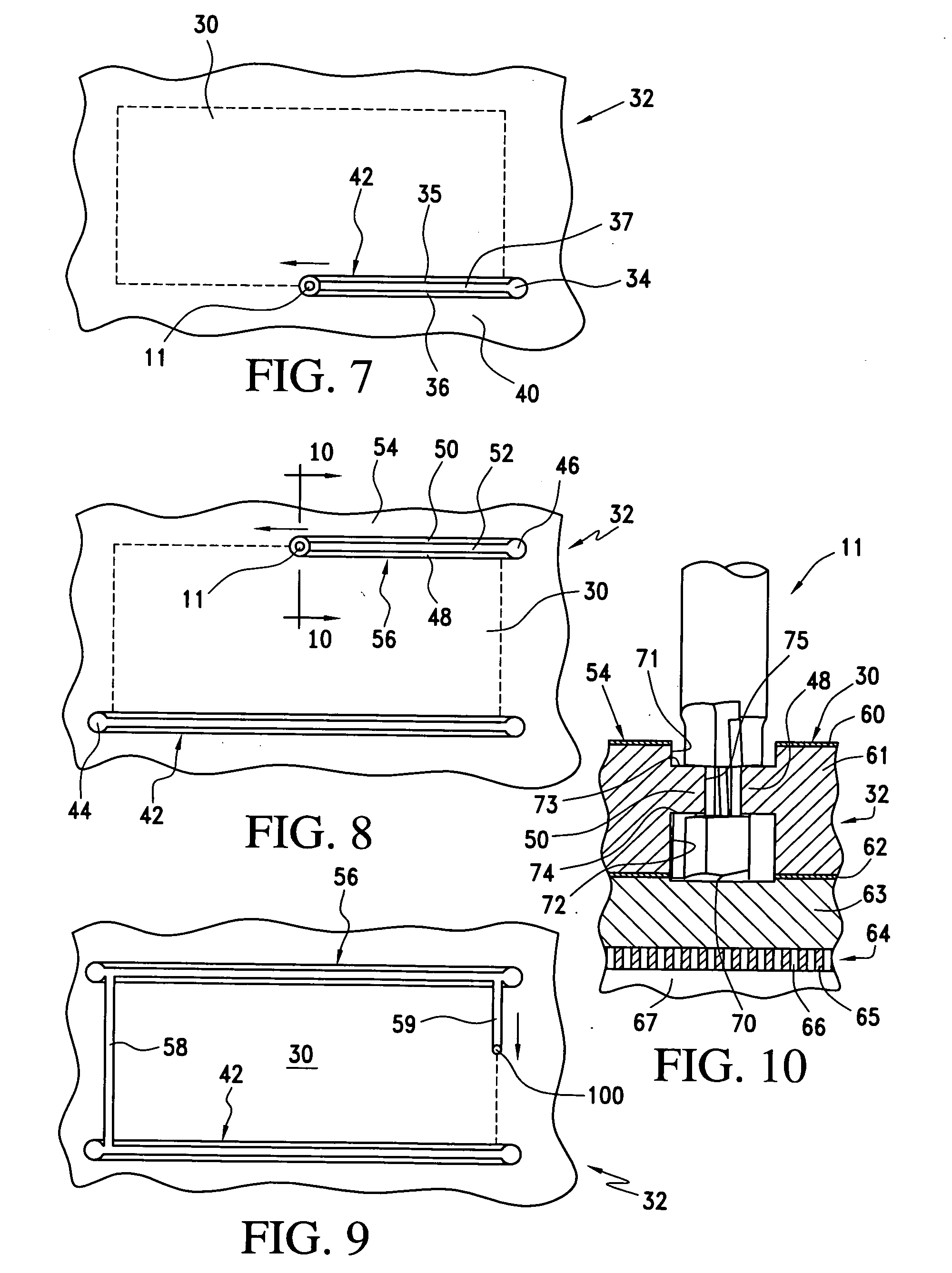

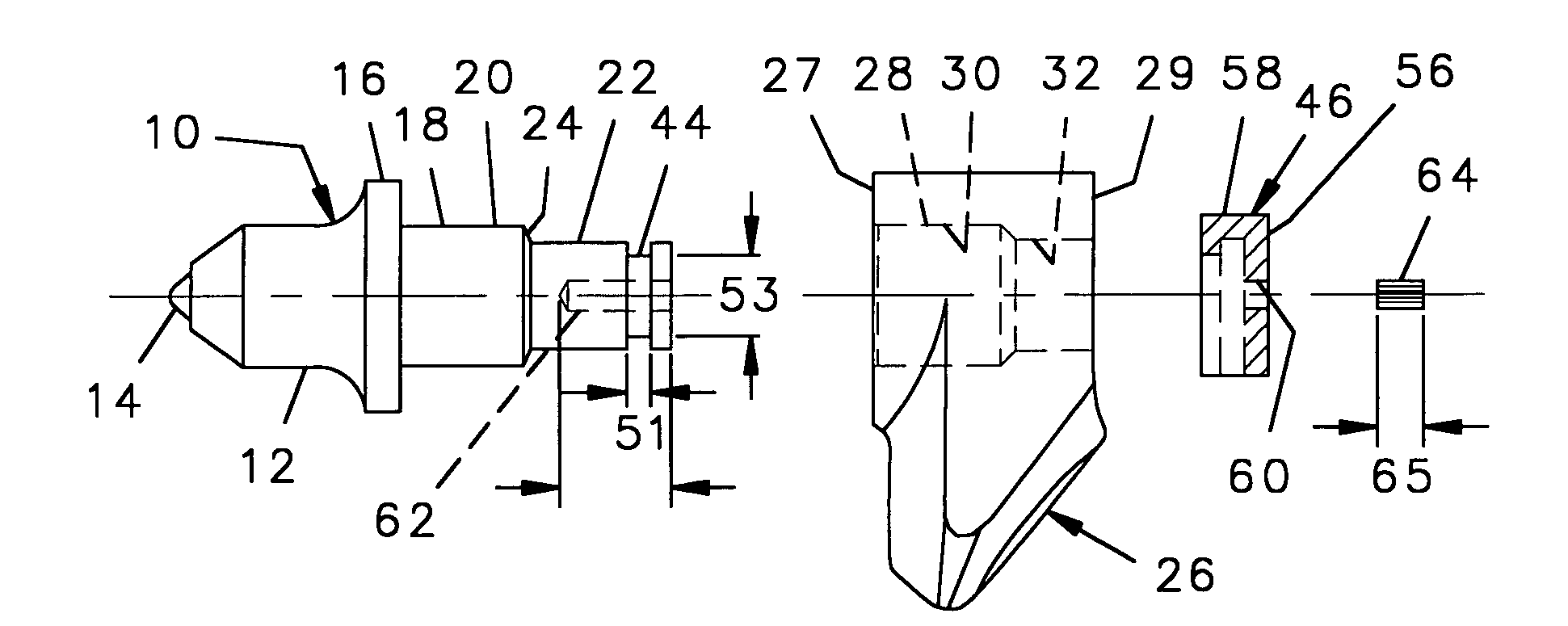

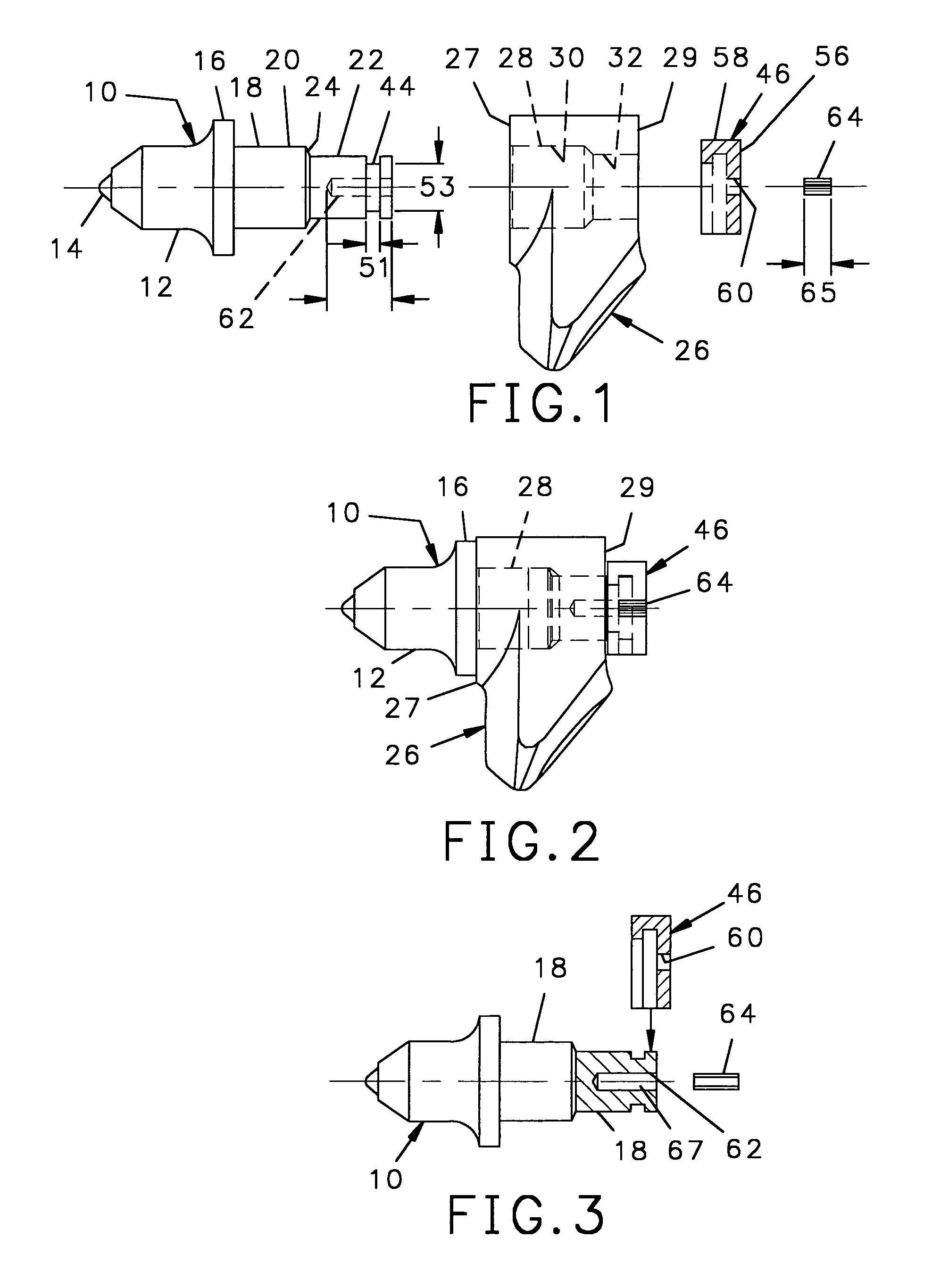

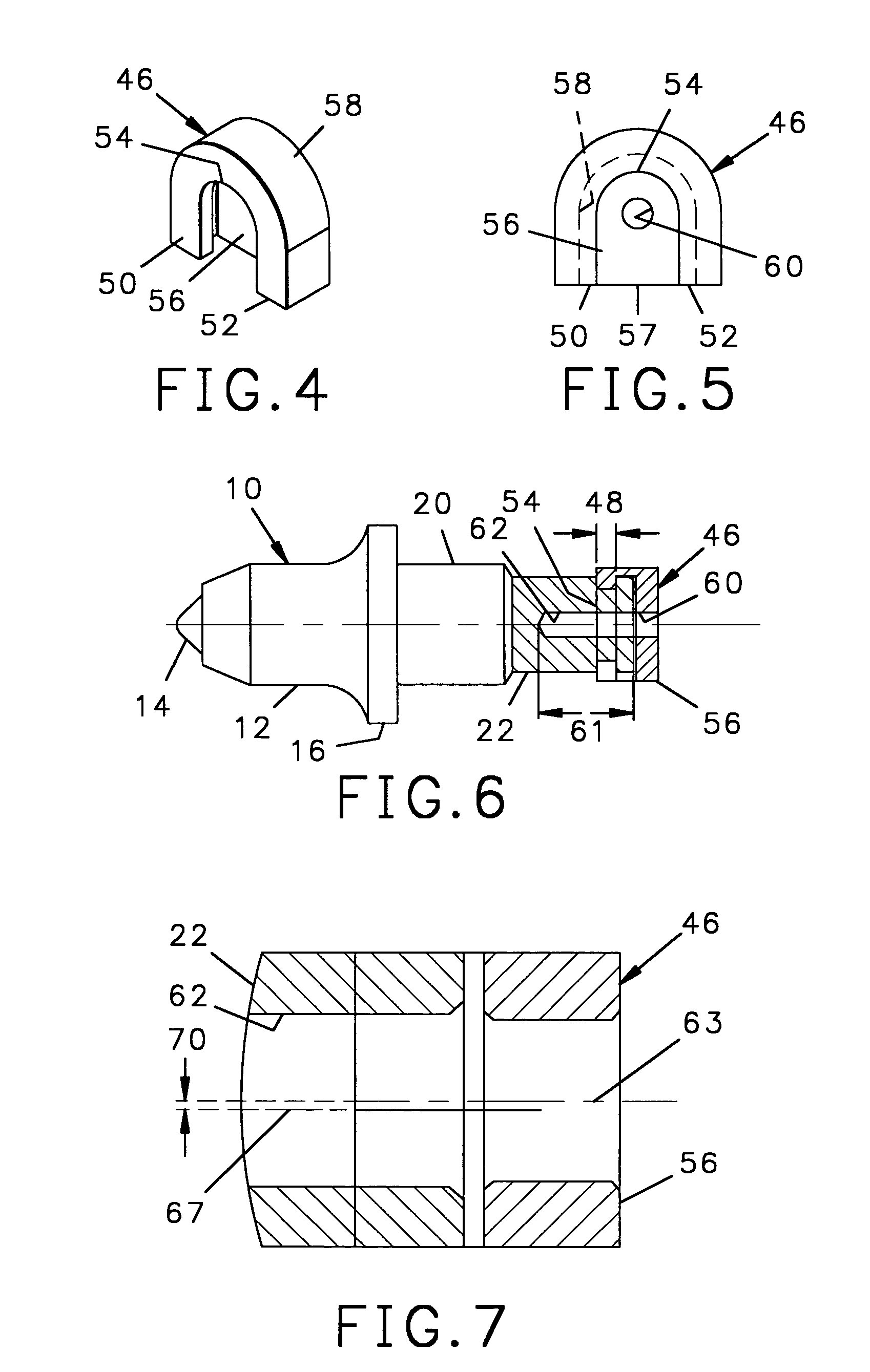

Retainer for a rotatable tool

The cylindrical shank of a rotatable tool is retained in the cylindrical bore of a tool holder by a retainer that engages an annular groove on a portion of the shank of the tool that extends outward of the rear surface of the tool holder. The tool has an axial bore in the distal end of the shank. The retainer has a pair of spaced ridges that engage the annular groove on the shank and a panel that extends across the distal end of the shank. The retainer is held in place by a pin extending through the panel and into the bore in the distal end of the shank.

Owner:THE SOLLAMI COMPANY

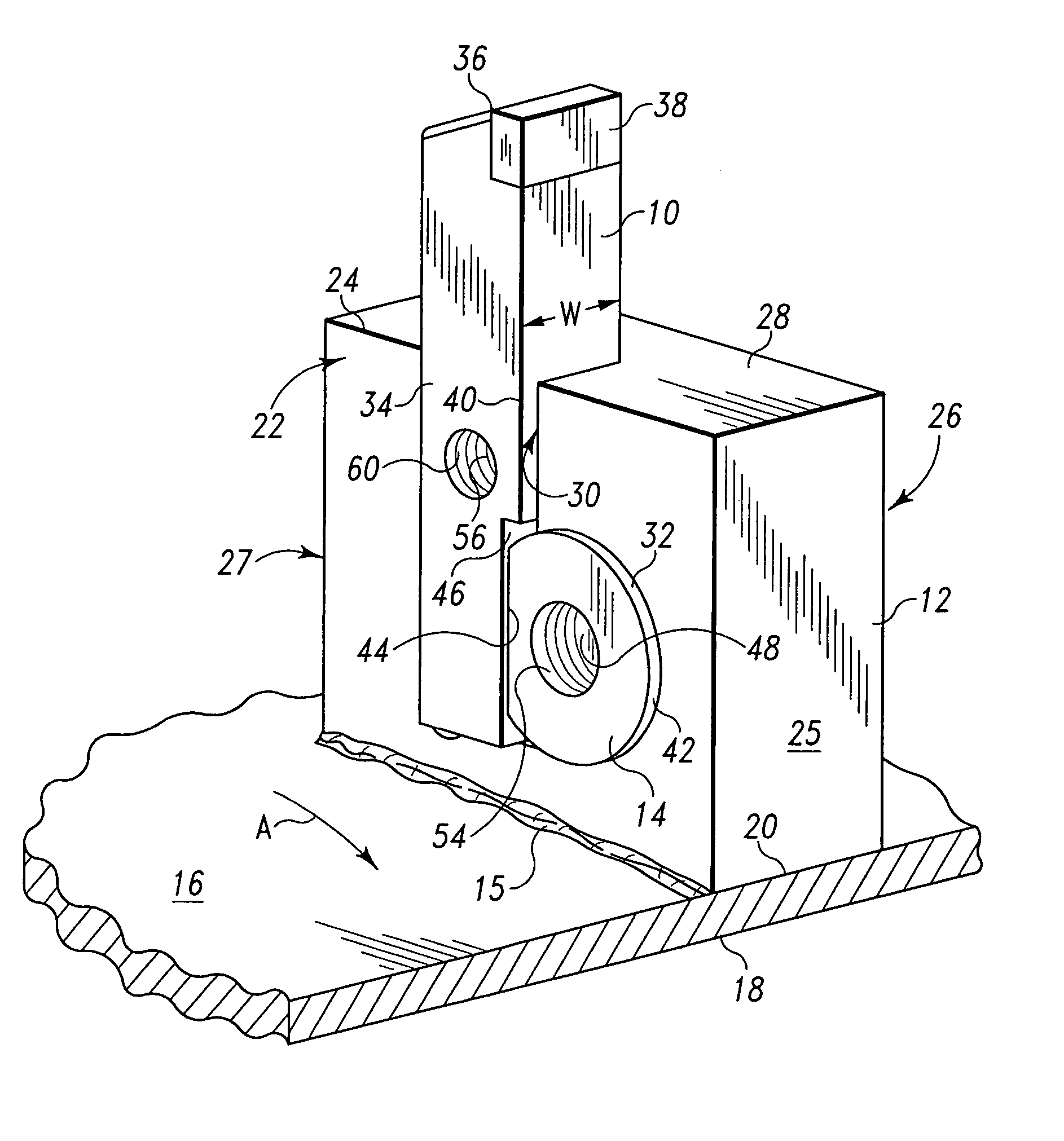

Angular tool and holding block

ActiveUS7108212B2Retainer and the cutting bit can be facilitatedMulti-purpose machinesProfiling/shaping machinesDrill bitTool holder

A cutting tool holder, a cutting bit, and a retainer maintaining the cutting bit at a prescribed position relative to the tool holder. The cutting bit is received in a slot located in a first lateral surface that extends through the top surface. The retainer is received in an opening included in the first lateral surface that intercepts the slot. The retainer includes a planar tapered surface that contacts an upwardly and laterally facing oblique surface on a lower end of the cutting bit to hold the lower end of the cutting tool in contact with a lower surface of the slot.

Owner:LATHAM WINCHESTER E

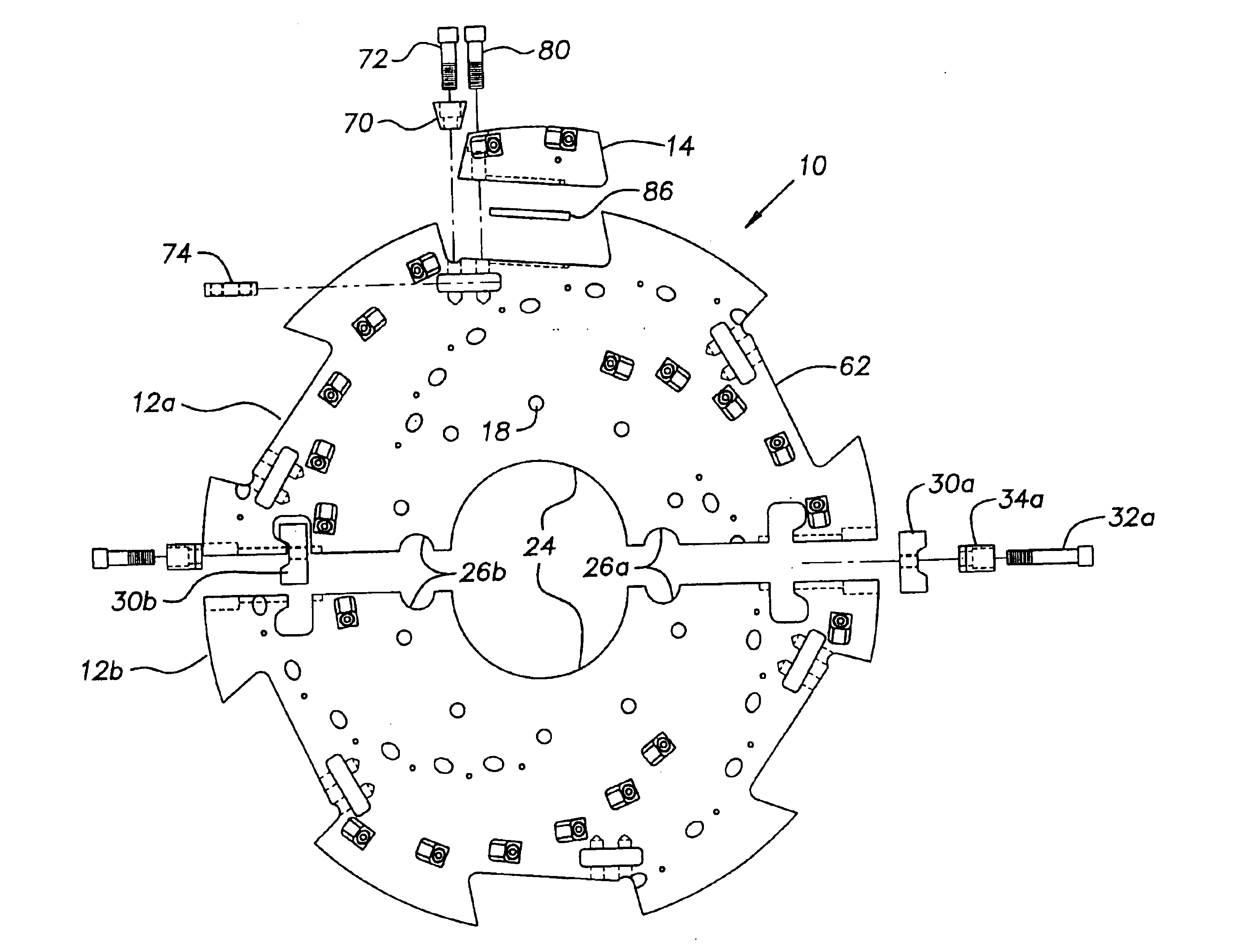

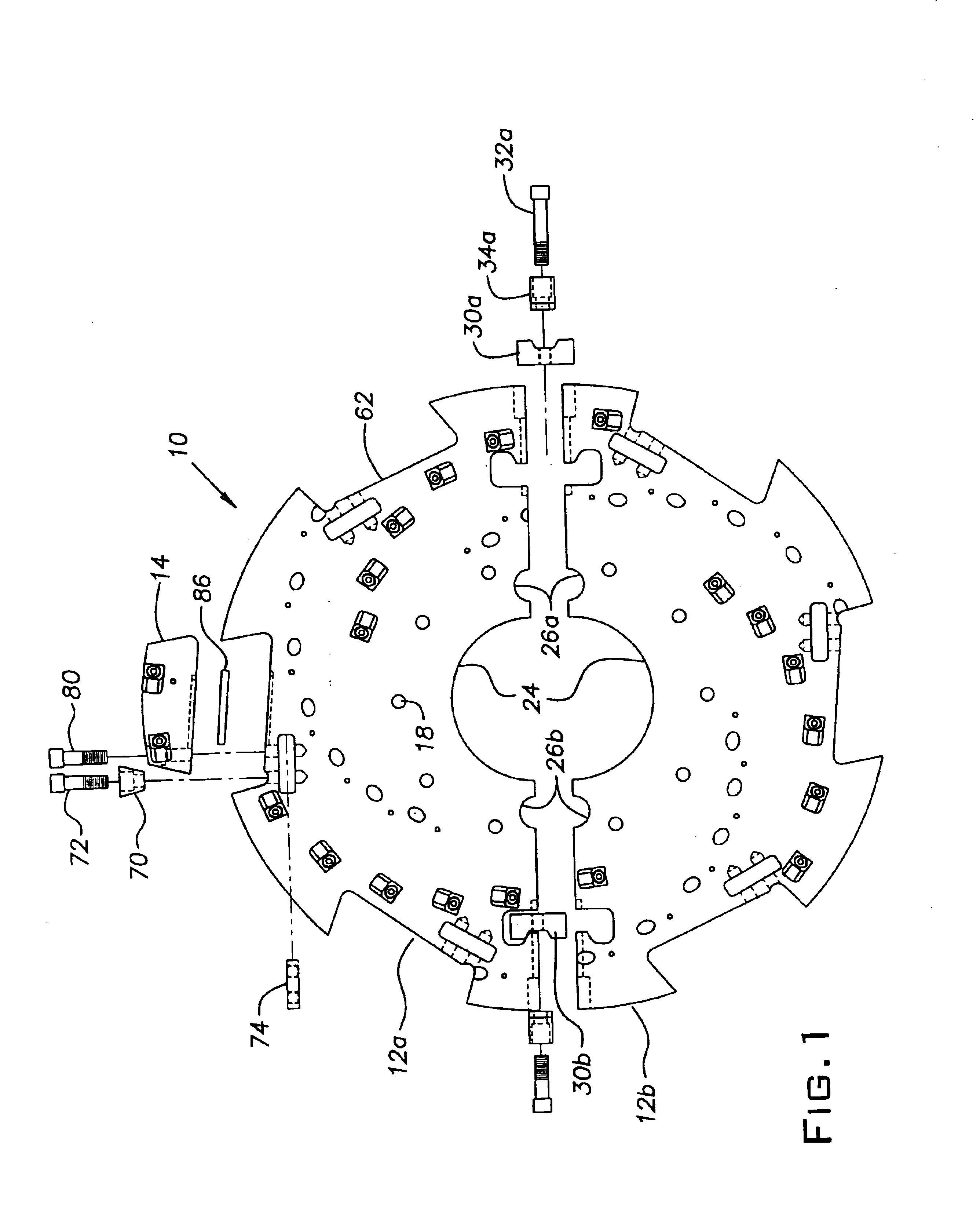

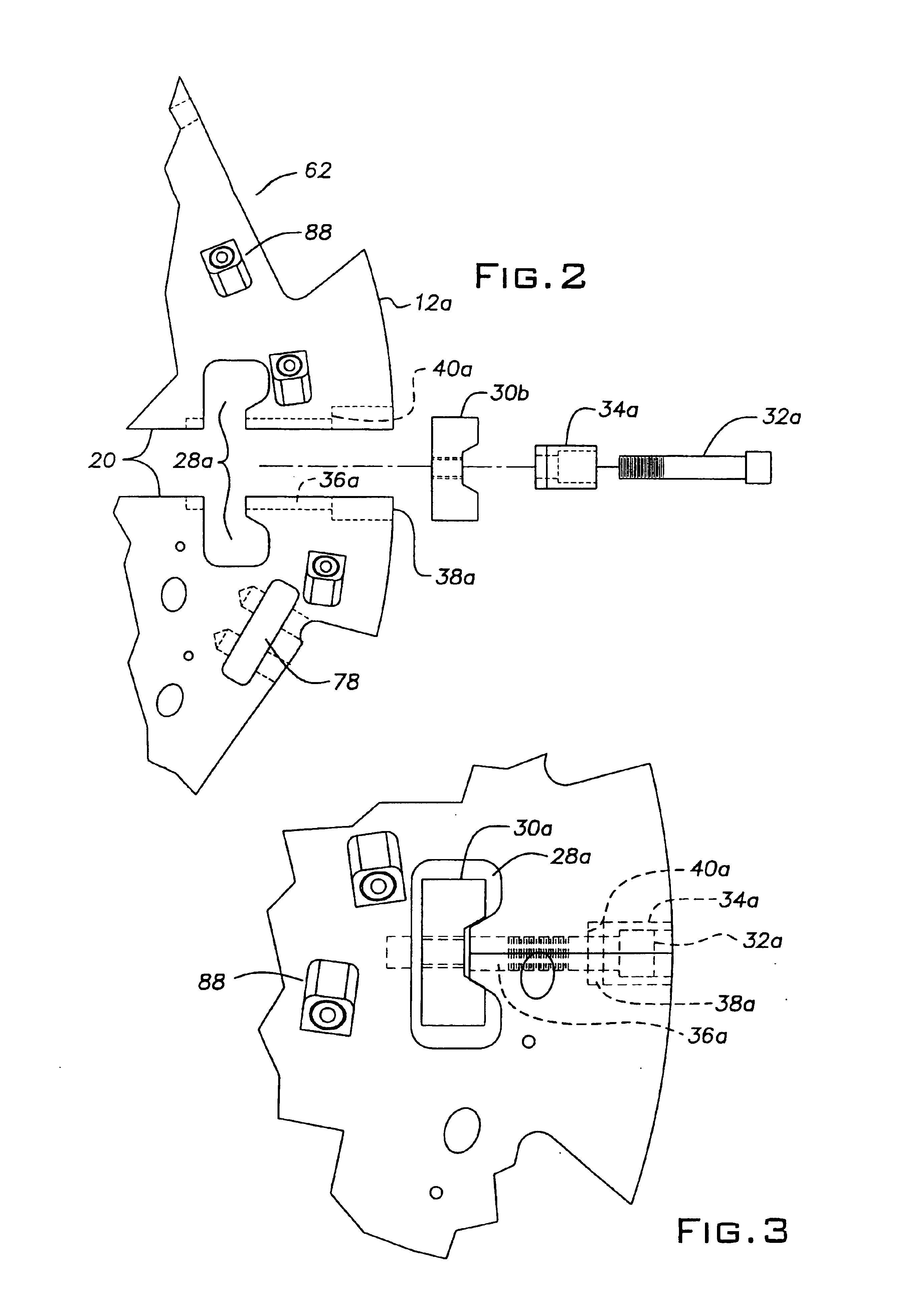

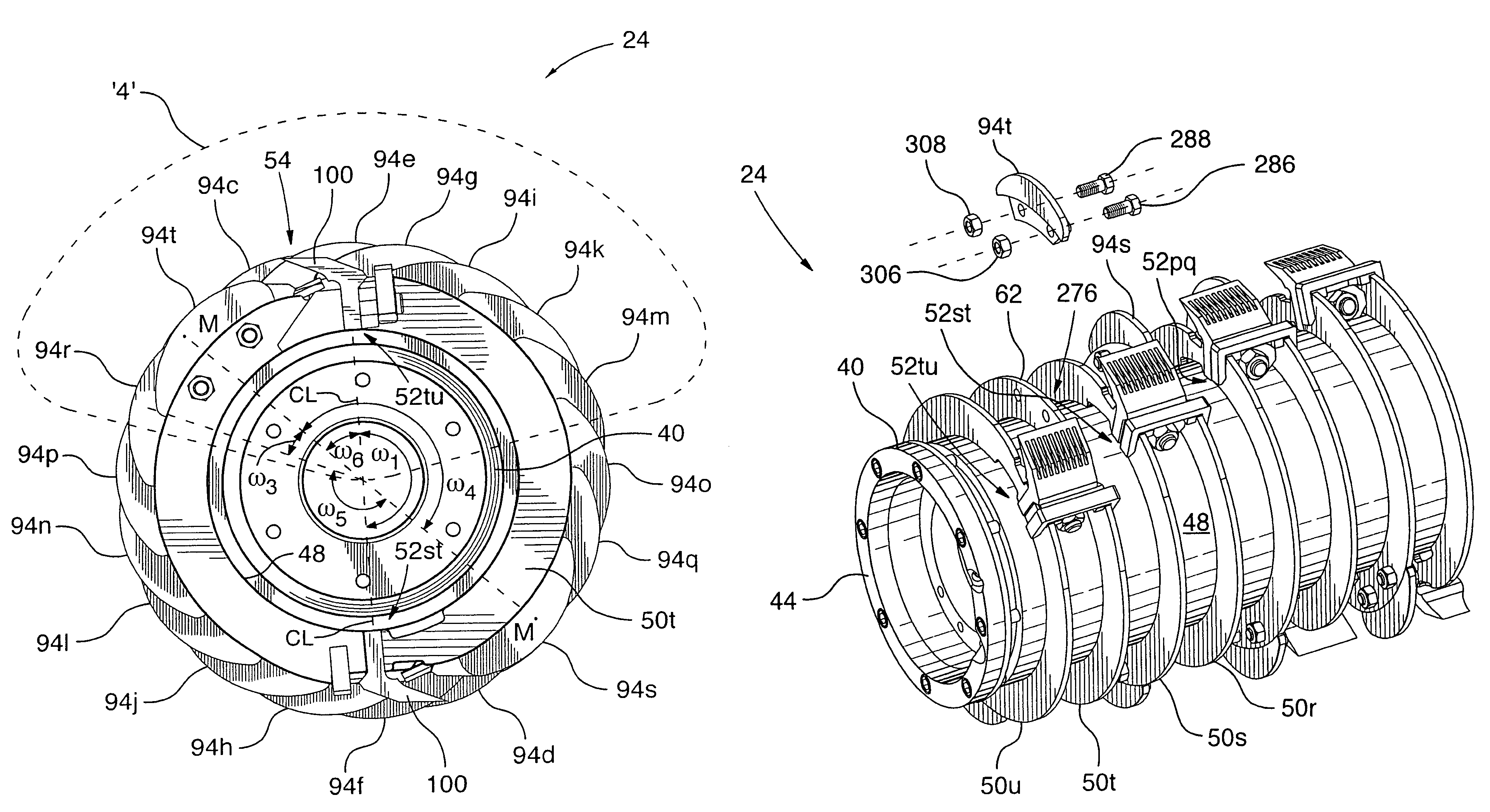

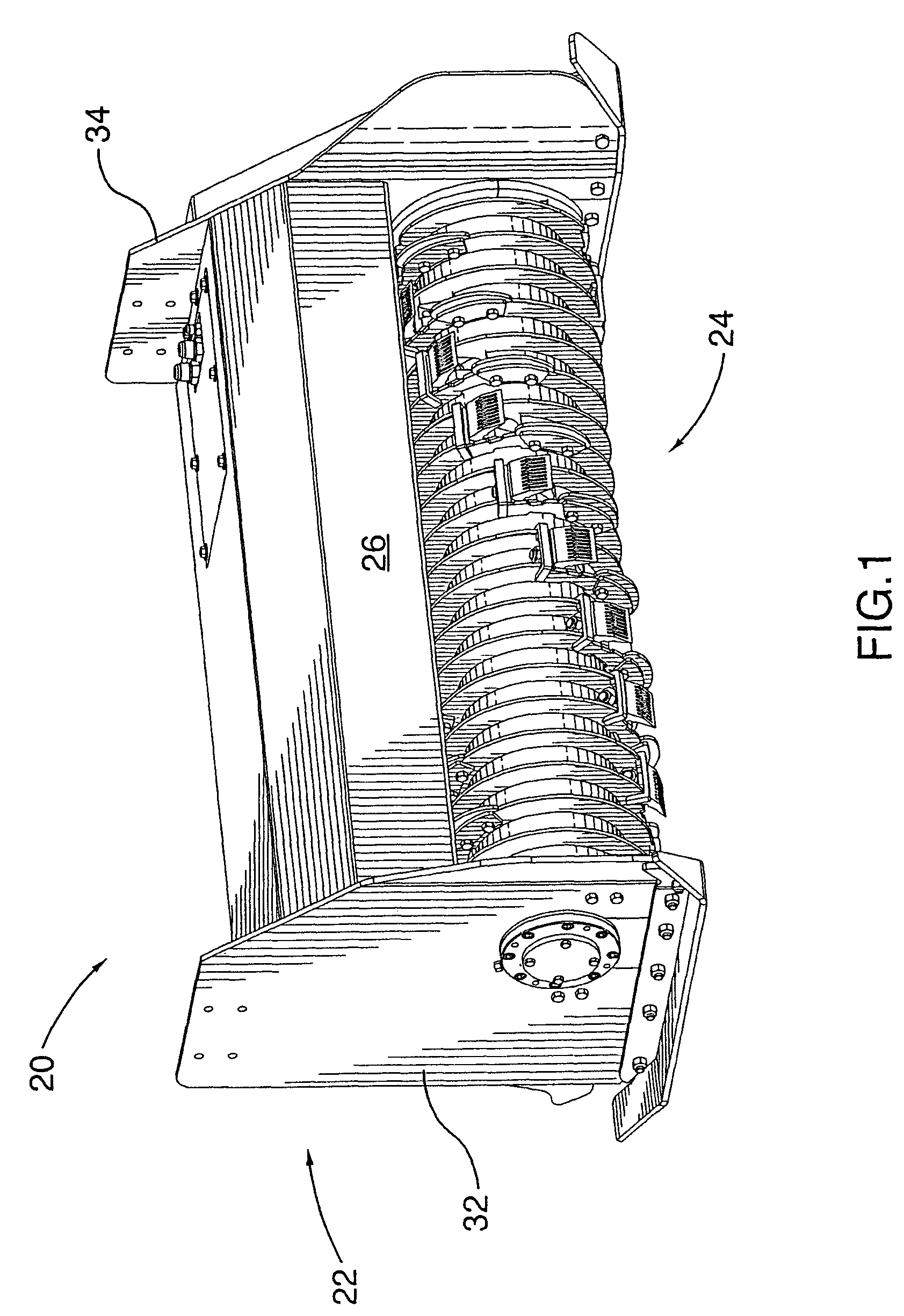

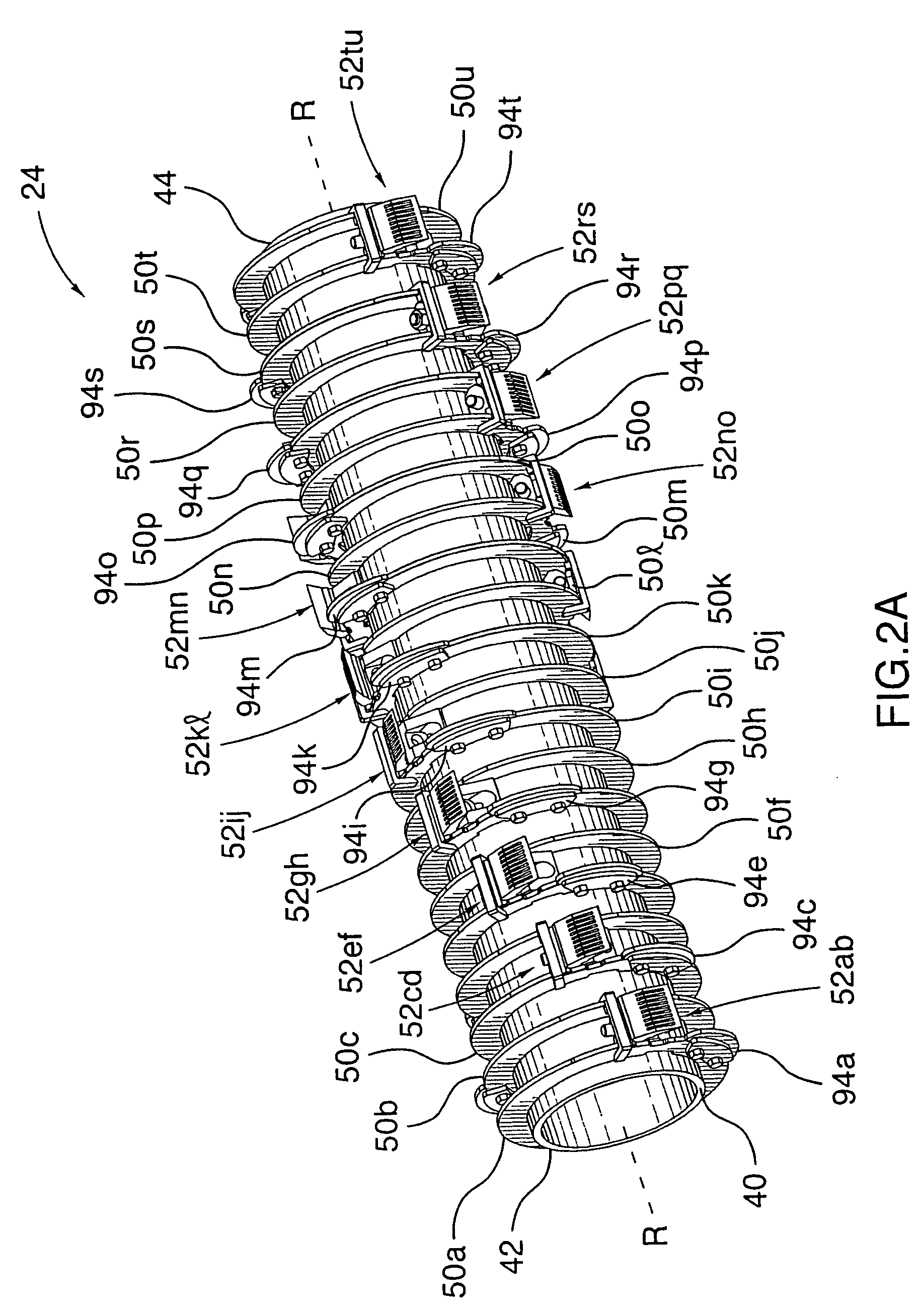

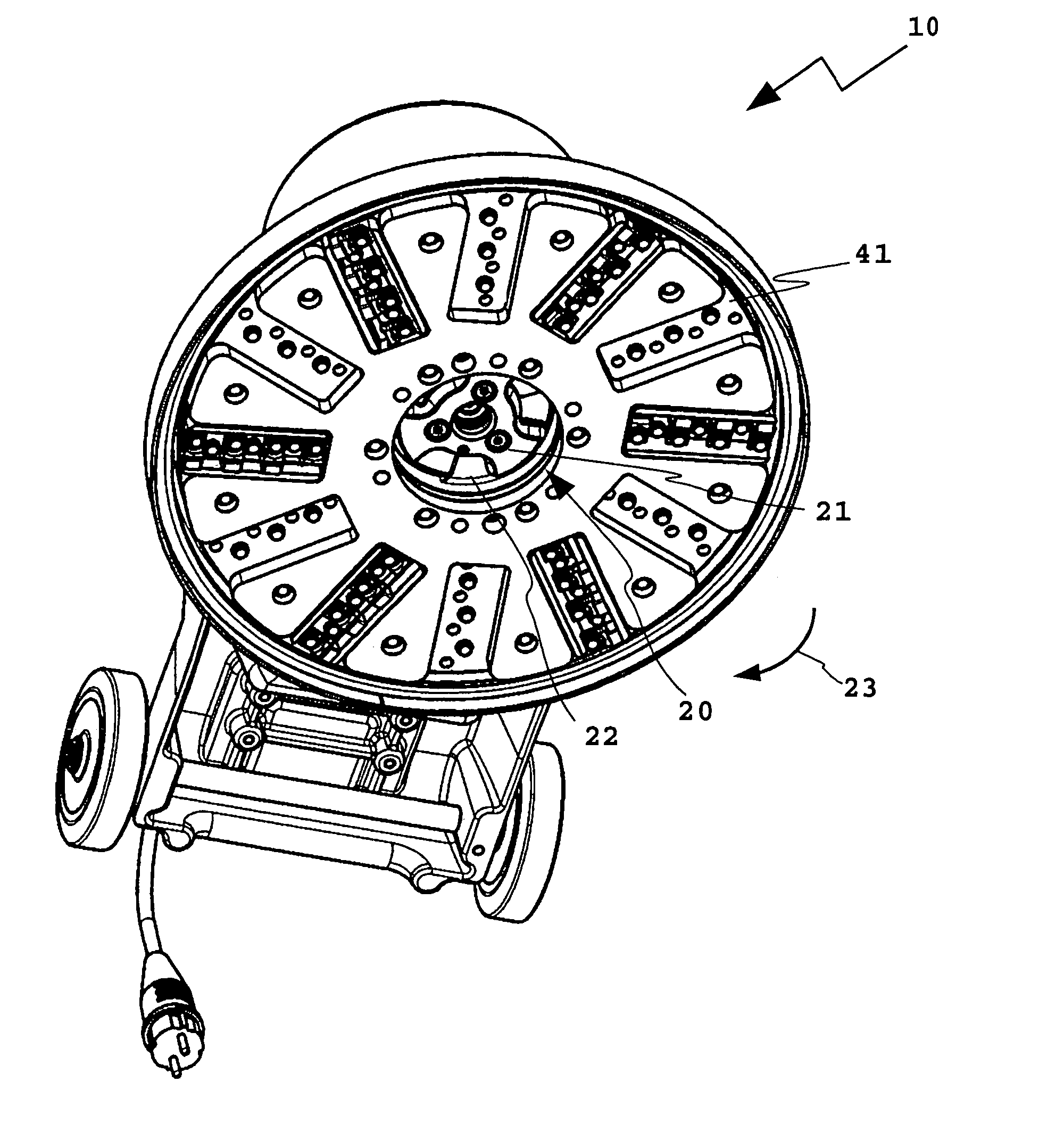

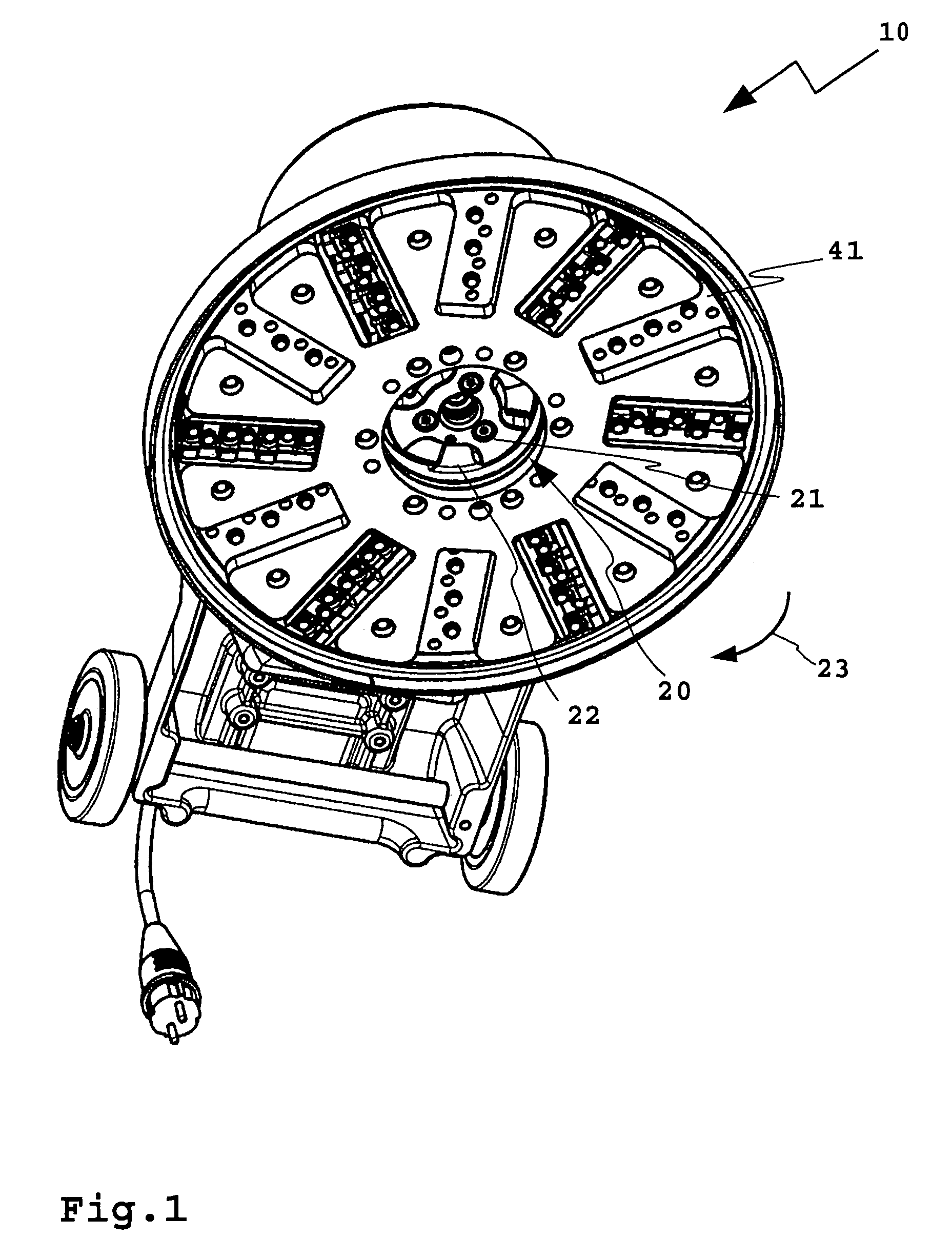

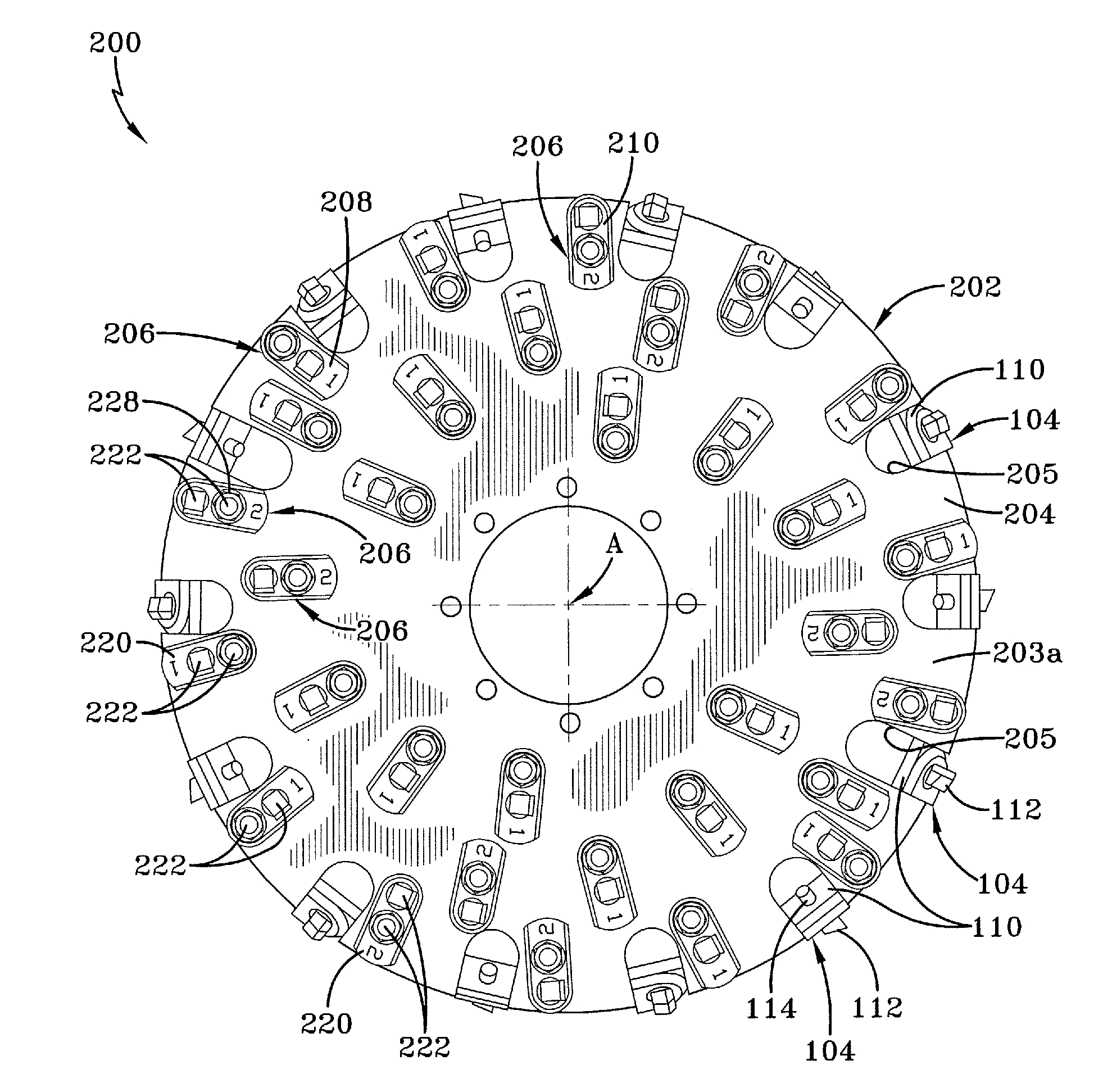

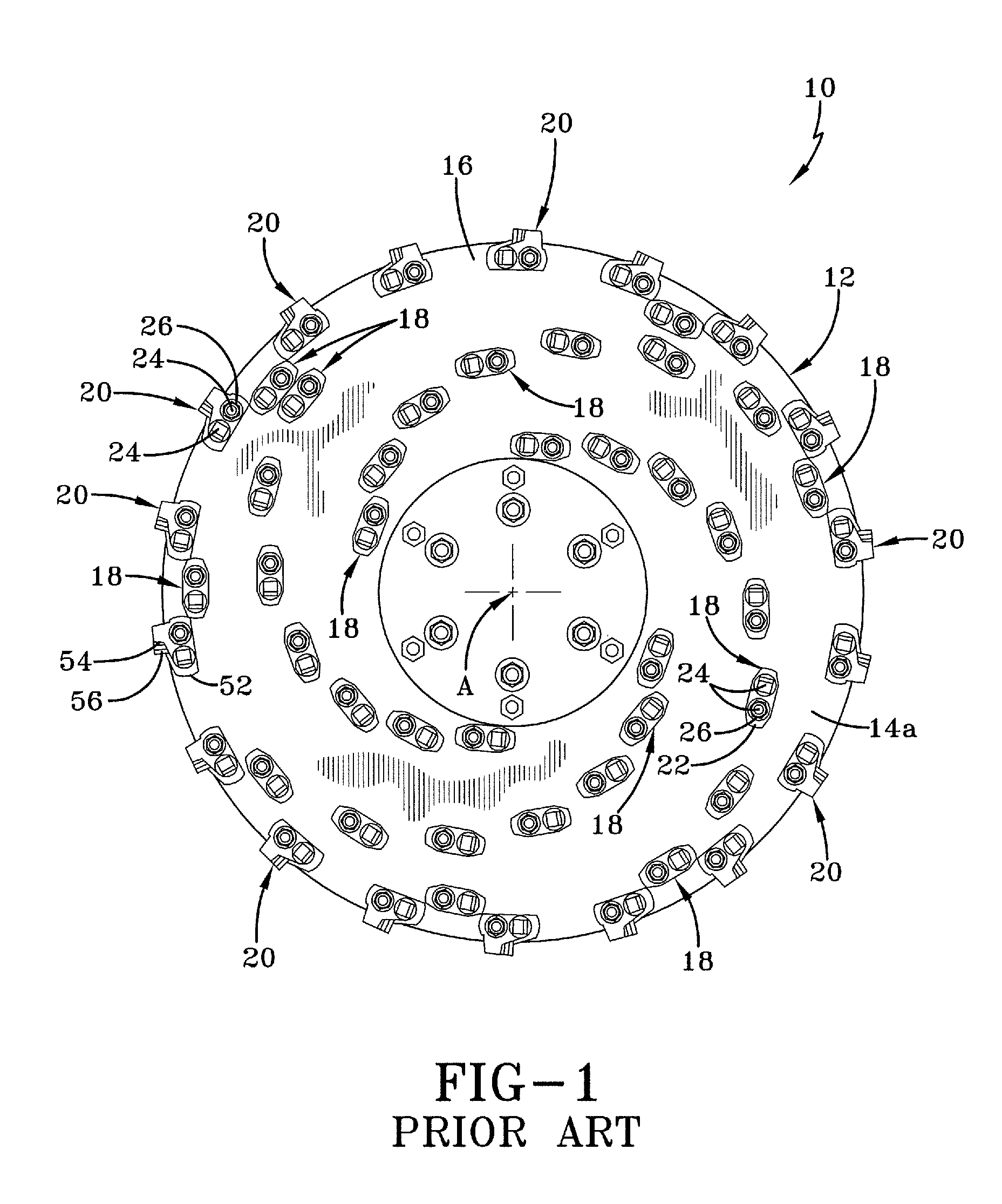

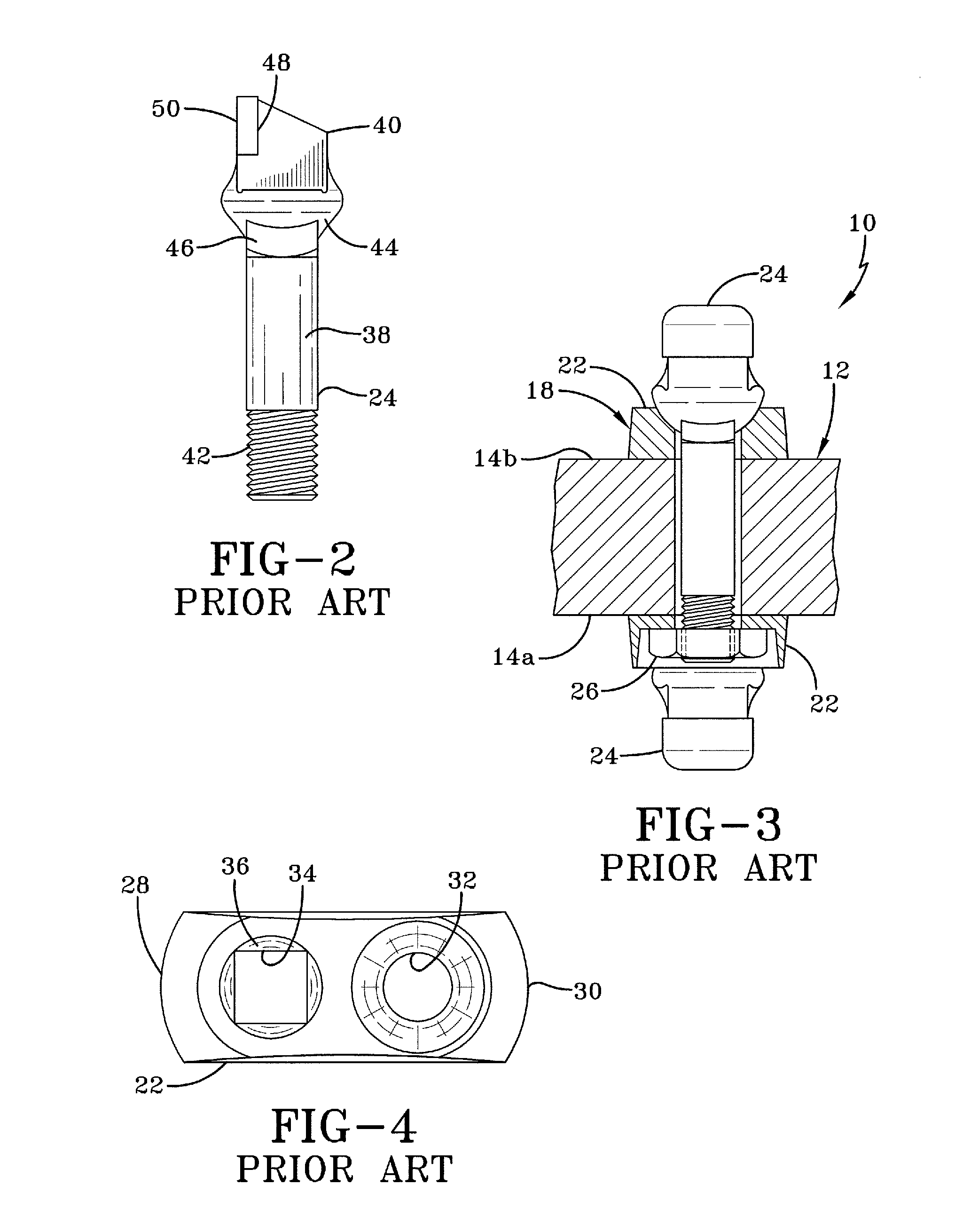

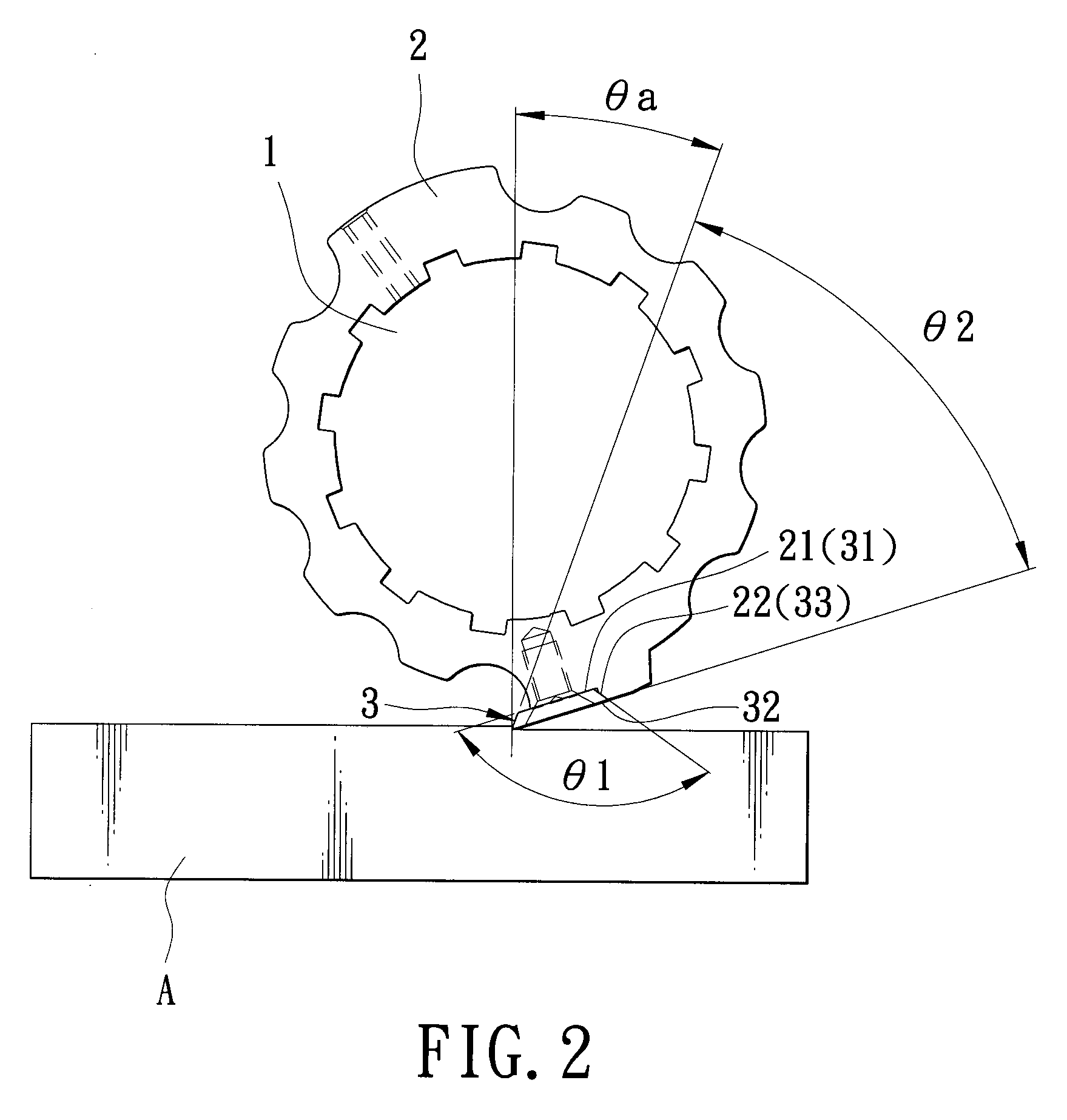

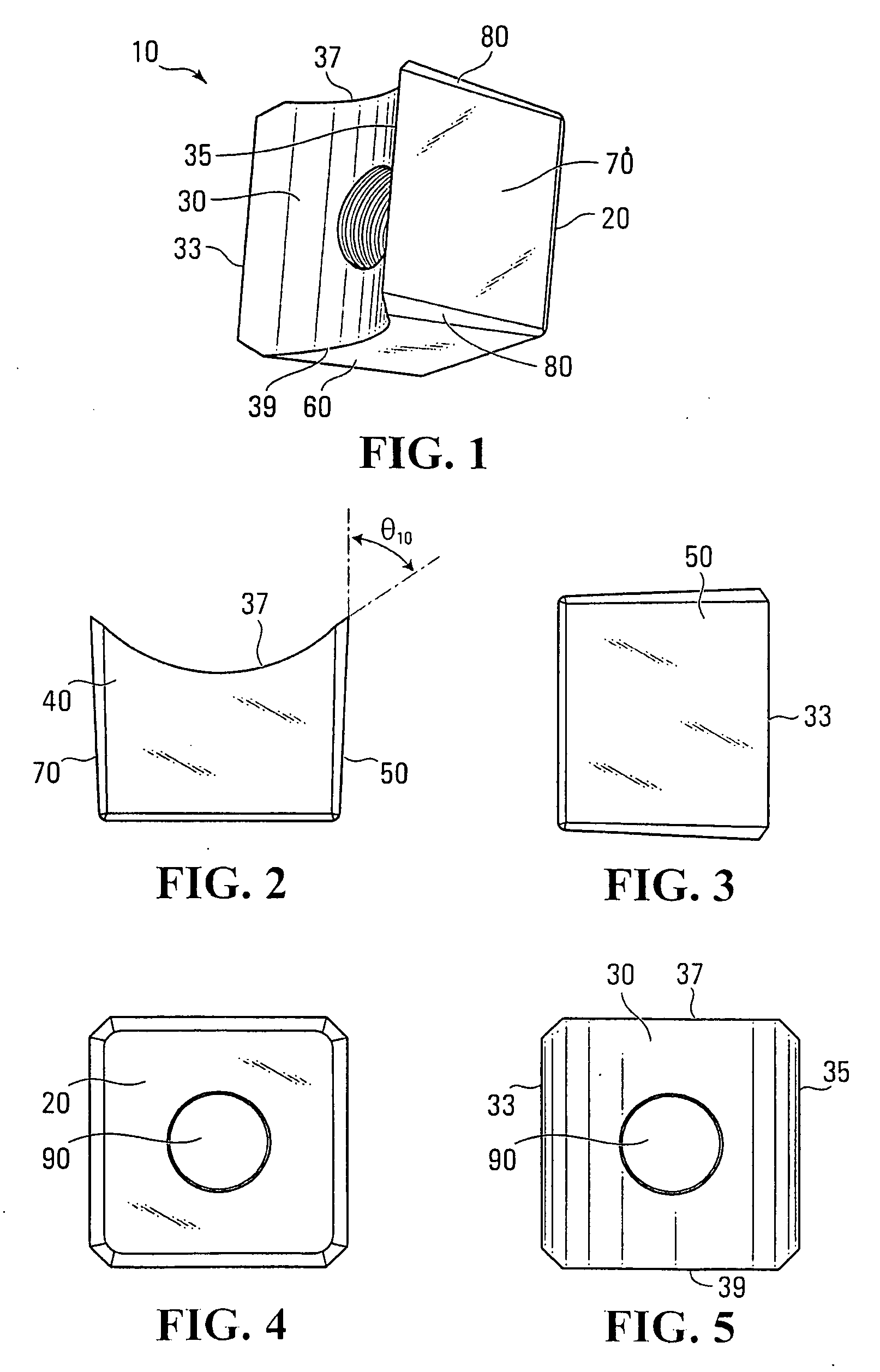

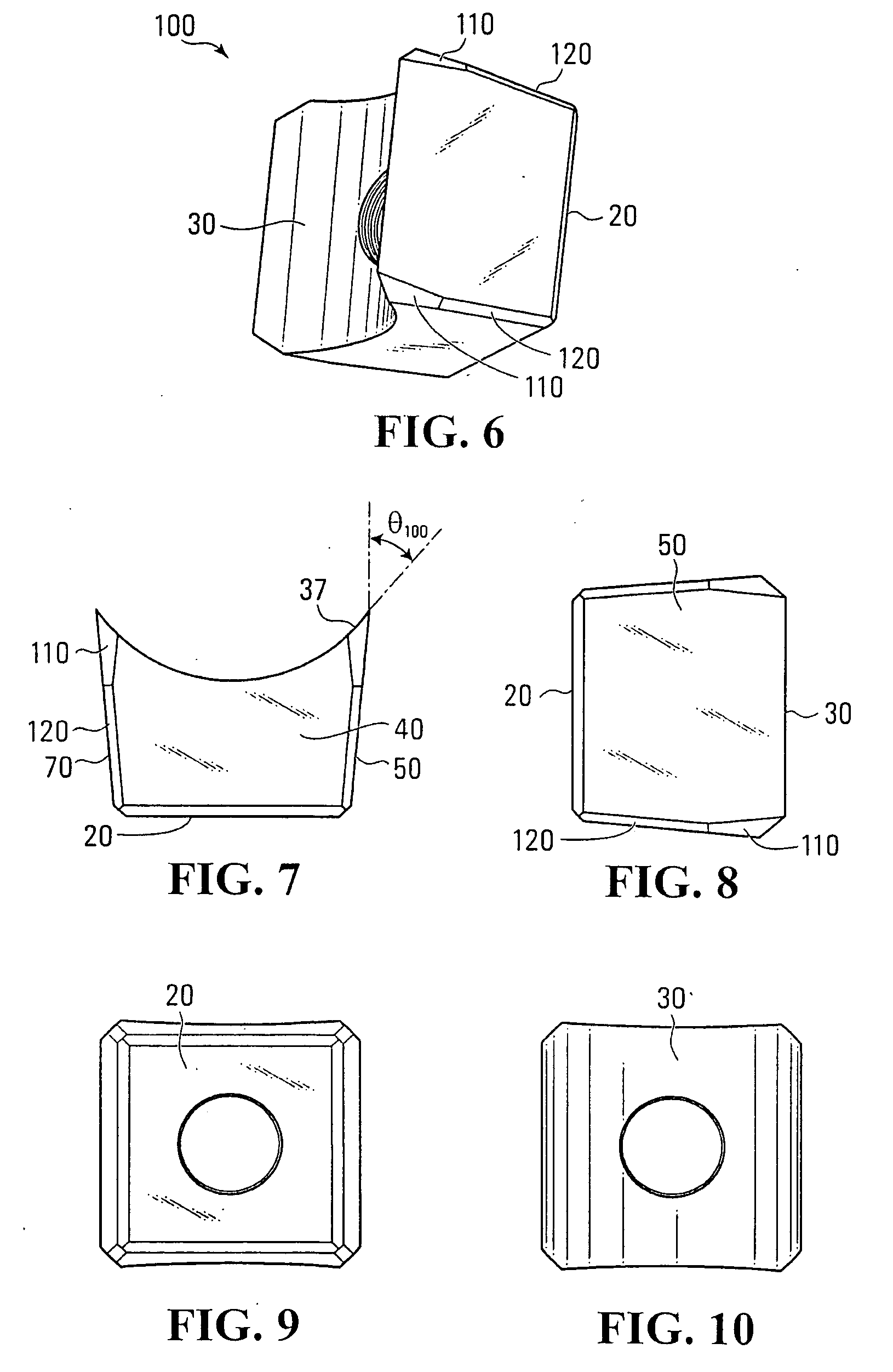

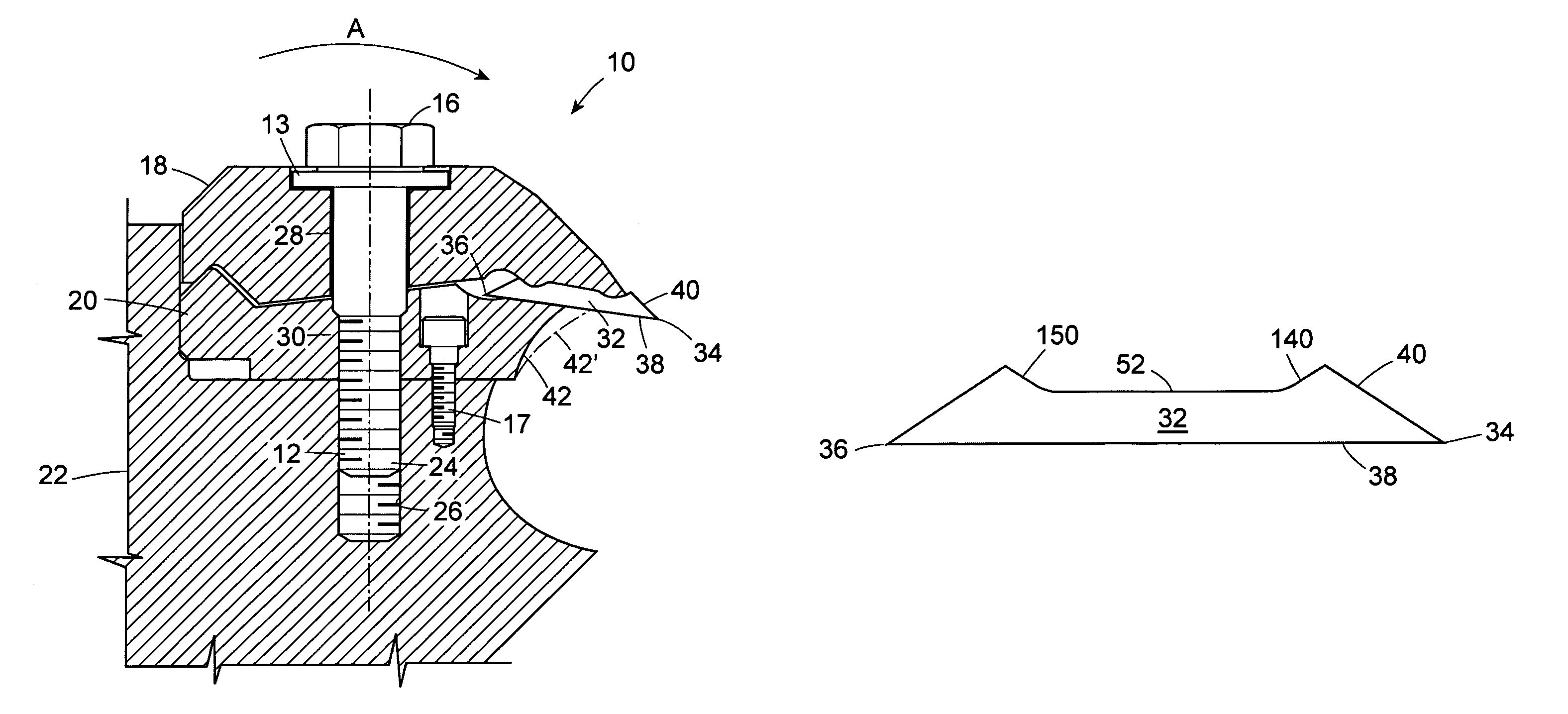

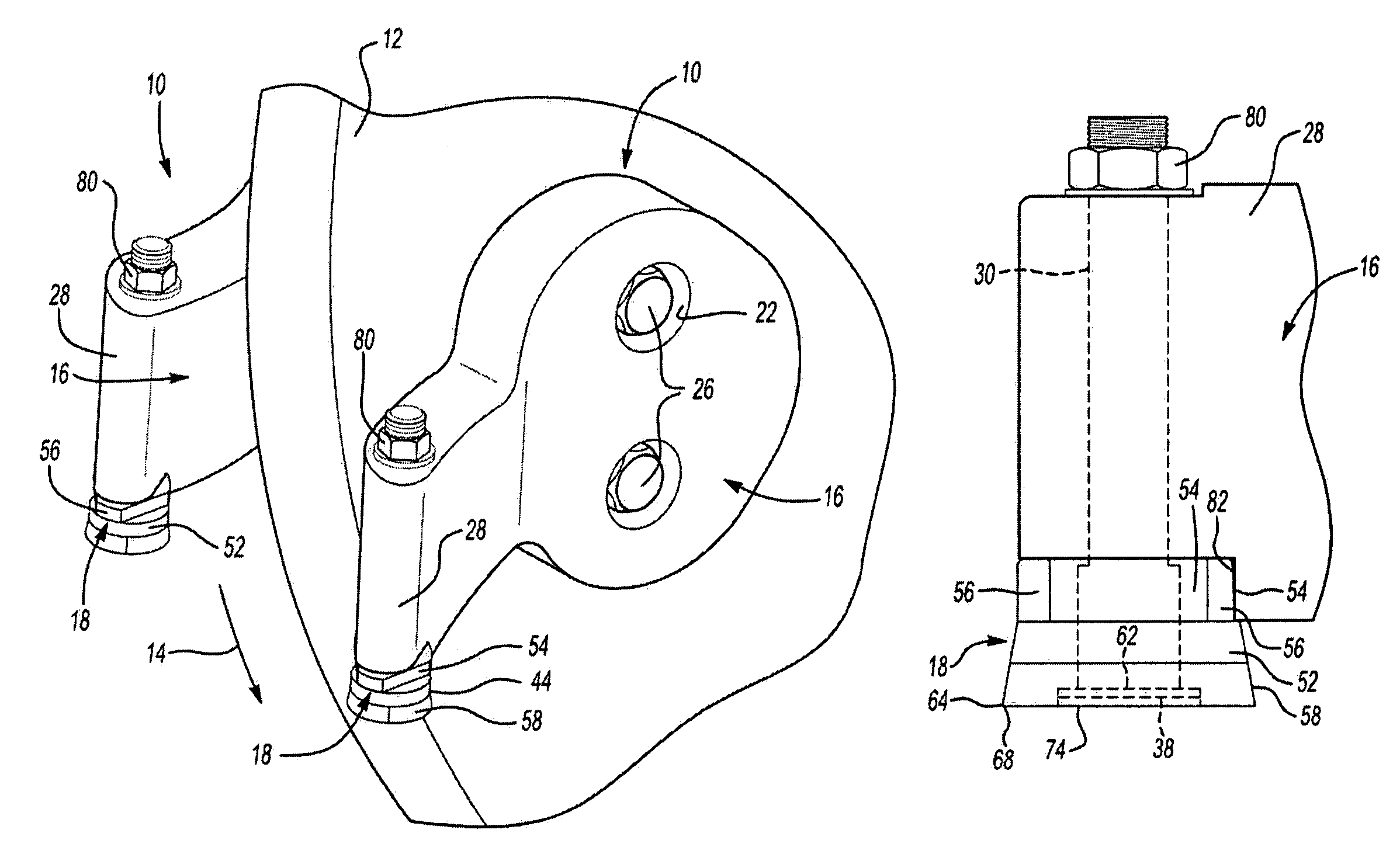

Rotary cutting machine with replaceable cutting teeth

A rotary cutting machine comprises a circular rotating element having a transverse axis of rotation and which is mounted to the rotary cutting machine for rotation about the axis of rotation. A plurality of cutting teeth are mounted to the circular rotating element at spaced apart locations about its circumferential periphery. The cutting teeth are reversible and removably fastened to the circular rotating element. Each cutting tooth includes opposed first and second cutting faces spaced apart by lateral surfaces extending therebetween. The first and second cutting faces define at least four of the cutting edges thereon, such that the cutting teeth are selectively mountable on the circular rotating element in any one of at least eight different positions, each of the positions providing a different one of the cutting edges in the operable cutting position.

Owner:QUADCO

Brush cutting head with internally housed drive and bearing assembly

A brush cutting head having internally housed drive and bearing assemblies which can be easily attached / detached from the brush cutter housing without having to dismantle the drive assembly for improved productivity. The brush cutting head includes a hollow support body, a drive and bearing assembly housed at least partially within the hollow of the support body, a drive block mounted to extend within the hollow of the support body, and a motor provided with a torque transmitting driveshaft.

Owner:ERNST & YOUNG INC +1

Protective guard members for cutting tooth assemblies mounted on a brush cutting head

Owner:ERNST & YOUNG INC +1

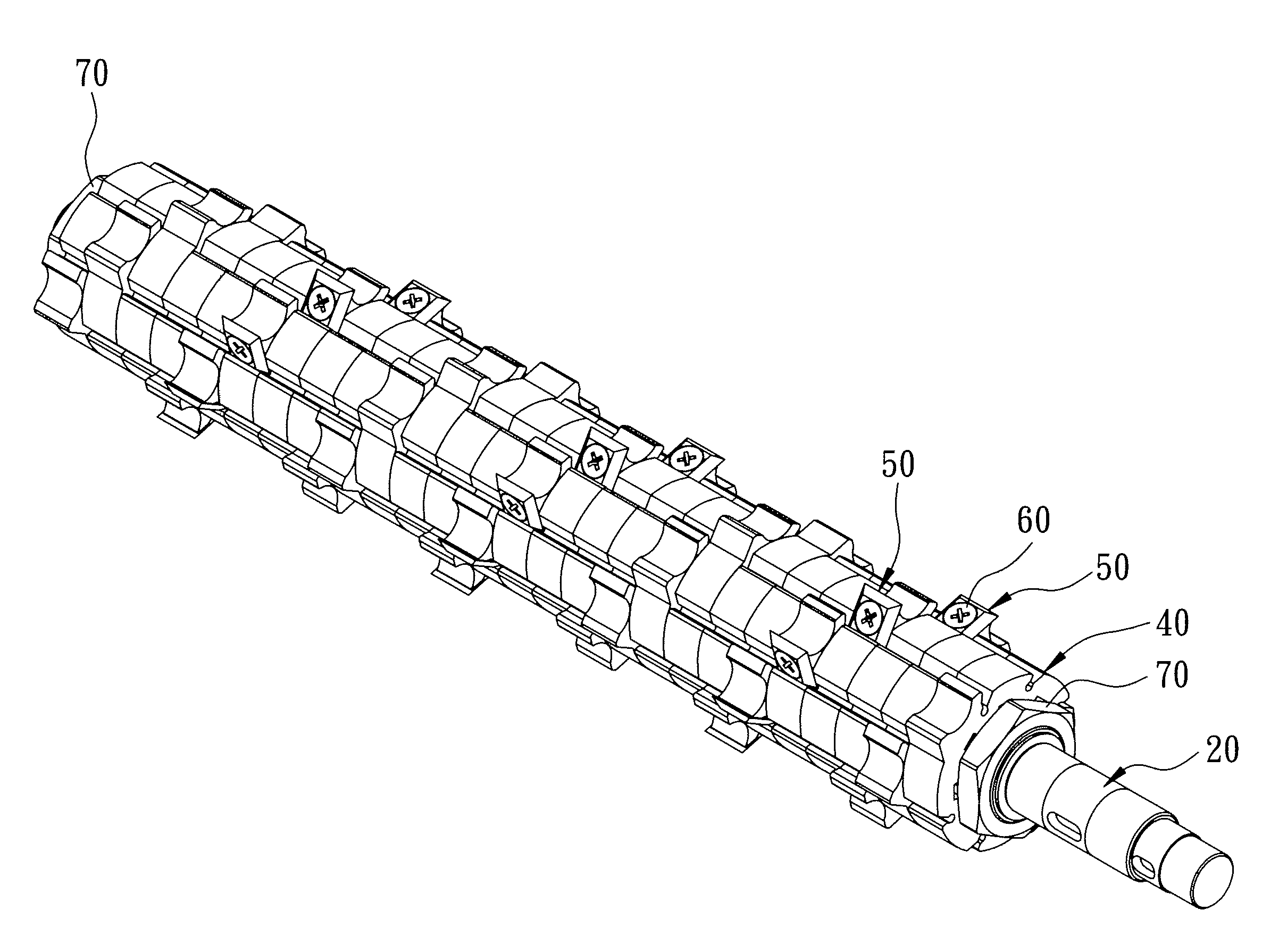

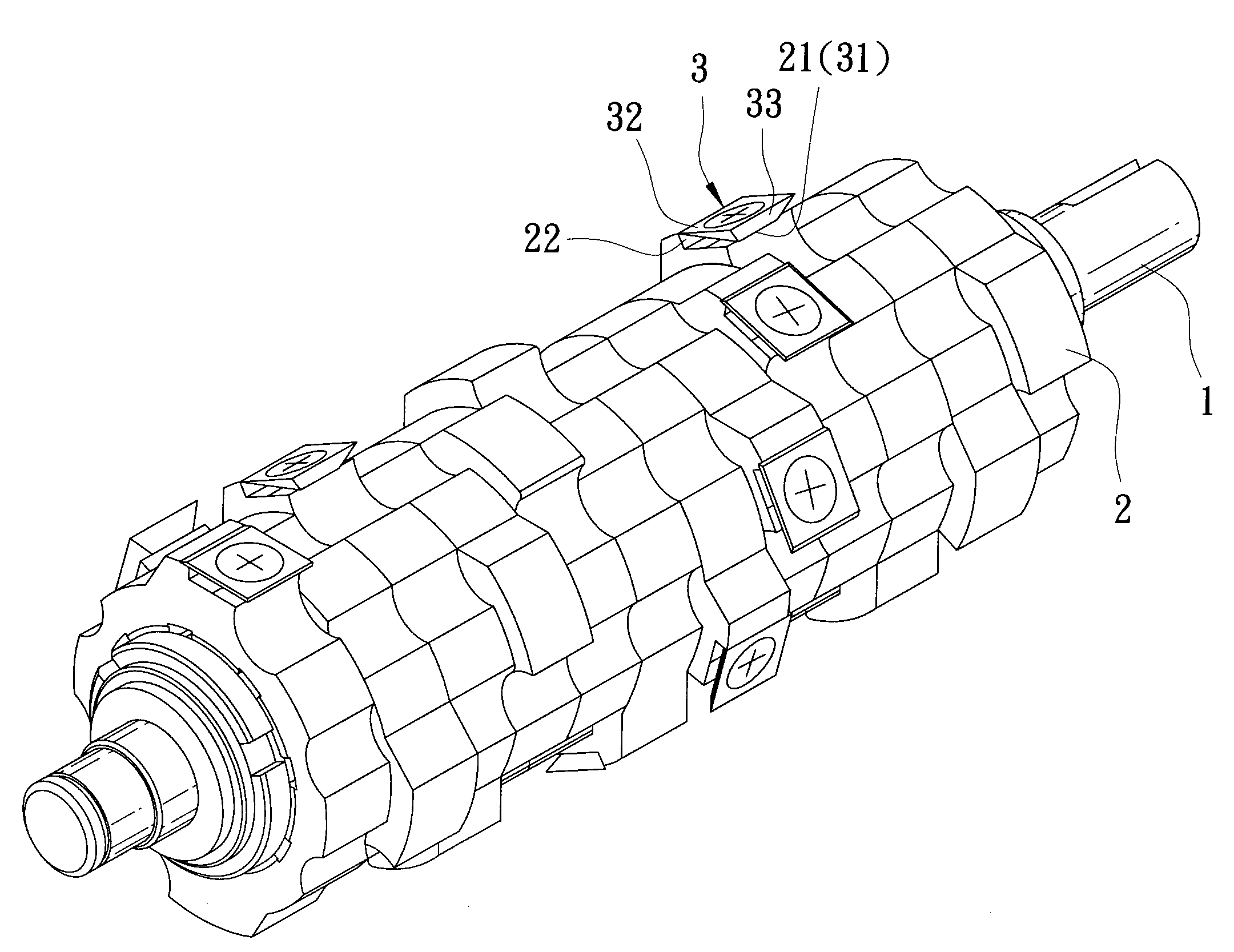

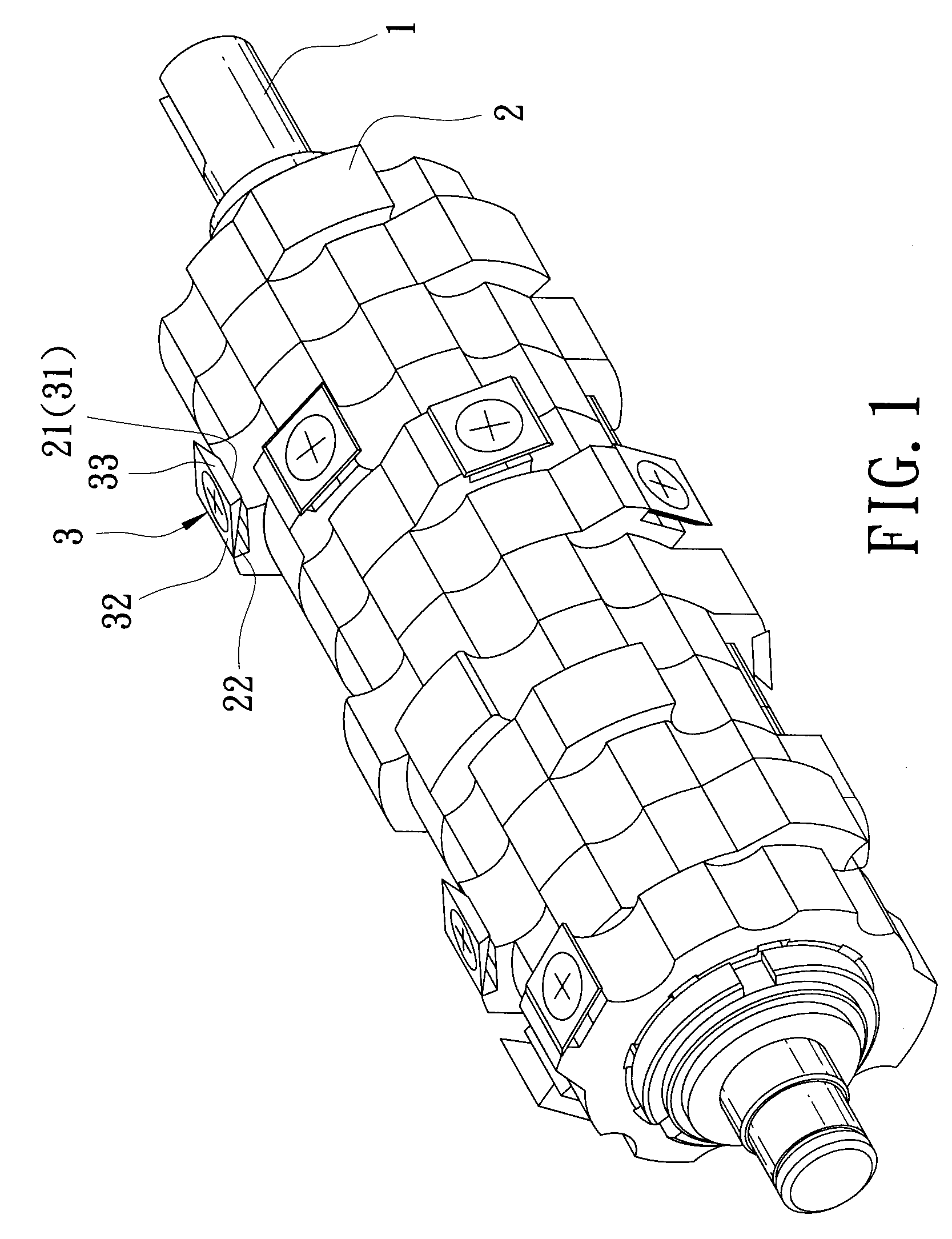

Cutter head assembly for a wood planing machine

ActiveUS7954523B2Convenient and less-costly to fabricateMulti-purpose machinesProfiling/shaping machinesEngineeringMechanical engineering

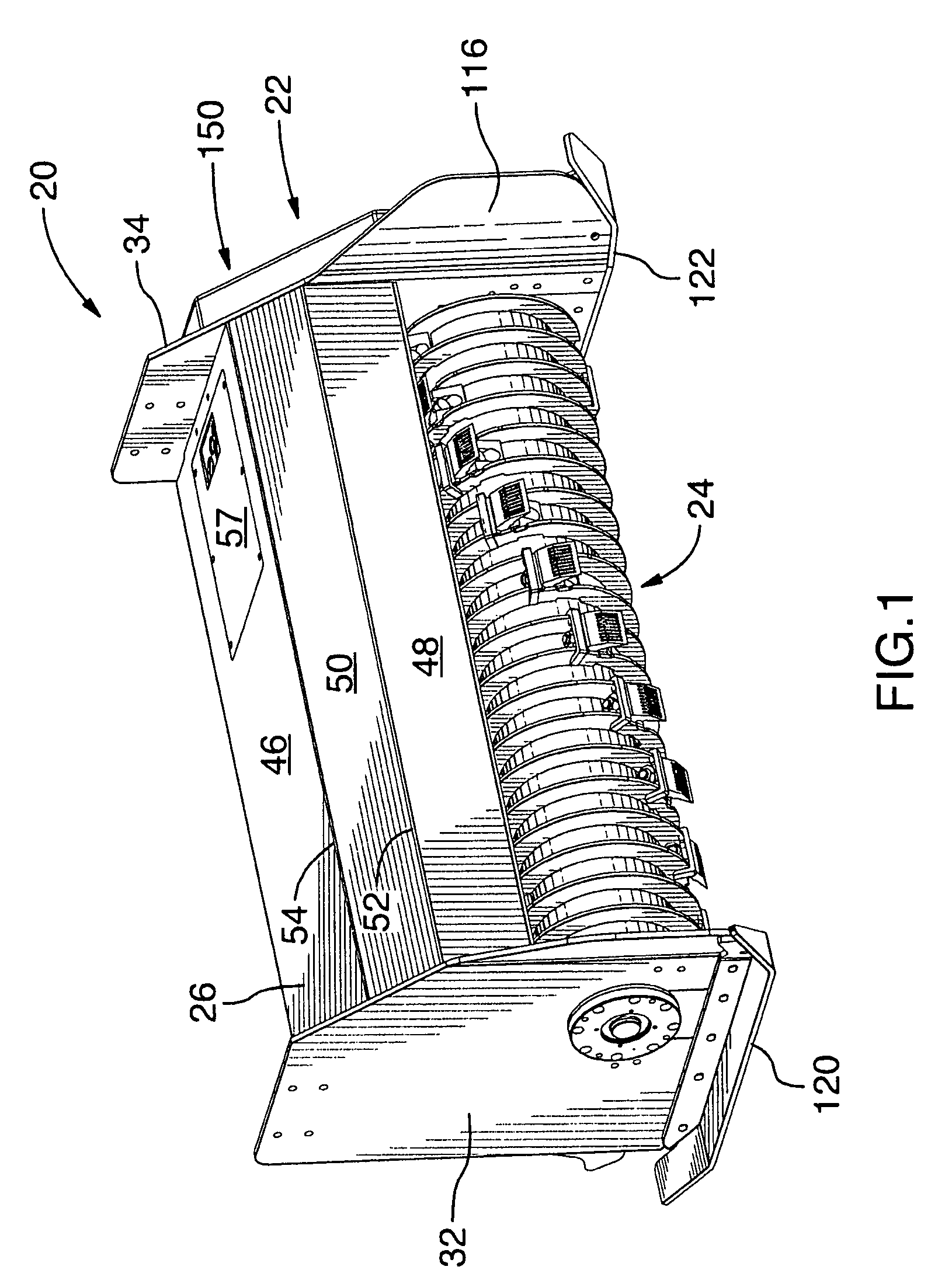

A cutter head assembly for a wood planing machine includes a shaft, a plurality of cutter-mounting sleeve modules sleeved on the shaft, and a plurality of cutter modules respectively secured to the sleeve modules such that cutting edges of the cutter modules extend beyond outer wall surfaces of the sleeve modules. An angularly variable positioning mechanism includes an axially extending guiding member disposed on the mount segment, and a plurality of axially extending guided members disposed on inner wall surfaces of the sleeve modules to mate with the axially guiding member. By virtue of fitting engagement between the guiding member and a selected one of the guided member of each sleeve module that are sequentially sleeved onto the shaft, the cutting edges together define a cutting contour line that winds around the shaft.

Owner:SHINMAX IND

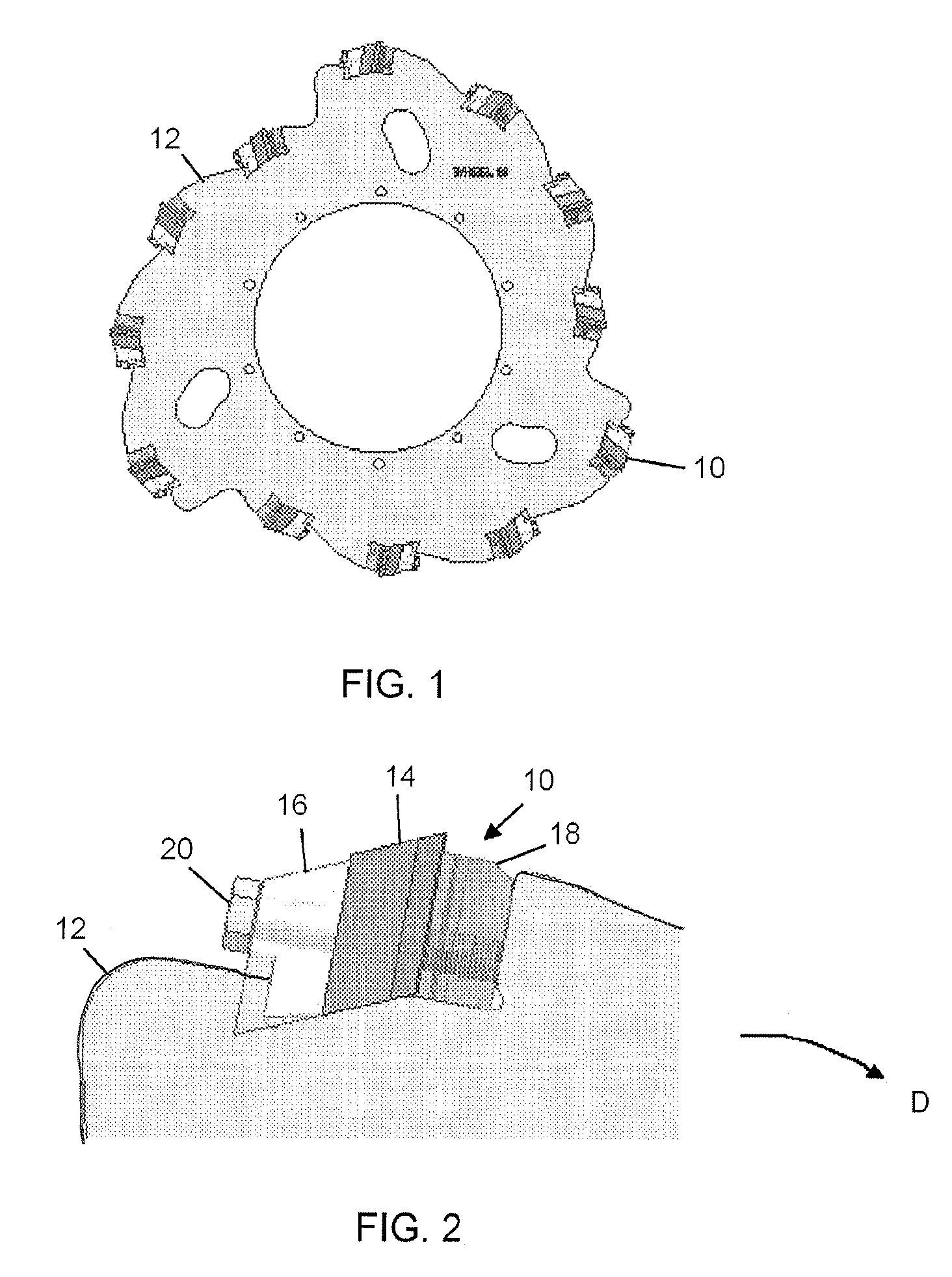

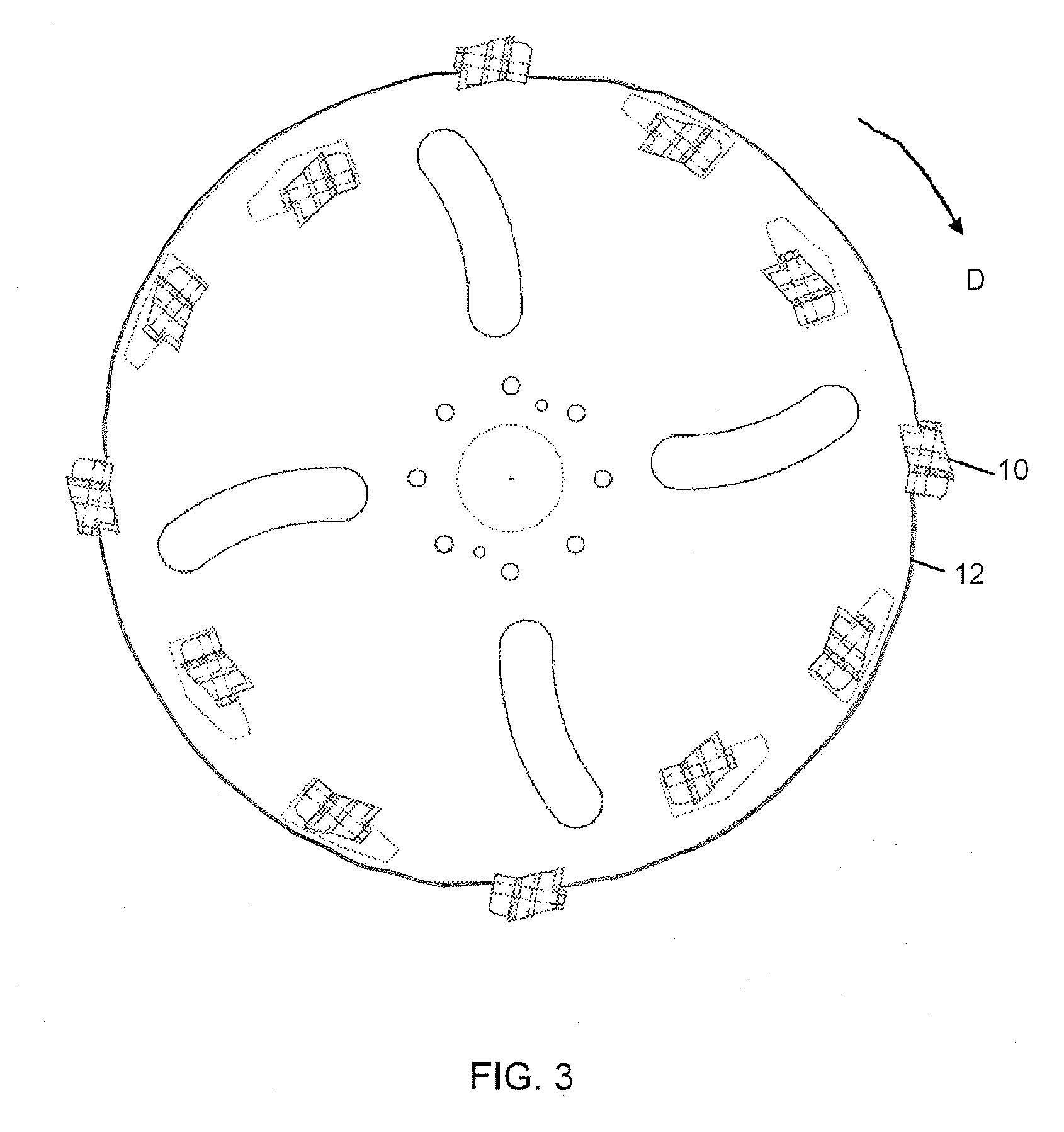

Milling disk for a floor machining appliance

ActiveUS7104739B2Avoid excessive wearHeavy loadMilling cuttersAttachable milling devicesEngineeringSubstructure

A milling disk for a floor machining appliance has a plurality of mounts for holding interchangeable plate-like milling tips, the milling disk being driven for rotation by the floor machining appliance and being held substantially parallel to the substructure to be machined so that the milling tips may bite into the substructure and remove matter from the surface thereof. The milling tips are constituted by ceramic cutting tips.

Owner:EUGEN LAEGLER

Dual cutter router bit

The router bit includes an upper and a lower cutter, axially aligned and separated by a fixed longitudinal displacement. No substantial portion of the bit extends beyond the lower end of the lower cutter. In some embodiments, the lower cutter may be configured with bottom face blades to allow the router to be used as a plunging bit. The cutters may use wing blades or spiral blades. The portion of the bit intervening between the upper and lower cutters may also be configured as a cutter. In some embodiments, the router bit is integral. In other embodiments, it comprises separate elements that may be axially secured.

Owner:HILKER DAVID

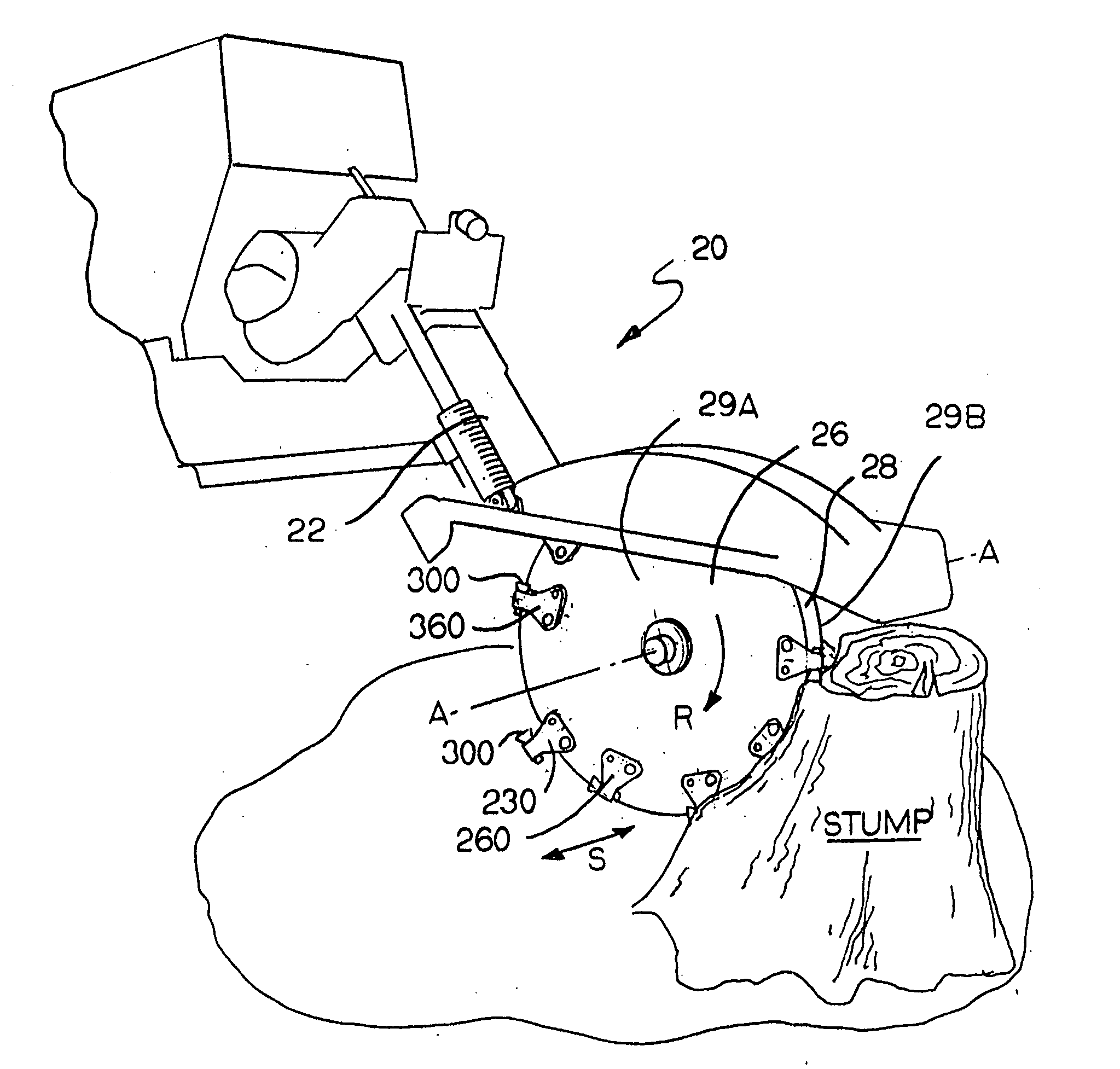

Stump grinding wheel

ActiveUS7743803B2Improved positioning and placement and orientationImprove cutting performanceMulti-purpose machinesProfiling/shaping machinesEngineeringScrew thread

Owner:NEW RIVER EQUIP

Clamping fixture including a chuck and a workpiece pallet releasably located thereon

ActiveCN101234435AIncrease contact surfaceAbsolute RepeatabilityRotary cutting toolsLarge fixed membersEngineeringPallet

Owner:EROWA

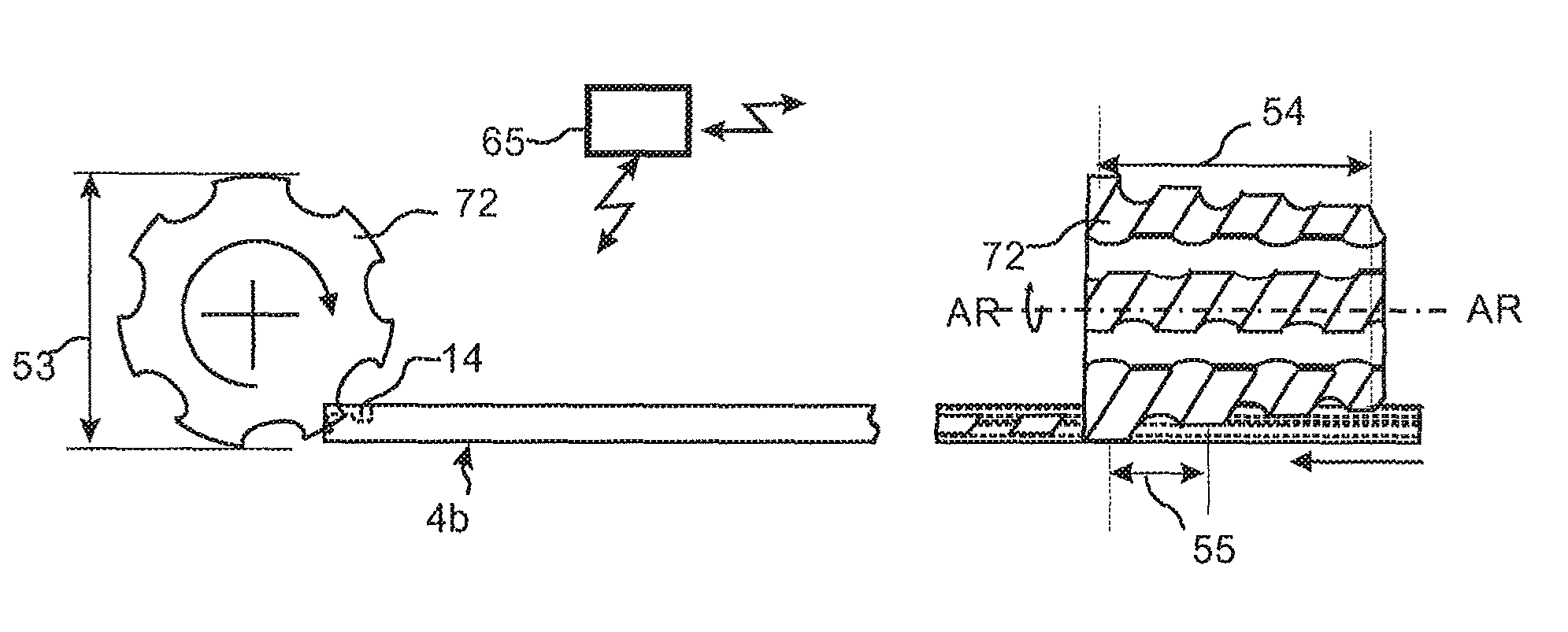

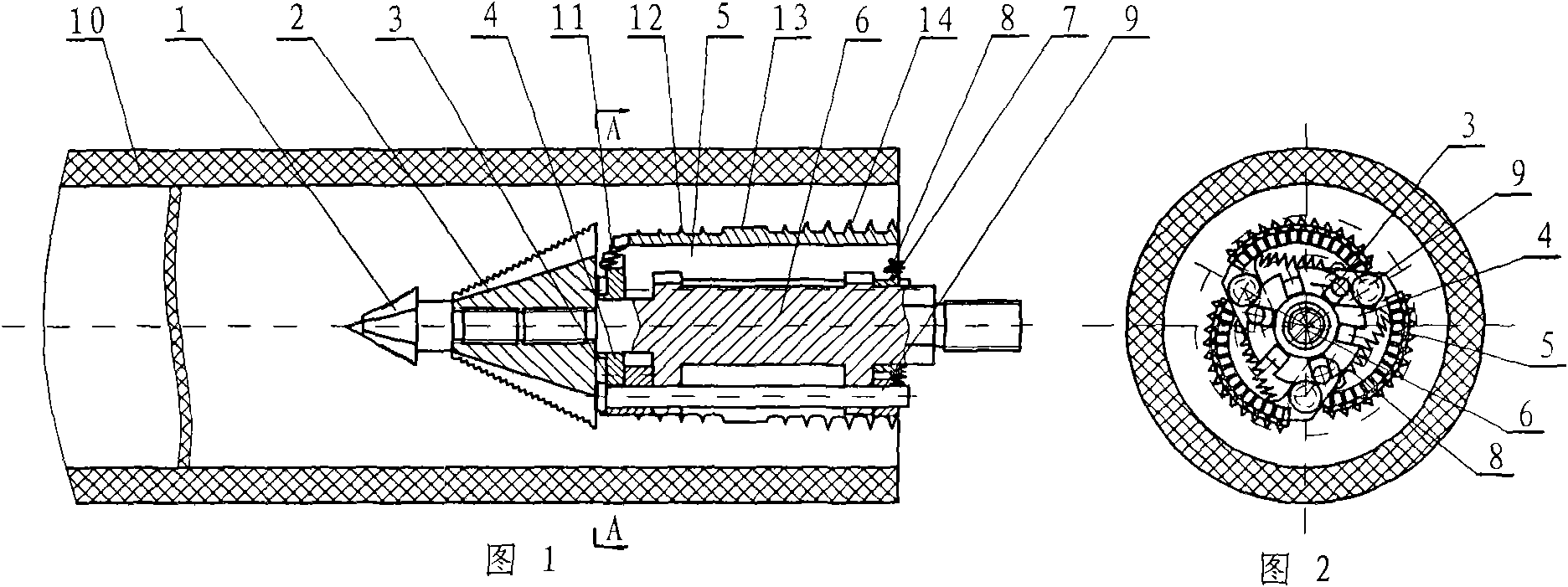

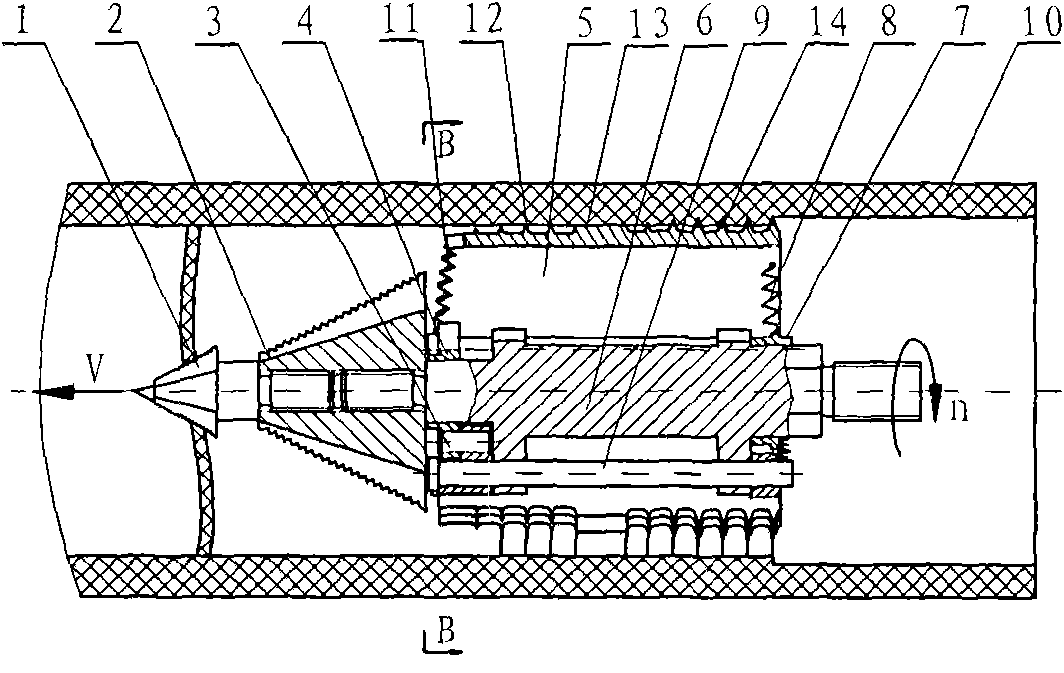

Combined cutting tool for taking inner bamboo joints and tabasheers out of intact bamboo tube

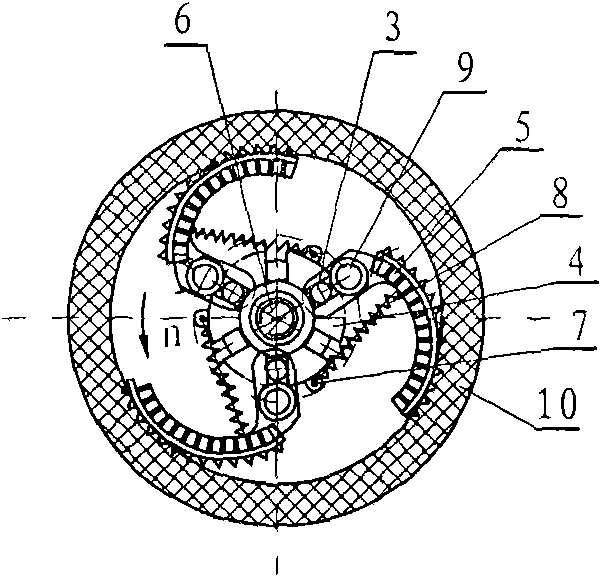

InactiveCN101670601AGuaranteed uniformityImprove cutting efficiencyRotary cutting toolsEngineeringCentrifugal force

The invention discloses a combined cutting tool for taking inner bamboo joints and tabasheer out of an intact bamboo tube. When the combined cutting tool rotates and moves in axial direction, three tabasheer cutting blades 5 synchronously open and cling to the inner wall of the bamboo tube under action of centrifugal force, plural rear cutter teeth 14 on the external curved surface of the tabasheer cutting blades 5 take the tabasheer out, at the same time, the inner bamboo joints are taken out by a small wimble 1, a large wimble 2, an end face tooth 11 on the front end face of the tabasheer cutting blades 5 and the plural front cutter teeth 12 on the external curved surface thereof; a section of depth limiting face 13 without cutter teeth is arranged in the middle of the external curved surface of the tabasheer cutting blades 5 and is used for limiting the depth of tabasheer cutting; each tabasheer cutting blade is provided with a synchronizing pin 3; the synchronizing pin 3 can slidein the radial groove of a synchronizing grooved pulley 4, thus ensuring that the three tabasheer cutting blades 5 can synchronously open under action of centrifugal force and can synchronously retractunder action of a resetting spring 8.

Owner:NANJING FORESTRY UNIV

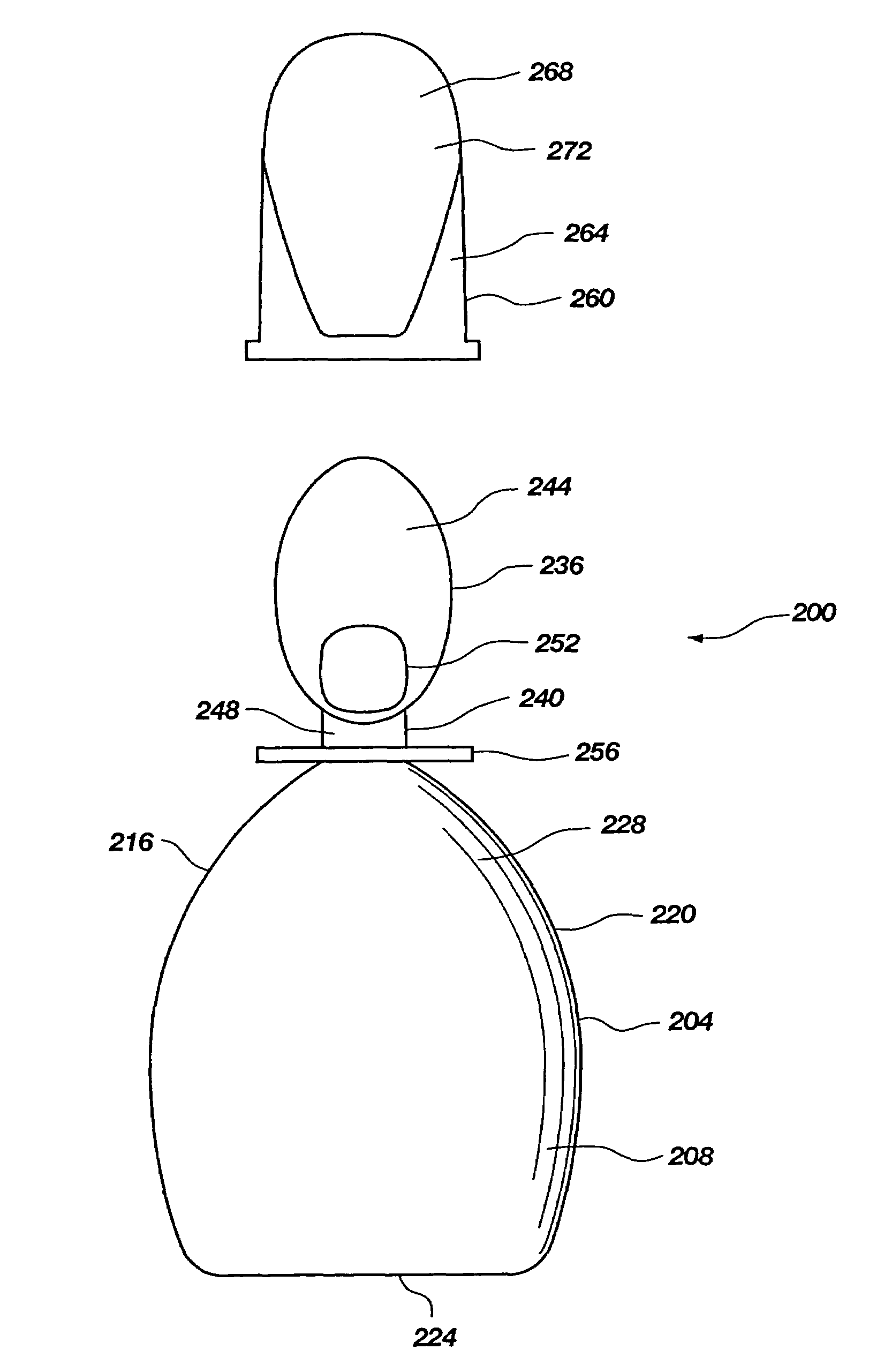

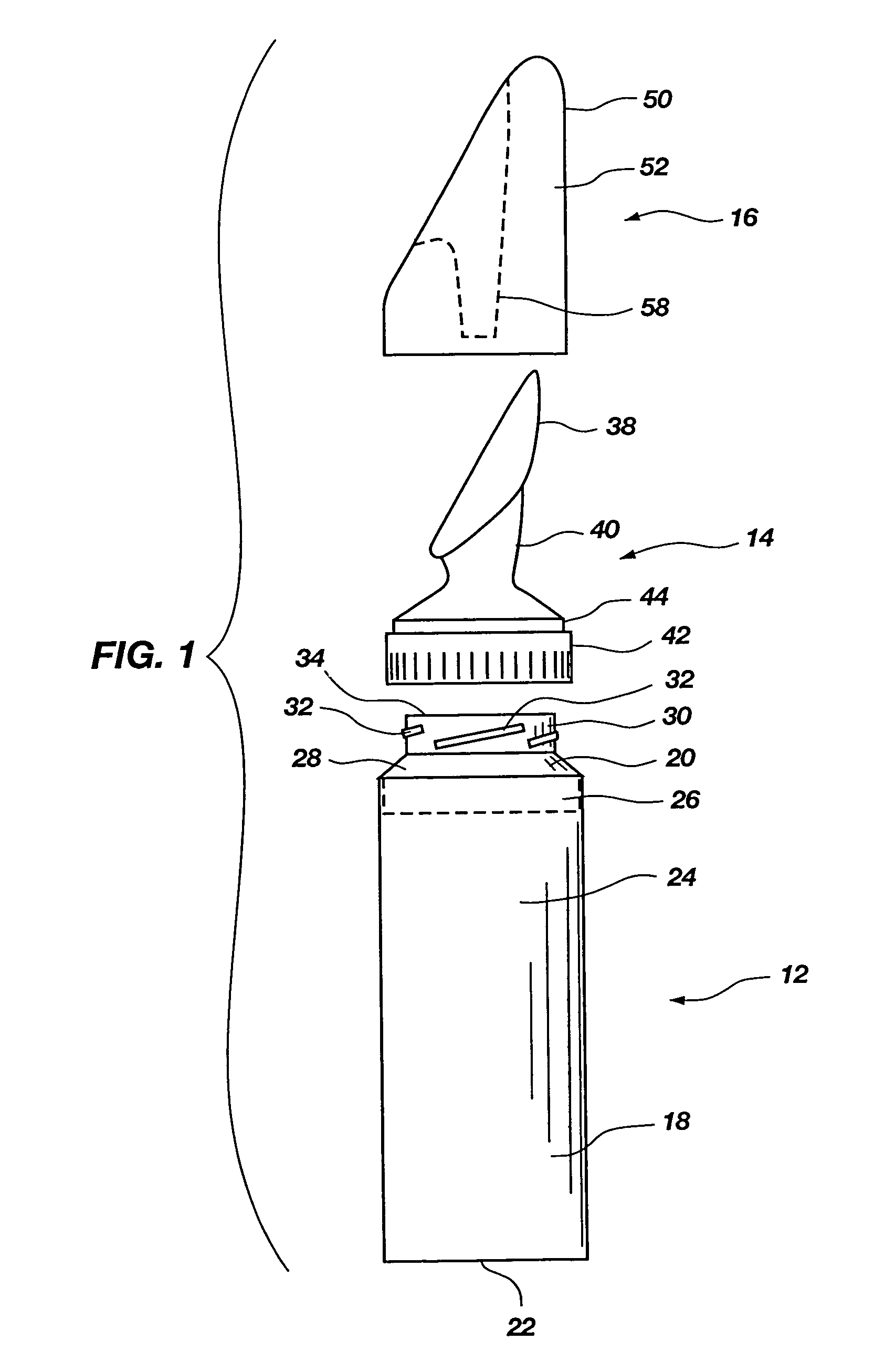

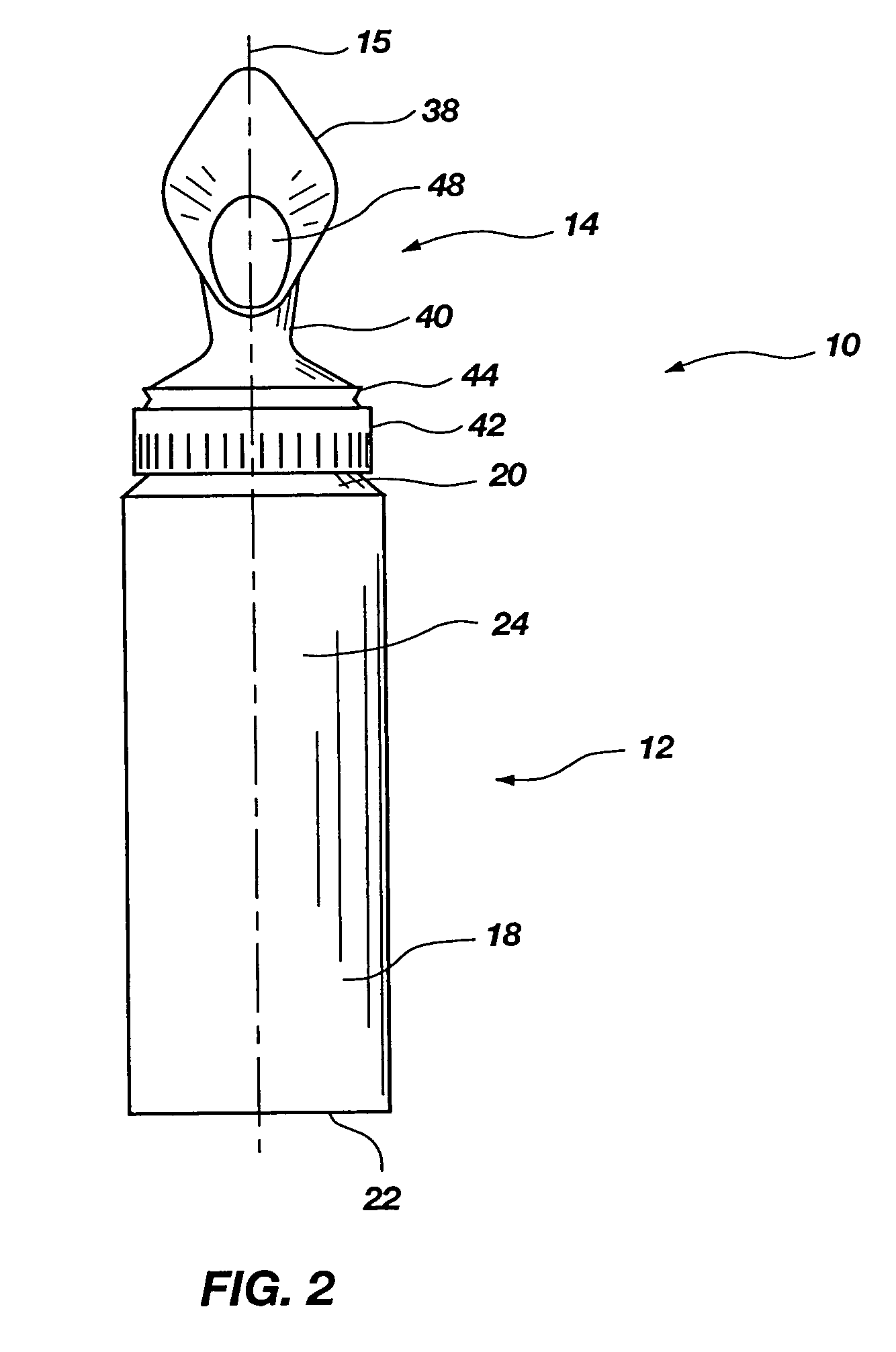

Disposable food delivery apparatus

A disposable food delivery device is disclosed. The device includes a food utensil coupled to a food container. The food container can be pre-charged with food, such as a dehydrated food, such that a liquid can be added to the dehydrated food to result in a ready-to-eat food at any selected time. The food container illustratively can include a port for receiving the liquid. The food container also illustratively can include a security seal for assuring that the food has not been contaminated prior to consumption. Another illustrative embodiment of the invention includes a valve for retaining liquid in the food container prior to consumption of the food.

Owner:OBRIEN JOHN J

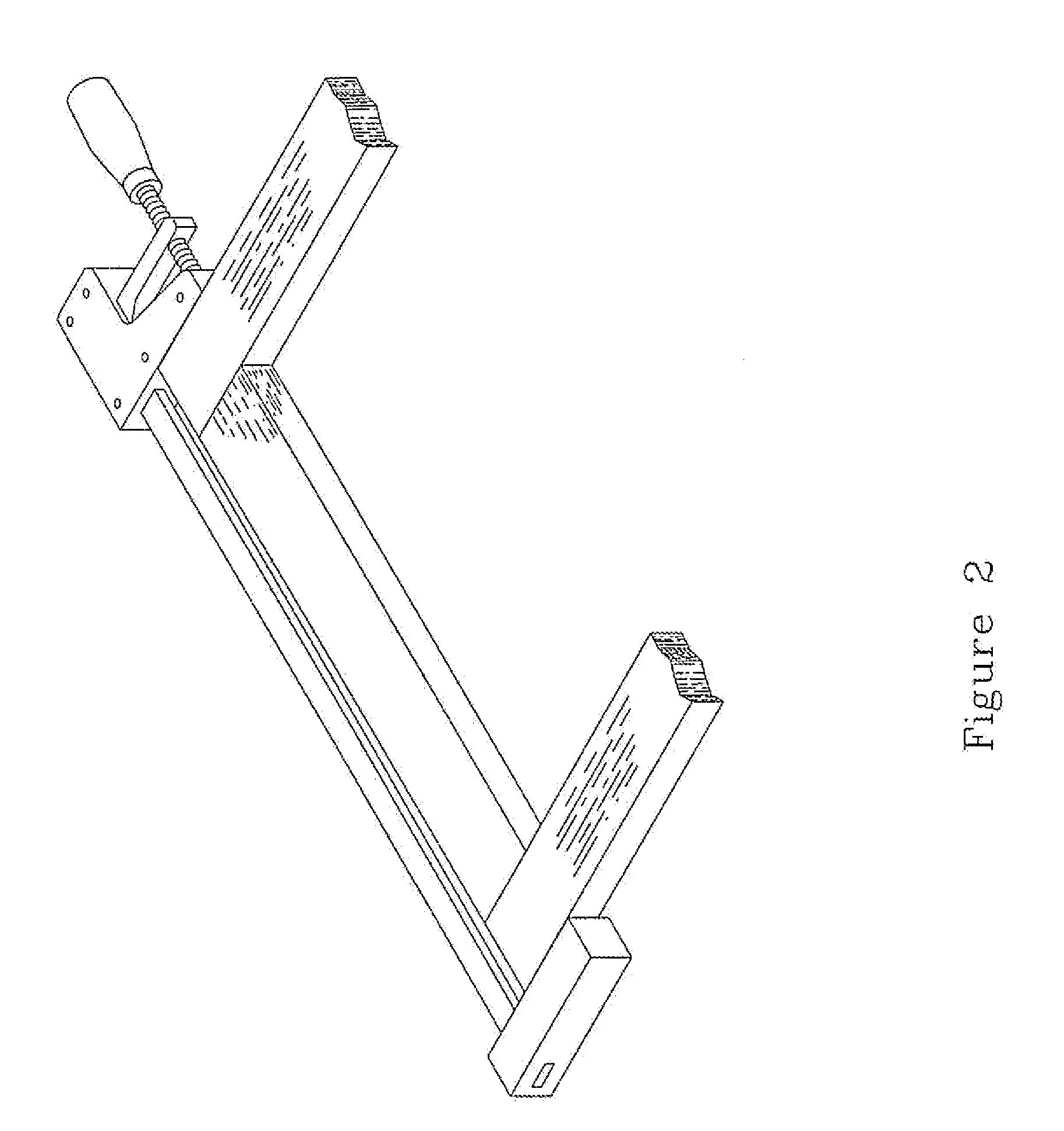

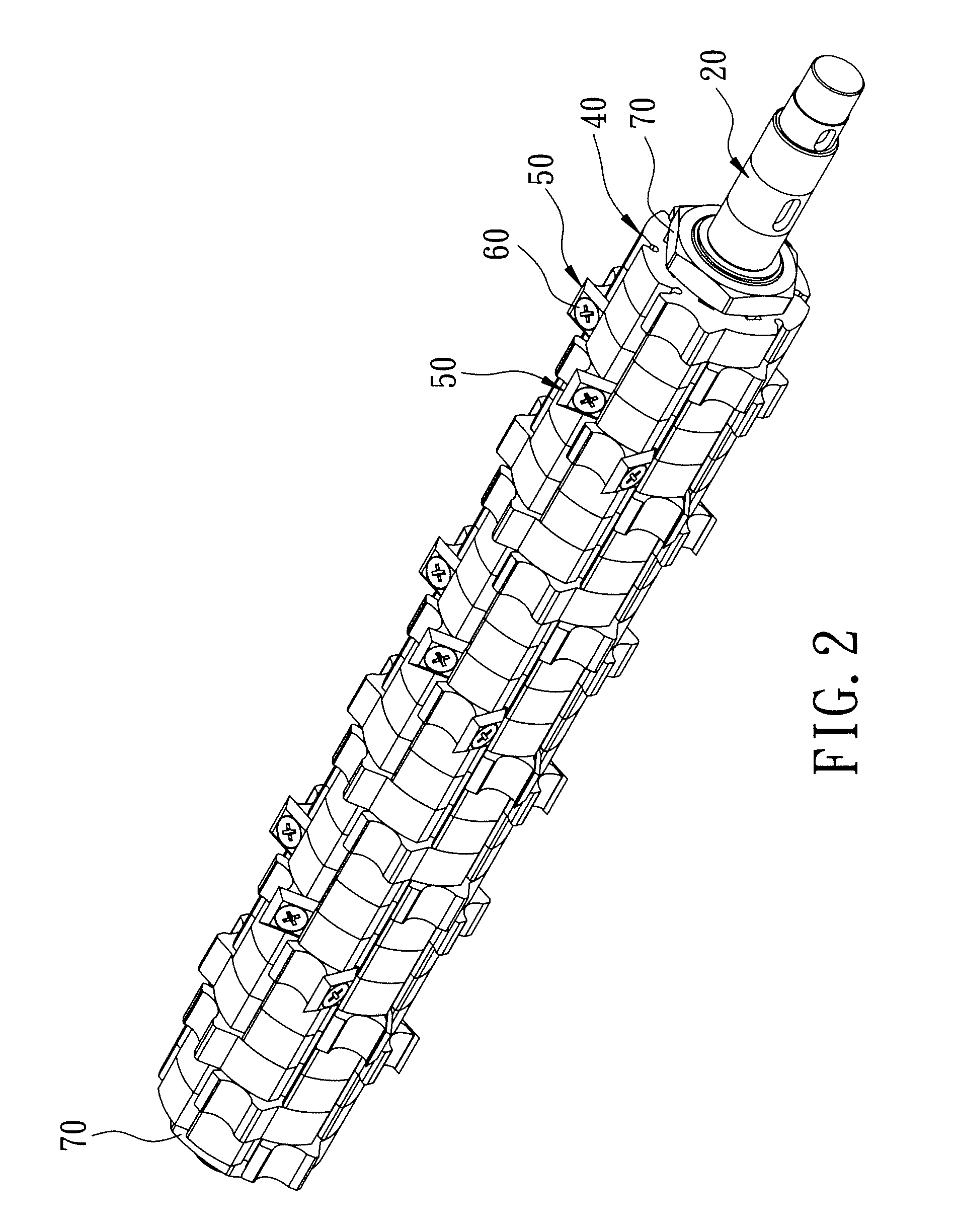

Cutter head assembly for a wood planing machine

InactiveUS20100043921A1Load minimizationMulti-purpose machinesProfiling/shaping machinesTrailing edgeKnife blades

A cutter head assembly for a wood planing machine includes a rotary shaft, a plurality of blade carriers non-rotatably retained on the shaft, and a plurality of cutter blades respectively secured on outer wall surfaces of the blade carriers by means of a plurality of screw fasteners. The outer wall surface of each blade carrier includes a leading region and a trailing region that form a first included angle of at least 90 degrees therebetween. Each blade has a first major wall surface abutting against the leading region, a second major wall surface disposed opposite to the first major wall surface, a cutting edge interposed between the first and second major wall surfaces and extending beyond the outer wall surface of the respective blade carrier, and an abutting edge disposed opposite to the cutting edge to abut against the trailing region. The cutting edge of each cutter blade intersects the second major wall surface at a second included angle ranging from 35 degrees to 45 degrees.

Owner:LIU CHIN YUAN

Tooth for a circular saw or mower drum

A tooth for a circular saw or a mower drum that can be used to cut standing trees or brush and undergrowth. The tooth has four cutting edges arranged in a first pair of opposed cutting edges that are generally straight and a second pair of opposed cutting edges that are generally concave. The tooth is mounted in a holder in a first or second cutting position that orients a cutting edge of the first or second pair to physically contact and effect a cutting method to a cuttable material. In a first cutting method, a generally straight cutting edge contacts the material, resulting in a slicing action. In a second cutting method, a generally concave cutting edge contacts the material, resulting in a gouging action. Teeth in the circular saw or brush mower alternate between first and second cutting positions, allowing both cutting methods to be applied to cuttable material.

Owner:QUADCO

Stump Cutting Tooth Assembly

ActiveUS20080105334A1Low costEasy to replaceMetal sawing devicesMulti-purpose machinesEngineeringFastener

A stump cutting assembly mounted to a stump cutting wheel. Stump cutting assembly is a stump cutting tooth interconnected to the wheel by a holder or block that is fixed to wheel by welding or other equivalent process, an optional debris deflector and a fastener that interconnects tooth and deflector to holder. As wheel rotates about its axis of rotation, the tooth cuts away at wood or other debris in which it comes into contact through the side to side and / or longitudinal movement of a stump grinder unit.

Owner:LEONARDI MFG

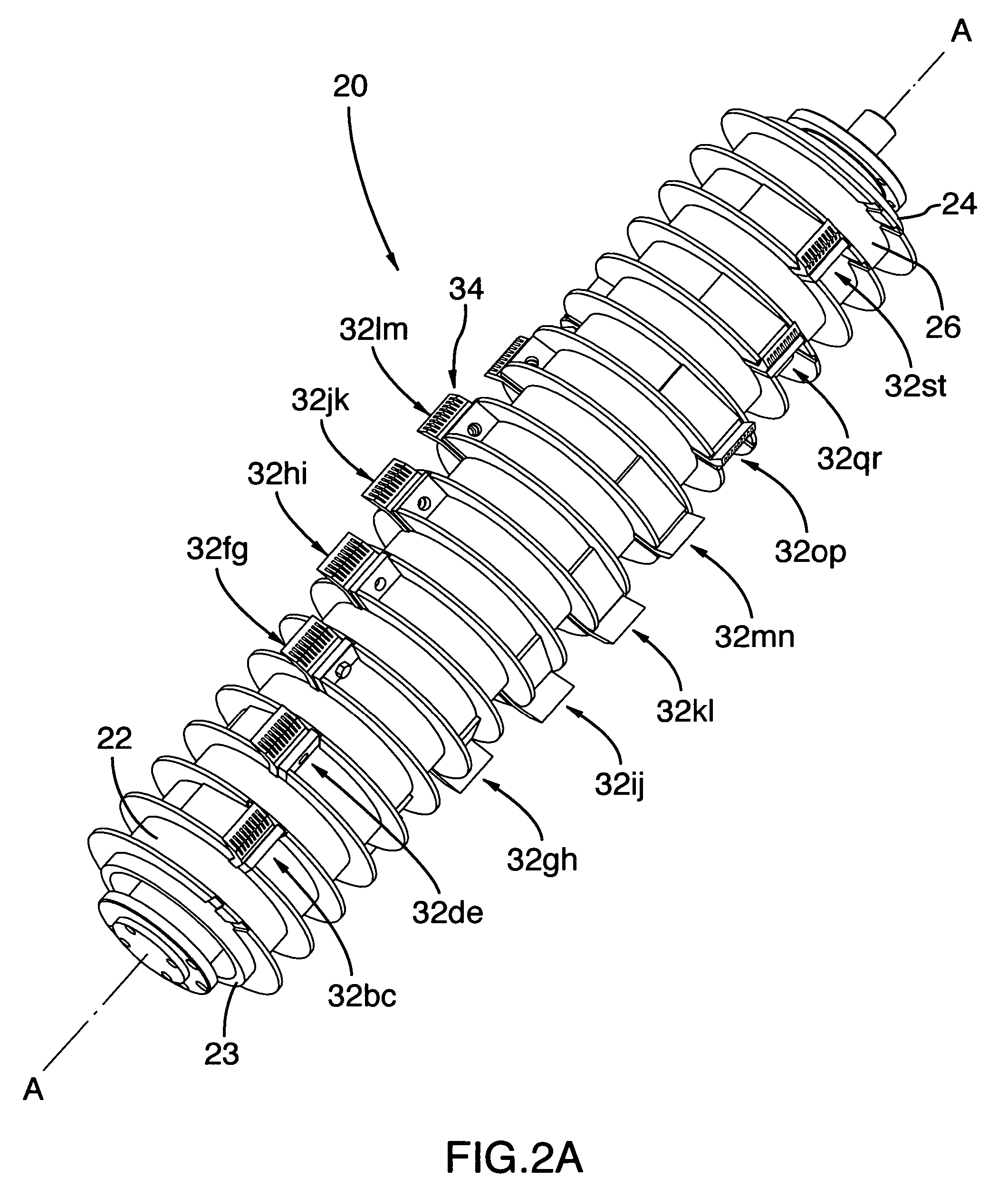

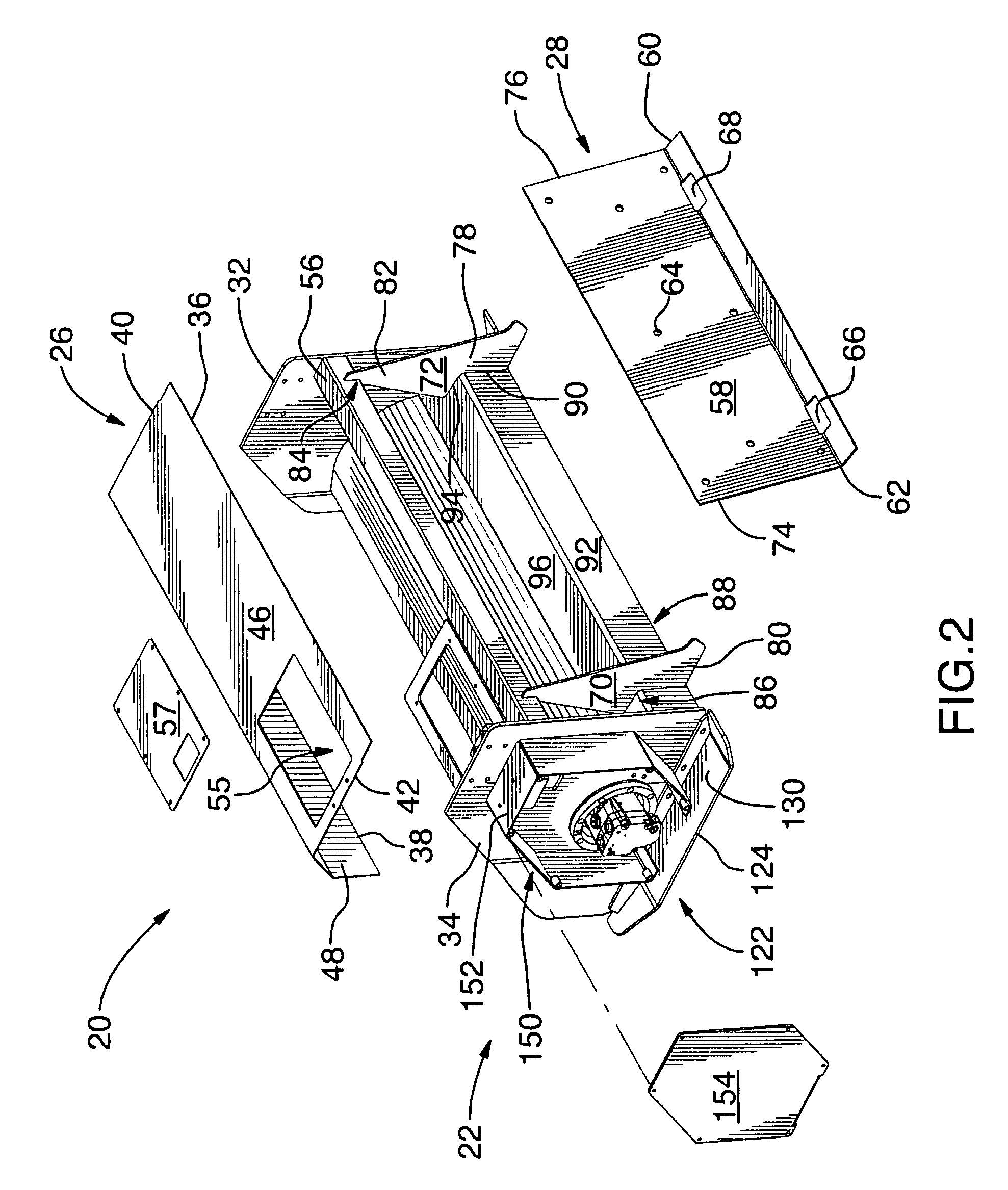

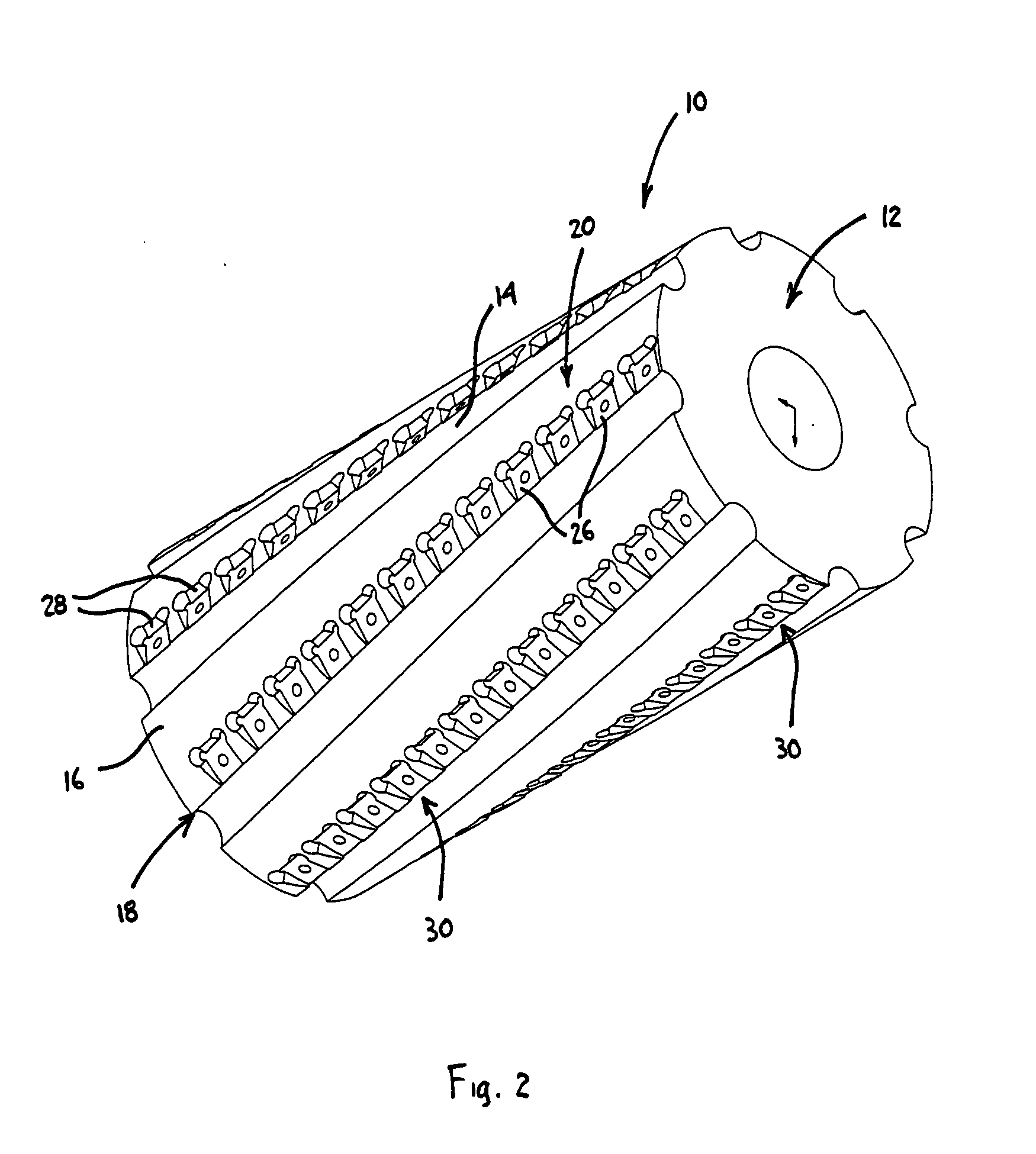

Helical cutterhead

A cutterhead for shaping materials. The cutterhead includes a substantially cylindrical body with at least one helically-shaped recess defining a helically-shaped projecting surface having a cutting side and multiple seats positioned along the projecting surface. The seats receive removable cutting blades and include a planar seat surface. The seat surfaces are oriented to appropriately align the projecting blade edge of the blade to a helical angle. In addition, the seats include a connection arrangement for removably attaching the blade.

Owner:HERMANCE MACHINE

Multi-application wood working knife and clamping assembly

InactiveUS7159626B2Reduce riskAvoid prolonged useMulti-purpose machinesProfiling/shaping machinesWood processorEngineering

A wood working knife for use in a wood working machine, comprising a knife body having a first cutting edge and an opposed second cutting edge, the knife body having a first clamping surface and a second clamping surface. The first clamping surface has opposed clamping features separated by a middle section, the opposed clamping features and the middle section being sized and shaped such that, upon the knife body being inserted into a clamping assembly, the clamping forces are localized towards the opposed cutting edges and away from the middle section.

Owner:IGGESUND TOOLS

Retainer for a rotatable tool

The cylindrical shank of a rotatable tool is retained in the cylindrical bore of a tool holder by a retainer that engages an annular groove on a portion of the shank of the tool that extends outward of the rear surface of the tool holder. The tool has an axial bore in the distal end of the shank. The retainer has a pair of spaced ridges that engage the annular groove on the shank and a panel that extends across the distal end of the shank. The retainer is held in place by a pin extending through the panel and into the bore in the distal end of the shank.

Owner:THE SOLLAMI COMPANY

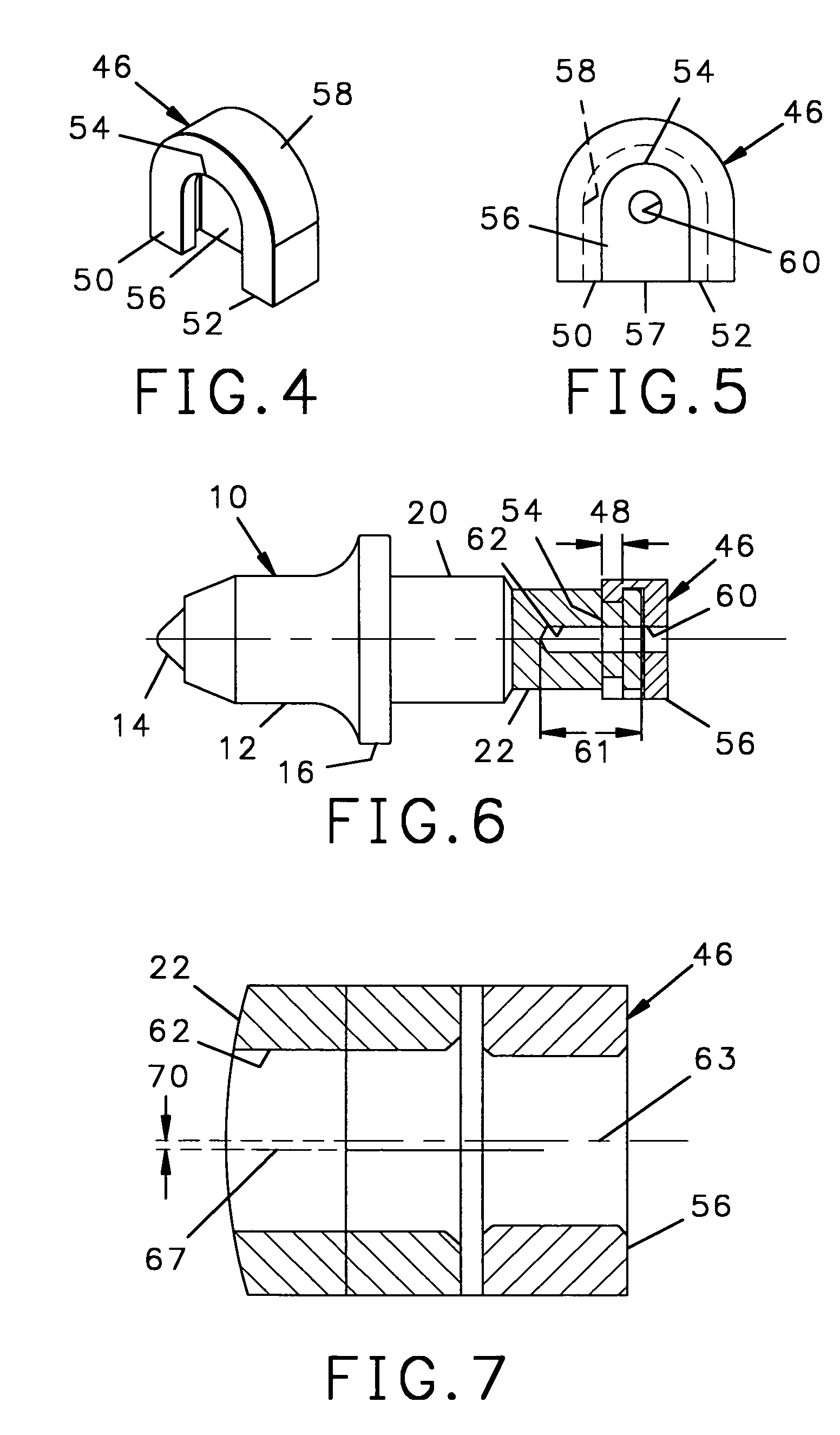

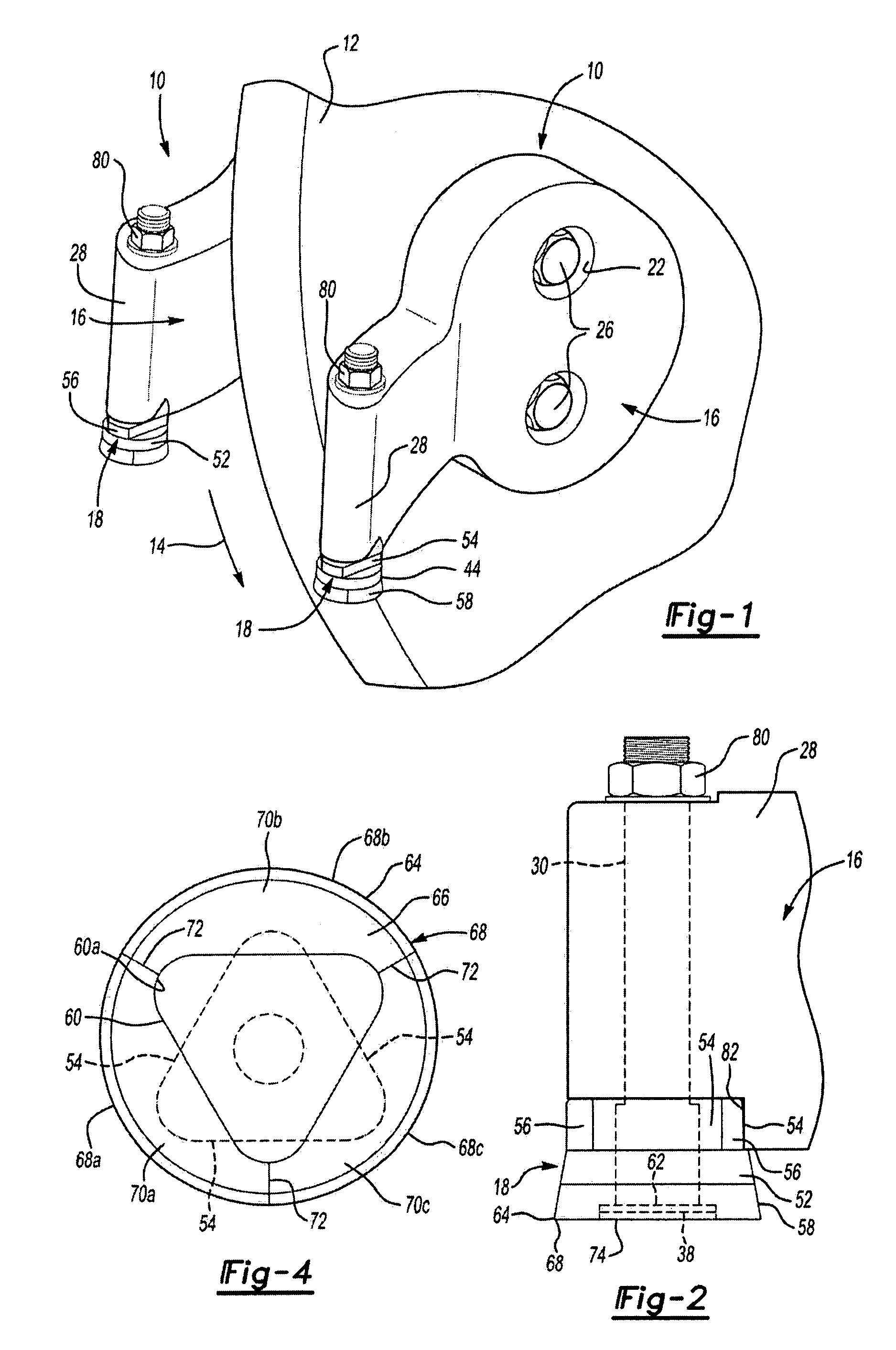

Cutting tooth for use with a stump cutting apparatus

ActiveUS7484541B2Reduces crack travel and migrationMulti-purpose machinesProfiling/shaping machinesMechanical engineeringDrill bit

A cutting tooth for use with a stump cutting apparatus wherein the cutting tooth has a removable and replaceable cutting bit. The cutting bit is removably and nonrotatably secured to a head of an elongated shank with the shank secured to a mounting block or pocket of a stump cutting tool. A support member having an indexing surface is also removably and nonrotatably secured to the head of the elongated shank. Accordingly, the support member enables indexing the cutting bit to expose and use a plurality of cutting edges located on the periphery of the cutting bit.

Owner:GREEN KEVIN J

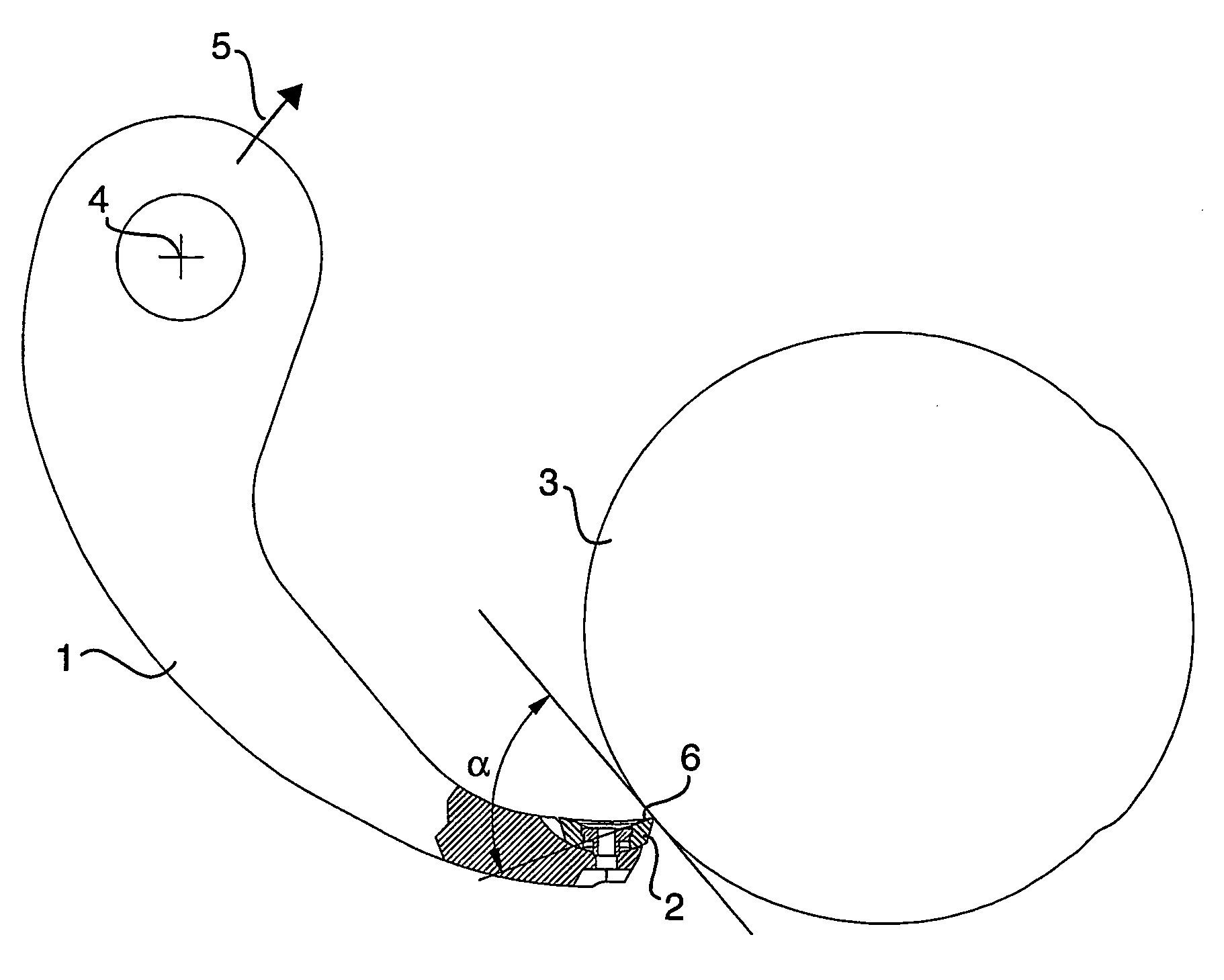

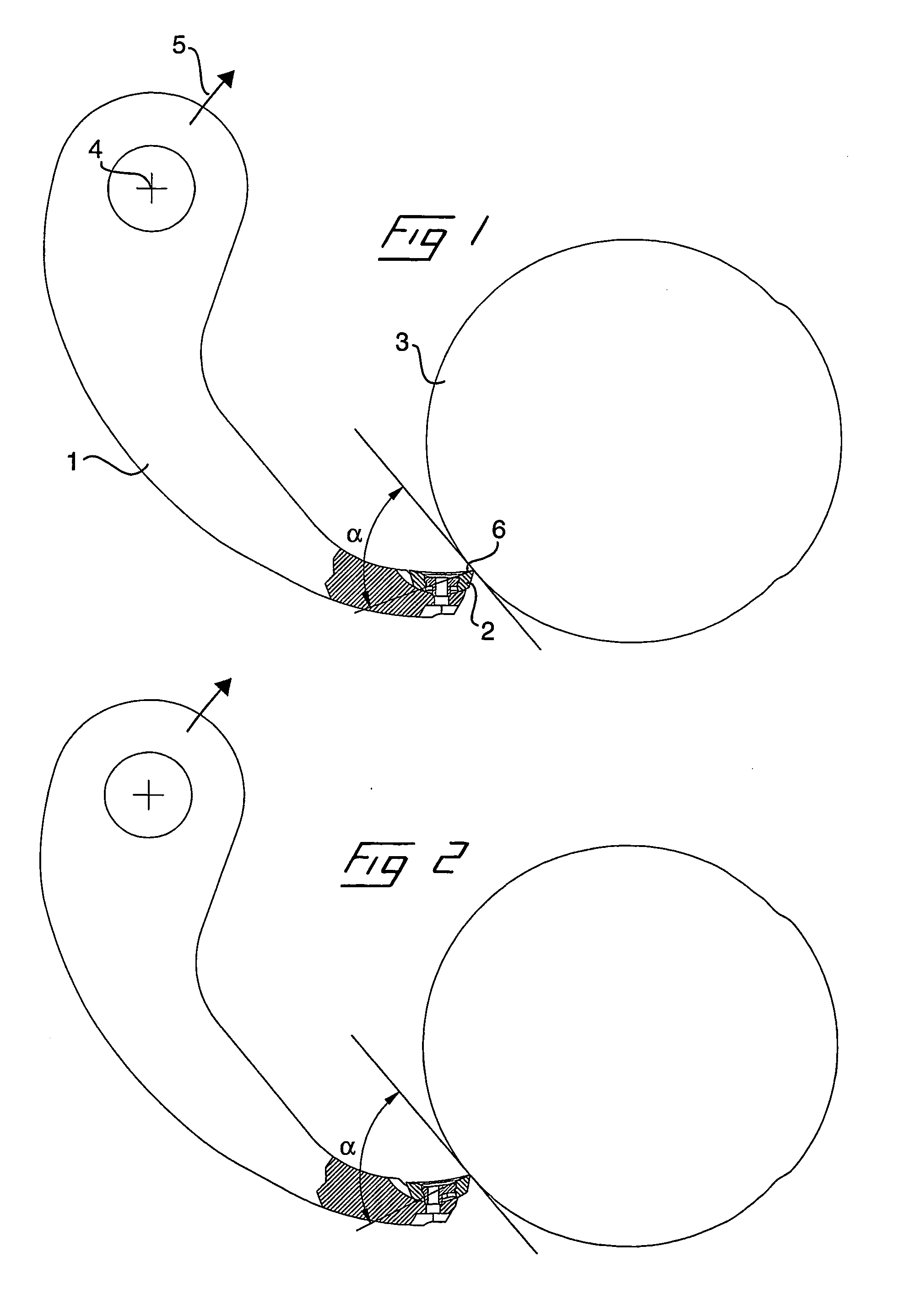

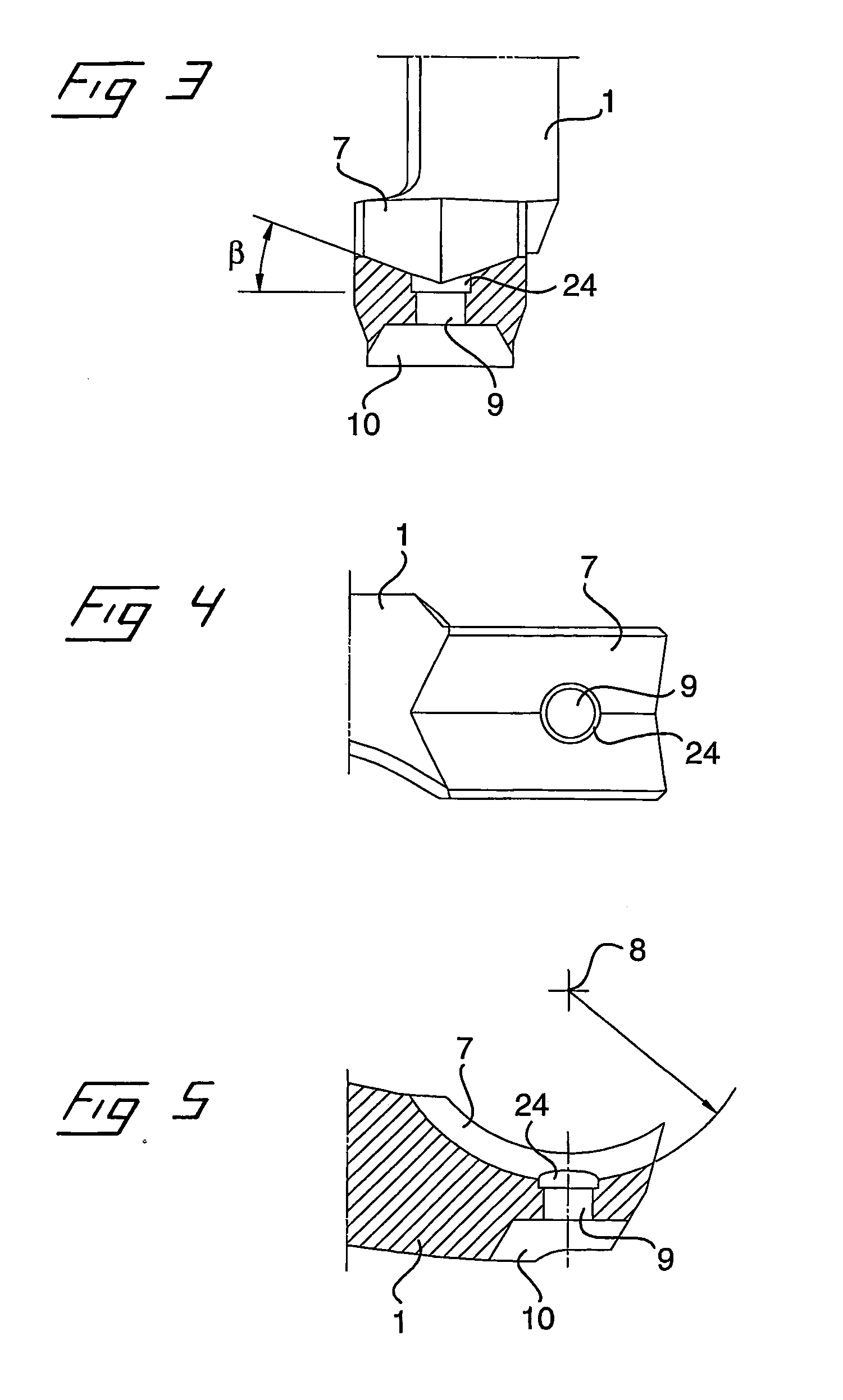

Barking Device and Barking Tool

ActiveUS20070261762A1Designing can be facilitatedExtra stepTree debarkingMulti-purpose machinesEngineeringMechanical engineering

Owner:IGGESUND TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com