Clamping fixture including a chuck and a workpiece pallet releasably located thereon

A technology for pallets and workpieces, which is applied to wood processing equipment, chucks, manufacturing tools, etc., and can solve problems such as limited tension transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

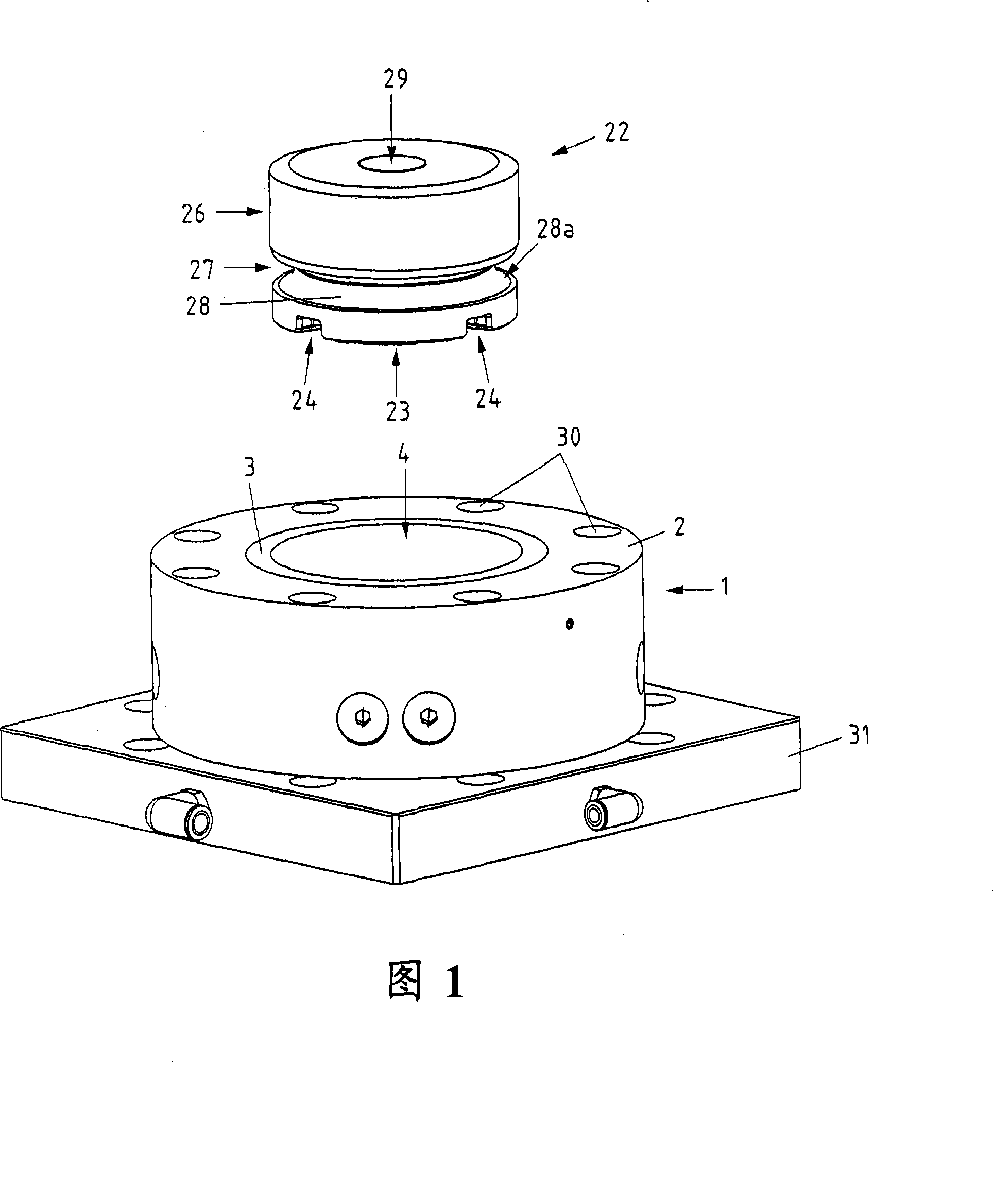

[0056] Referring to FIG. 1 , a perspective view of a holding device including a chuck 1 and a workpiece pallet 22 is shown. The chuck 1 is fastened to the base plate 31, but as far as possible the chuck 1 is fastened directly to the machine table. The workpiece pallet 22 is used to accommodate workpieces that are repeatedly positioned precisely on the chuck 1 . In the context of the present invention, however, the term workpiece pallet is by no means to be understood only for mounting workpieces, since tools and similar devices can also be fastened.

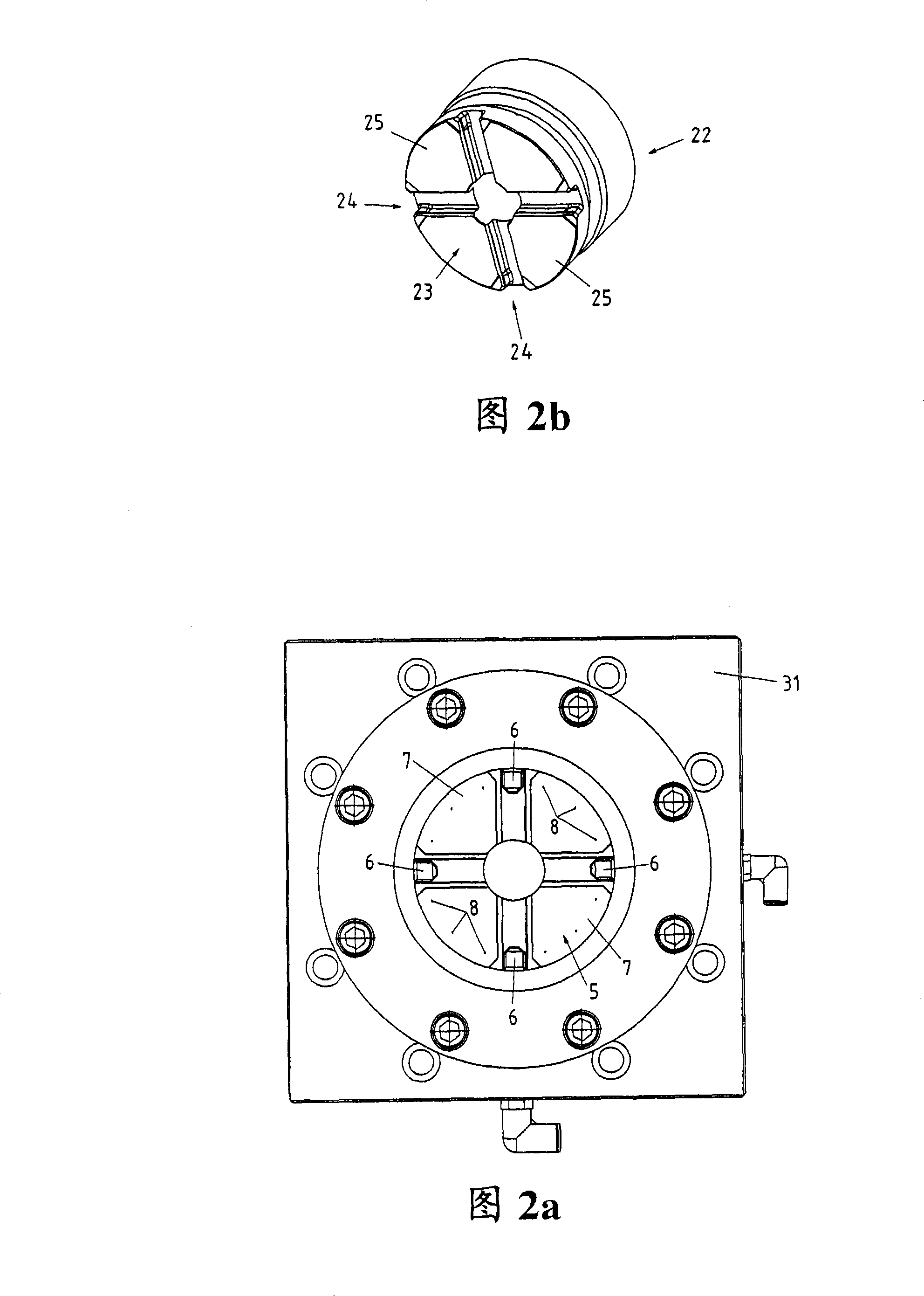

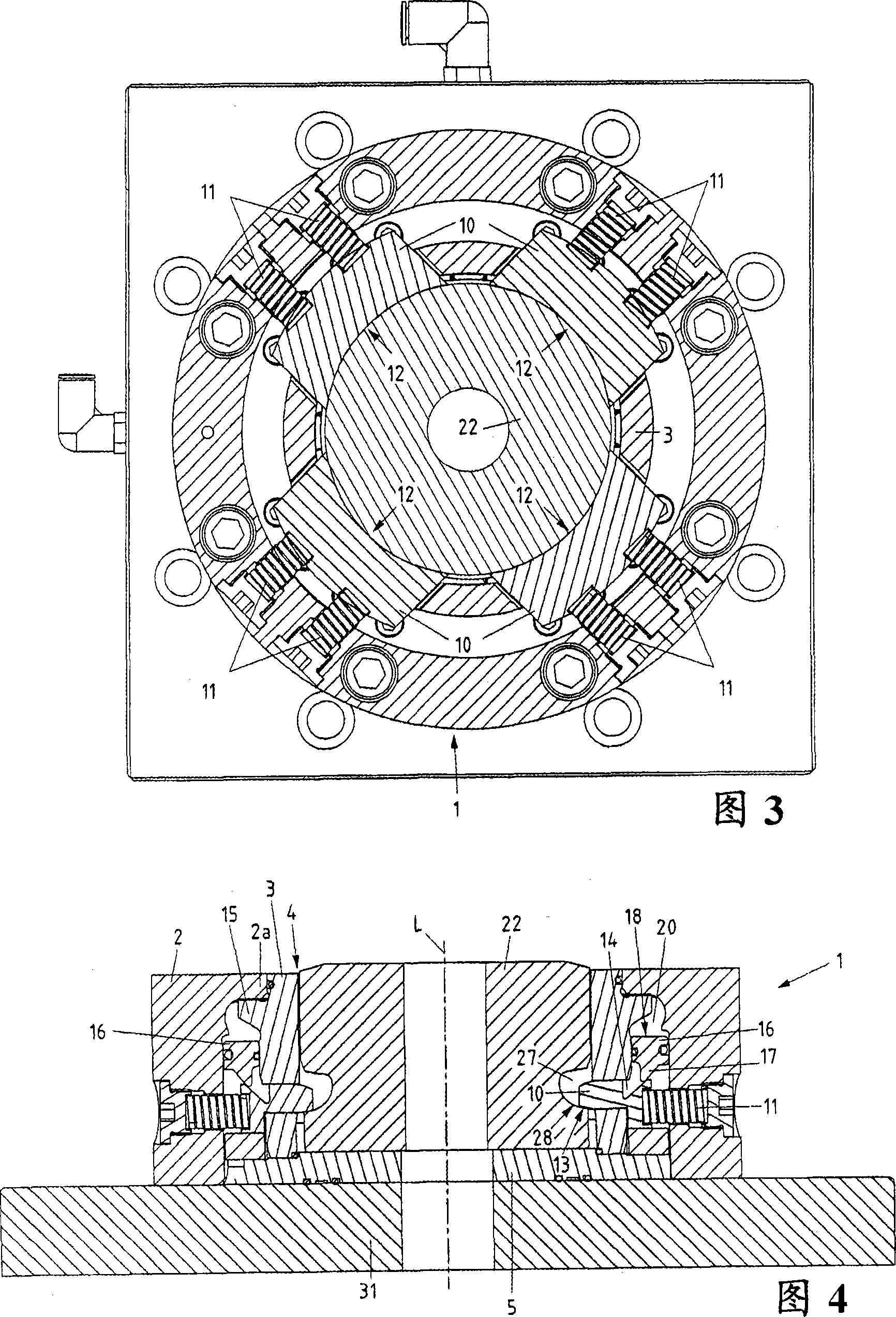

[0057]The chuck 1 comprises a cylindrical base 2 arranged along a bush 3 . The bushing 3 delimits a central opening 4 for receiving a workpiece pallet 22 and is configured substantially cylindrically. The flat bottom side 23 of the workpiece pallet 22 features a centering groove 24 for engaging a centering cam arranged on the chuck 1 when the workpiece pallet 22 is positioned on the chuck 1 . The complete fit of the centering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com