Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

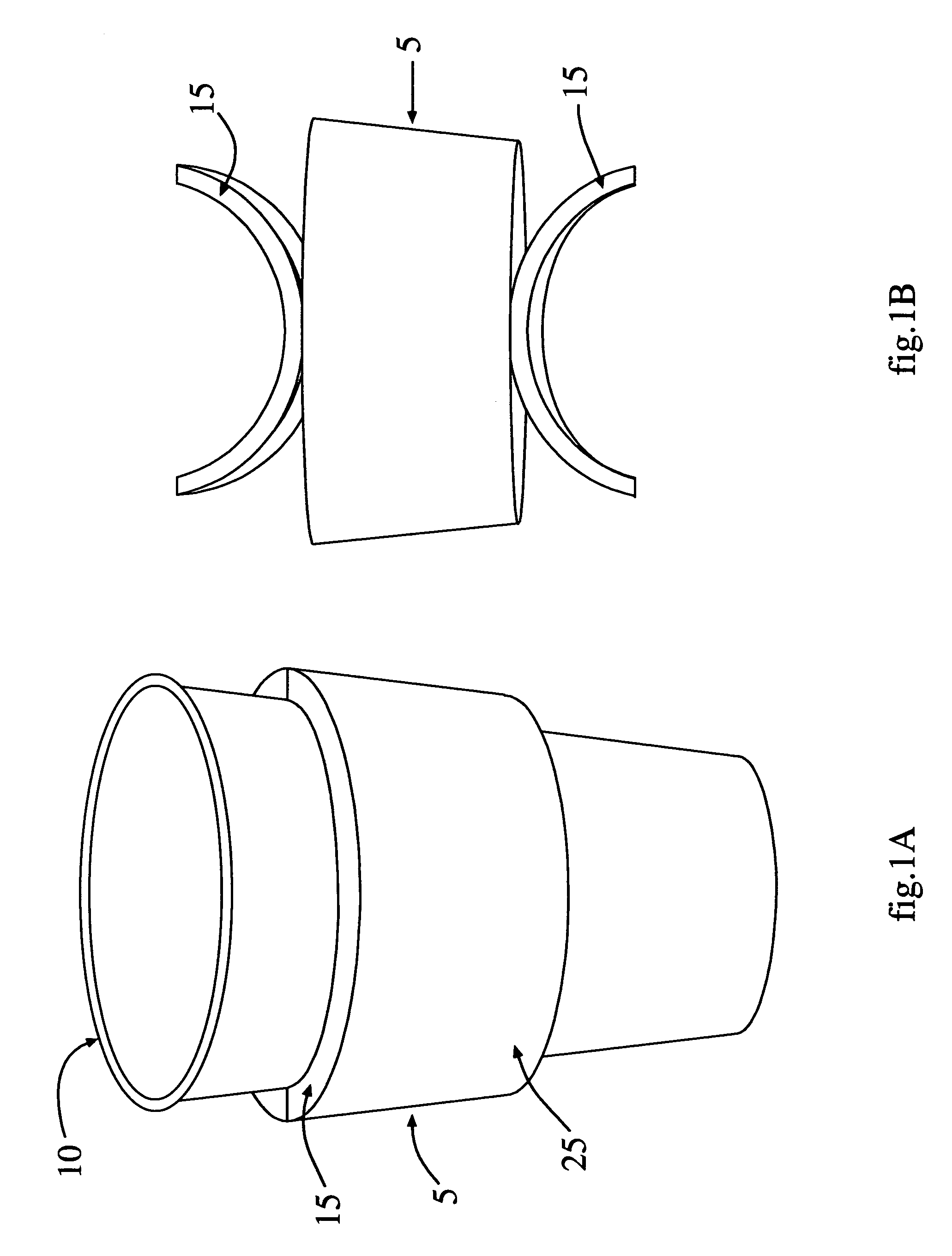

429 results about "Food contact materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food contact materials are materials that are intended to be in contact with food. These can be things that are quite obvious like a glass, a can for soft drinks, but also machinery in a food factory or a coffee machine.

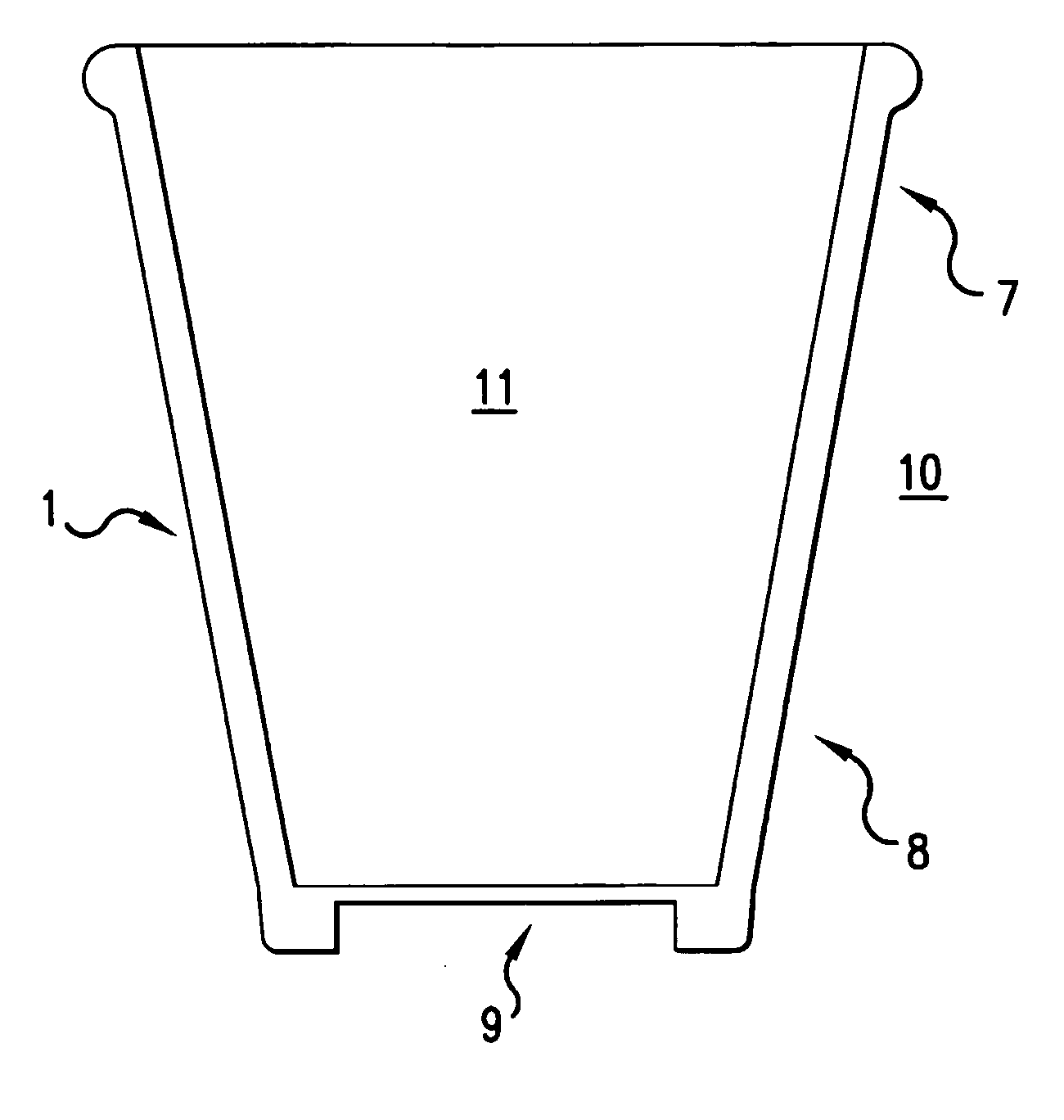

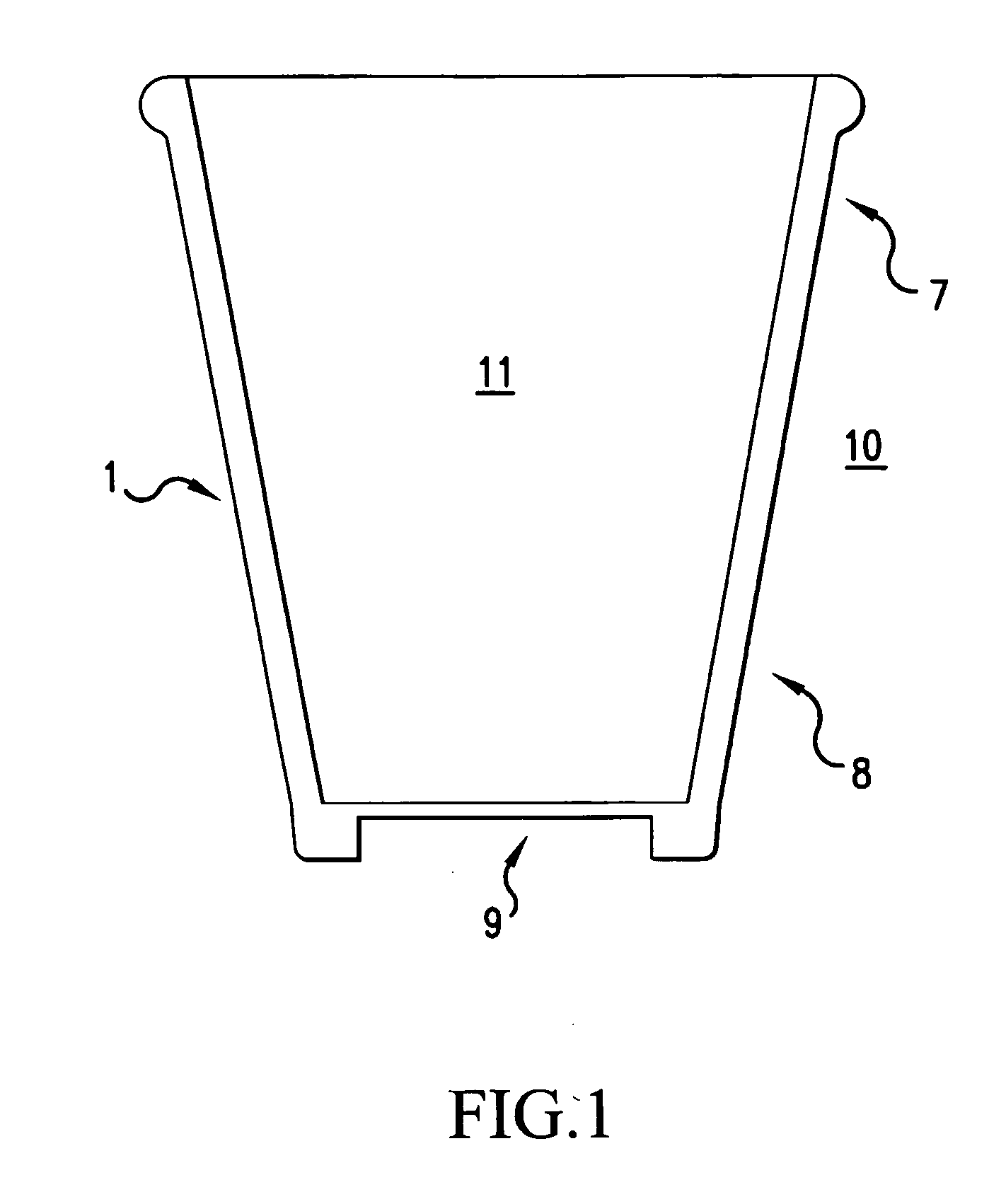

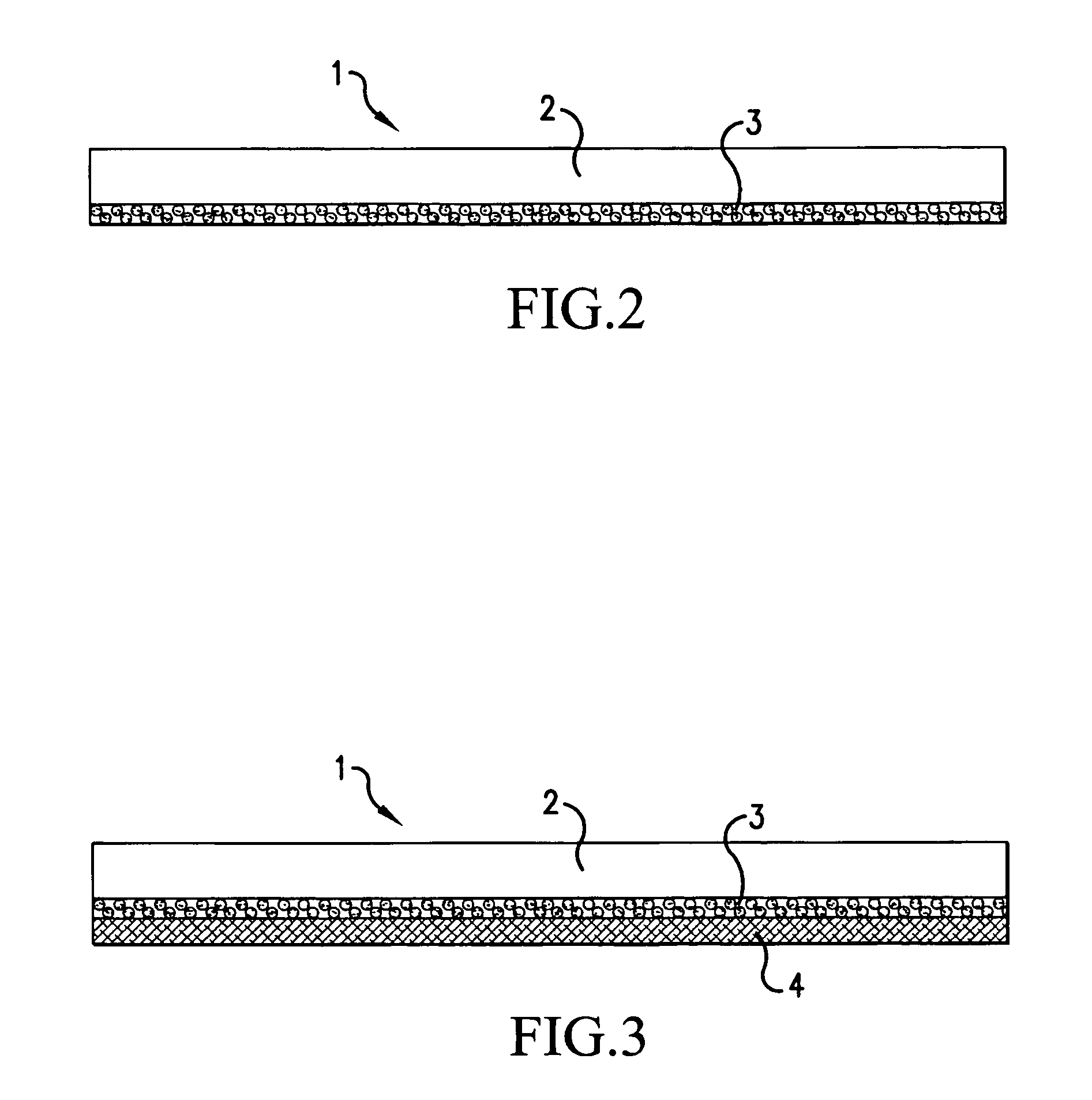

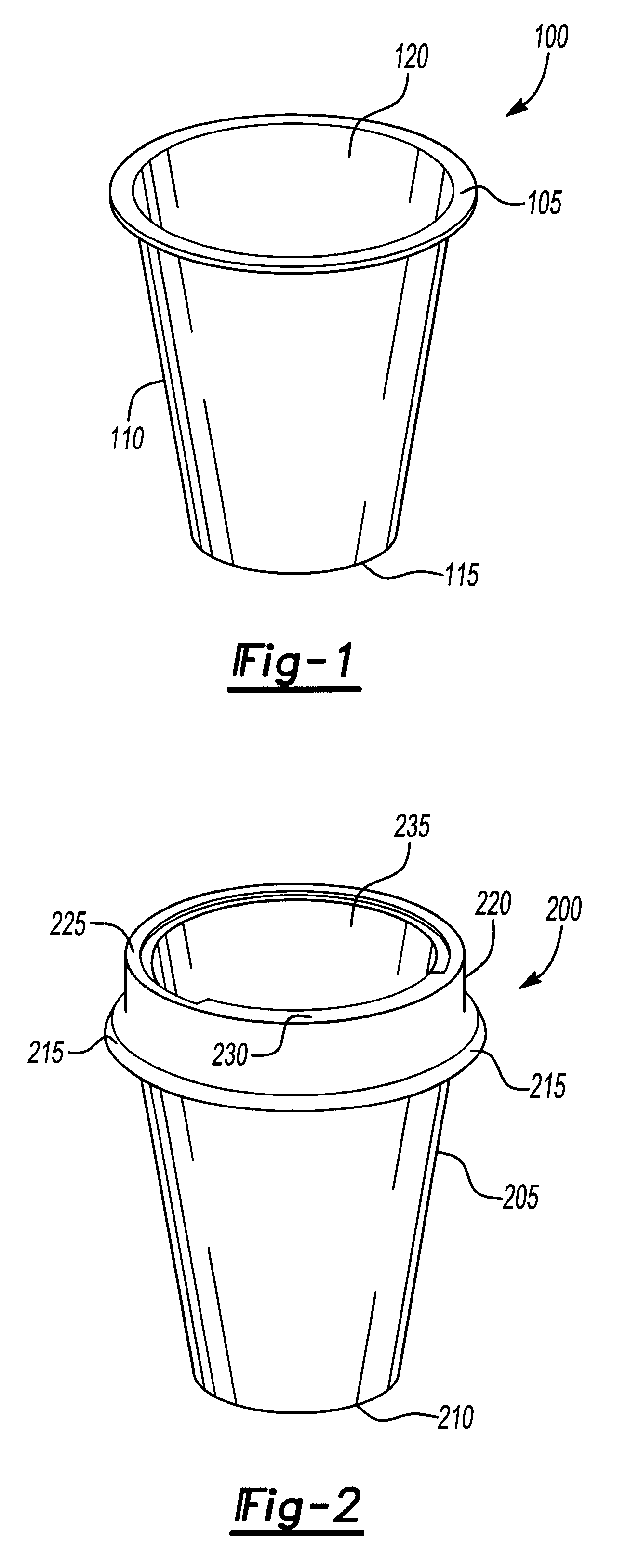

Insulated beverage or food container

InactiveUS20050003122A1Reduce energy transferImprove functionalityFibreboardWrappersEnergy transferEngineering

An insulating beverage cup or sleeve is produced with a foam layer disposed on an inner surface of a food or beverage paper stock. A polyethylene film layer is arranged in a position between a paper stock layer and an inside surface of the beverage container. The foam layer decreases the energy transfer between the beverage and the user's hands allowing the user to hold onto the cup for an extended period of time without causing user discomfort or pain, e.g. greatly extends the hold time of the paper cup. The exterior surface of the beverage cup remains highly printable and predisposed to high quality graphics both before and after cup manufacture.

Owner:APPLETON PAPERS INC

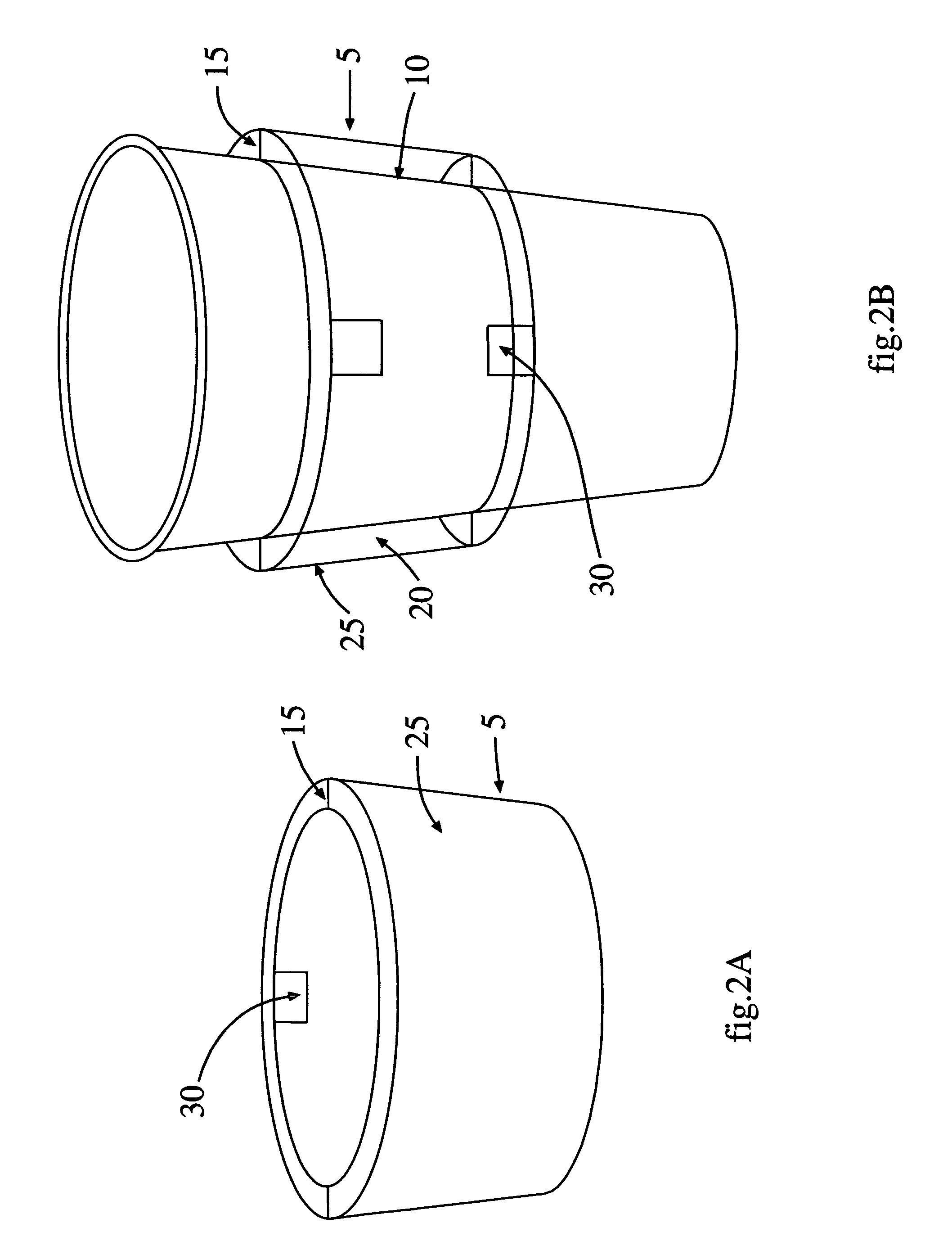

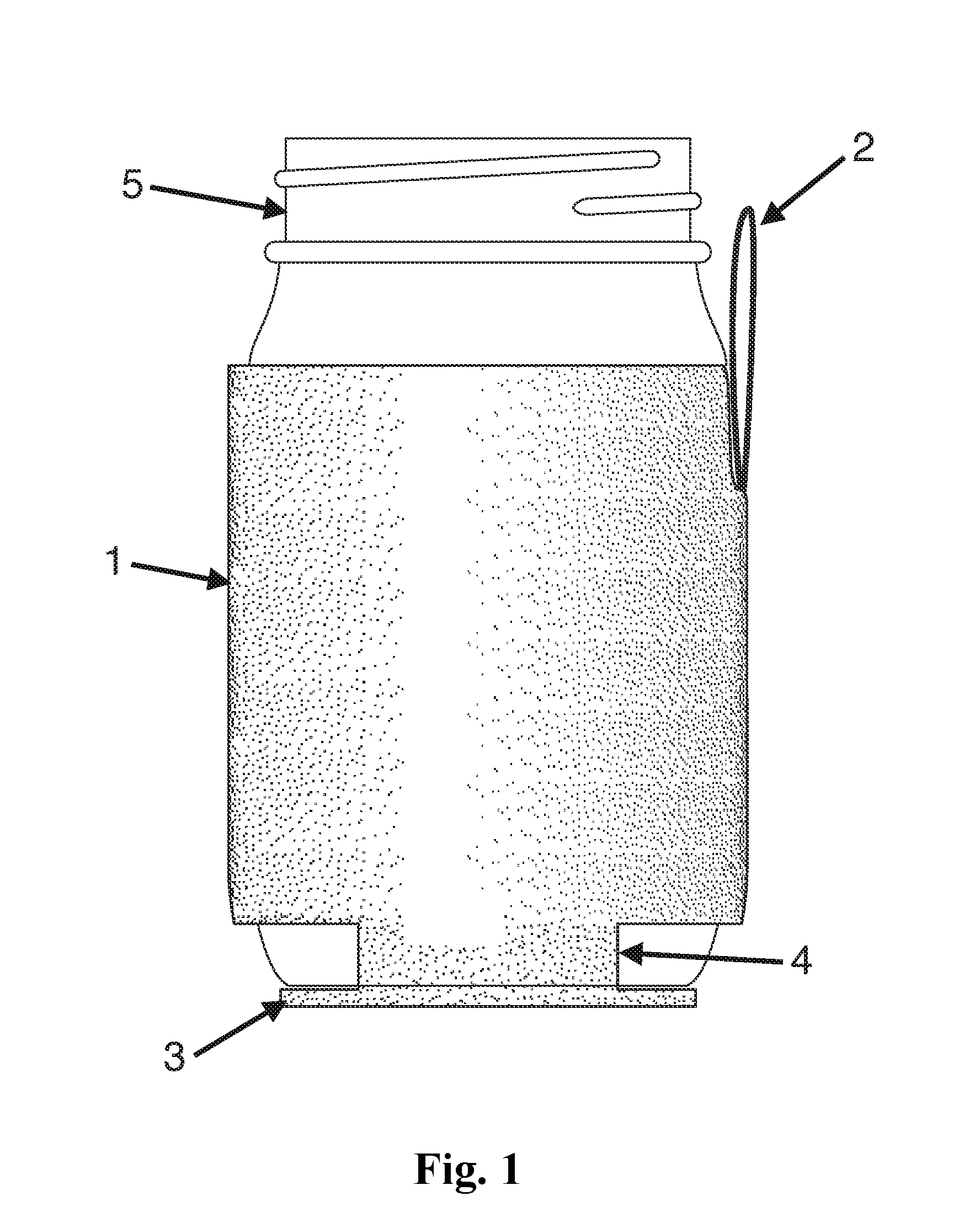

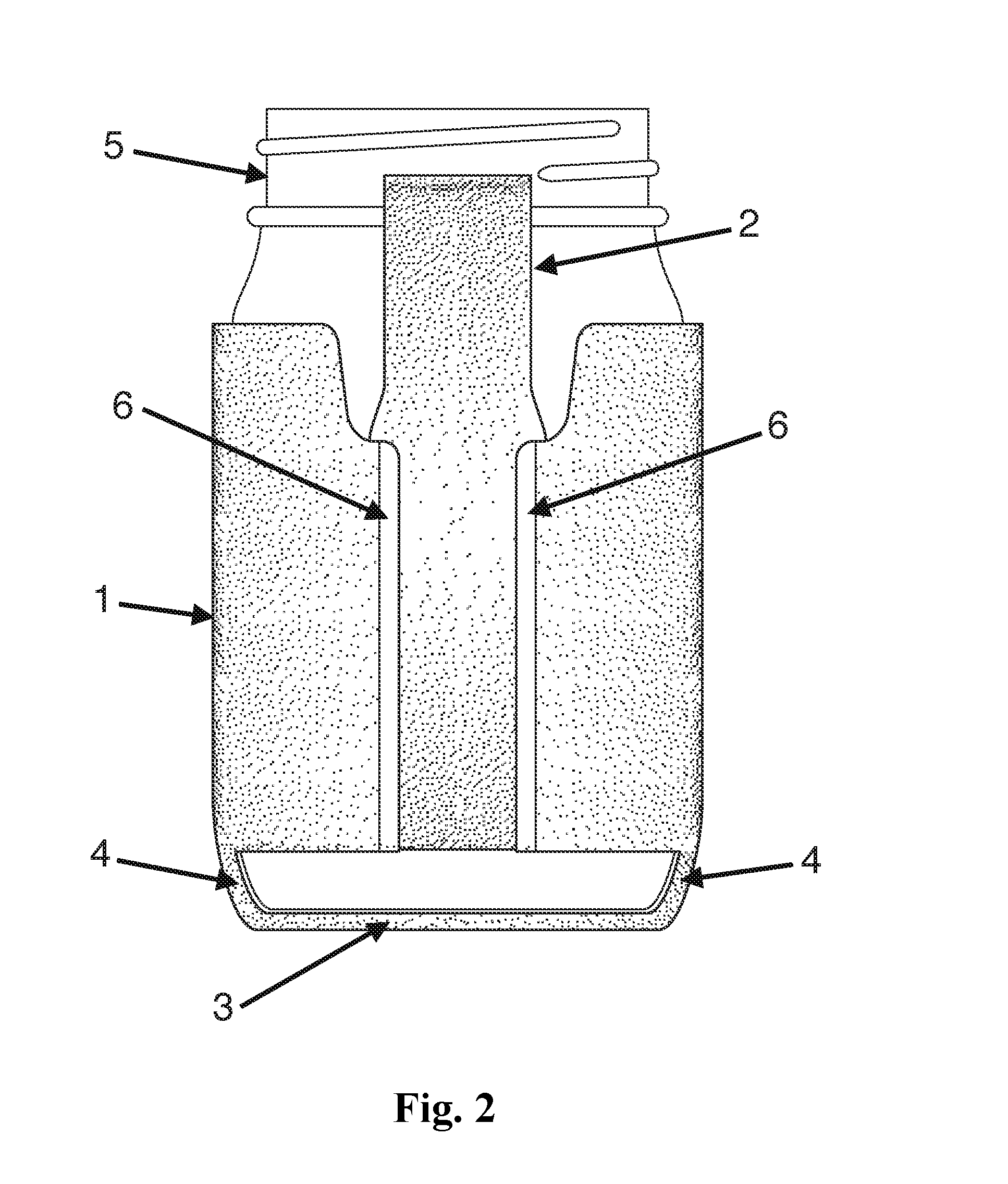

Single handed container for mixing foods

InactiveUS6528105B1Well mixedReady-for-oven doughsBottlesFood contact materialsMechanical engineering

The invention discloses a method and an apparatus for a food container which includes an inner member (which can be a cup or a bottle) for holding a particulate food; an outer member (which can be a second cup or a second bottle) adapted to receive the inner member, with a space between the inner and the outer members, for a liquid food; where the inner member interlocks with the outer member and openings are provided for the discharge of the liquid food; and the particulate food and the liquid food can be consumed simultaneously by tilting the container towards the mouth of the user to discharge or withdraw particulate food from the inner member and liquid food from the outer member through the aperture.

Owner:KELLOGG CO

Compositions for the preparation of void-containing articles

ActiveUS7273894B2Efficiently formedEfficient voidingSynthetic resin layered productsFoundry mouldsPolyesterCellulose

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

Injection molding polymer

An LLDPE produced using a single site catalyst, e.g., an LLDPE produced using a metallocene (m-LLDPE), is preferably used in injection moulding of food packaging material, especially closures for food containers. Such materials have been found to exhibit low levels of migration, typically less than 40 mg / dm<2>, e.g., less than 5 mg / dm<2>, and are particularly suitable for use in packaging foods having a high fat content.

Owner:BOREALIS TECH OY

Method of producing a weld-cut sealing/heat-shrinkable packaging film formed of a polyethylene terephthalate-based block copolymer polyester

A PET-based polyester packaging film capable of weld-cut sealing and heat-shrinkage refers to a film obtained by biaxially orienting a material prepared through block copolymerization of a PET / PETG / polyester elastomer with an epoxy resin and a catalyst. This film eliminates the most serious weak points in physical properties of conventional PET films, and is useful for packaging of books, bottlesets, food containers, etc., for general packaging, packaging of industrial materials, and the like, and is further useful in the field of packing and packaging of daily commodities, civil engineering and construction members, electric and electronic members, and automobile vehicle members, etc. Moreover, this film can be produced through effective use of the huge amount of recycled PET bottles and inexpensive PET for fiber as a prepolymer, and thus is also highly beneficial socially. Still further, even if incinerated after use, this film produces a combustion heat value lower than that of a polyethylene or polypropylene. Thus, this film barely damages incinerators or the like, and emits no toxic gases.

Owner:NAKAMOTO PAKKUSU

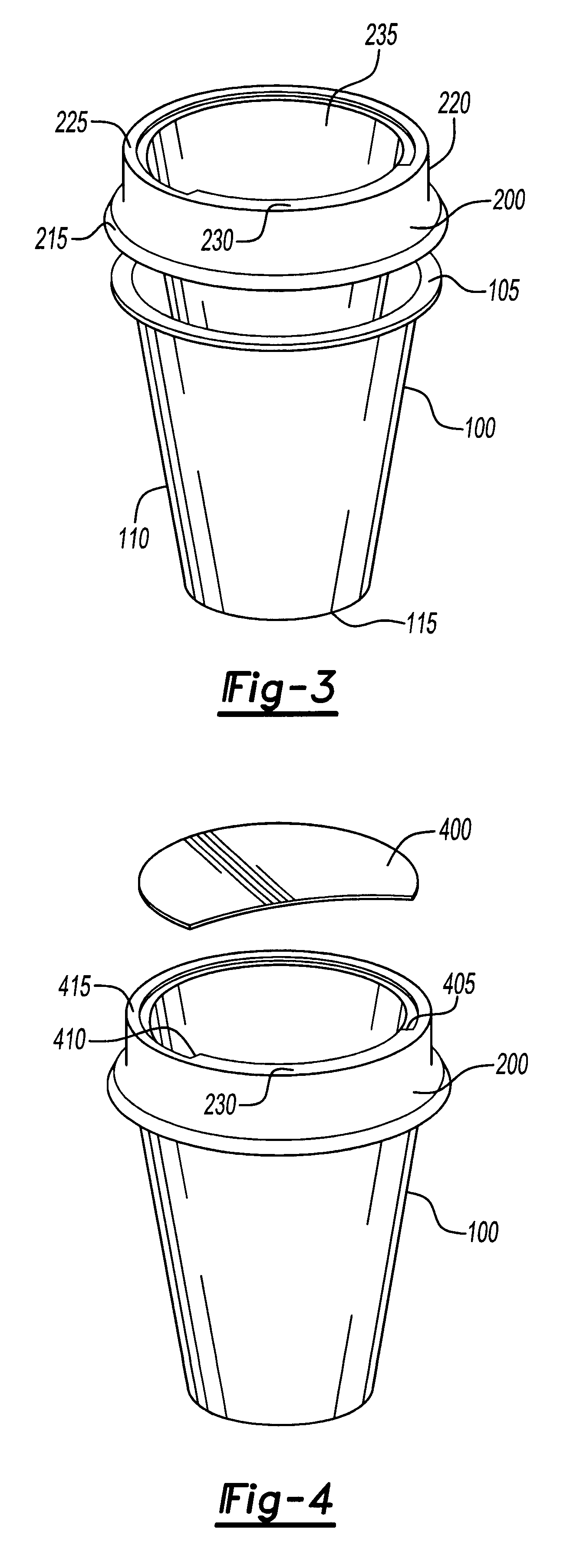

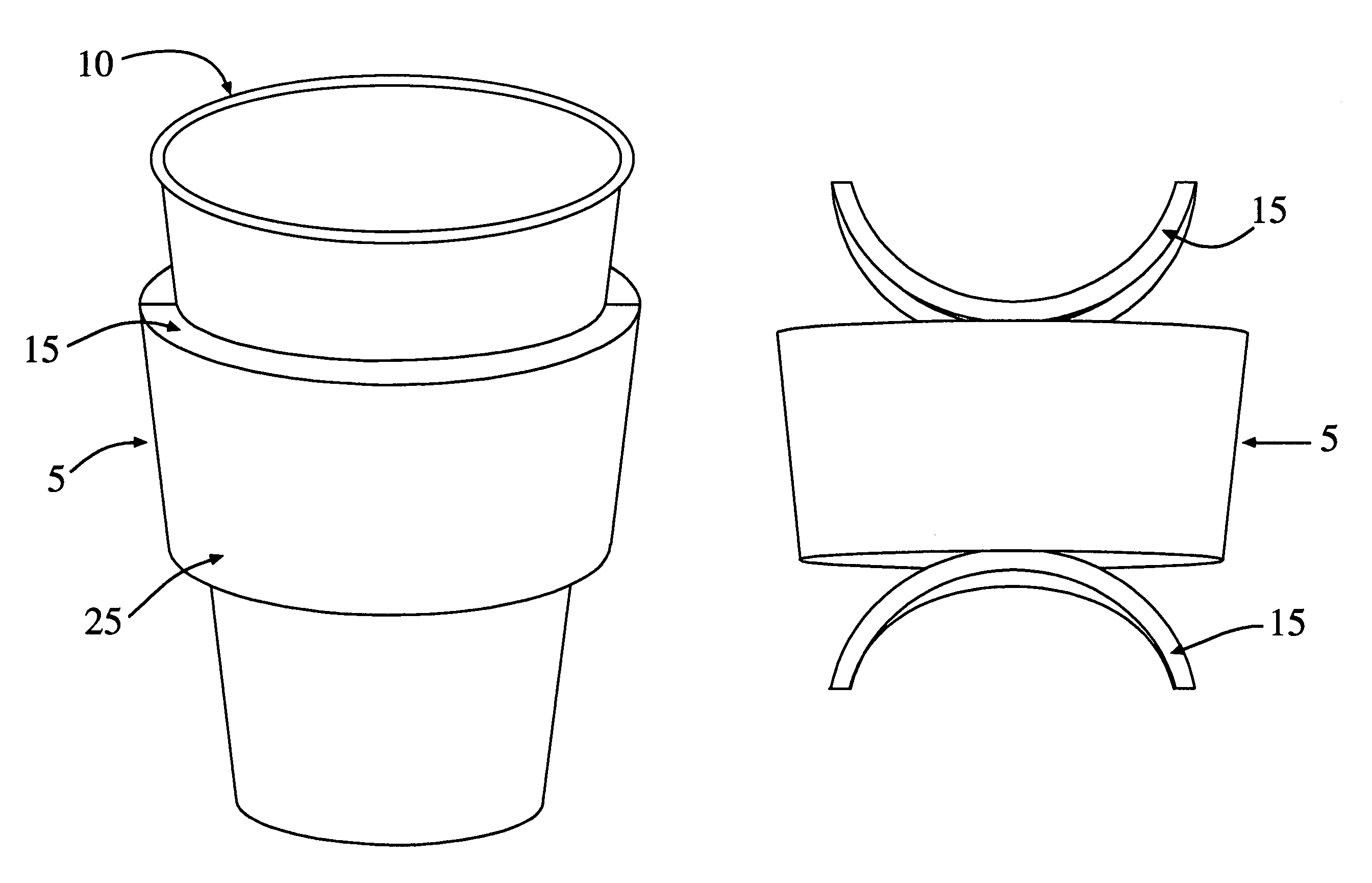

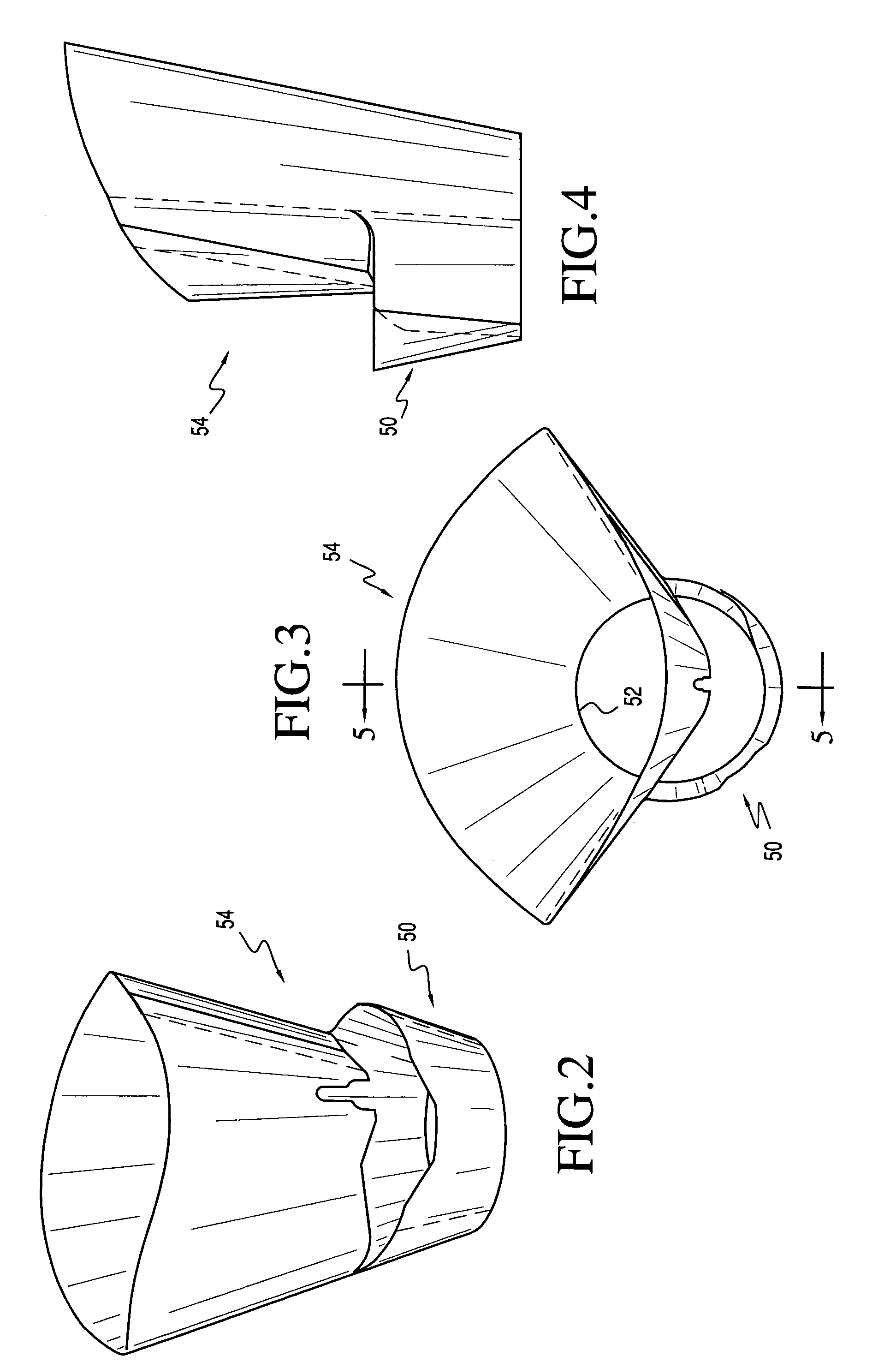

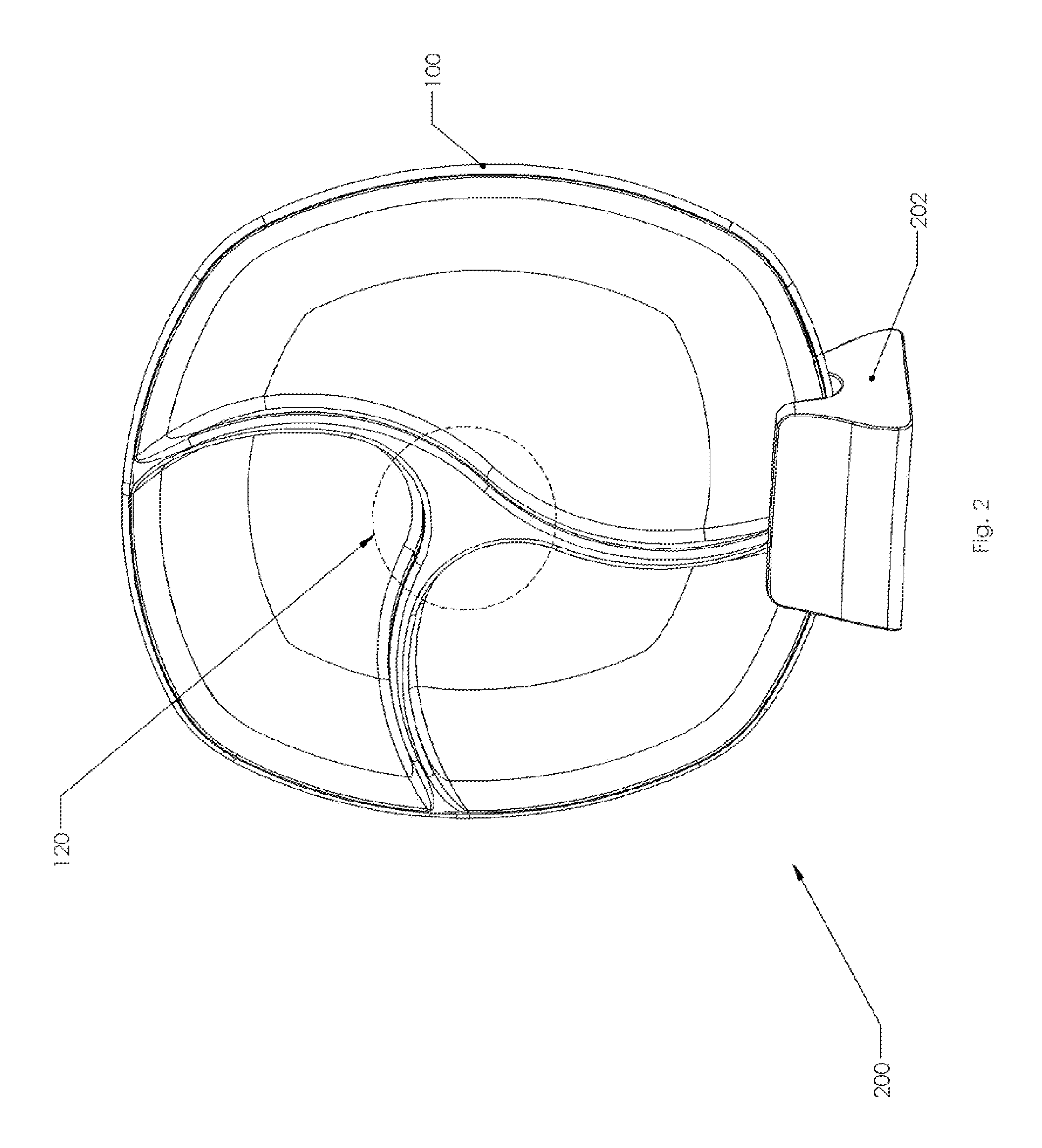

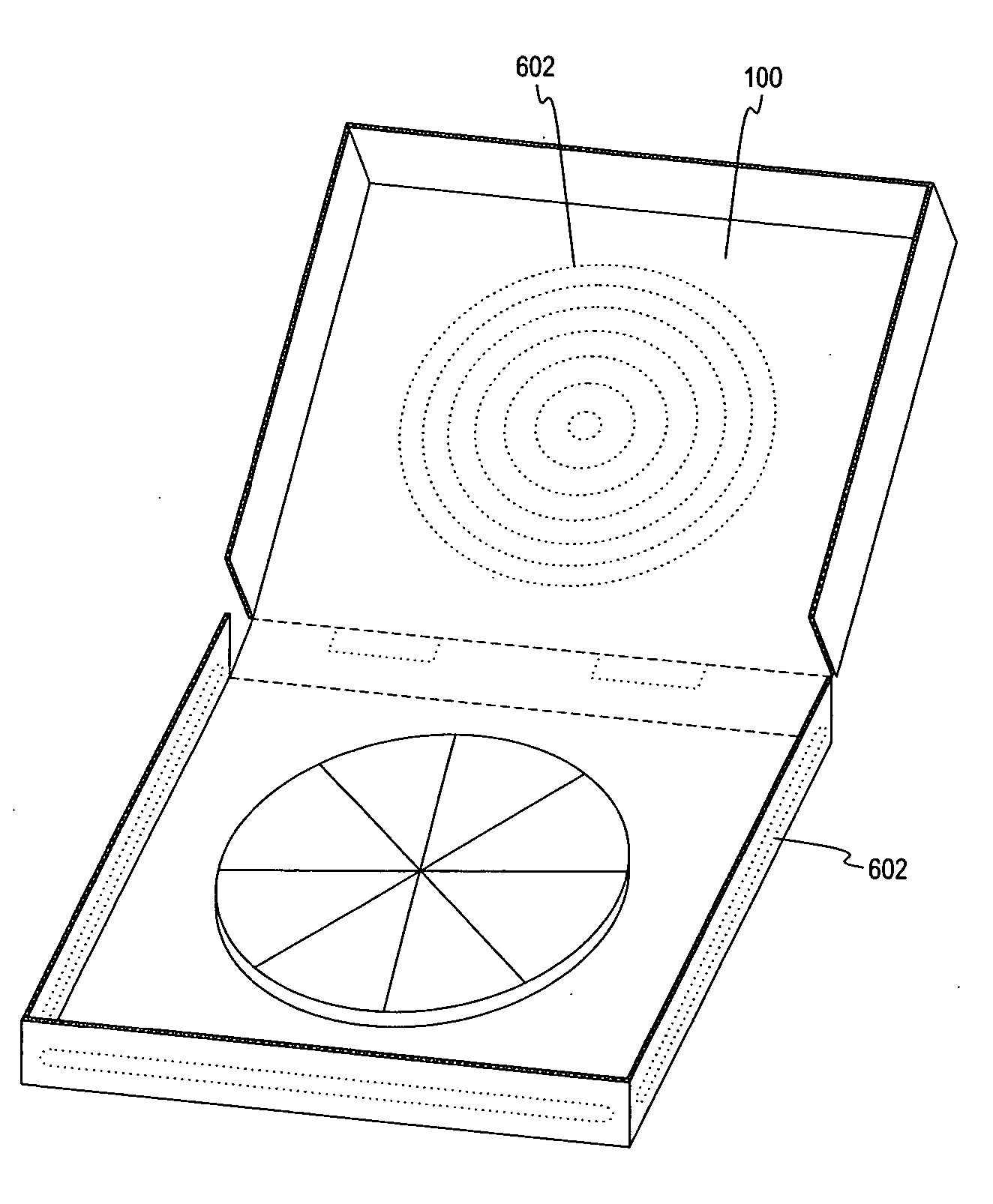

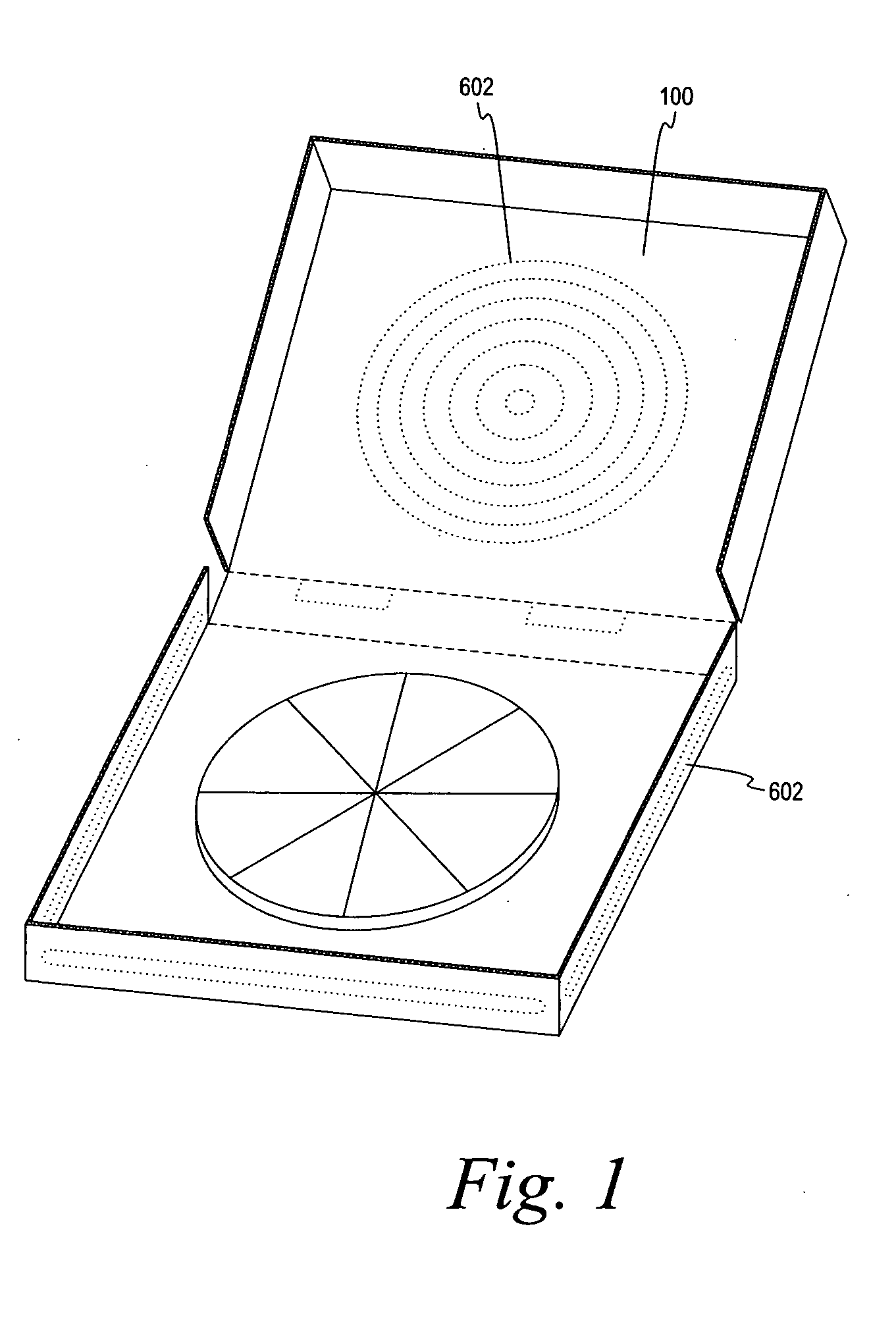

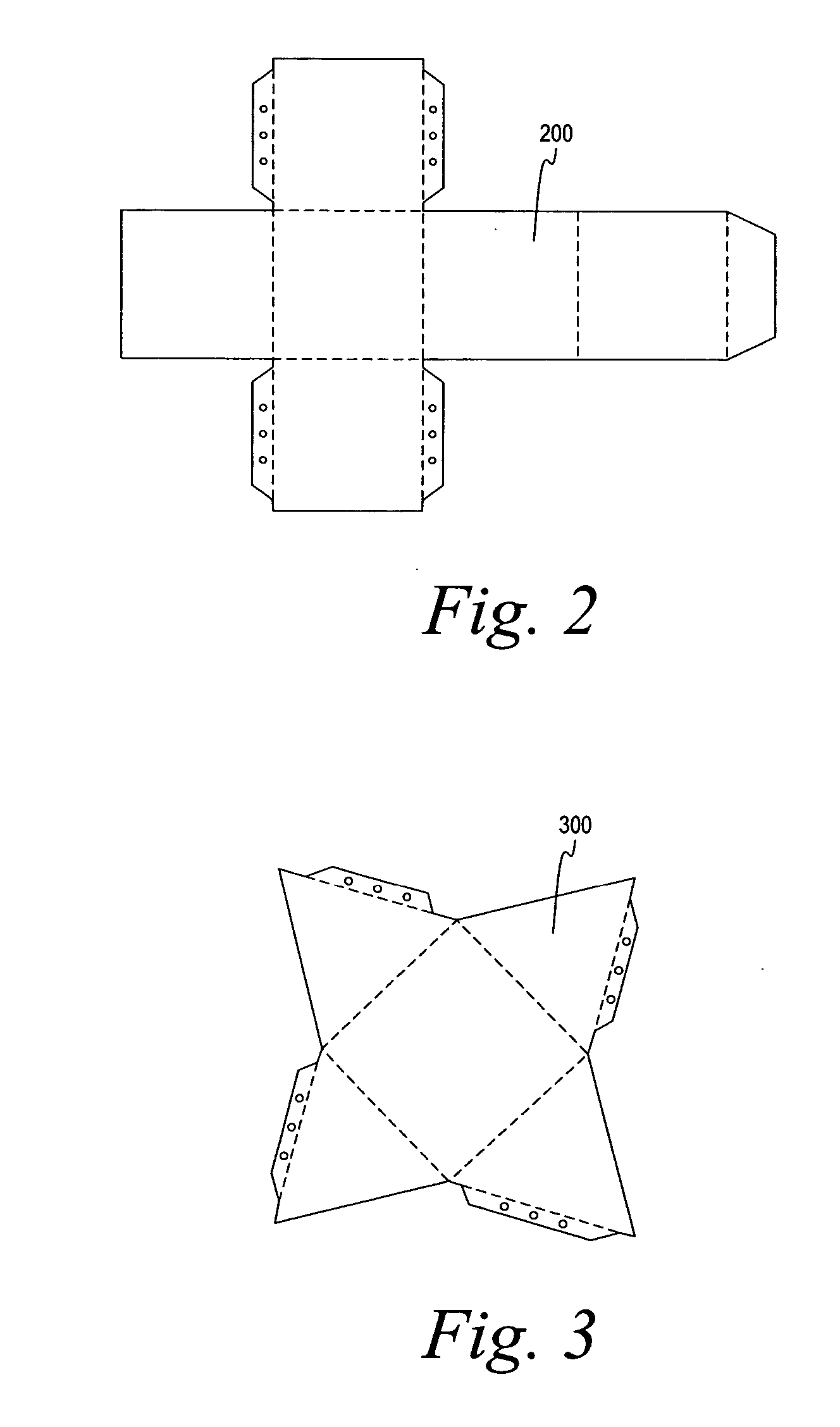

Foldable air insulating sleeve

ActiveUS7537136B2Improve stabilityImprove insulation performanceDomestic cooling apparatusLighting and heating apparatusThermal insulationDisposable cup

A foldable air insulating sleeve for insulating beverage and food containers is herein provided. More particularly, the foldable air insulating sleeve secures a cup in a manner that leaves a pocket of air surrounding the cup. This provides for improved temperature regulation and sufficient thermal insulation to assist the user in firmly grasping and handling the cup despite excess heat or condensation caused by the temperature of the cup's contents. Because the bases of most disposable cups are narrower than their respective rims, more air and thus greater insulation is found towards the bottom of cups secured by foldable air insulating sleeves. The wider base also gives such cups more stability. Support rings may be placed medially in on the inside of the sleeve to strengthen the sleeve and prevent it from collapsing when held by a user. The sleeve may also be short so as to insulate a medial portion of a cup. Printable material can also be affixed on the foldable air insulating sleeve's outer surface for advertising or other purposes. Some embodiments of the foldable air insulating sleeve include a lid to further improve thermal insulation.

Owner:HECHMATI LAURENT

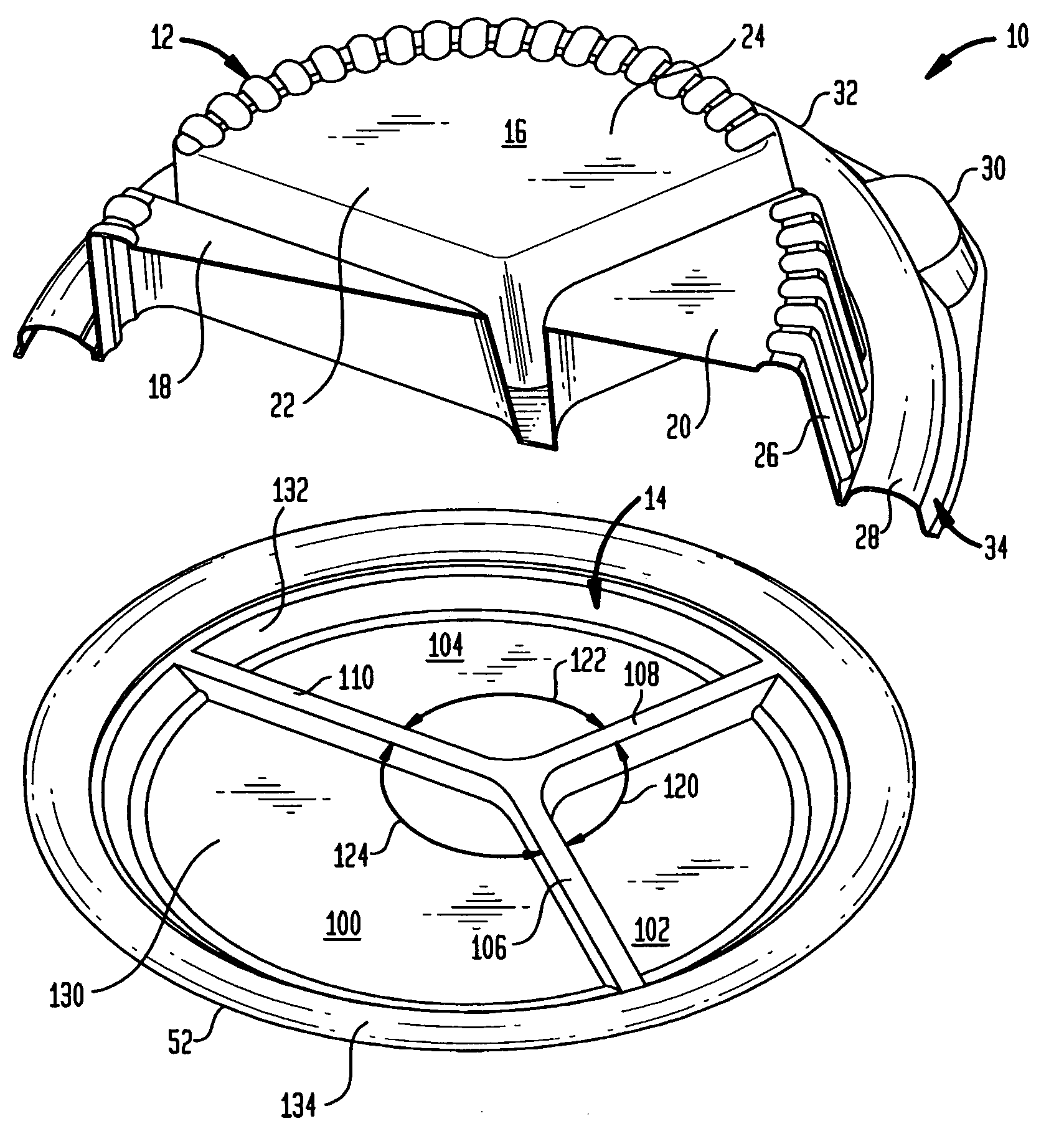

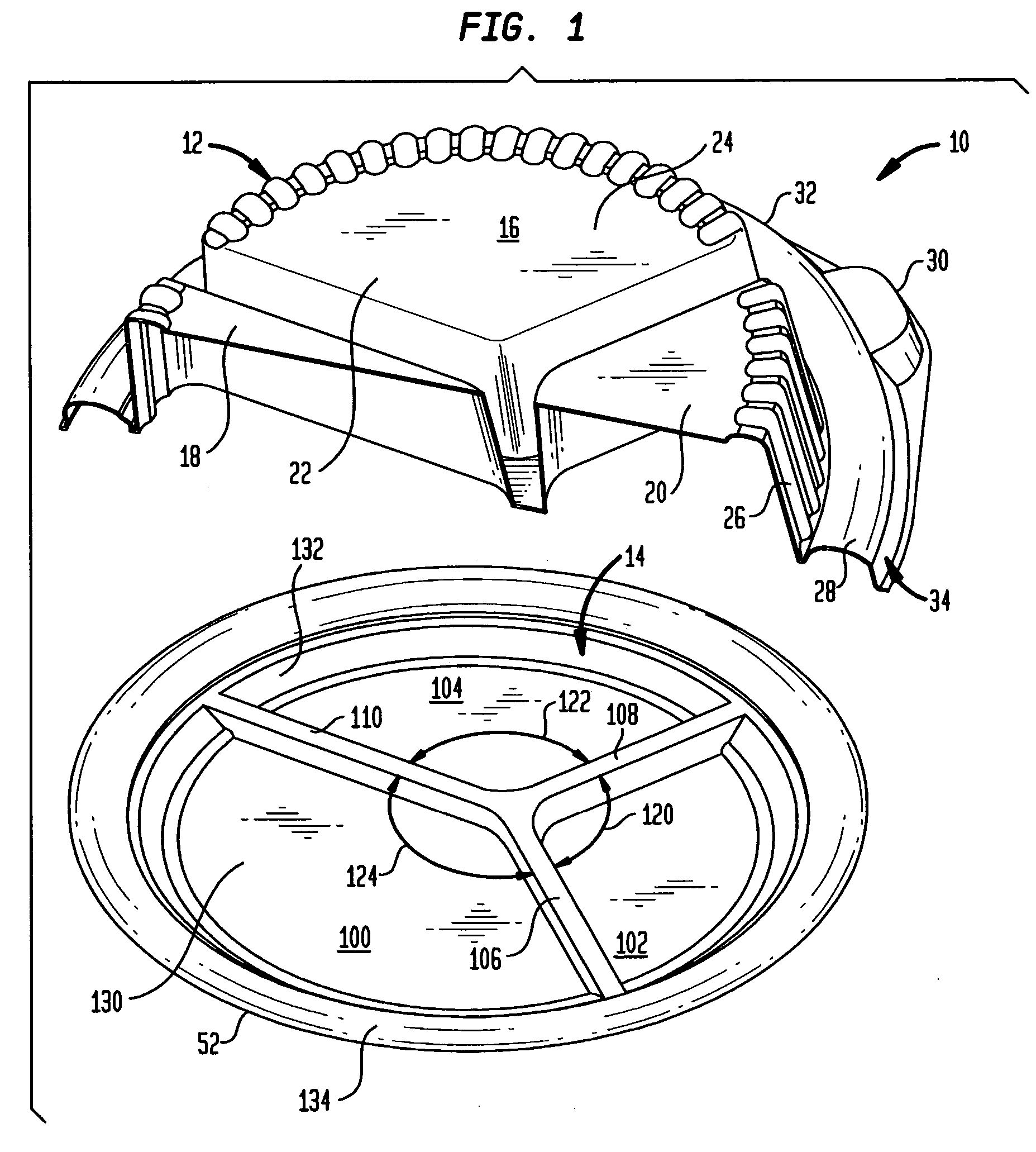

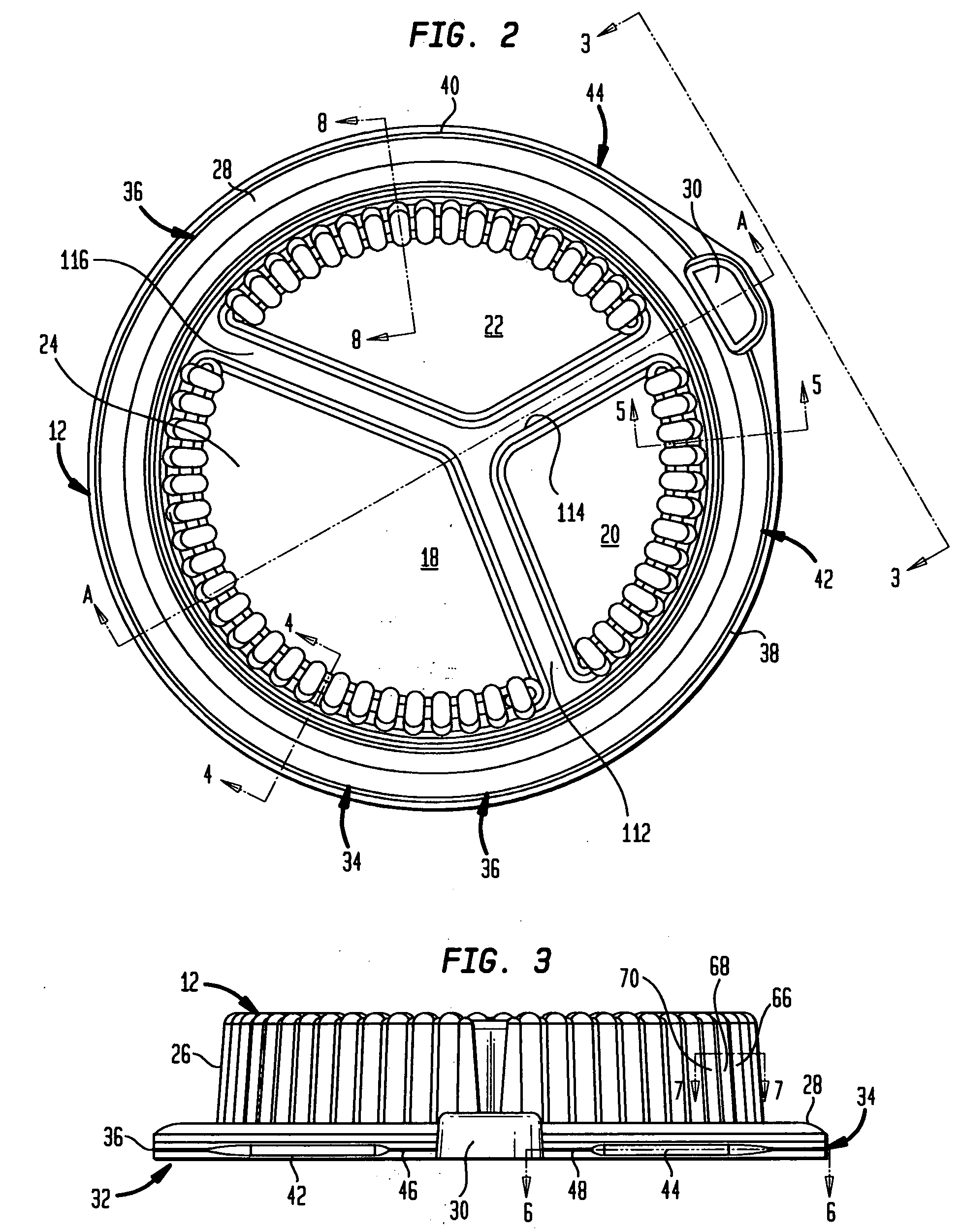

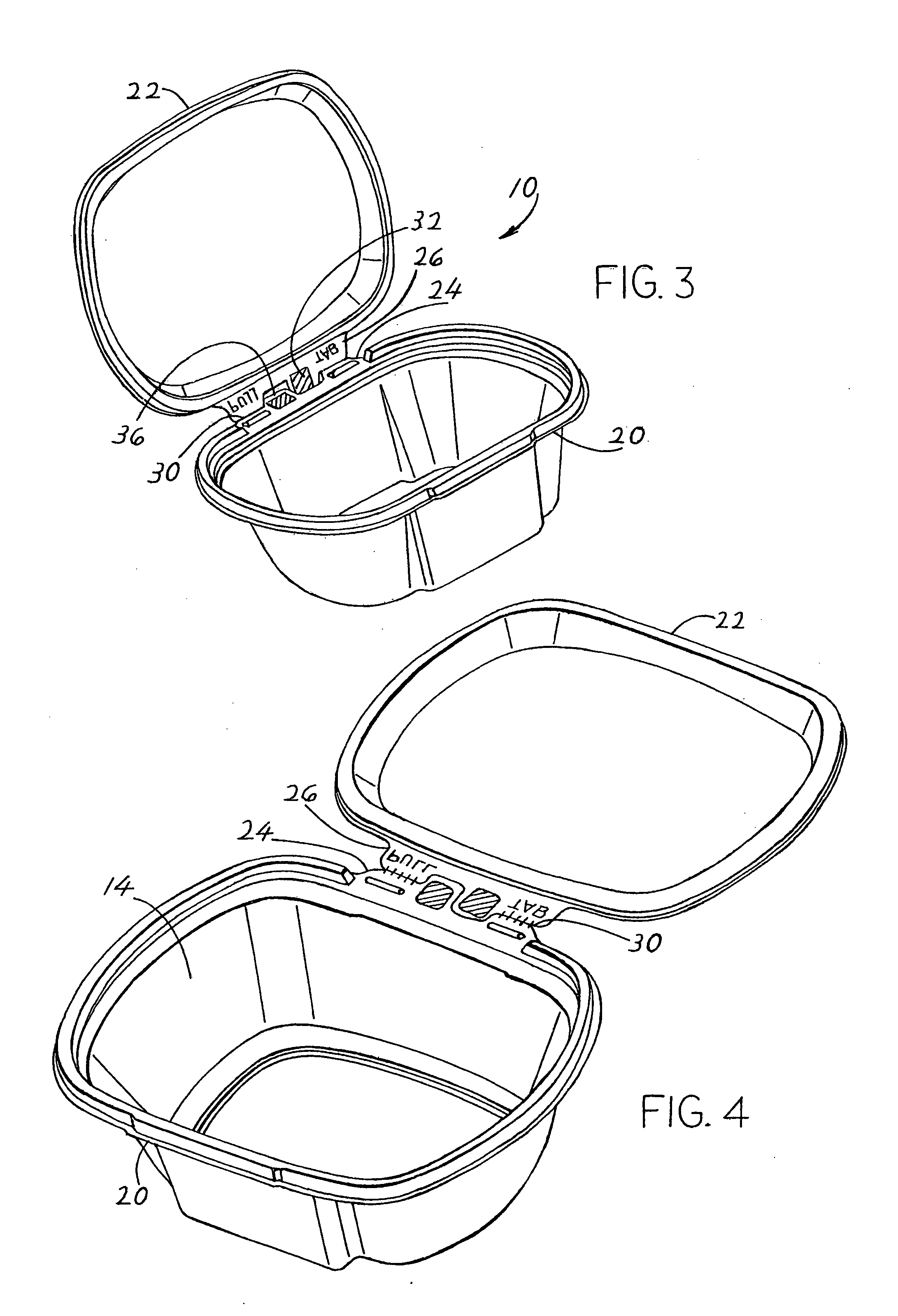

Crush-resistant disposable lid and containers utilizing same

InactiveUS20050145638A1Easy to participateEnvelopes/bags making machineryCapsFood contact materialsEngineering

A domed lid 12 for a food container 10 is configured for ease of engagement and removal from a container base 14. The lid characteristically includes: (a) a dome portion 16 with a top wall 24 and a sidewall 26; (b) a flange portion 28 extending outwardly away from a lower portion of the sidewall; and (c) a tab portion 30 extending outwardly from the flange. The flange portion is provided with a rim 32 having a variable profile around the rim characterized in that: (i) the rim is provided with a securing undercut portion 36 extending around the majority of its periphery adapted to secure the lid to an outer border of base 14; and (ii) the rim has a pair of relatively passive engagement profile portions 42, 44 on either side of tab 30, extending to the securing undercut portion of the rim, the passive engagement profile portions are configured so that they are undercut less than the securing undercut portion of the lid, thereby facilitating engagement of the lid with, or removal of the lid from, base 14.

Owner:GPCP IP HLDG LLC

Void-containing polyester shrink film with improved density retention

InactiveUS20060121219A1Improve shrinkageLow densityWrappers shrinkageShrinkage connectionsPolyesterSoft drink

Owner:EASTMAN CHEM CO

Compositions for the preparation of void-containing articles

ActiveUS20050118406A1Efficiently formedImprove performanceSynthetic resin layered productsFoundry mouldsCellulosePolyester

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

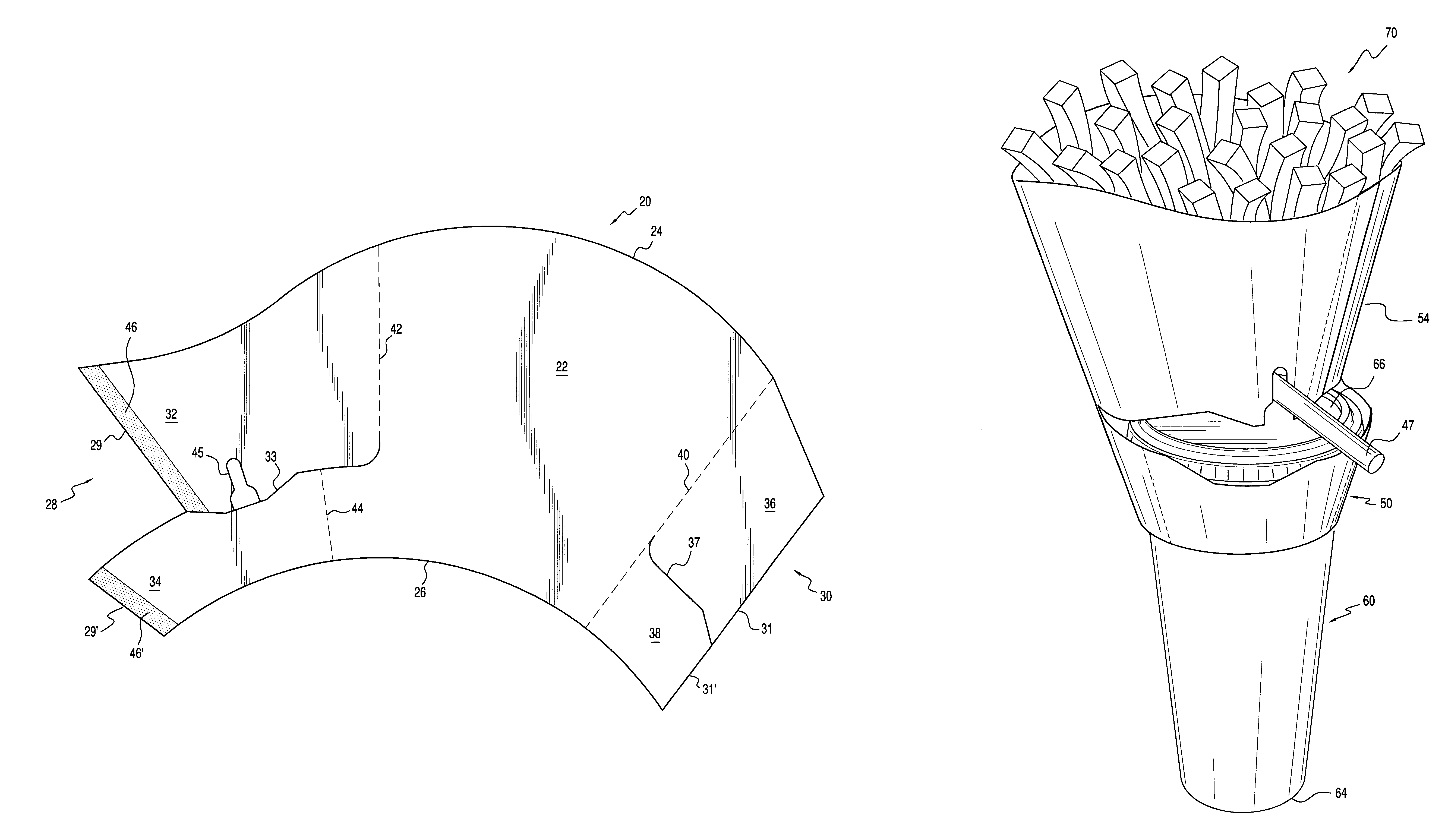

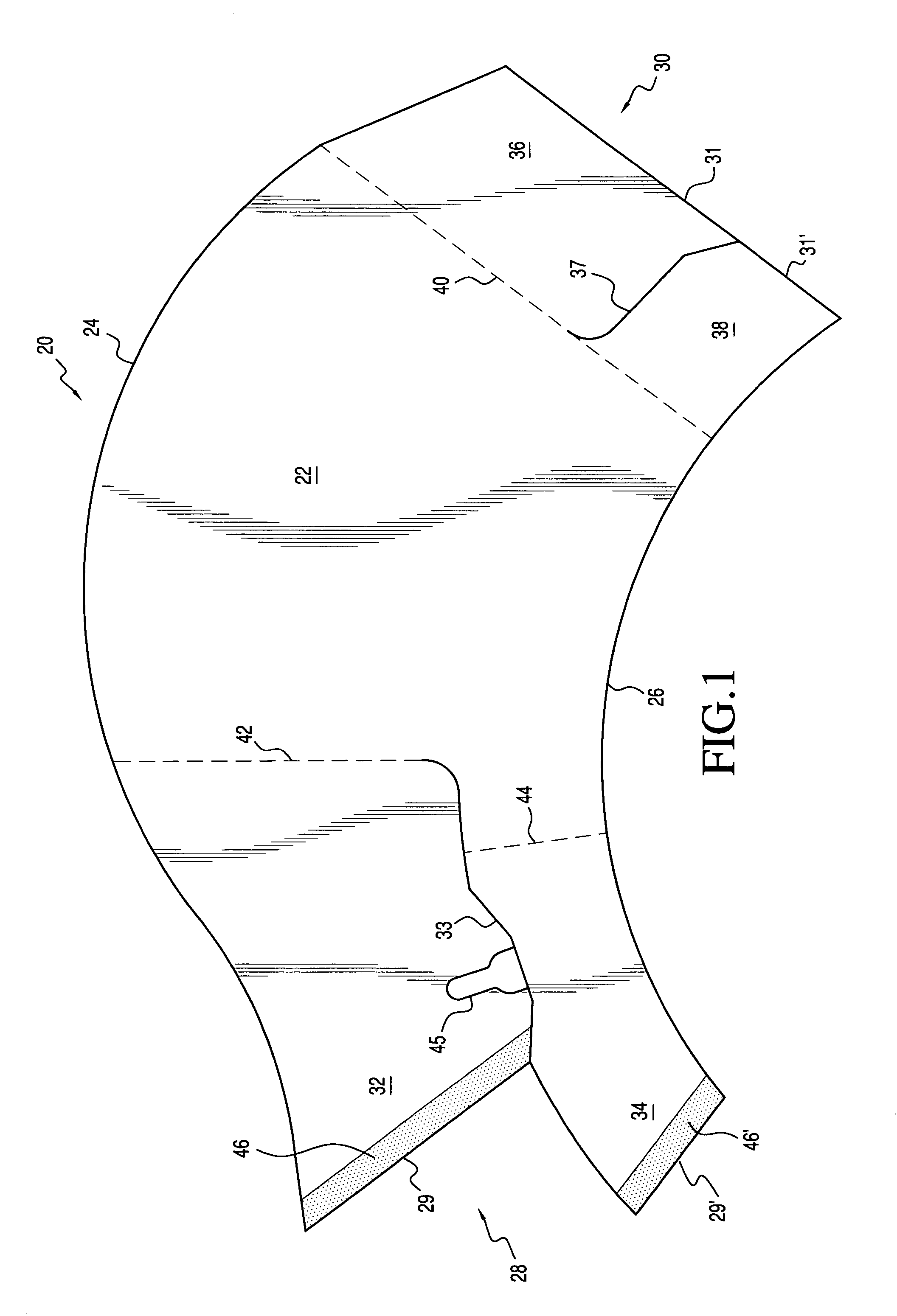

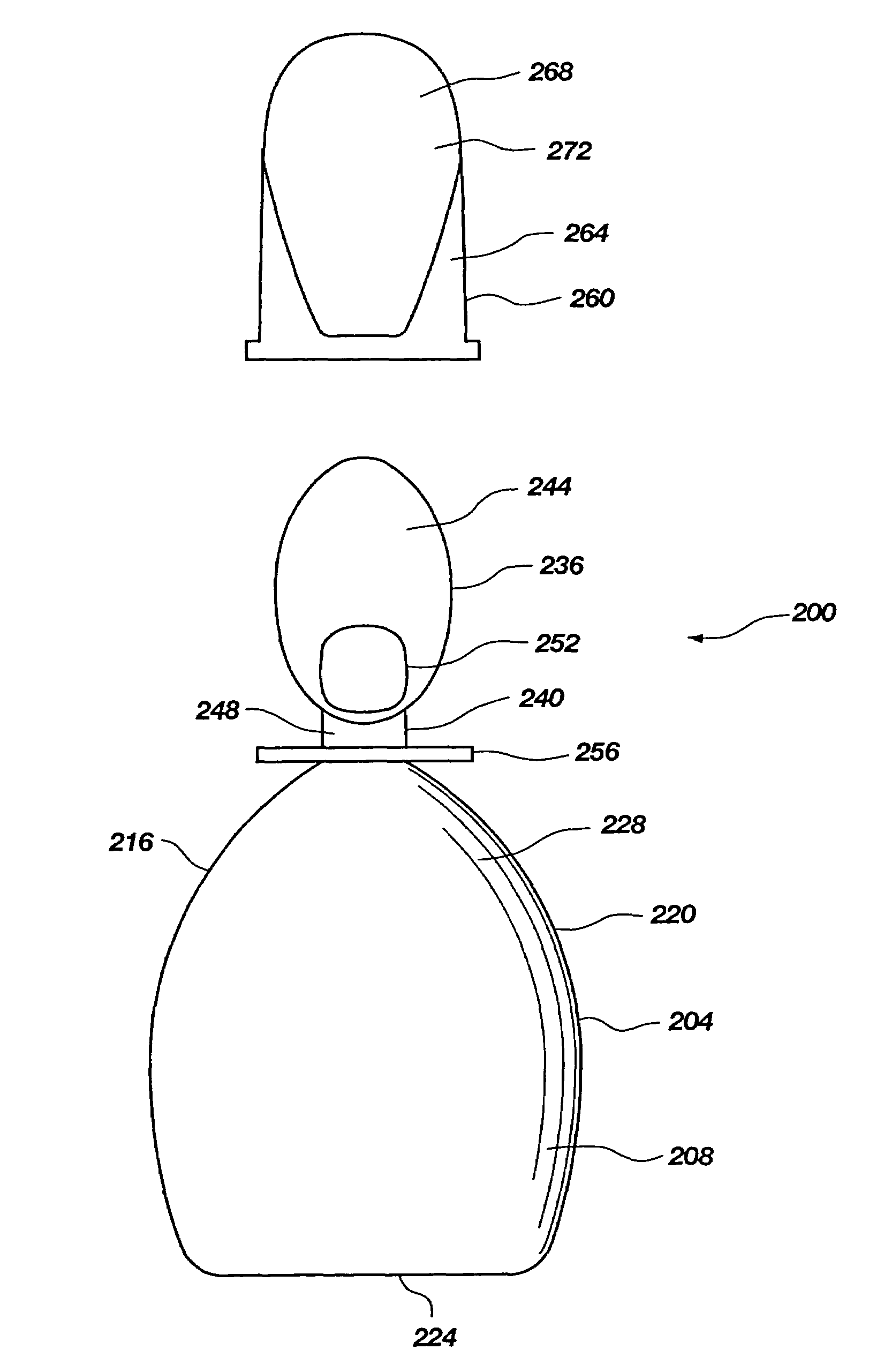

Food container for use with a beverage receptacle

InactiveUS7182242B2The combination is firmSmall dimensionInternal framesPaper/cardboardFood contact materialsEngineering

Owner:DOPACO

Sleeves for beverage and food containers

Owner:PANONE AARON BROOKS

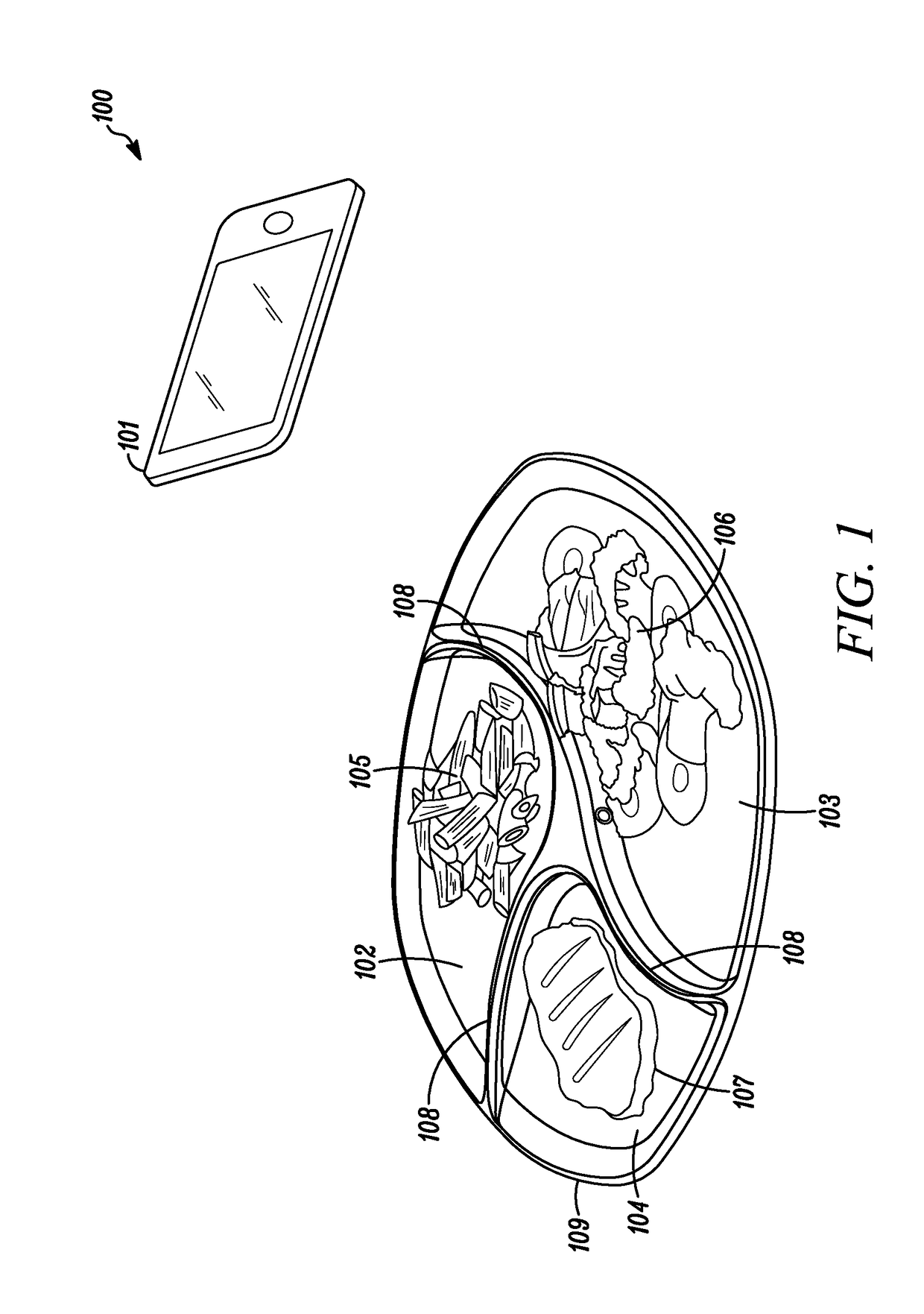

Apparatus and method for identifying, measuring and analyzing food nutritional values and consumer eating behaviors

System and method for identifying, measuring and analyzing food nutritional values and consumer eating behaviors is disclosed. A food container, having weight sensors and food identification sensors, identifies weight, type, and preparation status of the food item being consumed by the user from the food container. Based on the identified information, the nutritional value of the food item is determined and observed. The food container in communication with the system components may provide the user a recommended meal plan to improve the user's health condition. In addition, the food container issues an alert to the user when the user puts too much, too less, or the right amount of food items in the food container or eats the food items too fast.

Owner:FITLY

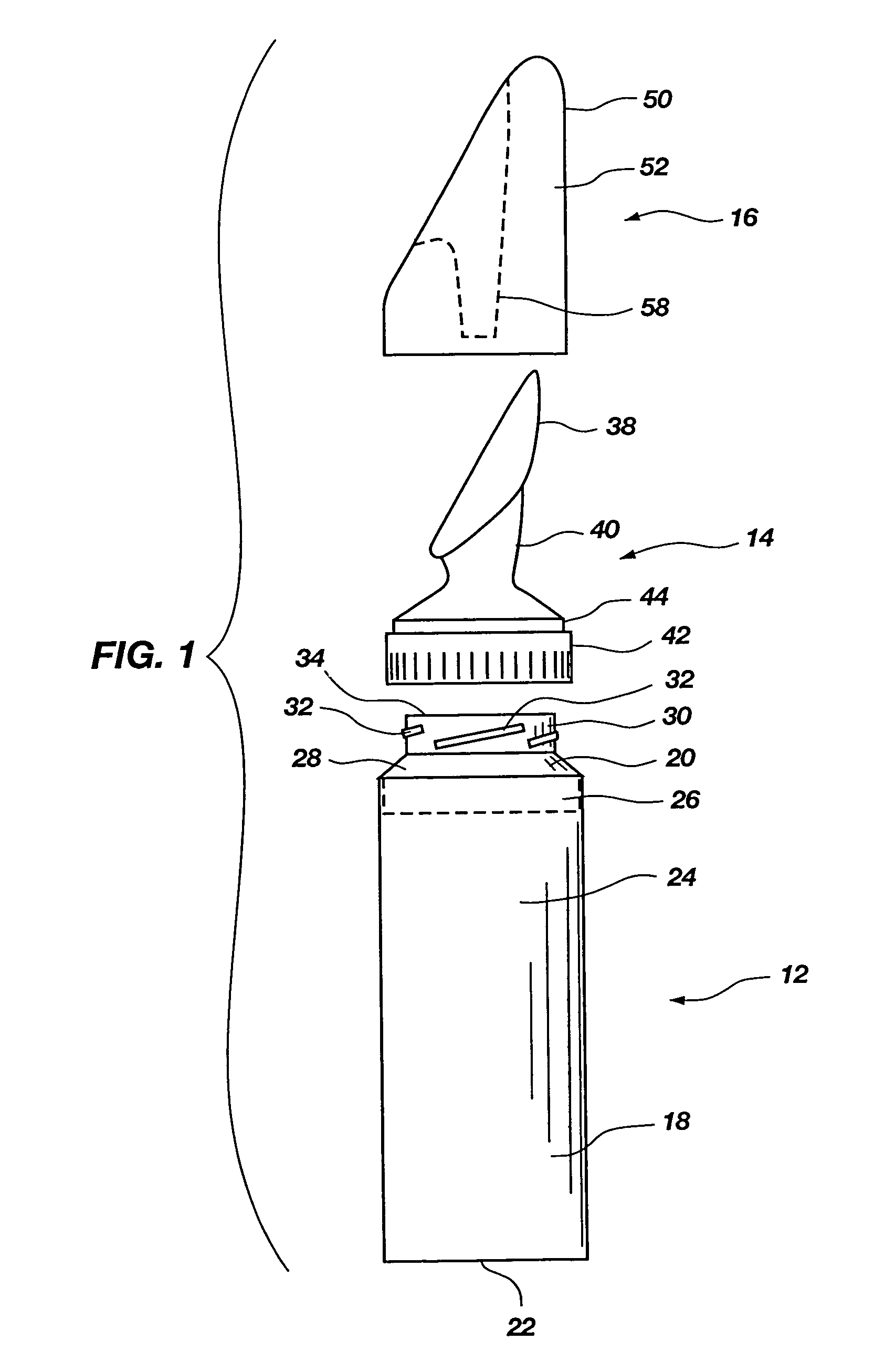

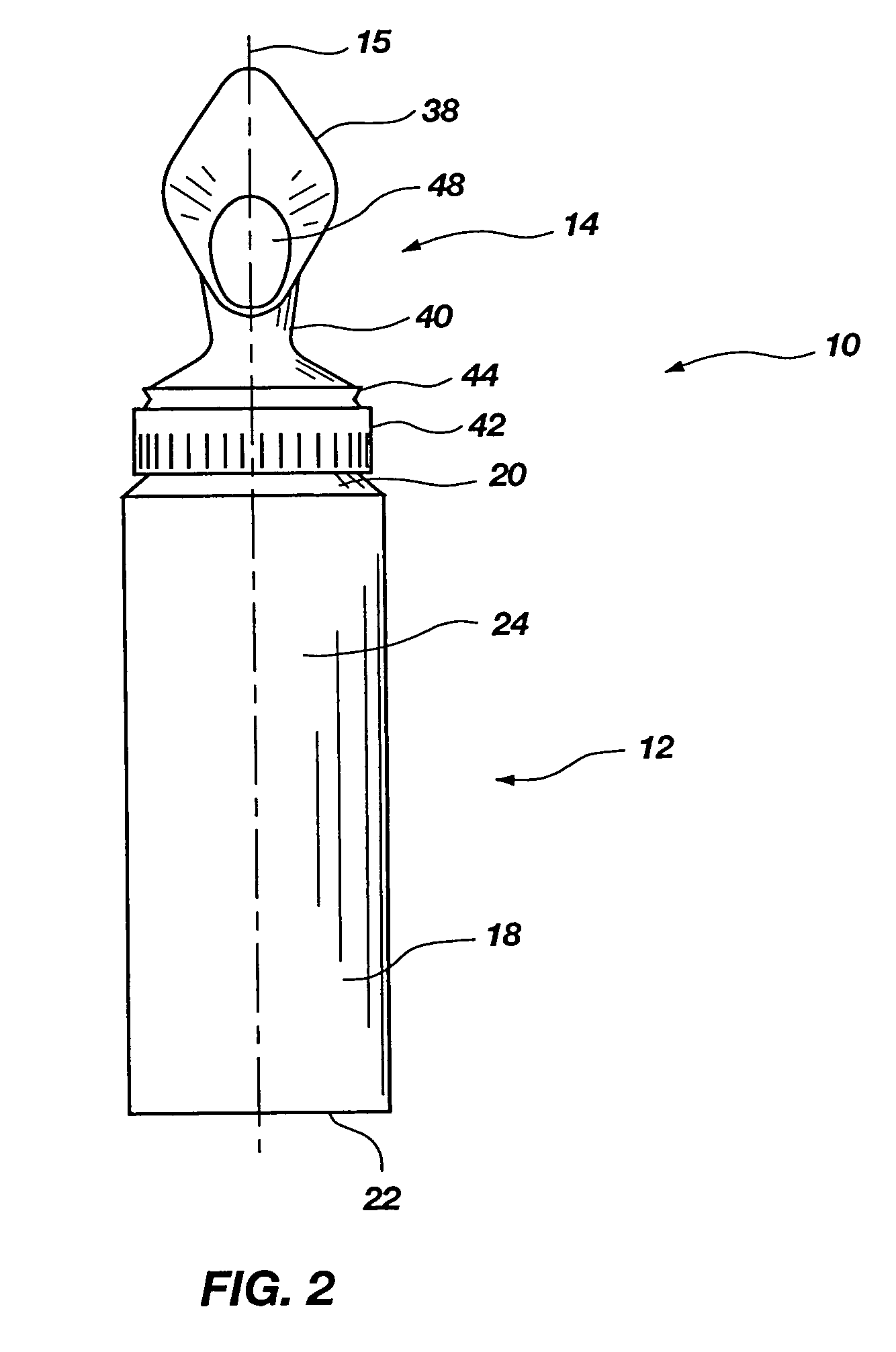

Disposable food delivery apparatus

A disposable food delivery device is disclosed. The device includes a food utensil coupled to a food container. The food container can be pre-charged with food, such as a dehydrated food, such that a liquid can be added to the dehydrated food to result in a ready-to-eat food at any selected time. The food container illustratively can include a port for receiving the liquid. The food container also illustratively can include a security seal for assuring that the food has not been contaminated prior to consumption. Another illustrative embodiment of the invention includes a valve for retaining liquid in the food container prior to consumption of the food.

Owner:OBRIEN JOHN J

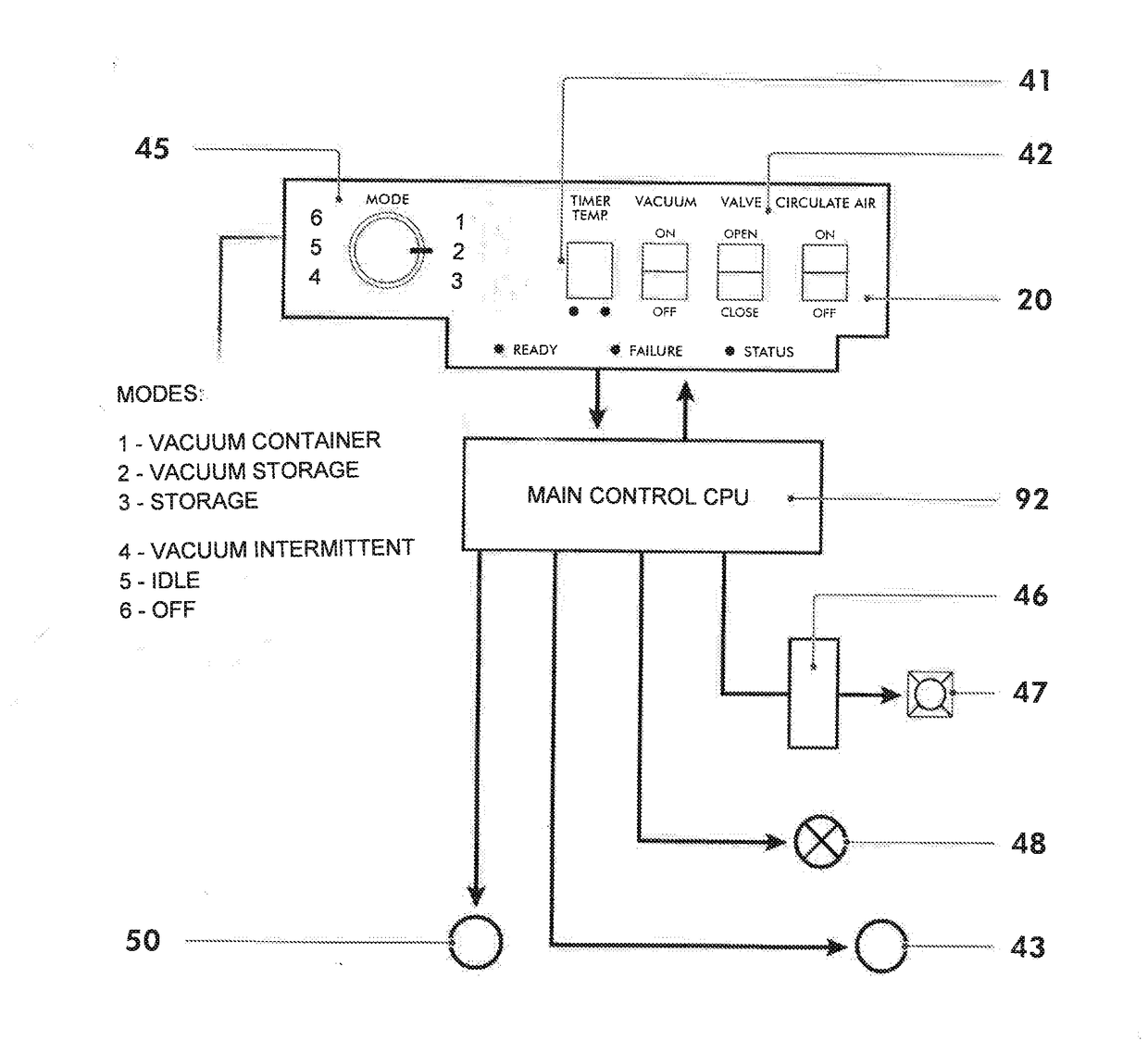

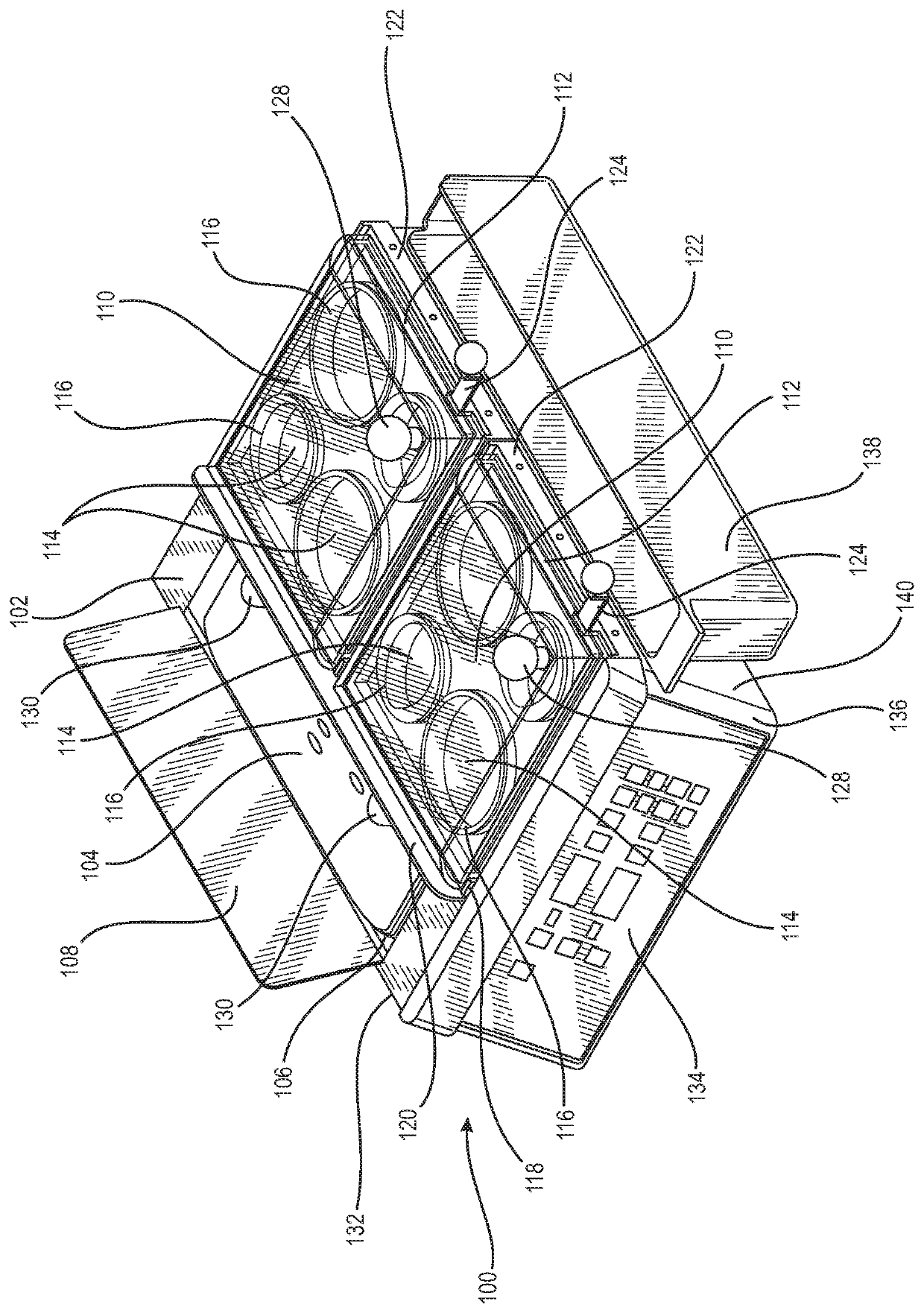

Appliance network with a smart control, host multi-function and external appliance with food containers and methods

PendingUS20180249735A1Efficient methodQuickly and efficiently obtainingStampsFood preservationPerishable foodFood contact materials

A multi-function appliance and methods and systems for manufacturing, packaging, displaying, selling, marketing, ordering and purchasing a perishable food or item in a container with a container technology for use with an appliance. A method and system for the use of multiple brand logos or names and communicative indicia on a container or product packaging wherein at least one of the brand logos or names, such as a secondary or tertiary brand logo or name can be used to represent different or distinct products, services or benefits from the primary brand logo or name.

Owner:MELCHER JEFFREY S

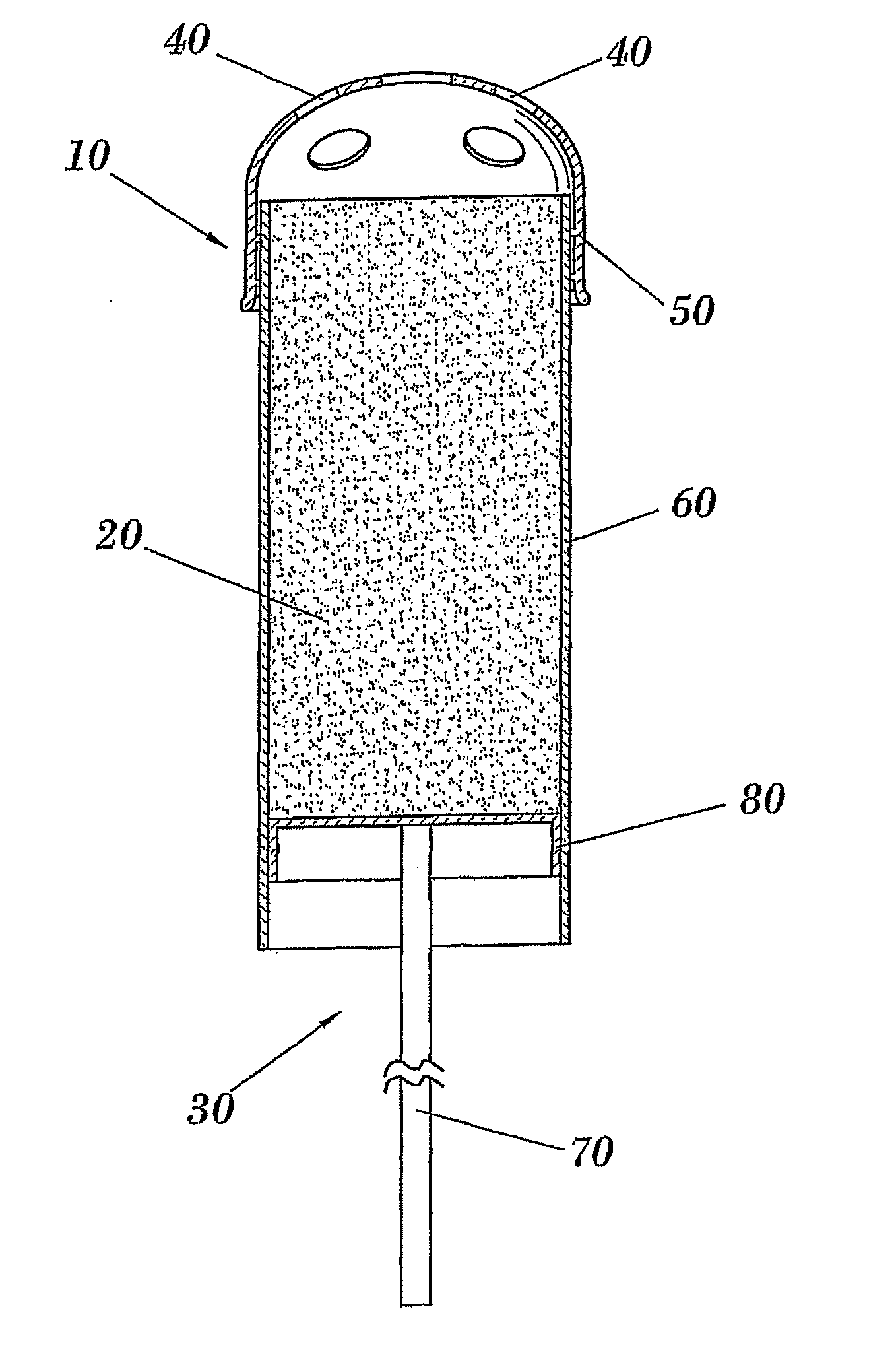

Method Container for Viscous Food Products

InactiveUS20080038414A1Pressure be exertReady-for-oven doughsDispensing apparatusEngineeringMechanical engineering

It consists of a hollow main body (10), composed preferably of a cover (50) attached to a tubular piece (60) containing the food (20), which is supplemented at its open lower end with thrust means (30), which consist of a plunger (80) assisted by a rod (70) that actuates snugly in the interior of said main body (10), determining the issue of said food (20) for its gradual consumption in a metered fashion, as this food (20) passes through multiple holes (40), provided in the closed upper end of the pack, being dispensed in portions of number, size and shapes defined by the holes (40). The pack also has a plunger (2,2′) associated with thrust means (3,3′) and the viscous food issues laterally by way of holes. Particularly applicable to the dispensing of ice creams, with a secure reliable seal, the pack proposed offers a system of consumption that is not only clean but also fun.

Owner:BIG DRUM IBERICA

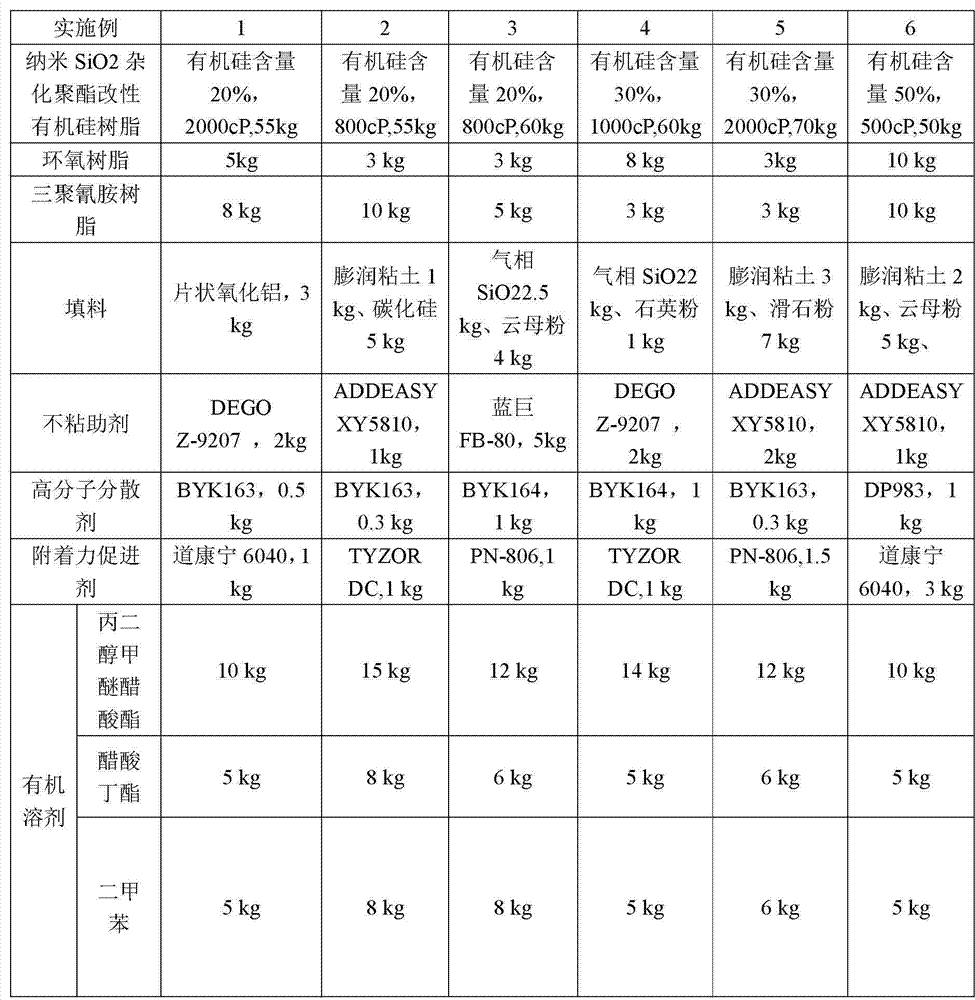

Nanometer SiO2 hybrid polyester modified organosilicon non-stick paint and coating method thereof

ActiveCN103205203ASolve defects that are not suitable for application on ferrous substratesGood non-stickPretreated surfacesEpoxy resin coatingsPolyesterEpoxy

The invention relates to a nanometer SiO2 hybrid polyester modified organosilicon non-stick paint. The non-stick paint is prepared mainly by mixing the following components by weight: 50 to 70 parts of a nanometer SiO2 hybrid polyester modified organosilicon resin, 3 to 10 parts of an epoxy resin, 3 to 10 parts of a melamine resin, 3 to 10 parts of a filling material, 20 to 30 parts of an organic solvent, 1 to 5 parts of a non-stick auxiliary agent, 0.3 to 1 part of a polymeric dispersant and 1 to 3 parts of an adhesion promoter. A coating prepared through coating of the non-stick paint has the characteristics of good non-stick performance, good temperature tolerance, excellent chemical resistance, corrosion resistance, high hardness and the like, is especially applicable to non-stick coatings for ferrous baking equipment and a cake mould and accords with relevant FDA and LFGB standards for food contact materials. According to the invention, the technical defect of a high sintering temperature (normally, higher than 380 DEG C) of a conventional fluoro paint is overcome; and the non-stick paint provided by the invention only needs a sintering temperature of about 280 DEG C, so a phosphating film on the surface of a ferrous substrate is protected, resistance to chemical corrosion is improved, and energy saving and environmental protection are realized.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

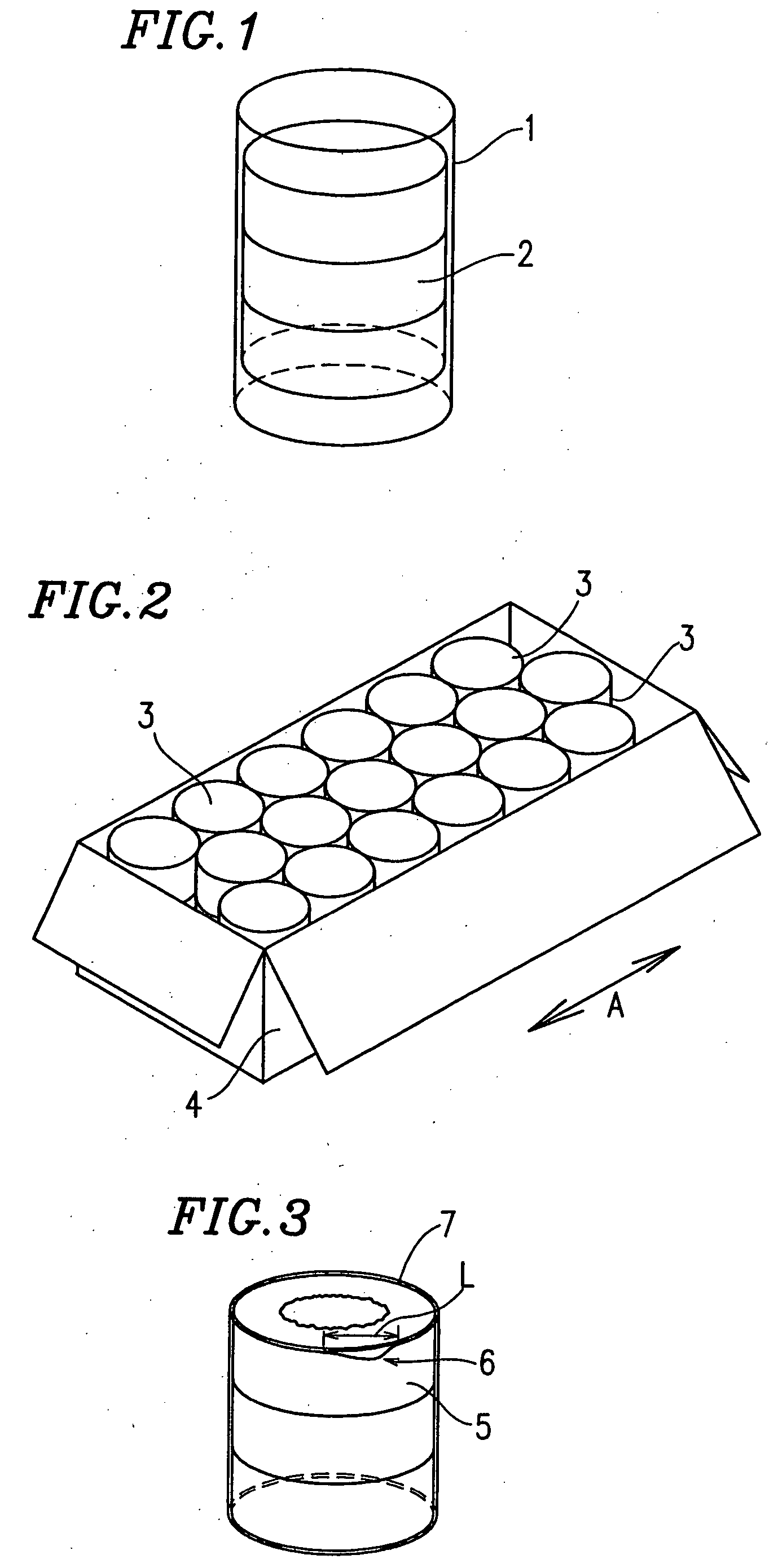

Heat shrinkable polyester film

InactiveUS20050196563A1Improve seismic performanceHigh adhesive retentionEnvelopes/bags making machineryLayered productsPolyesterPolymer science

A heat shrinkable polyester film of the present invention has a transverse tear defect percentage of about 20% or less as determined in the following vibration test: the film is rolled into a tubular shape, two of its opposite edges bonded together, and then the tubular film is placed around a vertical stack (total weight: 660 g) of three food container cans each having a diameter of 72 mm and a height of 55 mm; the can stack with the tubular film placed therearound is passed through a shrink tunnel to shrink the tubular film onto the can stack; a total of 18 packs of such can stacks are placed into a cardboard box having a length of 455 mm, a width of 230 mm and a height of 165 mm (6 packs in the length direction by 3 packs in the width direction), and the cardboard box is sealed; the cardboard box is vibrated along the width direction for 30 min by a stroke of 50 mm and at a vibration rate of 180 reciprocations / min, after which the transverse tearage of the tubular film is visually observed; and the transverse tear defect percentage (%) is determined based on the number of defective packs per 18 packs, wherein the defective pack is any pack having a tear flaw of 30 mm or longer along a can periphery. The heat shrinkable polyester film of the present invention has a good shock resistance during shipping especially under low temperatures, with a good finish after shrinkage and a sufficient solvent adhesiveness. Thus, the heat shrinkable polyester film of the present invention is suitable for use in a multi-packaging label for packaging, inter alia, a stack of cans.

Owner:ITO HIDEKI +4

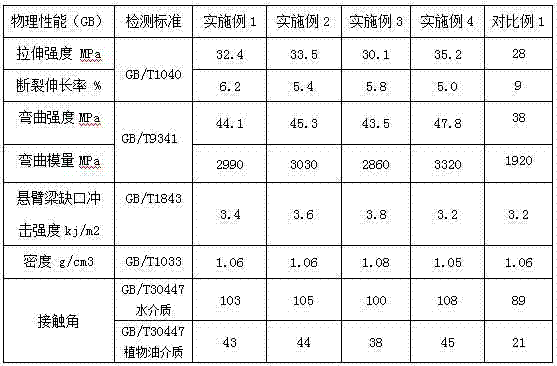

Reinforced greasy-dirt-resistant high-gloss polypropylene composite material and preparation method thereof

ActiveCN104744818ALower surface free energyGood oil resistancePolypropylene compositesPolymer science

The invention provides a reinforced greasy-dirt-resistant high-gloss polypropylene composite material and a preparation method thereof. The reinforced greasy-dirt-resistant high-gloss polypropylene composite material is prepared form the following components in parts by weight: 60-80 parts of PP resin, 10-15 parts of superfine precipitated barium sulfate, 6-10 parts of reinforced magnesium sulfate whiskers, 2-5 parts of fluoride, 0.2-0.4 part of an antioxidant, 0.1-0.3 part of a nucleating agent, 0.5-1 part of a lubricating agent and 0-3 parts of other auxiliaries. According to the reinforced greasy-dirt-resistant high-gloss polypropylene composite material prepared by the method disclosed by the invention, the surface polarity of the material is changed and the greasy dirt resistance of the material is improved; meanwhile, the composite material meets the European Union Regulation (EC) No.1935 / 2004 of related food contact materials, and has the characteristics of being high in gloss, low in after shrinkage, high in rigidity, and the like. The material is applied to a housing of a kitchen appliance, so that the surface of the kitchen appliance has capacity of resisting greasy dirt and self-cleaning capacity, and the self-cleaning anti-greasy-dirt environmental requirements of modern kitchen appliance are met.

Owner:ORINKO NEW MATERIAL CO LTD

Food container product

The present invention provides novel food containment devices comprising an insulating layer sandwiched between layers of construction materials, and which optionally includes a plurality of convection openings to emit moisture vapor or humidity emanating from a hot food product within the container.

Owner:AMATO DANIEL M

Food cooking appliance utilizing both steam and heat for rapidly cooking food products

ActiveUS10561273B2Overcome or eliminate the aforenoted disadvantages or operational drawbacksSmall sizeCooking-vessel materialsCooking-vessel lids/coversThermodynamicsFood contact materials

Owner:A J ANTUNES & CO

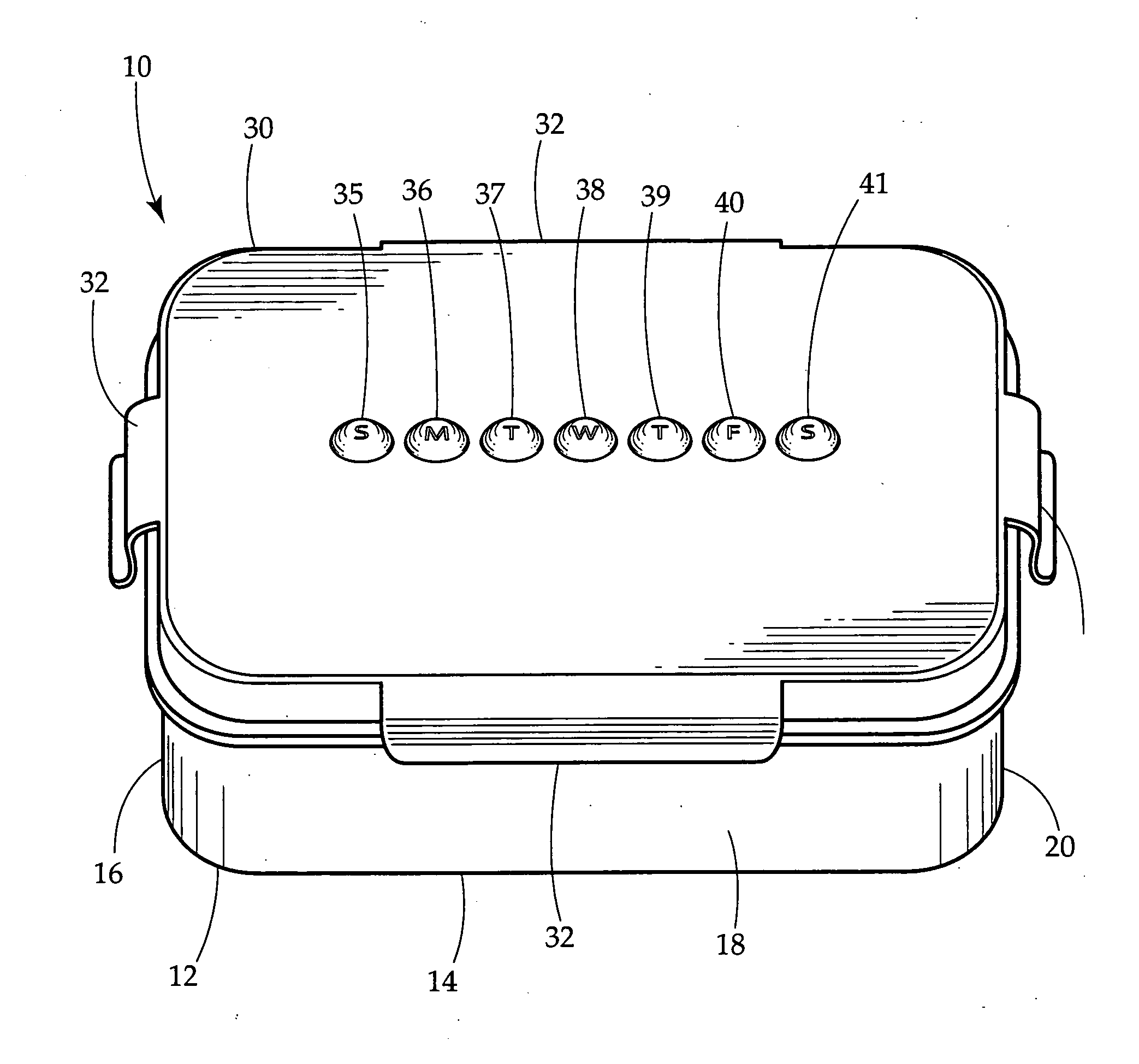

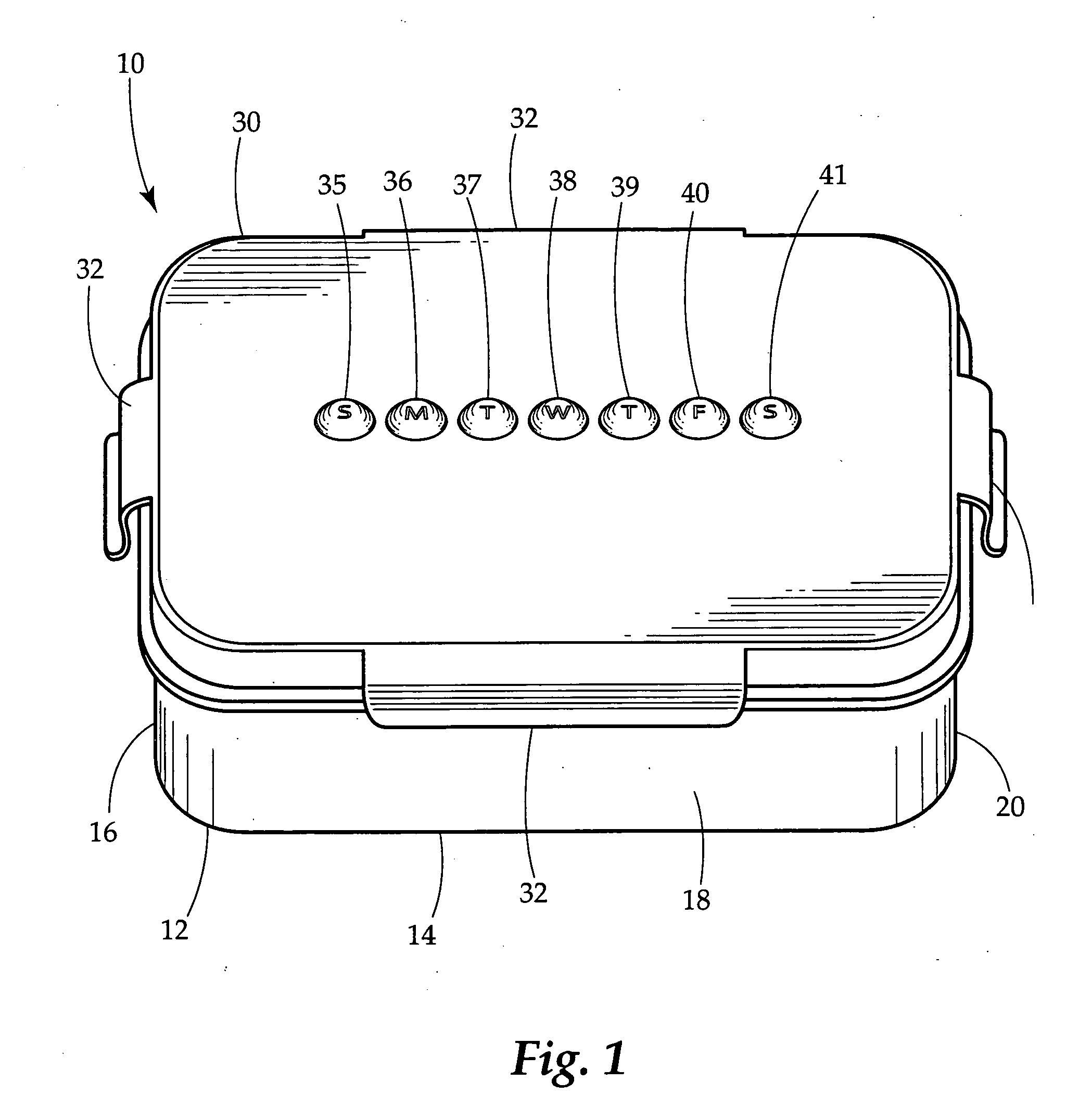

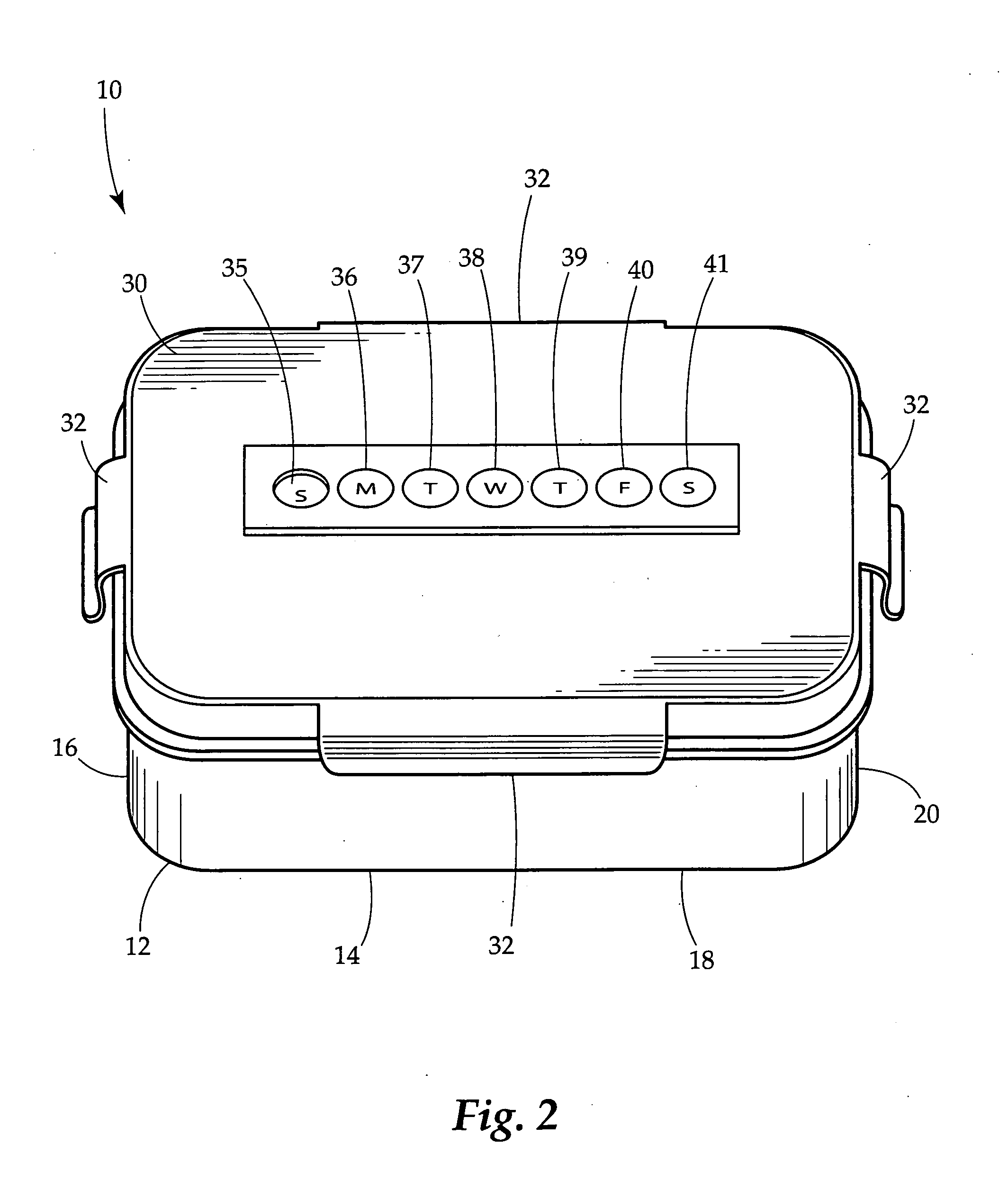

Food container

InactiveUS20160137364A1Easy to cleanEasy to identifyContainer decorationsLevel indicationsFood contact materialsIcebox

Owner:PIRRELLA KIMBERLY

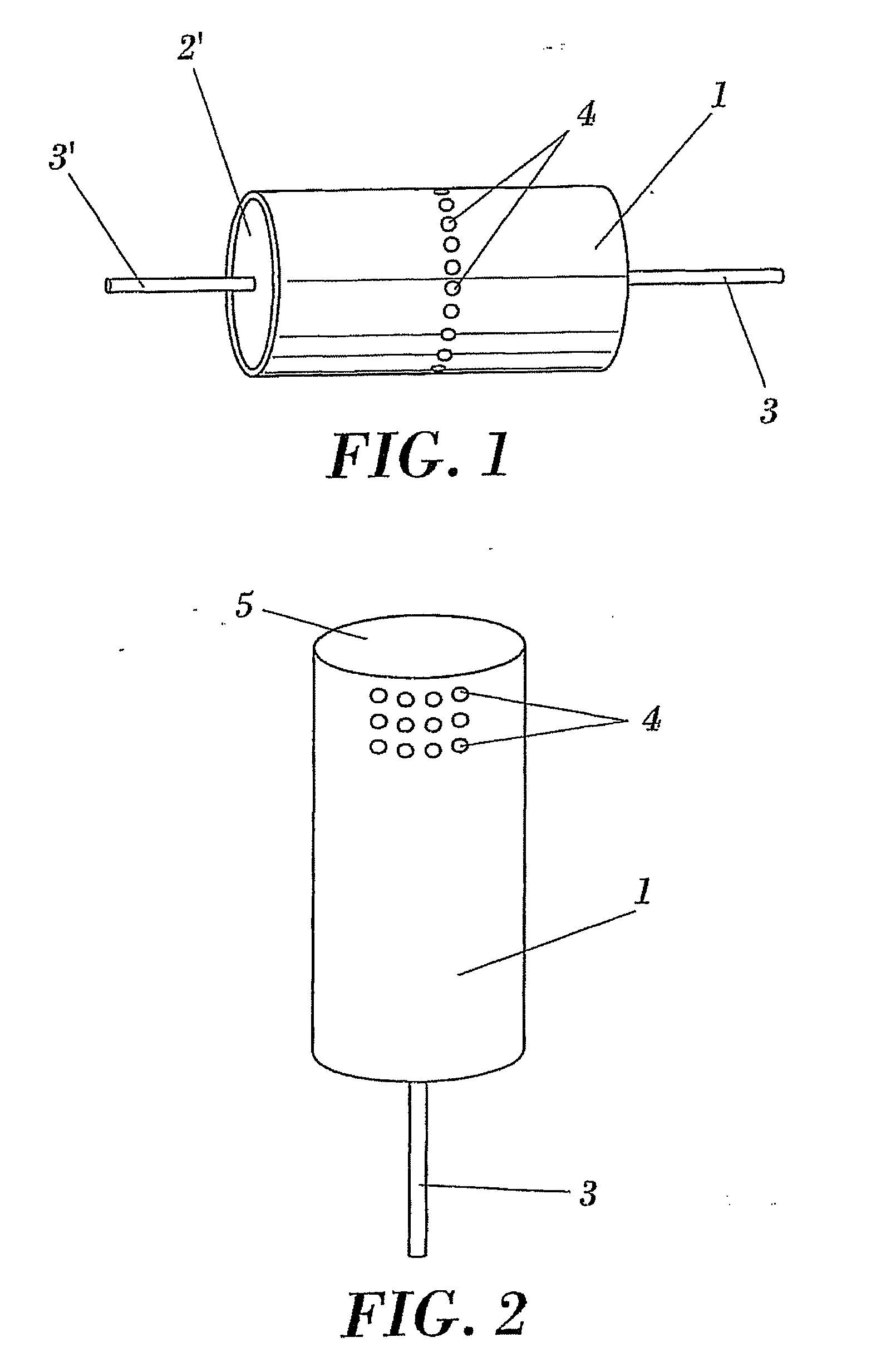

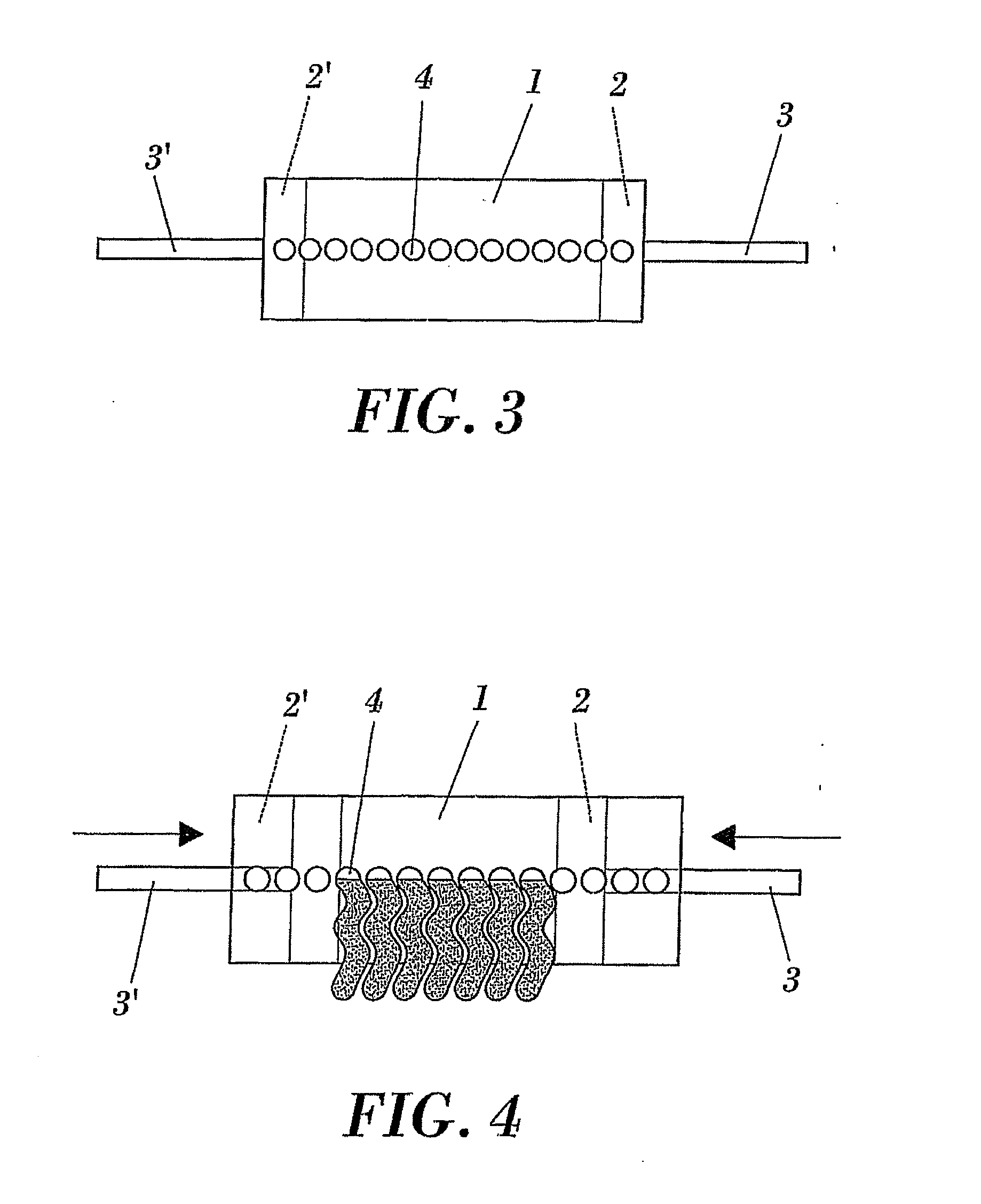

Foods in food container, and heating device for foods in food container

ActiveUS10368681B2Easy to reachQuickly subjected to steam heatingFood preservationCooking vesselsFood contact materialsEngineering

A heating device for a food item in a food container includes the food container that contains the food items, a cooking container that contains the food container, and a steam generation device that supplies steam into the cooking container. The food container has an opening hole that communicates with an internal space and an external space, and at least one of a food surrounding space provided between an inner wall of the food container and the food items, and between the food items. The food surrounding space and the external space are communicated with each other through the opening hole, and steam is supplied into the cooking container to heat the food items by the steam. Thereby, the heating device for a food item in a food container that can subject the food item in the cooking container to steam heating can be provided.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

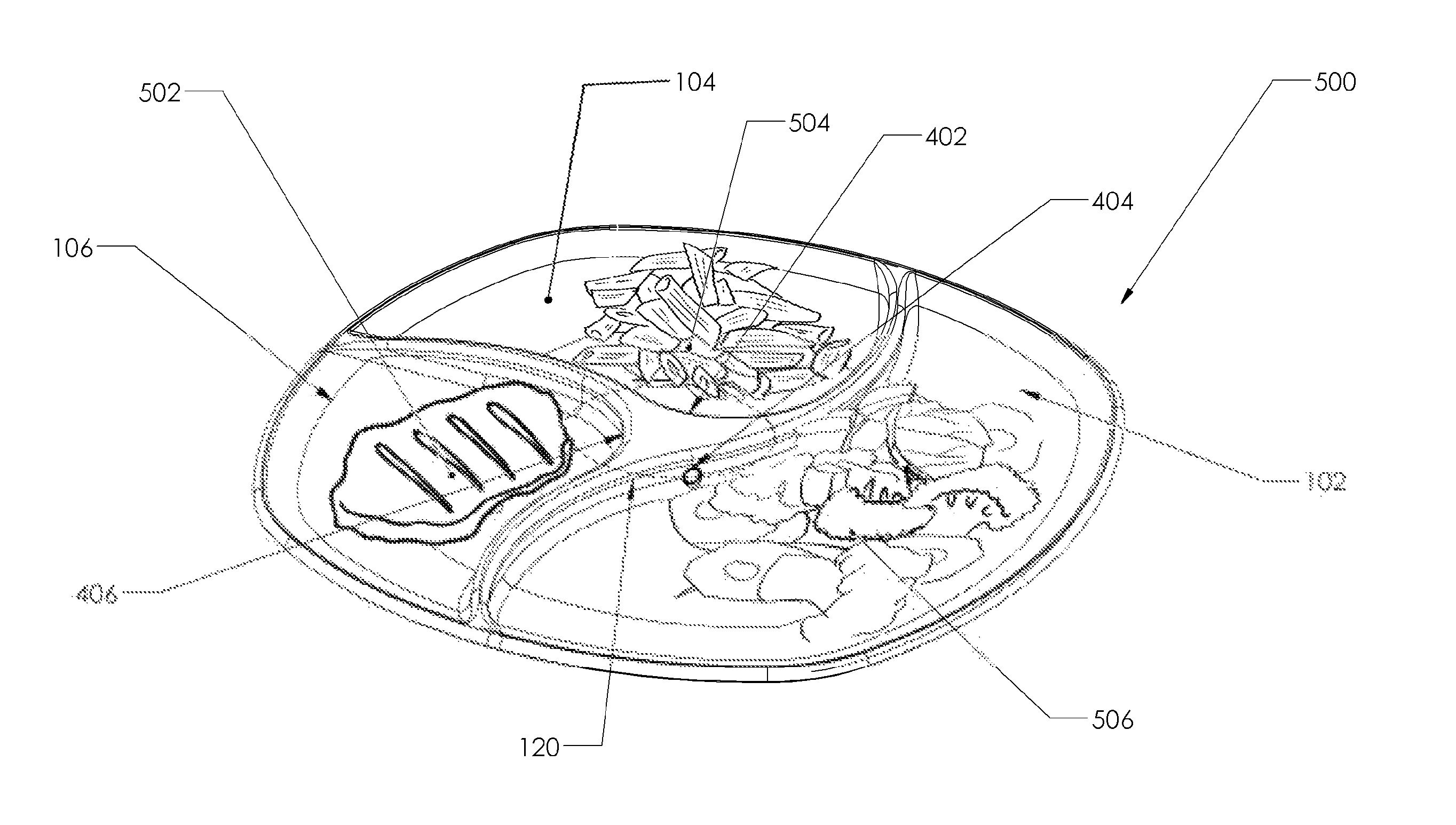

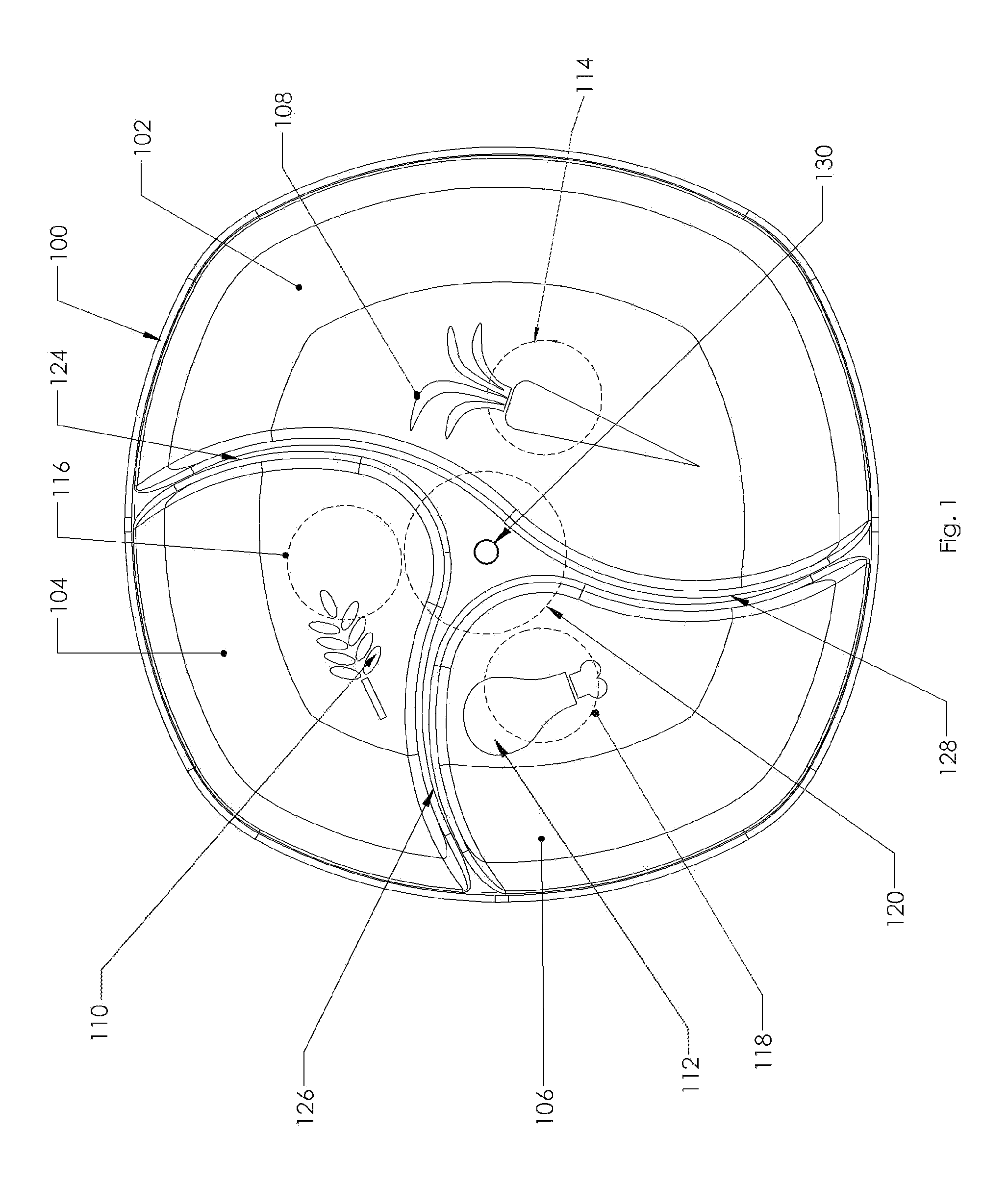

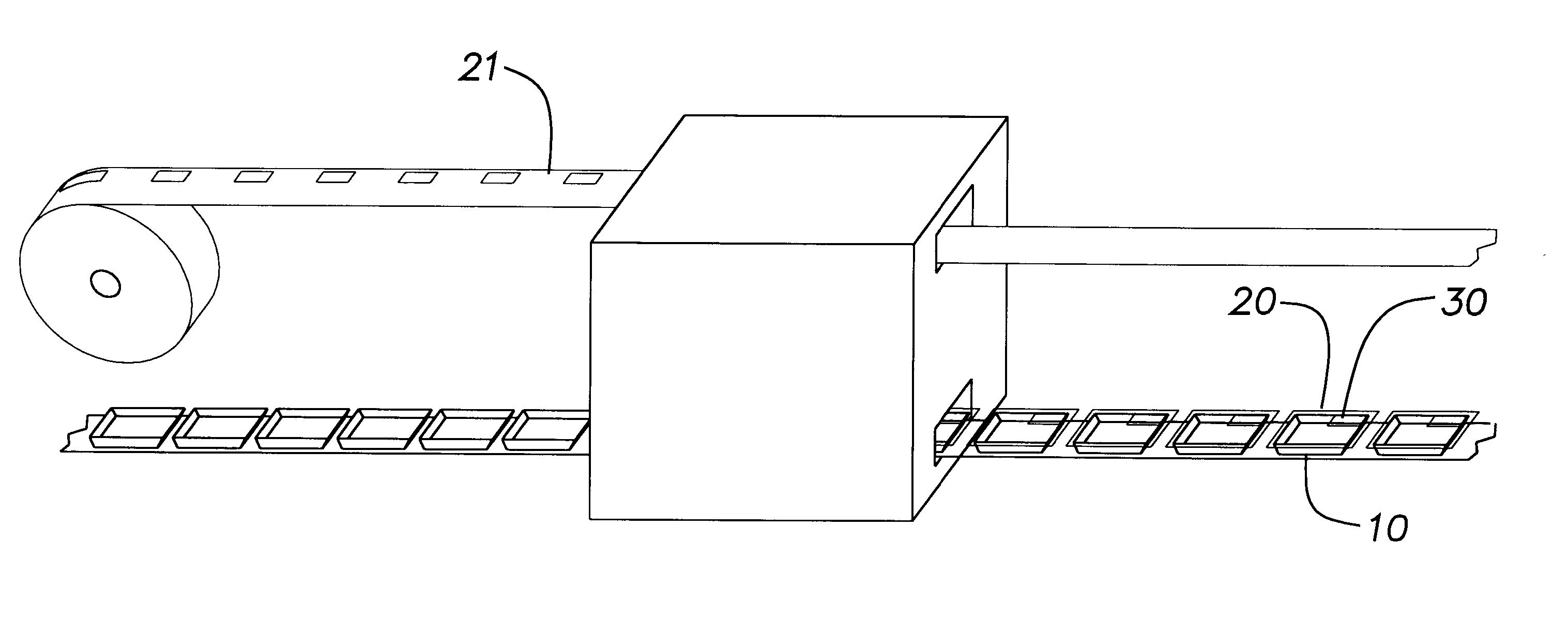

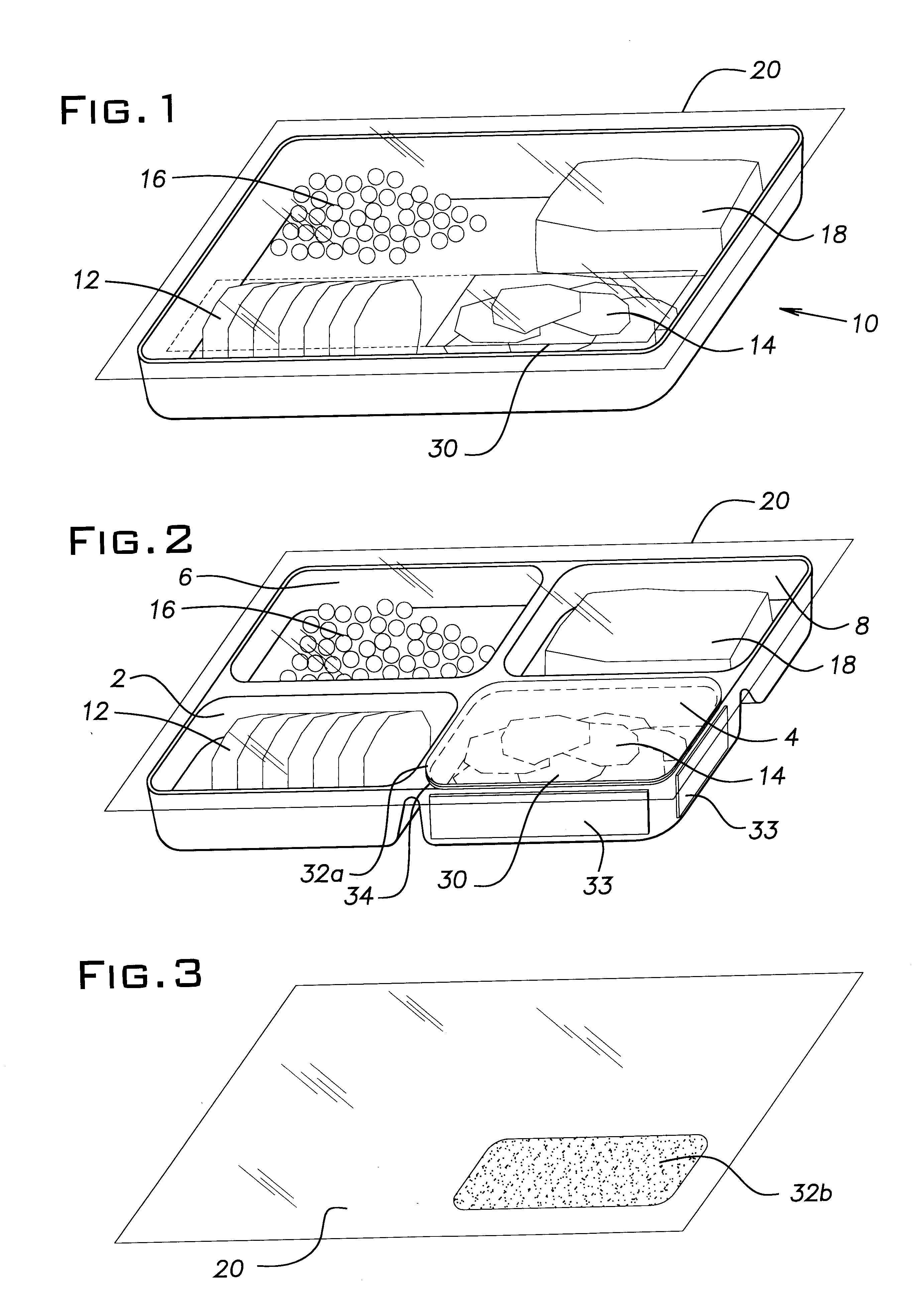

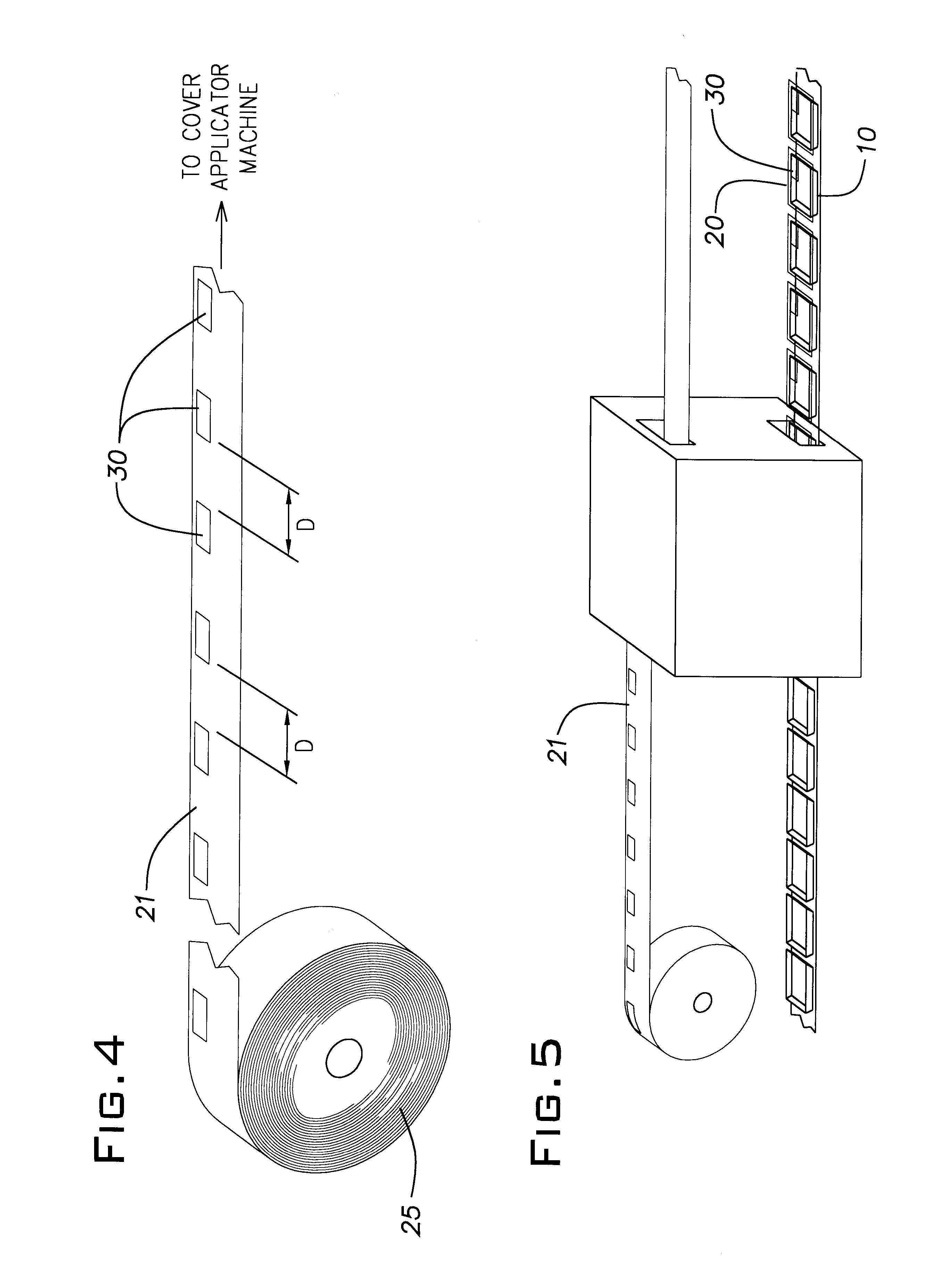

Method for applying microwave shield to cover of microwavable food container

A method for providing a microwave-shield on the cover member of a microwavable food tray having different foods therein requiring different degrees of microwave irradiation is provided. The method includes providing an adhesive label directly to a cover member of the food tray in register with one of the food products in the tray. The cover member is provided on the food tray from a sheet of cover material having a plurality of microwave shields pre-applied thereto at discrete intervals.

Owner:KENNEDY MICHAEL R +2

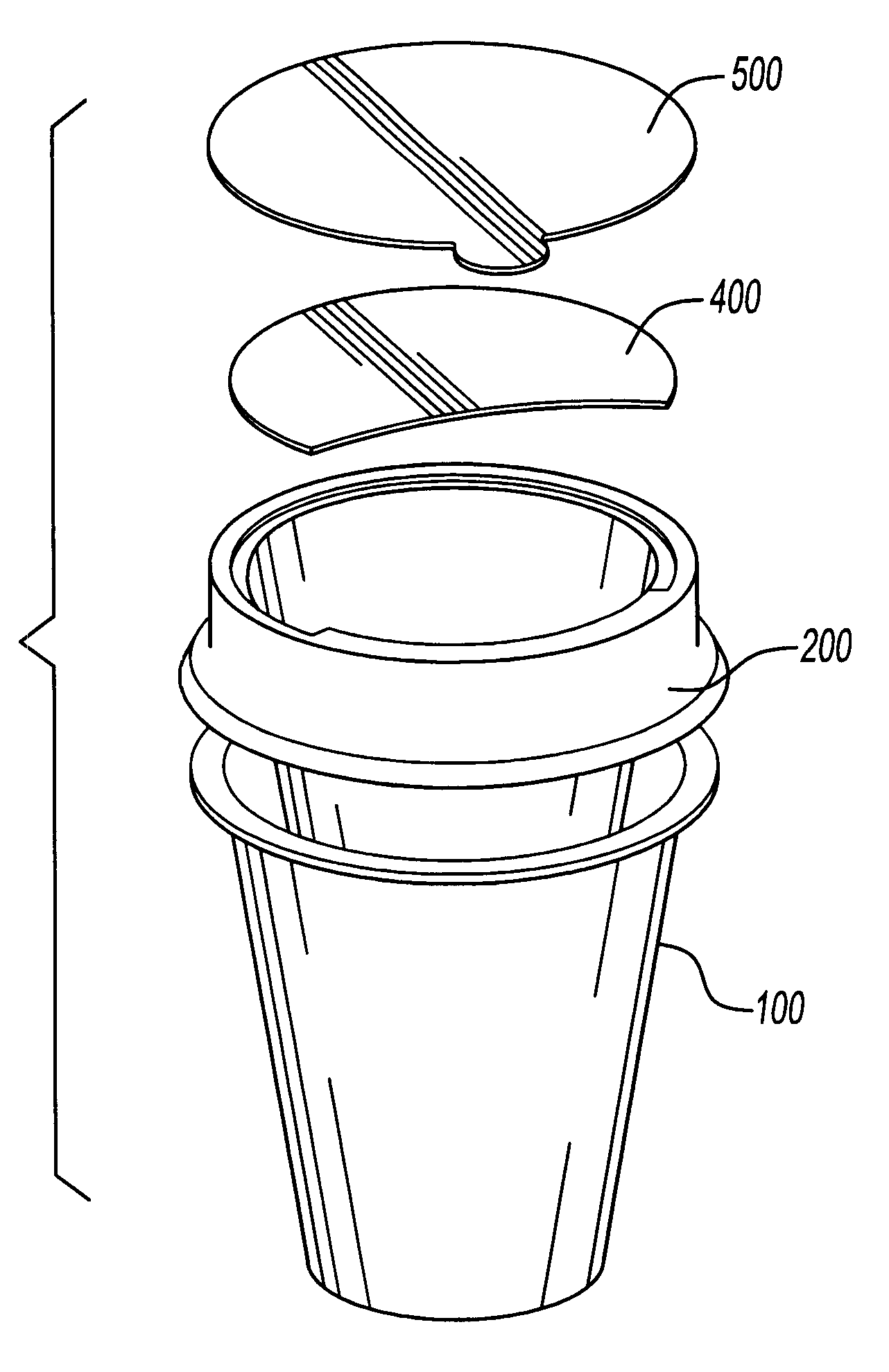

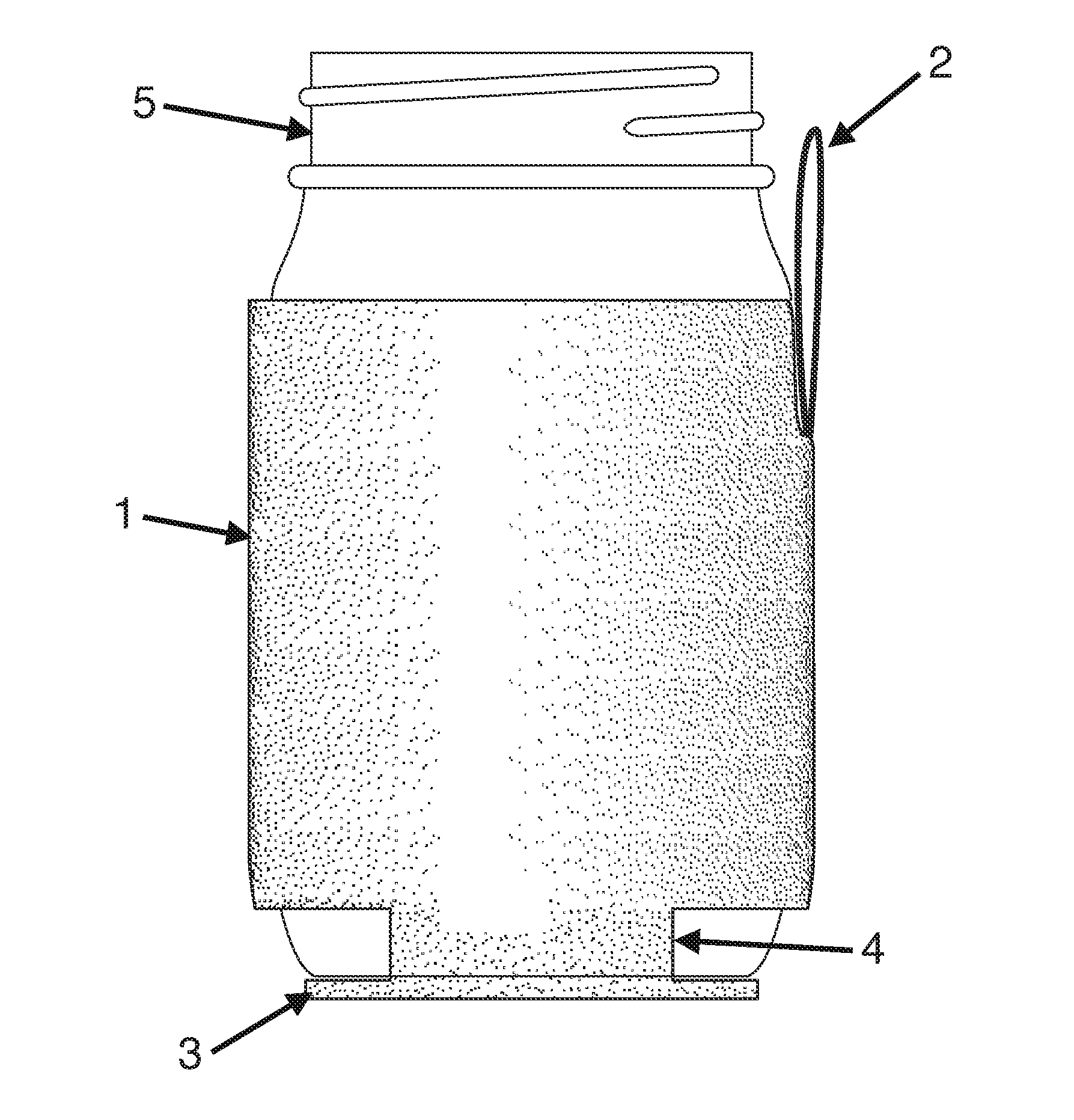

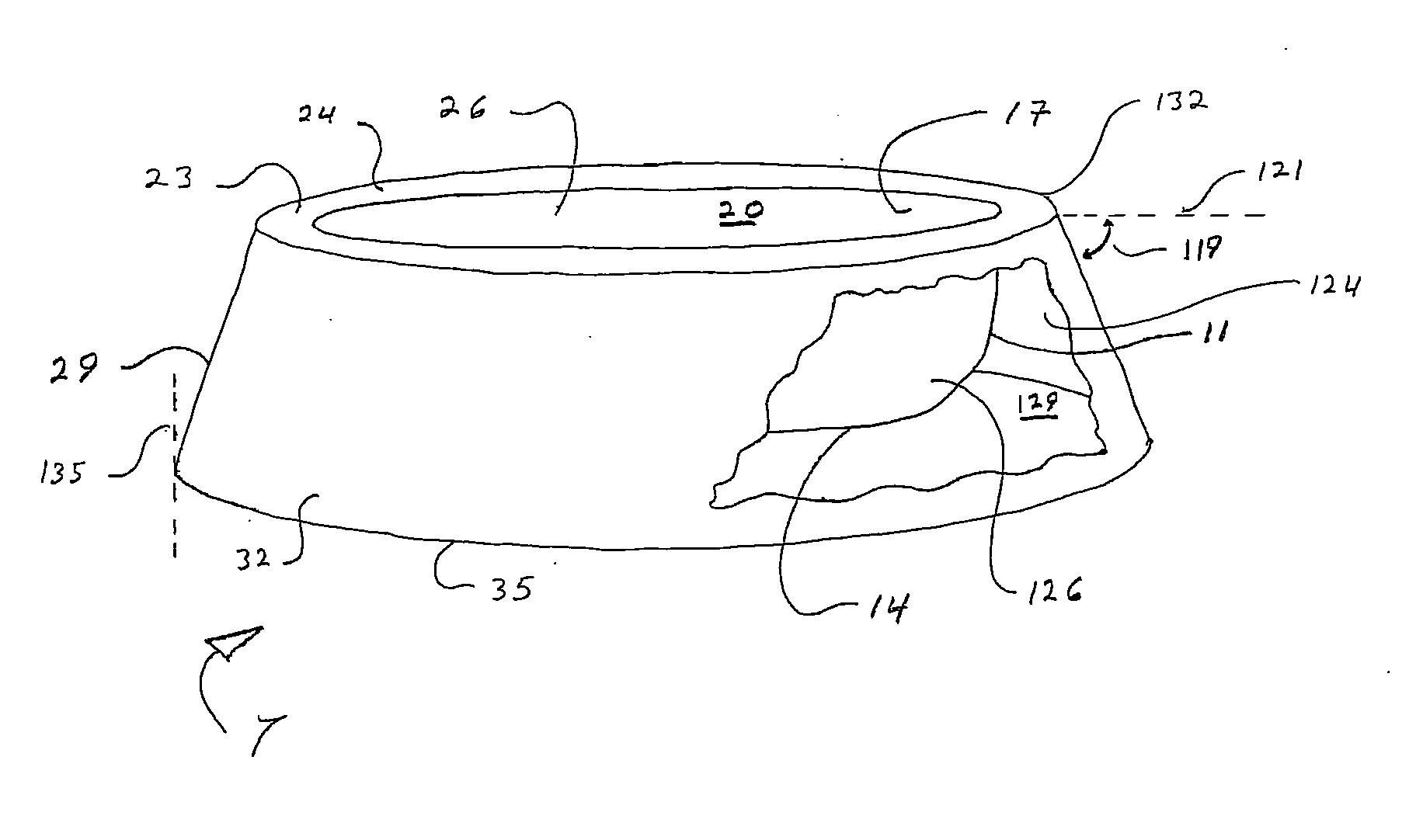

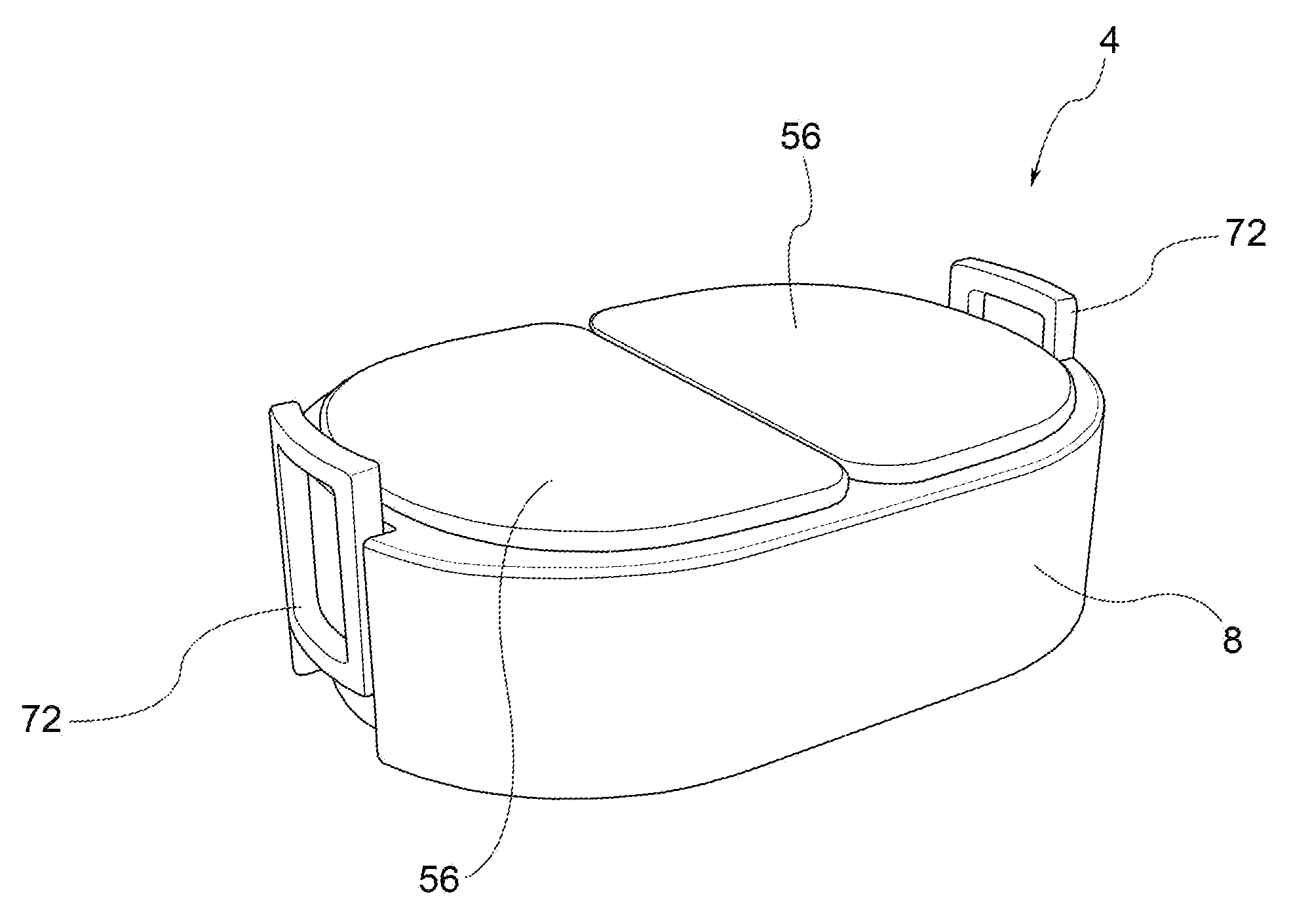

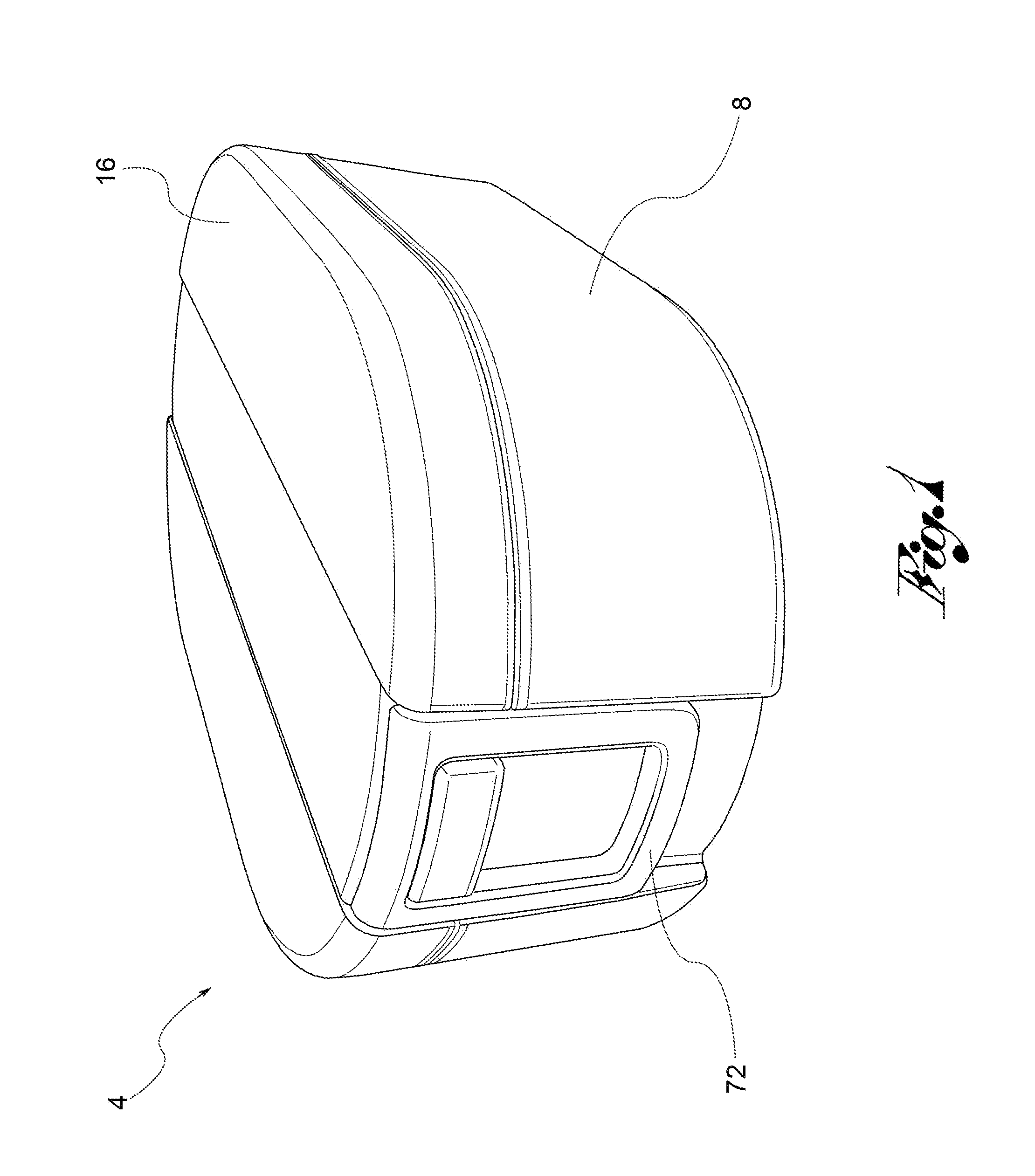

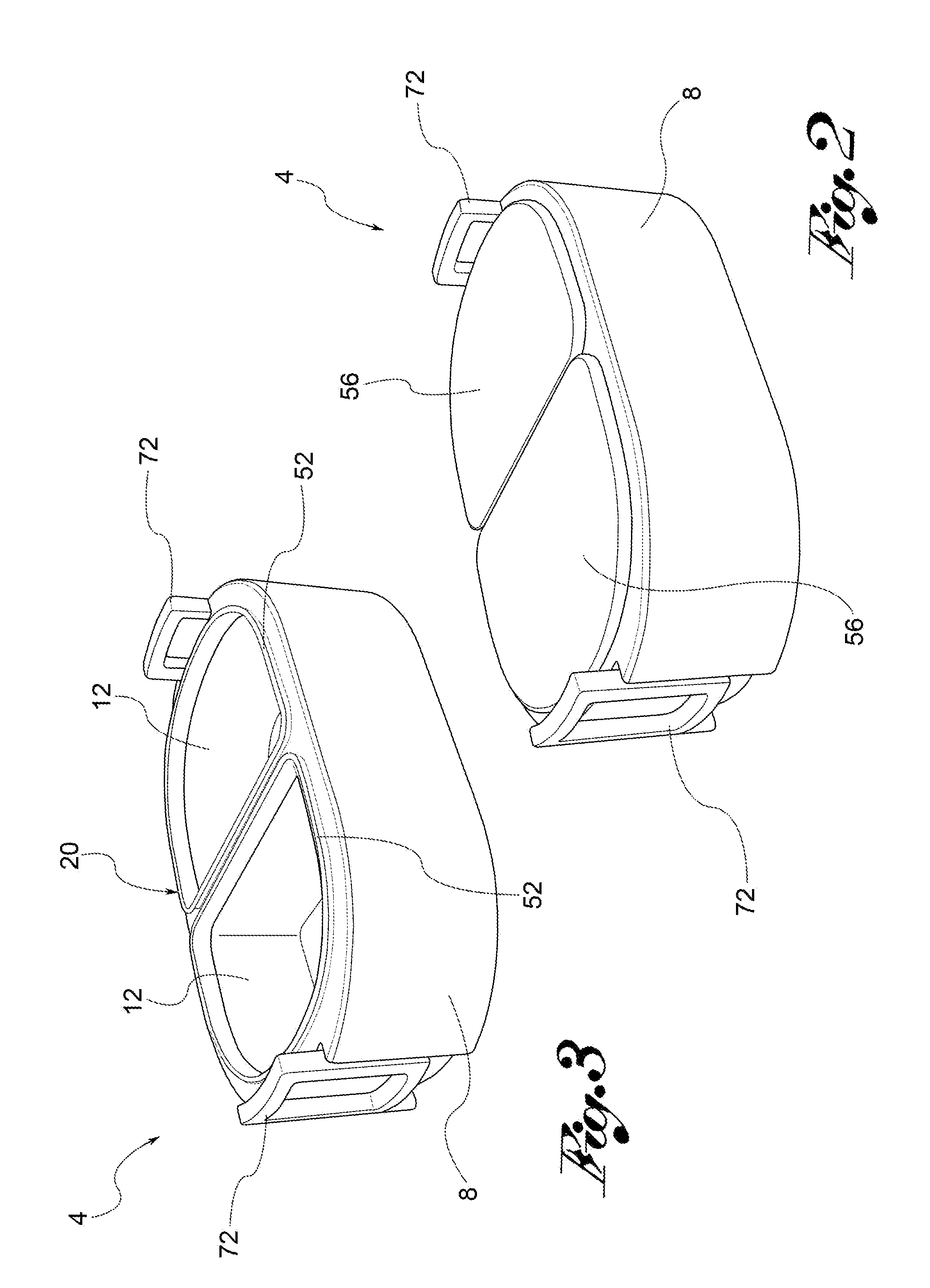

Food container assembly

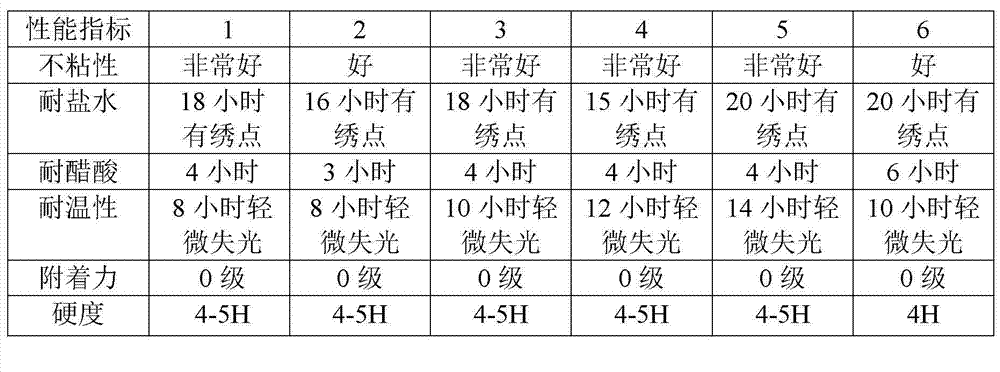

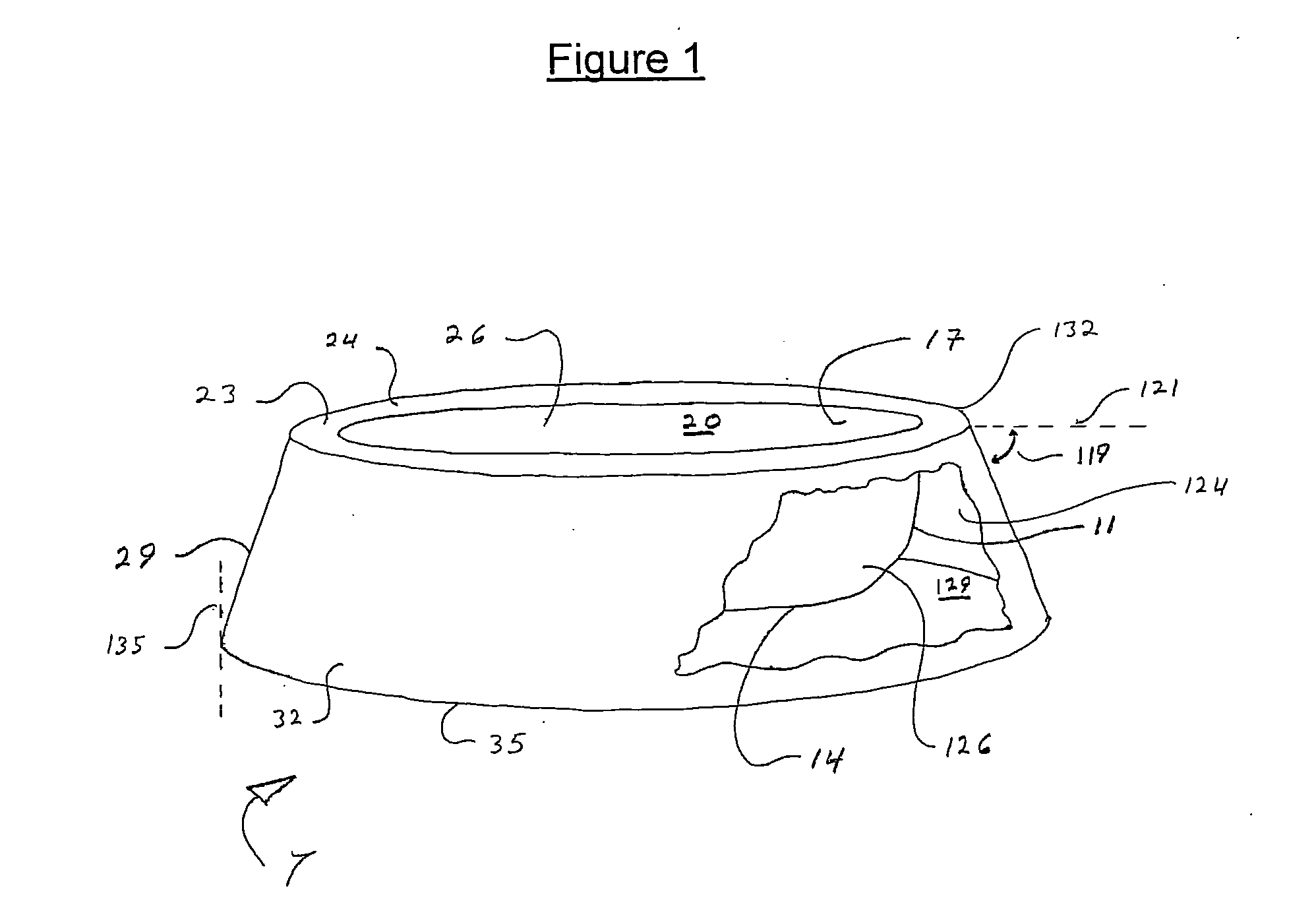

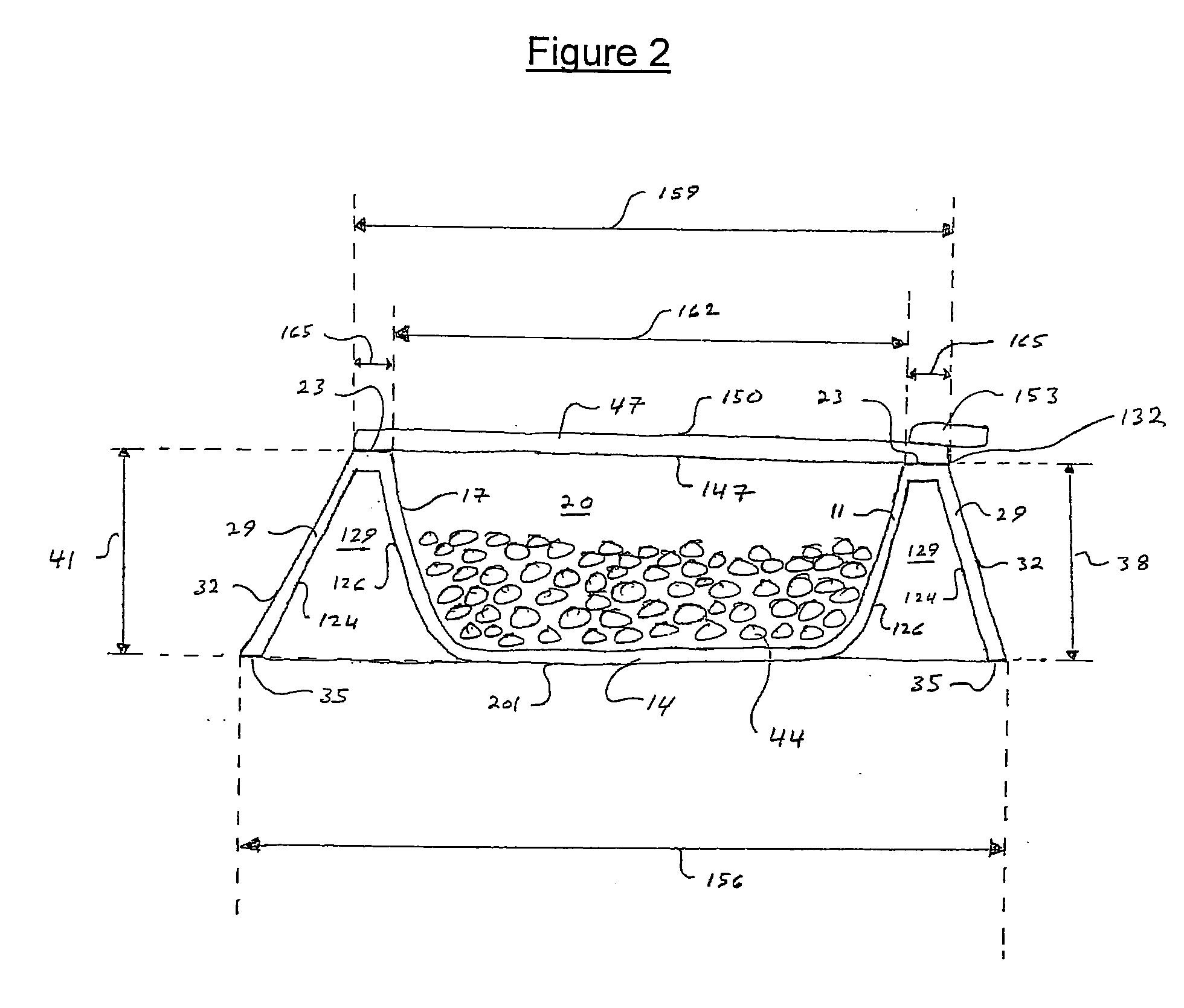

InactiveUS20080017655A1Animal feeding devicesClosure with auxillary devicesInterior spaceHuman animal

In accordance with the present invention, there is provided a food container assembly that includes a plurality of pre-packaged rigid containers, each containing an amount of food, that are vertically stacked within a tubular receptacle having oxygen (and optionally moisture) barrier properties. Each container (1) includes: (i) a bowl (11) having a closed bottom (14), an inner surface (17) defining a bowl interior (20), and an upper rim (23) defining an open top (26); (ii) a sleeve (29) having an outer surface (32) and a lower edge (35), and extending downwardly from upper rim (23) of bowl (11); (iii) an amount of food (44) residing within bowl interior (20); and (iv) a removable polymer film (47) sealingly engaging upper rim (23) of bowl (11), thereby sealing open top (26) of bowl (11) and containing food (44) within bowl interior (20). The plurality of containers (1) are arranged in a vertical stack (e.g., 2 or 3) having an outer edge (53). The assembly further includes a tubular receptacle (56) having a closed bottom (59), a closed top (62), and a sidewall (65) having an interior surface (68) defining an interior space (71). Tubular receptacle (56) is substantially continuous and has oxygen barrier properties. Interior space (71) is a substantially sealed interior space. The vertical stack (e.g., 2) resides within interior space (71) of tubular receptacle (56), and at least a portion of the outer edge (53) of vertical stack (56) abuts a portion of inner surface (68) of sidewall (65) thereof. The assembly of the present invention may be used to provide food for consumption by human and non-human animals, e.g., pets, such as dogs and cats.

Owner:NOVA CHEM (INT) SA

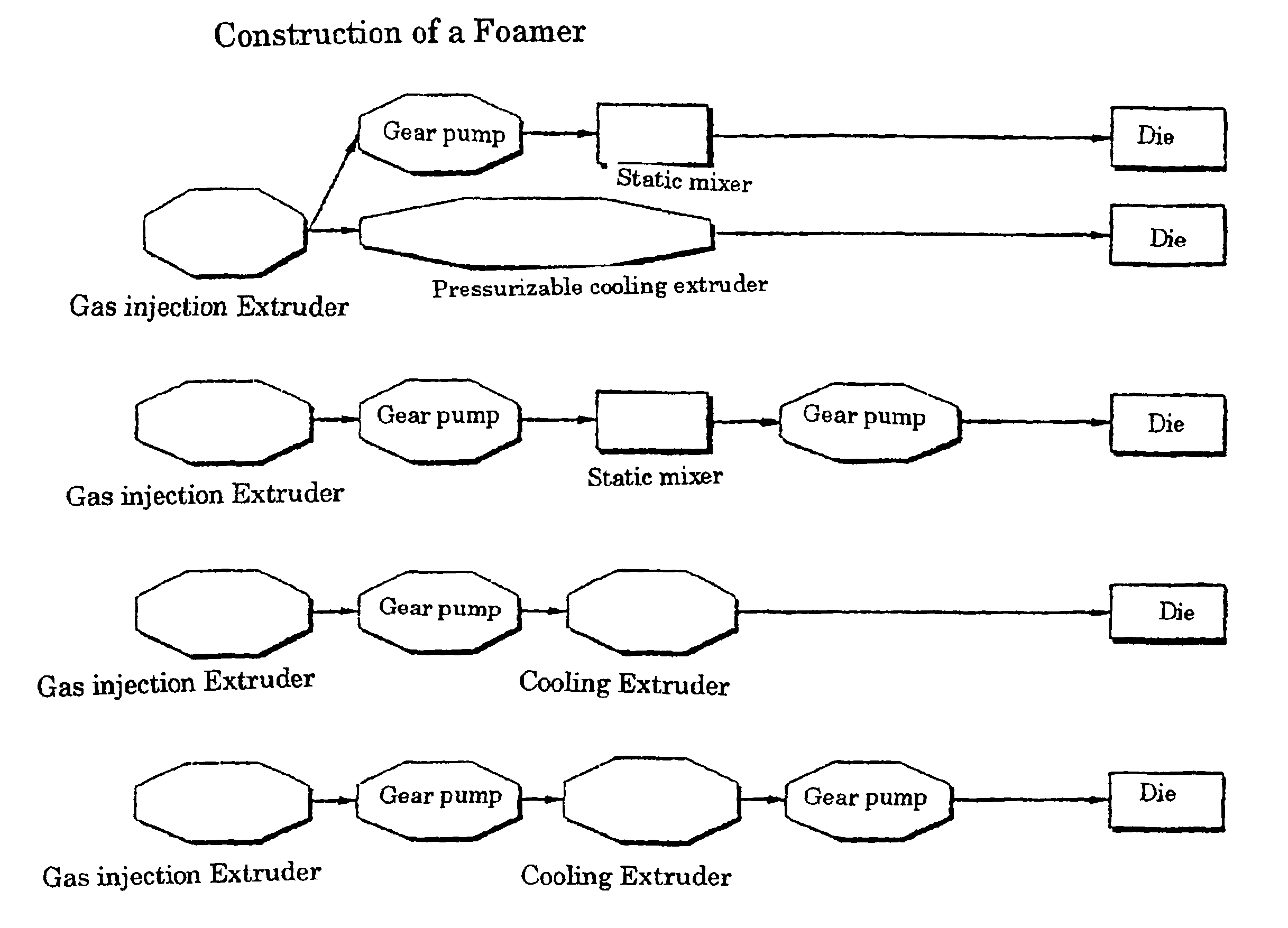

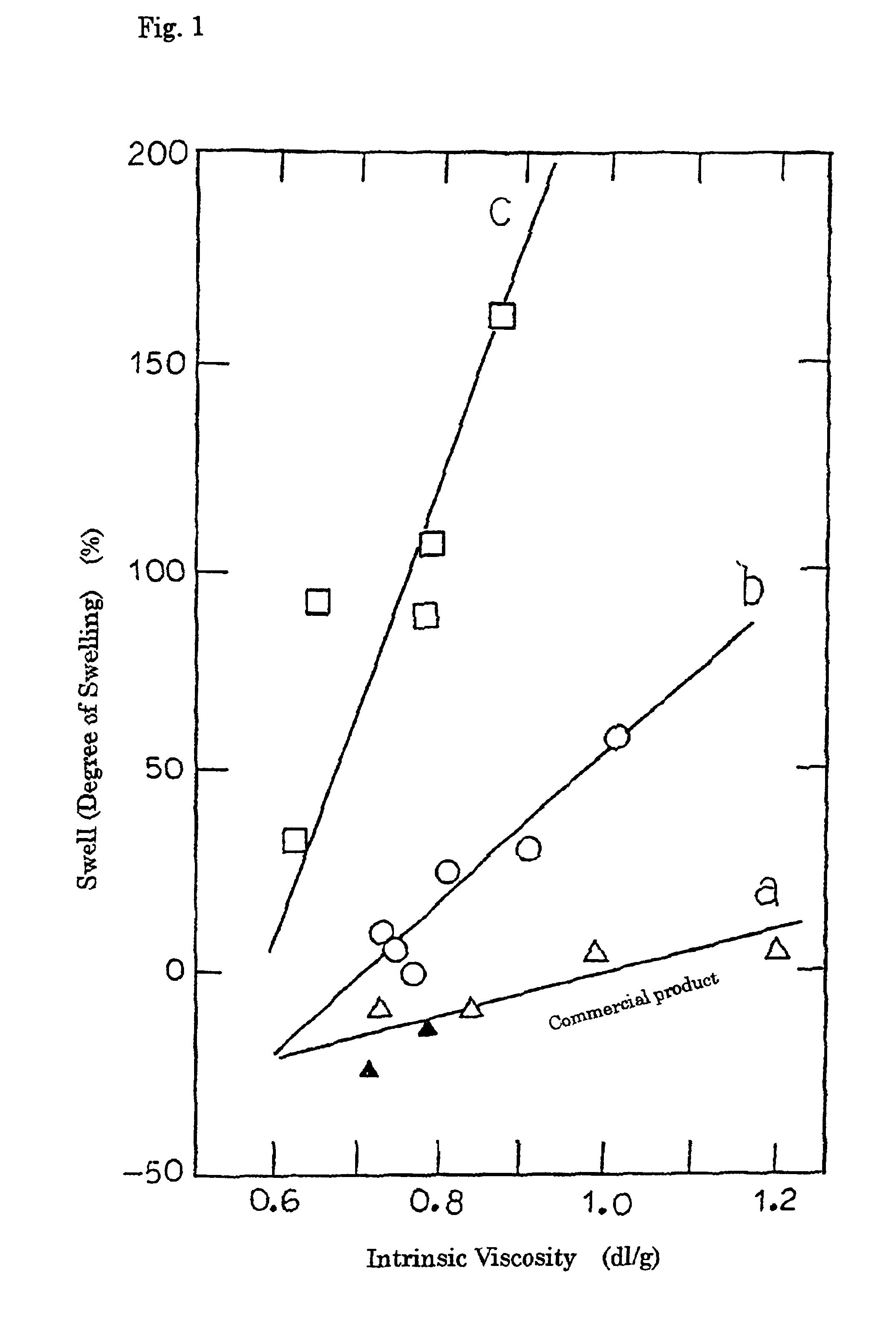

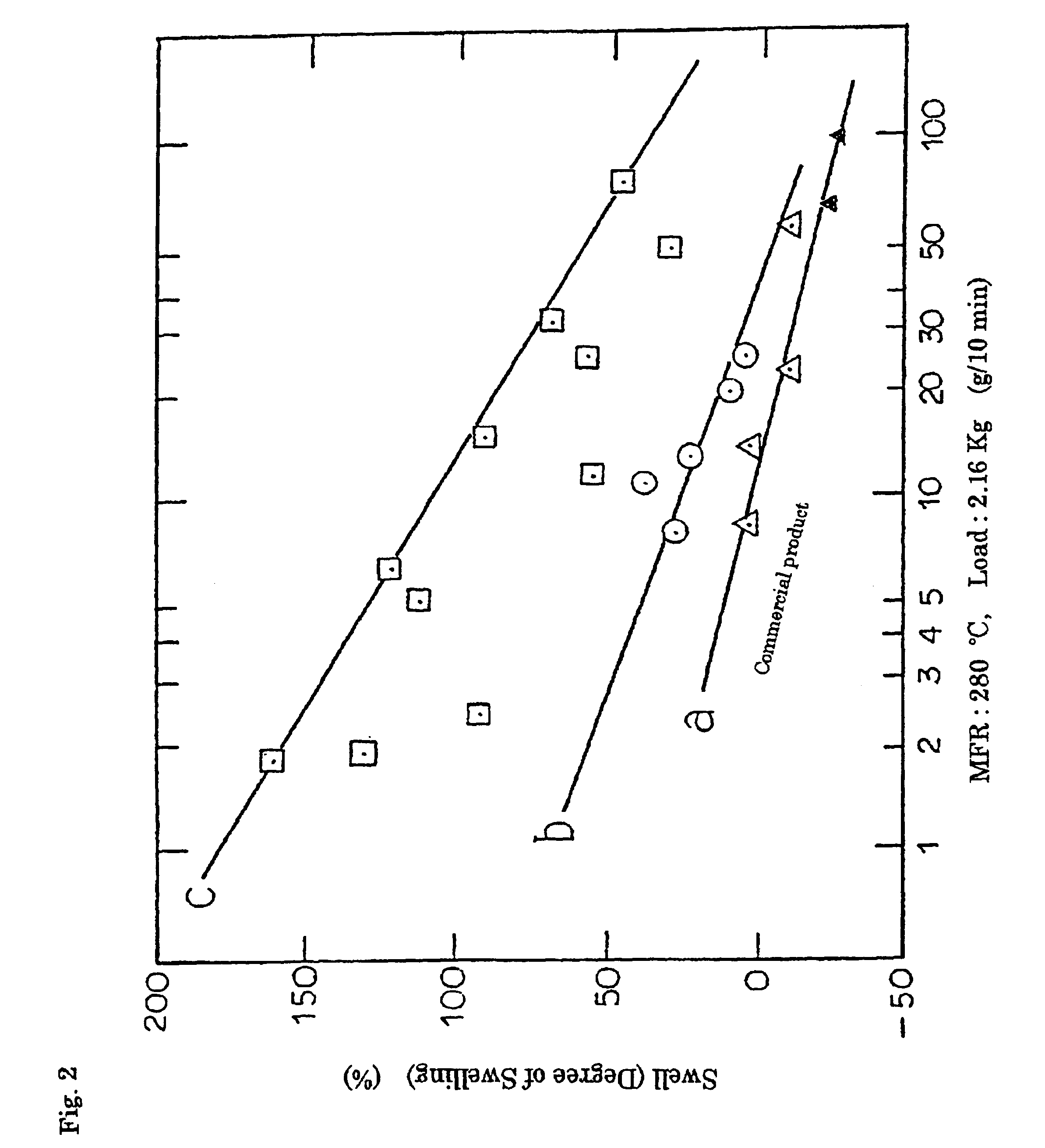

Foamed polyester resin molding and process for producing the same

InactiveUS6841106B1Easy to processReduce molecular weightOther chemical processesCushioningFoaming agent

The invention provides a method for producing a foamed article comprising the steps of: heating a mixture comprising (a) 100 parts by weight of linear saturated polyester, (b) 0.1 to 10 parts by weight of a mixture as a coupling agent of 0 to 100% by weight of a compound having two epoxy groups in the molecule, and 100 to 0% by weight of a compound having two or more epoxy groups, and (c) 0.01 to 5 parts by weight of a metal salt of a carboxylic acid as a coupling reaction catalyst, at a temperature of a melting point of the polyester or more to provide a melt flow rate of 50 g / 10 minutes or less and swell of 10 to 200%, whereby a polyester resin is formed; and heating and foaming the polyester resin using a foaming agent . A foamed article useful as cushioning material, heat insulating material, packaging material, food container, and dividers can be produced by increasing the molecular weight, melt viscosity, and swell (degree of swelling) of PET-based polyesters that have relatively low molecular weight and are brittle, especially recovered polyester, that is used as a prepolymer.

Owner:DAINIPPON JUSHI KENKYUSHO

Thermic Food Container and Relative Method of Manufacture

InactiveUS20130008909A1Domestic cooling apparatusLighting and heating apparatusFood contact materialsEngineering

A thermal food container has an outer body and at least two trays for containing foods, the trays being separate from each other and being contained inside the outer body. An outer closure lid is detachably associated with the outer body, and a thermally insulating element is positioned between the trays and the outer body. Advantageously, the trays are over moulded with a joining ring which joins them to each other, keeping them separate at the point of at least one separation septum. Furthermore, the joining ring is welded and / or glued to the outer body after insertion of said insulating element, so as to form a hermetic joint between the joining ring and the outer body.

Owner:ATER

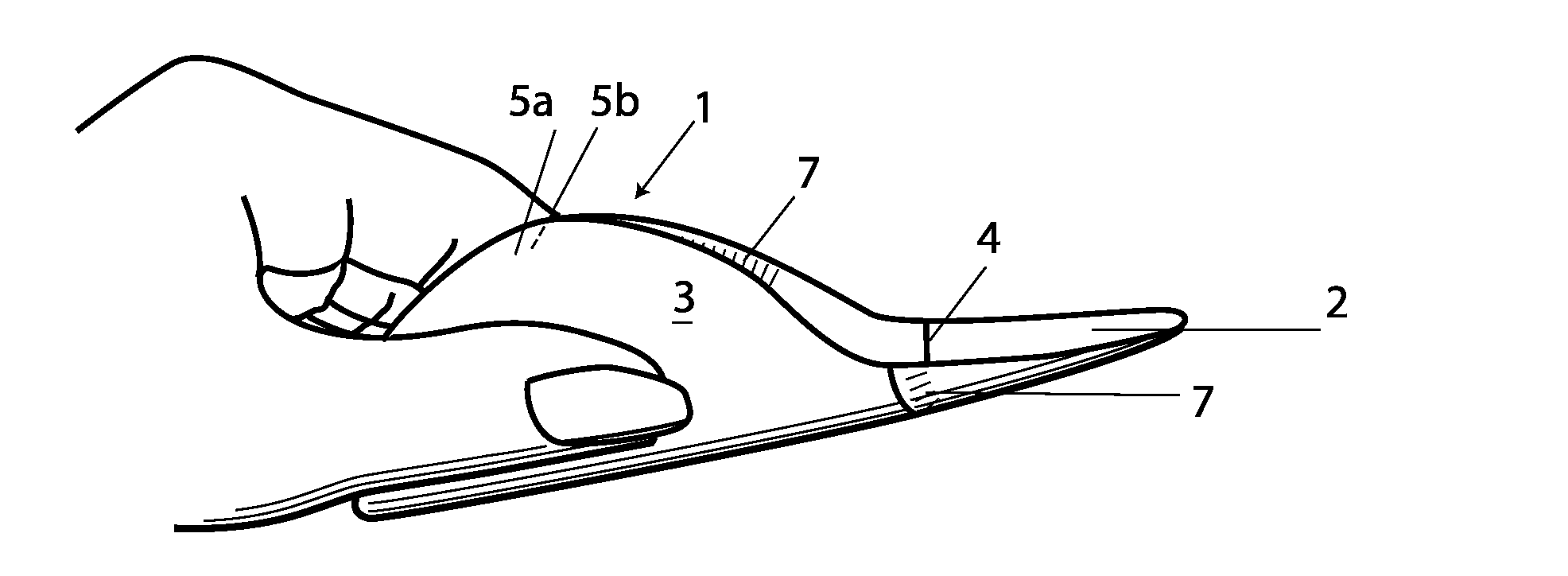

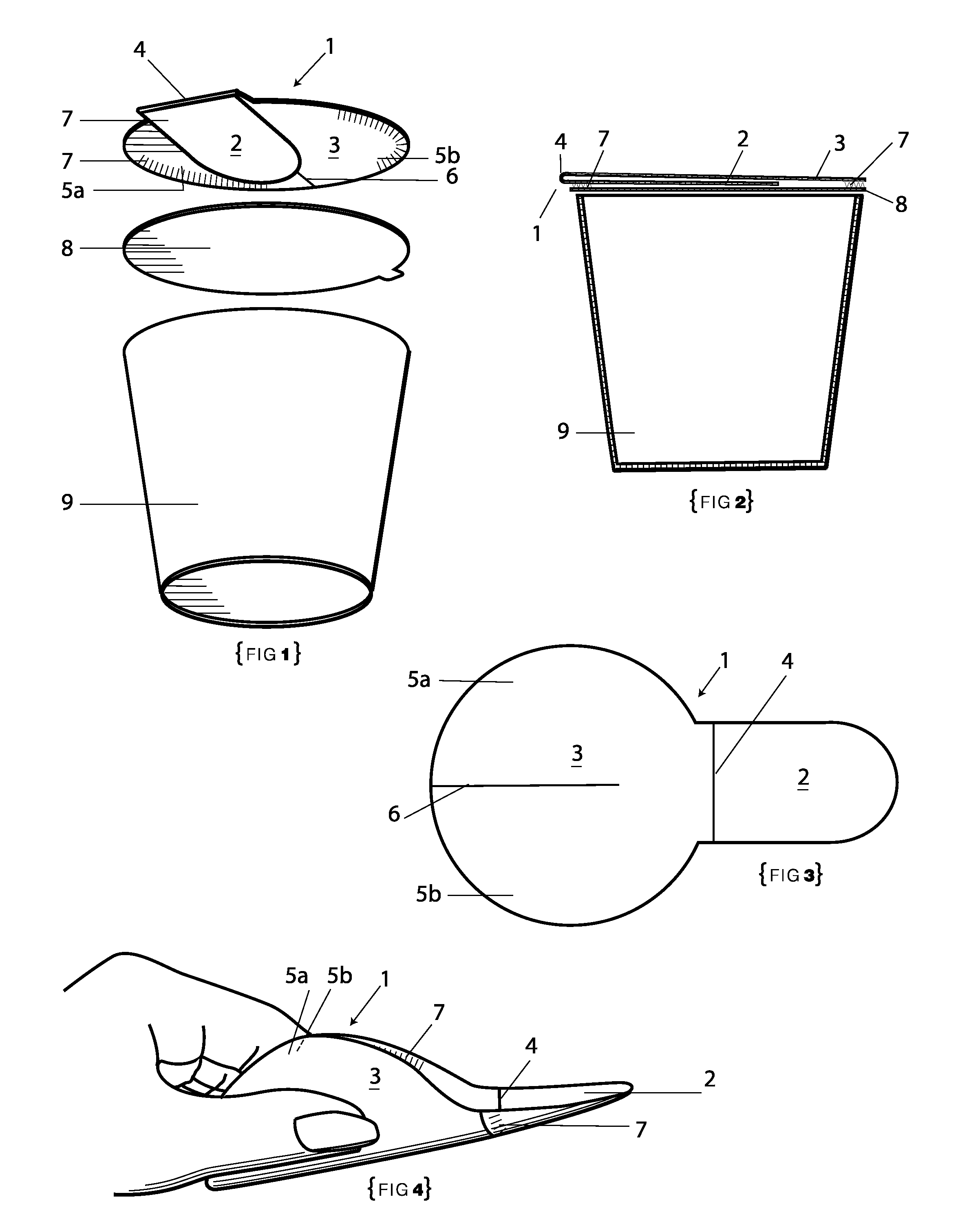

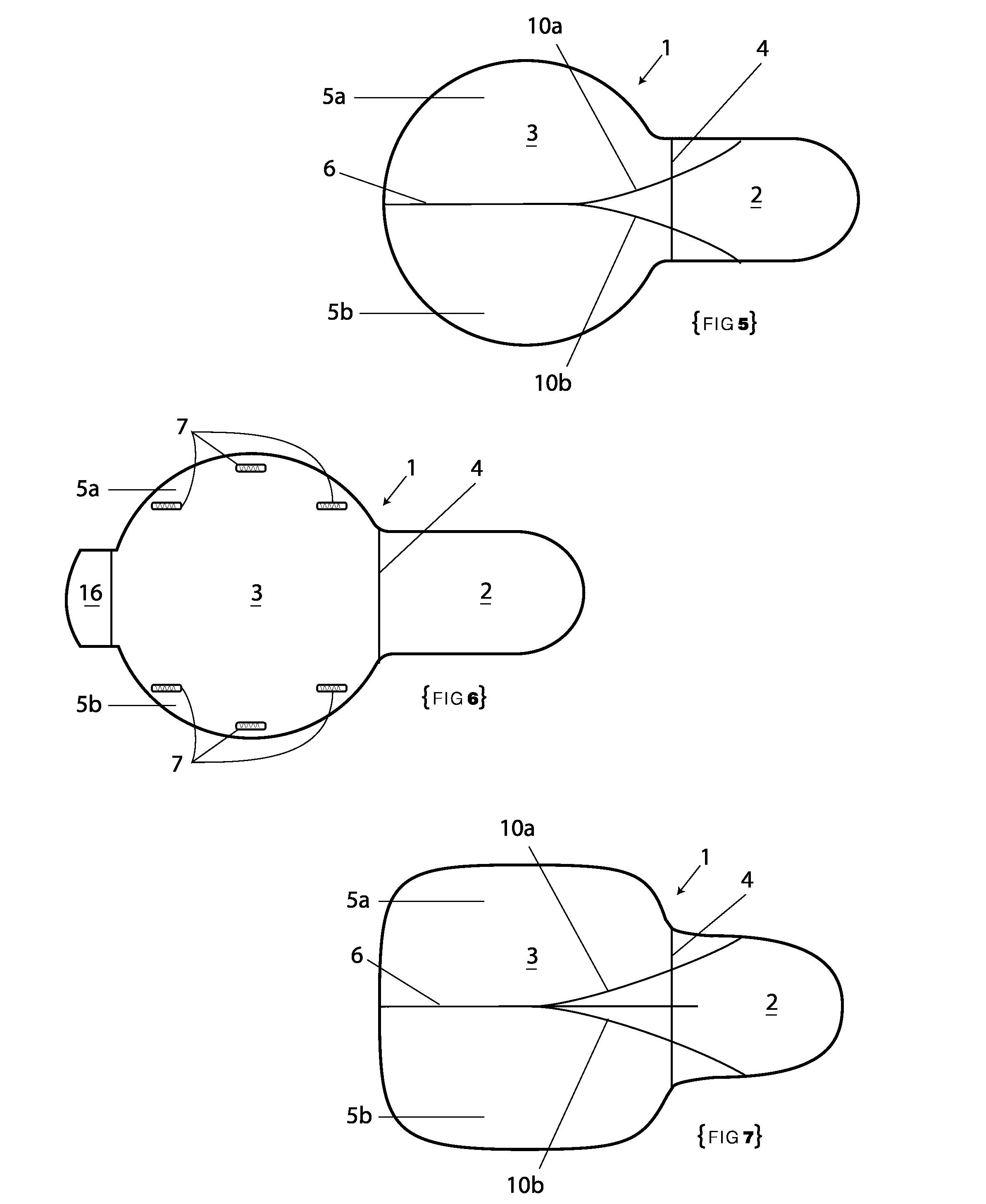

Folding eating utensil integrated or attachable to food cover

ActiveUS20080110885A1Cheap manufacturingInexpensive to attachCapsPortable power-driven toolsEating UtensilsEngineering

A single, thin piece of folded material attaches to a single serving container to provide a strong, sanitary spoon. Folding score lines on the handle portion of the spoon give the utensil strength and provide a simplicity of use suitable for children. The disclosed utensil may be attached to existing containers or may be built into containers during the manufacture of the underlying container, or may be available as a stand-alone product. The disclosed utensil may be integrated into packaging material such as overwrap sleeves used to package food containers.

Owner:ECOTENSIL

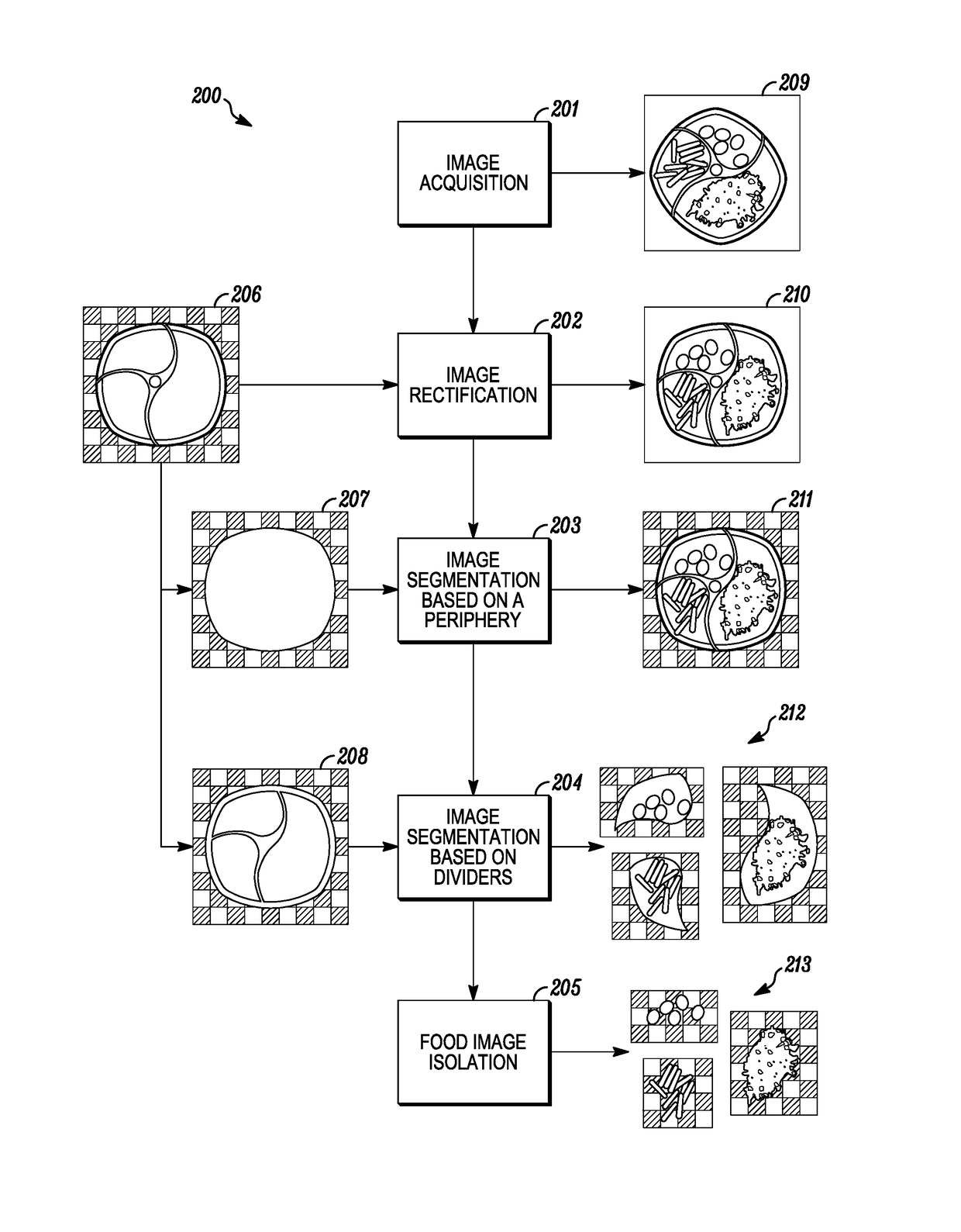

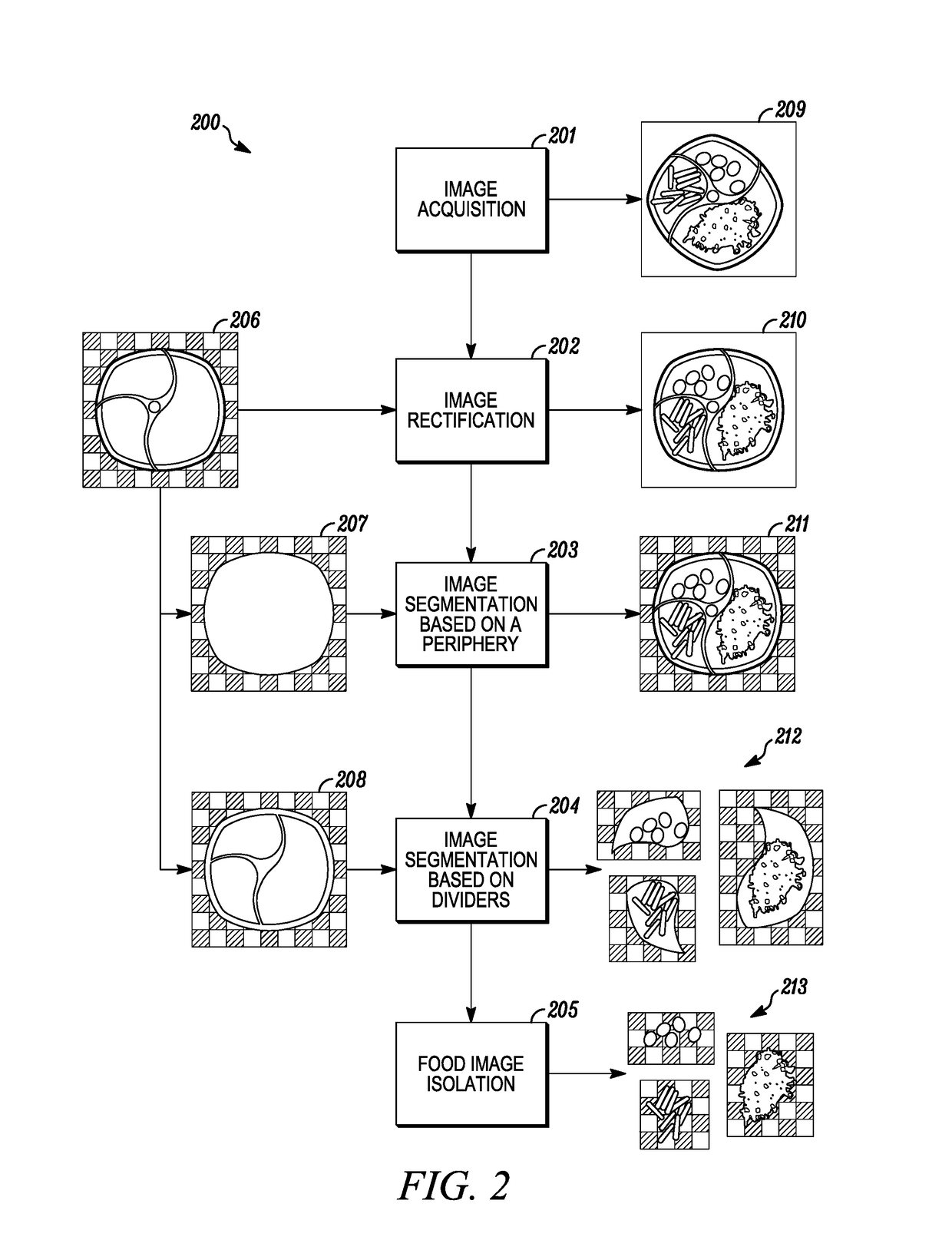

System and method for nutrition analysis using food image recognition

ActiveUS20170069225A1Precise positioningImage enhancementImage analysisNutrition analysisComputer science

The present disclosure provides a system and method for determining a nutritional value of a food item. The system and method utilizes a food container as a model to adjust various types of distortions that exists in an instant image of the food container that retains the food item. The instant image may be compared to the model image of the food container to correct any distortions. The food container includes a boundary which has a predetermined color. The predetermined color of the boundary can be used to adjust the color configuration of the instant image, thereby increasing the accuracy of the food identification.

Owner:FITLY

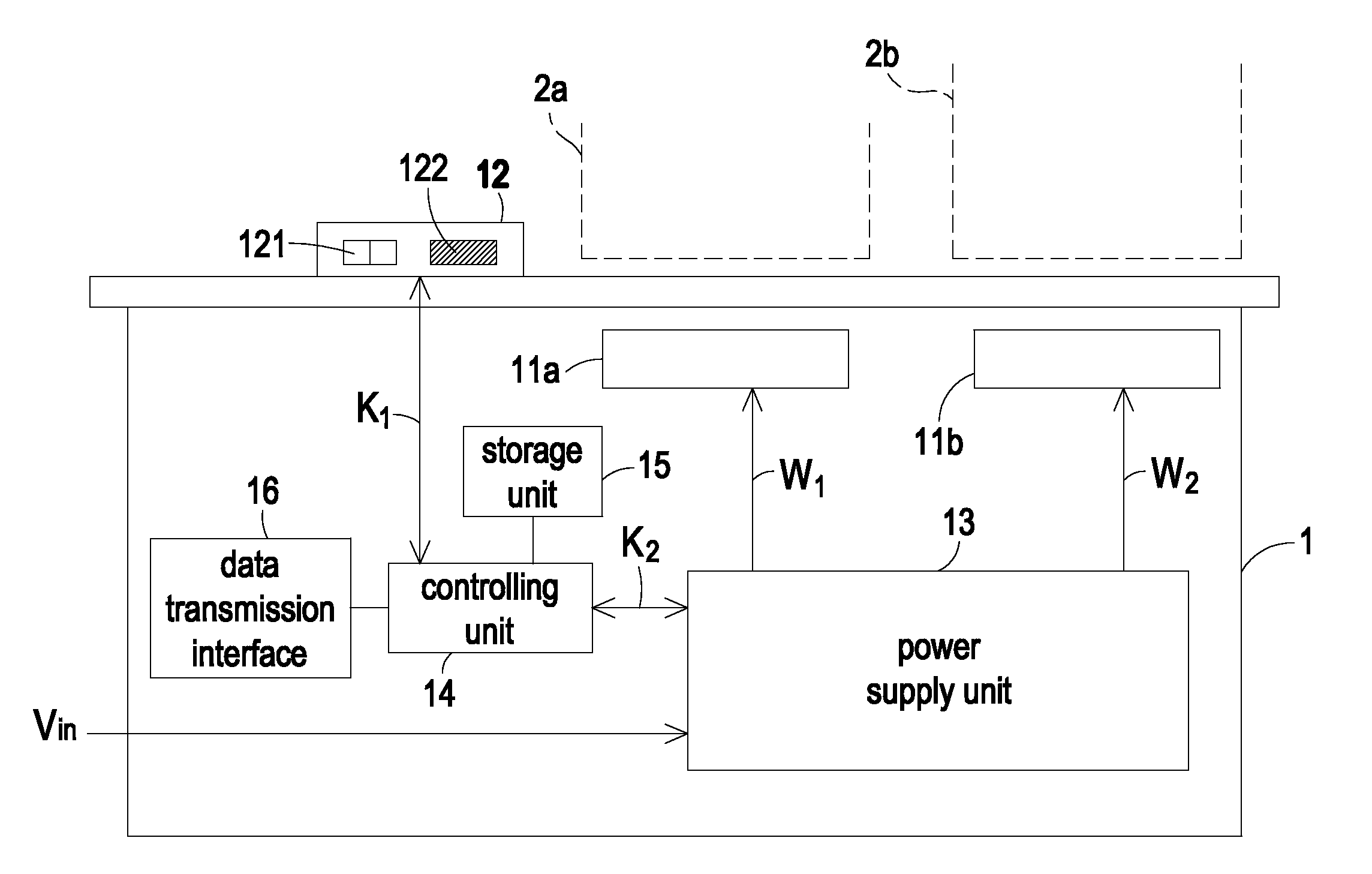

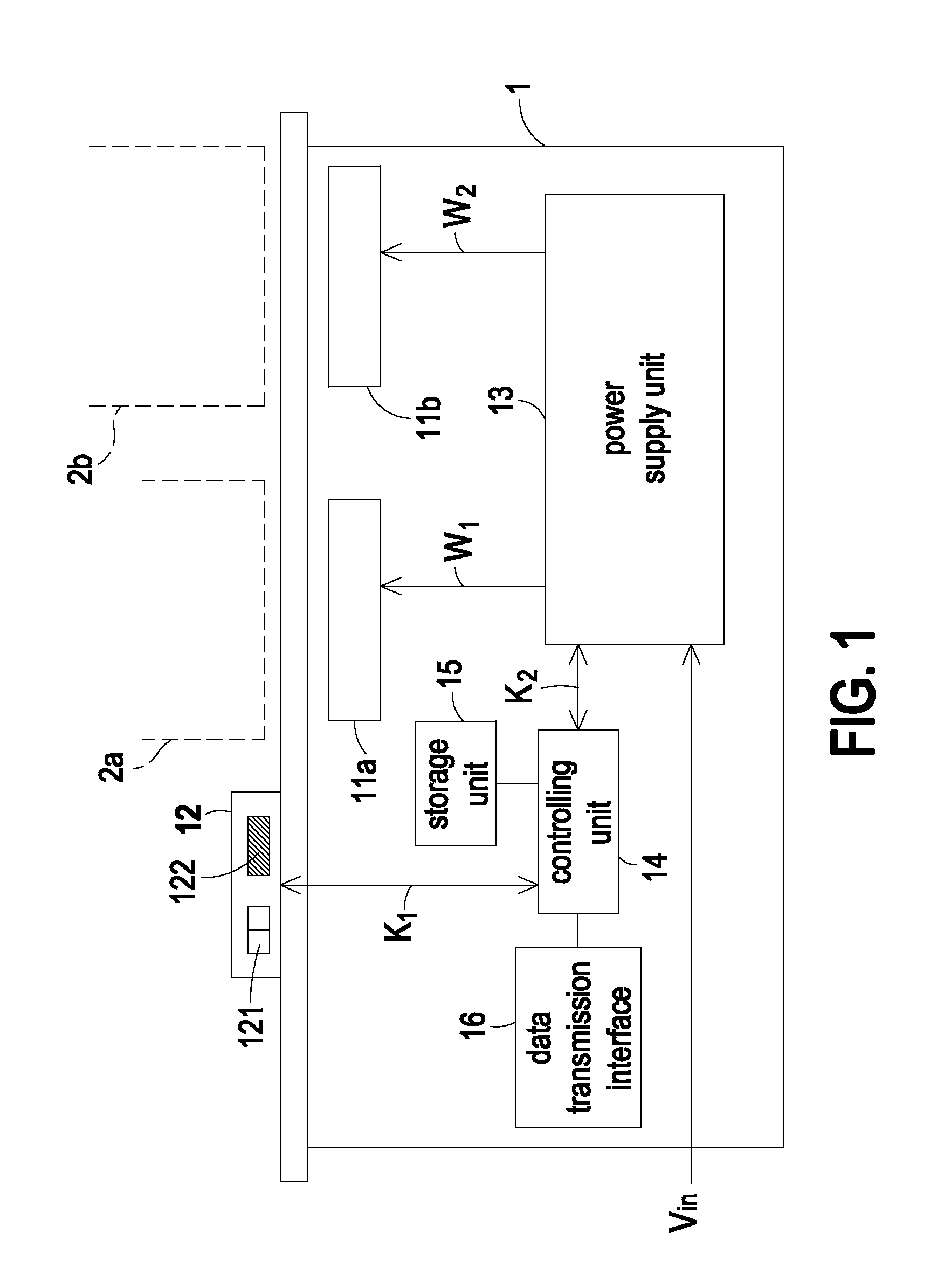

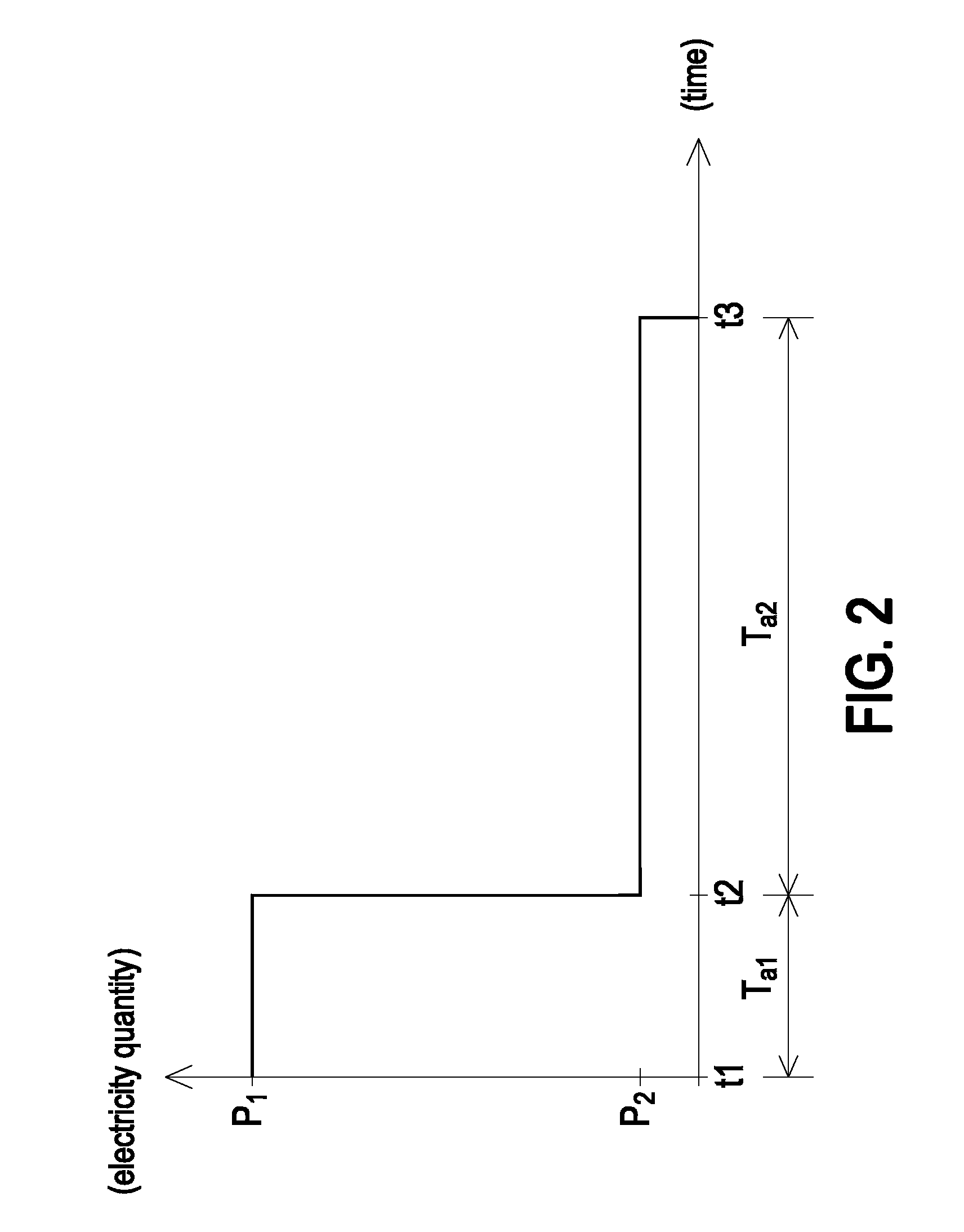

Intelligent heater and temperature measuring device

An intelligent heater includes a first induction coil, a control panel, a power supply unit, a storage unit, a data transmission interface, and a controlling unit. The control panel includes an input unit for inputting, adding, amending, deleting or refreshing a cooking data and a display unit for showing an operating condition of the intelligent heater. The power supply unit is connected with the first induction coil for providing a first power to the first induction coil. The storage unit is used for storing the cooking data. The data transmission interface is used for transmitting the cooking data. The controlling unit is used for controlling the power supply unit to provide an electricity quantity of the first power to the first induction coil according to the cooking data, so that a heat quantity and a heating time required for heating a first foodstuff container are adaptively adjusted.

Owner:DELTA ELECTRONICS INC

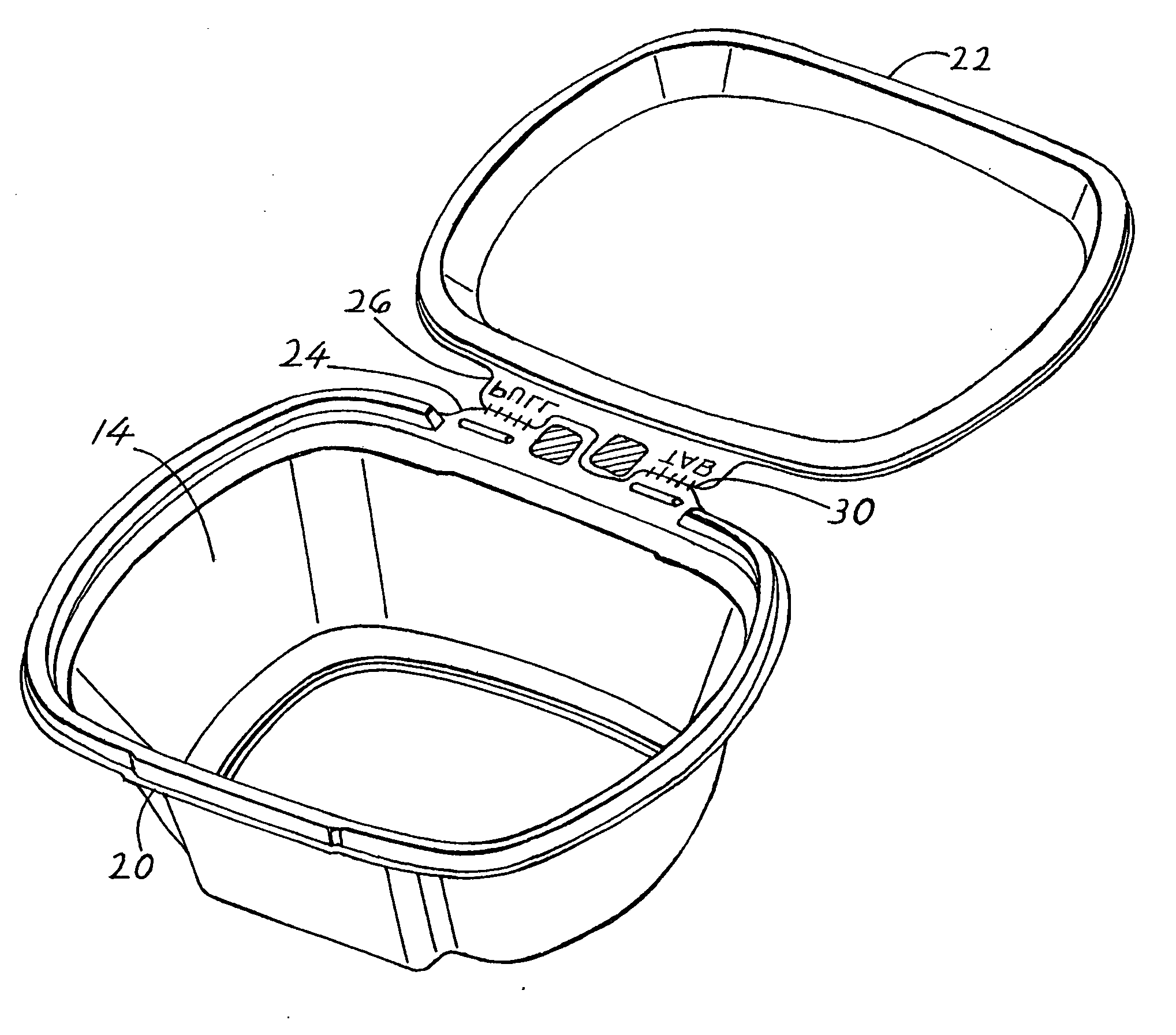

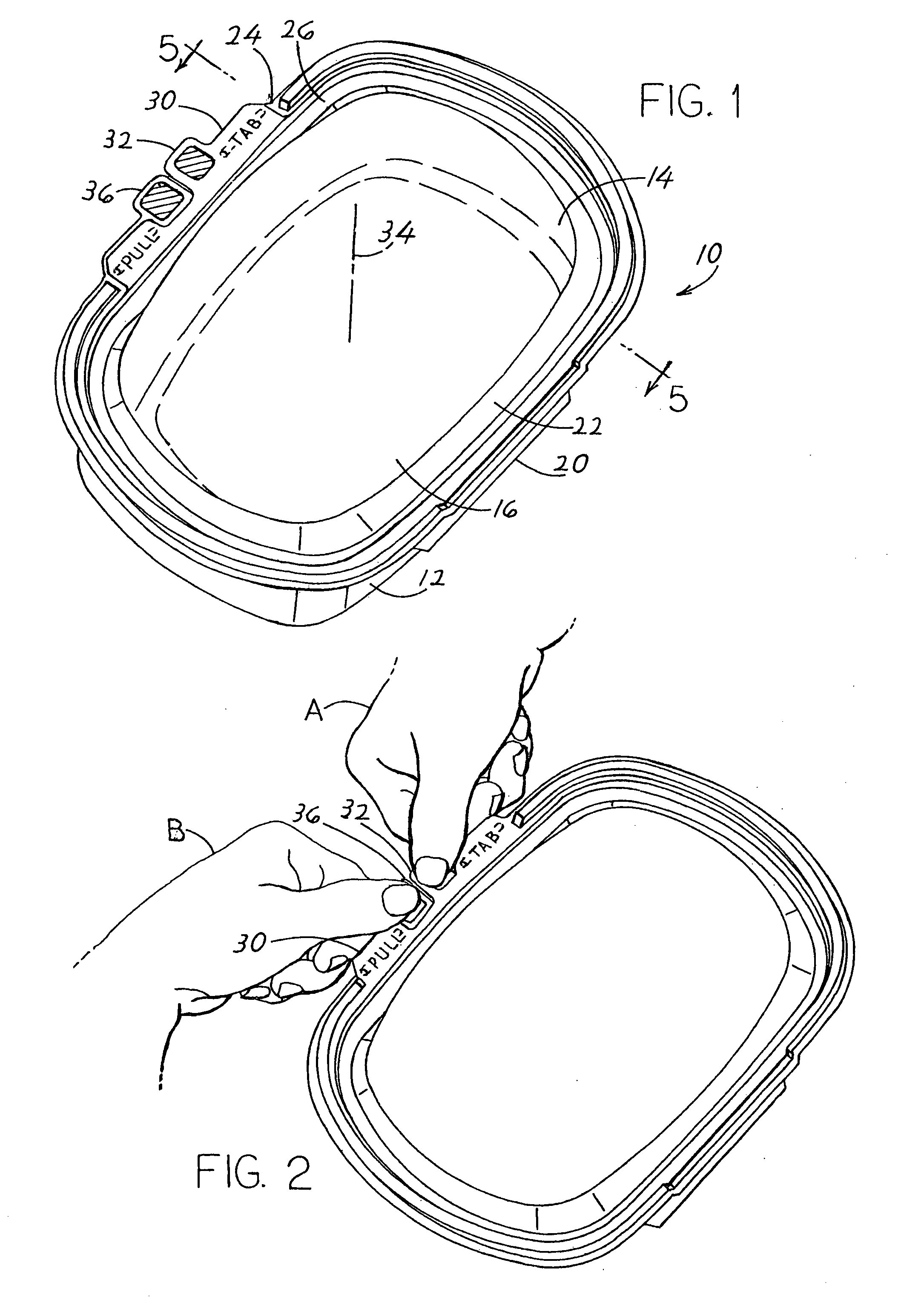

Edge-tearing tamper-evident container

InactiveUS20090223619A1Easy to tearLow costCapsPaper-makingFood contact materialsStructural engineering

A food container formed from plastic, can be loaded with food and then closed by a clerk, and thereafter cannot be opened without tearing apart first sides (24, 26) of the base (12) and lid (16). The container is formed by a single sheet of plastic that forms a base and lid with second sides (20, 22) that are latched together and with adjacent first sides that are joined by a joint line (30) in the plastic that is creased and that has slits (40). At the joint line, the lid has a projecting lid tab (32) and the base has a projecting base tab (36). A person grasps both tabs, and lifts only the lid tab to tear apart the first sides of the base and lid along the joint line (30). Thereafter, the lid can be easily closed and reopened on the base.

Owner:PACTIV PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com