Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

333results about How to "Good non-stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

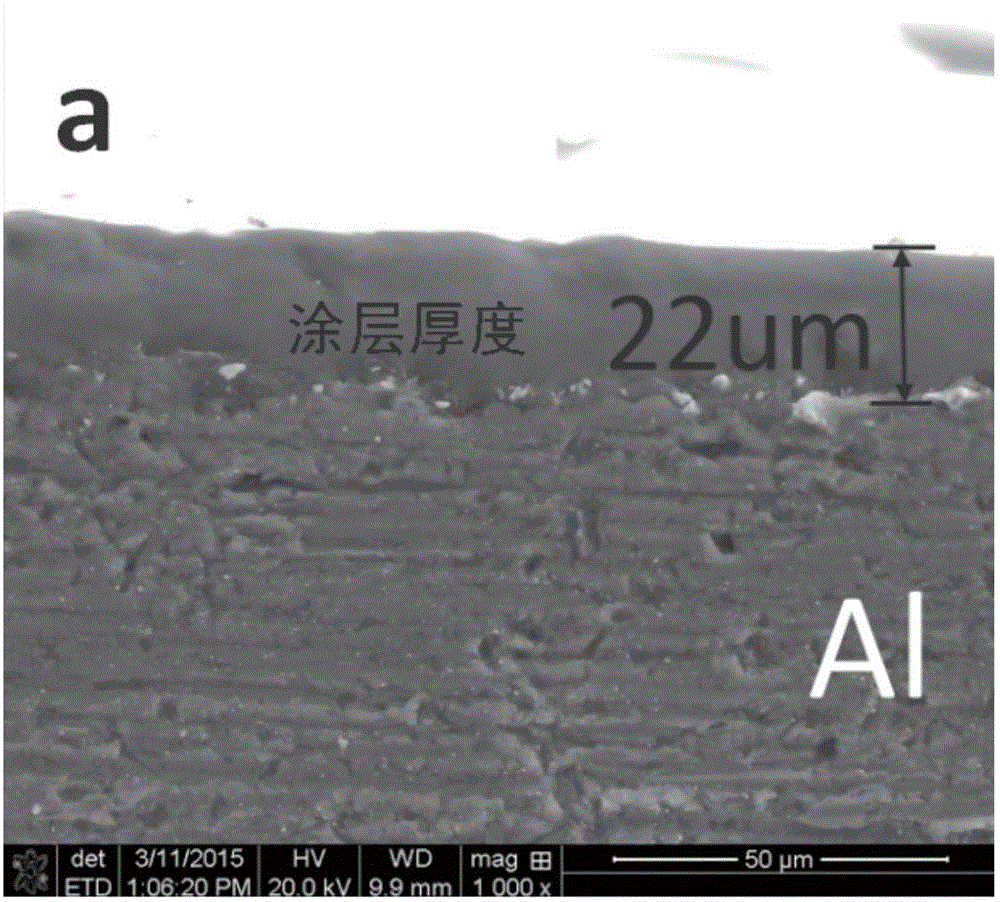

Method for preparing wear-resisting super-hydrophobic coating through cold spraying technology and product of method

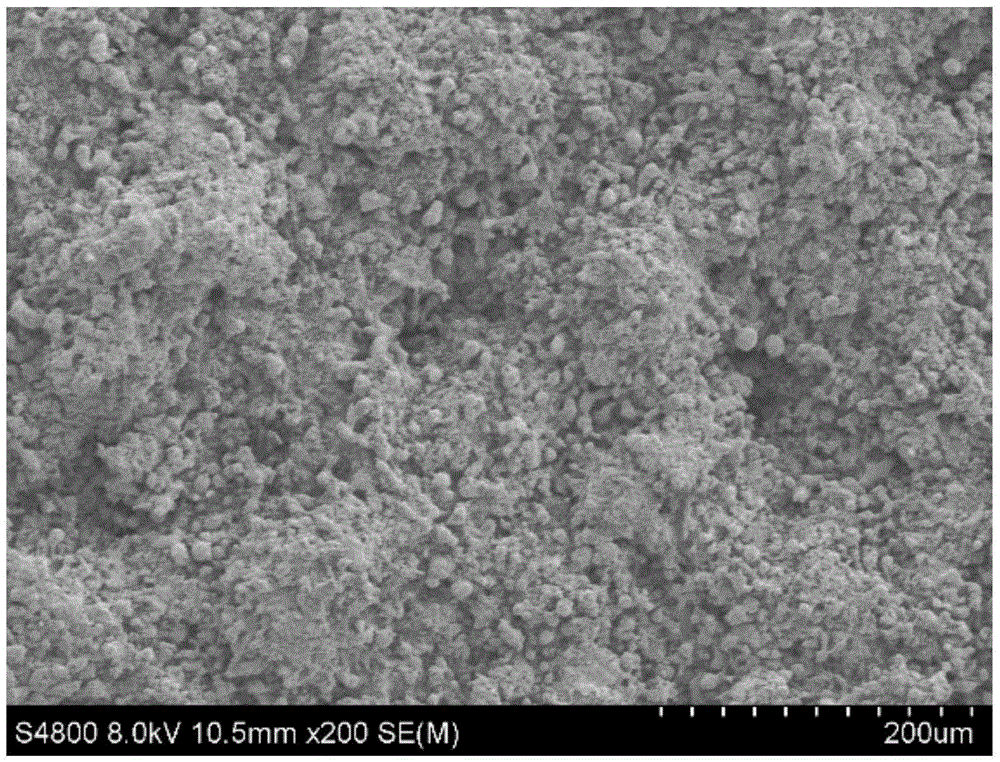

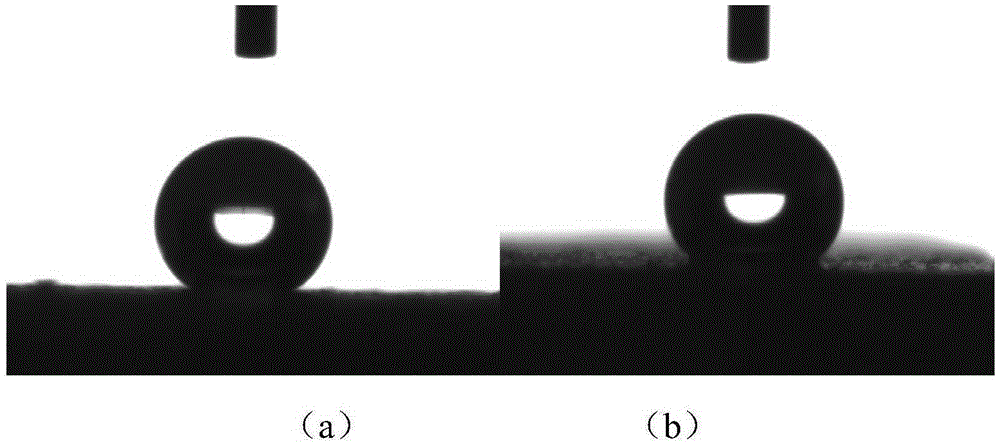

ActiveCN105386032APreserve physicochemical propertiesFast depositionPressure inorganic powder coatingWear resistanceRolling angle

The invention discloses a method for preparing a wear-resisting super-hydrophobic coating through a cold spraying technology and a product of the method. The method comprises the following steps that firstly, the surface of a base body is roughened; secondly, sprayed powder is modified with low-surface-energy matter; and thirdly, the wear-resisting super-hydrophobic coating is prepared on the surface of the base body through the cold spraying technology. The static contact angle of the coating prepared through the method can be 150-180 degrees, the rolling angle of the coating is smaller than 10 degrees, and good super-hydrophobicity is achieved. According to the method, the product of a non-stick pan is prepared and has good wear resistance and non-stick performance, and compared with non-stick pans in the market, the product is more resistant to wear and has the great competitive potential in the field. In addition, the method can be used for preparing different wear-resisting super-hydrophobic coatings based on different base materials (such as metal, ceramic, glass and plastic), and the application range is wide.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

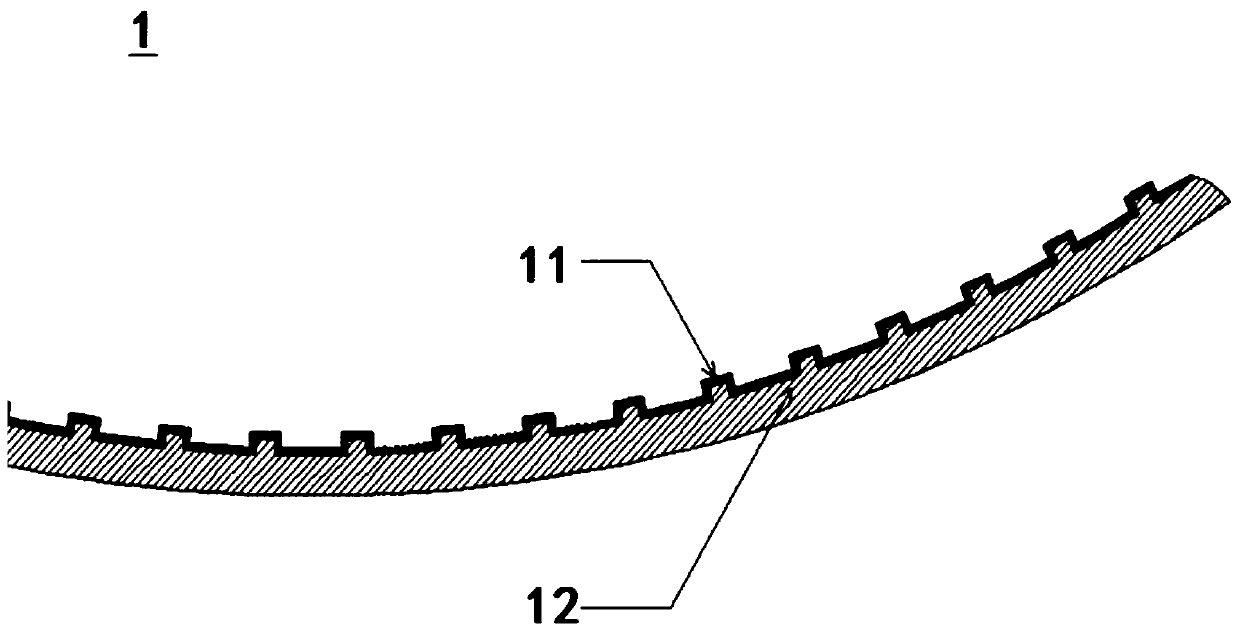

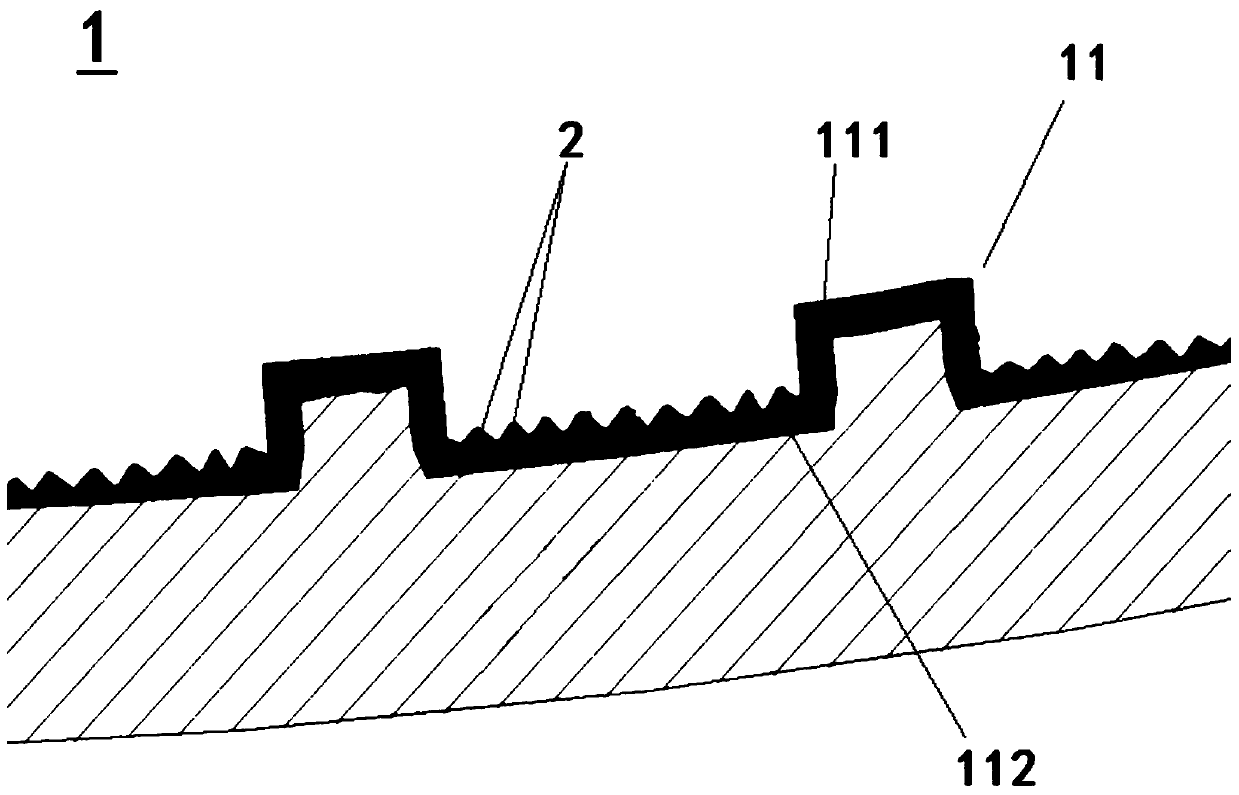

Nonstick cookware and manufacturing method thereof

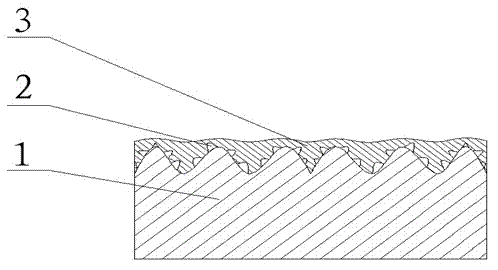

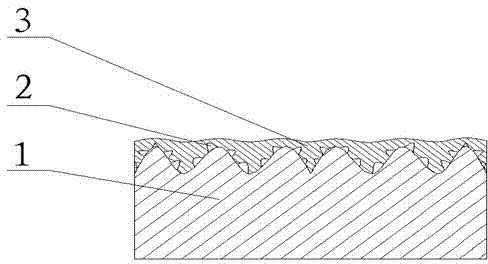

The invention discloses nonstick cookware and a manufacturing method thereof, wherein the inner surface of the pot body of the nonstick cookware is provided with an uneven raised structure; a grain structure is distributed on the raised structure; and a nonstick coating covers outside the raised structure and the grain structure. The manufacturing method of the cookware comprises the following steps of: (1) forming the pot body of the cookware; (2) carrying out inner surface treatment on the pot body of the cookware to ensure that the uneven raised structure is formed at the inner surface of the pot body of the cookware; (3) carrying out meltallizing treatment on the cookware blank after being subjected to the roughening treatment to ensure that nanoscale hard metal-based or nonmetal-based grain structure is distributed on the raised structure of the pot body of the cookware; (4) spraying nonstick coatings on the inner surface of the pot body of the cookware after being subjected to the meltallizing treatment to ensure that the nonstick coating covers outside the raised structure and the grain structure; and (5) putting in a sintering channel at a temperature of 350-440 DEG C after the spraying to sinter for 5-20 minutes so as to obtain a finished product. The nonstick cookware disclosed by the invention is good in nonstick effect and abrasive resistance, simple in manufacturing process and suitable for large scale production.

Owner:谛卓(北京)咨询顾问有限公司

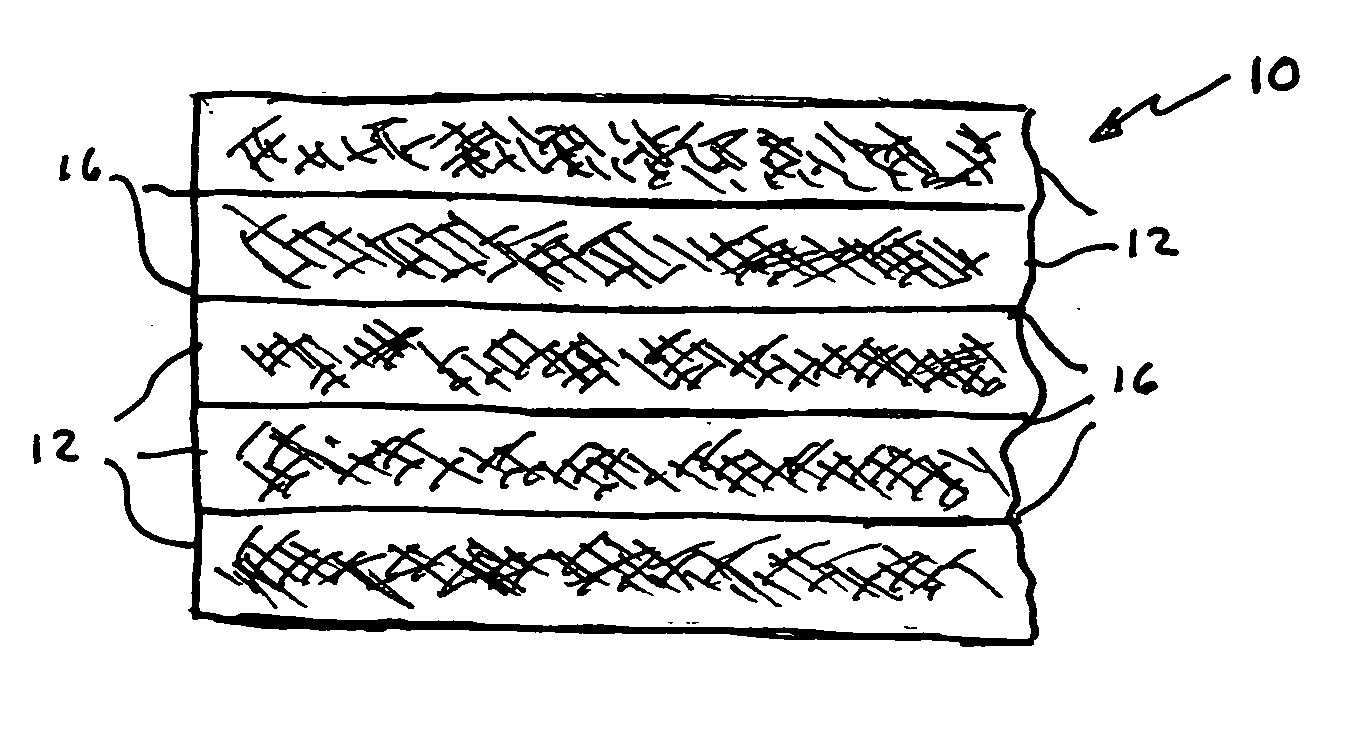

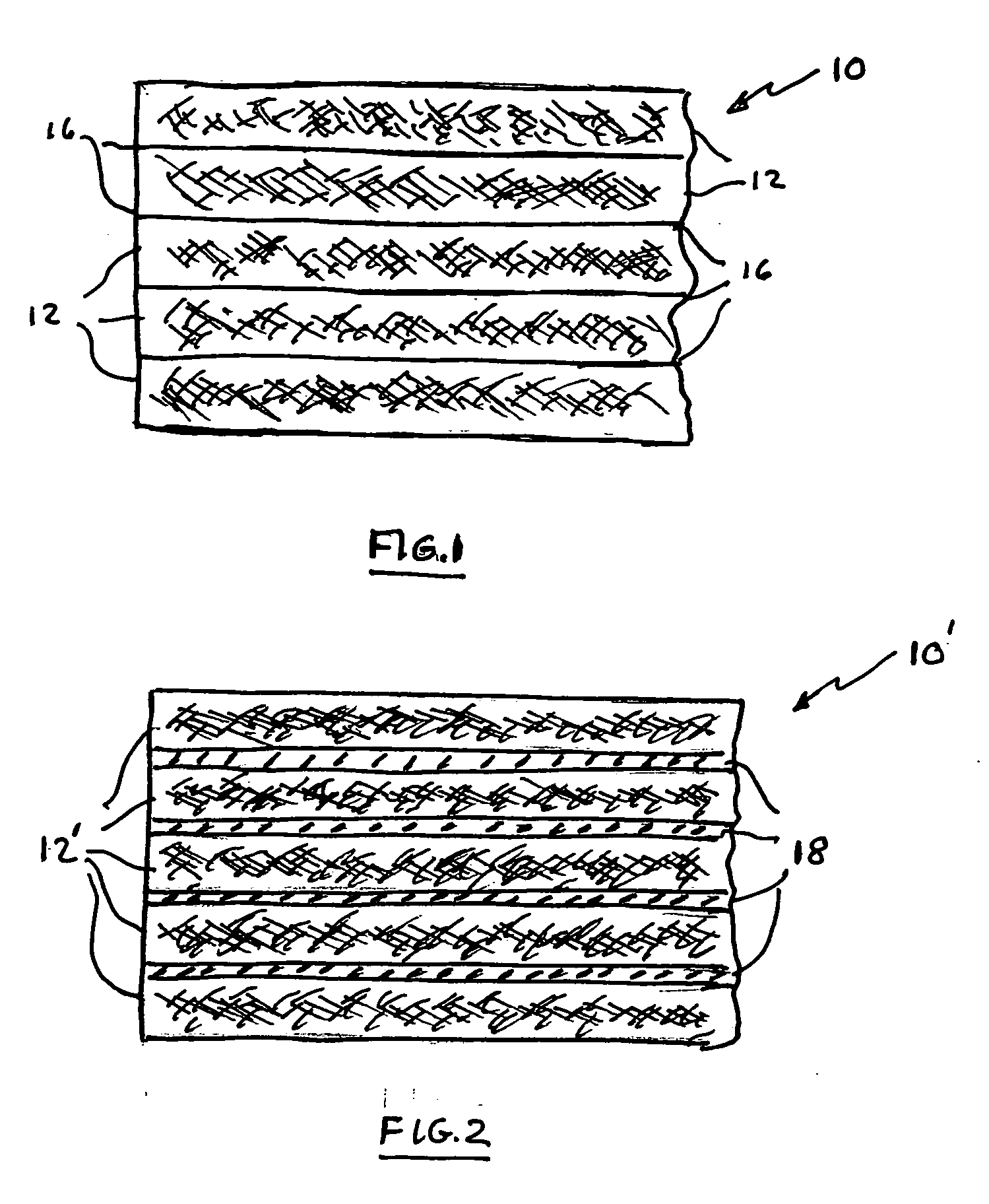

Planar elements for use in papermaking machines

InactiveUS20050279478A1Improve ultraviolet ray blocking propertyImprove performanceMaterial nanotechnologyLiquid surface applicatorsPolymer resinNanoparticle

A planar element for use in a papermaking machine comprising a synthetic construction incorporating nanoparticles in a polymeric resin matrix.

Owner:KADANT WEB SYSTEMS INC

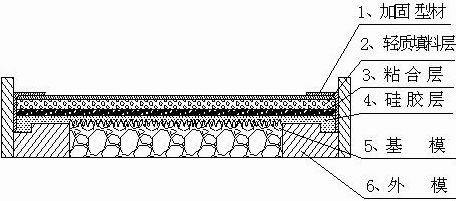

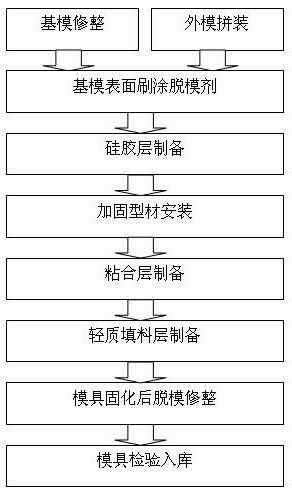

Die for building materials products and preparation method thereof

The invention discloses a die for building materials products and a preparation method thereof. The die provided by the invention contains a preformed female die and is prepared by the following steps of: cleaning the female die by an air pump, coating a mold releasing agent on the surface of the female die, uniformly laying a silica gel surface layer on the surface of the female die coated with the mold releasing agent to form a nonstick material surface layer, placing a bar of angle iron at each long side of the die; successively laying a silica gel bonding coat and a layer of gauze on the silica gel surface layer after its gelation, laying an epoxy resin bonding layer and a layer of glass fiber grid cloth after coagulation of the silica gel bonding layer to form a bonding layer; laying an insulation plate and flat iron on the bonding layer, pressing tightly by using a steel plate and simultaneously installing seal section bars at the four corners of the die; laying epoxy resin mortar on the surface of the insulation plate to form a light filling layer; laying a layer of glass fiber biaxial cloth on the light filling layer, and laying an epoxy adhesive coat on the glass fiber biaxial cloth to form a hard base material. The die provided by the invention has a simple structure, is easy to demould, and can be used to effectively guarantee the quality of moulded products. In the meantime, the preparation method provided by the invention is convenient to operate, requires low cost, and is easy to maintain.

Owner:ENERGY EFFICIENCY TECH

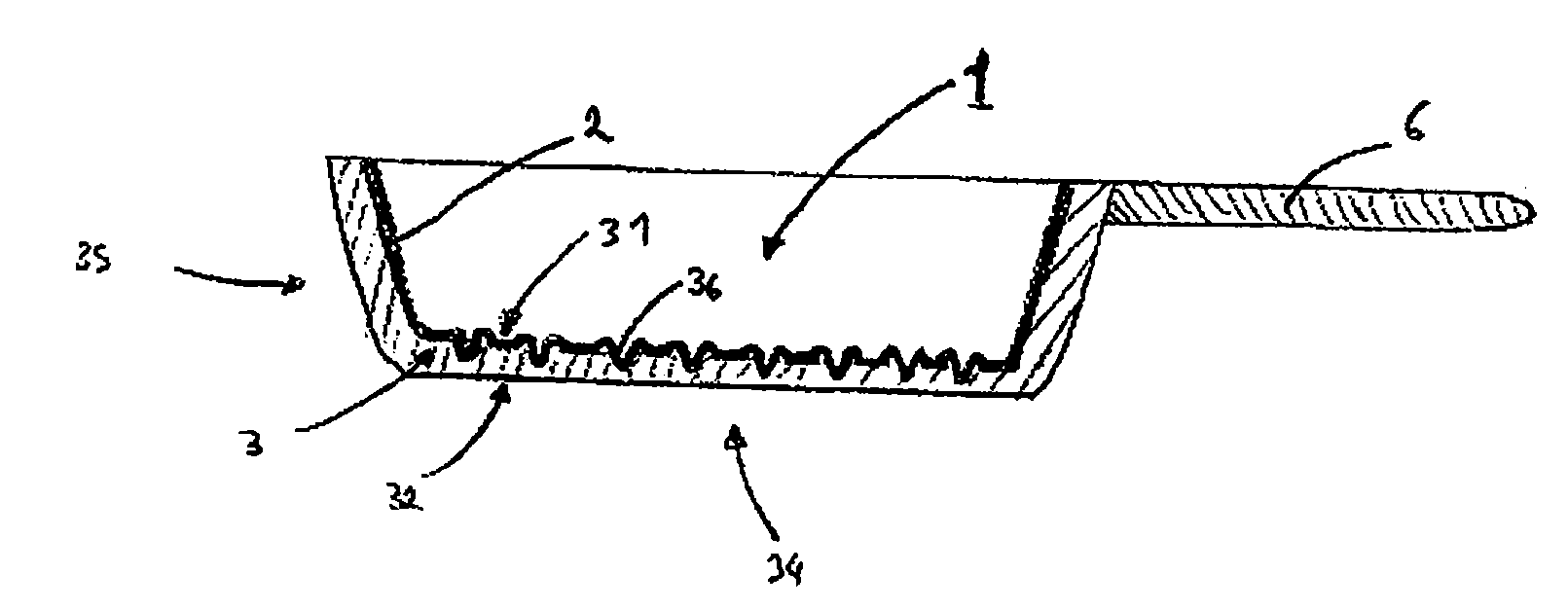

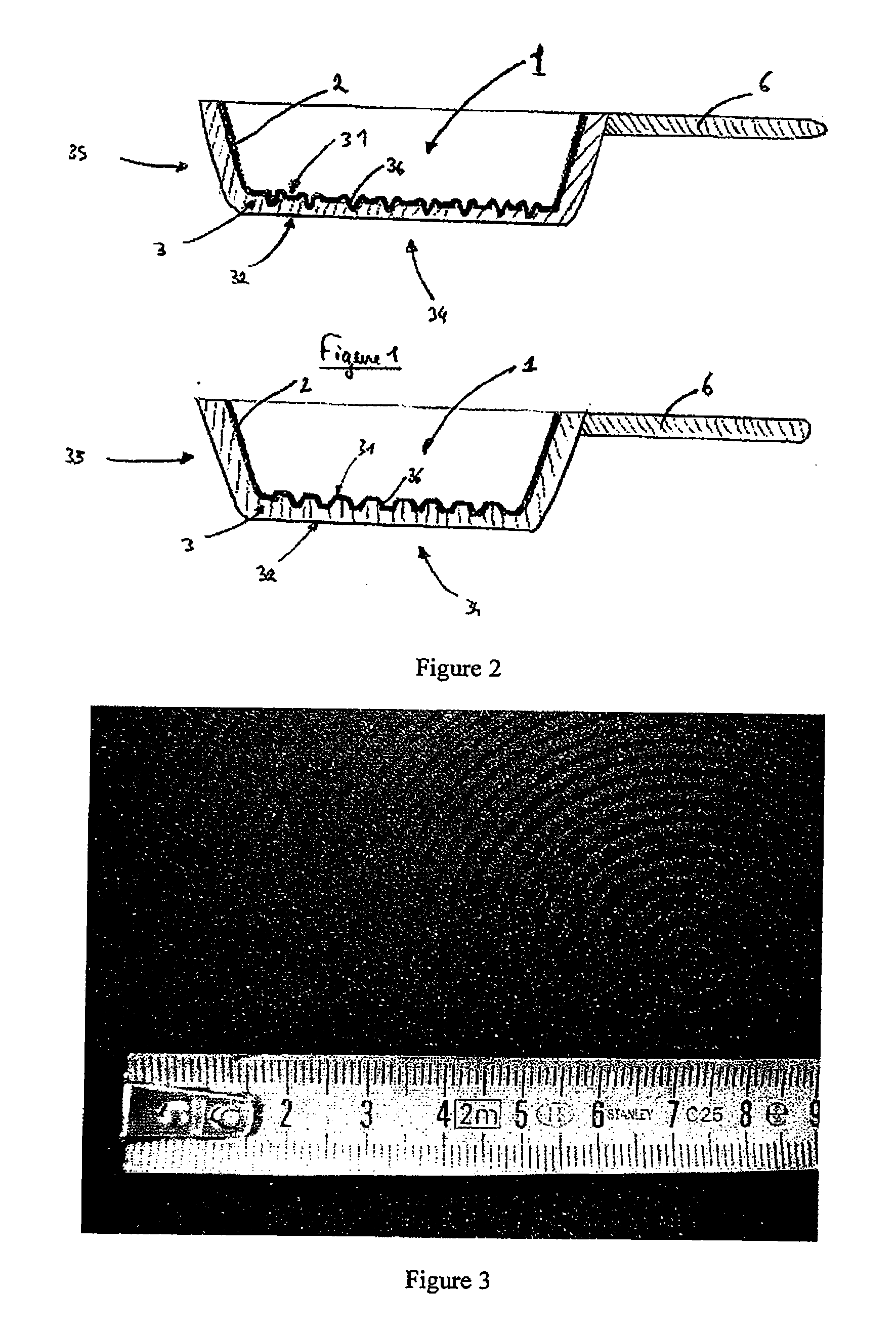

Culinary article comprising a non-stick coating having improved non-stick properties

InactiveUS20110192850A1Good non-stickImprove wear resistanceCooking-vessel materialsLiquid surface applicatorsCoatingPolymer science

A culinary article comprising a vitreous type coating which has improved non-stick properties. The present invention also relates to a process for manufacturing such an article.

Owner:SEB SA

Zisha ware ceramal non-cooking fume non-stick pan and preparation method thereof

InactiveCN101190097AGood non-stickAvoid direct contactCooking-vessel materialsHardnessWear resistance

The invention relates to a purple clay pottery alloy non-stick cookware without oil smoke and a preparation method thereof. The purple clay pottery alloy non-stick cookware without oil smoke comprises a cookware body and a cookware handle, wherein, the cookware body takes aluminium alloy as a substrate, the outer surface of the substrate of the cookware body is provided with a pottery crystal layer, and the inner surface of the substrate is provided with a purple clay pottery layer. The purple clay pottery alloy non-stick cookware without oil smoke of the invention consists of the non-stick purple clay pottery layer, the substrate of the cookware body and the pottery crystal layer, so the cookware is heated uniformly and does not generate partial high temperature when in use, thus generating no oil smoke when cooking dishes; in addition, the purple clay pottery layer avoids the direct contact between food and the aluminium alloy substrate, and improves surface hardness considerably, thus leading the cookware body to have more wear resistance and adhesion resistance, resist high temperature and be safe and non-toxic to the human body.

Owner:胡金高

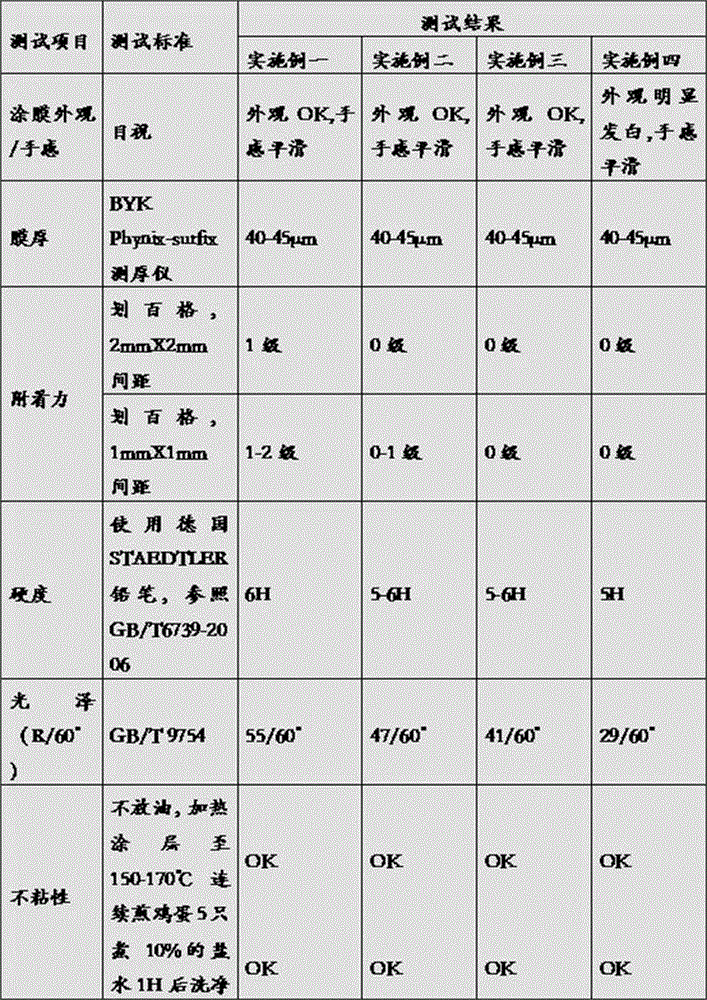

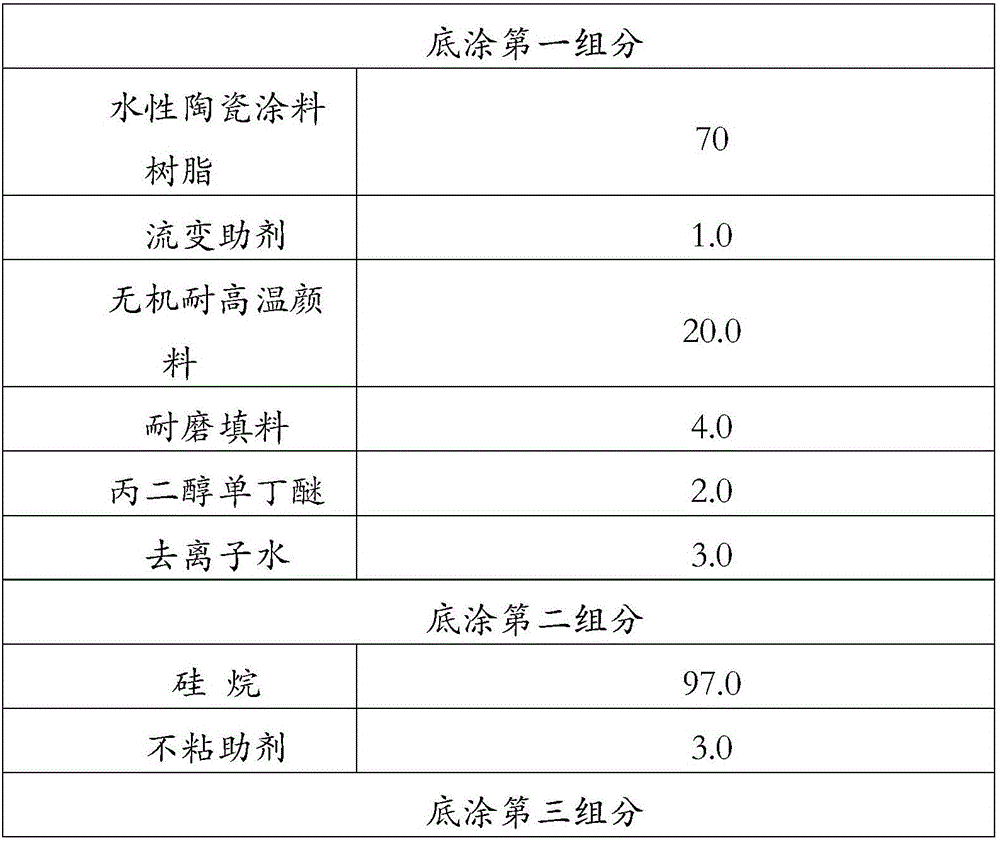

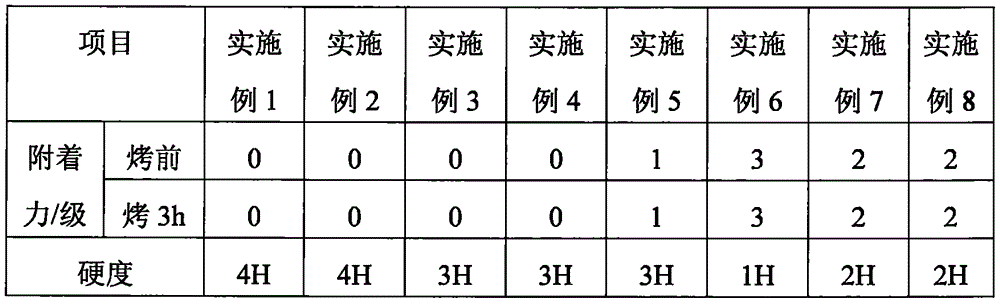

Aqueous ceramic non-stick coating material for kitchenware surfaces and preparation method for aqueous ceramic non-stick coating material

The invention discloses an aqueous ceramic non-stick coating material for kitchenware surfaces. The coating material comprises a base coat and a top coat, wherein the base coat contains a first component, a second component and a third component, the part ratio of the first component to the second component to the third component is 3.33: 1.65: 0.02, the top coat comprises a fourth component and the second component, and the part ratio of the fourth component to the second component is 3.33: 1.65; the first component contains aqueous ceramic coating resin, rheologic adjuvants, inorganic high-temperature resistant pigments, wear-resistant fillers, ethylene glycol monobutyl ether and deionized water; the second component contains silane and non-stick adjuvants; the third component is formic acid; and the fourth component contains ceramic coating resin, pearlescent pigments, ethylene glycol methyl-n-butyl ether and deionized water. The invention also discloses a preparation method for the aqueous ceramic non-stick coating material for the kitchenware surfaces. By implementing the aqueous ceramic non-stick coating material for the kitchenware surfaces and the preparation method for the aqueous ceramic non-stick coating material, disclosed by the invention, the coating material which has the advantages of high luster, smooth surface, high hardness, good toughness, lasting non-stick property and good stability can be prepared.

Owner:卡秀万辉(广州)高新材料有限公司

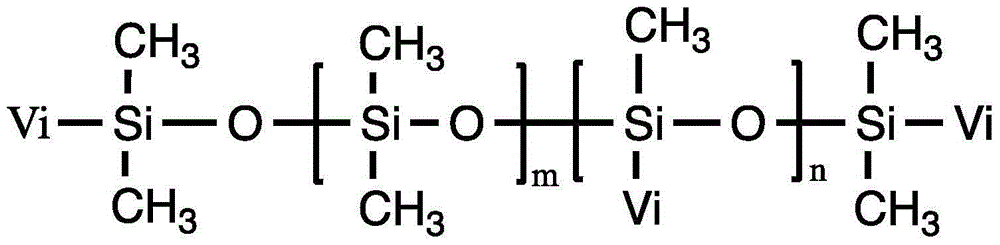

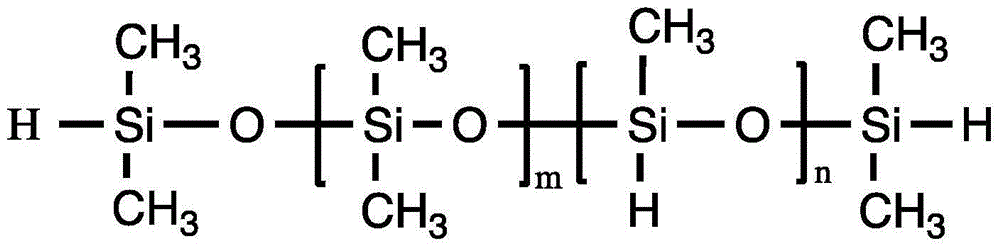

Method for preparing liquid silicone rubber for LCD screen protection film

ActiveCN104479622AWon't hurtImprove the performance of double 85 resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkPolymer science

Owner:浙江森日有机硅材料有限公司

Method for making a non-sticking diamond-like nanocomposite

InactiveUS6472062B1Reduce bias voltageReduce hardnessVacuum evaporation coatingSputtering coatingNanocompositeMaterials science

An improved non-sticking diamond-like nanocomposition includes networks of a-C:H and a-Si:O, wherein the H-concentration is between 85% and 125% of the C-concentration. The composition includes preferably 25 to 35 at % of C, 30 to 40 at % of H, 25 to 30 at % of Si, and 10 to 15 at % of O.

Owner:SULZER METAPLAS

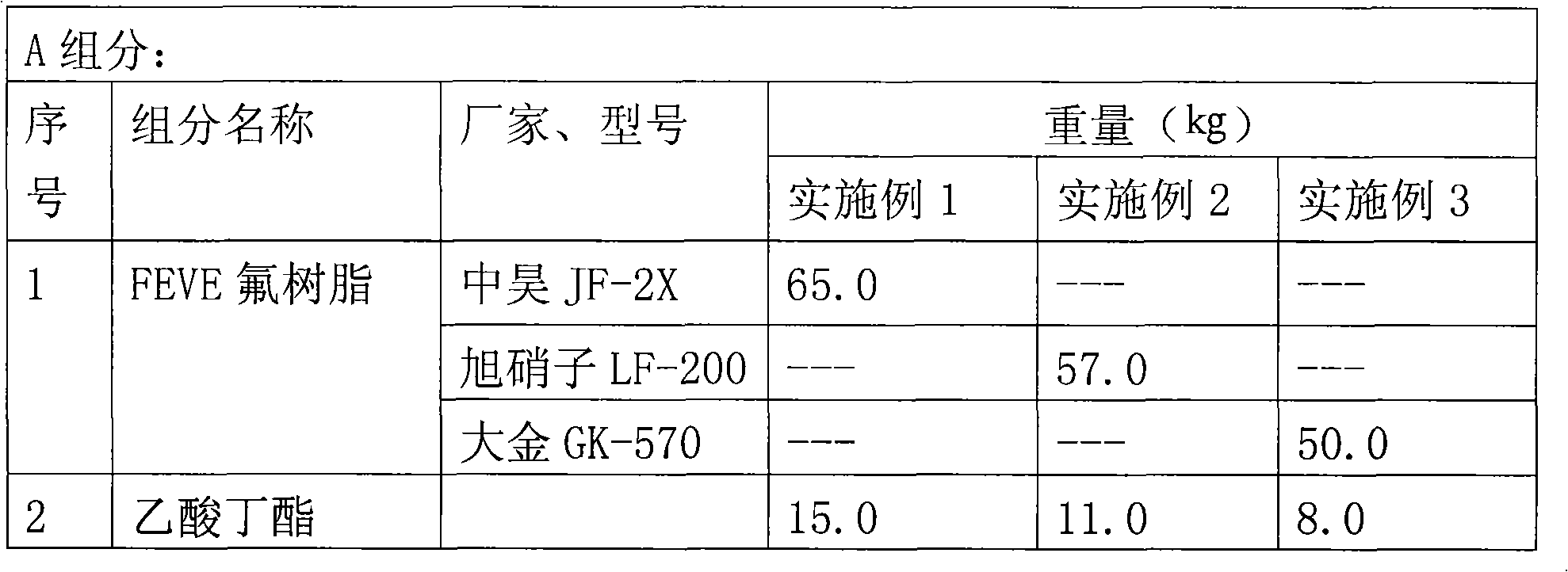

Anti-paste and anti-graffiti fluorocarbon coating and use method thereof

ActiveCN101629049AIncrease crosslink densityImprove the compactness of the paint filmPolyurea/polyurethane coatingsChemistryHardness

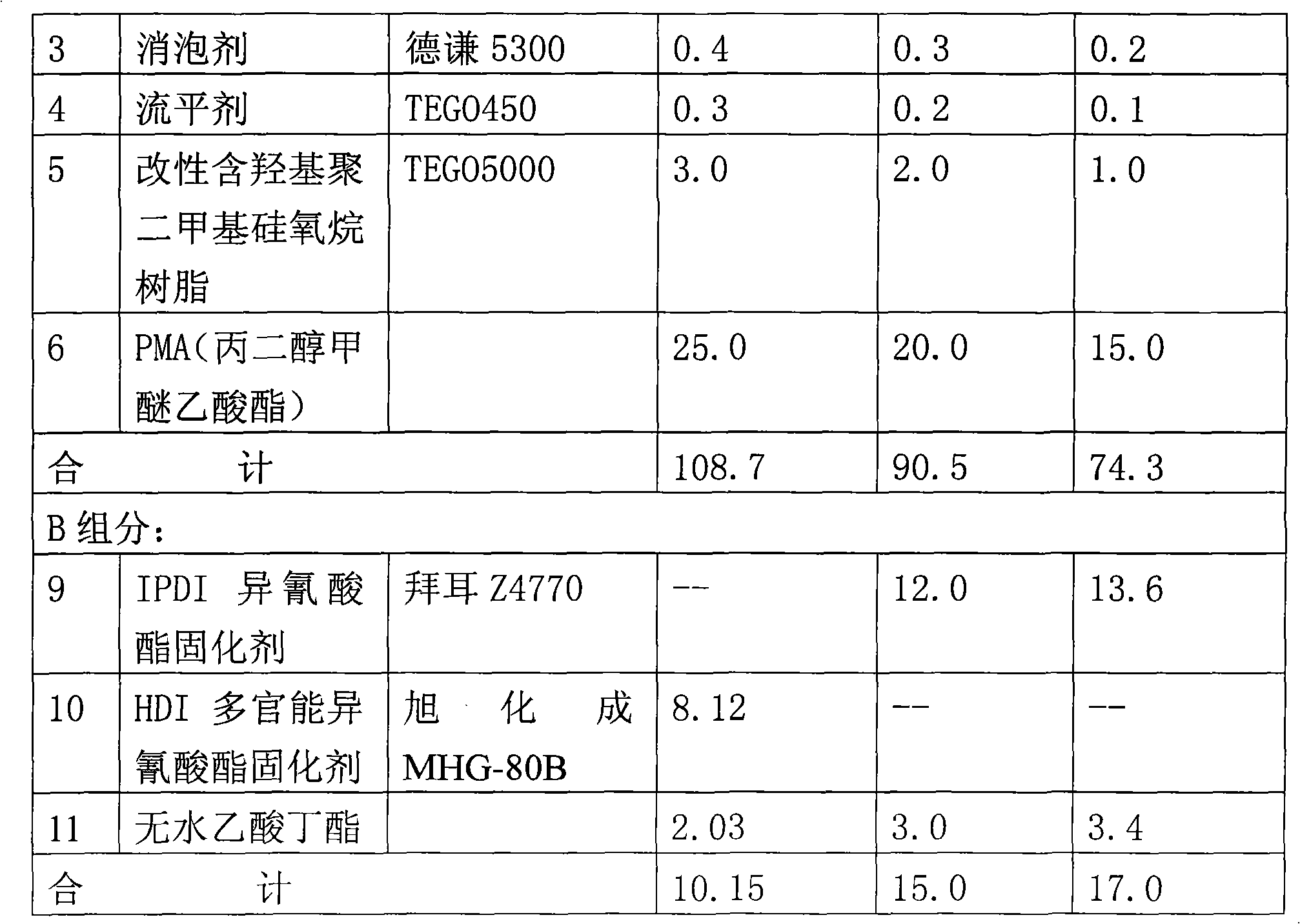

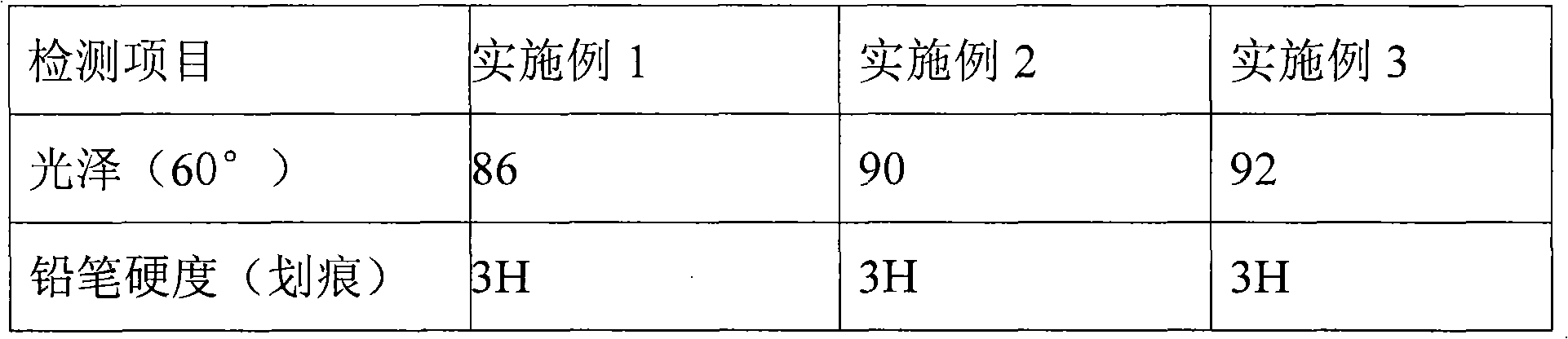

The invention relates to an anti-paste and anti-graffiti fluorocarbon coating which is prepared by mixing a component A and a component B in a proportion of OH / NCO=1:(1.0-1.1), wherein the component A comprises the following components in percentage by weight: 50-65 percent of FEVE fluororesin, 1-3 percent of modified polydimethylsiloxane resin containing hydroxide radicals, 8-15 percent of butyl acetate, 15-25 percent of propylene glycol methyl ether acetate, 0.2-0.4 percent of defoaming agent and 0.1-0.3 percent of flatting agent; and the component B is prepared by mixing 80 parts of IPDI isocyanate curing agent or GDI multifunctional isocyanate curing agent by weight and 20 parts of anhydrous butyl acetate by weight. The coating has high film crosslinking density and hardness, low surface tension, extremely strong permeability resistance and excellent anti-paste and anti-graffiti performance, and intractable oil pen graffiti can also be easily and completely wiped out. The coating also has excellent wear-resistant, scouring resistant and weather resistant properties and is suitable for long-term outdoor use. The coating can be painted and can also be sprayed after being diluted by adding 10-20 percent of PMA or polyurethane coating diluent.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

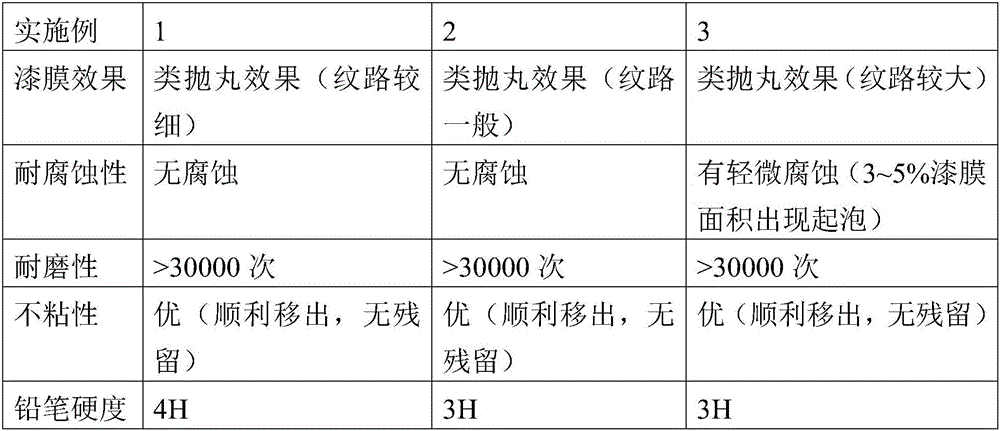

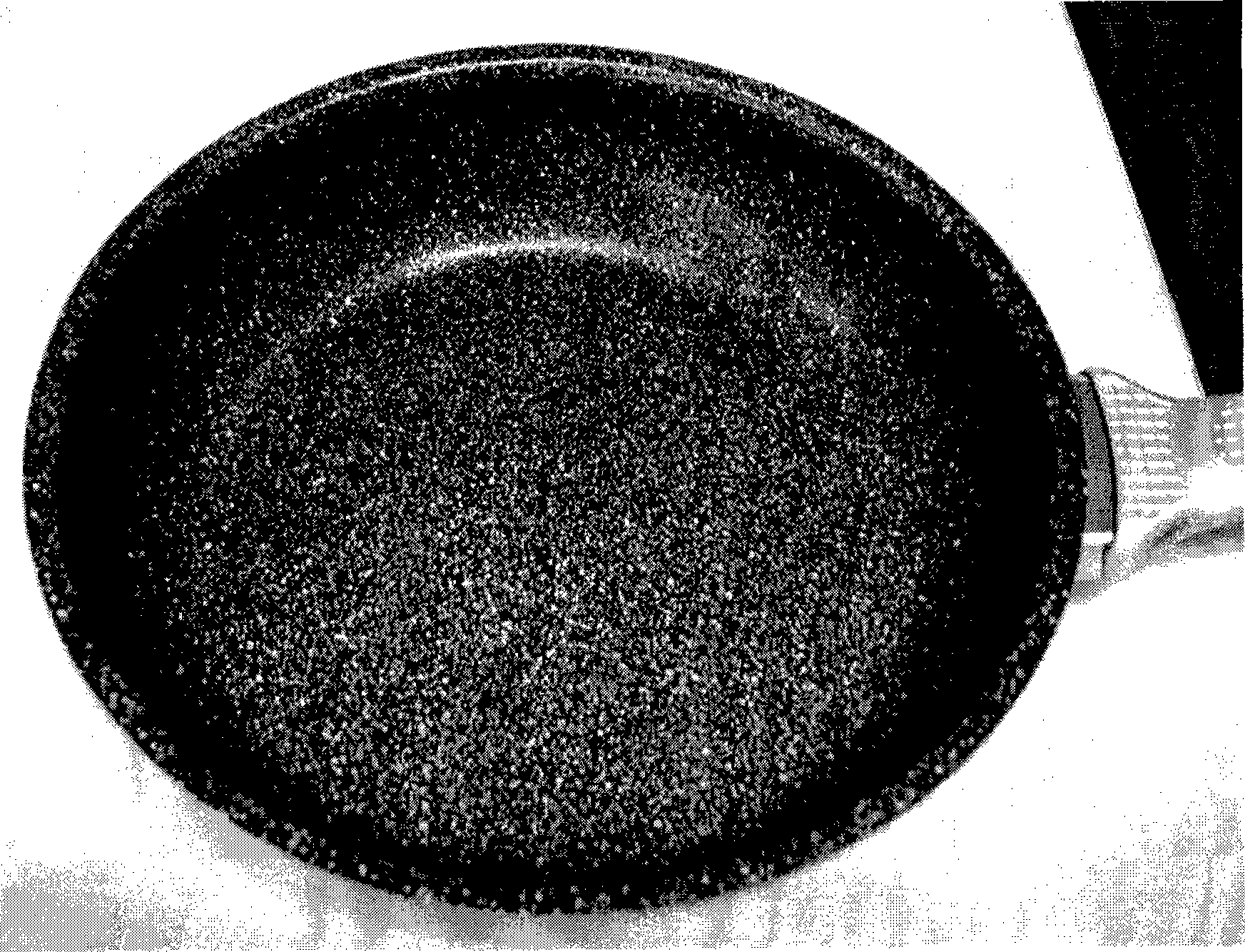

High-hardness non-stick coating with effect similar to shot blasting effect and preparation method thereof

InactiveCN106280975AHigh hardnessImprove wear resistanceCooking-vessel materialsPretreated surfacesHardnessWear resistance

The invention provides a non-stick coating used on the surface of a cooking utensil. The non-stick layer comprises a bottom coating body, a middle coating body and a surface coating body. The bottom coating body is cured first after construction to obtain a coating body with the effect similar to the shot blasting effect, then middle paint and surface paint are sprayed on the bottom coating body in a wet mode, and finally the coating with a special effect similar to the shot blasting effect is obtained. The coating is high in hardness, excellent in abrasion resistance and good in non-stick performance.

Owner:卡秀万辉(无锡)高新材料有限公司

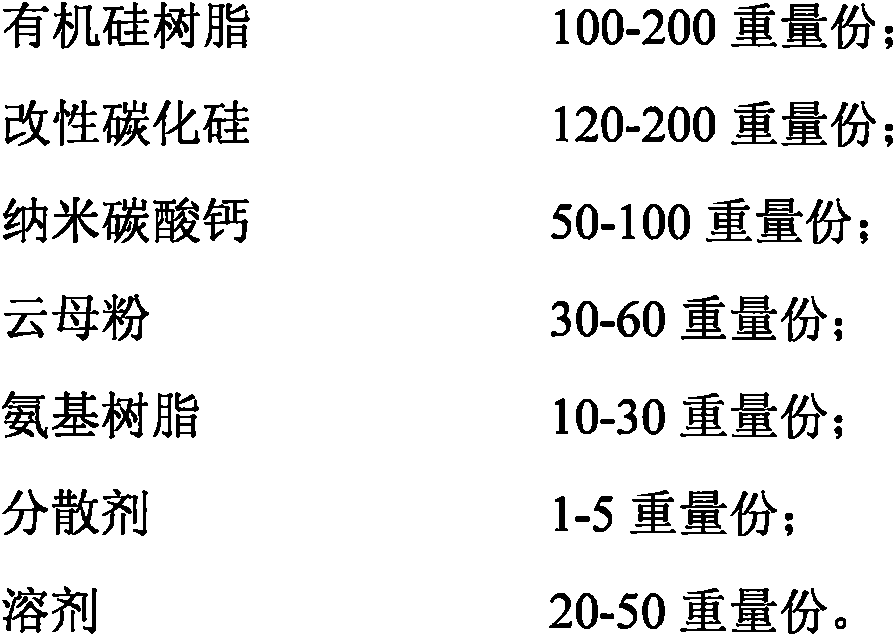

Nonstick pan coating layer, and production method and nonstick pan thereof

ActiveCN105925176AHigh hardnessImprove heat resistanceCooking-vessel materialsAnti-corrosive paintsPorositySolvent

The invention provides a nonstick pan coating layer, and a production method and a nonstick pan thereof. The production method comprises the following steps: mixing organosilicone resin, modified silicon carbide, nanometer calcium carbonate, mica powder, amino resin, a dispersant and a solvent, grinding the obtained mixture, dispersing the ground mixture, and filtering the dispersed mixture to obtain a coating; and spraying the coating on the surface of a metal pan matrix, and baking the sprayed metal pan matrix at 200-300DEG C for 10-30min to obtain the nonstick pan coating layer. The organosilicone resin, saturated modified silicon carbide and the nanometer calcium carbonate are simultaneously applied to the nonstick pan coating layer in order to form the coating layer with excellent performances of above three components. The modified silicon carbide has good thermal stability, corrosion resistance and thermal conduction performance, and guarantees the thermal distribution uniformity of the coating layer; the nanometer calcium carbonate makes the microscopic surface of the organosilicone coating layer be tight and have zero porosity, protects the matrix, and enhances the nonstick effect of the coating layer, and the nanometer calcium carbonate and the modified silicon carbide have synergism, and enhance the hardness and the heat resistance of the nonstick pan coating layer.

Owner:宁波贝得厨具有限公司

Cooker

InactiveCN101176616ADoes not cause peelingStrong adhesionCooking-vessel materialsMetallurgyCooking process

The invention relates to a pan, comprising a pan body; wherein, a handle is arranged on the pan body, which comprises a metallic layer and a ceramic layer compounded as a whole. The metallic layer and the ceramic layer are close compounded as a whole through partial fusing or fusing; the ceramic layer on the inner surface of the pan body is covered with a non-stick layer with the component of ceramic, which is bound on the ceramic layer through 200 to 420 DEG C baking. The invention has the advantages that: since the metallic layer and the ceramic layer are close compounded as a whole through partial melting or melting, and the adhesive power between the metallic layer and the ceramic layer is strong, the desquamation of the ceramic layer is avoided after the using of metallic spade in the cooking process or a long-time using of the pan; the non-stick layer and the ceramic layer are hard connected since the non-stick layer comprises the component of ceramic.

Owner:卢雄文

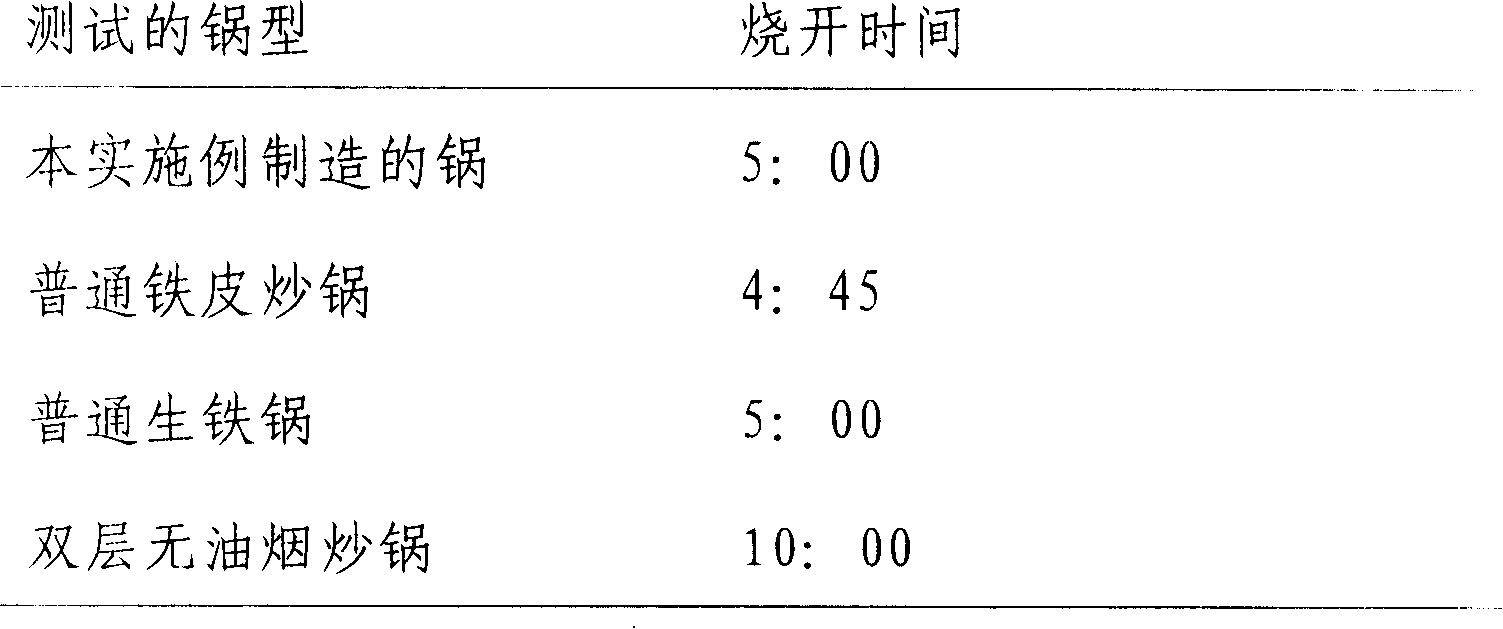

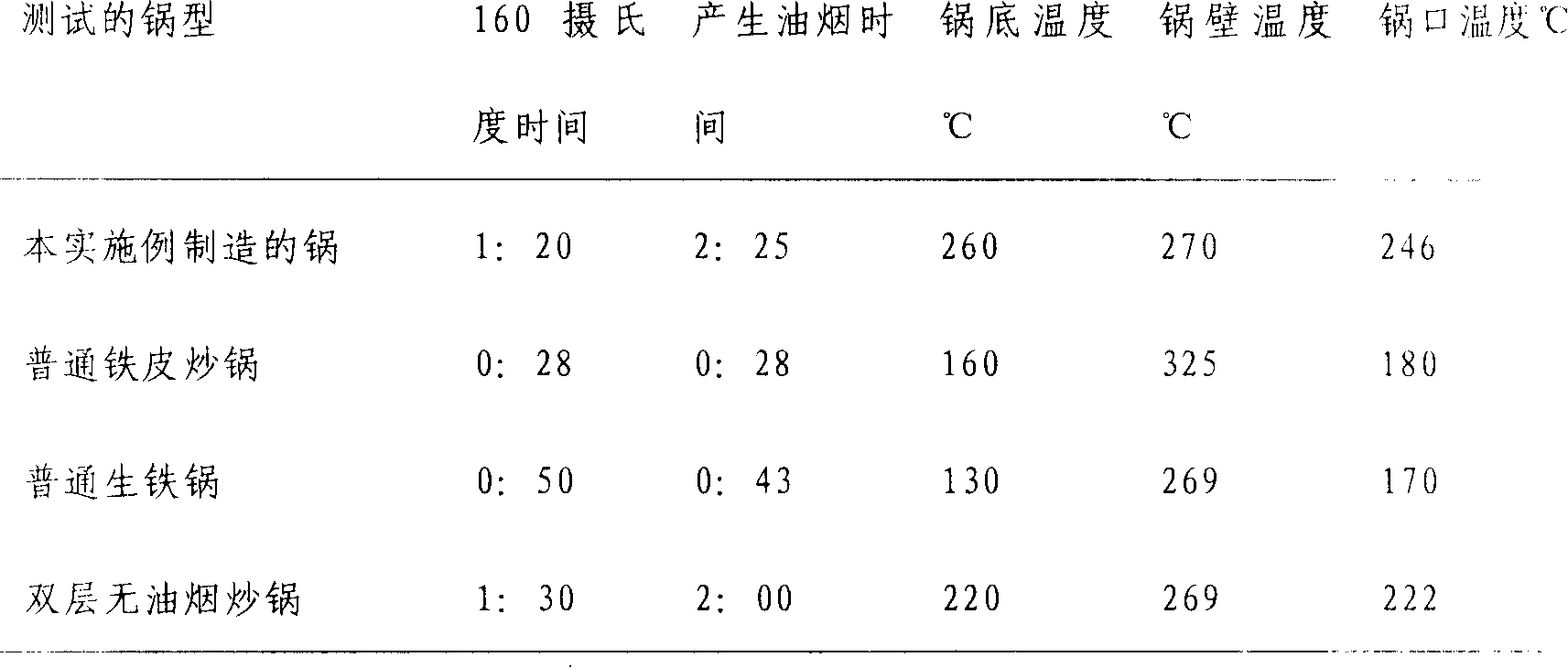

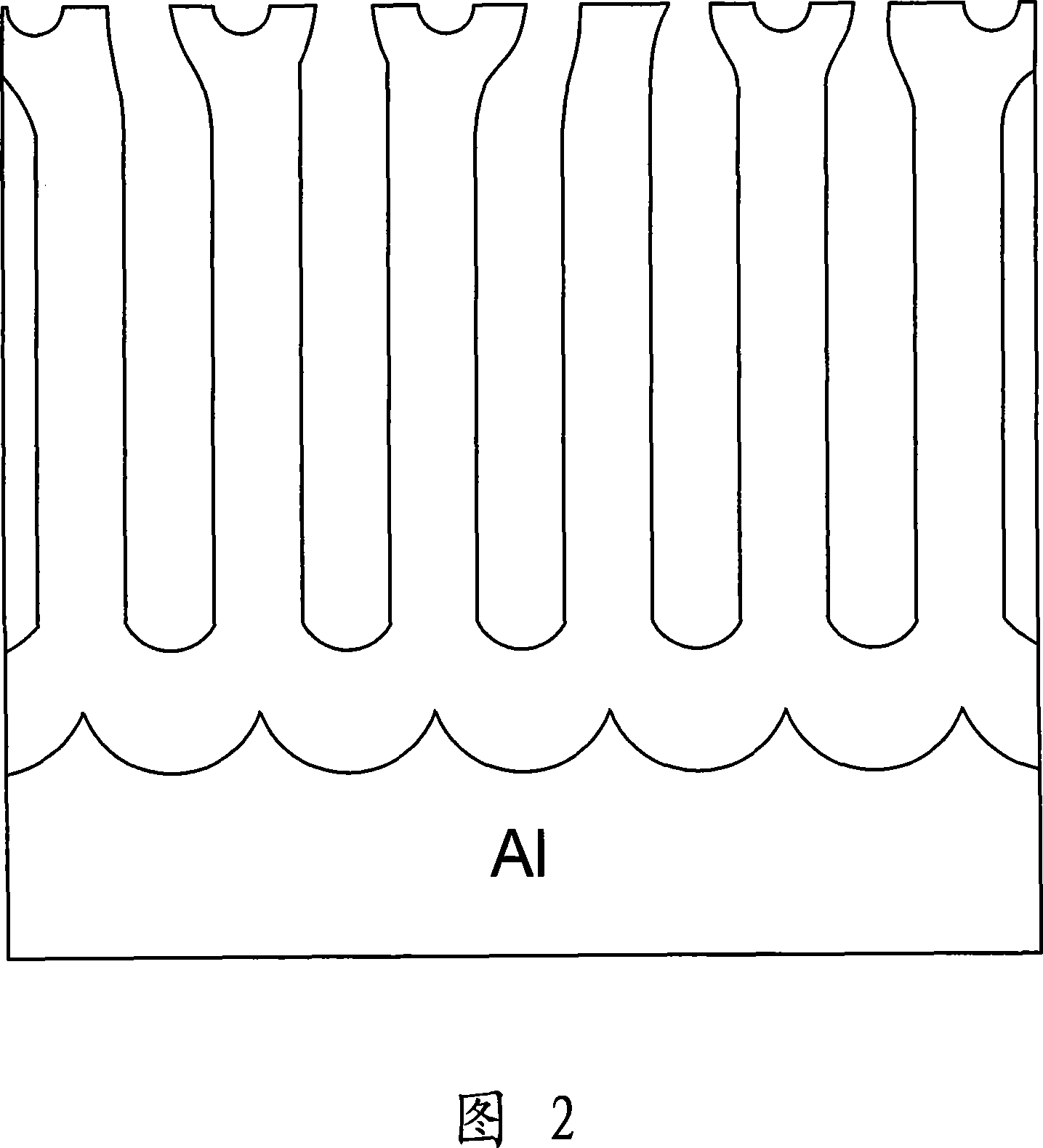

Fume-less cooker

InactiveCN101234001AIncrease the surface heating areaIncrease profitCooking-vessel materialsFrying pansConvex structureMetallurgy

The invention discloses an oil-free and smoke-free pan which comprises a pan body and a uniform heating layer of which thermal conductivity is lower than the thermal conductivity of the pan body. The uniform heating layer is arranged on the inner surface of the pan body. The invention adopts an aluminium alloy or magnesium alloy pan body with relatively high thermal conductivity, thus realizing a rapid heating. Furthermore, a purple sand ceramic uniform heating layer with relatively low thermal conductivity is sintered or a stainless steel uniform heating layer is compounded on the inner surface of the pan body to dissipate local high temperature on the pan body to the whole uniform heating layer, which ensures that no local high temperature, oil and smoke is produced in the pan, thus saving energy. A plurality of small convex structures are arranged on the uniform heating layer. Air is in a groove between the convex structures and the air is expanded after being heat, which results in the separation of food and the pan body to have physically non-stick effect. Compared with original immersion coating, the physical non-stick structure has better non-stick effect. A helical structure is adopted on the outer surface of the pan body, thereby increasing outer surface area of the pan body and improving energy utilization rate.

Owner:胡金高

Coating composition, preparation method and application thereof

InactiveCN101531853AImprove wear resistanceImprove anti-corrosion performancePretreated surfacesCoatingsVinyl etherImide

The invention relates to a coating composition, a preparation method and an application thereof. The coating composition comprises (a) priming paint which consists of (i) fluor resin, (ii) inorganic filler and (iii) bonding resin, and (b) surface layer coating. The fluor resin is selected from polytetrafluoroe thylene resin, tetrafluoroethylene-perfluorinated alkey vinye copolymer, fluorinated ethylene propylene copolymer and combinations thereof, with a content of 30 to 70 parts by weight, calculated by the total solid weight of the priming paint; the inorganic filler has a grain size of 0.1 to 50 microns and a content of 5 to 30 parts by weight, calculated by the total solid weight of the priming paint; the bonding resin is selected from daiamid-imide copolymer, polyimide, polyphenylene sulfide, polyethersulfone and combinations thereof, with a content of 10-40 parts by weight, calculated by the total solid weight of the priming paint; the surface layer coating comprises (i') tetrafluoroethylene-perfluorinated alkey vinye copolymer with a content of 80-100 parts by weight, calculated by the total solid weight of the surface layer coating; (ii') assisted film forming organic resin with a content of 0-20 parts by weight, calculated by the total solid weight of the surface layer coating; and (iii') mica flashlight powder with a content of 0-3 parts by weight, calculated by the total solid weight of the surface layer coating.

Owner:科慕有限公司

Physical non-stick pan with concave-convex structure and preparation method thereof

PendingCN111387795AAchieve hydrophobic effectRealize oil lock functionCooking-vessel materialsPolishing machinesConvex structureEngineering

The invention, which belongs to the field of kitchen supplies, relates to a non-stick pan, in particular to a physical non-stick pan with a concave-convex structure and a preparation method thereof. The non-stick pan comprises a pan body and is characterized in that a concave-convex structure is formed on the inner surface of the pan body. The concave-convex structure comprises convex edges protruding out of the inner surface of the pan and a concave area defined by the convex edges, and a physical non-stick layer is at least arranged on the inner surface of the pan body in the concave area. The concave-convex structure is arranged, the convex edges protect the non-stick layer arranged in the concave area, so that direct friction between the pancake turner and the non-stick layer is reduced, and the non-stick effect of the pan body is prolonged.

Owner:ZHEJIANG BAHE KITCHENWARE CO LTD

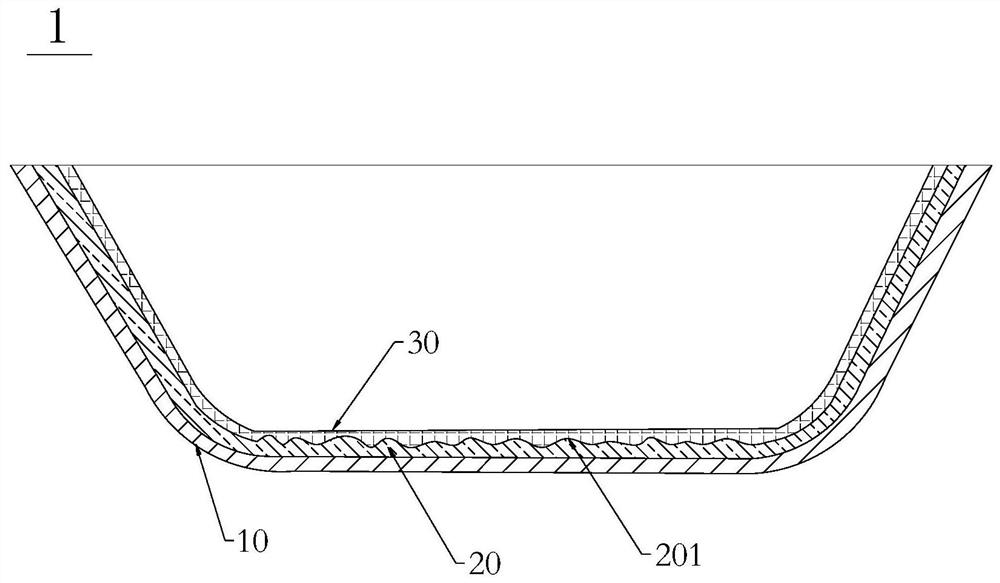

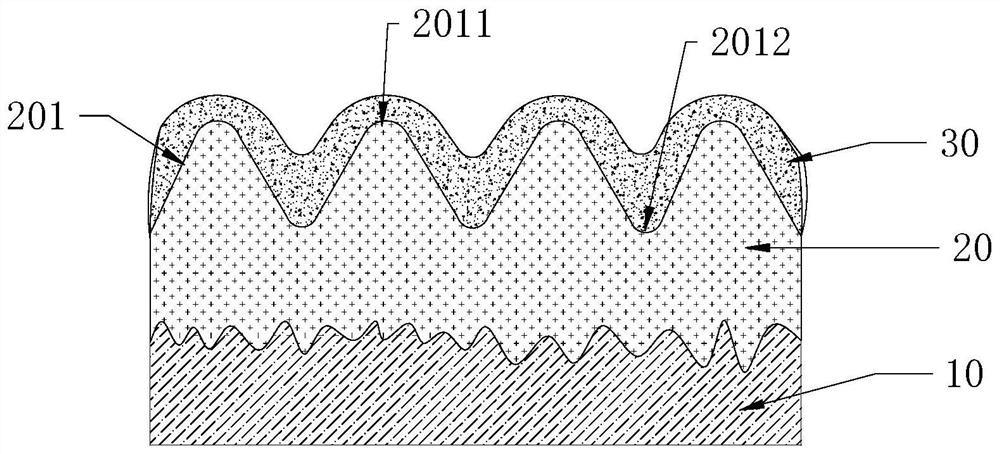

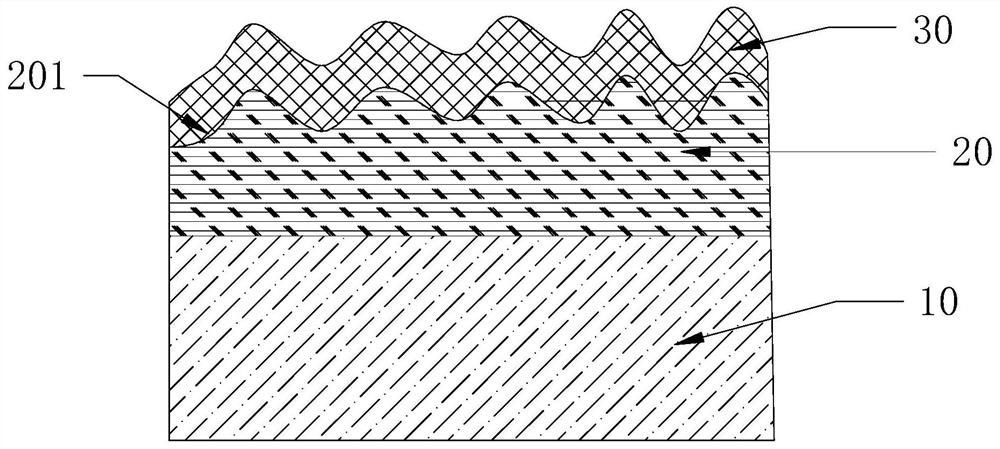

Container body and cooking utensil

PendingCN112137425AImprove long-lasting non-stick lifeImprove non-stick lifeCooking-vessel materialsWear resistanceMechanical engineering

The invention relates to the technical field of cooking utensils, in particular to a container body and a cooking utensil. The container body includes: a base body; a middle rough layer which is arranged on the inner surface of the base body; a non-stick layer which is arranged on the middle rough layer; wherein the non-stick layer comprises a non-stick coating, an inorganic porous material and / ora self-lubricating material, and the inorganic porous material and / or the self-lubricating material accounts for 1%-20% of the non-stick layer. According to the container body, the bonding force between the non-stick layer and the substrate can be increased, the wear resistance can be enhanced, the durable non-stick life is good, and the actual experience feeling of consumers is improved.

Owner:WUHAN SUPOR COOKWARE

Protection coating for petroleum equipment and construction method thereof

ActiveCN102504678AImprove corrosion resistanceNo peeling, peeling phenomenonPretreated surfacesAnti-corrosive paintsAdhesion forceSand blasting

The invention which relates to a protection coating for petroleum equipment and a construction method thereof belongs to the technical field of chemical engineering coatings. The protection coating comprises, by mass, 70-99% of polyaryletherketone, 1-30% of a fluororesin, and 0-6% of an inorganic filler. The construction method comprises the following steps: 1, sand-blasting the surface of a workpiece; 2, spraying a powdery pure polyaryletherketone coating on the surface of the workpiece by utilizing an electrostatic spraying technology; 3, placing the workpiece in an oven to fuse the powdery pure polyaryletherketone coating; 4, spraying a powdery composite polyaryletherketone coating while hot by utilizing the electrostatic spraying technology, and fusing the powdery composite polyaryletherketone coating; and 5, cooling to 220-300DEG C, maintaining the temperature for 30-90min, and cooling to room temperature. According to the invention, the process flow can be reasonably controlled, and the operation is simple; and the obtained coating layer has the advantages of strong adhesion force, and excellent resistance, abrasion resistance and non-stick performance, so the service life of the petroleum equipment can be increased, thereby the oil extraction cost reduction purpose is reached.

Owner:吉林省奕彤新材料有限公司

Making process of antiwear nonstick cooker

InactiveCN101019742ANot easy to produce oily smokeImprove thermal conductivityCooking-vessel materialsHardnessHigh wear resistance

The present invention is making process of antiwear nonstick cooker and belongs to the field of daily article making technology. The making process of antiwear nonstick cooker includes the following steps: forming, anode oxidation to form hard oxide layer, permeating, and pore sealing treatment. The antiwear nonstick cooker has the advantages of high nonstick performance, high hardness, high wear resistance and long service life. Besides, the cooker has fewer trend of generating oil smoke and easy cleaning.

Owner:严卫星 +1

Preparation method of modified polytetrafluoroethylene dispersion concentrated solution

InactiveCN107652386AHigh Limit Membrane ThicknessImprove application processabilityTetrafluoroethylenePolymer science

The invention relates to a preparation method of a modified polytetrafluoroethylene dispersion concentrated solution. The polymerization reaction is carried out in three stages: in the first stage, controlling a reaction pressure to be in a range of 1.0-1.8 MPa and adding 20-30% of tetrafluoroethylene monomers and 40-60% of modified monomers; in the second stage, controlling the reaction pressureto be in a range of 2.0-3.0 MPa and adding 60-70% of tetrafluoroethylene monomers; and in the third stage, controlling the reaction pressure to be in a range of 2.0-3.0 MPa and adding residual tetrafluoroethylene monomers and residual modified monomers. According to the method disclosed by the invention, the pressure is operated in a variable pressure mode in the polymerization process, and recycling is performed twice in an intermediate process for realize a soft-hard-soft three-layer molecular structure of particles, so that the application processing performance of the dispersed concentrated solution is improved fundamentally, and the obtained polytetrafluoroethylene dispersion concentrated solution has the characteristics of extremely high yellowing resistance, good surface glossiness,high limit film-crack thickness, high smoothness, high cracking resistance, excellent non-viscosity and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

High-temperature wear resistant nonstick coating layer material and preparation method thereof

ActiveCN104962144AImprove wear resistanceImprove high temperature resistanceCoatingsWear resistantWear resistance

The invention discloses a high-temperature wear resistant nonstick coating layer material and a preparation method thereof. The high-temperature wear resistant nonstick coating layer material comprises 80-99wt% of Teflon and 1-20wt% of metal oxide. A nonstick coating layer is produced from the high-temperature wear resistant nonstick coating layer material through a present nonstick coating layer coating technology, and a result of the wear resistance test of the nonstick coating layer shows that the bearable friction frequency can reach 90000 (test standard: CMA2005 Kitchenware Association Standard, and the qualified friction frequency is 30000).

Owner:李吉学 +1

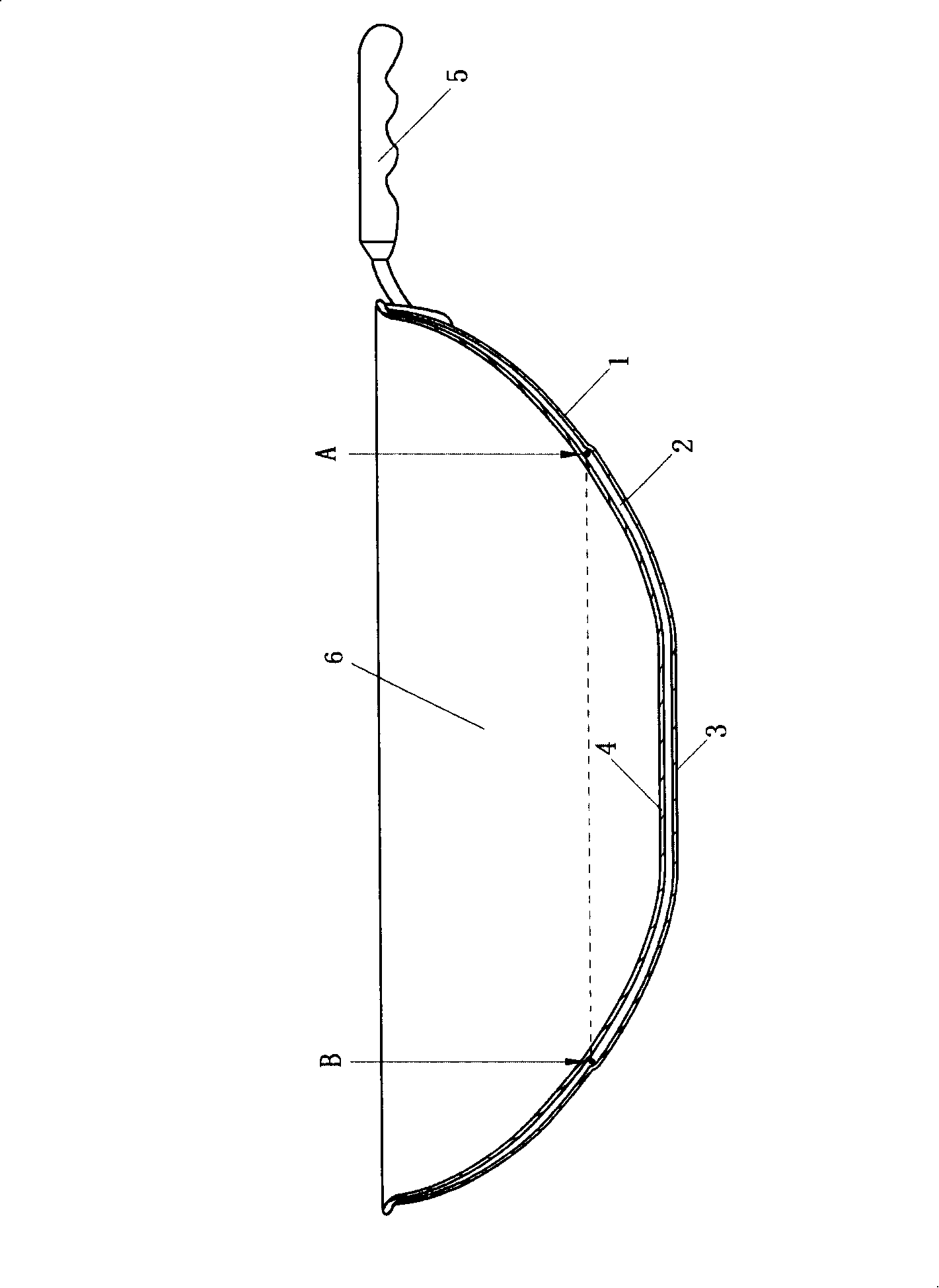

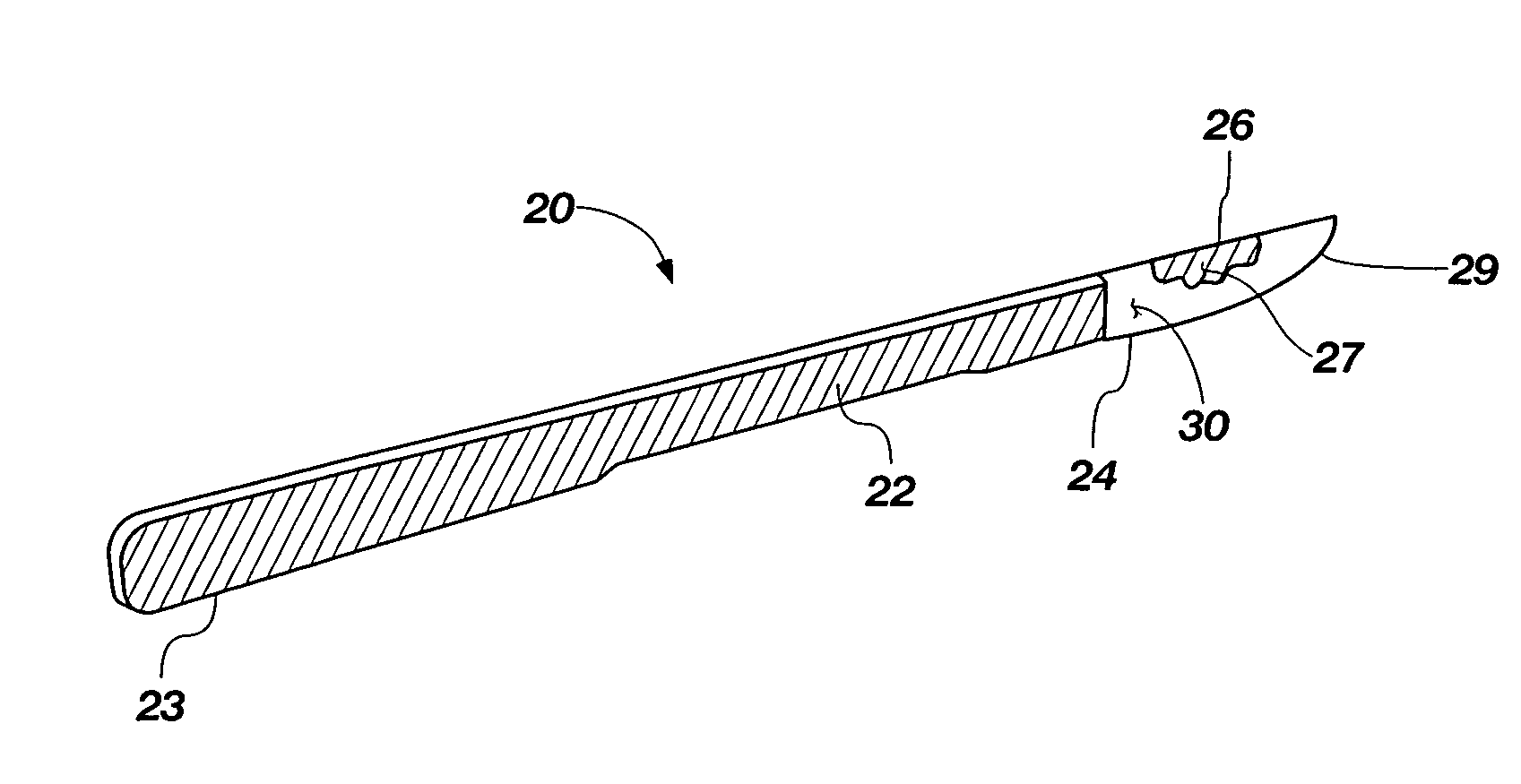

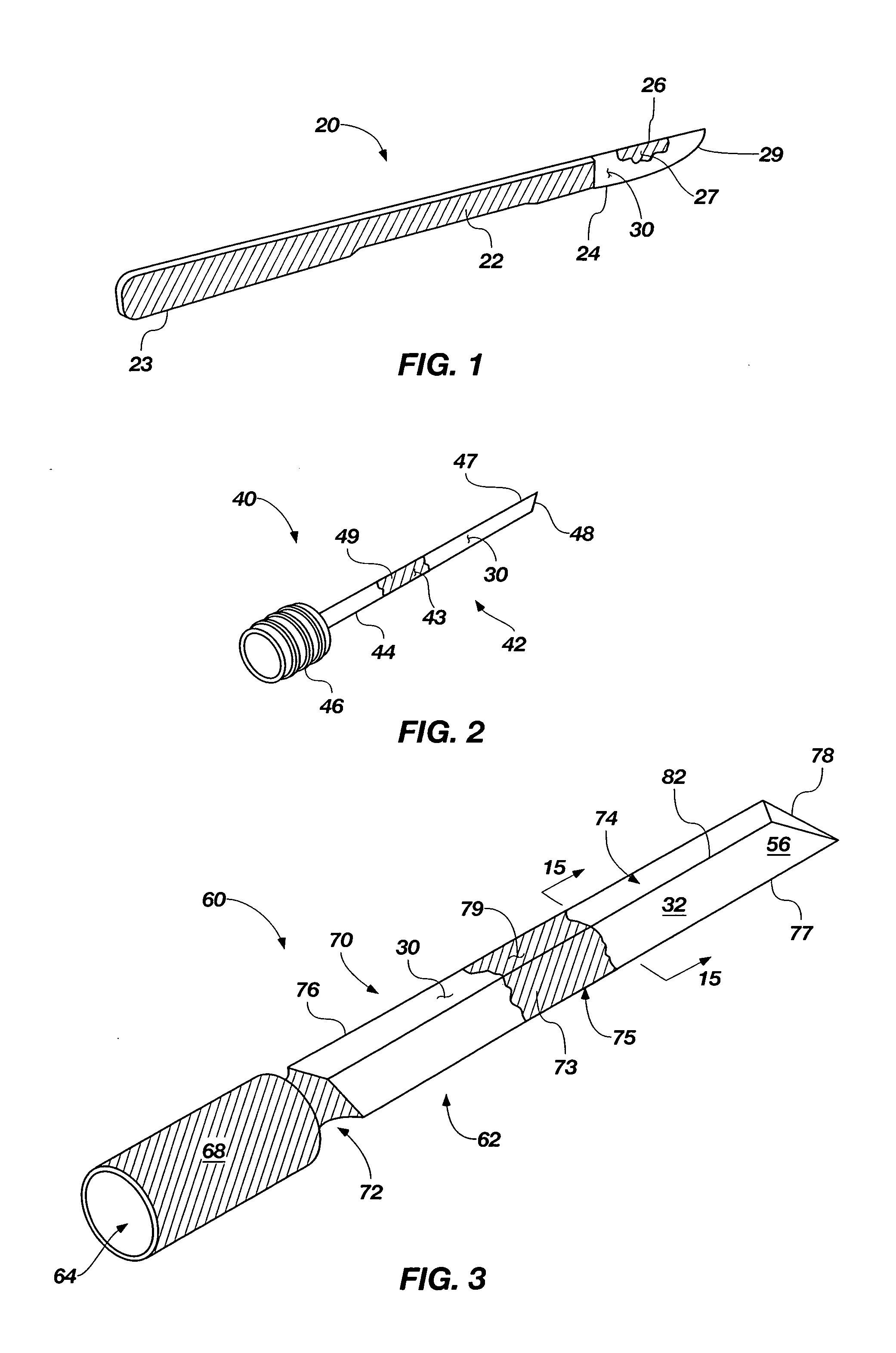

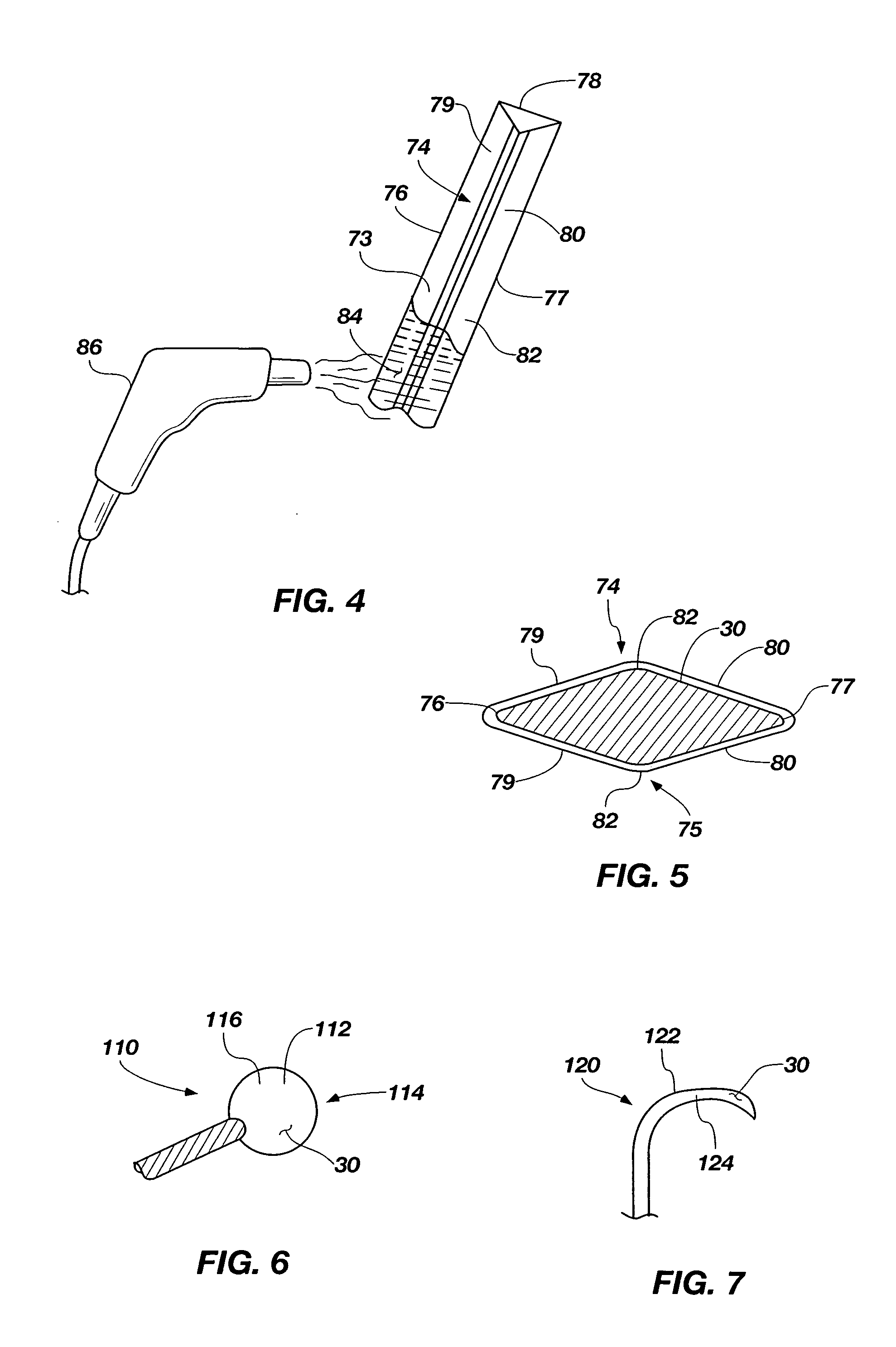

Silane coating for medical devices and associated methods

ActiveUS20120029514A1Low costGood non-stickIncision instrumentsSurgical needlesSilanesTitanium metal

A titanium electrosurgical instrument, such as a scalpel (20), and electrosurgical devices, e.g., needle (40), and Bovie tips (40), are provided with a silane coating (30) directly against the solid titanium metal (26, 43, 73) of the body tissue-contacting distal ends (24, 47, 70) thereof whereby to impart advantageous non-stick properties thereto.

Owner:ORGANIC CAUTERY

Fluororesin powder liquid dispersion capable of forming thick coatings

InactiveCN1302317AInhibit sheddingImprove corrosion resistanceAnti-corrosive paintsOrganic solventDyne

A fluororesin powder liquid dispersion comprising heat-flowable fluororesin powder, liquid dispersion medium having a surface tension of not more than 45 dyne / cm, and colloidal particles having an average particle size of not more than 1 [mu]m provides thick corrosion resistant coated films. Preferred colloidal particles for the dispersion are particles of polyether sulfone (PES) which are added in an aqueous dispersion containing an organic solvent and a water-miscible solvent. An aqueous dispersion of PES colloidal particles having an average particle size of not more than 1 [mu]m is preferably prepared by (1) dissolving PES in an organic solvent capable of solubilizing PES; (2) combining the dissolved PES with a water-miscible solvent which is capable of being dissolved in the organic solvent; and (3) combining water in which there is a dissolved surfactant with the dissolved PES.

Owner:DUPONT MITSUI FLUOROCHEMICALS CO LTD

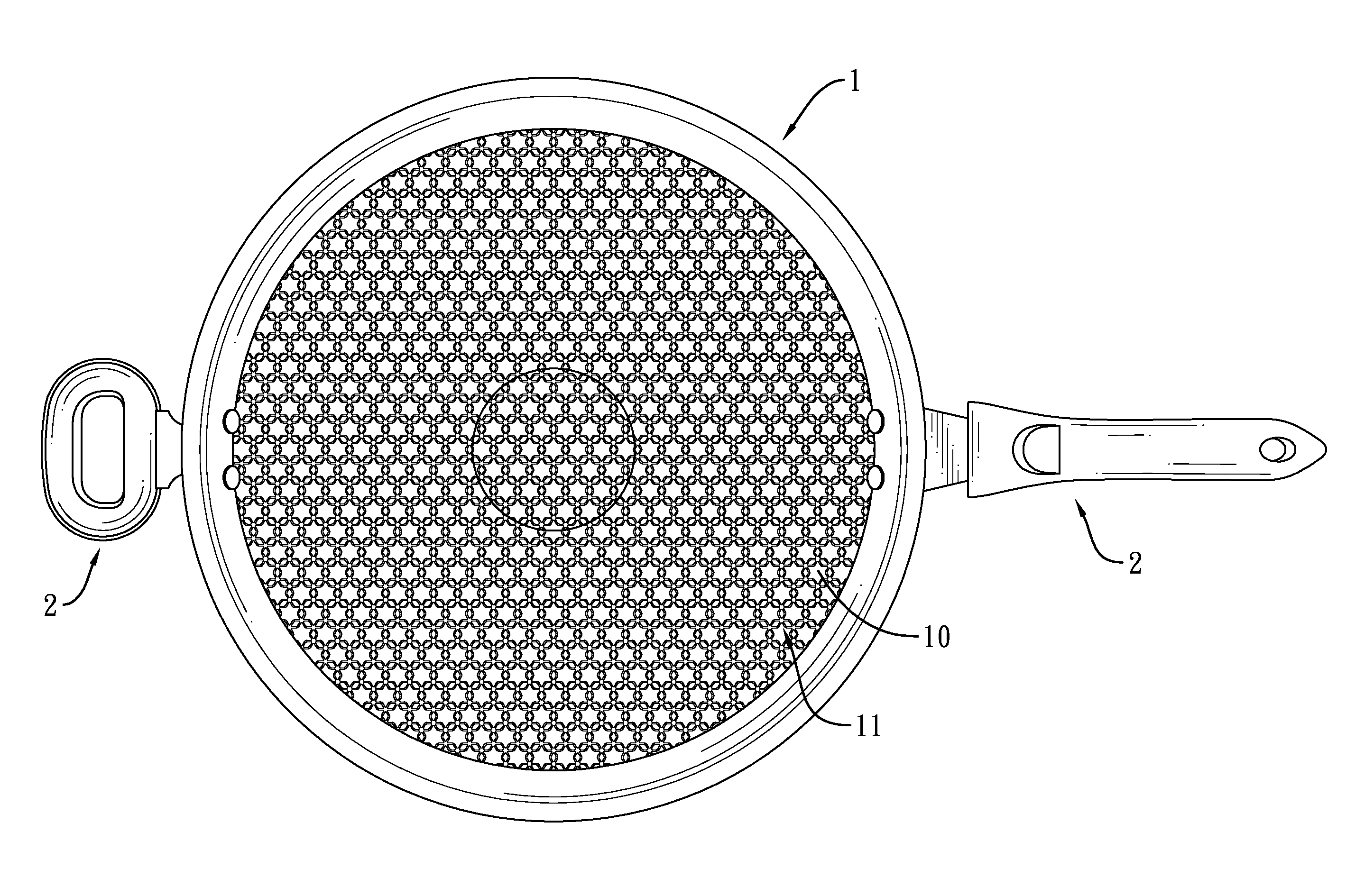

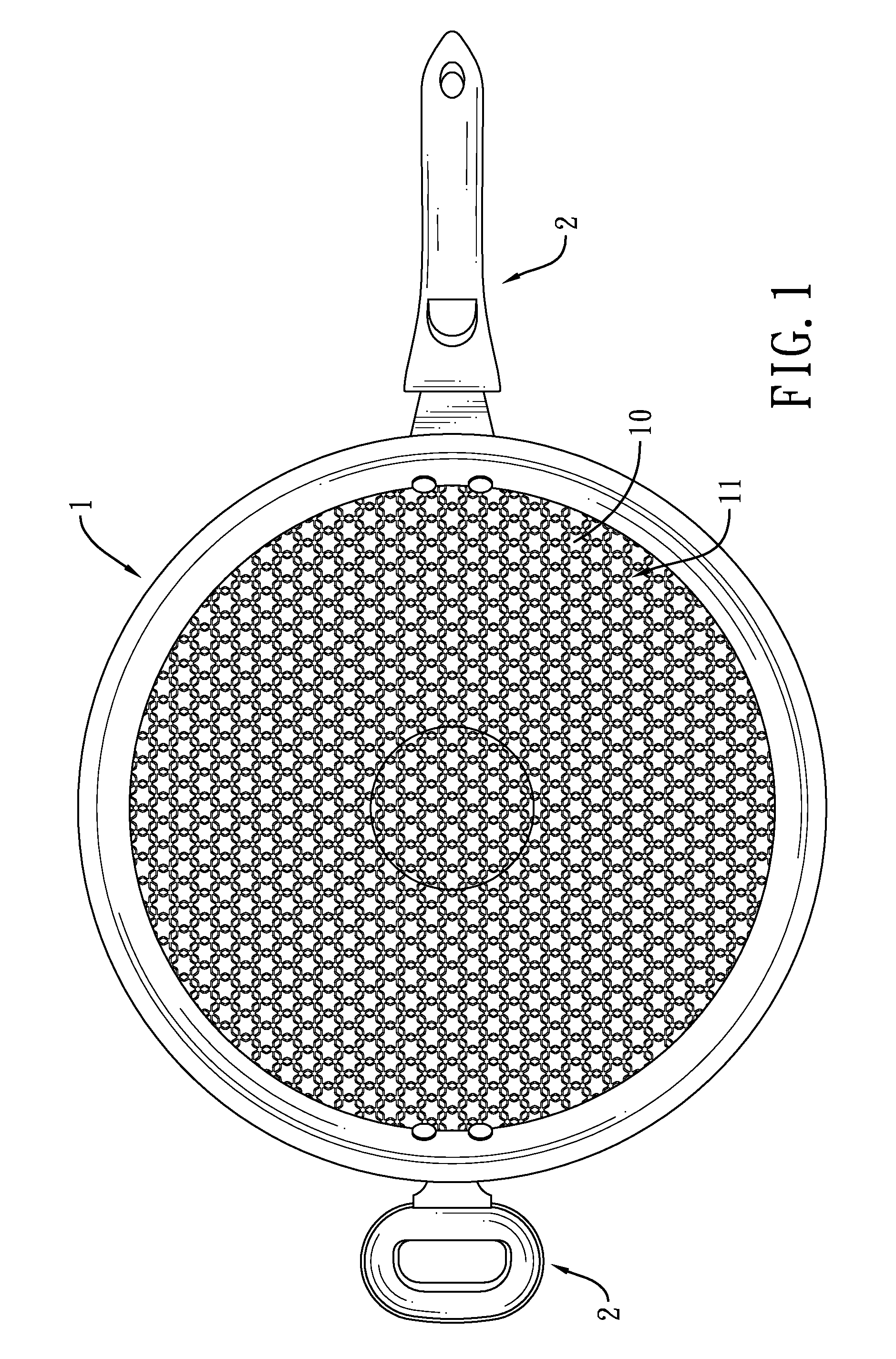

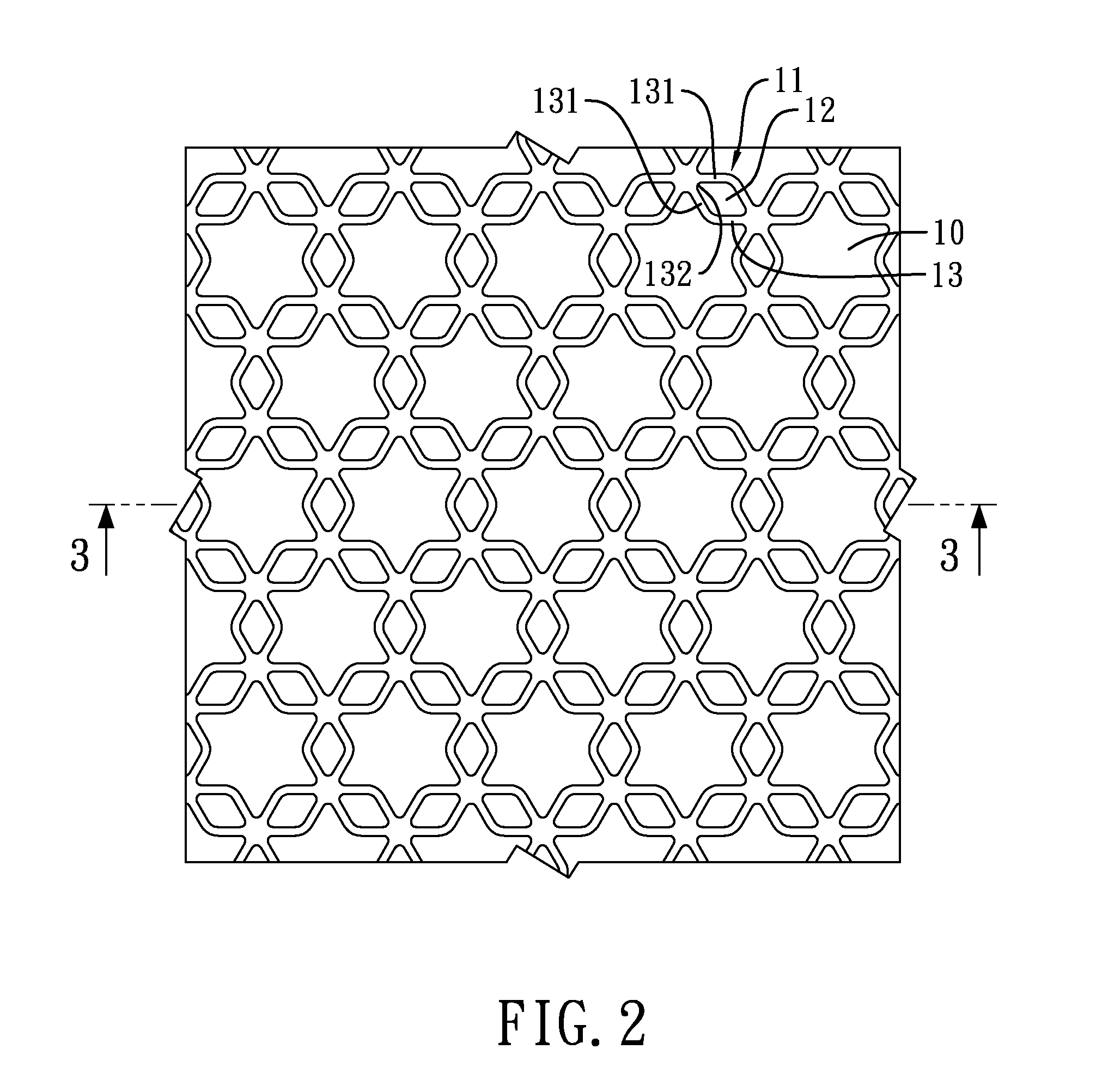

Non-stick cookware

InactiveUS20140061205A1Easy to cleanReduce contact areaCooking vesselsBaking vesselsCookerEngineering

Owner:CHIU TE MING

Oleophobic and hydrophobic waterborne paint and manufacturing and spraying method thereof

The invention discloses a waterborne paint and a manufacturing and spraying method thereof. The invention aims to provide a safe, environment-friendly, oleophobic and hydrophobic waterborne paint anda manufacturing and spraying method thereof. The oleophobic and hydrophobic waterborne paint comprises the following components by mass: 5-20 parts of nano-silica, 5-10 parts of modified organic silicon resin; 5-20 parts of modified organic polysilazane; 5-10 parts of polysiloxane; 1-5 parts of a titanate coupling agent; 5-20 parts of nano-alumina; 5-20 parts of nano-zirconia; 1-10 parts of a siloxane coupling agent; 0.1-1 part of a leveling agent; 0.1-1 part of a wetting agent; 0.5-5 parts of a film-forming assistant; 0.1-3 parts of a non-stick assistant; 0.5-5 parts of a dispersant; 0.1-2 parts of a defoaming agent; 1-10 parts of a curing agent; and 10-30 parts of a diluents. The invention is mainly used for paint production.

Owner:GUANGDONG FRUTO NEW MATERIALS CO LTD

Inorganic ceramic non-stick pan composite coating and manufacturing method thereof

InactiveCN109321007AImprove hydrophobicityGood non-stickCooking-vessel materialsLiquid surface applicatorsCeramic coatingMetallurgy

The invention discloses an inorganic ceramic non-stick pan composite coating and a manufacturing method thereof. The inorganic ceramic non-stick pan composite coating is prepared from a bottom coatingand a surface coating, wherein the bottom coating is an inorganic ceramic coating which is 15 to 50 mum in thickness, is more than or equal to 1.2 and is less than or equal to 3.5 mum in roughness Ra; the surface coating is an inorganic ceramic coating which is 3 to 10 mum in thickness, and is more than or equal to 0.6 and is less than 1.2 mum in roughness Ra. By adopting the inorganic ceramic non-stick pan composite coating, the long-effect non-stick property of the non-stick pan is improved effectively. In particular, when the surface film is slightly damaged, high non-stick property can bekept.

Owner:浙江宇达新材料有限公司

Nano-composite coating with low surface energy and preparation method thereof

The invention discloses a nano-composite coating with low surface energy and a preparation method thereof. The nano-composite coating consists of a transition layer and a surface layer, wherein the thickness of the transition layer is between 2 and 200 mu m, and the transition layer consists of more than one layer of mixture of bulbs, clubs and flakes; and the thickness of the surface layer is between 2 and 40 mu m, and the surface layer consists of a reticulated silica glassy substance. The method comprises the steps of: performing cleaning and roughing treatment on the surface of a substrate first, then mixing the bulbs, the clubs, the flakes, a slurry forming agent and a solvent to obtain slurry of the transition layer, using the slurry of the transition layer to coat the substrate, placing the coated substrate at a temperature of between 180 and 250 DEG C to obtain the transition layer, then mixing organosiloxane water solution and alcohol solution of ethyl orthosilicate to obtain hydrolytic polycondensation reaction solution first, then dripping acid into the hydrolytic polycondensation reaction solution to obtain coating solution of the surface layer, coating the substrate coated with the transition layer by the coating solution of the surface layer, and then placing the substrate at a temperature of between 180 and 250 DEG C to obtain the nano-composite coating with low surface energy. The coating has the characteristics of low surface energy, high density, adjustable hardness, good flexibility and strong adhesion force.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-performance air filter paper and preparation method and application thereof

InactiveCN107245908AImprove temperature resistanceGood non-stickInorganic fibres/flakesPaper/cardboardCarbon fibersAir filter

The invention provides an air filter paper, comprising base paper and an impregnating agent for impregnating the base paper, the fibers used in the base paper include 20-40 parts of high-density cotton linter pulp and 5-5 parts of polypropylene fiber in parts by weight. 12 parts, 20-40 parts of alkali-free glass fiber chopped strands, 3-8 parts of ceramic fiber and 10-20 parts of carbon fiber, 0.1-4 parts of amphoteric polyacrylamide used in the preparation of base paper, 0.2 parts of modified starch light calcium carbonate ‑0.8 part, 0.5‑5 part of polyethylene oxide with a molecular weight of 2.5 million to 3 million, and 0‑0.2 part of a defoamer; the impregnating agent includes: modified phenolic resin; modified nano-titanium dioxide polytetrafluoroethylene emulsion ; Stearic acid modified liquid. In the present invention, the water resistance, temperature resistance, good non-stickiness, acid and alkali resistance, corrosion resistance, abrasion resistance, strength and deformation resistance of the obtained air filter paper are greatly improved through the formulation of the base paper and three times of impregnation. It can be blown back to remove dust, can be cleaned and used repeatedly, and has increased hydrophobic and lipophilic functions, and can be used for oil-water separation.

Owner:杭州特种纸业有限公司

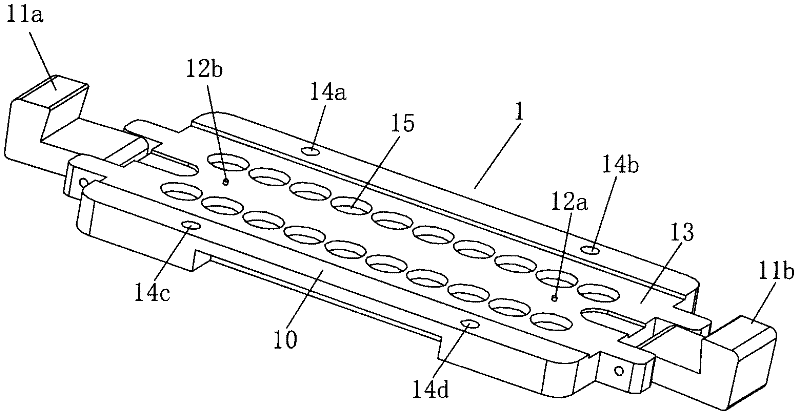

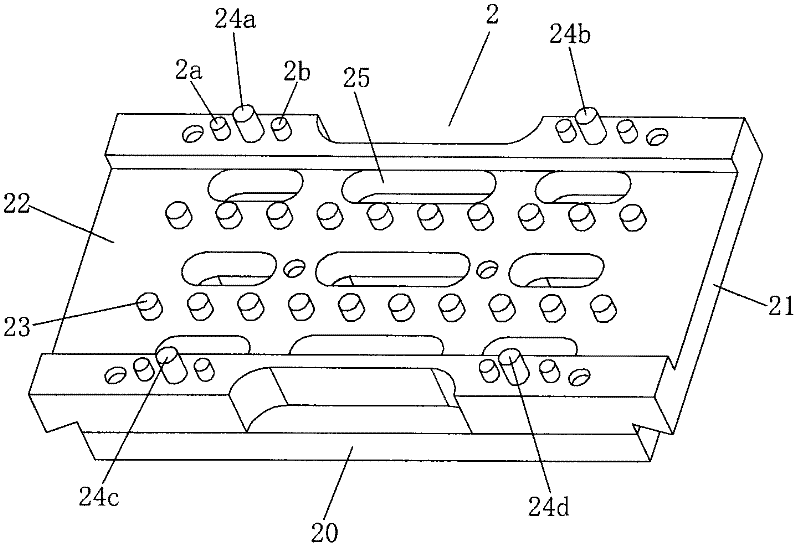

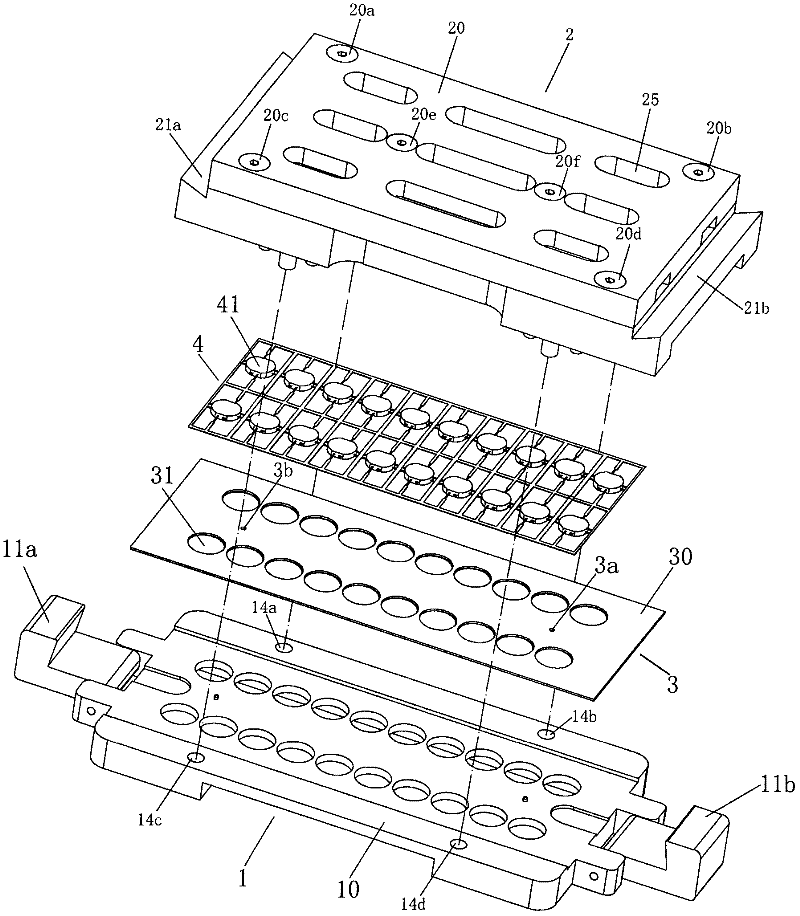

A jig for making led silicone lens

InactiveCN102299217ANot easy to damageImprove cleanliness levelSemiconductor devicesEngineeringSilica gel

The invention discloses a clamp for manufacturing a light emitting diode (LED) silica-gel lens, which comprises an upper pressure plate and a lower press plate, wherein the upper press plate and the lower press plate are in mutually independent two-piece type split structures, a mold strip and a support frame strip are sequentially placed between the upper press plate and the lower press plate from bottom to top, the upper press plate is positioned on the lower press plate through a positioning post and a positioning hole , both sides of the upper press plate are respectively hinged with fixed clamp buckles, the back side of the upper press plate is provided with fixed grooves matched with the fixed clamp buckles, and the upper press plate and the lower press plate are tightly clamped in the fixed grooves through the fixed clamp buckles so that the upper press plate and the lower press plate are tightly locked. In the technical scheme of the clamp, the completely independent two-piecetype structure is adopted, the elastic clamping is realized through the fixed clamp buckles arranged on the lower press plate and the fixed grooves arranged on the upper press plate, no dust is generated in the whole manufacture process, in addition, the clamping and the dismounting are convenient, the time consumption is short, accessories are not easy to damage, the dustless degrade of an LED encapsulation workshop can be obviously improved, the production efficiency is improved, and the production cost is reduced.

Owner:SHENZHEN GLORY SKY OPTOELECTRONICS CO LTD

Intelligent environment-friendly green plant decoration wall for indoor decoration

InactiveCN110692389AChange distancePromote healthy growthSelf-acting watering devicesCultivating equipmentsAgricultural engineeringStructural engineering

The invention relates to the technical field of indoor decoration design and discloses an intelligent environment-friendly green plant decoration wall for indoor decoration. The decoration wall comprises a wallboard and multiple supporting plates for supporting bonsais and further comprises an irrigation component positioned on the wallboard and a water receiving disc positioned at the lower end of the wallboard, multiple fixing holes for embedding of the bonsais are formed in each supporting plate, a supporting rod with extending direction perpendicular to the surface of the wallboard is arranged on each of two sides of the lower end of the wallboard, an upright upwards extending along the vertical direction is arranged at each of two ends of each supporting rod, a through hole for the corresponding upright to penetrate is formed in each supporting plate, and an adjusting member for fixing the corresponding supporting plate at different height positions of each upright is arranged between the upright and the corresponding supporting plate. Each supporting plate moves up and down along the corresponding upright; after each supporting plate moves to a proper position, the supportingplate can be fixed on the corresponding upright through the corresponding adjusting member, then the bonsais of green plants can be embedded through the fixing holes in each supporting plate, and atthe moment, a distance between each two adjacent supporting plates can be changed according to height of different green plants after growing.

Owner:绍兴市亮戈装饰设计工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com