Zisha ware ceramal non-cooking fume non-stick pan and preparation method thereof

A technology of purple sand ceramics and no oil fume, which is applied in applications, kitchen utensils, and special materials for cooking utensils. It can solve problems such as easy decomposition, high temperature resistance, and non-stick layer peeling off of pots, and achieve human safety, non-toxic, and non-stick properties. Excellent effect of improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

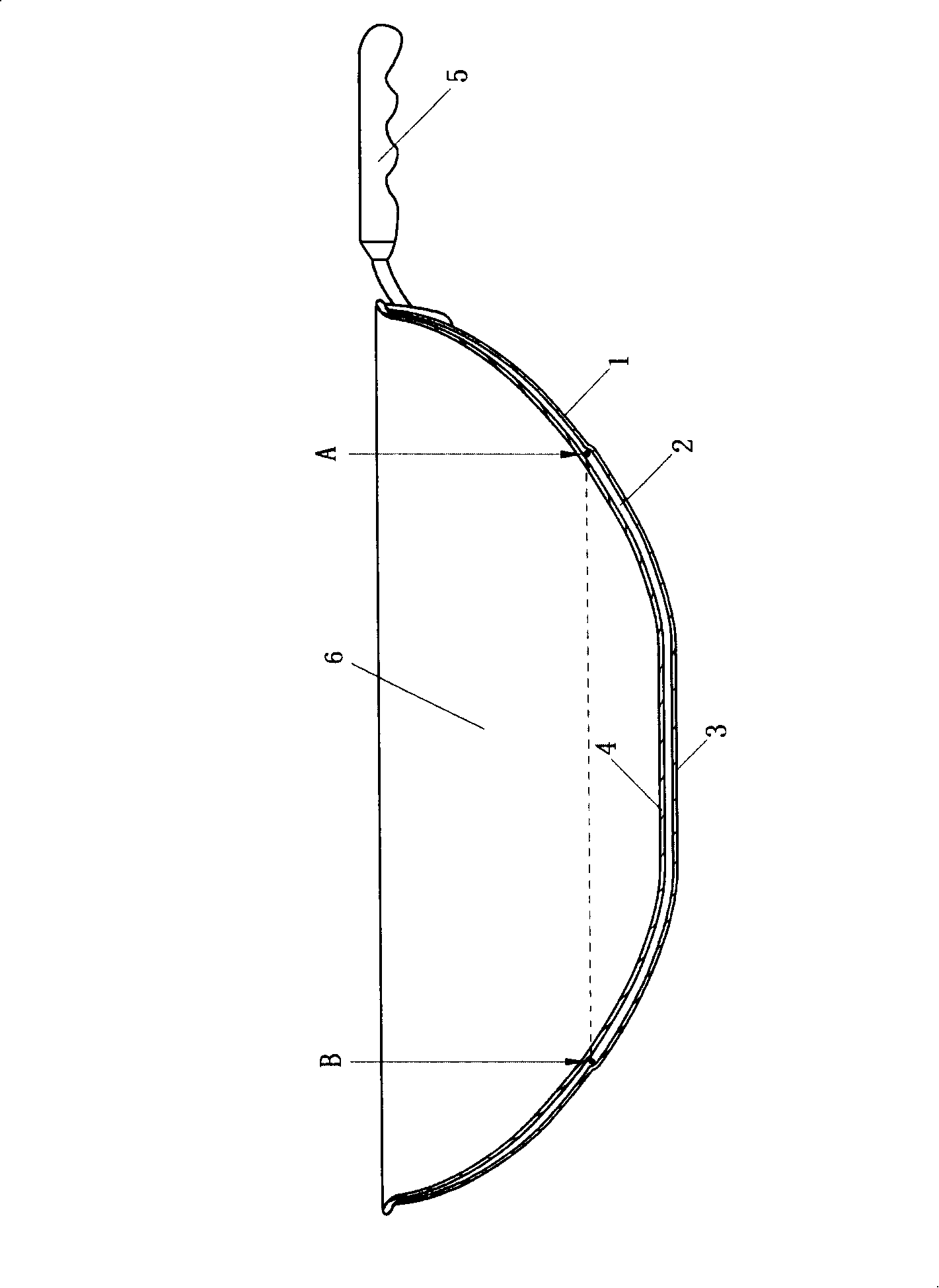

[0033] like figure 1 The shown purple sand ceramic alloy oil-smoke-free non-stick pan includes a pan body 6 and a pan handle 5, and the pan body base is made of aluminum alloy. A ceramic crystal layer 1 is provided on the outer surface of the pot base 2, the thickness of the ceramic crystal layer 1 is 20 μm, and the surface Chrome hardness of the ceramic crystal layer 1 is HRC80. A purple sand ceramic layer 4 is sintered on the inner surface of the pot base 2 . The thickness of the purple sand ceramic layer 4 is 18 μm, and the Chrome hardness of the surface of the purple sand ceramic layer 4 is HRC80. In order to increase the contact area between the pot and the heat source and save energy, a flat portion 3 with a diameter of 160 mm is provided at the bottom of the pot. The diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com