Nonstick cookware and manufacturing method thereof

A production method and technology for cooking utensils, which are applied to household utensils, kitchen utensils, cooking utensils, etc., can solve problems such as increased battery corrosion, poor non-stick effect, and reduced oxide layer adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

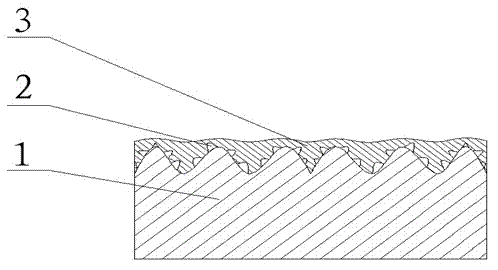

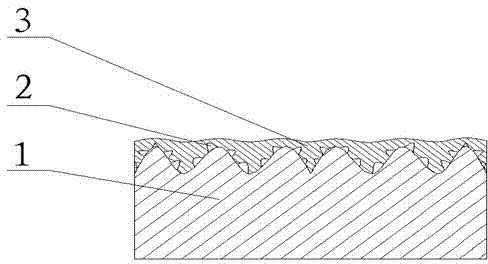

[0040] Example 1: The base material of the pot body is an aluminum plate, and the silk thread used for spraying is a medicinal wire material containing nano-sized particles, and the medicinal wire contains stainless steel particles. This method is used to obtain an aluminum-nano, micron-particle stainless steel spray layer-non-stick wax The lotus leaf-like non-stick structure of the texture layer structure.

[0041] In this embodiment, step 5) after spraying, place it in a sintering channel at a temperature of 350° C. for sintering for 20 minutes to obtain a finished product.

[0042]In the above step 3), the method used for the spraying is supersonic flame spraying; the wire used for the spraying is the medicinal wire material containing nano-sized particles, and the nanoparticles wrapped in the medicinal wire material are sprayed into the inside of the pot. On uneven hills, or directly spray nano-sized particles, the spray angle is controlled at 30°.

[0043] In the above s...

Embodiment 2

[0045] Embodiment 2: The base material of the pot body is an aluminum plate, and the silk thread used for fusion spraying is a medicinal wire material containing nano-sized particles, and the medicinal wire contains inorganic non-metallic particles Al 3 o 2 , using this method to obtain aluminum-nano, micron particle inorganic non-metallic Al 3 o 2 Melting layer-non-stick waxy layer structure imitating lotus leaf non-stick structure.

[0046] In this embodiment, step 5) after spraying, place it in a sintering channel at a temperature of 440° C. for sintering for 5 minutes to obtain a finished product.

[0047] In the above step 3), the method used for spraying is powder spraying; the wire used for spraying is the medicinal wire material containing nano-sized particles, and the nanoparticles wrapped in the medicinal wire material are sprayed to the unevenness inside the pot body. On the small peaks, or directly spray nano-sized particles, the spray angle is controlled at 60...

Embodiment 3

[0050] Embodiment 3: The base material of the pot body is iron or stainless steel, and the silk thread used for spraying is the medicinal wire material containing nano-sized particles, and the medicinal wire contains stainless steel particles. This method is used to obtain aluminum-nanometer, micron particle stainless steel spray layer-not Sticky wax layer imitation lotus leaf non-stick structure.

[0051] In this embodiment, step 5) after spraying, place it in a sintering channel at a temperature of 420° C. for 10 minutes and sinter to obtain the finished product.

[0052] In the above step 3), the method used for the spraying is supersonic flame spraying; the wire used for the spraying is the medicinal wire material containing nano-sized particles, and the nanoparticles wrapped in the medicinal wire material are sprayed into the inside of the pot. On uneven hills, or directly spray nano-sized particles, the spray angle is controlled at 45°.

[0053] In the above step 4), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com