Dehydration and concentration gas circuit system and method for volatile organic compounds in atmosphere

A volatile organic compound and gas path system technology, applied in the field of water removal, can solve the problems of low recovery rate of high-boiling point components, affecting the authenticity and accuracy of data, and low content of high-boiling point components, etc. The effect of dividing loss, improving authenticity and accuracy, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

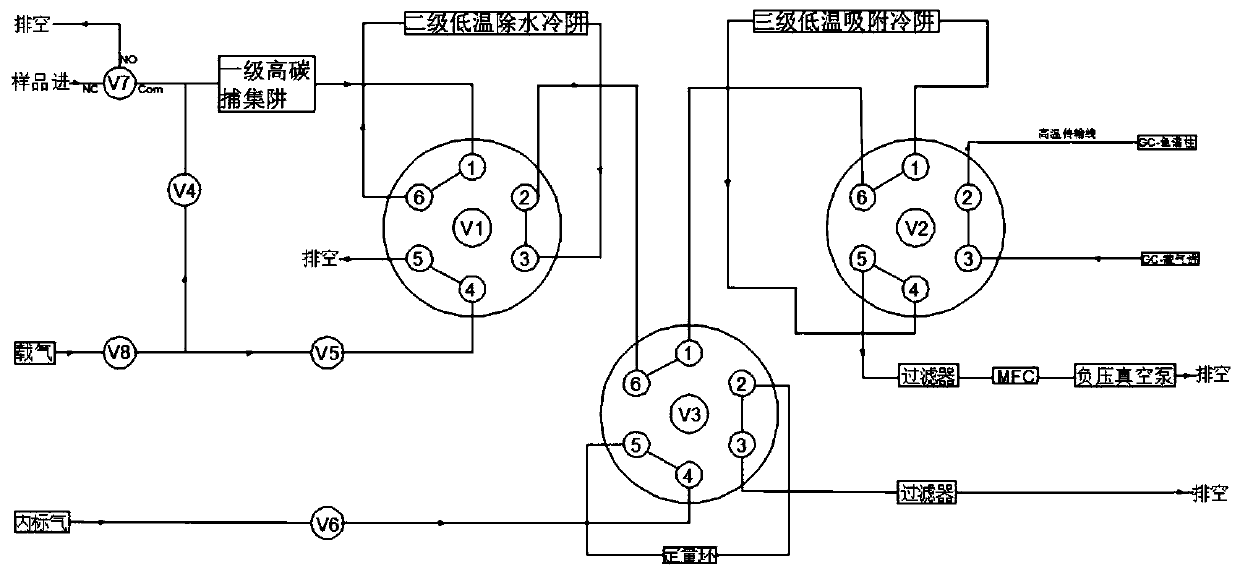

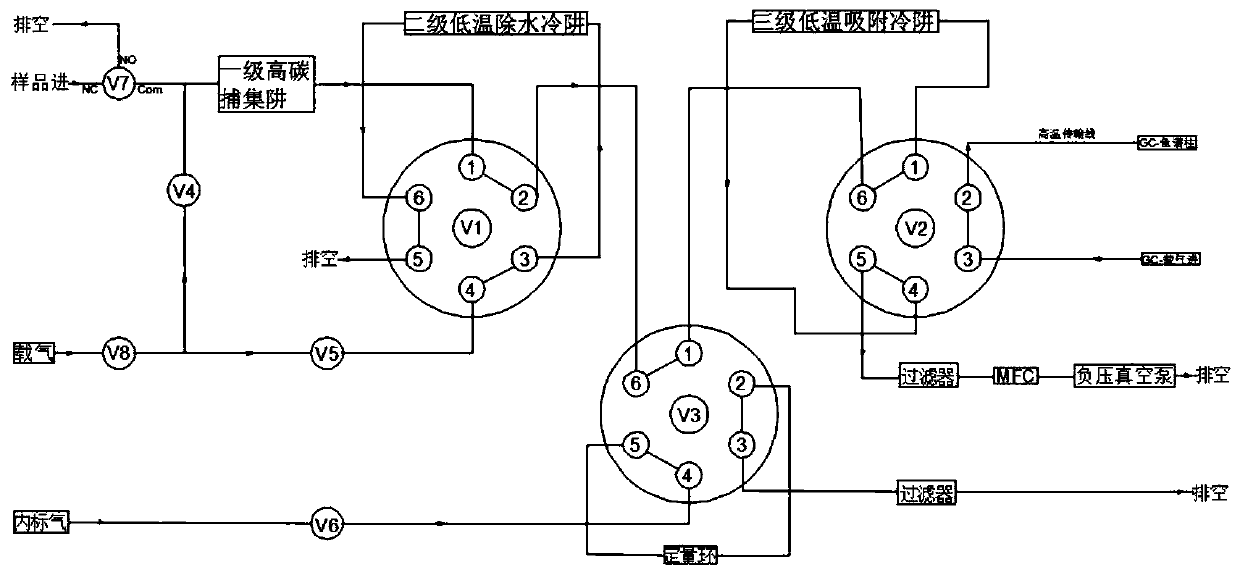

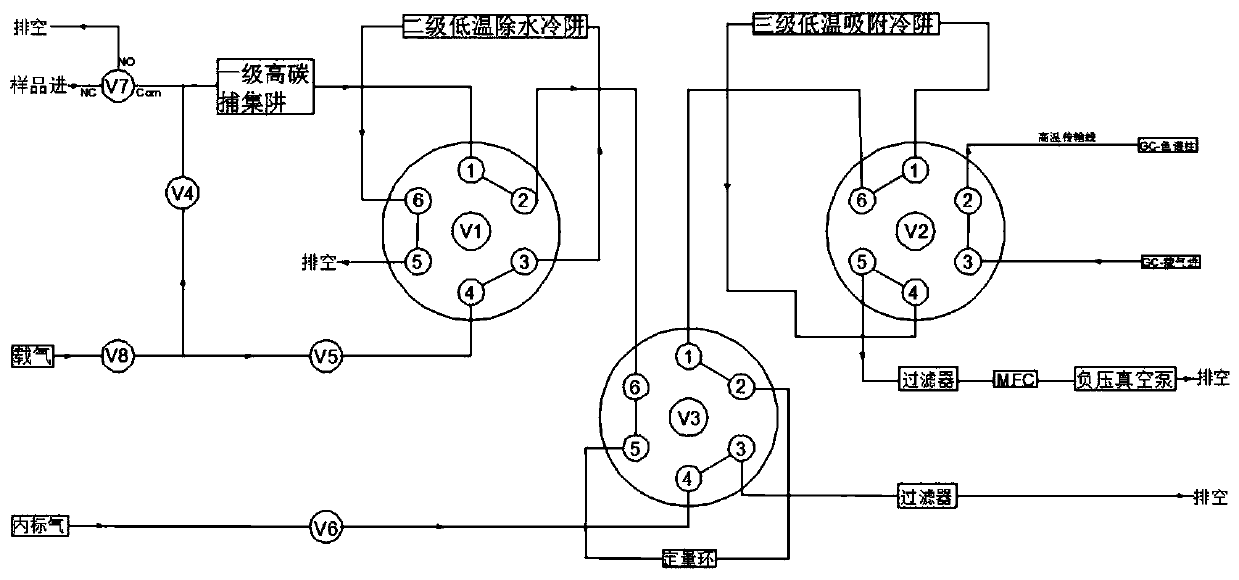

[0029] Embodiment one: if Figure 1-4As shown, a gas circuit system and method for removing water and concentrating volatile organic compounds in the atmosphere includes V1 water removal valve, V2 sample injection analysis valve, V3 internal standard addition valve, V4 on-off valve, V5 on-off valve, V6 on-off valve, V7 two-position three-way solenoid valve, V8 proportional valve, pressure sensor, first-level high-carbon trap, second-level low-temperature water removal cold trap, third-level low-temperature adsorption cold trap, negative pressure vacuum pump, MFC mass flow controller, V1 water removal Valve, V2 sample injection analysis valve, V3 internal standard addition valve are six-way valves, V4 on-off valve, V5 on-off valve, V6 on-off valve are two normally closed on-off valves, V7 two-position three-way solenoid valve NC (normally closed) terminal It is connected with the external sample inlet through pipe fittings. The NO (normally open) end of the V7 two-position thre...

Embodiment 2

[0042] Embodiment two: if Figure 1-4 As shown, a gas circuit system and method for removing water and concentrating volatile organic compounds in the atmosphere includes V1 water removal valve, V2 sample injection analysis valve, V3 internal standard addition valve, V4 on-off valve, V5 on-off valve, V6 on-off valve, V7 two-position three-way solenoid valve, V8 proportional valve, pressure sensor, first-level high-carbon trap, second-level low-temperature dewatering cold trap, third-level low-temperature adsorption cold trap, fourth-level cryofocusing trap, negative pressure vacuum pump, MFC mass flow Controller, V1 water removal valve, V2 sample injection analysis valve, V3 internal standard addition valve are six-way valves, V4 on-off valve, V5 on-off valve, V6 on-off valve are two normally closed on-off valves, V7 two-position three-way solenoid valve The NC (normally closed) end is connected with the external sample inlet through a pipe fitting, the NO (normally open) end ...

Embodiment 3

[0054] Embodiment three: as Figure 5-6 As shown, a gas circuit system and method for dewatering and concentrating volatile organic compounds in the atmosphere, including V1 ten-way valve, V2 six-way valve, V3 two-position three-way solenoid valve, V4 two-way switch valve, one-stage high-carbon capture Collecting trap, two-stage low-temperature water removal cold trap, three-stage low-temperature adsorption cold trap, negative pressure vacuum pump, MFC mass flow controller, the sample inlet is connected to the NO (normally open) port of the V3 two-position three-way solenoid valve, and the carrier gas is 1 It is connected with the NC (normally closed) port of the V3 two-position three-way solenoid valve, the Com port of the V3 two-position three-way solenoid valve is connected with the first valve port of the V1 ten-way valve, and the internal standard gas inlet is connected with the V4 two-way switch The valve is connected, the end of the V4 two-way switch valve away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com