Manganese additive for aluminum alloy and preparing method of manganese additive

A technology of manganese additives and aluminum alloys, which is applied in the field of manganese additives for aluminum alloys and its preparation, can solve the problems of long melting time, high melting temperature, and high production cost, and achieve short melting time, low melting temperature, and less impurity content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

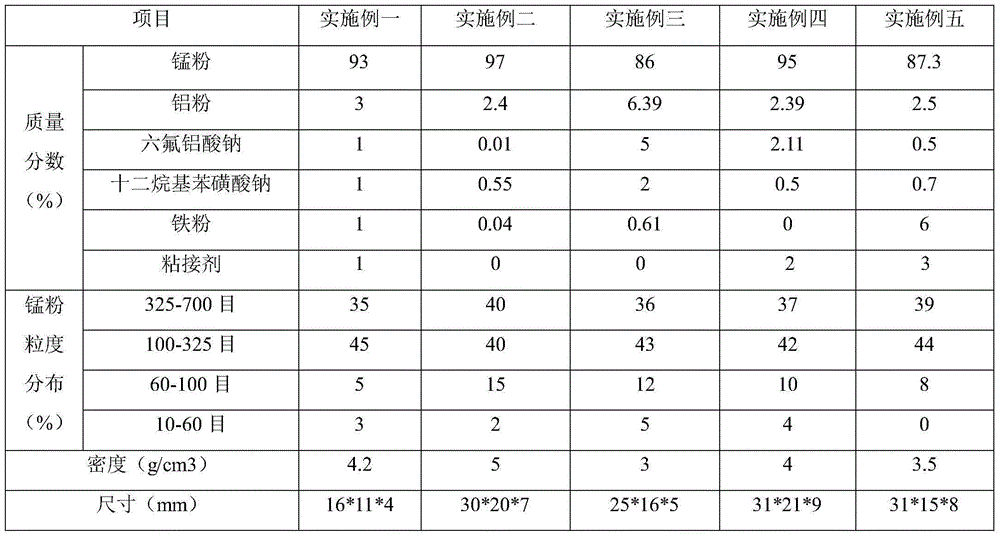

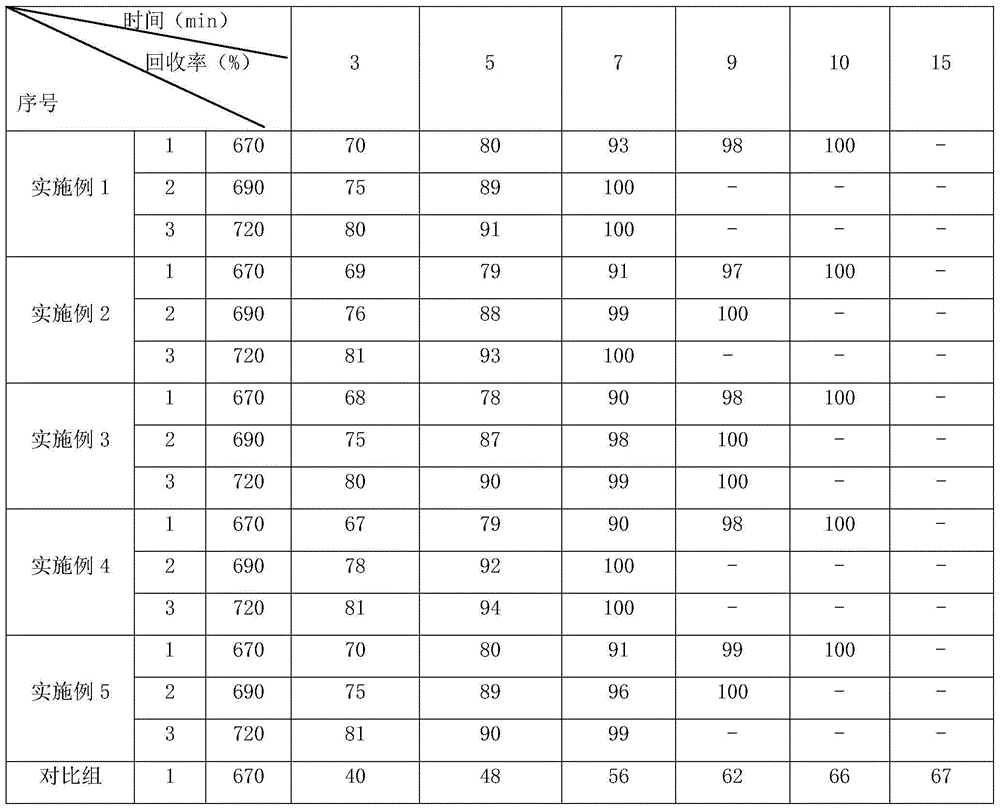

[0033] The manganese additive for aluminum alloy of the present invention is in the shape of a cake, of course it is also possible to make a spherical shape, an ellipsoid, etc. with a corresponding density. The raw material components of the manganese additive include manganese powder, aluminum powder, flux, surfactant, iron powder and polyanionic cellulose binder.

[0034] The inventor has proved through many experiments that the above-mentioned surfactants can be used regardless of types, and can be stearic acid, sodium dodecylbenzenesulfonate, fatty acid glycerides, polysorbate, etc. The surface active agents in the following examples Sodium dodecylbenzenesulfonate is selected as the active agent; the above-mentioned flux can be sodium hexafluoroaluminate, sodium chloride, potassium chloride, sodium fluoride, potassium fluoride, sodium sulfate, sodium carbonate, etc., the following examples The flux in the selection of sodium hexafluoroaluminate.

[0035] The mass fraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com