Method for preparing liquid silicone rubber for LCD screen protection film

A liquid silicone rubber, screen protector technology, applied in film/sheet adhesives, adhesives, adhesive additives, etc., can solve the problems of incompatibility, troublesome replacement, and the performance of double 85 resistance cannot meet the requirements. Improve the performance of double 85 resistance, simple production process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The embodiment of the present invention provides a preparation method of liquid silicone rubber for LCD screen protective film, which comprises the following steps:

[0012] S01: Mix vinyl silicone oil, methyl vinyl raw rubber and methyl vinyl MQ silicone resin with a mass ratio of (4-8):(1-5):(0.5-5) to obtain base rubber;

[0013] S02: Take 100 parts by mass of the base rubber, add 0.005 to 0.05 parts by mass of catalyst, and stir to obtain the mixed rubber I;

[0014] S03: Take 100 parts by mass of the base rubber, add 1-5 parts by mass of a crosslinking agent, 0.0001-0.01 parts by mass of an inhibitor, and 1-5 parts by mass of a tackifier, and stir to obtain Mixed Rubber II;

[0015] S04: mix rubber I, rubber II, and a solvent in a mass ratio of 1:(0.8-1.2):(1-5), apply it on a base material and cure it, and obtain the liquid silicone rubber for LCD screen protection film.

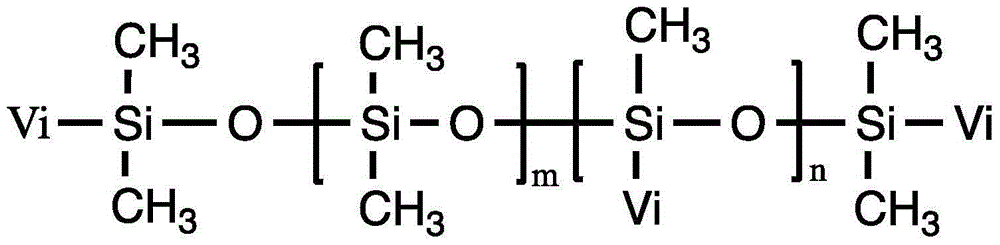

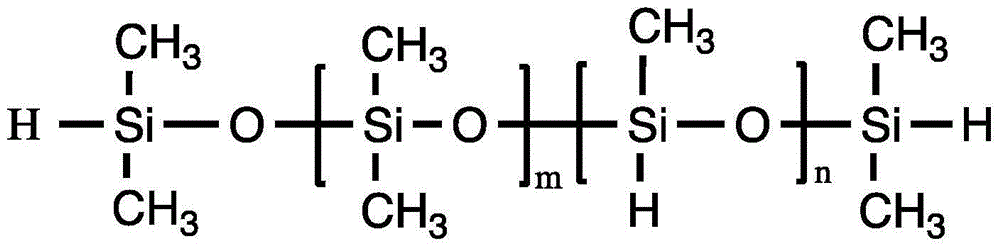

[0016] Specifically, in step S01, vinyl silicone oil, methyl vinyl raw rubber and methyl vi...

Embodiment 1

[0035] Take 100 parts of base rubber, wherein the content of methyl vinyl MQ silicone resin is 10%, add 0.01 part of catalyst, stir well, and use it as rubber mixture I; take another 100 parts of base rubber, wherein the content of methyl vinyl MQ silicone resin is 10% %, add 5 parts of cross-linking agent, add 0.0005 parts of inhibitor, add 2 parts of tackifier, stir evenly, and use it as rubber compound II; after mixing rubber compound I, compound rubber II and solvent at a mass ratio of 1:1:1 Apply to PET substrate and cure.

Embodiment 2

[0037] Take 100 parts of base rubber, wherein the content of methyl vinyl MQ silicone resin is 20%, add 0.01 part of catalyst, stir well, and use it as rubber mixture I; take another 100 parts of base rubber, wherein the content of methyl vinyl MQ silicone resin is 20% %, add 5 parts of cross-linking agent, add 0.0005 parts of inhibitor, add 2 parts of tackifier, stir evenly, and use it as rubber compound II; after mixing rubber compound I, compound rubber II and solvent at a mass ratio of 1:1:1 Apply to PET substrate and cure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com