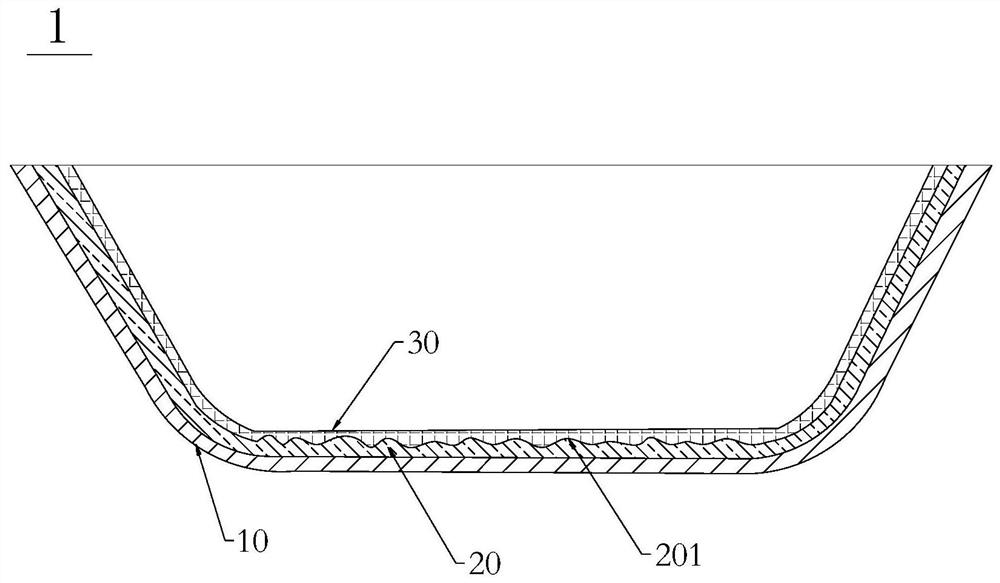

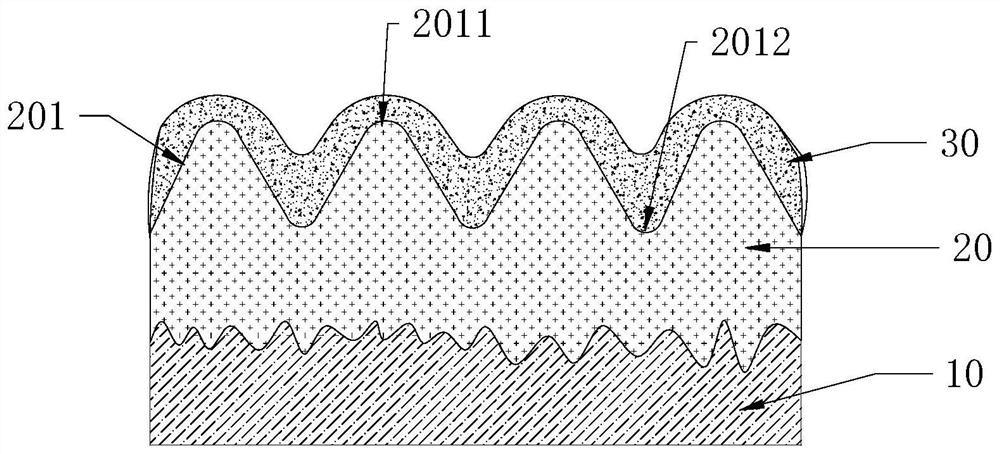

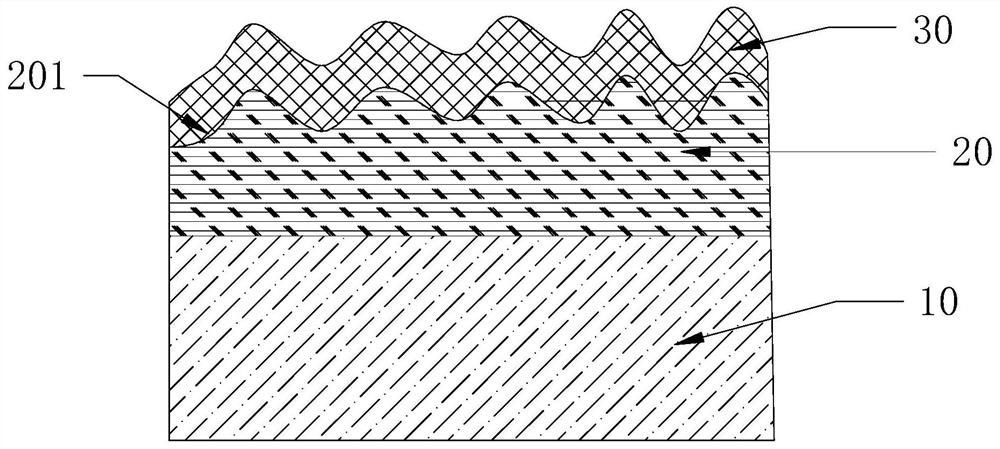

Container body and cooking utensil

A container body and substrate technology, which is applied to special materials for cooking utensils, cooking utensils, household appliances, etc., can solve the problems of short service life, reduced non-stickiness, difficult non-stick effect, etc., achieve strong adhesion, improve scratch resistance , enhance the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the purpose, technical solution and advantages of this application clearer, the technical solution of this application will be clearly and completely described below in conjunction with the drawings and embodiments of this application. Obviously, the described embodiments are part of the embodiments of this application , but not all examples. All other embodiments obtained by those skilled in the art on the basis of the technical solutions and given embodiments provided in this application without creative efforts shall fall within the scope of protection of this application. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased from the market.

[0064] Neither the endpoints nor any values of the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com