Physical non-stick pan with concave-convex structure and preparation method thereof

A technology of concave-convex structure and non-stick pan, applied in the field of kitchen utensils, can solve the problems of wearing the physical non-stick layer and unable to achieve long-term non-stick, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

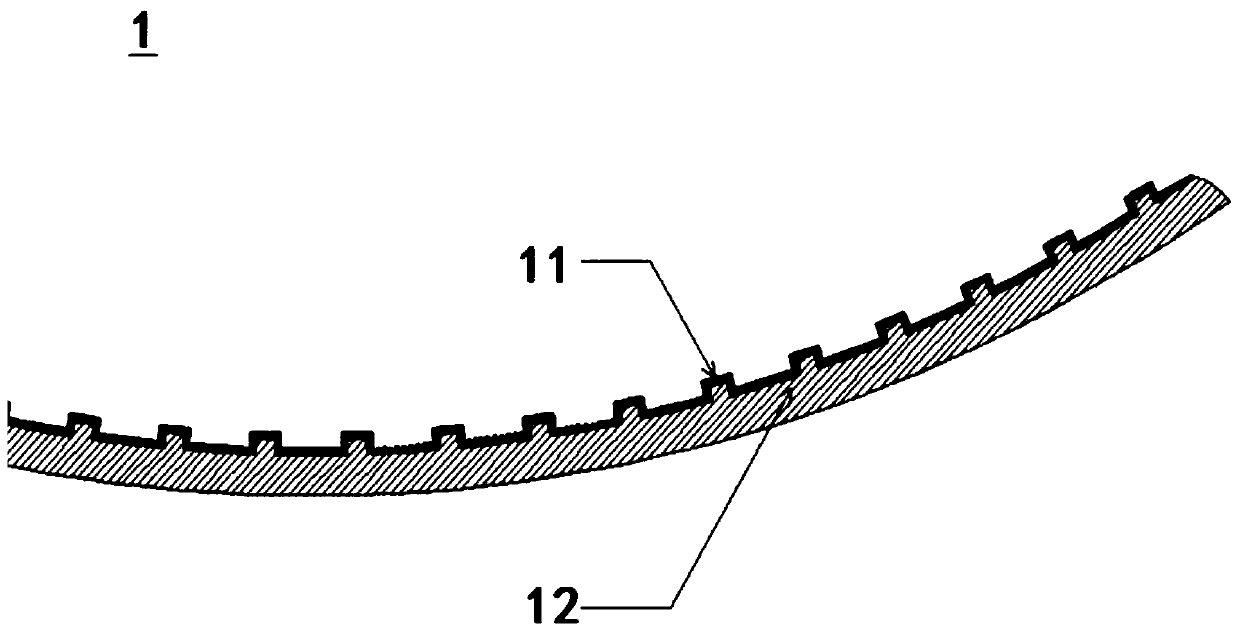

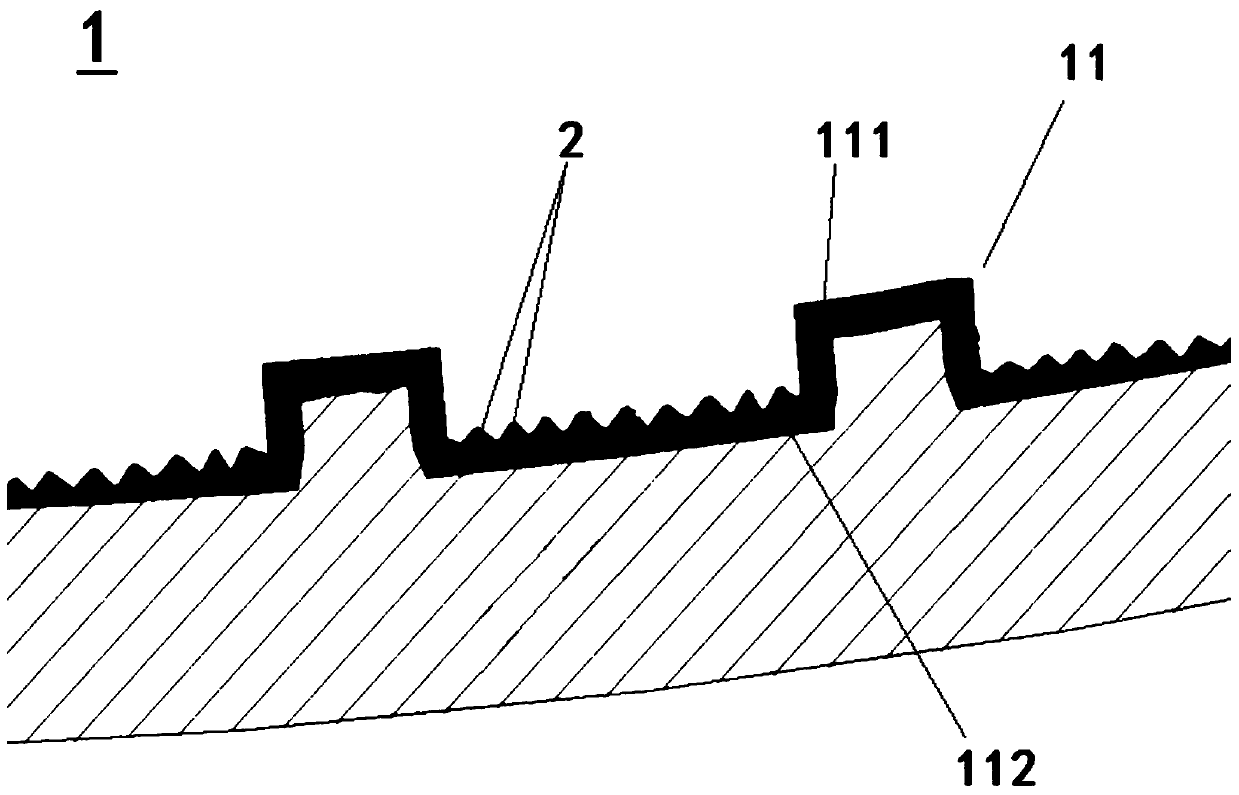

[0044] Referring to Fig. 1 to Fig. 1 of the accompanying drawings of the description of the present invention Figure 4 As shown, a physical non-stick pan with a concave-convex structure according to a preferred implementation of the present invention is illustrated. The types of non-stick pans include cooking pans, frying pans, frying pans, milk pans, etc. In this embodiment, the frying pan For example, its non-stick pan includes a pan body 1, the pan body 1 can be single-layer or multi-layer, when the pan body 1 is a single-layer material can be iron or stainless steel, the alloy elements in the stainless steel are Cr, Ni , Ti, Mn, N, Nb, Mo, Si, Cu and other elements, among which the main alloying element is Cr. For example figure 1 and figure 2 , The pot body 1 is a single layer, including the inner working layer 12. When the pot body 1 is multi-layered, the material can be iron or stainless steel or a composite material, but whether it is single-layer or multi-layer, ...

Embodiment 2

[0049] A method for making a non-stick pan described in Embodiment 1 is described, comprising the steps of:

[0050] (1) Production of the pot body 1: making the pot body 1 from the plate;

[0051] (2) Sandblasting process: choose abrasives, use compressed air as the power, and spray the abrasives on the surface of the pot body 1, so that the surface of the pot body 1 forms a rough surface of at least micron level;

[0052] (3) Surface treatment: harden and oxidize the surface of the pot body 1, and further form an oxide film with a nanoscale rough porous structure on the rough surface.

[0053] (4) Grinding process: perform mechanical grinding on the preset area of the inner surface of the pot body 1, remove the rough surface at the convex edge 111 in the concave-convex structure 11, and retain the rough surface on the concave area 112 in the concave-convex structure 11, and then The pot body 1 of the non-stick pan is obtained; since the top of the ribs is not provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com