High-temperature-resistant flame-retardant fiber for preparing firefighter uniform and preparation process of fiber

A technology of flame retardant fiber and preparation process, which is applied in the manufacture of fire retardant and flame retardant filaments, chemical characteristics of fibers, and rayon manufacturing, etc. problem, to achieve the effect of improving flame retardancy, improving flame retardant performance, and strengthening the degree of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

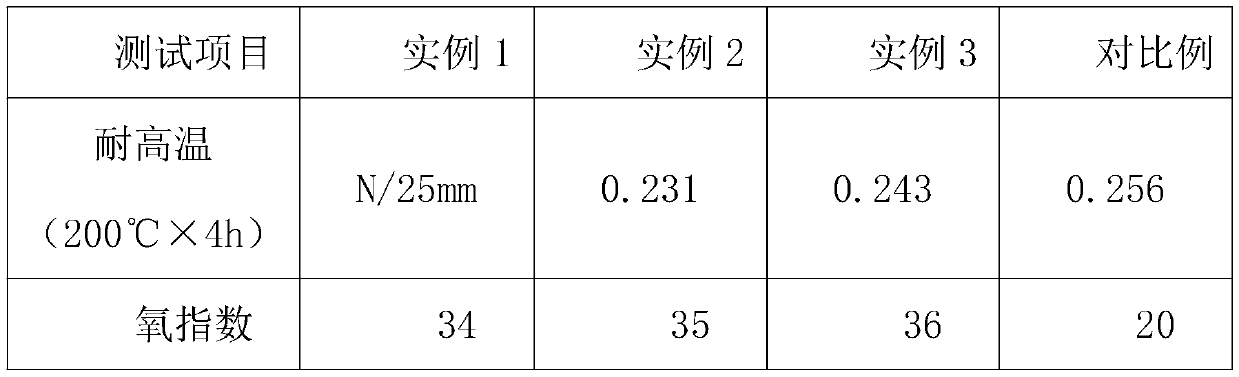

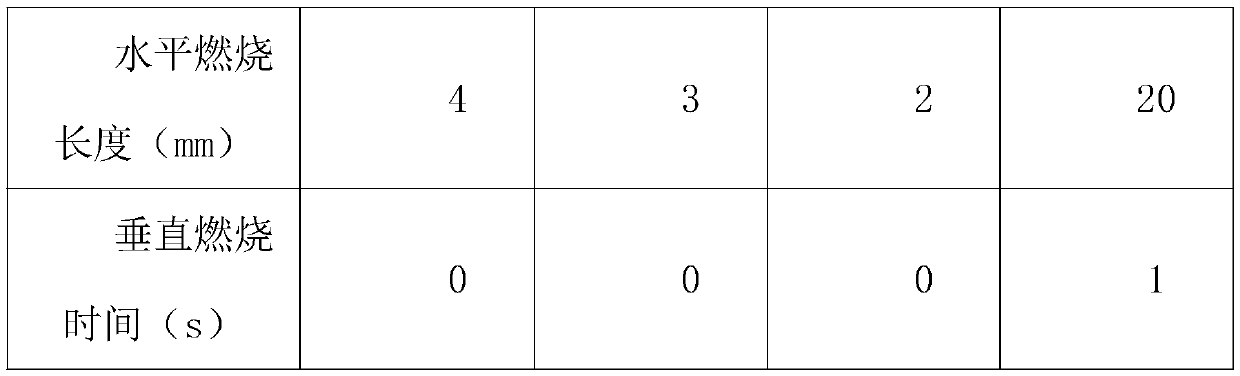

example 1

[0022] Weigh 55-60g of diatomite, grind it for 9 minutes, pass it through a 120-mesh sieve, collect the sieved powder, pour the sieved powder into 15mL of 3mol / L sodium hydroxide solution and 8mL of 2mol / L partial silicon Mix and stir for 1 hour at a temperature of 70°C in a mixer of sodium acid solution to obtain an activated sol; mix peanut oil, diethanolamine, and sodium ethylate in a reaction kettle at a mass ratio of 5:2:1, and place them in a reaction vessel at a temperature of 115°C. Stir and react for 32 minutes under nitrogen protection to obtain the amino product. Mix sodium alginate and absolute ethanol with a mass ratio of 5:1 and stir for 27 minutes to obtain a self-made suspension. Mix the amino product with deionized water at a mass ratio of 3:1 Mix and stir for 15 minutes to obtain an aqueous solution of ammonia, then mix the aqueous solution of ammonia and the self-made suspension at a volume ratio of 1:3, and stir and react for 3 hours at room temperature with...

example 2

[0024] Weigh 58g of diatomite and grind it for 10min to pass through a 120 mesh sieve, collect the sieved powder, pour the sieved powder into 16mL of sodium hydroxide solution with a concentration of 3mol / L and 9mL of sodium metasilicate with a concentration of 2mol / L In a solution mixer, mix and stir for 1.5h at a temperature of 80°C to obtain an activated sol; mix peanut oil, diethanolamine and sodium ethylate in a reaction kettle at a mass ratio of 5:2:1, and place them in a reaction kettle at a temperature of 117°C, Stir and react for 34 minutes under nitrogen protection to obtain the amino product. Mix sodium alginate and absolute ethanol with a mass ratio of 5:1 and stir for 29 minutes to obtain a self-made suspension. Mix the amino product with deionized water at a mass ratio of 3:1 Mix and stir for 17 minutes to obtain an aqueous solution of ammonia, then mix the aqueous solution of ammonia and the self-made suspension at a volume ratio of 1:3, and stir and react for 4 ...

example 3

[0026] Weigh 60g of diatomite and grind it for 11min to pass through a 120 mesh sieve, collect the sieved powder, pour the sieved powder into 18mL of sodium hydroxide solution with a concentration of 3mol / L and 10mL of sodium metasilicate with a concentration of 2mol / L In a solution mixer, mix and stir for 2 hours at a temperature of 90°C to obtain an activated sol; mix peanut oil, diethanolamine and sodium ethoxide in a reaction kettle with a mass ratio of 5:2:1, and place them in a reaction kettle at a temperature of 120°C under nitrogen Stir and react for 35 minutes under protected conditions to obtain the amino product. Mix sodium alginate and absolute ethanol with a mass ratio of 5:1 and stir for 32 minutes to obtain a self-made suspension. Mix the amino product with deionized water at a mass ratio of 3:1 Stir for 18 minutes to obtain an aqueous ammonia solution, then mix the aqueous amino solution and the self-made suspension at a volume ratio of 1:3, and stir and react f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com