High-flame-retardance composite heat-insulating foam material and preparation method thereof

A technology of composite thermal insulation and foam materials, applied in the direction of coating, etc., can solve the problems of non-existence, environmental pollution, high toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

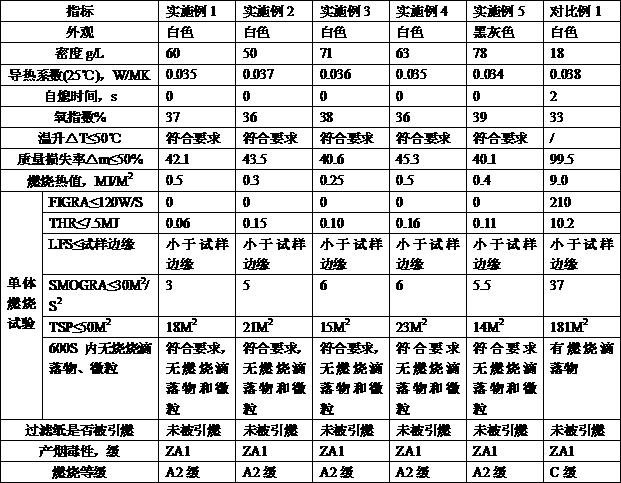

Examples

Embodiment 1

[0082] A high flame-retardant composite thermal insulation foam material, comprising the following preparation steps:

[0083] A, foaming the expandable polystyrene raw material through a pre-expanding machine into polystyrene foam particles with a density of 18g / L;

[0084] B. Take 900 grams of melamine formaldehyde resin, add 50 grams of curing agent, then add 50 grams of phenolic resin, 25 grams of triethyl phosphate, and 25 grams of triphenyl phosphate, and stir evenly in a mixing device with a stirring speed of 100 rpm at room temperature into 1050 grams of liquid flame retardant binder;

[0085] C. Put the polystyrene foam particles with a volume of 60L into a mixer with a stirring function, then start stirring at a stirring speed of 80rpm, add a liquid flame-retardant binder, and mix evenly;

[0086] D. Configure 2000 grams of inorganic flame retardant, and then add the inorganic flame retardant to the mixer under stirring. After stirring evenly, polystyrene foamed par...

Embodiment 2

[0103] The main technical scheme of this embodiment is the same as Embodiment 1, the difference is:

[0104] A high flame-retardant composite thermal insulation foam material, comprising the following preparation steps:

[0105] A, foaming the expandable polystyrene raw material through a pre-expanding machine into polystyrene foam particles with a density of 18g / L;

[0106] B. Take 670 grams of melamine formaldehyde resin, add 30 grams of curing agent, then add 60 grams of phenolic resin, 100 grams of tributyl phosphate, and stir evenly in a mixing device with a stirring speed of 100 rpm at room temperature to form 860 grams of liquid flame retardant binder;

[0107] C. Put the polystyrene foam particles with a volume of 60L into a mixer with a stirring function, then start stirring at a stirring speed of 80rpm, add a liquid flame-retardant binder, and mix evenly;

[0108] D. Configure 1500 grams of inorganic flame retardant, then add the inorganic flame retardant to the mi...

Embodiment 3

[0118] The main technical scheme of this embodiment is the same as Embodiment 1, the difference is:

[0119] A high flame-retardant composite thermal insulation foam material, comprising the following preparation steps:

[0120] A, foaming the expandable polystyrene raw material through a pre-expanding machine into polystyrene foam particles with a density of 18g / L;

[0121] B. Take 950 grams of melamine formaldehyde resin, add 90 grams of curing agent, then add 80 grams of phenolic resin, 40 grams of triethyl phosphate, and 60 grams of triphenyl phosphate, and stir evenly in a mixing device with a stirring speed of 100 rpm at room temperature into 1220 grams of liquid flame retardant binder;

[0122] C. Put polystyrene foam particles with a volume of 60L into a mixer with a stirring function, then start stirring at a stirring speed of 120rpm, add a liquid flame-retardant binder, and mix evenly;

[0123] D. Configure 2250 grams of inorganic flame retardant, and then add the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com