Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

854results about How to "Optimized formula" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin care compositions

InactiveUS20050232876A1Improve the immunityOptimized formulaCosmetic preparationsHair cosmeticsGlycerolCarboxylic acid

Disclosed are skin care compositions comprising an admixture of sucrose acetate isobutyrate and certain diol and glycerol carboxylate esters. The liquid skin care compositions are useful as cosmetic, protective and therapeutic dermatological compositions and comprise an admixture of sucrose acetate isobutyrate and one or more carboxylic acid esters of a polyol selected from propylene glycol and glycerol wherein the carboxylate ester residues contains from 2 to 10 carbon atoms. The skin care compositions exhibit smoothness and water resistance when applied to the skin such as the human body including eyelids and lips.

Owner:EASTMAN CHEM CO

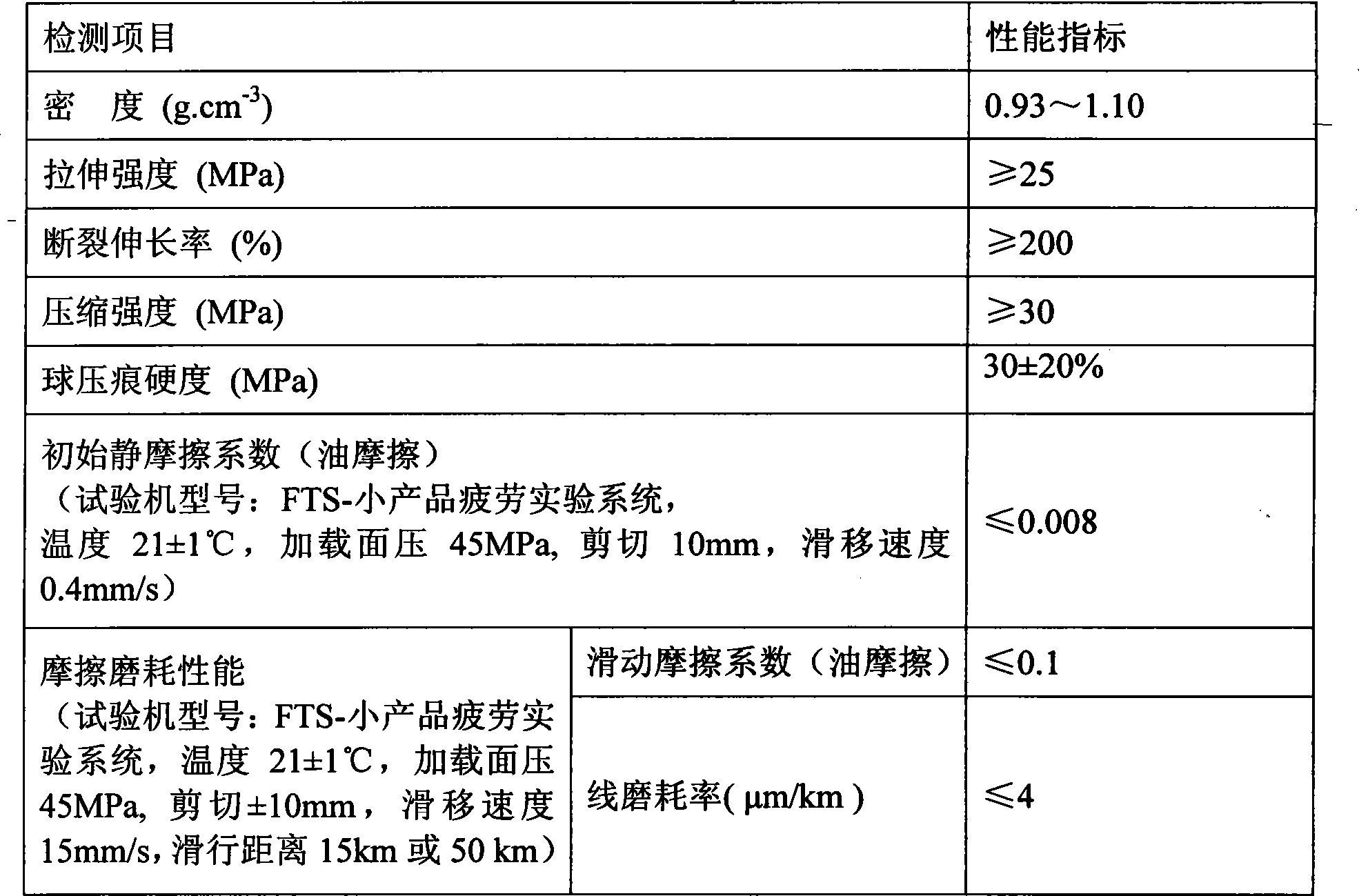

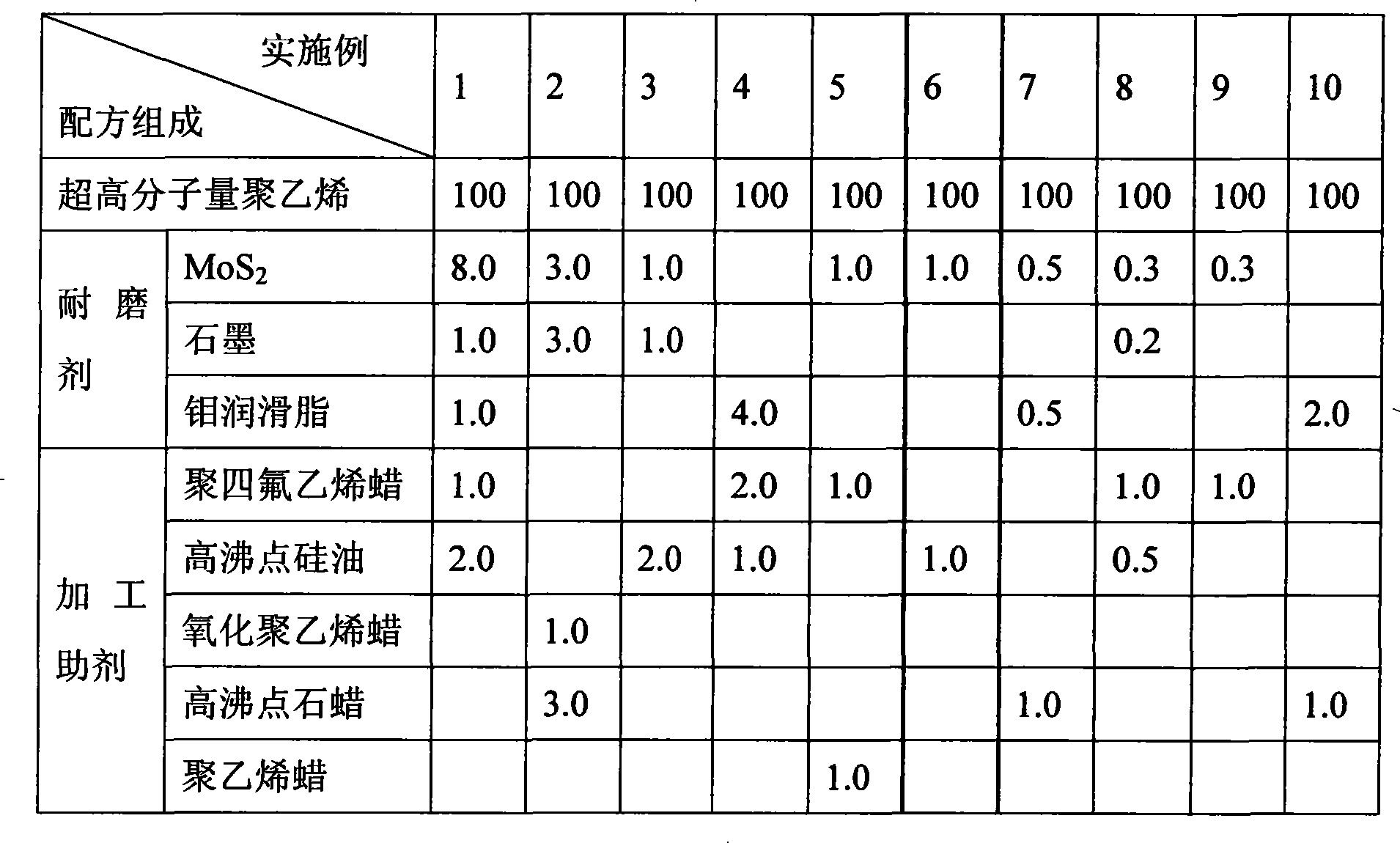

Super-high molecular weight polyethylene low frictional coefficient wearable composite material and its preparation and use

InactiveCN101240092AImprove performanceExcellent formulaBridge structural detailsParaffin waxProcedure Agents

Ultra high molecular weight polyethylene composite with low molar mass and high friction resistance, preparation and application thereof. Raw materials of 100 parts by weight of ultra high molecular weight polyethylene, 0.1-10 parts by weight of wear-resisting agent, 0.1-5.0 parts by weight of processing aid is prepared into highly friction resistant composite by mixing, chill-pressing, heating to melt, compression molding, cooling for shaping and cutting. The mentioned utra high molecular weight polyethylene has a matrix molecular weight of greater than 6 millionl. The mentioned wear-resisting agent is MoS2 surface treated by coupling agent, black lead, lubricating grease of molybdenum, copper powder, or mixture of more than two of them. The mentioned processing agent is organic silicon oil with high boiling point, polytetrafluroethylene, oxidized polyethylene wax, olefin or polyethylene wax with high boiling point, or mixture of more than two of them.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Compositions and process for cleaning and finishing hard surfaces

InactiveUS6017872ASaving in time and moneyOptimized formulaNon-ionic surface-active compoundsOrganic detergent compounding agentsChemistryMetal

Hard surfaces such as tile, metal, glass, etc. typically in hospitality locations can be cleaned to a bright, shiny, residue-free appearance using a process comprising cleaning the surface with a first cleaning composition and removing the resulting cleaner residue with a finish cleaner composition. The finish cleaner composition removes all trace of soil and cleaner from the first step and dries to a bright, shiny, spot-free, streak-free, and film-free appearance without a need for a final wipe step.

Owner:ECOLAB USA INC

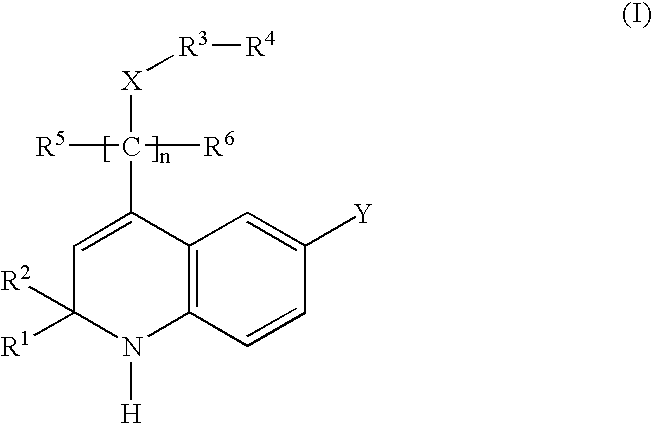

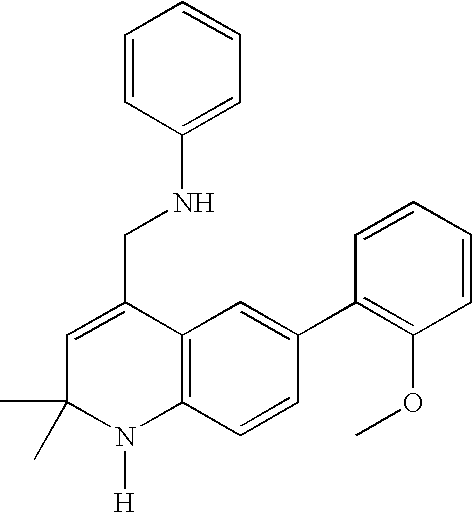

Glucocorticoid mimetics, methods of making them, pharmaceutical compositions, and uses thereof

InactiveUS6858627B2Sufficient amountTreatment effectBiocideSenses disorderDiseaseGlucocorticoid receptor

Compounds of Formula (I) wherein R1, R2, R3, R4, R5, R6, X, Y, and n are as defined herein, or a tautomer, prodrug, solvate, or salt thereof; pharmaceutical compositions containing such compounds, and methods of modulating the glucocorticoid receptor function and methods of treating disease-states or conditions mediated by the glucocorticoid receptor function or characterized by inflammatory, allergic, or proliferative processes in a patient using these compounds.

Owner:BOEHRINGER INGELHEIM PHARMA INC

Treatment of Cancer and Other Diseases

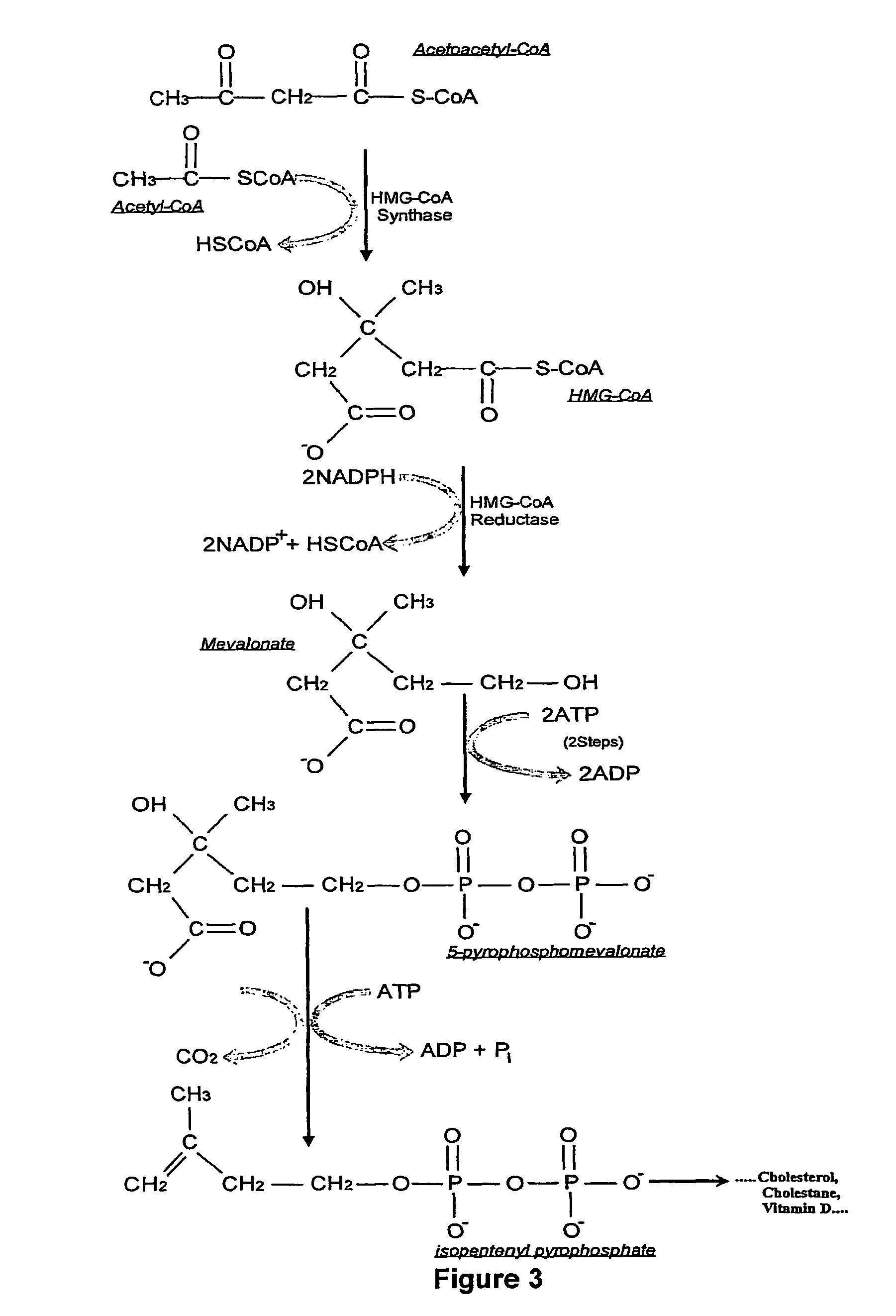

InactiveUS20090226431A1Easy to prepareGood chemical stabilityBiocideOrganic active ingredientsNeoplasmCholestane

The present invention relates to a novel compound (e.g., 24-ethyl-cholestane-3β,5α,6α-triol), its production, its use, and to methods of treating neoplasms and other tumors as well as other diseases including hypercholesterolemia, autoimmune diseases, viral diseases (e.g., hepatitis B, hepatitis C, or HIV), and diabetes.

Owner:VIANOVA LABS

Water-control fracturing yield increasing method for oil gas well

The invention relates to a method for increasing the yield of an oil gas well by controlling water pressing crack, in particular to water control pressing crack technology which takes a jelly glue system capable of automatically reducing the viscosity when encountering bottom water as a pressing crack liquid and wax-coated sand as partial supporting agent. At present, when hydraulic pressing construction is performed on low permeating bottom water oil pool, because the stress difference between layers is small or no interlayer forms the stress difference between the layers, the extending of cracks in the vertical direction can be effectively prevented, cracks formed by the hydraulic pressing crack extend and enter a water layer on the bottom in the vertical direction and jump to flow into a shaft along the cracks, and violent flooding of an oil well is generated. When pressing crack construction is carried out, the method adopts a coated supporting agent formed by mixing a thickening agent and a cross-linking agent carrying wax and quartz sand to undergo chemical degradation to coat and block so as to form a blocking layer. The method effectively solves the problems that the prior manual shielding layer cannot effectively prevent the oil well from being flooded by water, and a pressing crack liquid carrying a diversion agent or a temporary plugging agent cannot reduce viscosity basically when encountering the water and has slower settling.

Owner:QINGYANG CHANGQING DOWN HOLE OILFIELD AUXILIARIESCO

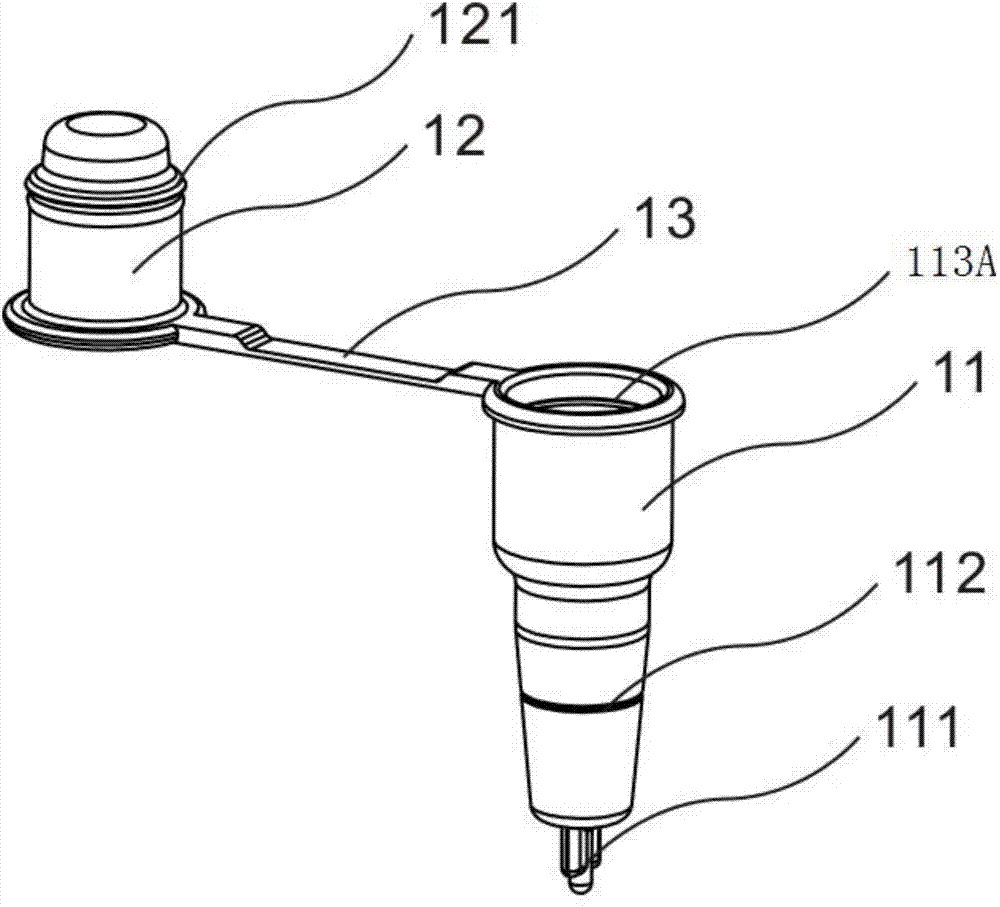

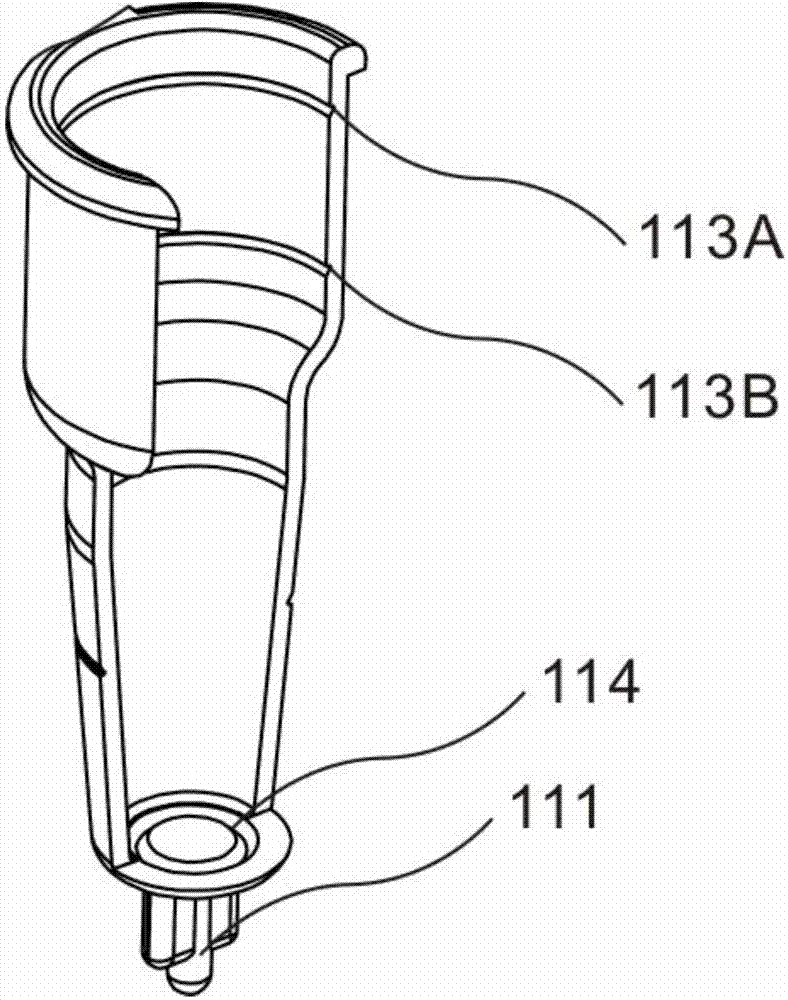

Closed nucleic acid chromatographic test paper detection kit preserved at normal temperature and detection method

InactiveCN103243087AChemically stableHigh recovery rateMicrobiological testing/measurementDNA preparationNucleic acid detectionImmunochromatographic test

The invention discloses a method for preserving nucleic acid amplification reagents at normal temperature. Partial nucleic acid amplification reagents or all reagents are converted to solid state through a solidifying process and preserved stably at normal temperature. The invention further discloses a closed nucleic acid chromatographic test paper detection kit preserved at normal temperature. The kit comprises a nucleic acid extraction reagent of a sampler, the nucleic acid amplification reagent preserved at normal temperature, a closed chromatographic test paper detection device and an innocent treatment method of nucleic acid amplification products. The closed chromatographic test paper detection device comprises immunochromatographic test paper and a closed detection device, wherein the immunochromatographic test paper is fixedly arranged in the closed detection device, and sample liquor detected cannot be contacted with external environment. In addition, the invention further discloses a method for nucleic acid detection by using the kit. According to the invention, the nucleic acid reagents can be conveyed and preserved at normal temperature and extracted simply and quickly, and the nucleic acid amplification products are hermetically, quickly and sensitively detected, so that cross infection is avoided.

Owner:QUICKING BIOTECH

Treatment of cancer and other diseases

InactiveUS8293726B2Easy to prepareGood chemical stabilityBiocideOrganic active ingredientsAutoimmune responsesAutoimmune disease

The present invention relates to a novel compound (e.g., 24-ethyl-cholestane-3β,5α,6α-triol), its production, its use, and to methods of treating neoplasms and other tumors as well as other diseases including hypercholesterolemia, autoimmune diseases, viral diseases (e.g., hepatitis B, hepatitis C, or HIV), and diabetes.

Owner:VIANOVA LABS

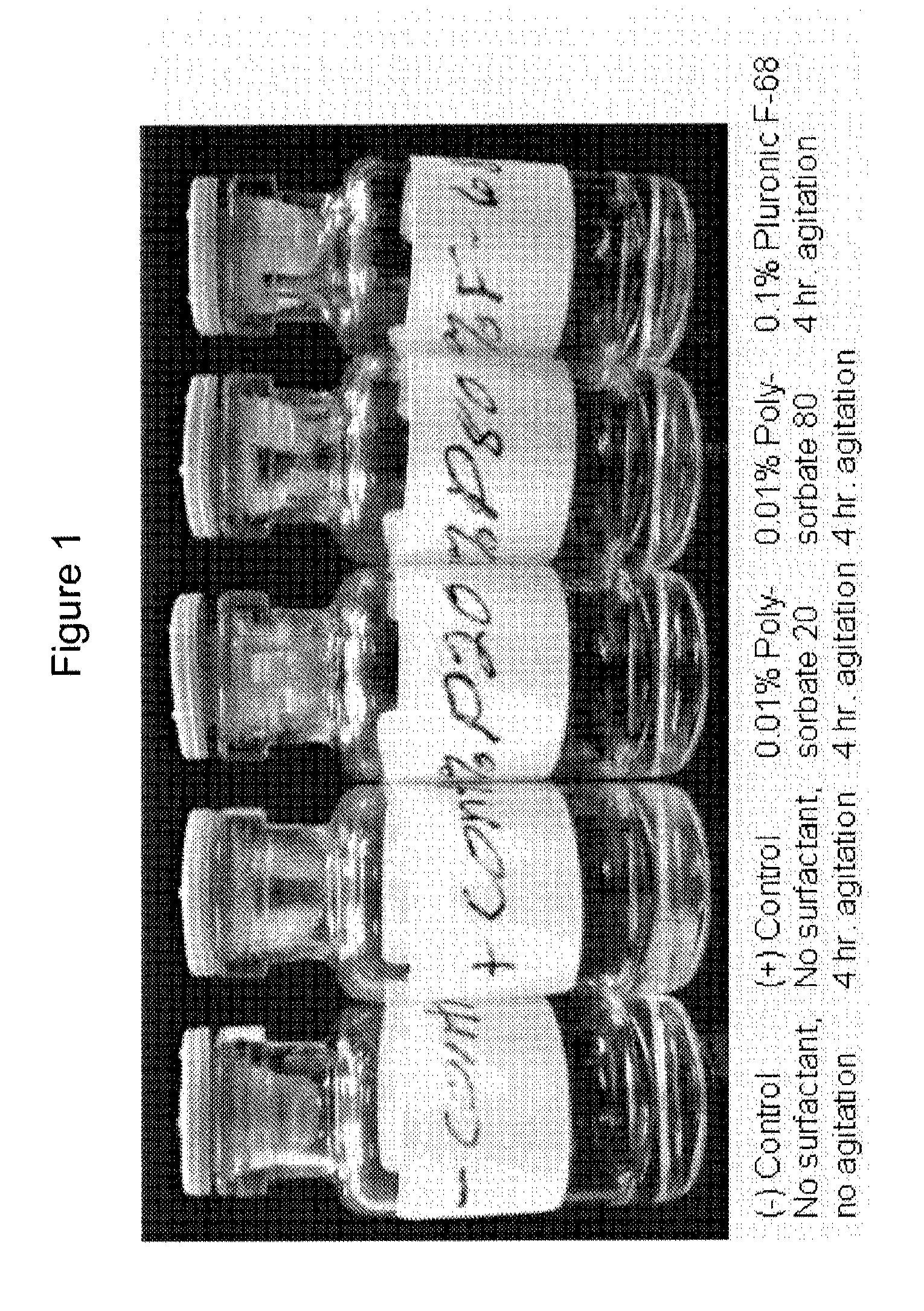

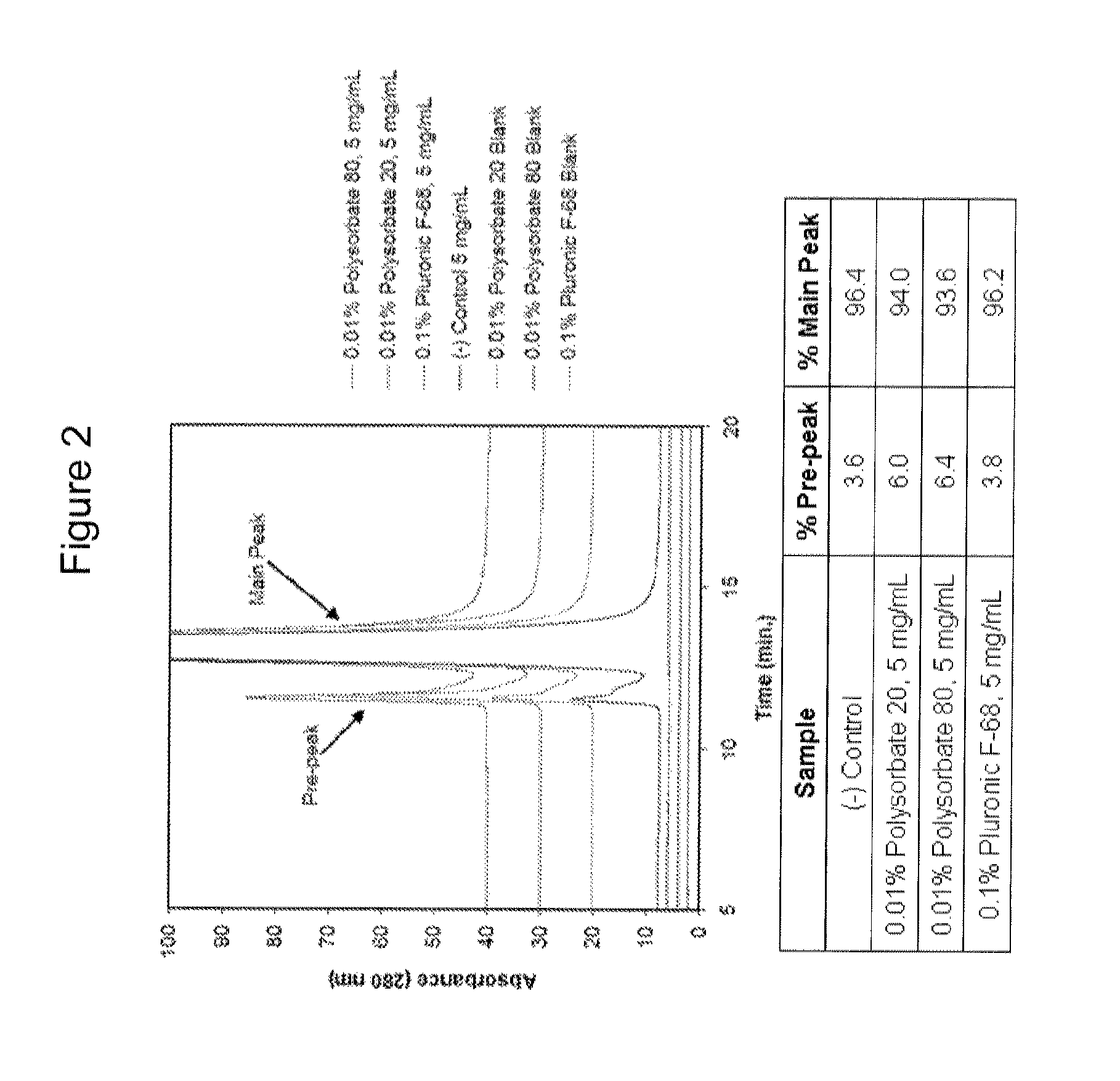

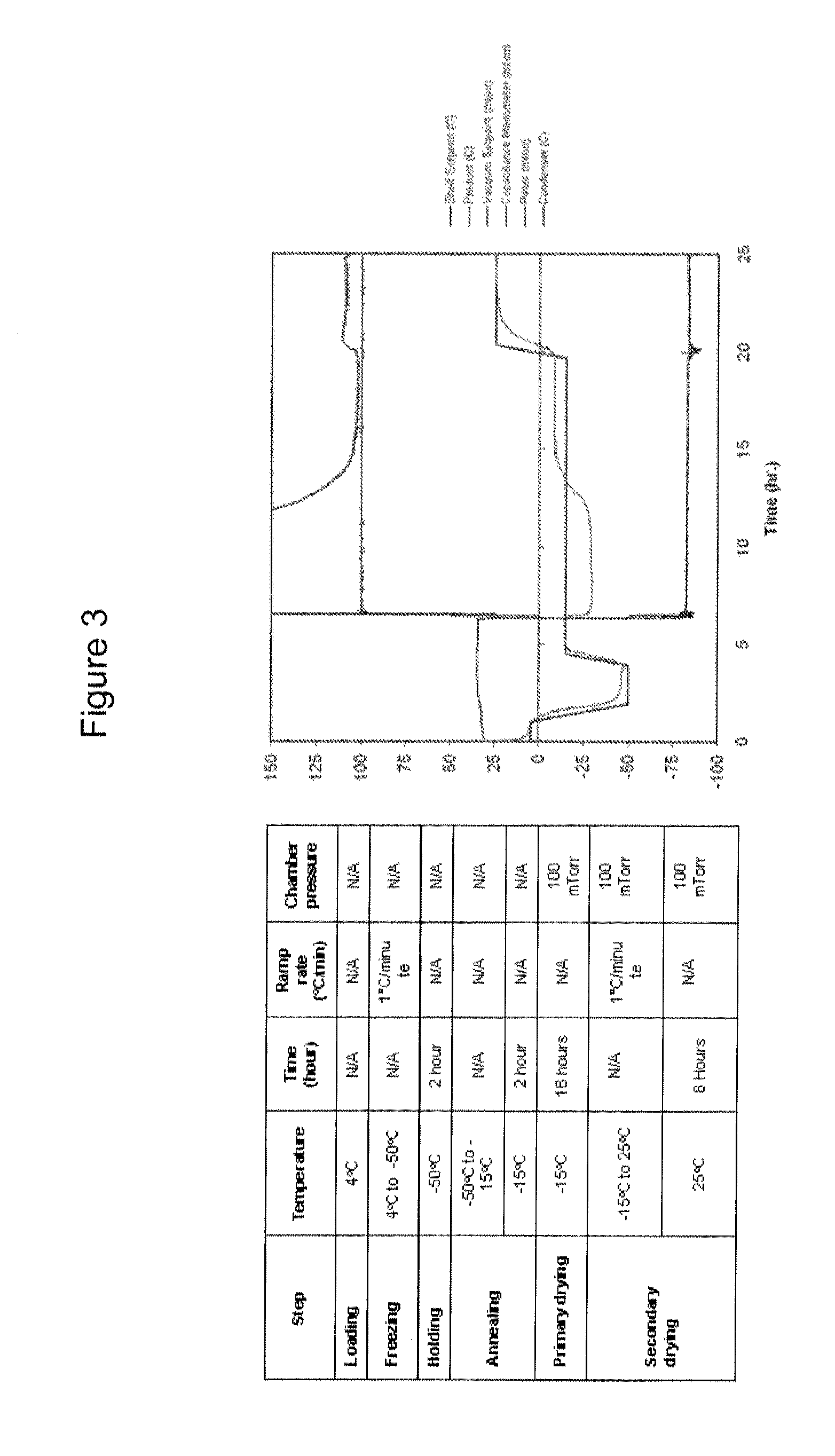

Formulations for Lysosomal Enzymes

ActiveUS20120148556A1Preserve and enhance stabilityPreserve and enhance and efficacyPeptide/protein ingredientsMetabolism disorderAcid alpha-glucosidaseLysosome

The present invention provides improved formulations for lysosomal enzymes useful for enzyme replacement therapy. Among other things, the present invention provides formulations that preserve or enhance the stability and / or efficacy of a lysosomal enzyme such as acid alpha-glucosidase.

Owner:BIOMARIN PHARMA INC +1

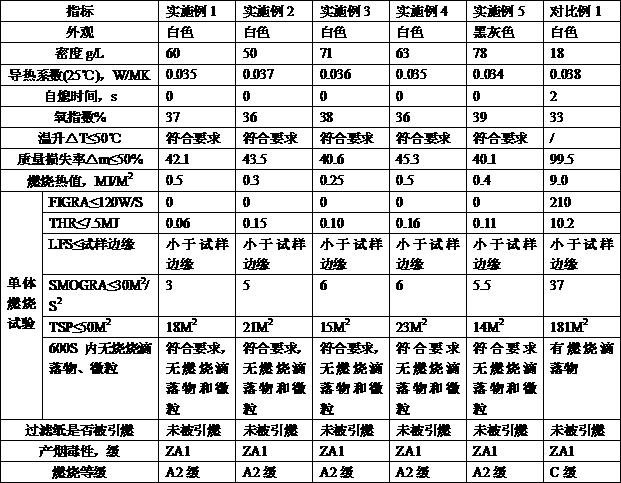

High-flame-retardance composite heat-insulating foam material and preparation method thereof

The invention relates to the technical field of polystyrene foam materials, in particular to a high-flame-retardance composite heat-insulating foam material and a preparation method thereof. The high-flame-retardance composite heat-insulating foam material comprises polystyrene foaming particles with the density of 18 to 20 g / L and a flame-retardant composite layer wrapped on the surface of the polystyrene foaming particles, wherein the flame-retardant composite layer consists of a flame-retardant binder of 5 to 50 g / L and an inorganic flame retardant of 5 to 75 g / L. Compared with the prior art, the invention optimizes the formula of the flame retardant and adopts environment-friendly, non-toxic and low-price organic and inorganic flame retardants. The prepared composite heat-insulating material has low production cost. After the product is combusted, the product has the advantages of alveolate skeleton structure, no melted drop, low smoke output quantity, no combustion dripping substance and no particle, so the flame-retardant performance and the flame-retardant grade of the product are obviously improved and the product has wide development prospect in the heat insulation field of buildings such as roofs and walls.

Owner:宁波龙利钜能新材料有限公司 +1

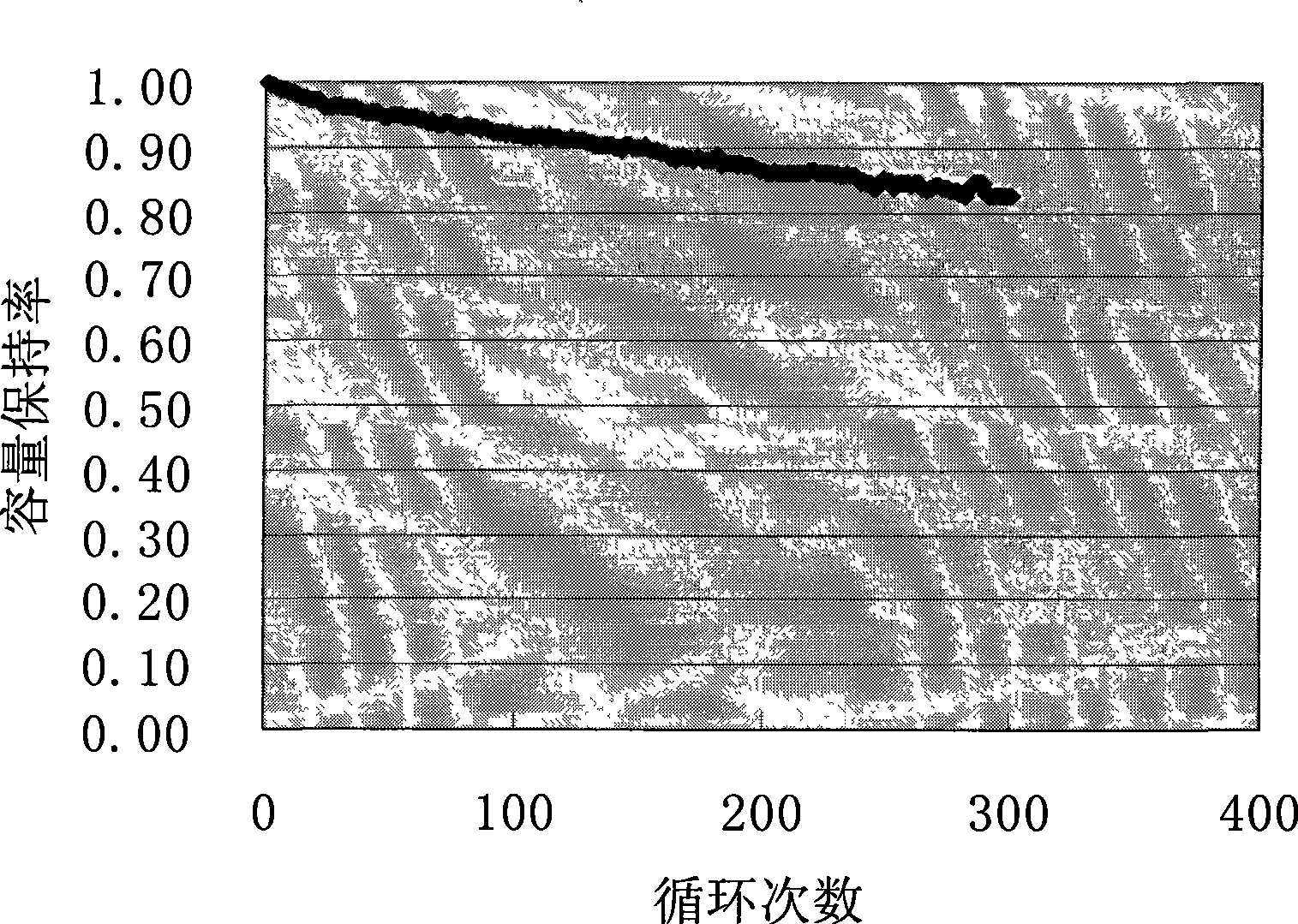

Negative pole material, preparation for battery and battery manufactured by the negative pole material

ActiveCN101393985AOptimized formulaHigh densityElectrode manufacturing processesSecondary cellsSolventAdhesive

The invention relates to a negative material of a battery, which comprises a carbon negative active material, a conductive agent, a thickening agent, an adhesive and a solvent, and the proportion of the parts by weight among ingredients is 110-140:1-10:1-10:1-10:80-200, wherein the carbon negative active material is a mixture of natural graphite and artificial graphite in proportion of 10: 1-4. The invention further relates to a method for preparing the negative material of the battery and a battery prepared by adopting the negative material. The invention optimizes the formula for the carbon negative material, improves the density of an electrode sheet of the negative electrode, improves the compacted density of the natural graphite used as the negative active material of a lithium battery, and meanwhile improves the volume capacity of the negative electrode, and greatly improves the circulation performance of a prepared finished product battery core.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Low-molecular environmentally-friendly fracturing fluid and use of recovery liquid thereof

The invention relates to a low-molecular environmentally-friendly fracturing fluid and use of recovery liquid, wherein the fracturing fluid comprises low molecular thickening agent, cross linking agent, water, pH regulator, crude oil demulsification agent, surface active agent, clay stabilizer and bactericidal agent, thus no glue-breaking agent is needed, and very good rheological property can be achieved.

Owner:CHANGQING GASOLINEEUM EXPLORATION BUREAU

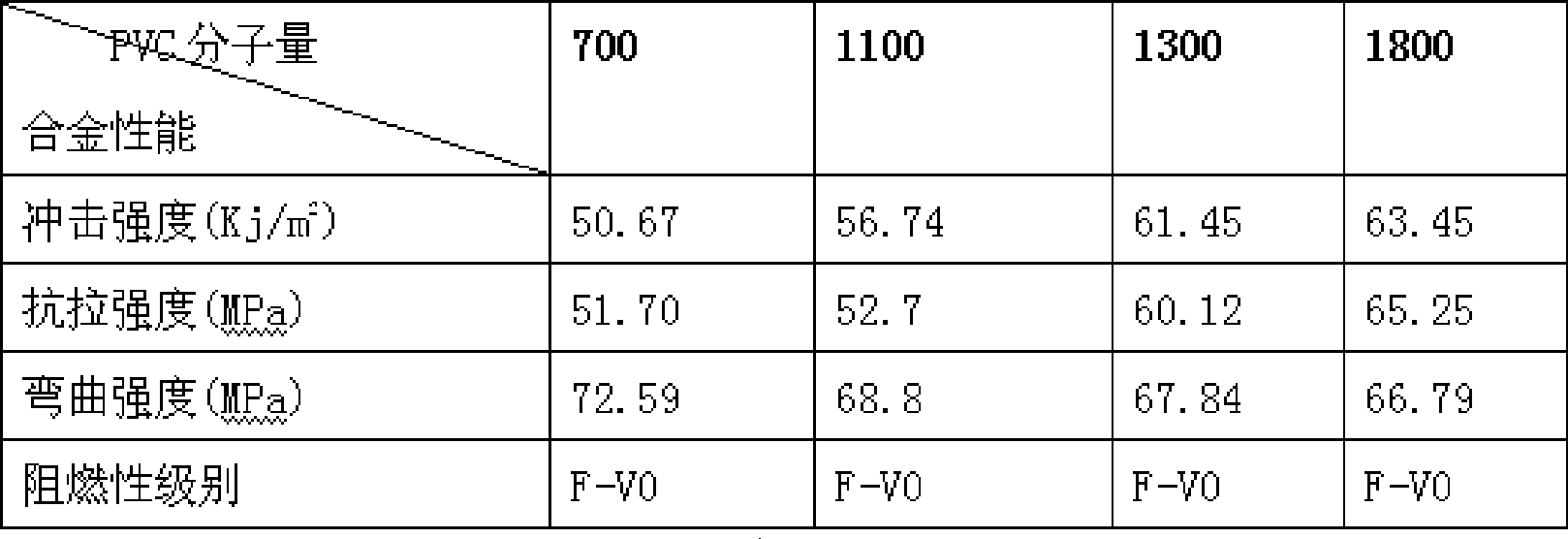

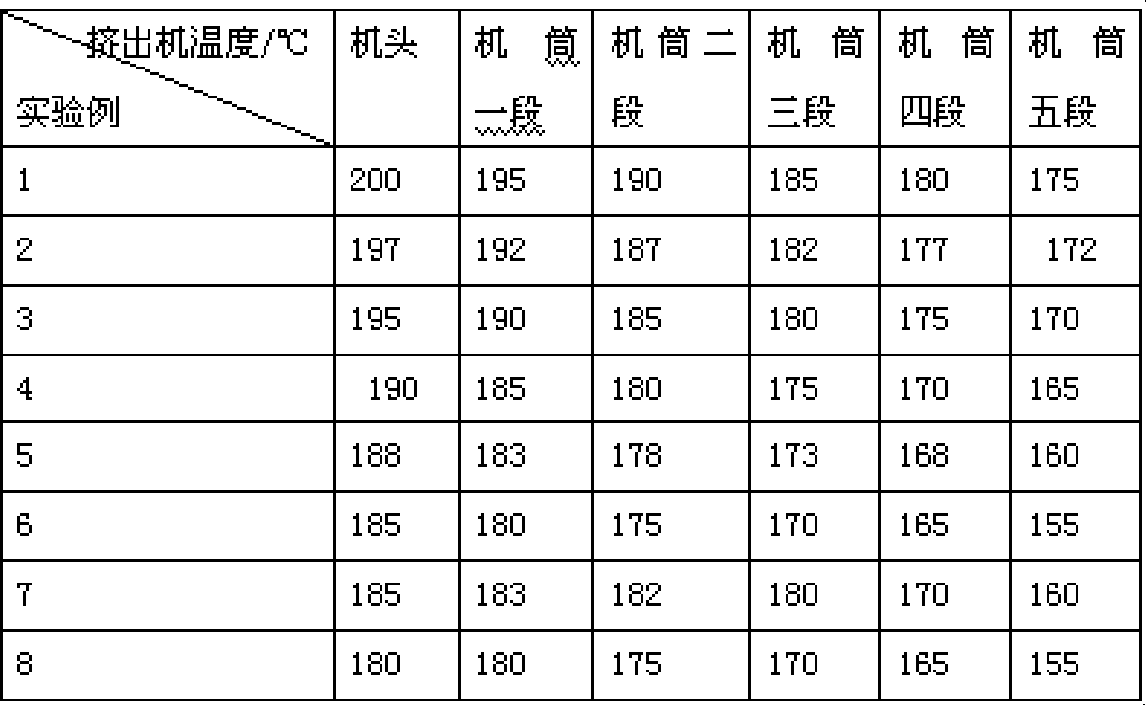

A polyvinyl chloride/ASA alloy

The invention discloses a polyvinyl chloride (PVC) / ASA alloy, which is prepared by polyvinyl chloride resin, ASA resin and right amount of processing aids. The preparation method includes: mixing uniformly the polyvinyl chloride resin and processing material at 60-120 DEG C, adding ASA resin powders, mixing evenly, dropping the temperature to 43 DEG C, to obtain the mixture; extruding the mixture through a screw extruder to obtain the alloy, wherein, the temperature of the extruder head is 165 DEG C - 185 DEG C, and the revolution speed is 120-160 r / min. Compared with the existing technology, the PVC / ASA alloy prepared by the invention has high impact resistance, weather resistance, fire-retardant, superior synthesized dynamic performance, good processing performance, stable preparation process, non three wastes pollution. The alloy can be formulated into various colors according to requirements, can be produced by screw rod extruding continuous manufacturing method, and can also be produced by extrusion molding and injection molding according to manufacturing requirements of products.

Owner:国家复合改性聚合物材料工程技术研究中心

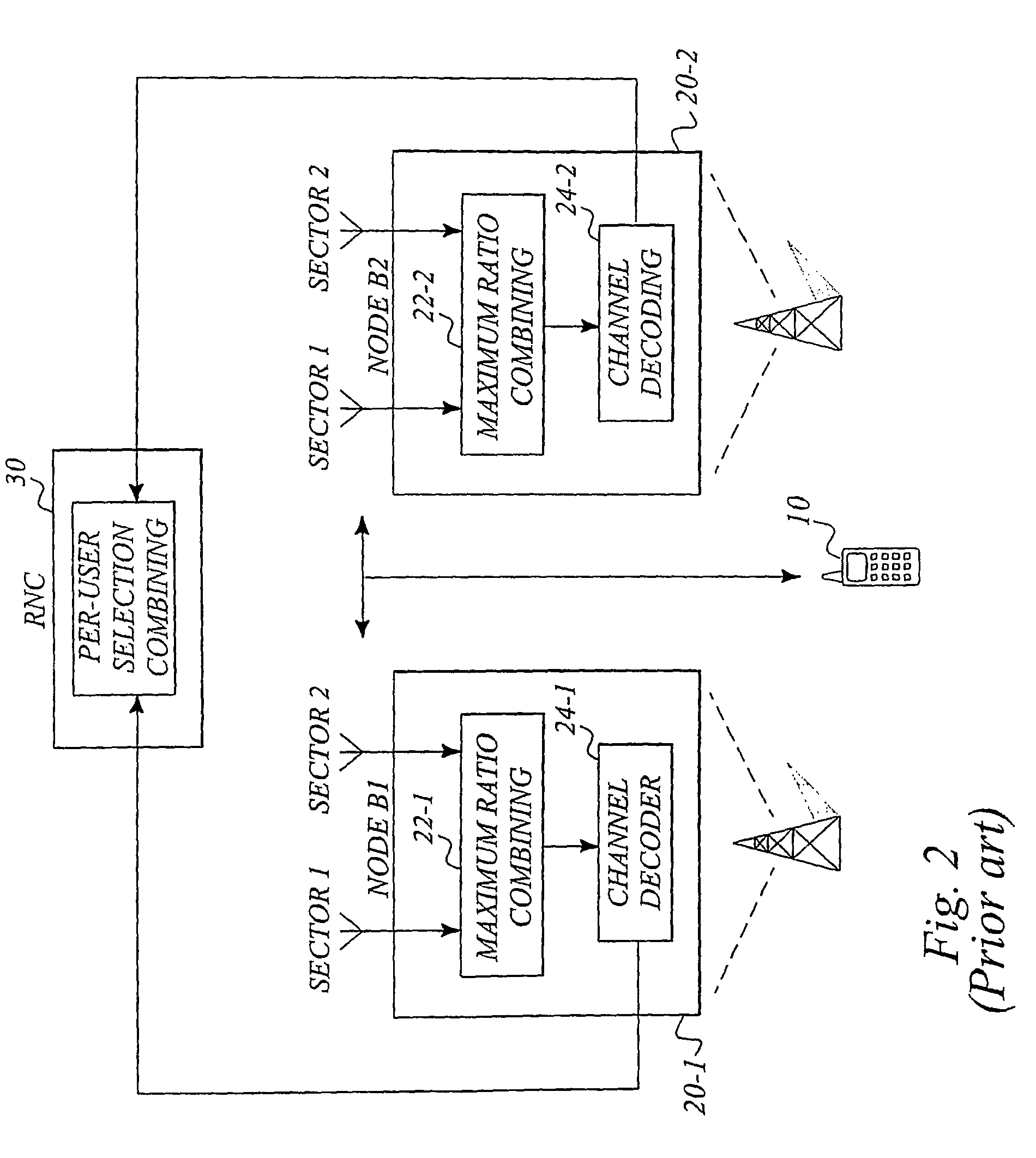

Advanced multi-sensor processing

ActiveUS7924949B2Optimized formulaHigh transportation costPower managementSite diversityMulti sensorWireless network

Each receiving node (120) of a plurality of receiving nodes (120-1, 120-2 and 120-3) in a wireless network converts a superposition of signals received from a plurality of transmitting nodes (10) to produce soft complex signal information. The soft complex signal information associated with the considered plurality of receiving nodes are collected, and jointly detect signal information transmitted from at least a subset of the plurality of transmitting nodes (10) based on the collected soft complex signal information. The collected soft signal information generally retains phase and amplitude information, and the transmitted signals are preferably detected in a joint detection process based on a complex channel representation and collected soft signal information.

Owner:TELEFON AB LM ERICSSON (PUBL)

Soil conditioner used for treating heavy metal pollution

InactiveCN105199737AReasonable durabilityOptimized formulaAgriculture tools and machinesOrganic fertilisersPopulationNon functional

The invention provides a soil conditioner used for treating heavy metal pollution. The soil conditioner comprises the following chemical components by weight: 40 to 60% of CaO, 20 to 30% of SiO2, 3 to 10% of MgO and 10 to 30% of other non-functional mineral elements consisting of Al2O3 and Fe2O3. Polluted soil contains the following heavy metals: no more than 5 ppm of mercury, no more than 10 ppm of cadmium, no more than 10 ppm of arsenic, no more than 50 ppm of lead and no more than 50 ppm of chromium. The soil conditioner is prepared from a calcareous raw material, a magnesian raw material, a siliceous material and flux minerals through batching, raw grinding, sintering, grinding after cooking, detection and packaging after detection is passed. According to testing results, the soil conditioner can completely passivate and chelate soil containing less than 20 ppm of cadmium, enables yield to be increased by more than 30%, particularly guarantees agricultural products produced by obstructed soil reach the standard within 20 to 30 years and poses no adverse influence to the microbial populations, enzyme and granular structure of soil.

Owner:湖南博川农业发展有限责任公司

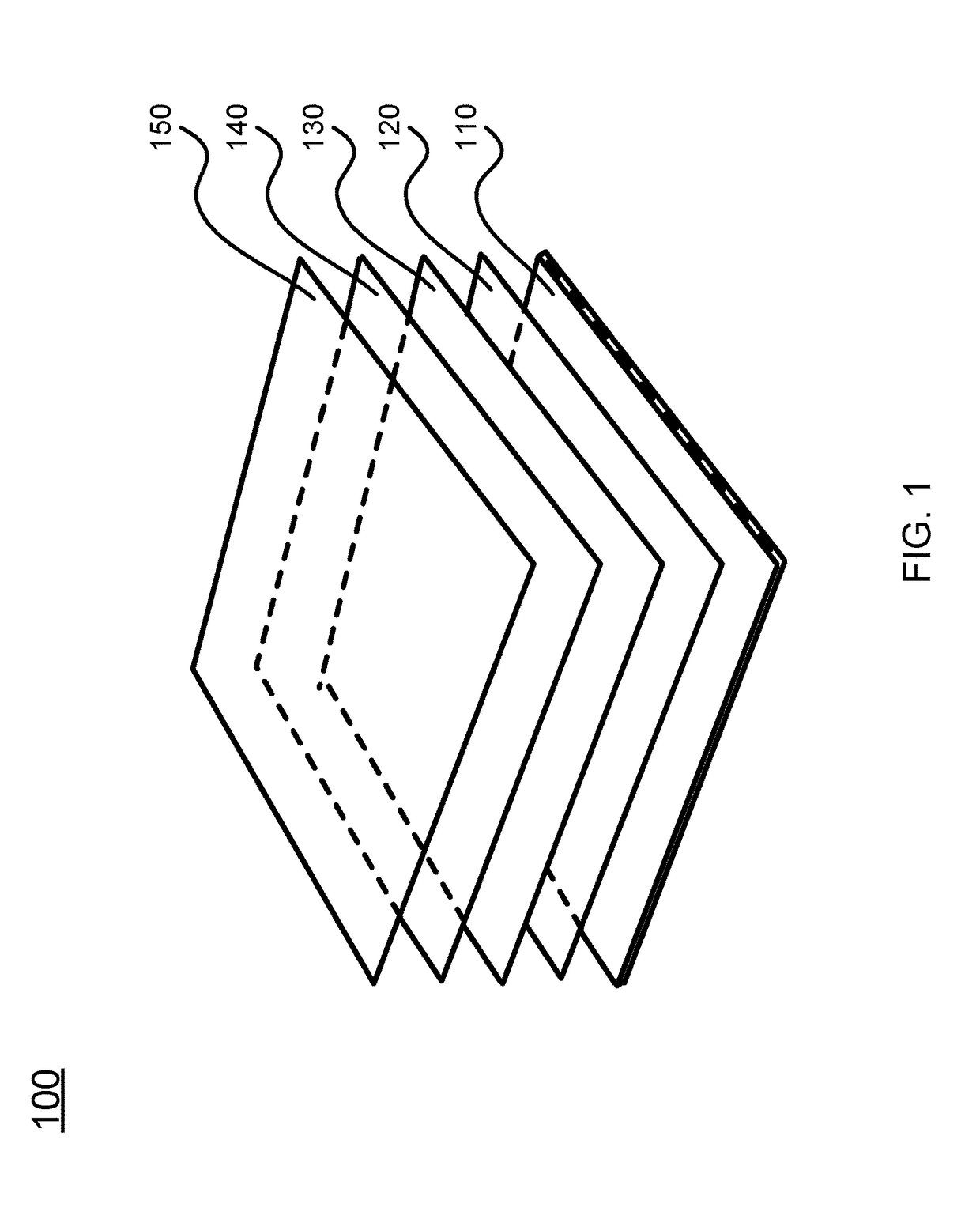

Floor and Wall Covering Assembly

InactiveUS20170217133A1Reduce in quantityLow costCovering/liningsSynthetic resin layered productsThermoplasticUv protective

A floor and wall covering plank includes sequentially, from bottom to top, a waterproof substrate, an adhesive layer, a veneer layer, a paint protective layer, a UV protective layer. The plank may further include optionally one or more of a padding layer and veneer layer below the waterproof substrate. The edges of the planks are routed to form a click locking system, squared or angled edges, or a tongue and groove configuration for assembling different planks together to form a floor or a wall covering. The waterproof substrate includes, in weight percentage, about 20-50% polymer material such as vinyl containing thermoplastics resin, about 20-50% calcium carbonate filler, and about 3-20% of the wood flour. A method is provided to make the floor and wall covering plank. The method includes extruding the waterproof core substrate.

Owner:AMERICAN AQUAWOOD INC

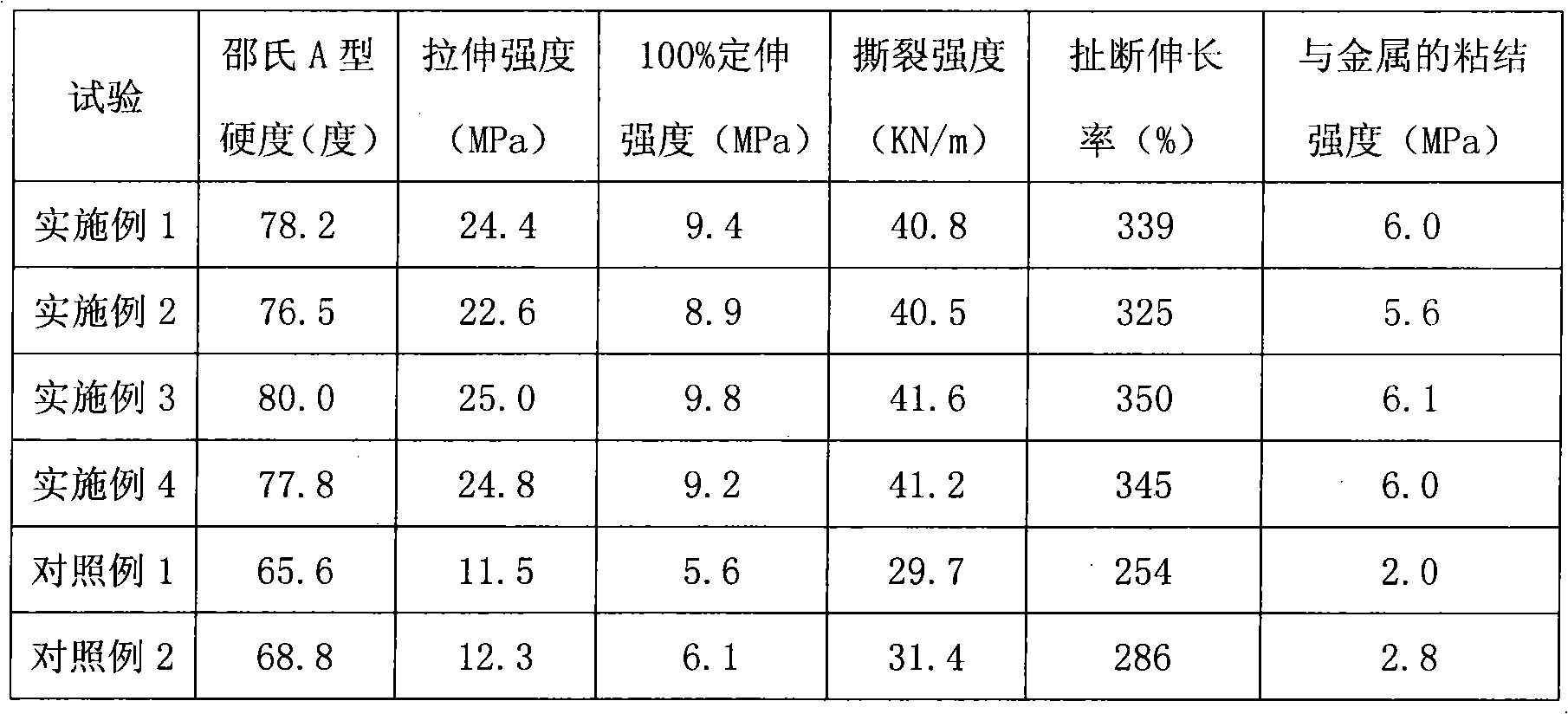

Unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and preparation method thereof

ActiveCN103131088ANo pollution in the processSimple preparation processSuperoxideEthylene-propylene-diene-monomer

The invention discloses unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and a preparation method thereof. Carbon black, metallic compound, stearic acid, accelerant, inert filler, sulphur, superoxide and unsaturated carboxylic acid are added in the EPDM, then mixing treatment and sulfidizing are conducted, and therefore the unsaturated carboxylic acid metal salt modified EPDM is obtained. According to the unsaturated carboxylic acid metal salt modified EPDM and the preparation method thereof, unsaturated carboxylic acid metal salt in in-situ reaction is used for modifying the EPDM, preparation process is simple, modification effect is good, the prepared modified rubber has good physical mechanical performance and especially has good bonding strength with metal, and the application range is wide.

Owner:TIANJIN XINZHONGHE RUBBER IND

Prelithiated positive electrode material for lithium ion secondary battery

InactiveCN106058168AOptimized formulaImprove the first delithiation capacityMaterial nanotechnologyCell electrodesLithiumCharge and discharge

The invention discloses a prelithiated positive electrode material for a lithium ion secondary battery. The prelithiated positive electrode material for the lithium ion secondary battery is prepared from, by weight, 88 to 95 parts of a positive electrode active substance, 0.5 to 3 parts of a conductive agent, 0.7 to 4 parts of a bonding agent and 2 to 10 parts of nanometer lithium fluoride. According to the invention, a formula for the positive electrode material is optimized, and in particular, nanometer lithium fluoride is added; so the whole positive electrode material is prelithiated, has good stability, and can improve the initial delithiation capacity, initial charge and discharge efficiency and energy density of the battery.

Owner:WANXIANG 123 CO LTD +1

Coating of devices with effector compounds

InactiveUS20100215708A1Reduce systemic toxicityPrevention and diminishment and reduction in incidenceBiocideGenetic material ingredientsDiseaseSolvent

This invention is directed to substrates, materials and devices coated with a gel, foam, film, particle or composition comprising a polymei solvent and effector compounds attached thereto, processes of producing the same, and methods of use thereof, of in, inter-alia, biological applications, including preventing infection and the treatment of various diseases.

Owner:ZUMBUEHL ANDREAS +4

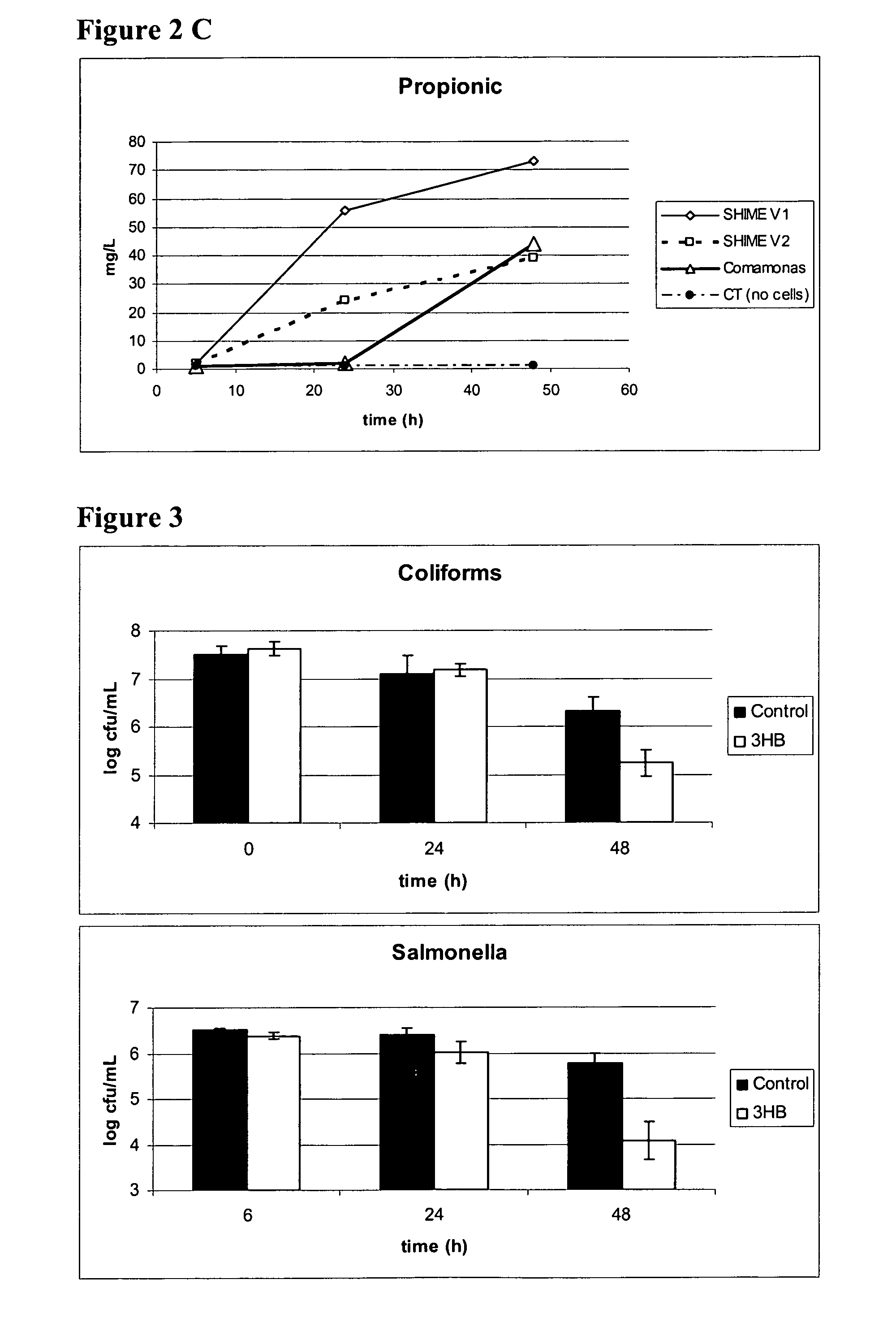

Hydroxybutyrate and poly-hydroxybutyrate as components of animal feed or feed additives

ActiveUS20100093860A1Optimized formulaSmall particlesAntibacterial agentsBiocideEscherichia coliFood additive

This invention relates to the use of hydroxybutyrate and poly hydroxybutyrate as components of animal feed or feed additives, as well as to compositions, feed additives and feed containing them. The inventors surprisingly found that hydroxybutyrate and poly-hydroxybutyrate, preferably 3-hydroxybutyrate and poly-3-hydroxybutyrate, have a great potential for use in animal feed for modulation of the gut flora. More precisely, it has been found that poly-3-hydroxybutyrate or a microbial strain capable for producing poly-3-hydroxybutyrate can be used as a potential growth promoter or gut flora modulator by releasing SCFA, preferably 3-hydroxy butyric acid, in the gut micro flora. Further, the inventors found that 3-hydroxybutyrate and poly-3-hydroxybutyrate have a great potential for suppressing or inhibiting pathogenic bacteria in the gastro intestinal tract, e.g. have a antimicrobial activity against strains of Vibrio, E. coli and Salmonella.

Owner:UNIV GENT

Stabilization of quinapril using magnesium oxide

InactiveUS20060106057A1Minimizes cyclization degradationOptimized formulaBiocideInorganic non-active ingredientsQuinaprilACE Inhibitor Fetopathy

The present invention is directed to ACE inhibitor-containing compositions stabilized by the presence of magnesium oxide. Preferably, the ACE inhibitor, quinapril, is protected from certain forms of degradation when prepared in a pharmaceutical composition consisting essentially of magnesium oxide as the stabilizing agent. The presence of magnesium oxide also lends itself to favorable processing conditions during the manufacture of ACE inhibitor-containing compositions, especially processing by wet granulation.

Owner:WARNER LAMBERT CO LLC

Pharmaceutical formulation

InactiveUS6218374B1Effective preventionImprove combination effectBiocideHydroxy compound active ingredientsIrritationCytotoxicity

Compositions of matter comprising a substituted cyclodextrin and cytotoxic compound, especially cytotoxic drugs such as antibiotic, anti-fungal and anti-neoplastic, drugs are claimed. The compositions cause significantly less ulceration compared to the same formulation of cytotoxic compound without cyclodextrin compound when extravasated. The compositions may also cause less vascular irritation compared to the same formulation of cytotoxic compound without cyclodextrin when administered intravenously without extravasation. Compositions of matter comprising watersoluble cytotoxic agents, especially anticancer drugs and anti-ulceration effective or anti-irritation effective amounts of cyclodextrin compounds are also claimed. Methods for reducing the likelihood of ulceration and or irritation when administering the compositions according to the invention are also disclosed and claimed.

Owner:SUPERGEN

Model predictive control with reference tracking

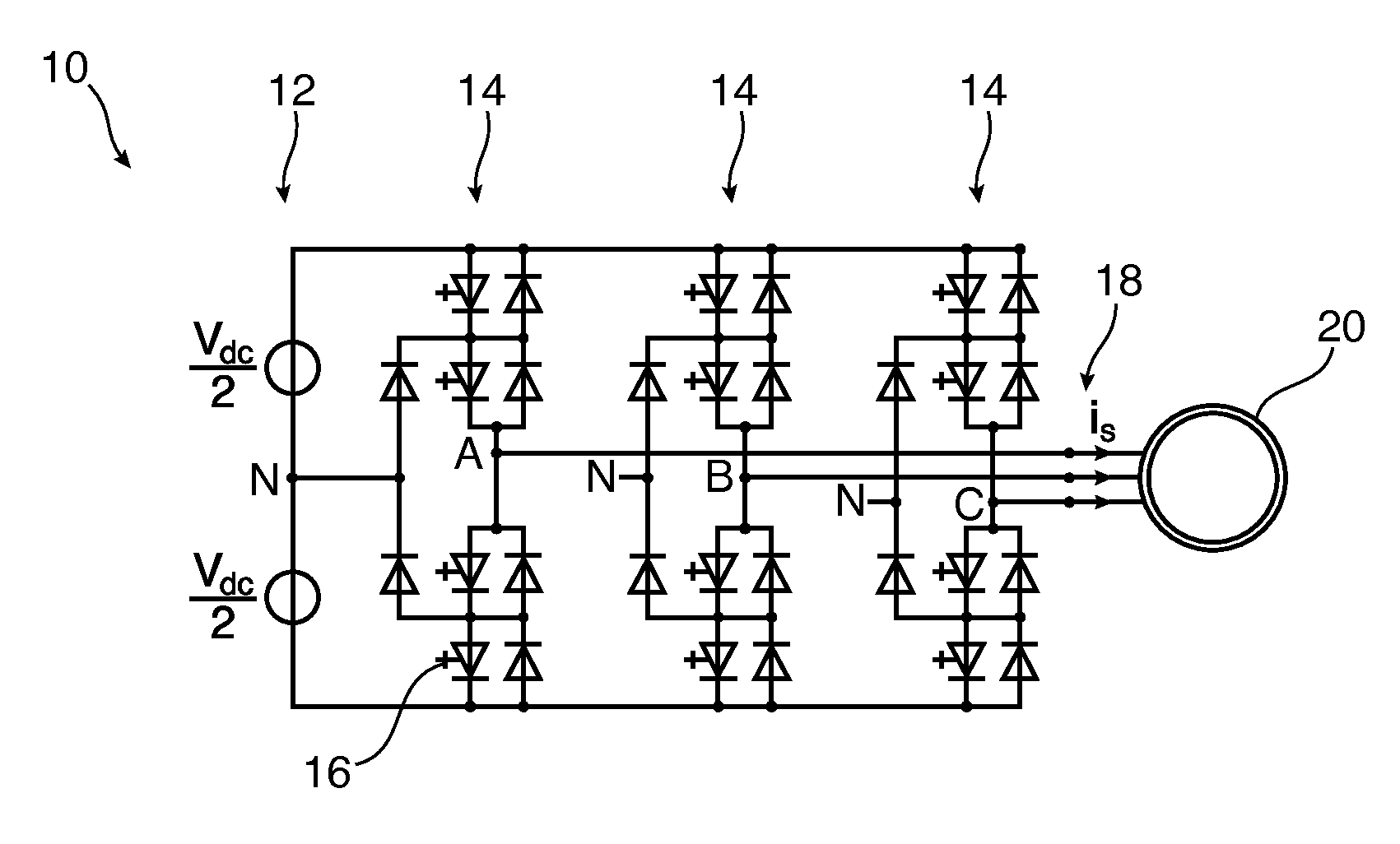

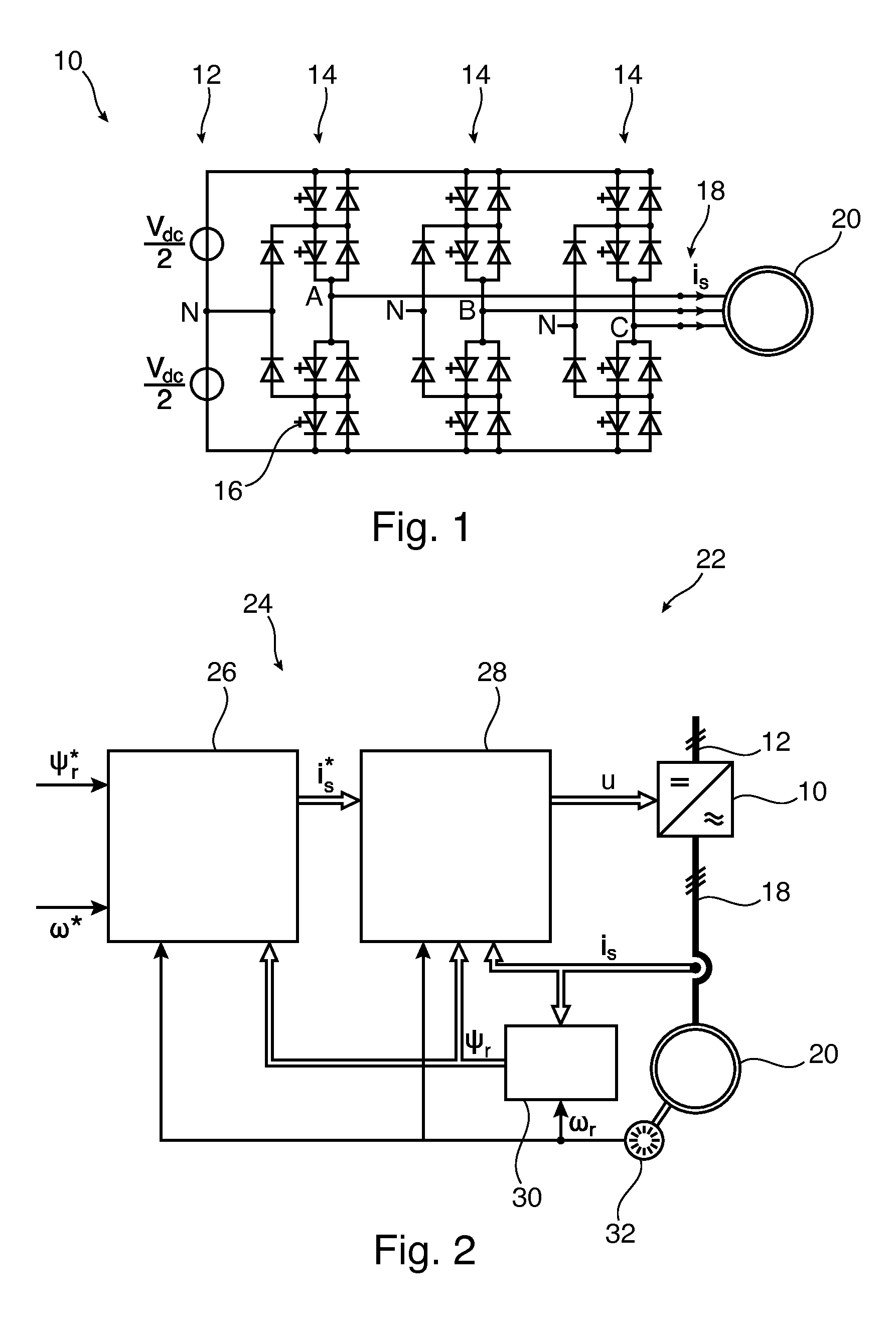

ActiveUS20150229233A1Reduce Harmonic DistortionTransient response time can be very fastMotor/generator/converter stoppersAC motor controlEngineeringModel predictive control

An exemplary electrical converter includes a plurality of semiconductor switches. The electrical converter is configured for generating a two-level or multi-level output voltage from an input voltage by switching the plurality of semiconductor switches. A method for controlling the electrical converter includes receiving a reference electrical quantity (iS*) and an actual electrical quantity (iS), determining a sequence of future electrical quantities of the electrical converter from the actual electrical quantity, determining a maximal cost value based on the sequence of future electrical quantities, and iteratively determining an optimal switching sequence for the electrical converter. A switching sequence includes a sequence of future switching states for the semiconductor switches of the electrical converter. The method also includes selecting the first switching state of the optimal switching sequence as the next switching state (u) to be applied to the semiconductor switches of the electrical converter.

Owner:ABB (SCHWEIZ) AG

Environment-friendly aerial fog type foam cleaning agent and preparation and filling method thereof

InactiveCN101665747AEasily biodegradableOptimized formulaNon-ionic surface-active compoundsDetergent materialsIonAlkene

The invention discloses an environment-friendly aerial fog type foam cleaning agent and preparation and filling method thereof. The environment-friendly foam cleaning agent contains base stock and deodorized liquefied petroleum gas with the ratio of 5-20:1 by parts by weight, and the base stock and deodorized liquefied petroleum gas are filled in an aerosol sealing tank equipped with a matched valve and a press head. The product is applicable to cleaning of multiple hard surfaces such as furniture, glass, floor board and the like and is applicable to cleaning of soft texture surface such as leather, carpet and the like. The base stock is composed of emulsifier, surfactant, antifreeze agent, antiseptic, bactericide, chelating agent, D-lemon alkene, inhibiter and deionized water. The invention has the following advantages: 1, production and usage of product are environmentally friendly; 2, half water system product usage is less restricted by environment factor; 3, product application iswide; 4, usage is convenient.

Owner:GUANGDONG SANVO CHEM IND TECH

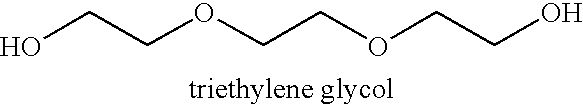

Combination air sanitizer, soft surface deodorizer/sanitizer and hard surface disinfectant

ActiveUS20070142260A1Optimized formulaInorganic/elemental detergent compounding agentsBiocideDisinfectantAir cleaning

An improved combination air sanitizer, soft surface sanitizer, soft surface deodorizer and hard surface disinfectant is disclosed. The preferred active ingredient for the air sanitization and soft surface odor treatment functions is triethylene glycol (TEG). The preferred active ingredient for soft surface sanitization and hard surface disinfection functions is a mixture of various alkyl dimethyl benzyl ammonium saccharinates. The formulation may be provided in an aerosol spray form and is useful for sanitizing and removing bacteria and malodorant molecules from the air as well as disinfecting hard surfaces. A unique combination of corrosion inhibitors is disclosed for convention steel or tin-plated steel cans. A single produce can be used as an air sanitizer / air freshener, a soft surface sanitizer, a soft-surface odor remover / reducer and, a hard surface disinfectant.

Owner:SC JOHNSON & SON INC

Opioid Sustained Release Formulation

InactiveUS20060263431A1Optimized formulaBiocidePowder deliveryIon-exchange resinSustained Release Formulations

A solid, oral, controlled release dosage form comprising a therapeutically effective amount of an opioid compound, or a salt thereof, a matrix-forming polymer and an ionic exchange resin.

Owner:ROXANE LAB

A form-fill- seal (FFS) single layer heavy-duty film and a preparation method thereof

ActiveCN103059402AHigh tensile strengthHigh impact strengthLinear low-density polyethyleneLow-density polyethylene

The present invention relates to the technical field of packaging film, and concretely relates to a form-fill- seal (FFS) single layer heavy-duty film and a preparation method thereof. The single layer heavy-duty film is composed of 30-50% of metallocene linear low density polyethylene, 5-20% of an ethylene-vinyl acetate copolymer, 5-20% of ultra low density polyethylene, 20-50% of linear low density polyethylene, and 3-5% of masterbatch, and is obtained via blending in a single screw extruder, and processes of extrusion molding via a machine head, traction, cooling, winding, and printing. Compared with the prior art, the single layer heavy-duty film of the present invention optimizes product formulation, has good tensile strength, impact strength and tear strength; in the preparation process, a gradual cooling mode is adopted, so the resulting product is more stable in performance; and aids are not added in the raw materials, so the product is low in cost and has a good market prospect.

Owner:GUANGDONG SUNION CHEM & PLASTIC

High-strength high-conductivity heatproof copper alloy wire rod and preparation method thereof

The invention provides a high-strength high-conductivity heatproof copper alloy wire rod and a preparation method thereof. The wire rod comprises the following components: on the basis of weight percentage, 1 to 1.2 of silicon, 0.2 to 0.3 of magnesium, 0.02 to 0.04 of vanadium, 0.01 to 0.02 of titanium, 0.06 to 0.08 of manganese, 0.025 to 0.035 of lutecium and 0.05 to 0.07 of yttrium, with the balance being copper. According to the invention, the component silicon may lead to slight reduction of conductivity, improvement of strength and reduction of toughness, which causes easier fracture of the wire rod in the process of wire drawing; however, the components consisting of magnesium, vanadium and the like are added and a formula and proportions are optimized, so the copper alloy wire rod has high strength and high conductivity.

Owner:铜陵兴怡金属材料有限公司

Pharmaceutical formulation

InactiveUS6048845AEffective preventionImprove combination effectBiocideHydroxy compound active ingredientsIrritationCyclodextrin

Compositions of matter comprising a substituted cyclodextrin and cytotoxic compound, especially cytotoxic drugs such as antibiotic, anti-fungal and anti-neoplastic, drugs are claimed. The compositions cause significantly less ulceration compared to the same formulation of cytotoxic compound without cyclodextrin compound when extravasated. The compositions may also cause less vascular irritation compared to the same formulation of cytotoxic compound without cyclodextrin when administered intravenously without extravasation. Compositions of matter comprising watersoluble cytotoxic agents, especially anticancer drugs and anti-ulceration effective or anti-irritatioin effective amounts of cyclodextrin compounds are also claimed. Methods for reducing the likelihood of ulceration and or irritation when administering the compositions according to the invention are also disclosed and claimed.

Owner:SUPERGEN

Hair regrowth agent

InactiveCN1795006AOptimized formulaAchieve cosmetic effectCosmetic preparationsHair cosmeticsMedicineCurative effect

The invention relates to a pilatory, which contains: panax notoginseng, ginseng, polygonum capitatum, angelica, gastrodia elata, medlar, rhizomaligusticichuanxiong, astragalus, lanceolata, white peony root, safflower, capsicum, sichuan paprika, cynomorium sougaricam. The process comprises: roast, wash, filter, bake roast drying, natural drop in temperature, superfine comminution, mixed stirring, filtering, adding glycerin and suitable laurocapram as penetrating agent. The using method is daubs on affected part 1-3 times one day, and the pilatory is effective and non-toxic.

Owner:孟悦华 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com