A polyvinyl chloride/ASA alloy

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of polyvinyl chloride/ASA alloy and its preparation, and can solve the problems of PVC blend alloy comprehensive mechanical properties, poor weather resistance and processing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

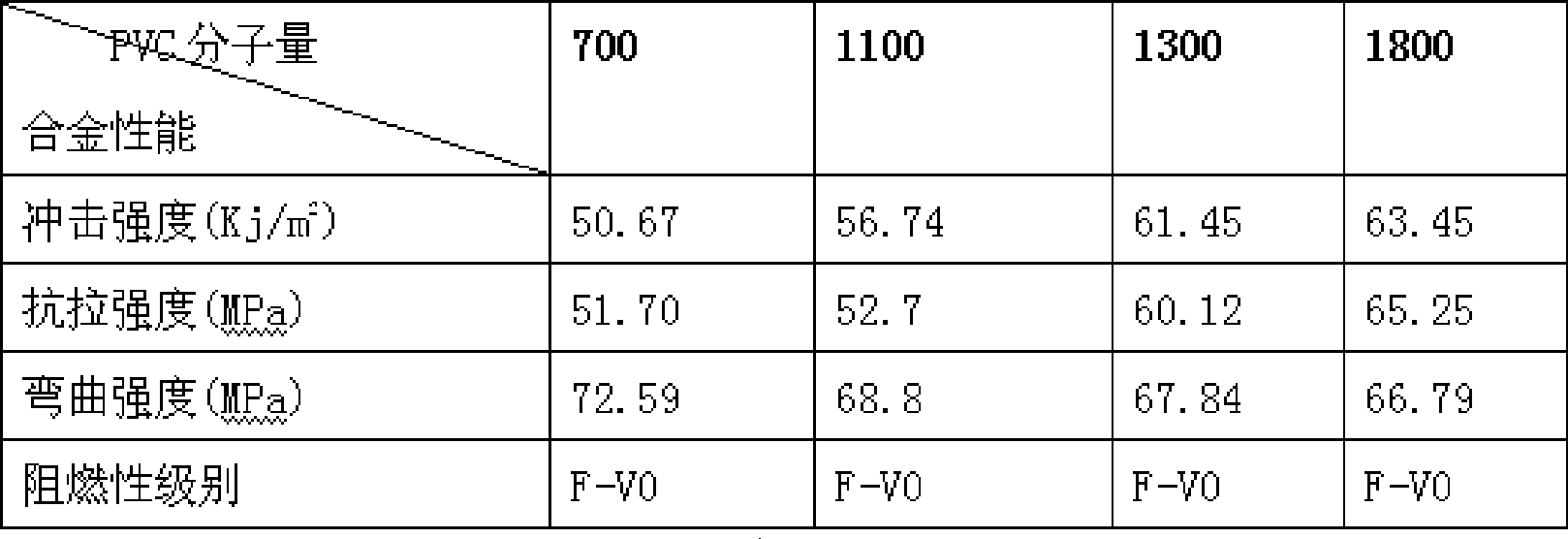

Method used

Image

Examples

Embodiment 1

[0080] Raw materials: PVC 100kg, ASA resin 10kg, stabilizer 5kg, lubricant 5kg, calcium carbonate 30kg

[0081] S-700 type low molecular weight polyvinyl chloride resin is selected, no plasticizer is added, the stabilizer is prepared by methyl tin and calcium stearate stabilizer according to the ratio of 7:1, and the lubricant is made of stearin Acid and polyethylene wax are formulated in a 2:1 ratio.

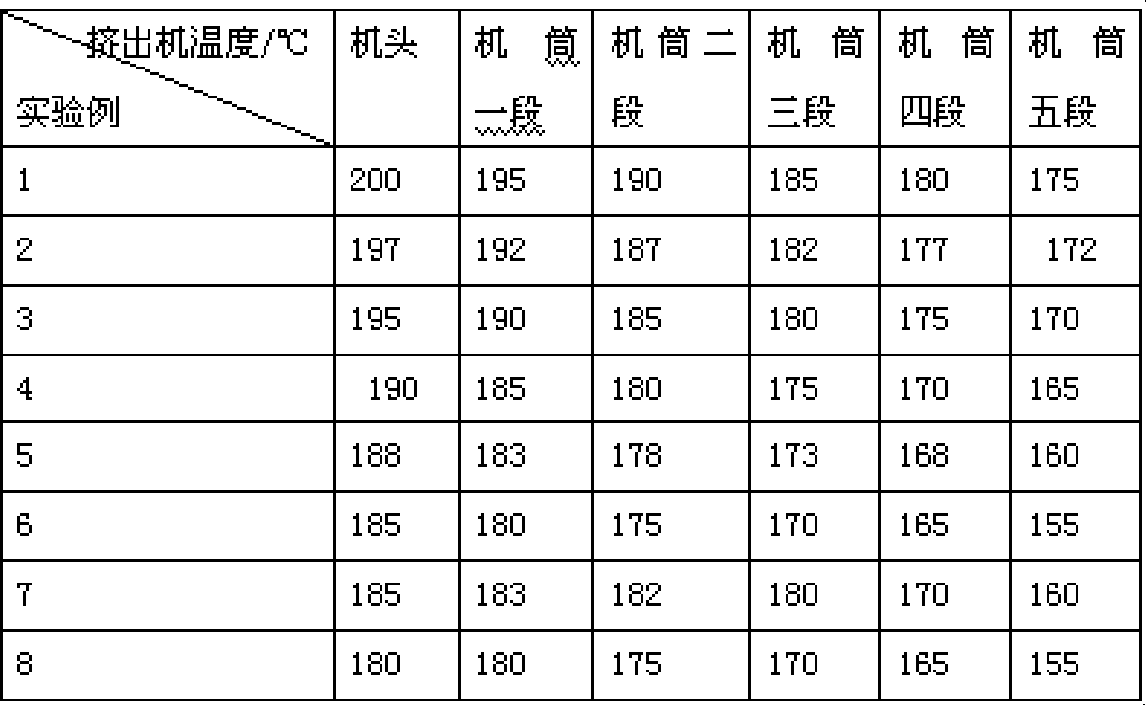

[0082] Preparation method: add polyvinyl chloride to the high-temperature mixing device of the high-speed mixing unit, then add the stabilizer, close the lid, and mix at a speed of 1300r / min. After the temperature reaches 90 ℃, add lubricant and mix, and wait until the temperature exceeds 100 ℃ When the temperature reaches 120°C, open the discharge port, transfer the material to the low-speed mixing device, add ASA powder and inorganic filler in turn, and mix at 650r / min for 10 minutes. Then the material is taken out to obtain a mixture, and the mixture is extruded and granula...

Embodiment 2

[0085] Raw materials: PVC 100kg, ASA resin 30kg, stabilizer 2kg, plasticizer 4kg, lubricant 9kg, titanium dioxide 1kg, calcium carbonate 60kg

[0086] S-1300 type low molecular weight polyvinyl chloride resin is selected. The stabilizer is made up of methyl tin and rare earth composite stabilizer according to the ratio of 3:1. The plasticizer is made of dioctyl phthalate (DOP). ) and tricresyl phosphate (TCP) in a ratio of 2:1, and the lubricant is prepared from stearic acid and polyethylene wax in a ratio of 2:1.

[0087] Preparation method: add polyvinyl chloride to the high-temperature mixing device of the high-speed mixing unit, then add the stabilizer, close the lid, and mix at a speed of 1300r / min. When the temperature reaches 80 ℃, add plasticizer and continue to mix, and the temperature reaches 90 After the temperature reaches 100°C, add lubricant and mix. When the temperature exceeds 100°C, open the air diffuser on the top cover to let the water vapor out. When the te...

Embodiment 3

[0090] Raw materials: PVC 100kg, ASA resin 15kg, stabilizer 7.5kg, plasticizer 7kg, lubricant 7kg, titanium dioxide 2kg, calcium carbonate 20kg

[0091] HDP-1800 type medium and high molecular weight polyvinyl chloride resin is selected. The stabilizer is prepared by calcium zinc stabilizer and calcium stearate according to the ratio of 7:1. The plasticizer is dioctyl phthalate. (DOP) and tricresyl phosphate (TCP) in a ratio of 2:1. The lubricant is prepared from n-butyl stearate, paraffin, and oxidized polyethylene wax in a ratio of 2:1:1. to make.

[0092] The preparation method is the same as that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com