Negative pole material, preparation for battery and battery manufactured by the negative pole material

A technology of battery negative electrode and negative electrode active material, which is applied in electrode manufacturing, battery electrode, secondary battery and other directions, can solve the problems of affecting the compaction density of negative electrode active material, the difficulty of battery volume specific capacity, and affecting the electrical performance of finished batteries, etc. To achieve the effect of improving compaction density, increasing volume capacity and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Anode material formula:

[0022] Natural spherical graphite (including artificial graphite): natural flake graphite conductive agent: thickener CMC: binder SBR: solvent water = 100:2.5:1.5:4.0:100.

[0023] 2. Preparation of negative electrode slurry

[0024] Preparation of rubber compound: first add thickener CMC (molecular weight distribution in 8-15W) and add 35% of the total solvent water, stir in a mixer for 30 minutes, and then add 25% of solvent water to continue stirring , The stirring time is 15 minutes, and finally 35% of the solvent is added for stirring, and the stirring time is 45 minutes to complete the process of preparing the adhesive glue;

[0025] Pulping: Stir the natural spherical graphite (including artificial graphite) and natural flake graphite conductive agent in a vacuum mixer at 10Hz revolution for 1 hour, add 10% of the rubber material prepared above and stir for 0.5 hour at 10Hz revolution, then add 55% of glue Stir the material at 40Hz revolu...

Embodiment 2

[0032] 1. Anode material formula:

[0033] Natural spherical graphite (including artificial graphite): natural flake graphite conductive agent: thickener CMC: binder HPMC: solvent = 100:2.5:1.5:3:100, wherein the molecular weight distribution of binder CMC is 10-30W.

[0034] 2. Preparation of negative electrode slurry

[0035] To prepare the rubber compound, first add the thickener CMC and 80% of the solvent (the solvent can also be added step by step), and stir in a mixer (which can be an egg beater or other type of mixer), and the stirring time is 10 minutes ~12 hours to complete the process of preparing the binder glue on the premise of ensuring the full dissolution and dispersion of the binder glue;

[0036] The preparation process of the negative electrode slurry is the same as in the first embodiment.

[0037] 3. Preparation of finished batteries

[0038] The above-mentioned negative electrode material is pressed into a negative pole piece, and the electrolyte system and th...

Embodiment 3

[0043] 1. Anode material formula:

[0044](a) Natural graphite: artificial graphite: conductive agent: thickener CMC: binder SBR: solvent = 90:10:2.5:1.0:3.0:100;

[0045] (b) Natural graphite: artificial graphite: conductive agent: thickener CMC: binder PTFE: solvent=80:20:2.5:1.0:3.0:100;

[0046] (c) Natural graphite: artificial graphite: conductive agent: thickener CMC: binder PVO: solvent=70:30:2.5:1.0:3.0:100;

[0047] 2. Preparation of negative electrode slurry and finished battery

[0048] The artificial graphite and the conductive agent in the above formula were added to natural graphite for dry blending at the same time, and the other preparation process was the same as in Example 2.

[0049] 3. Performance test

[0050] The finished battery specific capacity and battery cycle performance test are the same as above.

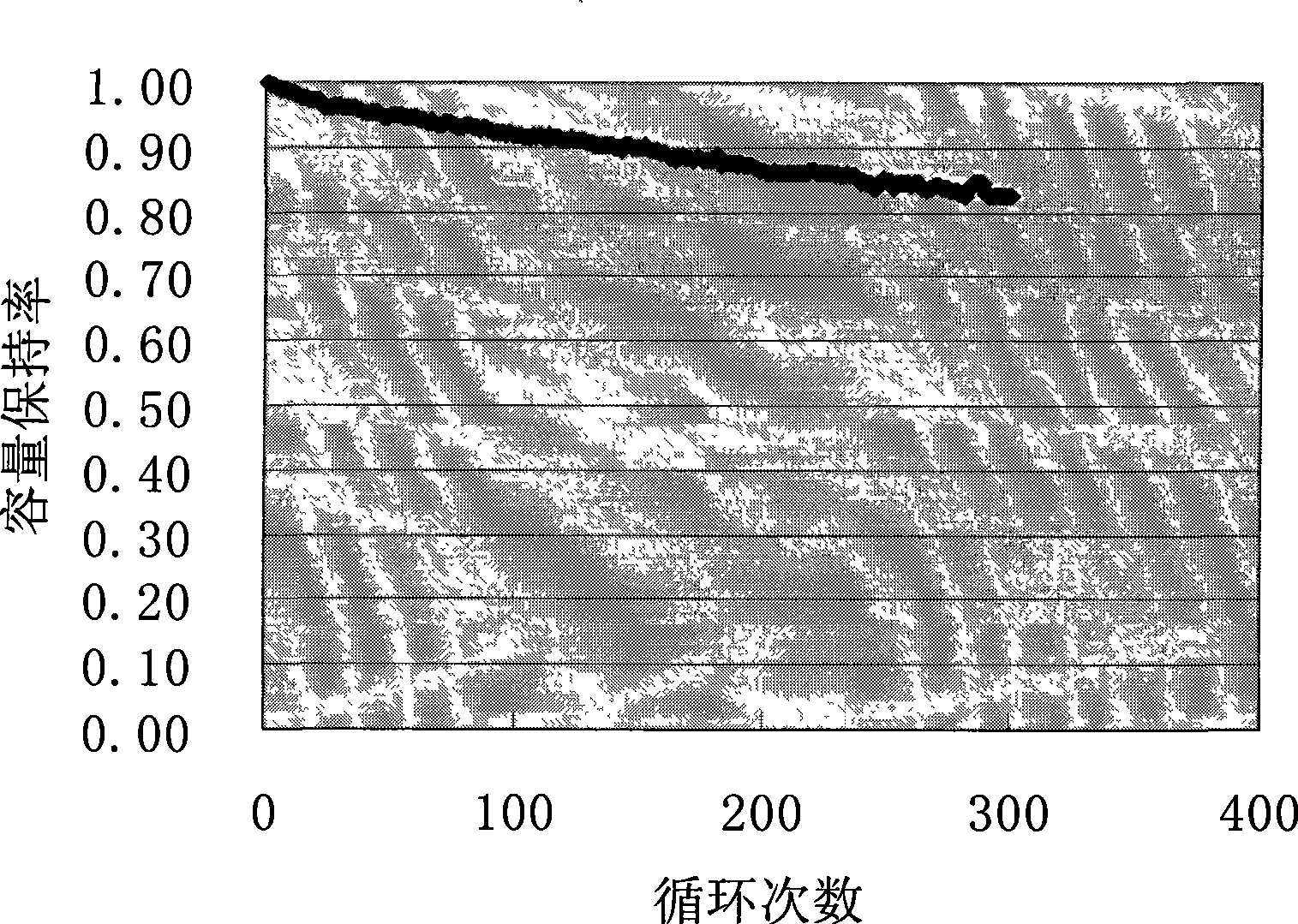

[0051] After testing, the maximum usable compaction ratio of the negative pole piece of the battery prepared in this embodiment is 1.70 g / cc, and the volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com