Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1207results about How to "Effective insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

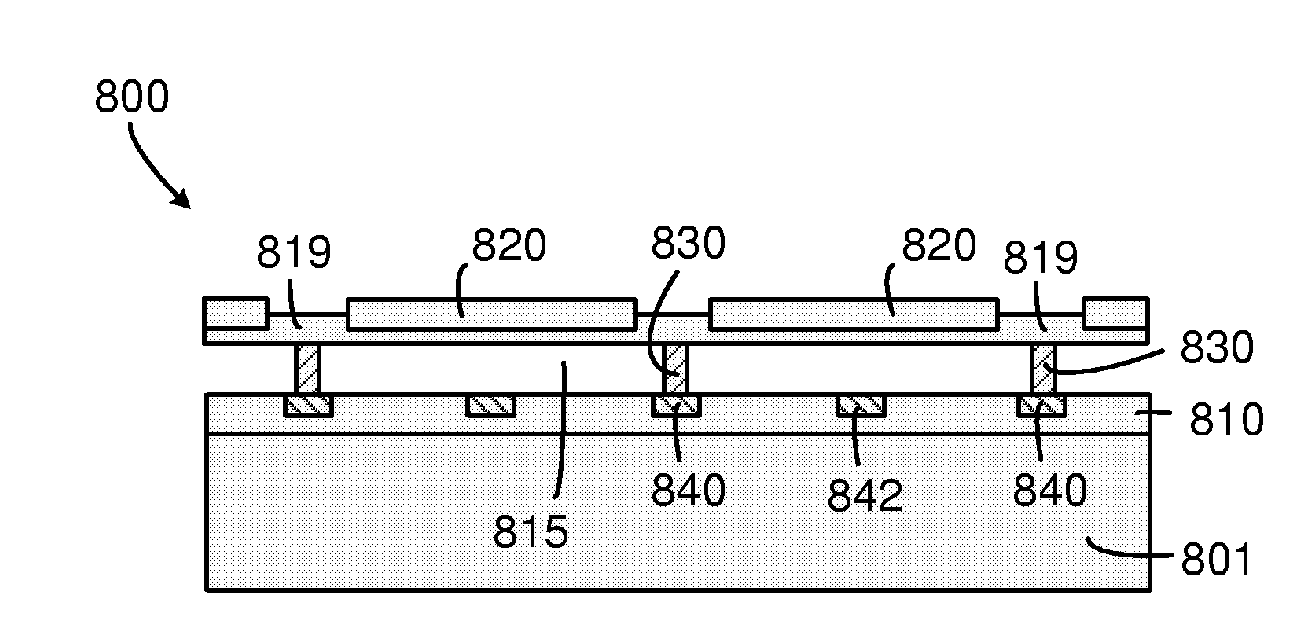

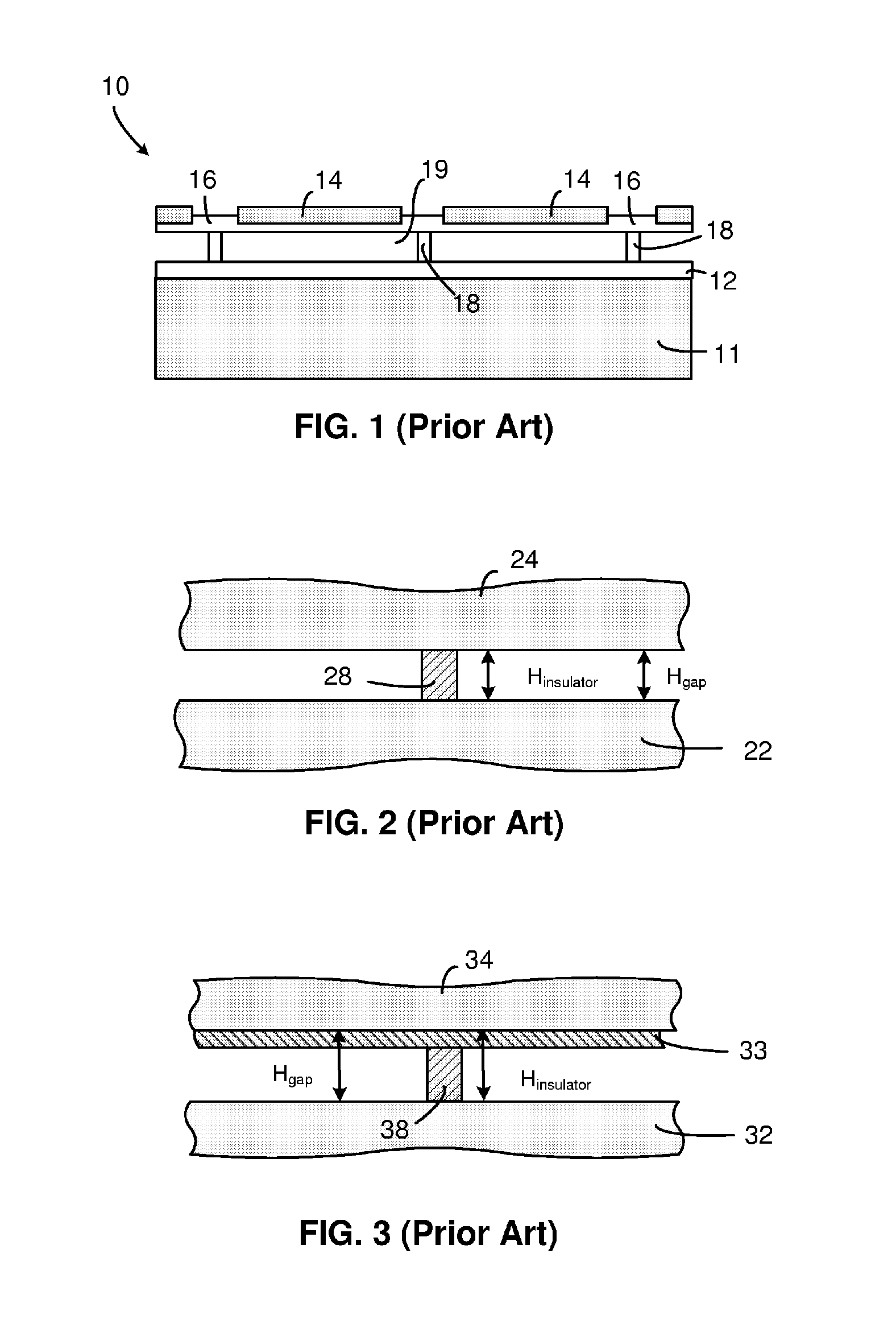

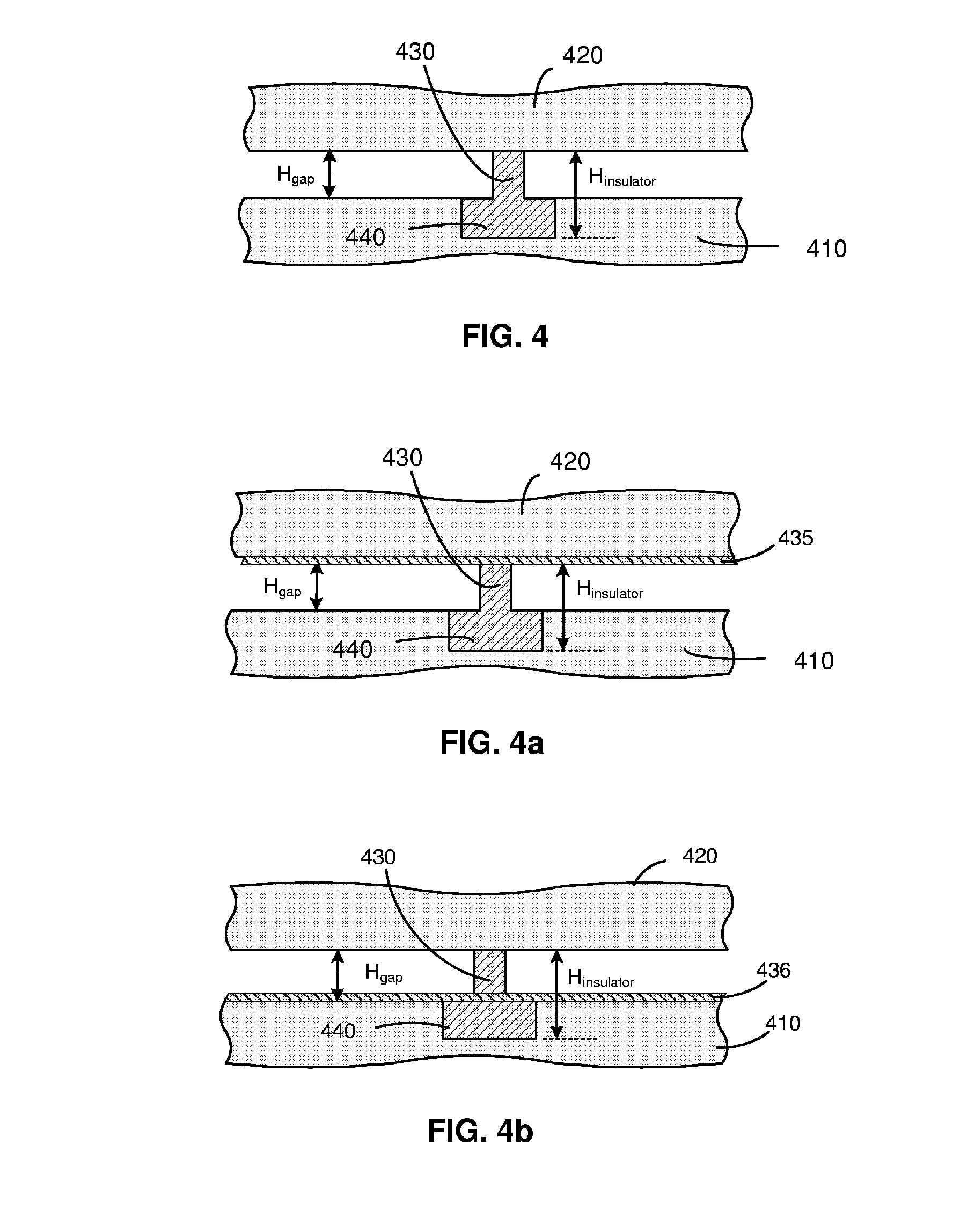

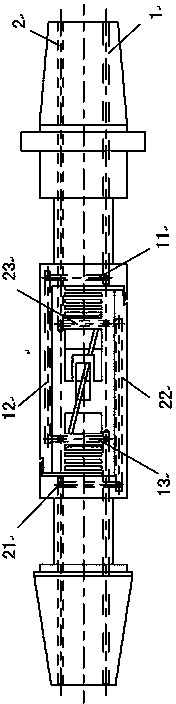

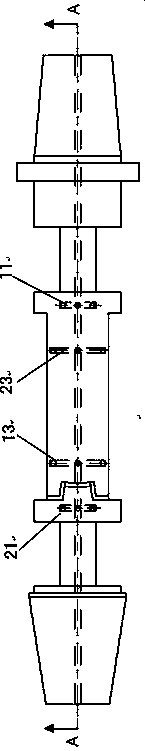

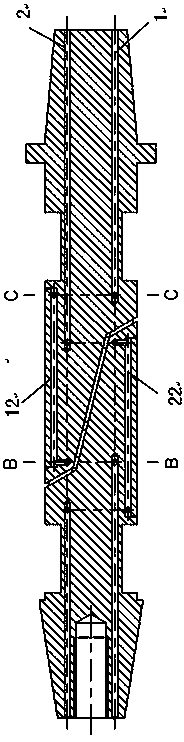

Micro-Electro-Mechanical Transducer Having an Insulation Extension

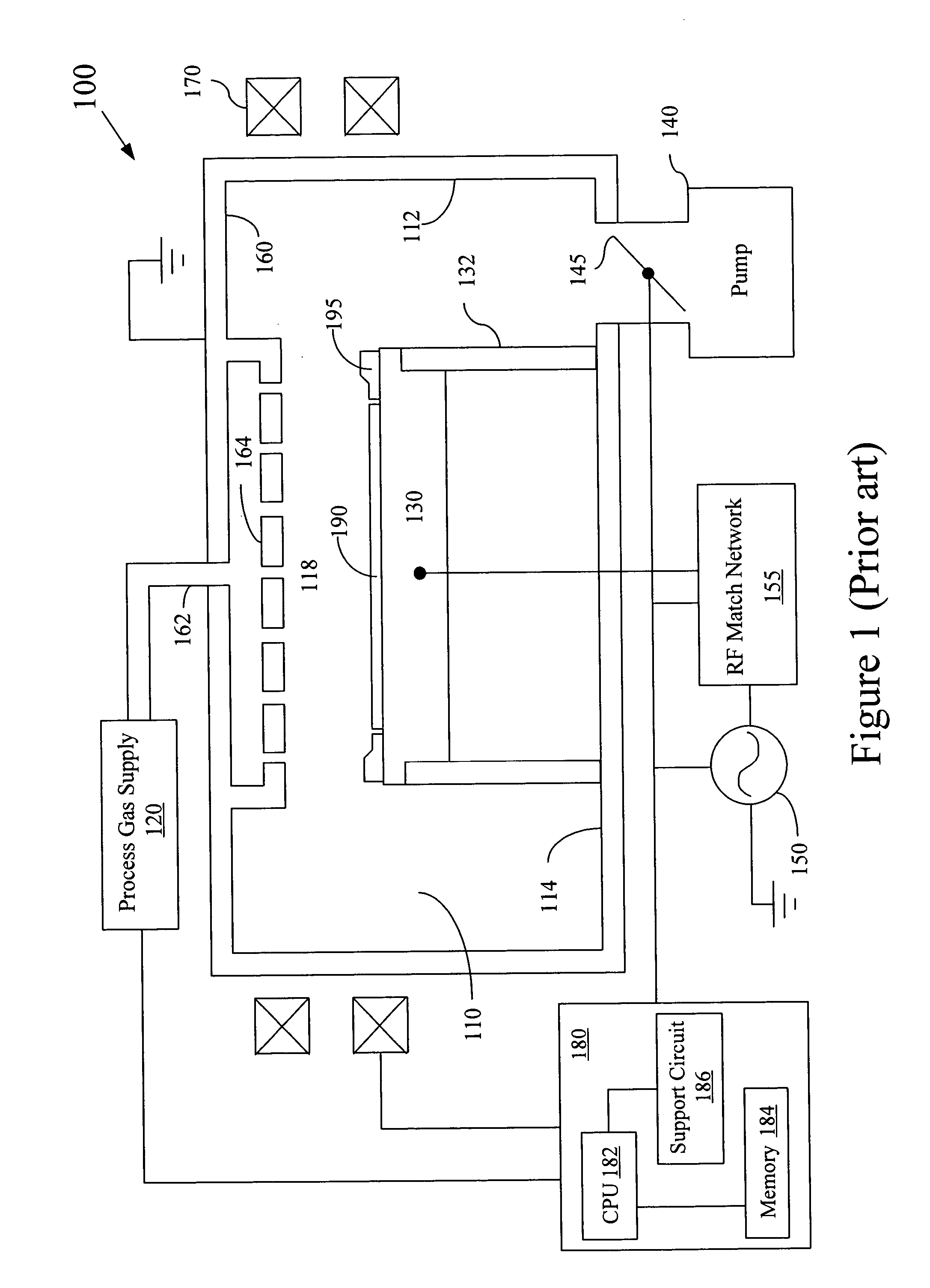

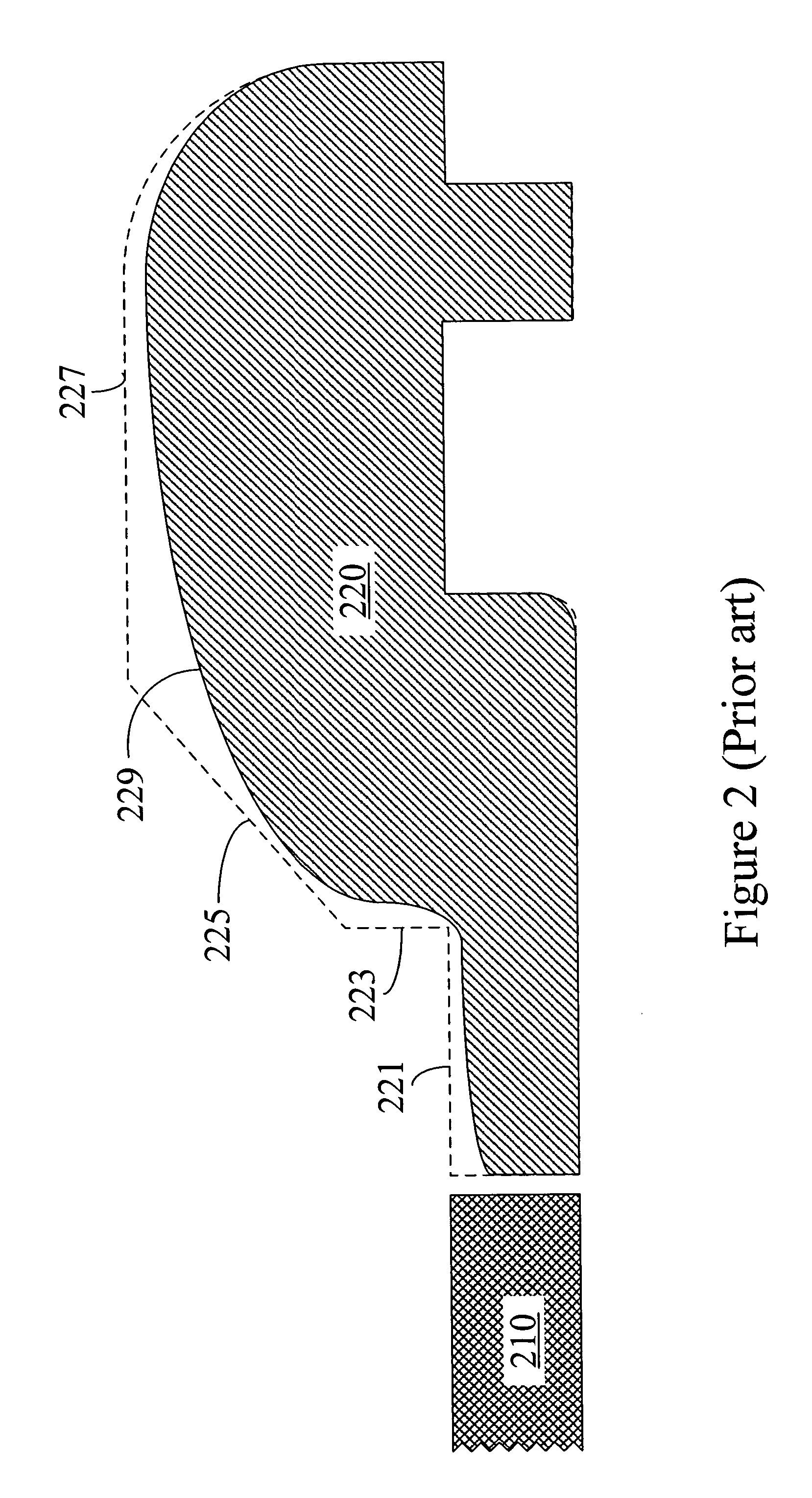

ActiveUS20080290756A1Effective insulationIncrease the gapElectrical transducersMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringElectromechanical transducer

A micro-electro-mechanical transducer (such as a cMUT) having two electrodes separated by an insulator with an insulation extension is disclosed. The two electrodes define a transducing gap therebetween. The insulator has an insulating support disposed generally between the two electrodes and an insulation extension extending into at least one of two electrodes to increase the effective insulation without having to increase the transducing gap. Methods for fabricating the micro-electro-mechanical transducer are also disclosed. The methods may be used in both conventional membrane-based cMUTs and cMUTs having embedded springs transporting a rigid top plate.

Owner:KOLO MEDICAL (SUZHOU) CO LTD

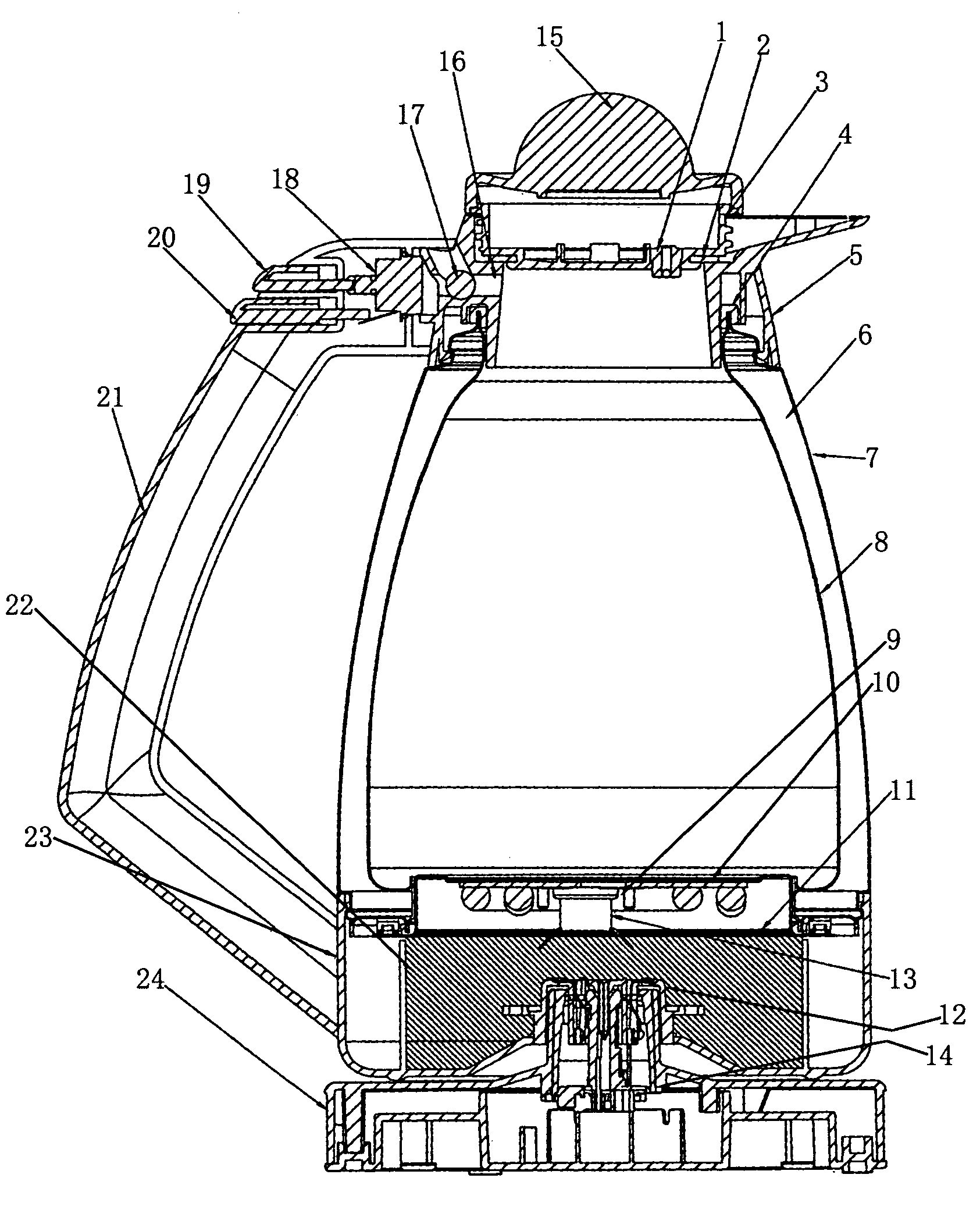

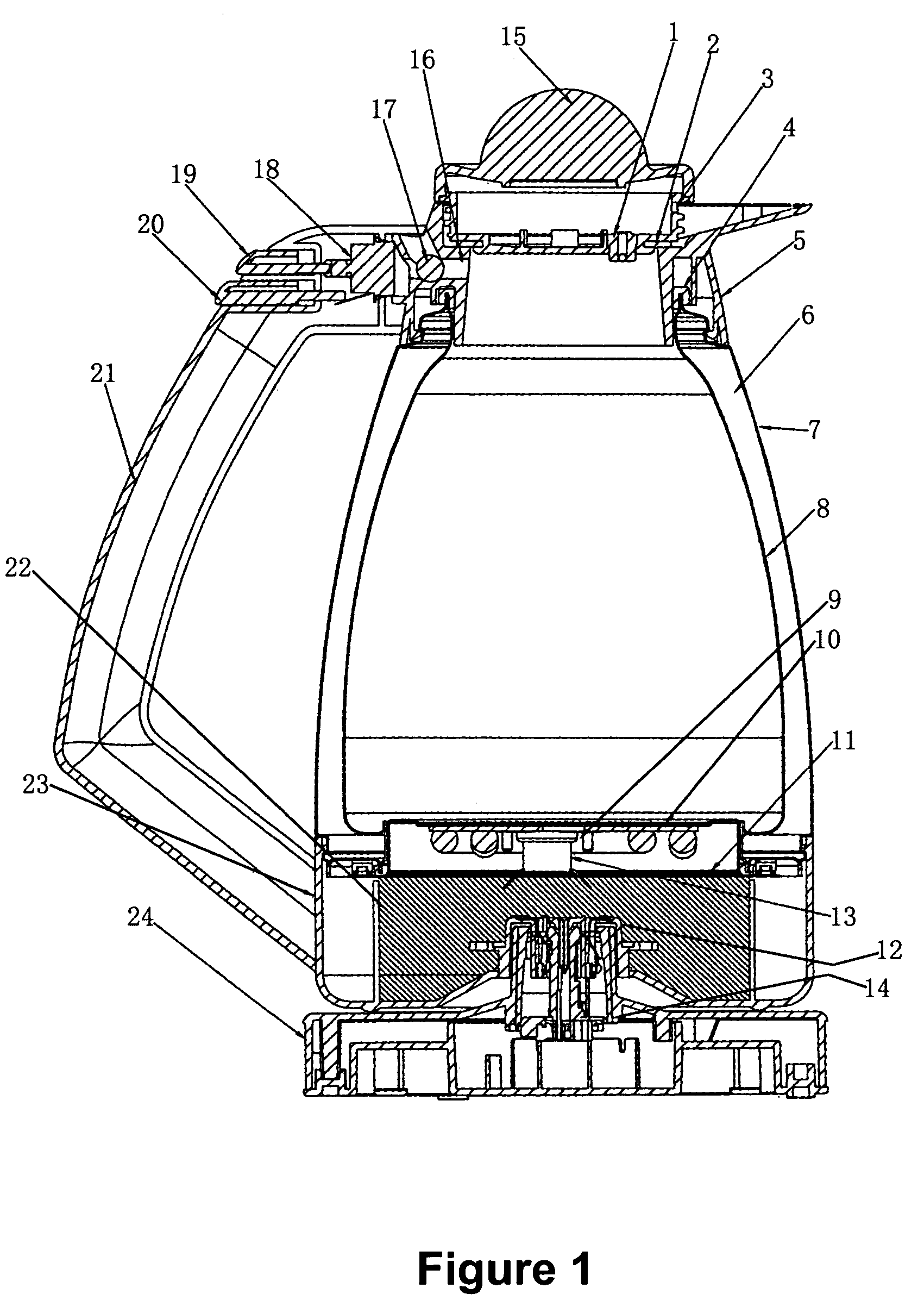

Electric thermos jug

InactiveUS7091455B2Improve air tightnessEasy to useCooking-vessel materialsDomestic cooling apparatusElectricityWater quality

Owner:FUNG SHIU PO

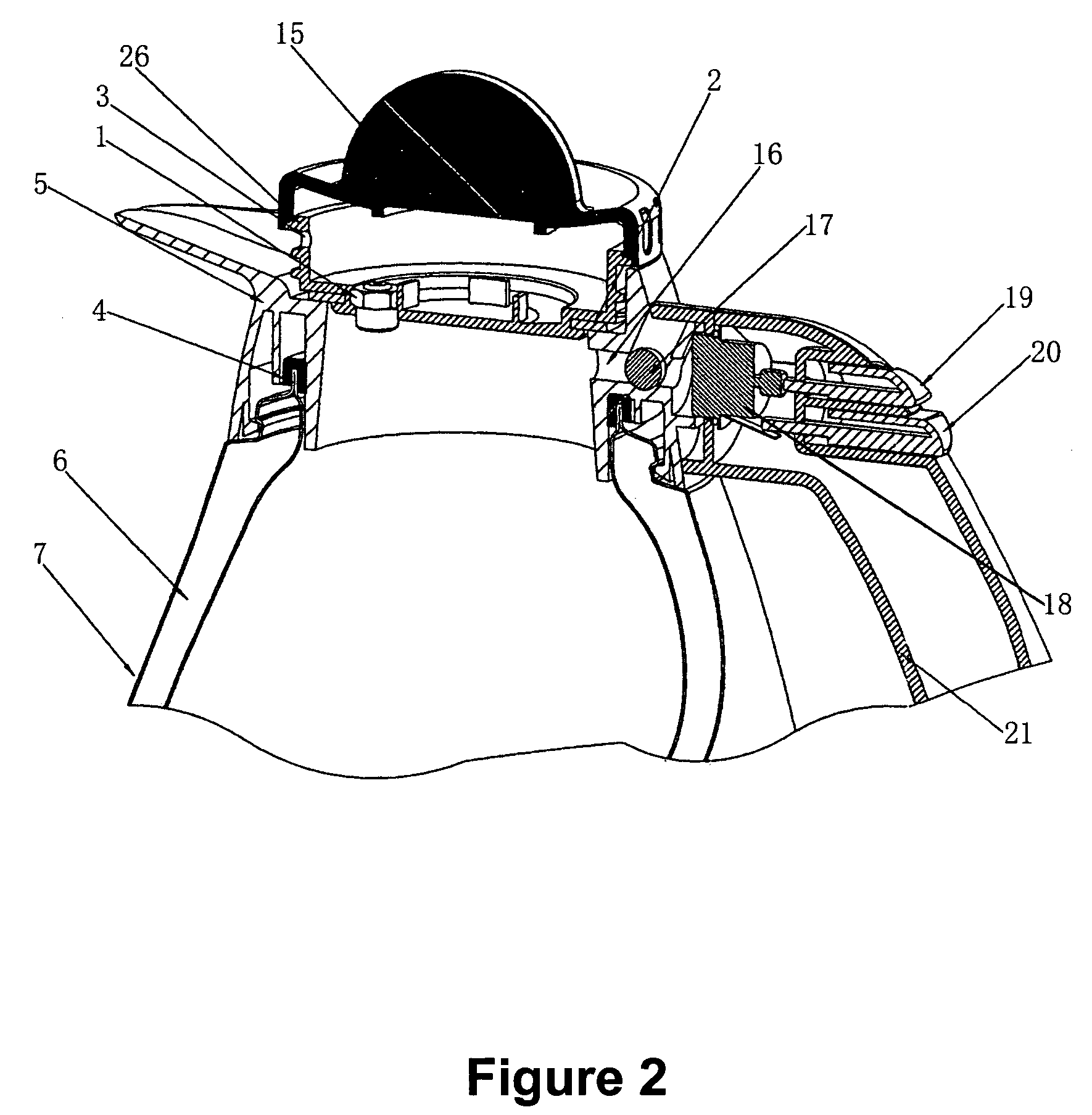

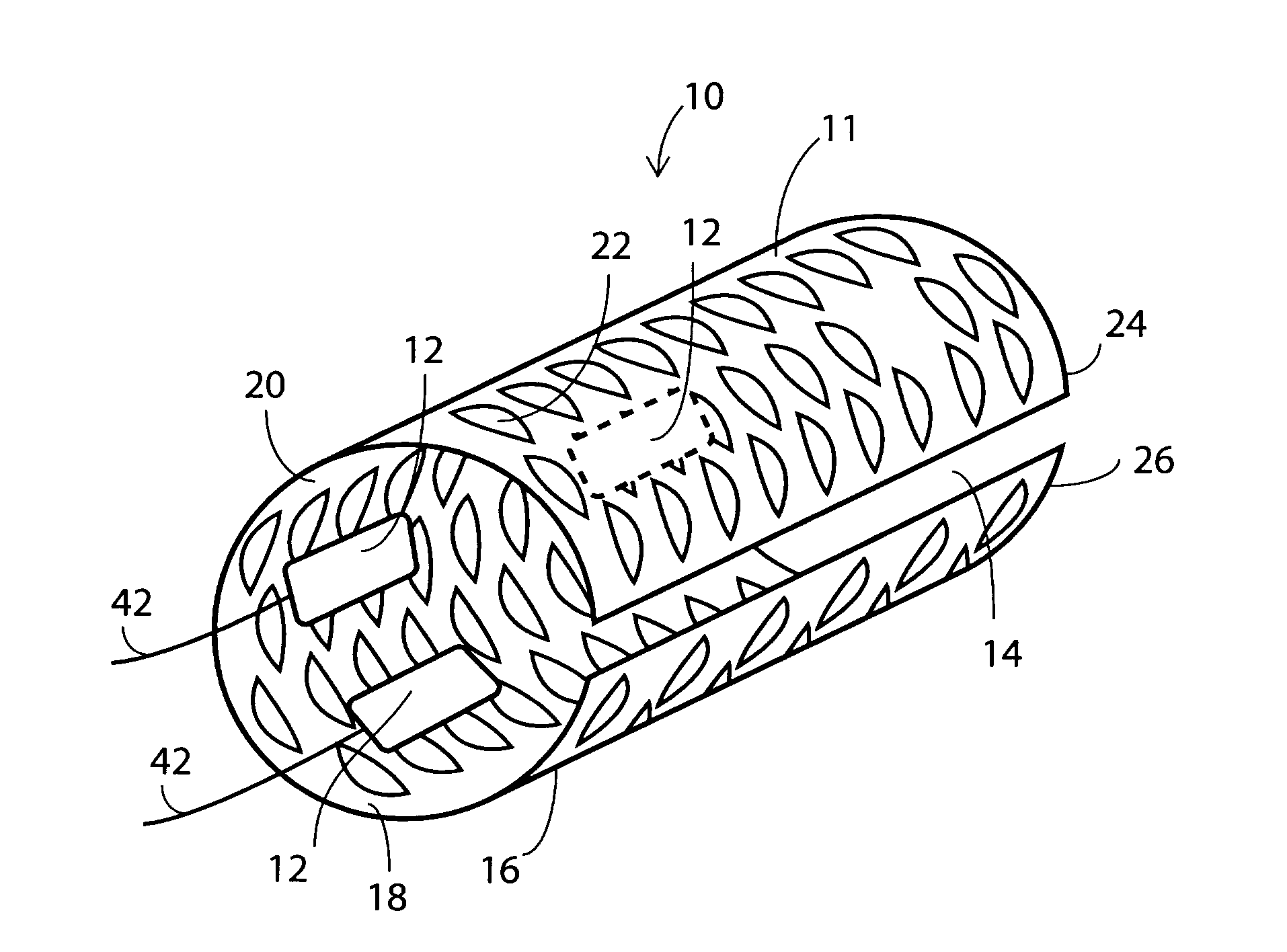

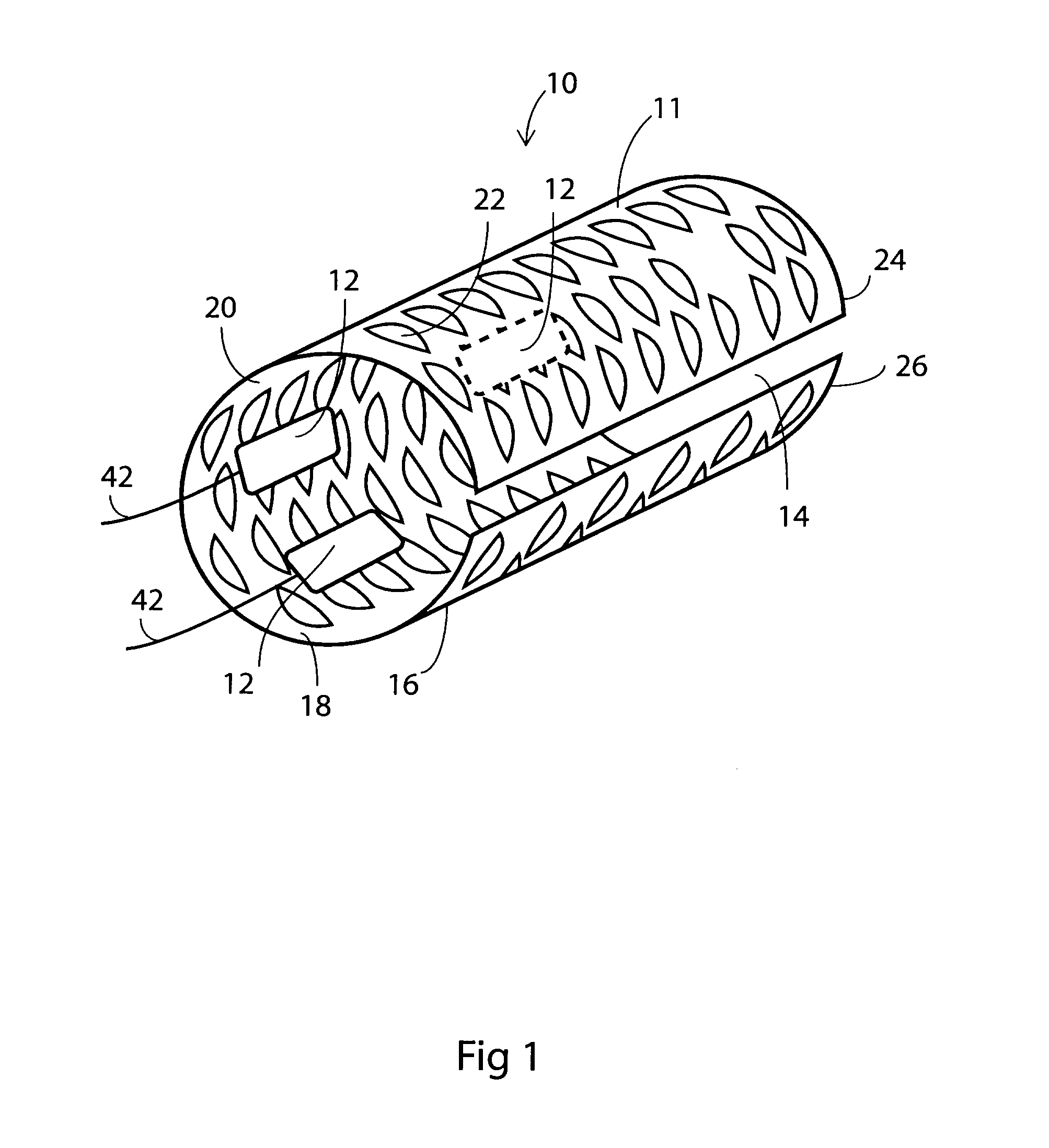

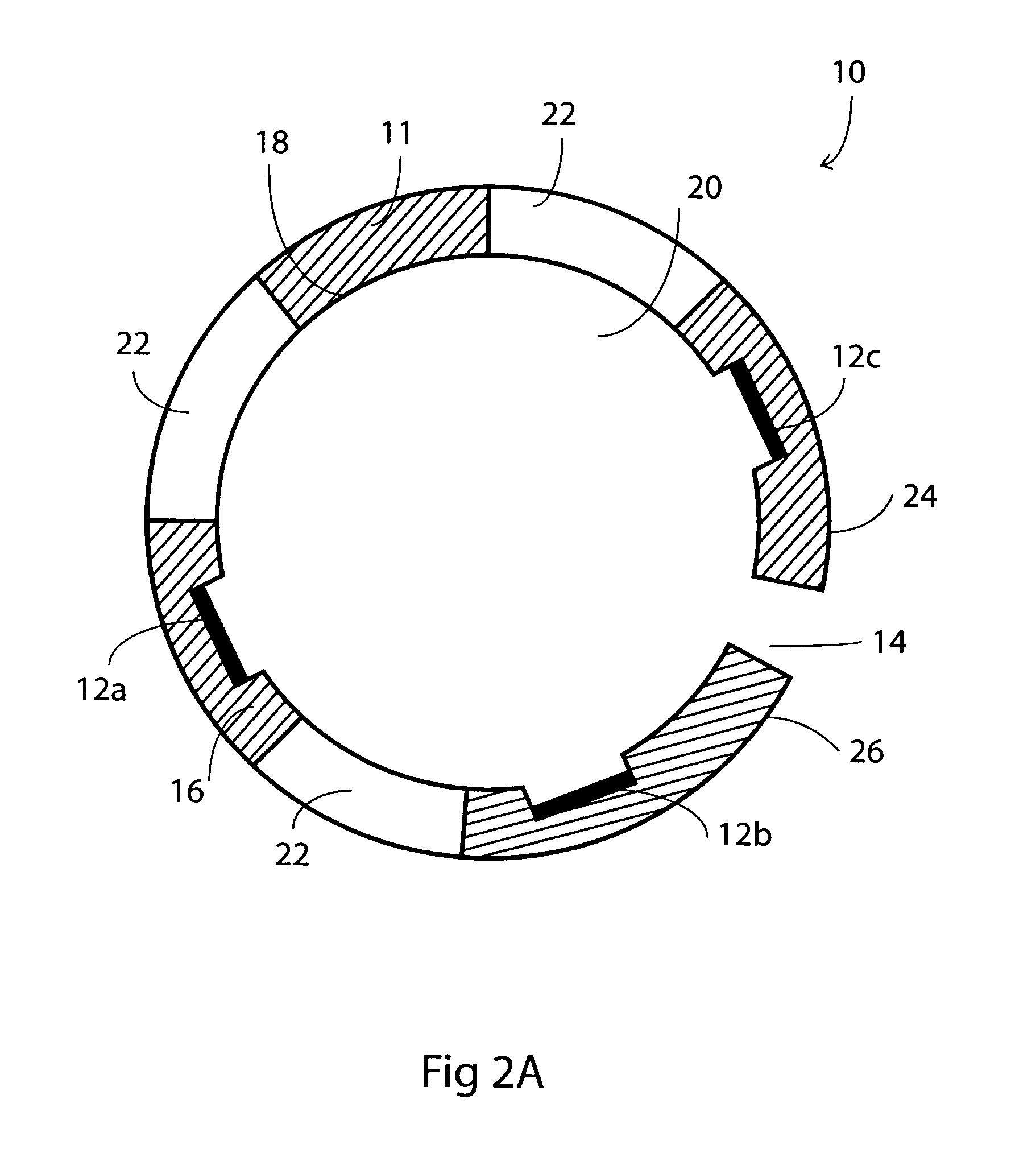

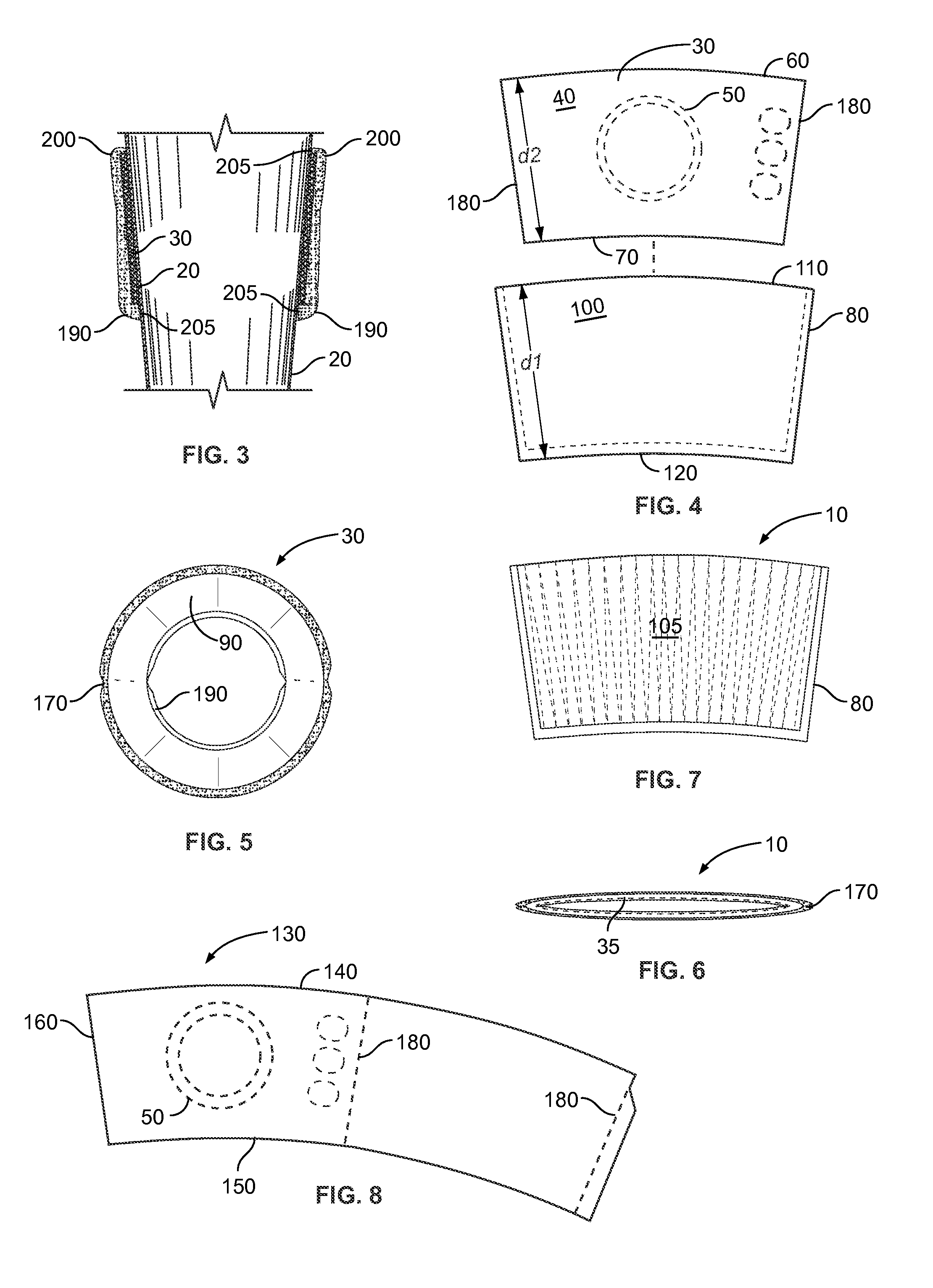

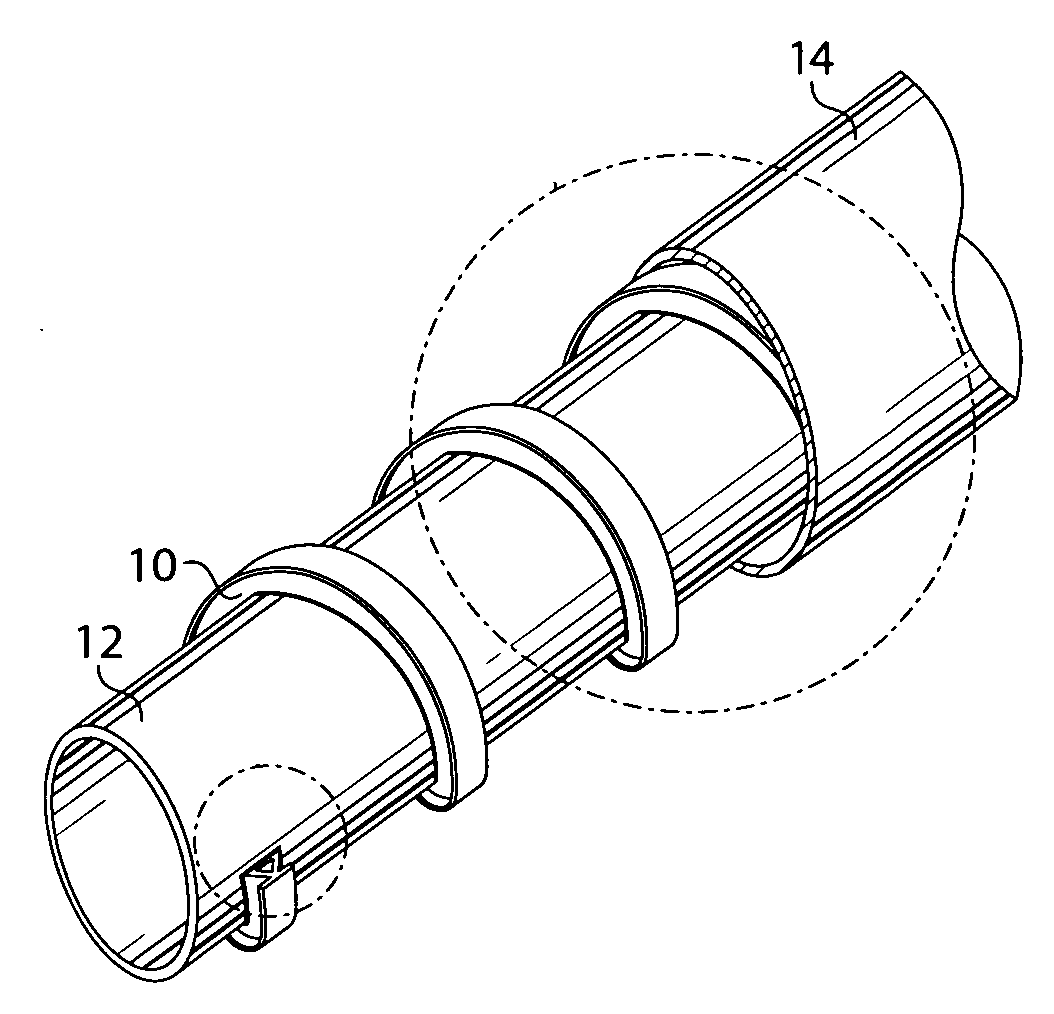

Implantable Medical Cuff with Electrode Array

InactiveUS20100241207A1Minimal manipulationSoftnessSpinal electrodesElectrocardiographyCuffElectrode array

An implantable medical assembly comprising at least one electrode carried on an inside surface of a web comprising a biocompatible film wound into a generally tubular configuration, the film containing a plurality of distinct apertures distributed throughout the web to increase its flexibility and to create a means by which biological fluids can penetrate the assembly. The assembly may further comprise at least one wire connected to the electrode to provide a stimulation signal.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

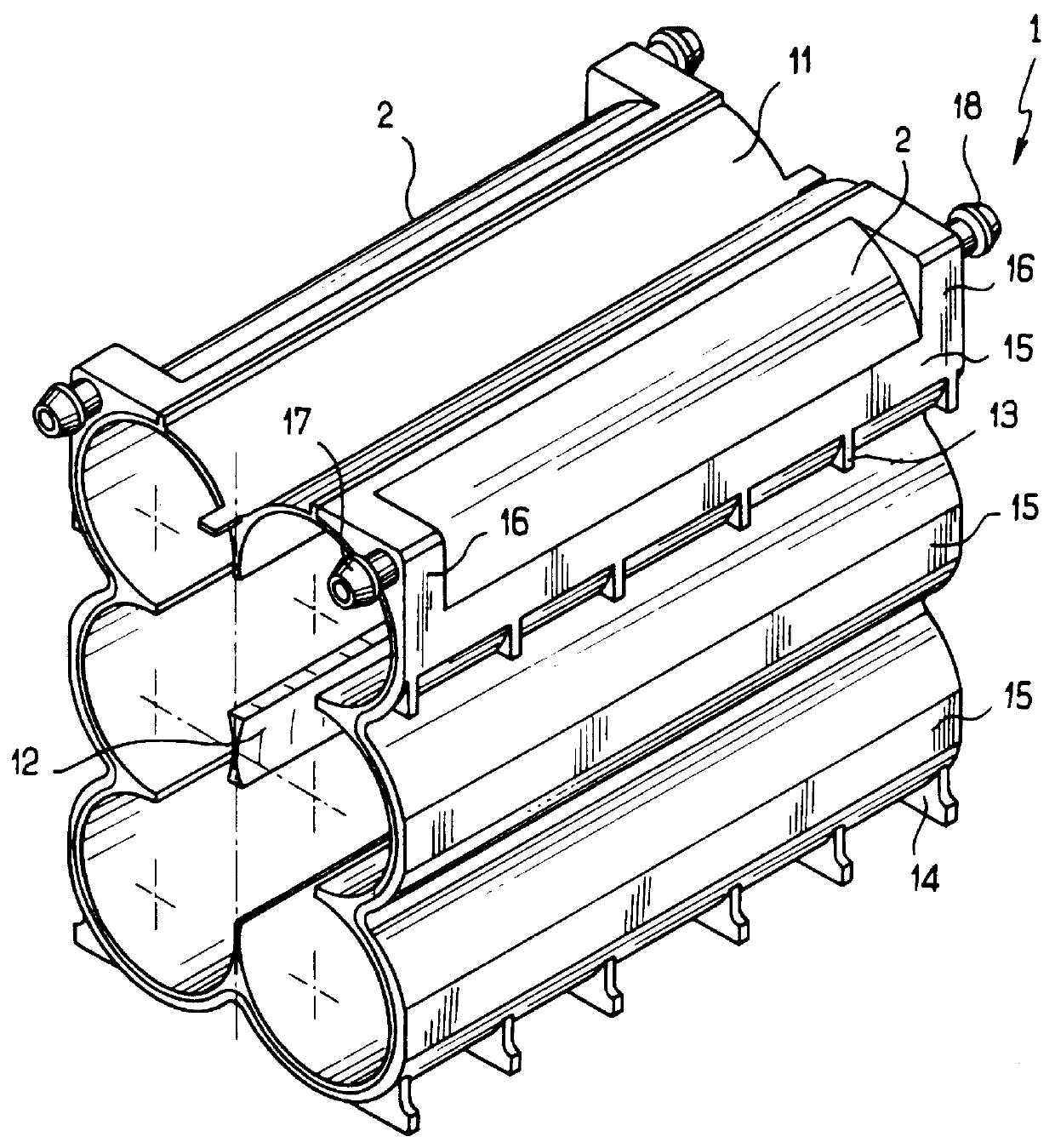

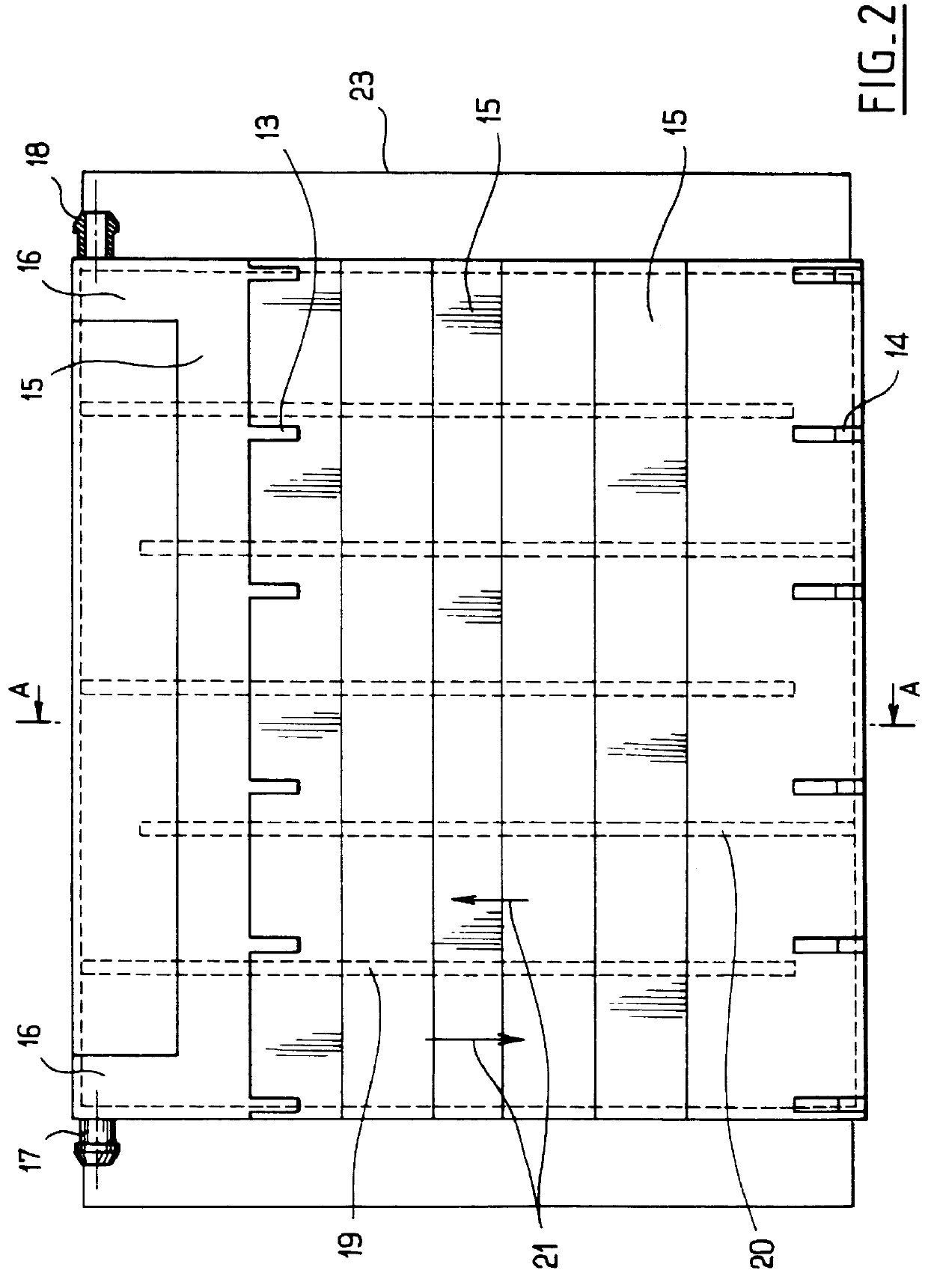

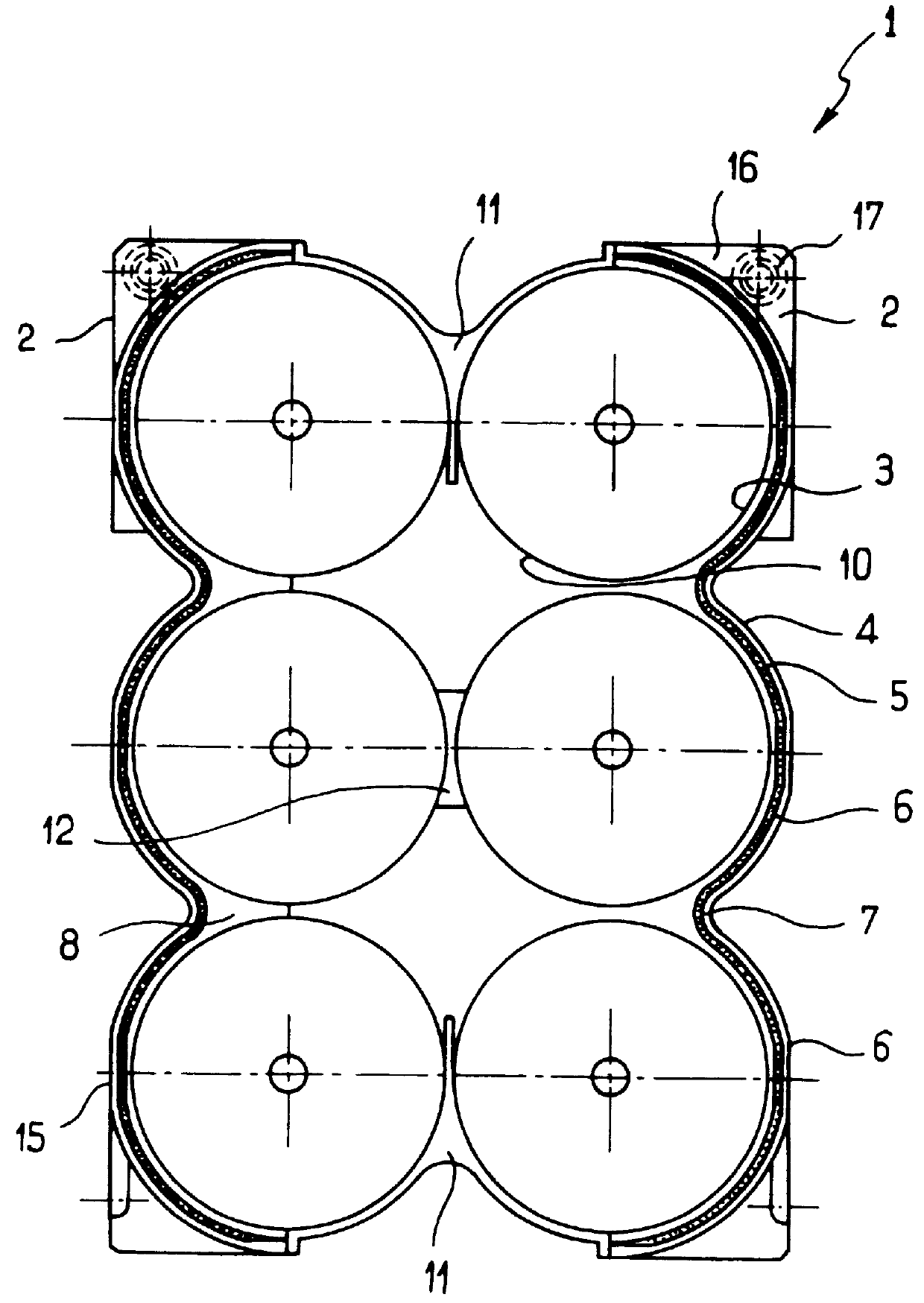

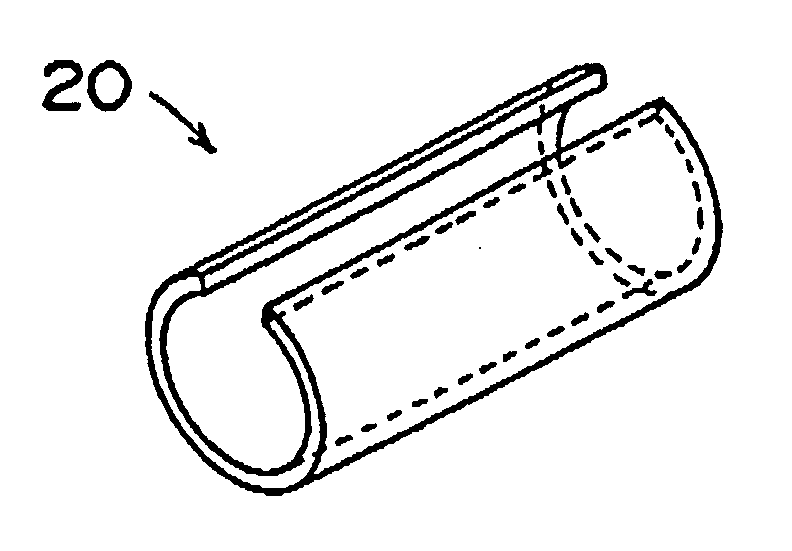

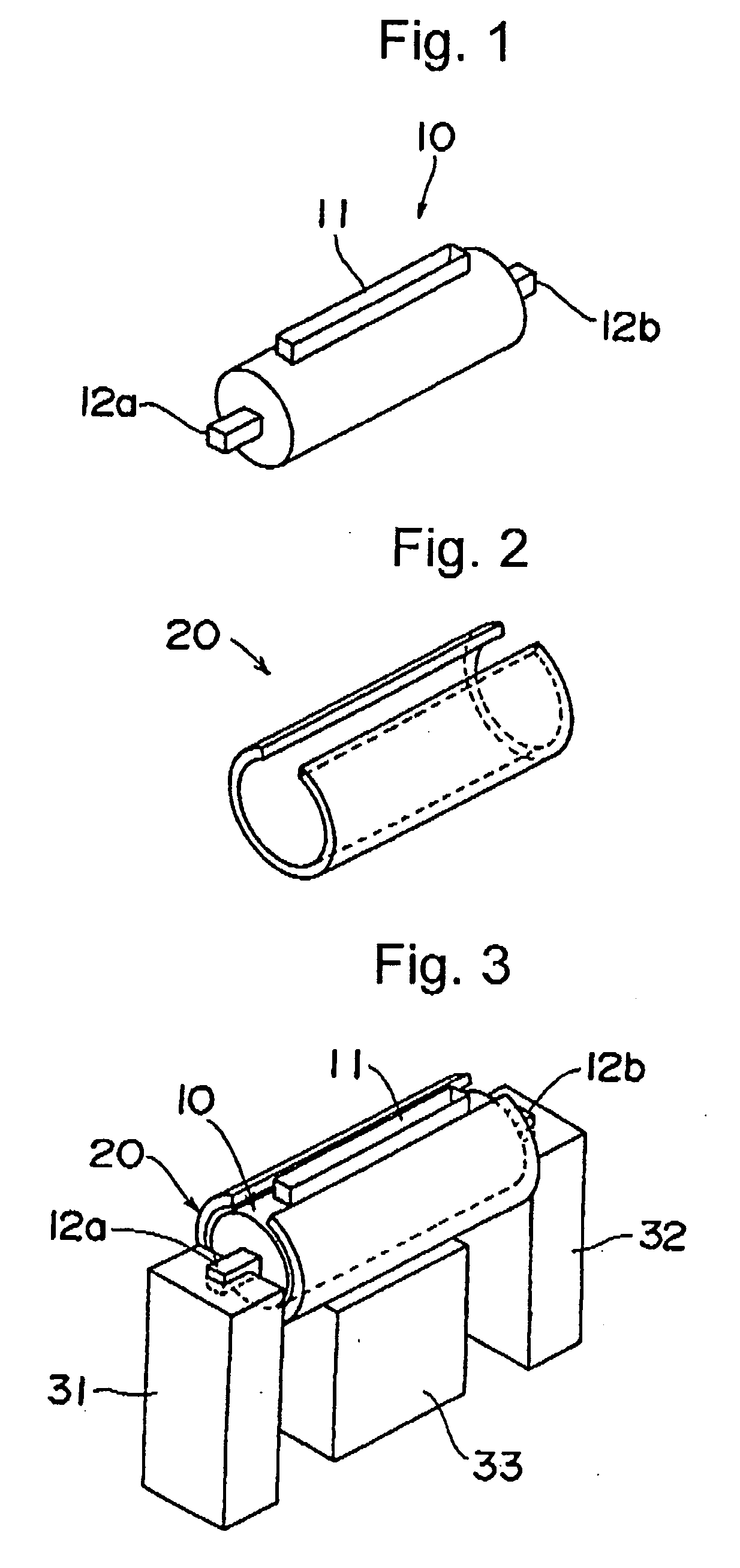

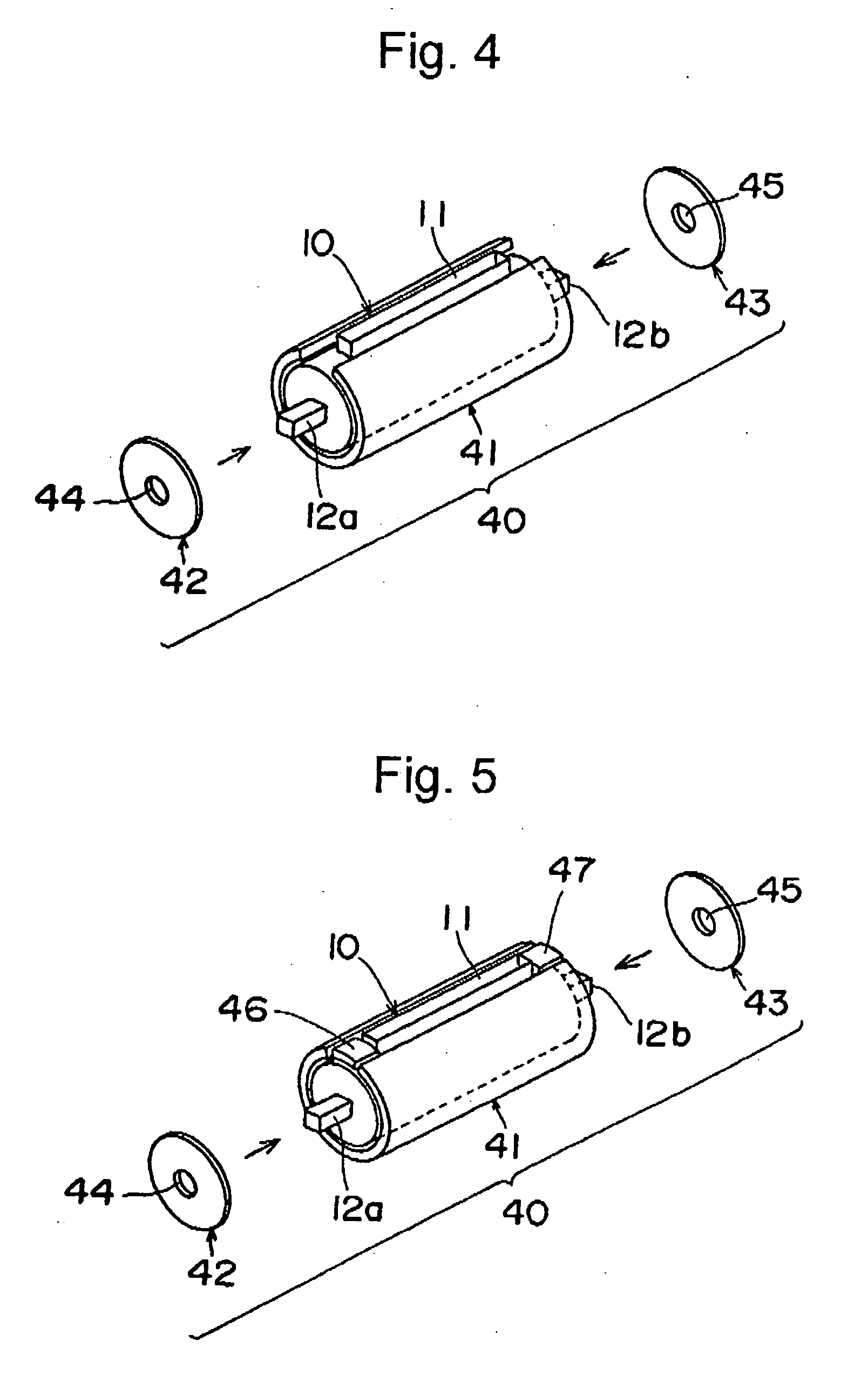

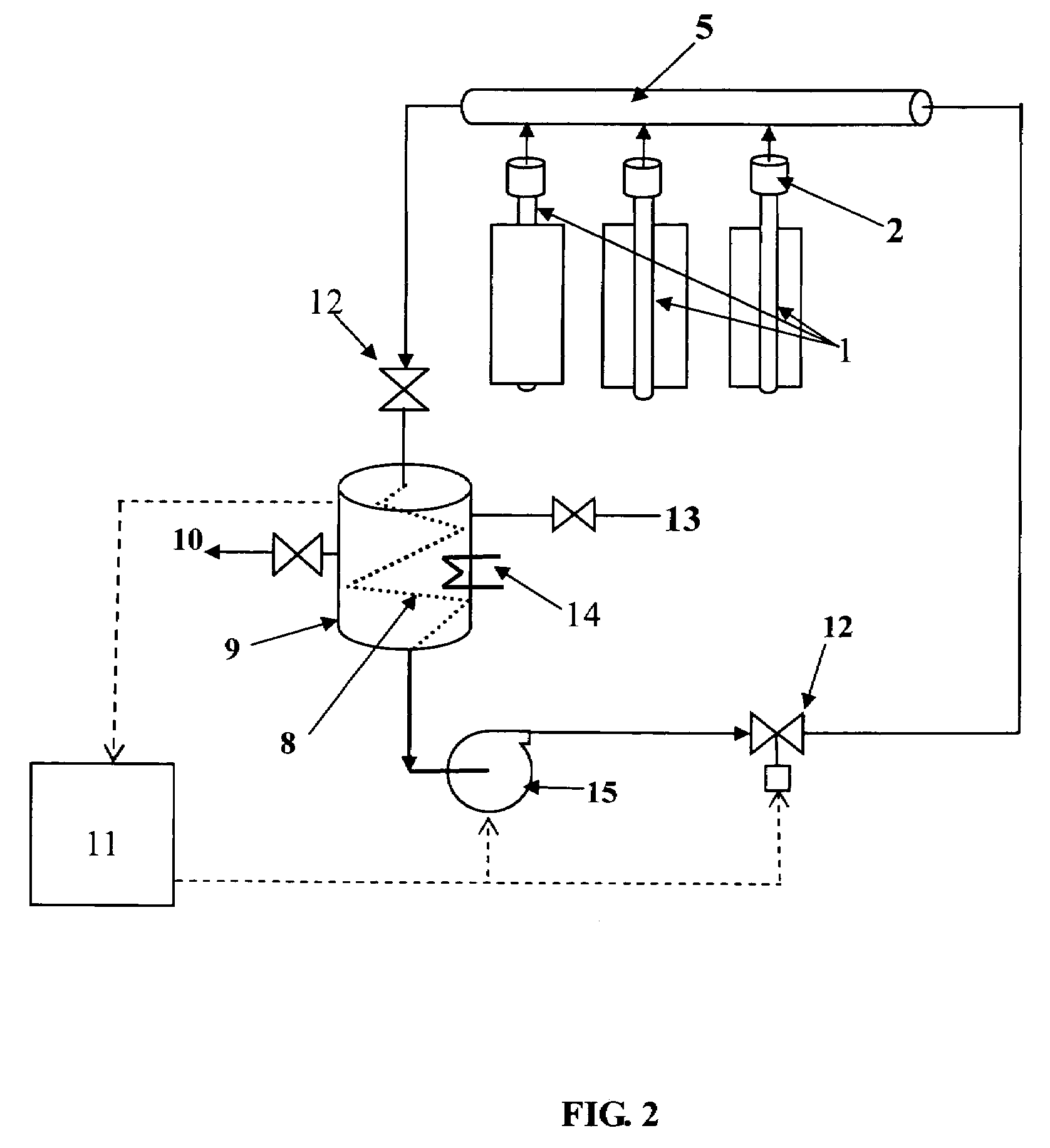

Device for controlling the temperature of a battery of electrochemical cells

InactiveUS6087038AImprove temperature uniformityReduce temperature gradientNon-aqueous electrolyte accumulatorsCell temperature controlDouble wallJunction point

In this device for controlling the temperature of a battery of cylindrically-shaped electrochemical cells placed side by side, heat is conveyed by the flow of a heat-conveying fluid, which flow takes place inside a double wall whose section is in the form of circular arcs interconnected at their ends so that the junction points between the arcs are substantially in alignment. Relief is disposed in a baffle configuration inside the double wall to constrain the fluid to flow parallel to said section, alternately in one direction and then in the opposite direction. The wall is disposed against the battery in such a manner that each of the circular arcs is disposed coaxially against one of the cells.

Owner:SAFT FINANCE S AR L

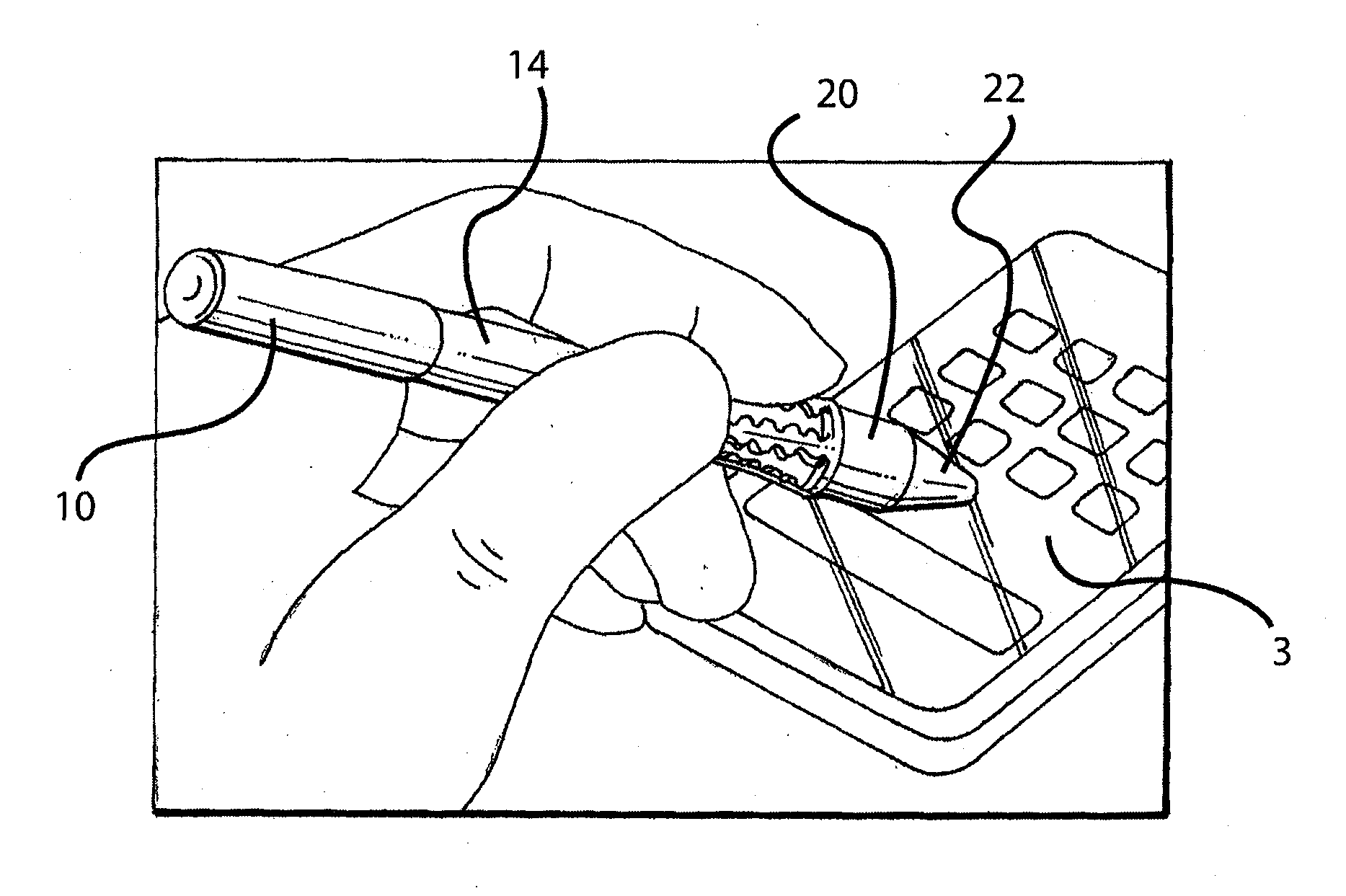

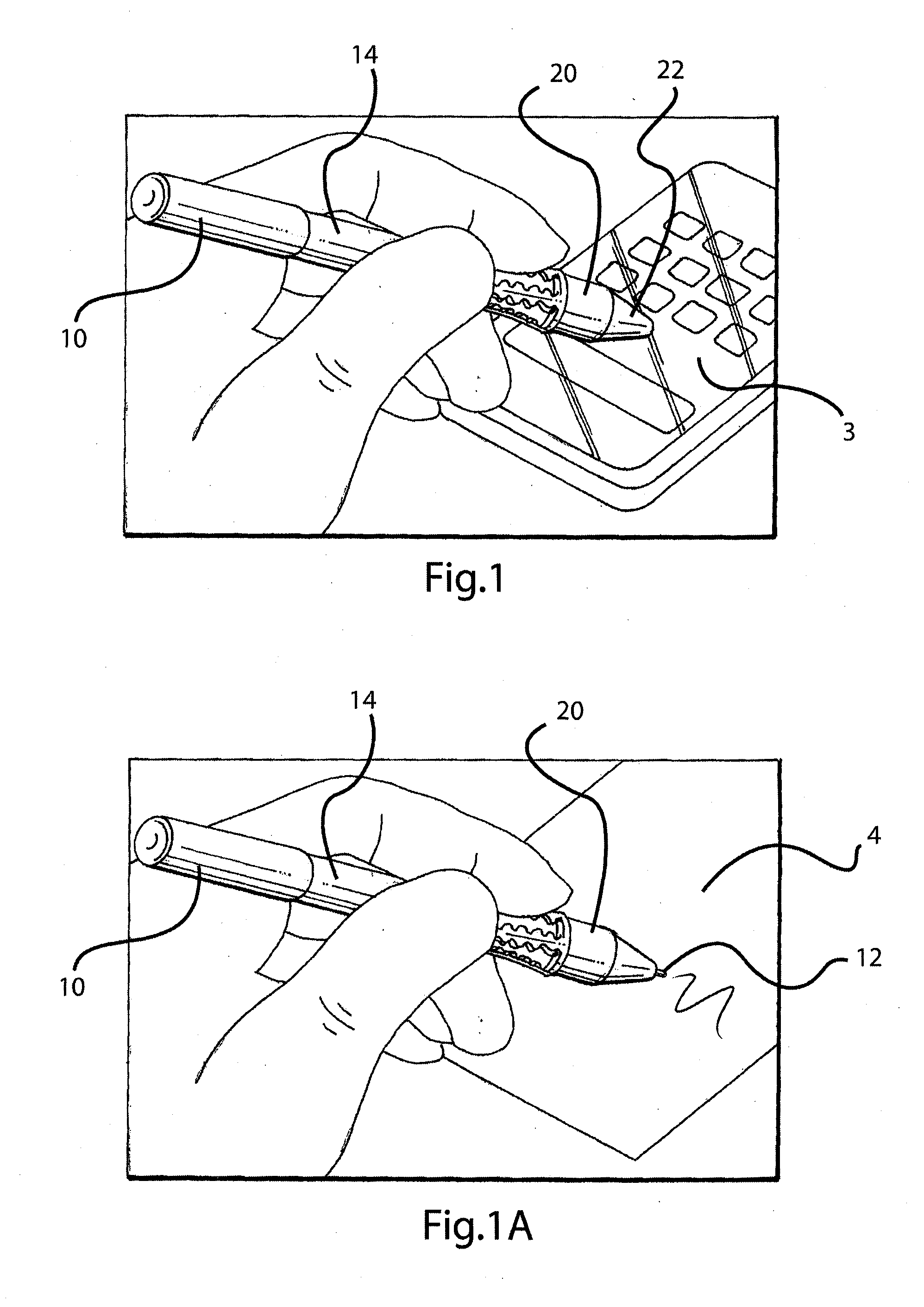

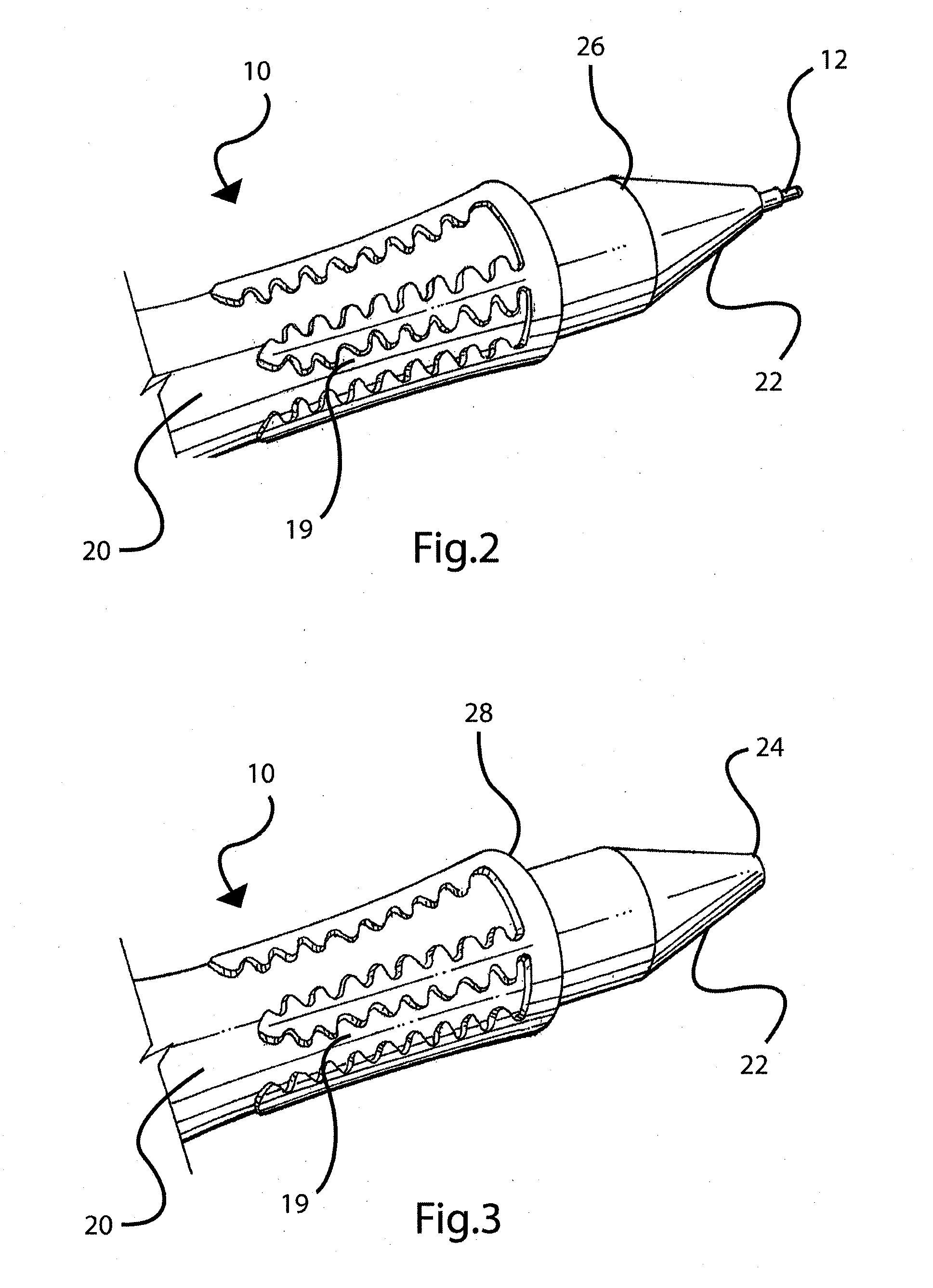

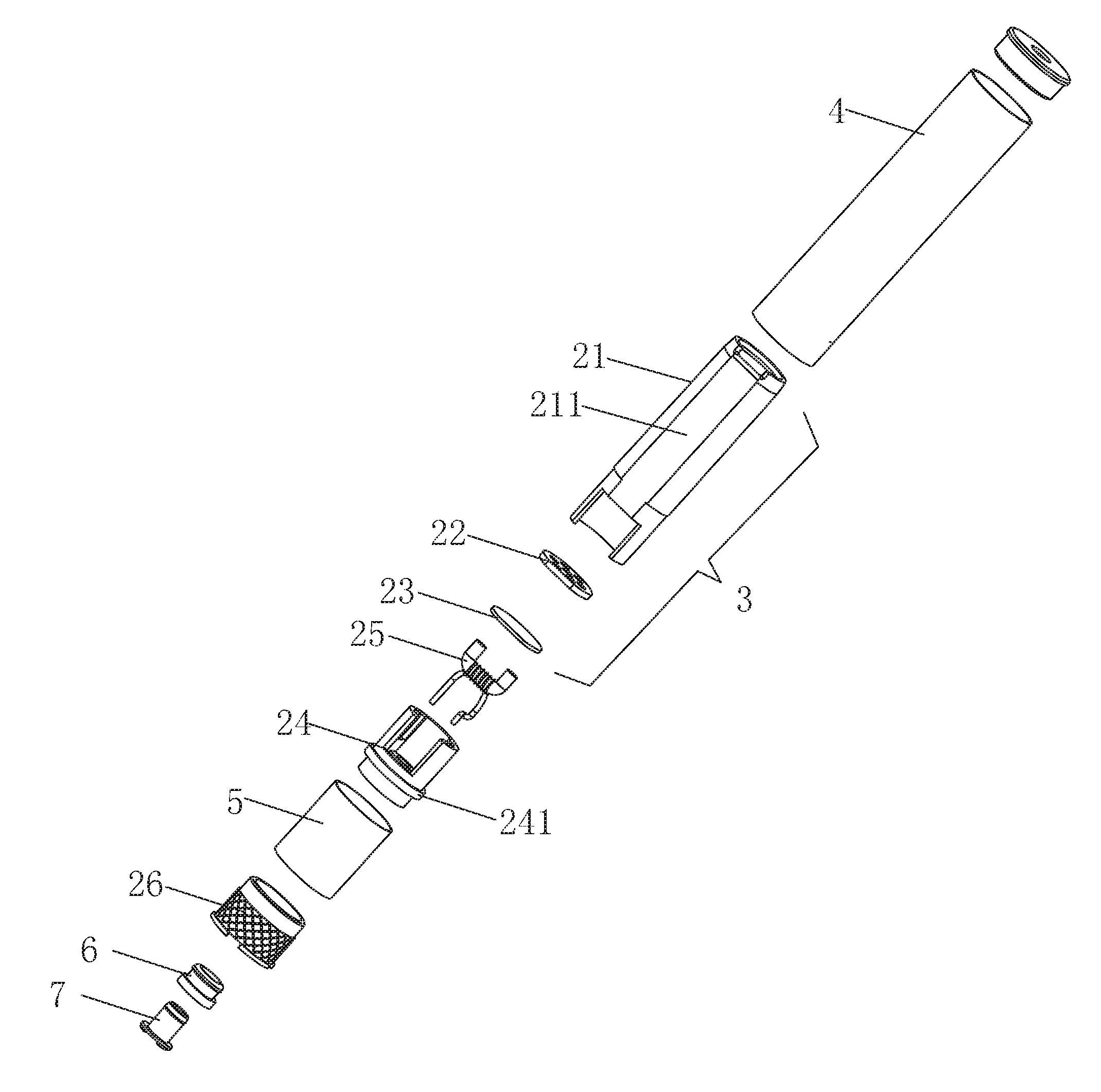

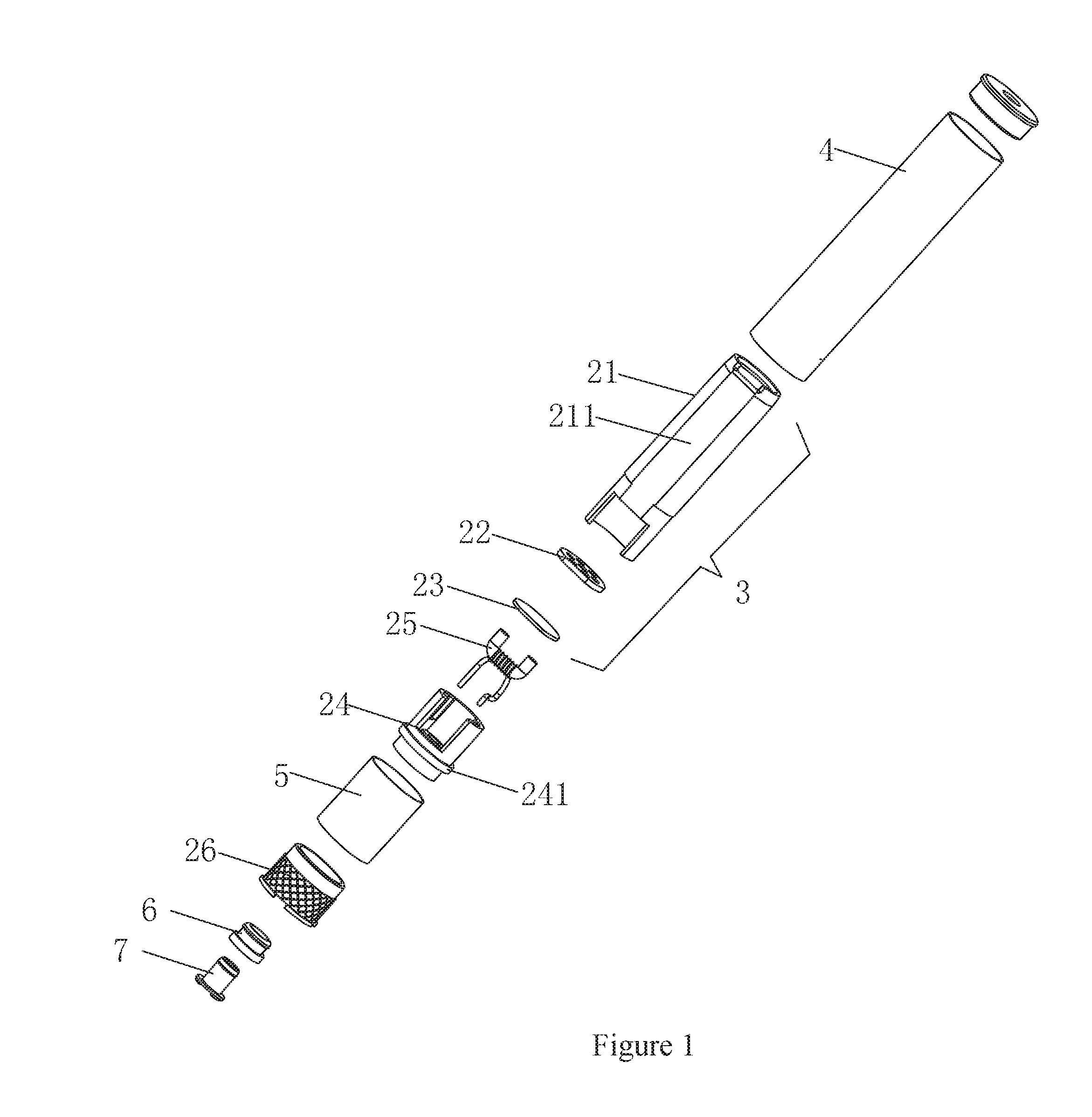

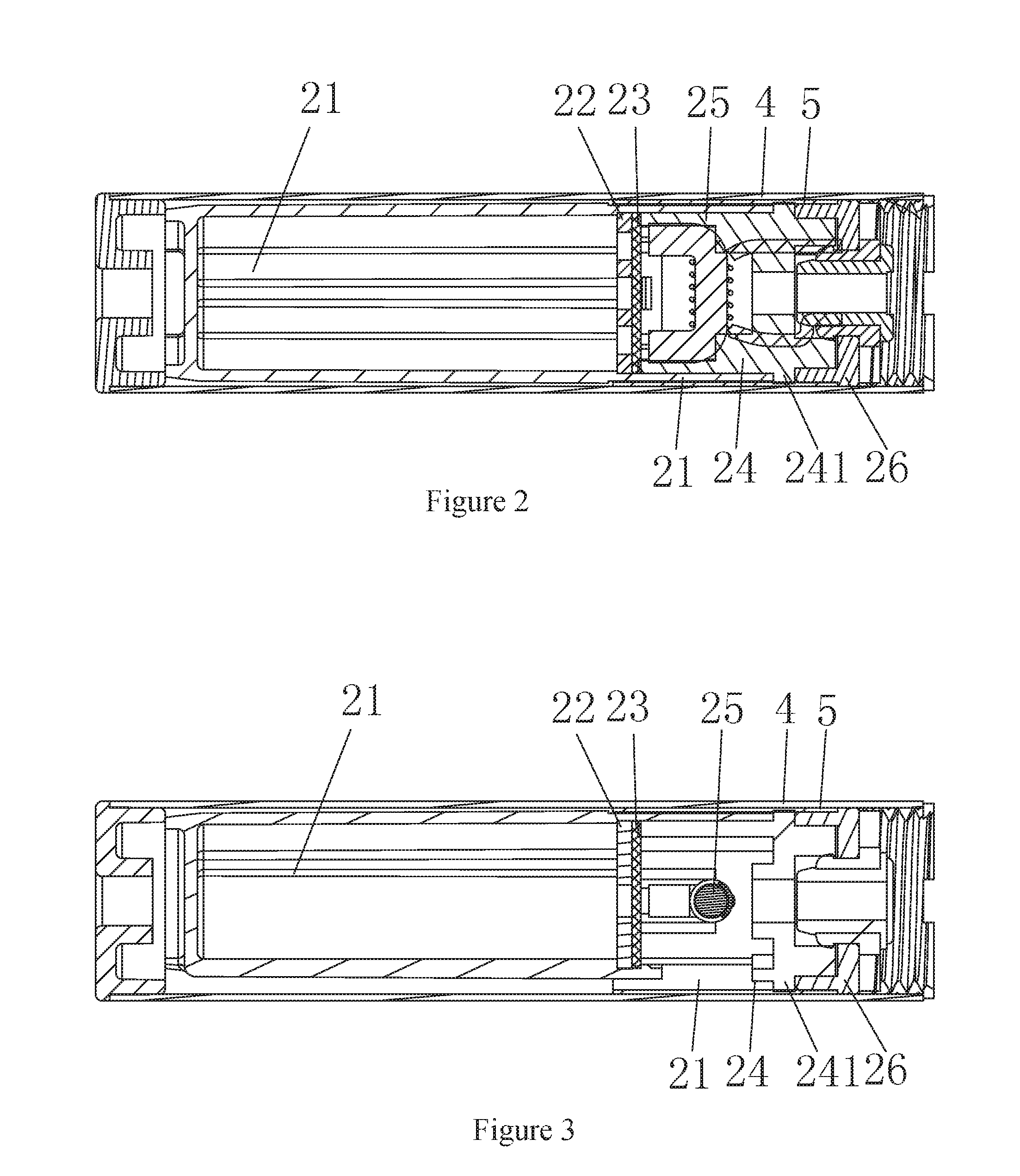

Electrically conductive touch pen

ActiveUS20130038579A1Easy to useEffective insulationWriting connectorsBall-point pensEngineeringTouchscreen

A combination writing pen and stylus is disclosed. The device has an internal ink cartridge deployable through a hole in the stylus tip. The stylus tip extends from a sleeve that is formed of a conductive elastomeric material. The sleeve extends up a rigid shaft of the device such that it contacts a sufficient ground. The stylus tip may be coated with a protective material that adjusts the coefficient of friction and prevents carbon deposits on the touch screen. A sufficient contact patch is achieved to simulate a human finger so as to overcome false positives from common touch screen logic. This is done by altering tip geometries around an air cavity within the sleeve.

Owner:PIXEL PEN LLC

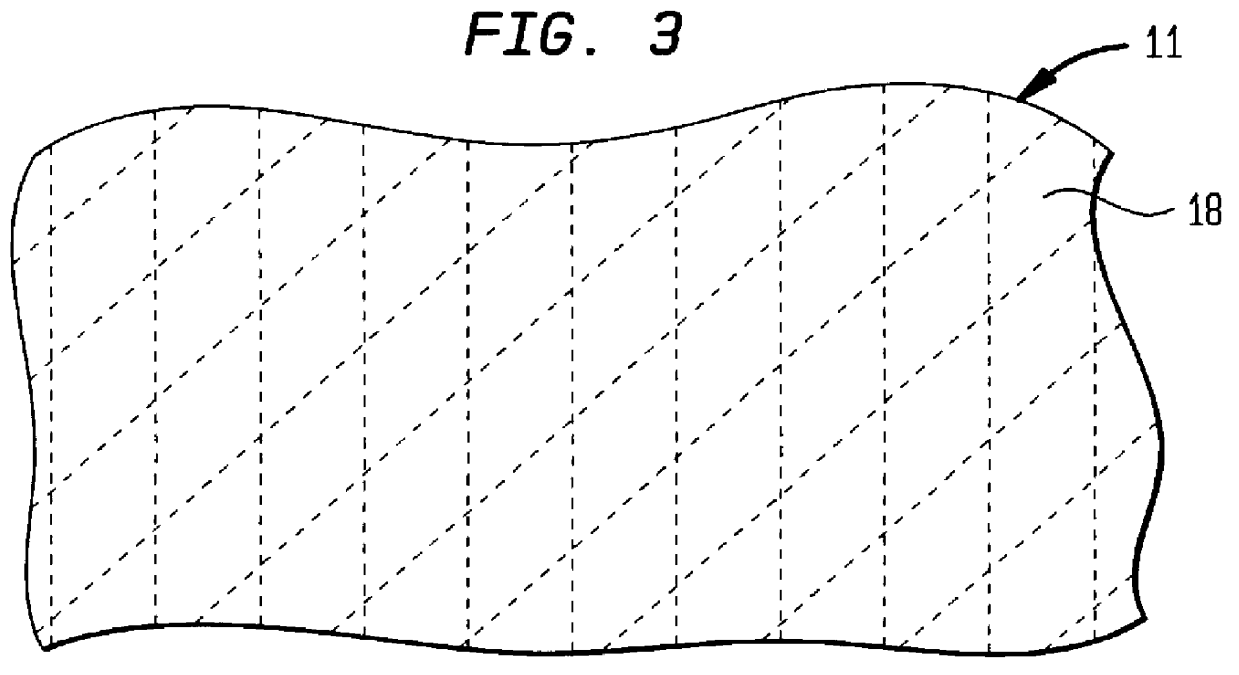

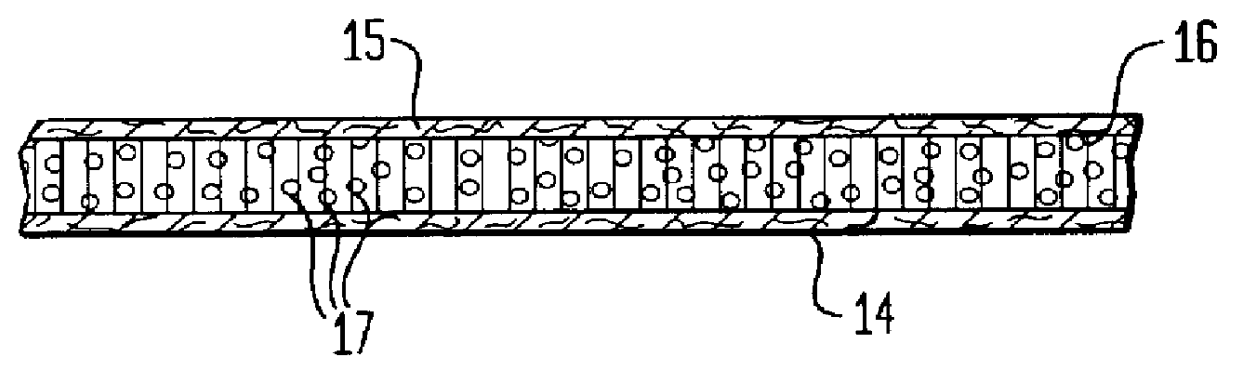

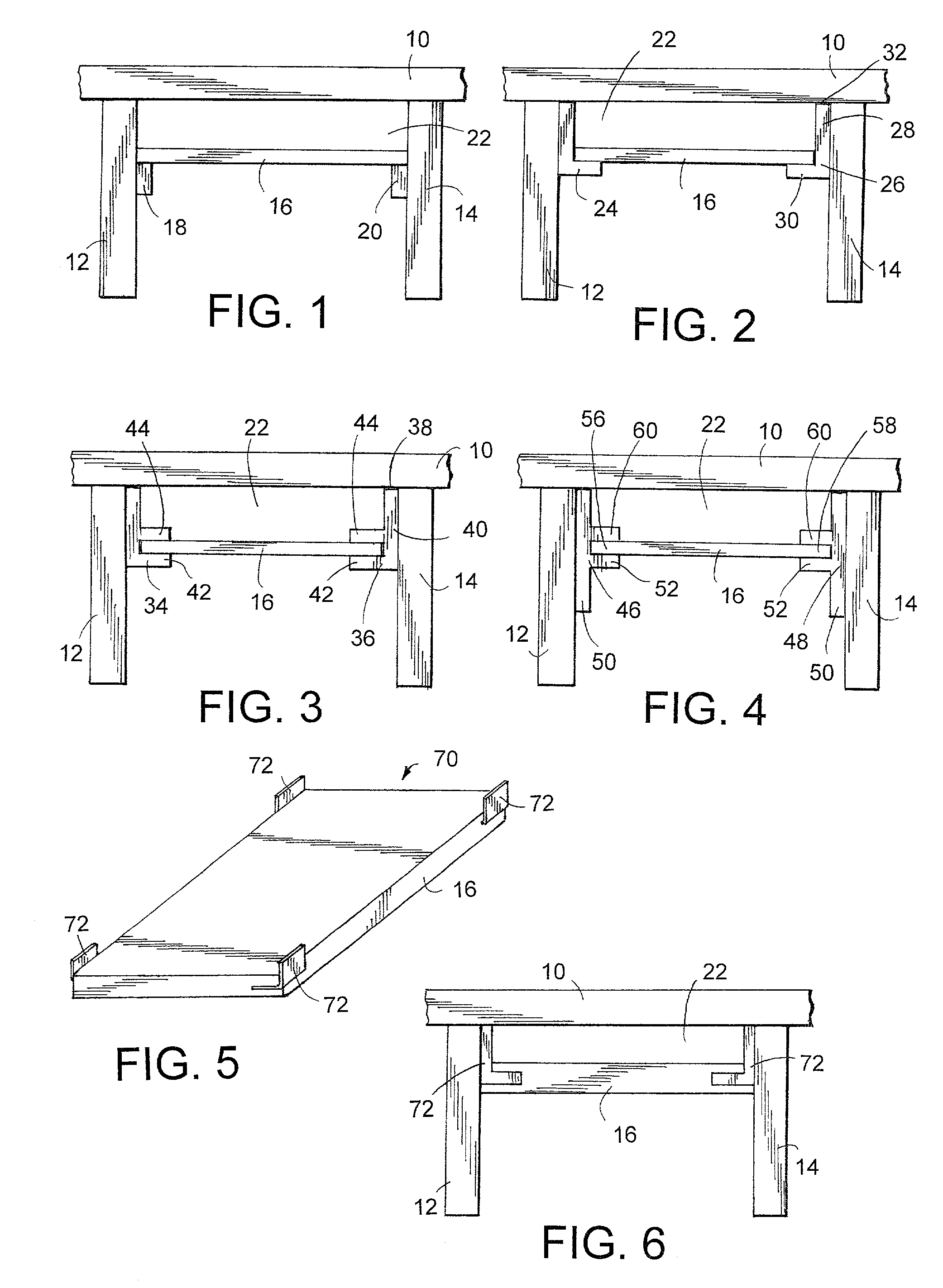

Composite structural panel and method

InactiveUS6913667B2Labor savingReduce construction costsAdhesive processesConstruction materialHoneycombEngineering

A composite structural panel (10) is provided, where the composite structural panel (10) includes a central honeycomb layer (16) having a plurality of box-like channels extending therethrough along a vertical direction. The honeycomb layer (16) is sandwiched between bonding layers (18) formed from a porous reinforcement material. Exterior support layers (22) are bonded or laminated to respective bonding layers (18) by adhesive layers (20). The one-piece composite structural panel is then positioned on an exterior surface of a building (12) and structurally fixed to a building stud or other building element.

Owner:NUDO THOMAS +1

Cotton-free electronic cigarette, heat-insulating and heat-dissipating component of vaporizer device, and method for heat insulation and heat dissipation

ActiveUS20160286864A1Improve safety and reliabilityEffective insulationTobacco devicesThermal insulationThermal conductivity

Disclosed is a cotton-free electronic cigarette, a heat-insulating and heat-dissipating component of a vaporizer device of the cotton-free electronic cigarette, and a method for heat insulation and heat dissipation. The heat-insulating and heat-dissipating component consists of a heat insulation sleeve and a vapor flow passage. The heat insulation sleeve is provided inside an outer pipe and outside a vaporizer unit. The heat insulation sleeve, the outer pipe and the vaporizer unit have a same central longitudinal axis. A method for heat insulation and heat dissipation of the cotton-free electronic cigarette comprises: dissipating heat generated from the vaporizer unit along the vapor flow passage formed between an exterior longitudinal flat surface of a liquid storage cup and the heat insulation sleeve, and discharging the heat outside the cotton-free electronic cigarette through thermal conductivity of the heat insulation sleeve.

Owner:LIN GUANGRONG

Waterborne heat-insulating flame-retardant multifunctional nano coating and preparation method thereof

InactiveCN101824270AImprove performanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsTin dioxideMicrosphere

The invention relates to a waterborne heat-insulating flame-retardant multifunctional nano coating and a preparation method thereof. The coating consists of the following components in part by weight: 48 to 52 parts of waterborne resin and 30 to 50 parts of nano pigment fillers (nano titanium dioxide, nano titanium dioxide-coated hollow glass microspheres, nano titanium dioxide-coated hollow ceramic microspheres and nano antimony-doped tin dioxide (ATO) particles), size and auxiliary materials such as film-forming additive and coupling agent. The preparation method includes the steps that: the nano fillers and the size are first dipped into the waterborne resin, the auxiliary materials are then sequentially added and stirred, and thereby the heat-insulating flame-retardant multifunctional nano coating is obtained. The processing technique is simple, the component proportion is reasonable, and the prepared coating has the advantages of high heat resistance, high reflectivity, high radiative heat conductivity, certain fire resistance, high-efficient heat insulation, excellent mechanical and chemical properties, environment-friendliness, stain resistance, flame retardance and energy saving. The coating can be coated on outside facilities such as outer walls and building roofs.

Owner:长沙新凯化工有限公司

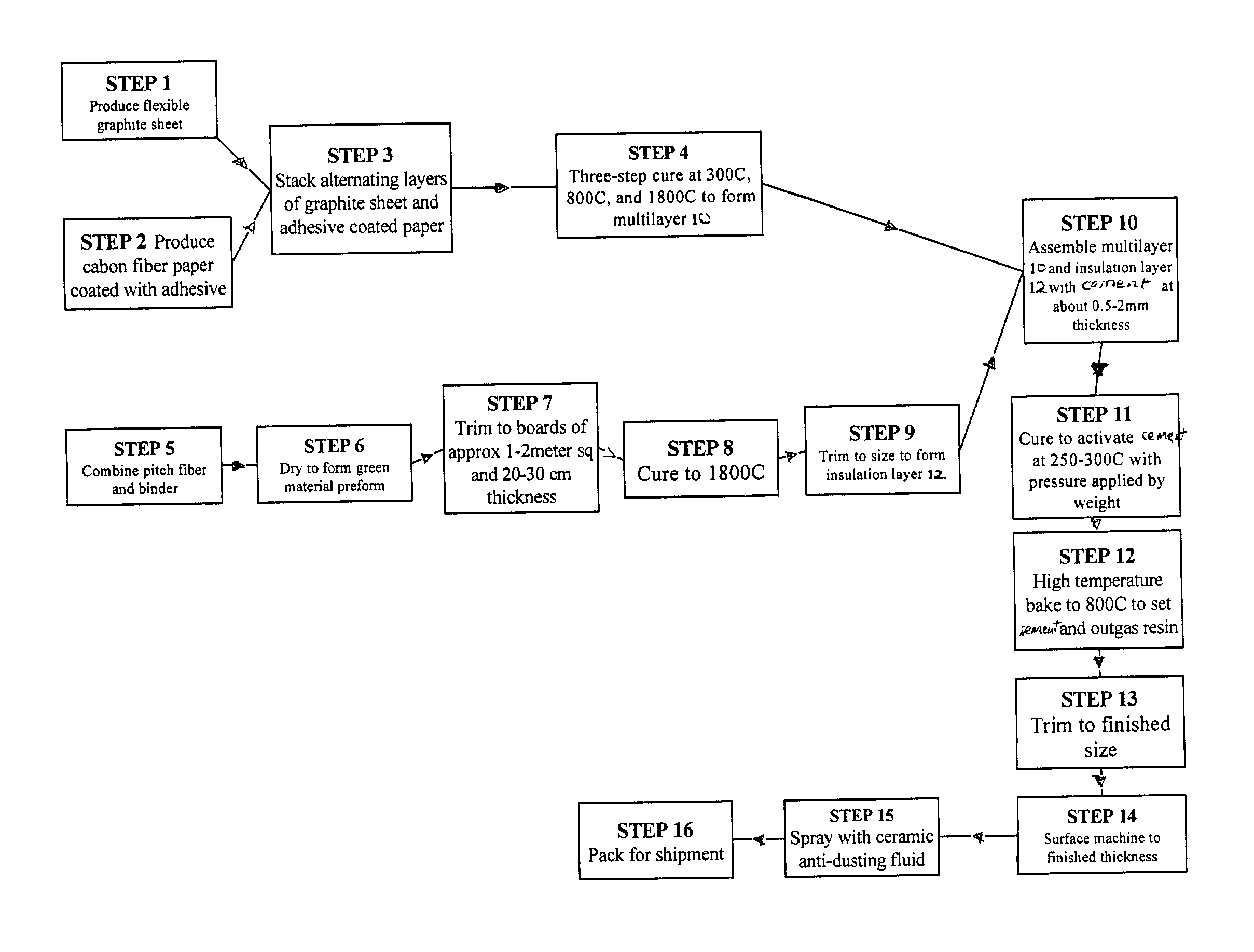

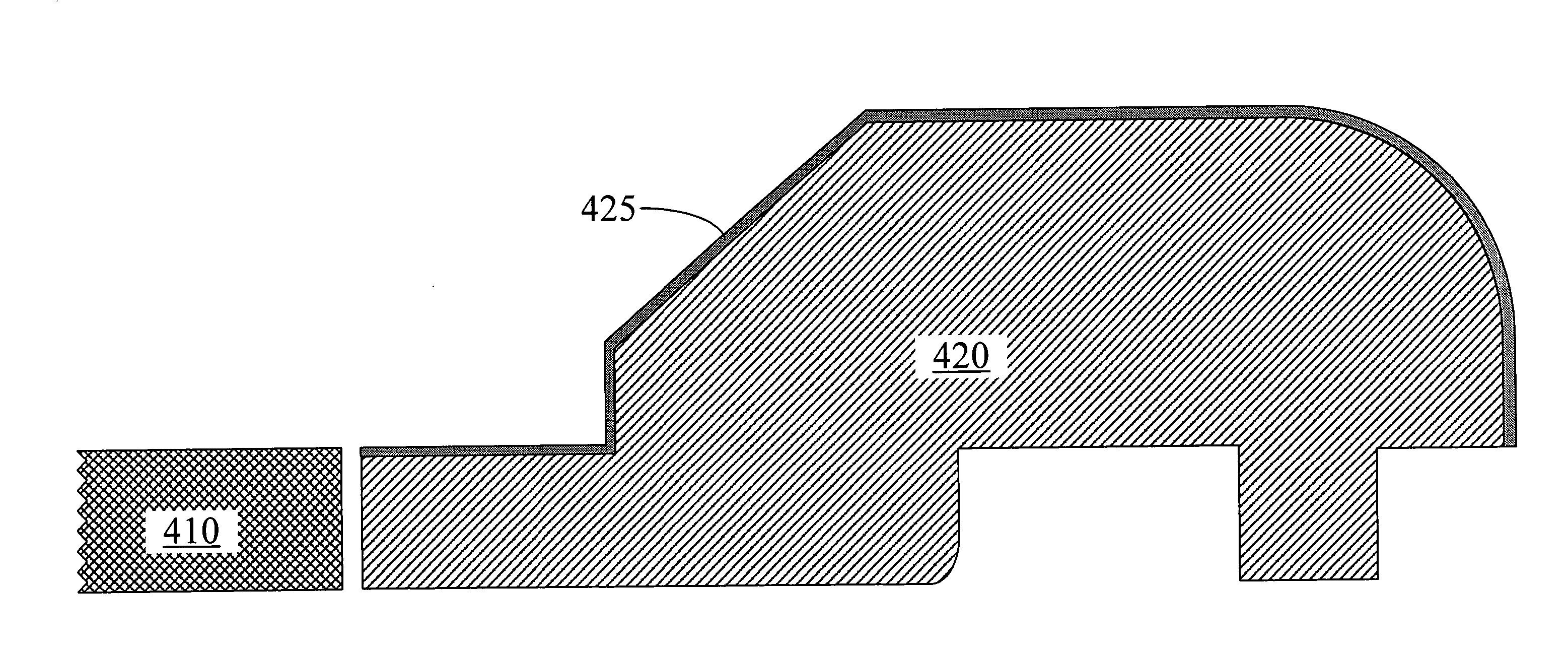

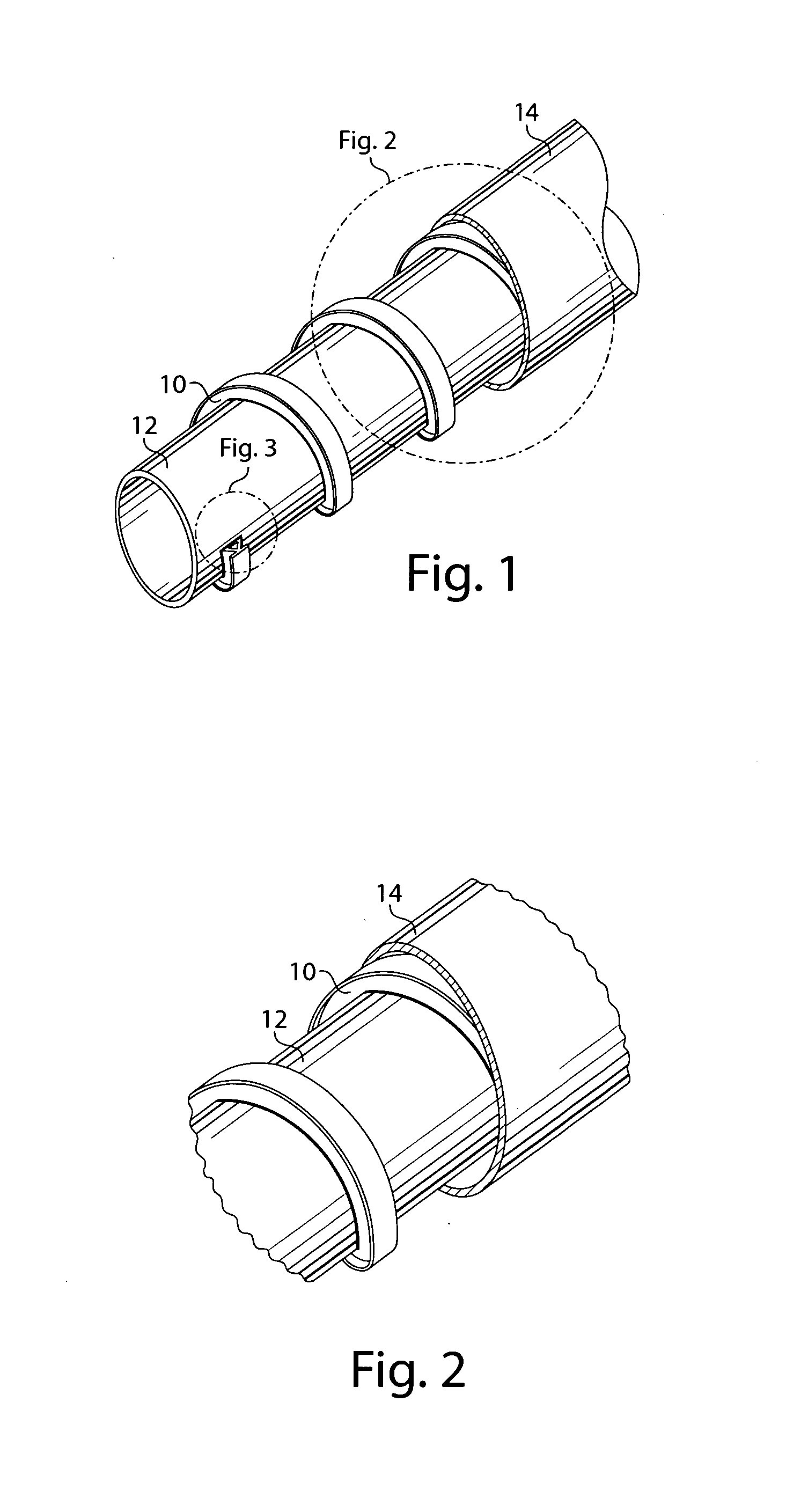

Composite high temperature insulator

InactiveUS20040076810A1Inhibit the formation of hot spotsHeat dissipationSolid waste managementCeramic layered productsFiberCarbon fibers

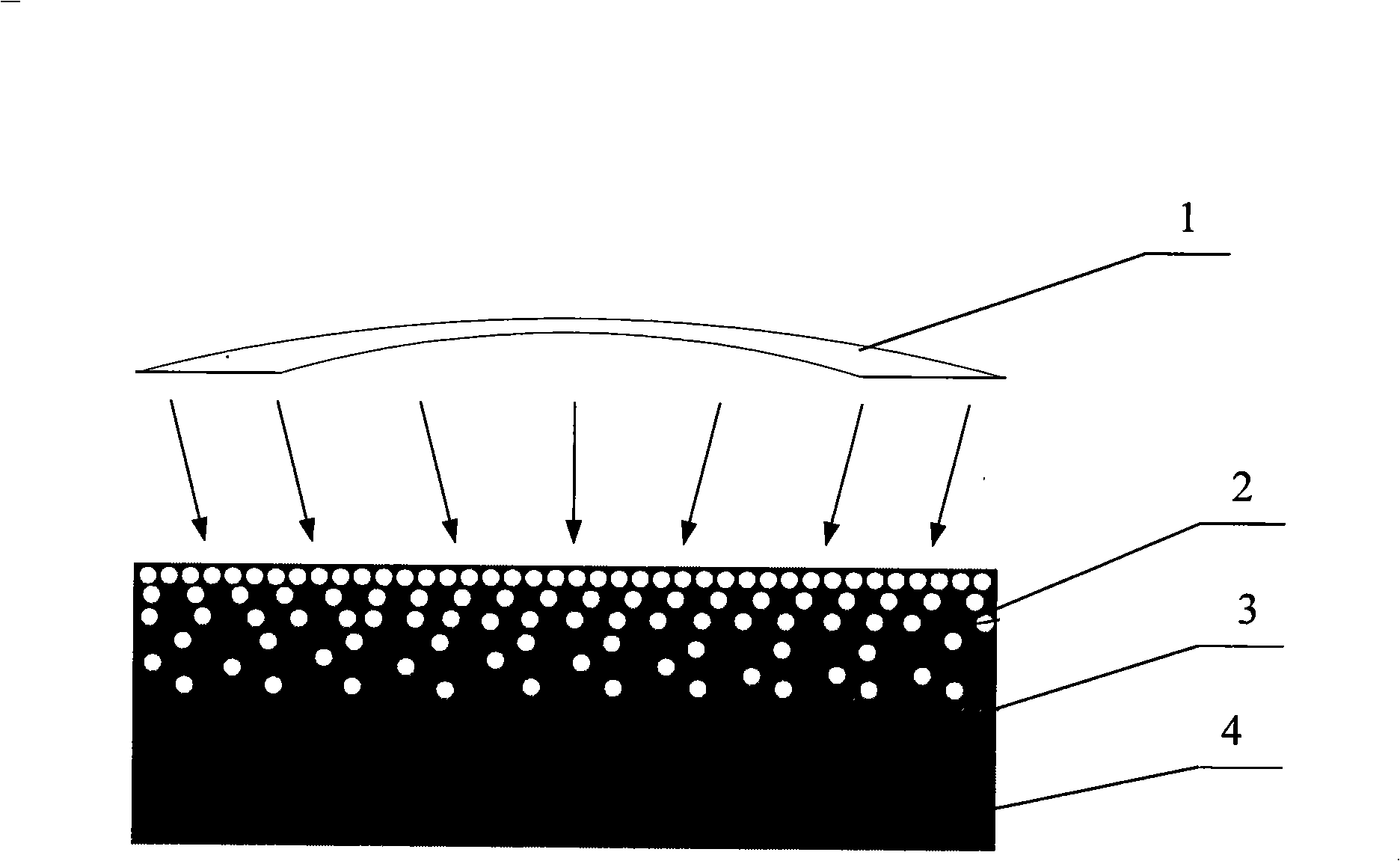

A composite high temperature insulator (A) includes a planar layer (10) having anisotropic thermal conductivity properties. A second planar layer (12) is formed from a rigid insulation material, such as a carbonized mixture of carbon fibers and a binder. The second layer is coextensive with the first layer and is preferably bonded thereto by a carbonaceous cement (44). When used to insulate a heat source, such as a furnace (50), convective heat is directed back to the source by the reflective surface (16) of the inner, anisotropic layer (10). Heat which enters the anisotropic layer is dissipated evenly through the plane of the layer along a plurality of heat paths defined by a plurality of layers (14) of flexible graphite. Accordingly, heat which reaches the outer, second layer (12) results in fewer hot spots than occur with a conventional rigid insulation material, thereby reducing the total amount of insulation material required to achieve a desired level of thermal insulation.

Owner:UCAR CARBON TECH

Process kit for erosion resistance enhancement

InactiveUS20050016684A1Minimize impactExtended service lifeElectric discharge tubesSemiconductor/solid-state device manufacturingPolymer sciencePermittivity

A process kit is described that resists plasma erosion, preserves the spatial uniformity of plasma properties, reduces particle generation in the chamber, and significantly enhances the lifetime of the process kit. A layer of polymer material covers the top surface of the process kit. The polymer material is fluorocarbon-based and not reactive with the species in the plasma. The polymer material not only protects the process kit from progressive erosion, but also prevents the generation of particles in the chamber. The polymer material has similar permittivity to that of the process kit and therefore maintains the spatial uniformity of plasma properties, e.g., etch rate, near the wafer perimeter. The thickness of the layer is controlled between 0.5 and 1.5 mm such that the difference between its coefficient of thermal expansion and that of the process kit will not cause the layer to peel off the process kit's top surface.

Owner:APPLIED MATERIALS INC

Water-resistant outerwear

A light-weight fabric for producing outerwear garments suitable for wear on boats, beaches and in other environments in which the wearer may be exposed to rain or water, as well as to cold temperature. The fabric is composed of inner and outer skins formed of woven synthetic plastic fibers, such as nylon, which render the skins water-resistant, yet permeable to vapor whereby the fabric is breathable. Sandwiched between the skins is a layer of polyester fiberfill which imparts thermal insulation-characteristics to the fabric. Dispersed throughout the fiberfill and imprisoned therein are fine, closed-cell foam plastic beads which impart buoyancy and quick-dry properties to the fabric.

Owner:SPECTOR DONALD

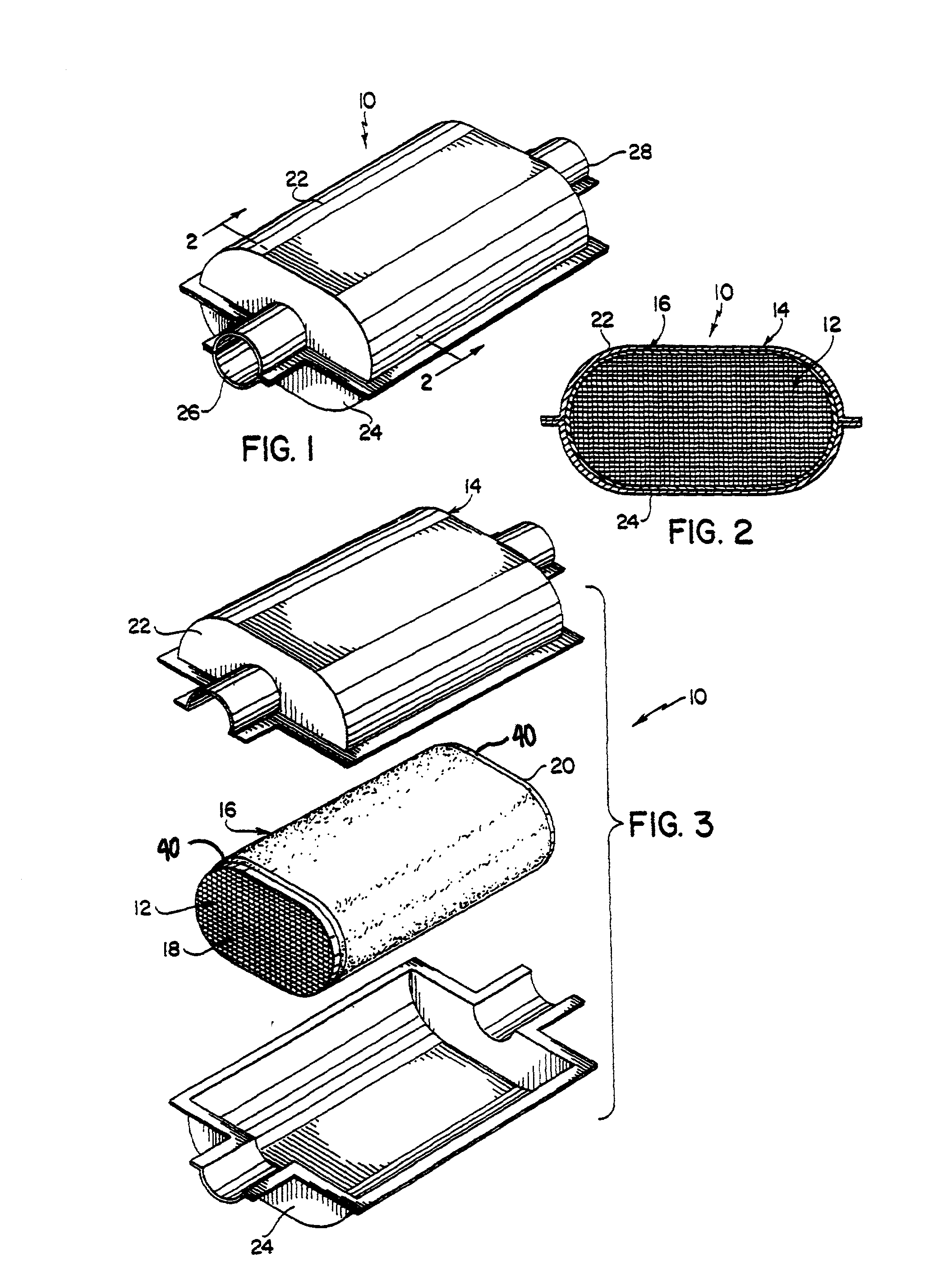

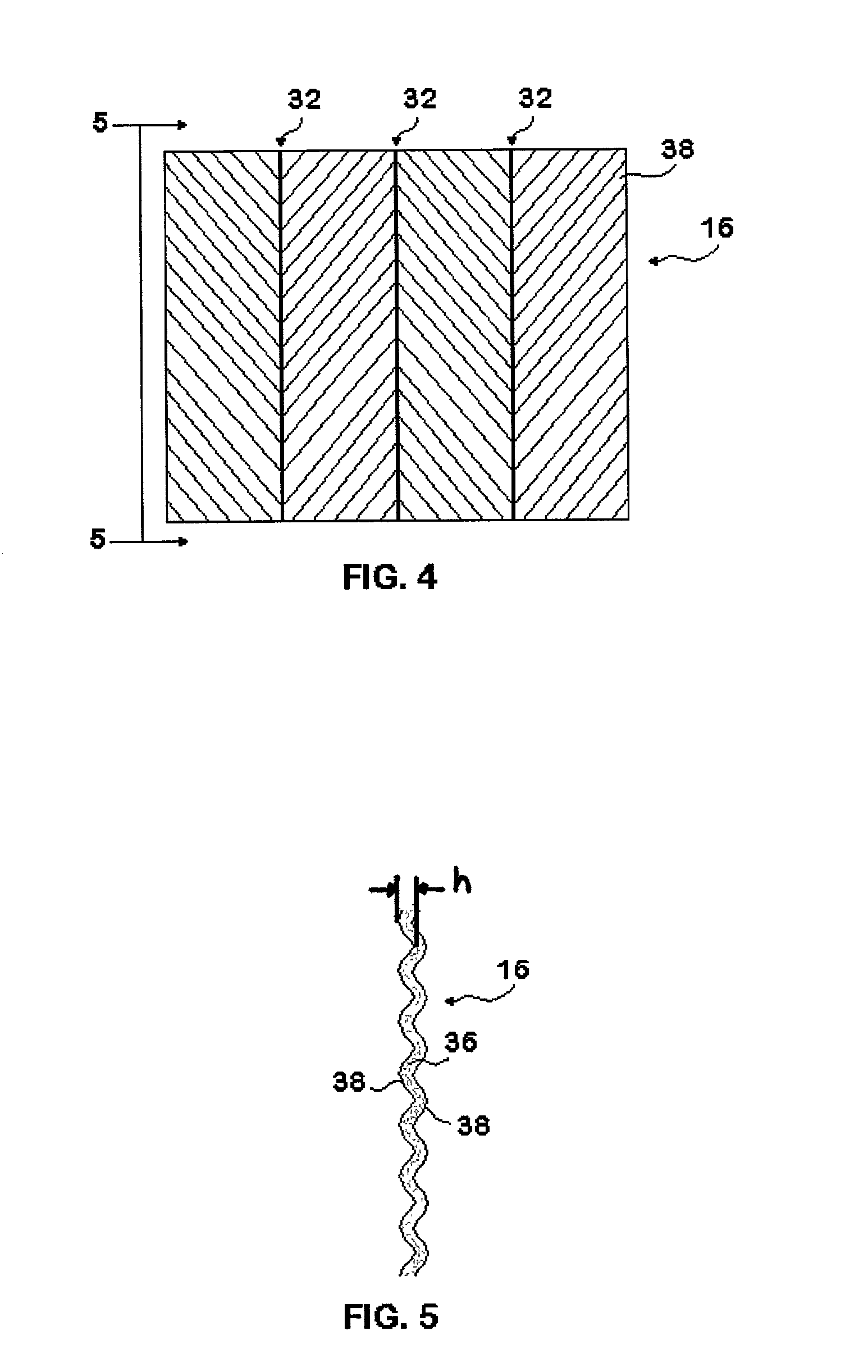

Catalytic monolith support system with improved thermal resistance and mechanical properties

InactiveUS20030129101A1Effective supportEffective insulationCombination devicesSilencing apparatusCatalytic transformationSupporting system

The instant invention provides a new high temperature catalytic monolith support system which can be effectively utilized for sealing between the catalytic monolith and the housing of a catalytic converter, as well as physically cushioning the catalytic monolith within the housing. The support system preferably is made form wire mesh and a non-intumescent thermoresistant paper, in which the wire mesh and thermoresistant paper are integral and crimped together to produce a multi-herringbone configuration, providing multiple perpendicular barriers that prevent the gas-flow from bypassing the monolith.

Owner:ACS IND INC

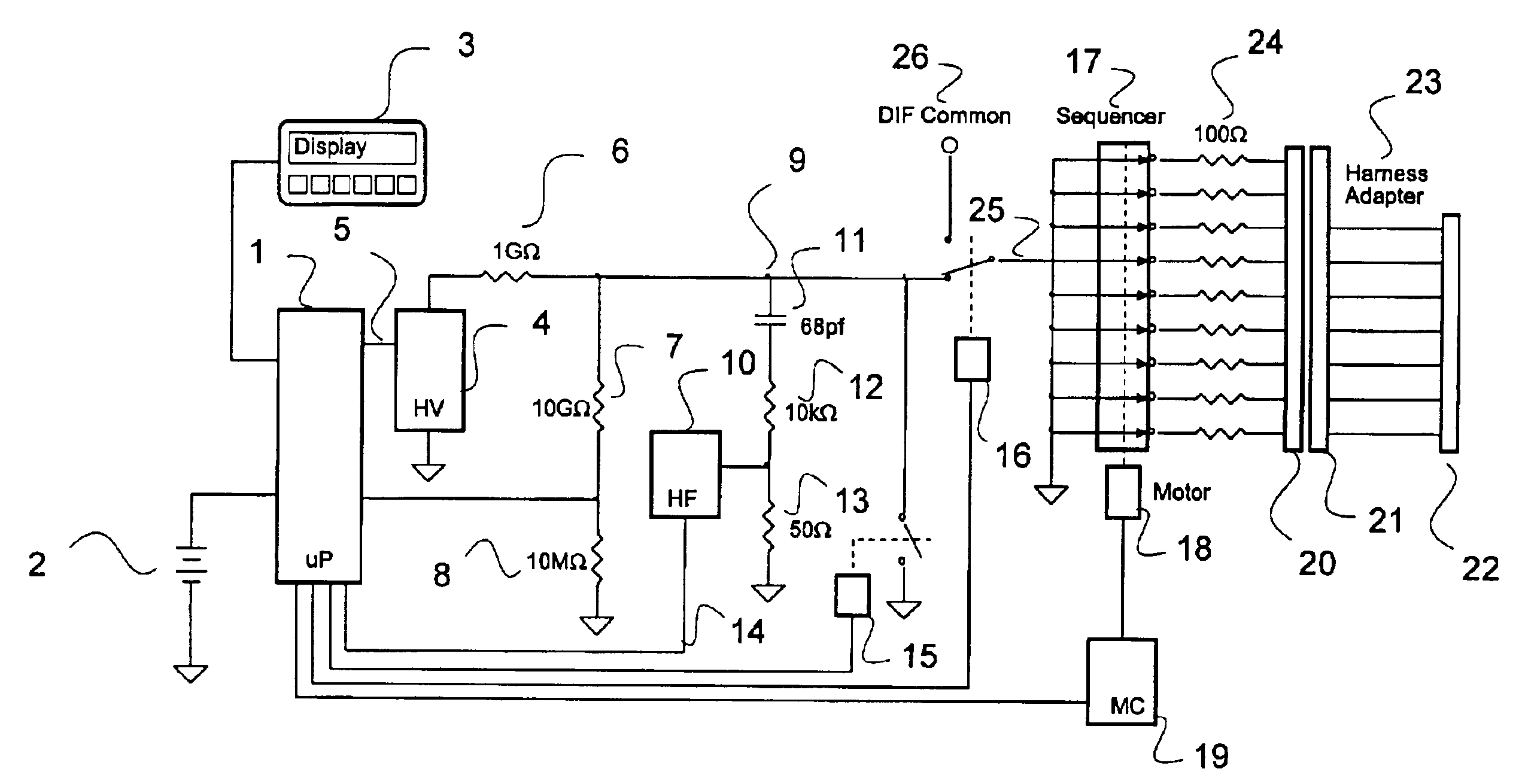

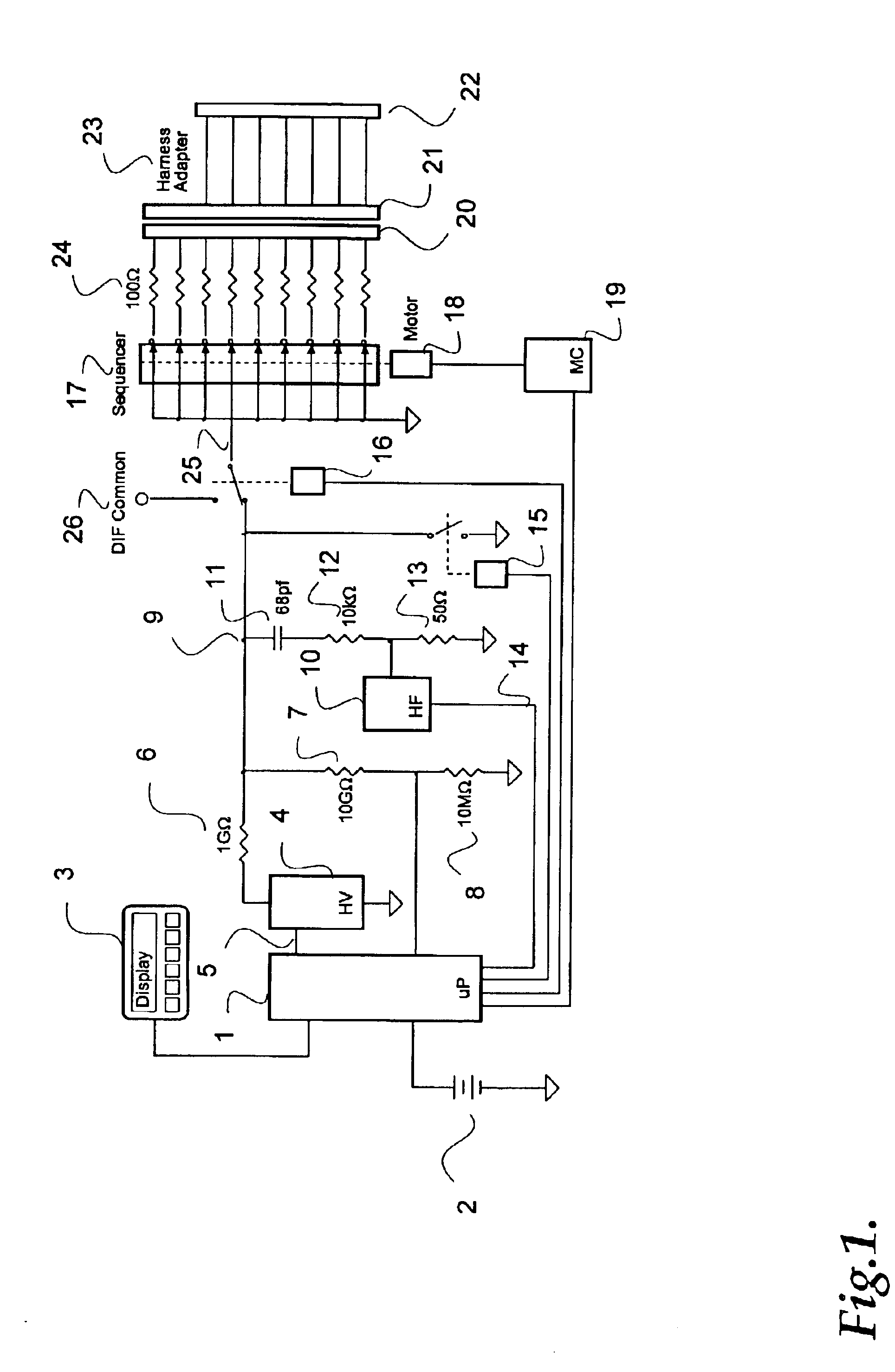

Parallel insulation fault detection system

InactiveUS6876203B2Reduce decreaseEffective insulationTesting dielectric strengthElectric switchesControl signalEngineering

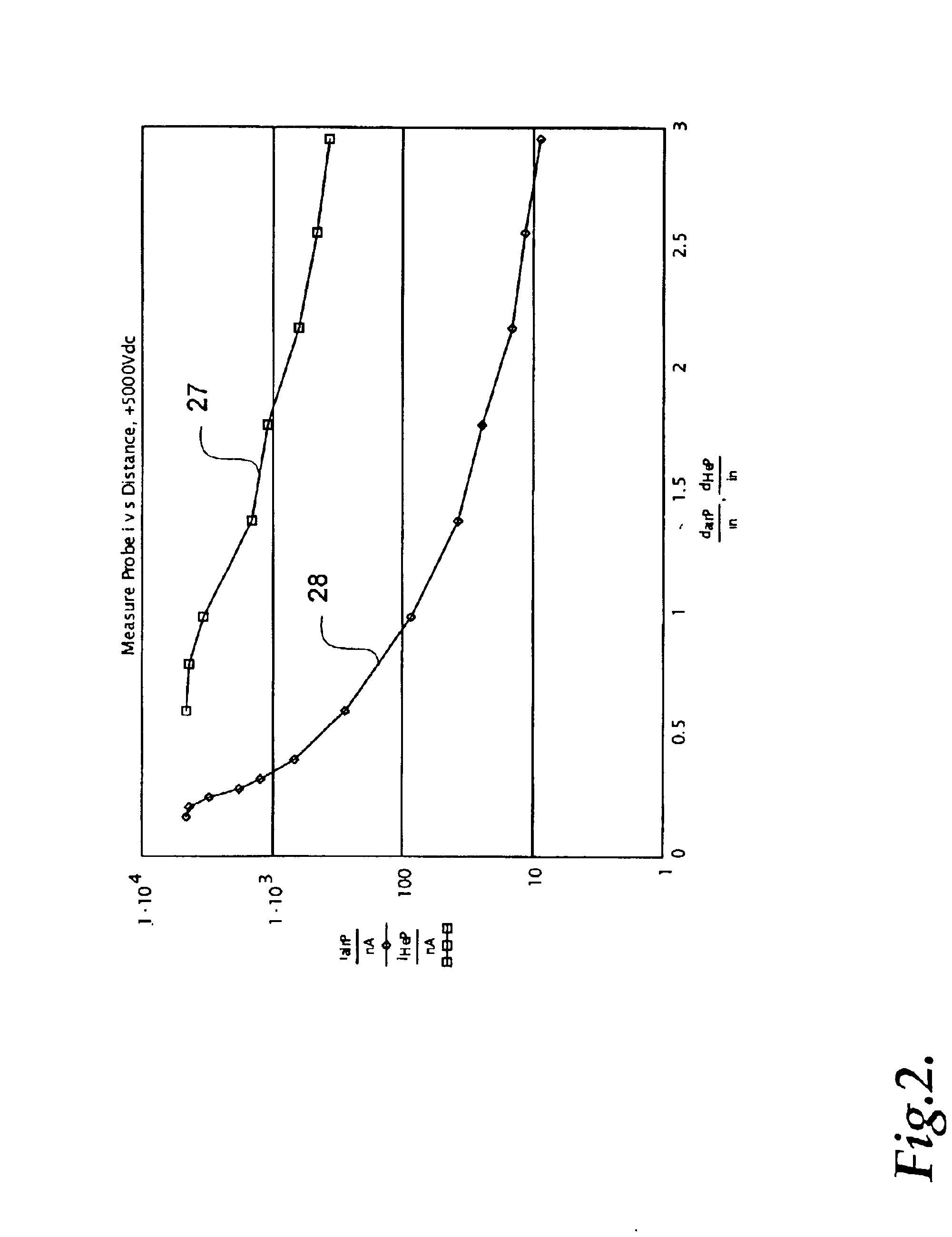

A device for detecting and locating arcs in a set of wires is discussed. The device comprises a probe for discharging controlled current to an exposed portion of a wire in the set of wires. The probe includes a handleable enclosure and an elongated structure which projects from the enclosure for conducting a gas and for enclosing a needle that has a tip. A suitable gas includes gases that have low electron attachment, such as helium. The device further comprises a control unit for communicating control signals as well as the gas to the probe. The control unit includes a controller, a valve being controllable by the controller and being capable of regulating the flow of the gas, and a high-voltage generator being controllable by the controller to generate a high-voltage signal, which can be communicated to the probe by the control unit.

Owner:ASTRONICS ADVANCED ELECTRONICS SYST

Polymer/porous ceramics structure and function integrated gradient composite material and preparation method thereof

ActiveCN101259766ALow densityAchieve self-protection effectSynthetic resin layered productsCeramic layered productsHeat fluxWashout

The invention relates to a function-integration gradient composite material with polymer / porous ceramic structure and a preparation method. The invention solves the problems that single material can not meet the requirement for the performance of the material made by the application condition in an extreme environment and the multilayer composite-structure material is easily layered and has poor safety and reliability. The product of the invention is made from a polymer layer, a gradient connecting layer and a ceramic layer from the inside to the outside. The preparation method comprises the following steps that: 1. the polymer layer, the gradient connecting layer and the ceramic layer are sequentially paved and then are put into a die to be formed by compression so as to obtain the green body of the composite material; 2. the ceramic layer of the green body of the composite material is loaded with high-density heat flux and then is naturally cooled. The composite-structure material of the invention has the advantages of small weight, strong structural strength and high effective heat insulation, is suitable for being used under the extreme working conditions of high temperature, airflow washout, etc., and is safe as well as reliable. The preparation method of the invention is simple and easy to be operated, and can prepare large-scale products with a complicated shape.

Owner:HARBIN INST OF TECH

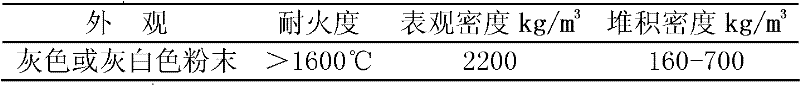

Unitary or polybasic aerogel thermal insulation material and preparation method thereof

ActiveCN102584162AGood application effectApplicability is differentThermal insulationSingle component

The invention discloses a unitary or polybasic aerogel thermal insulation material and a preparation method of the material. The method comprises the steps of preparing sol, solidifying sol to form gel, aging and drying, or comprises the steps of preparing sol, preparing a prefabricated body, infiltrating, coagulating sol, aging and drying. The aerogel component in the thermal insulation materialdisclosed by the invention is formed in a unitary or polybasic way, and can be formed by flexibly adjusting a single component, so that the characteristic of aerogel can be given a full play to the greatest extent, the material can be used in different temperature resisting fields, and aerogel formed by different components can be used aiming at the different temperature resisting fields, so thatthe heat insulation effect of the aerogel thermal insulation material can be more high-efficiency. The production and forming method of the unitary or polybasic aerogel thermal insulation material, disclosed by the invention, is a set of technology which is complete, continuous, and low in cost, and can be used in industrial method production, the produced aerogel thermal insulation material withhigh performance is wide in application field, is wide in using temperature, can meet different using requirements of war industry fields, civil fields, heat-protection fields with special requirements, and the like.

Owner:GUANGDONG ALISON HI TECH

Rechargeable batteries

InactiveUS20050029986A1Shorten the timeEffective insulationCharge equalisation circuitCircuit monitoring/indicationRechargeable cellEngineering

An improved rechargeable battery which comprises: a plurality of battery cells connected together to discharge in parallel, each of the cells, or each group or groups of the cells having its own respective recharging input; and an electrical switching circuit to switch a number of the battery cells or groups of cells to connect to their respective recharging input for recharging each cell or group of cells individually.

Owner:MORGAN RICHARD

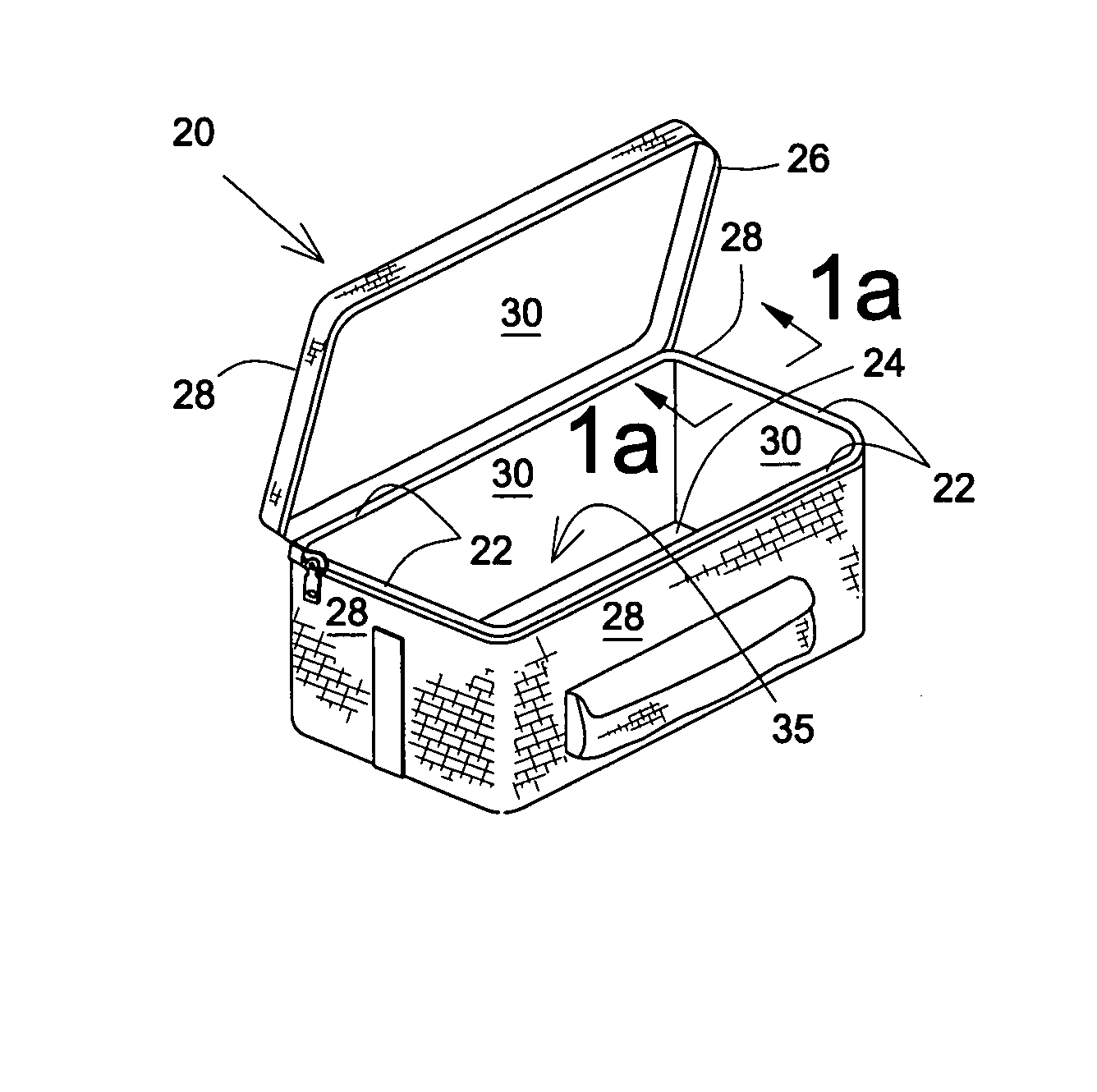

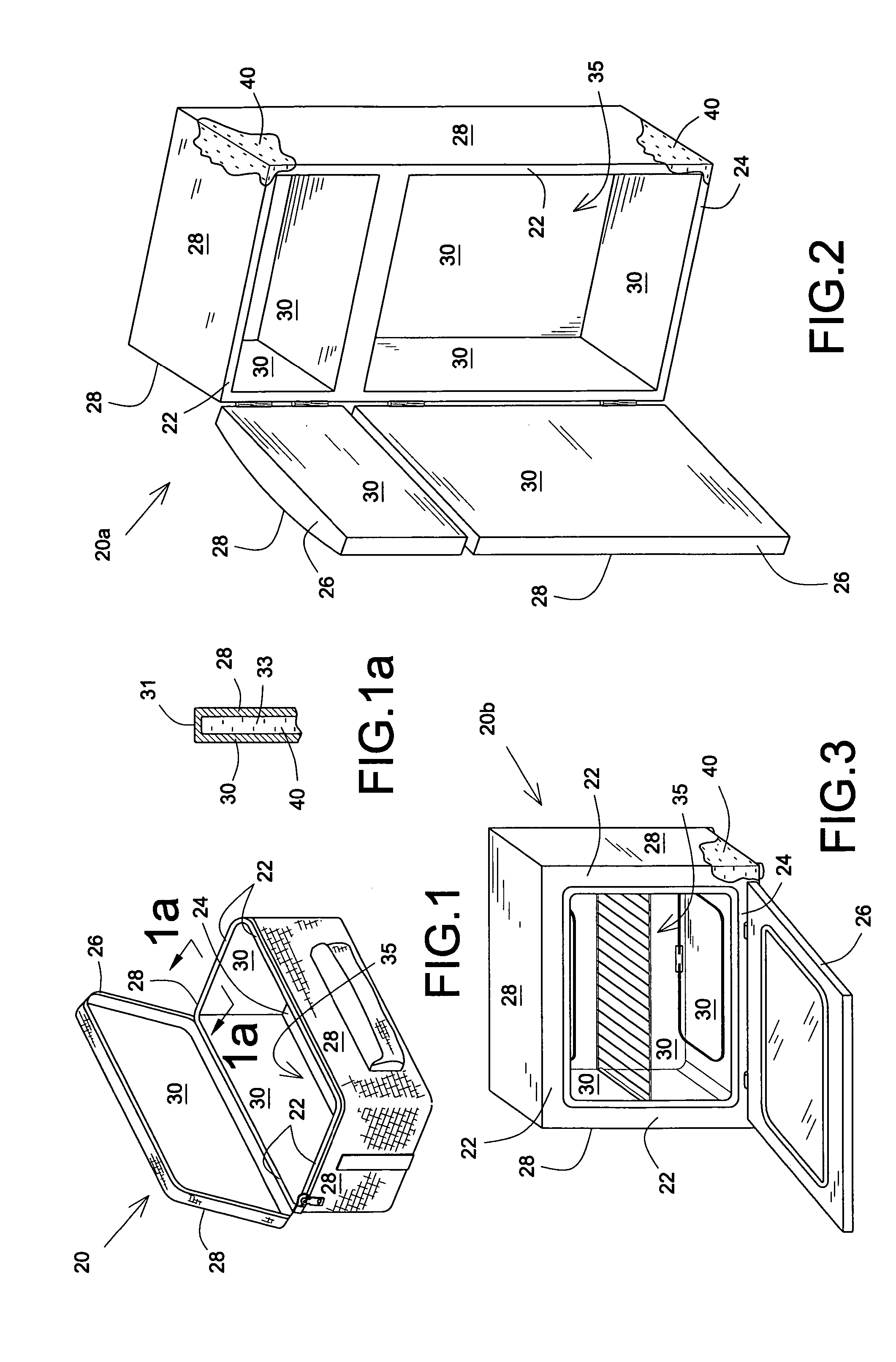

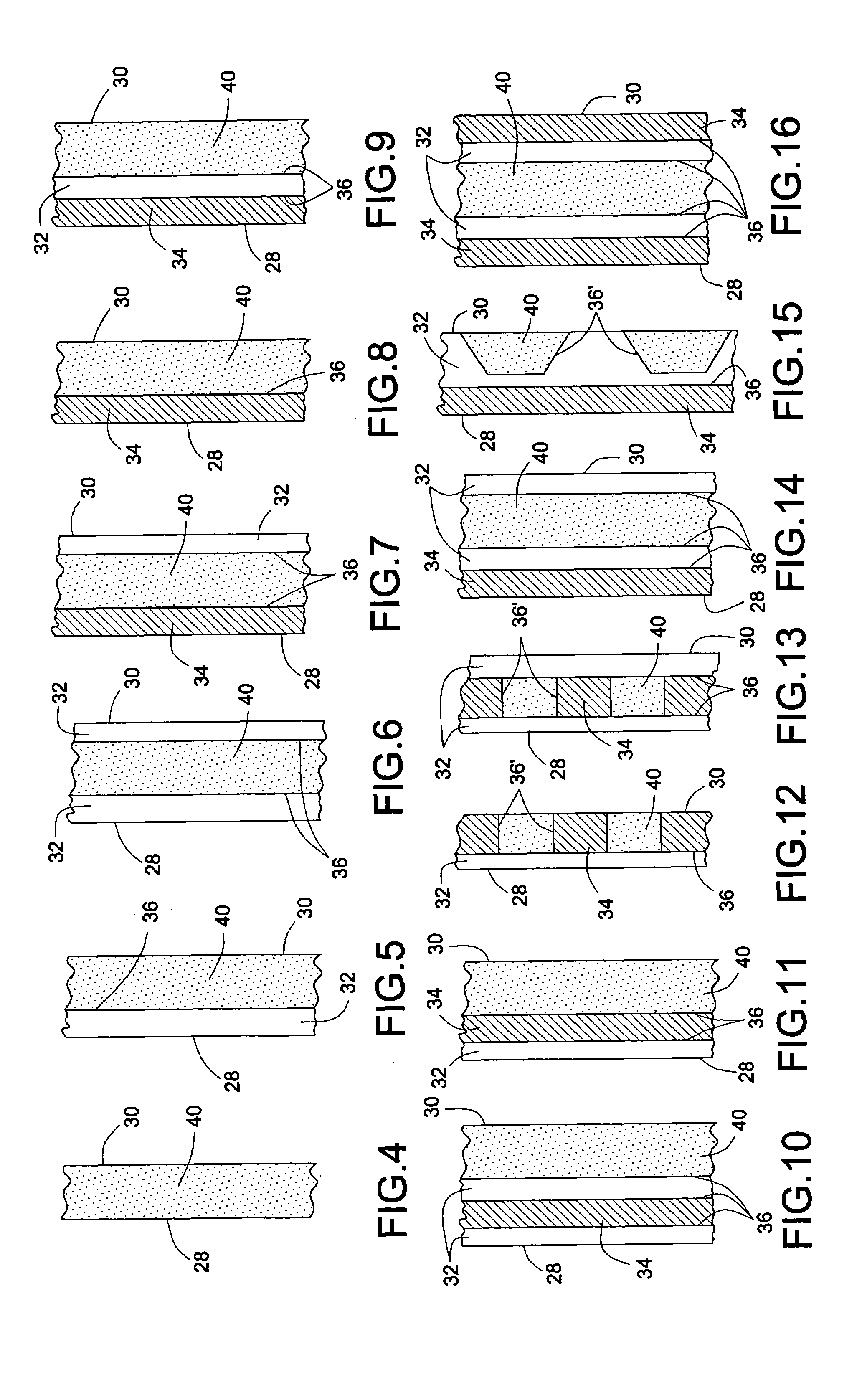

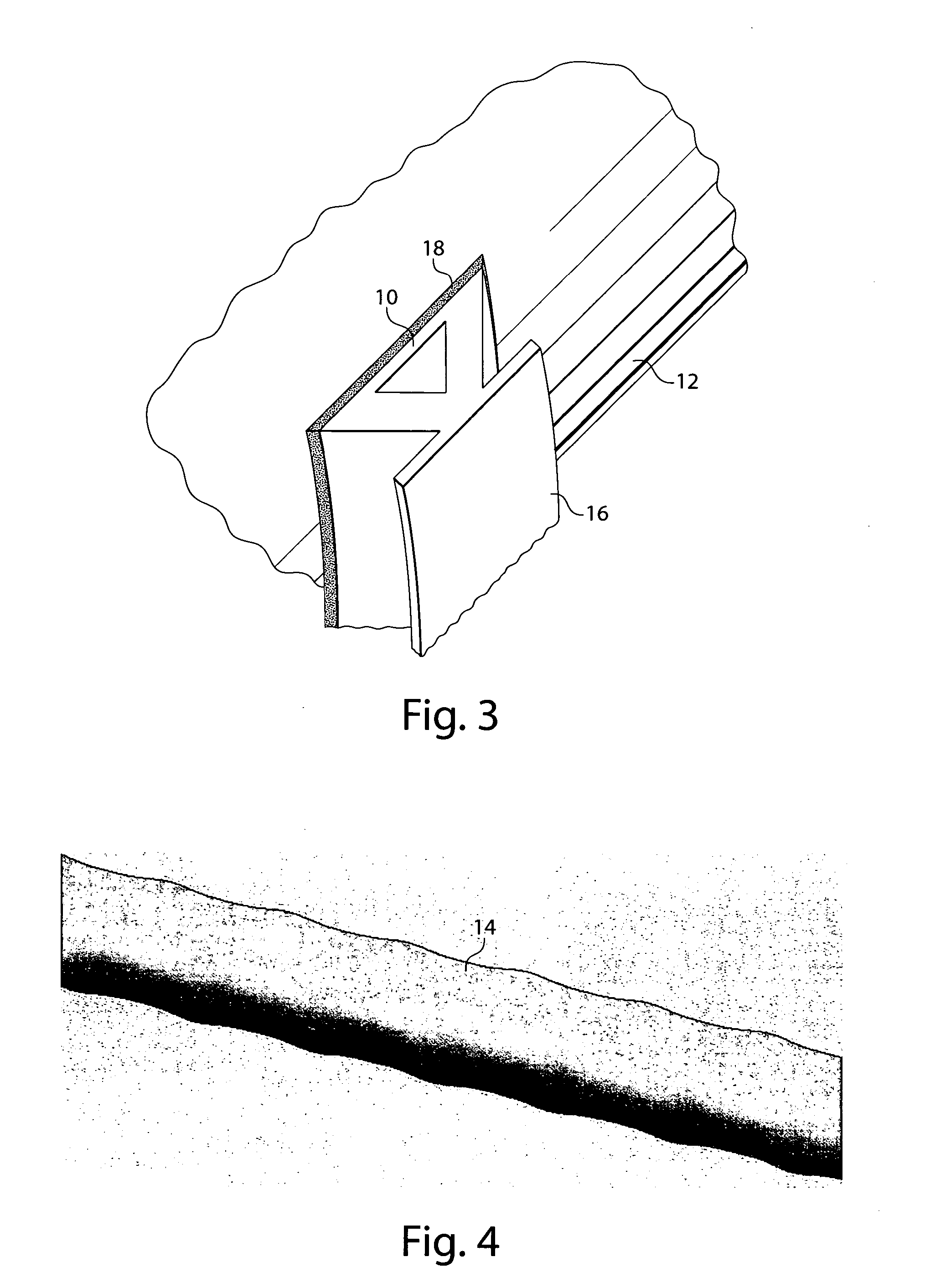

Insulator sleeve for a beverage container

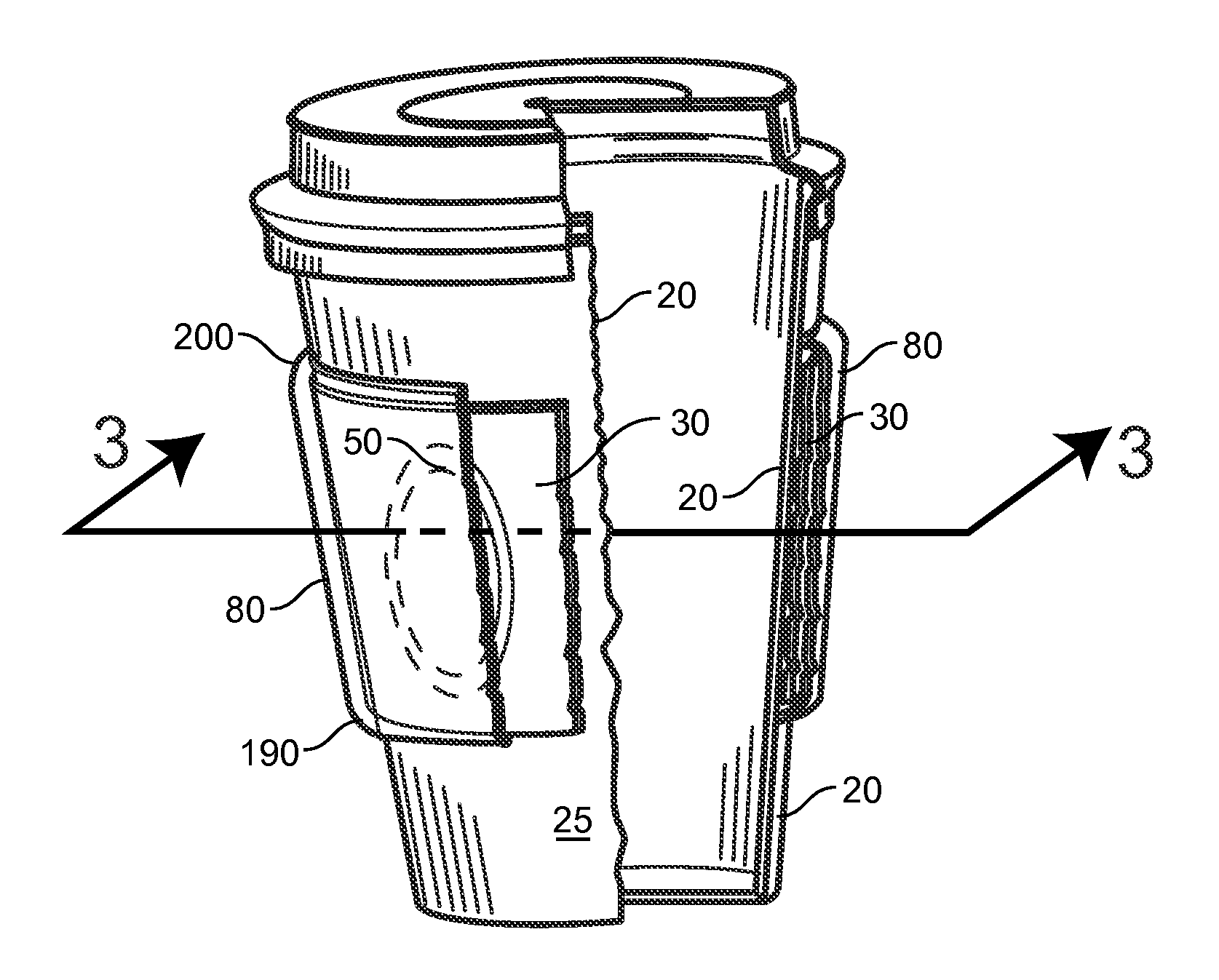

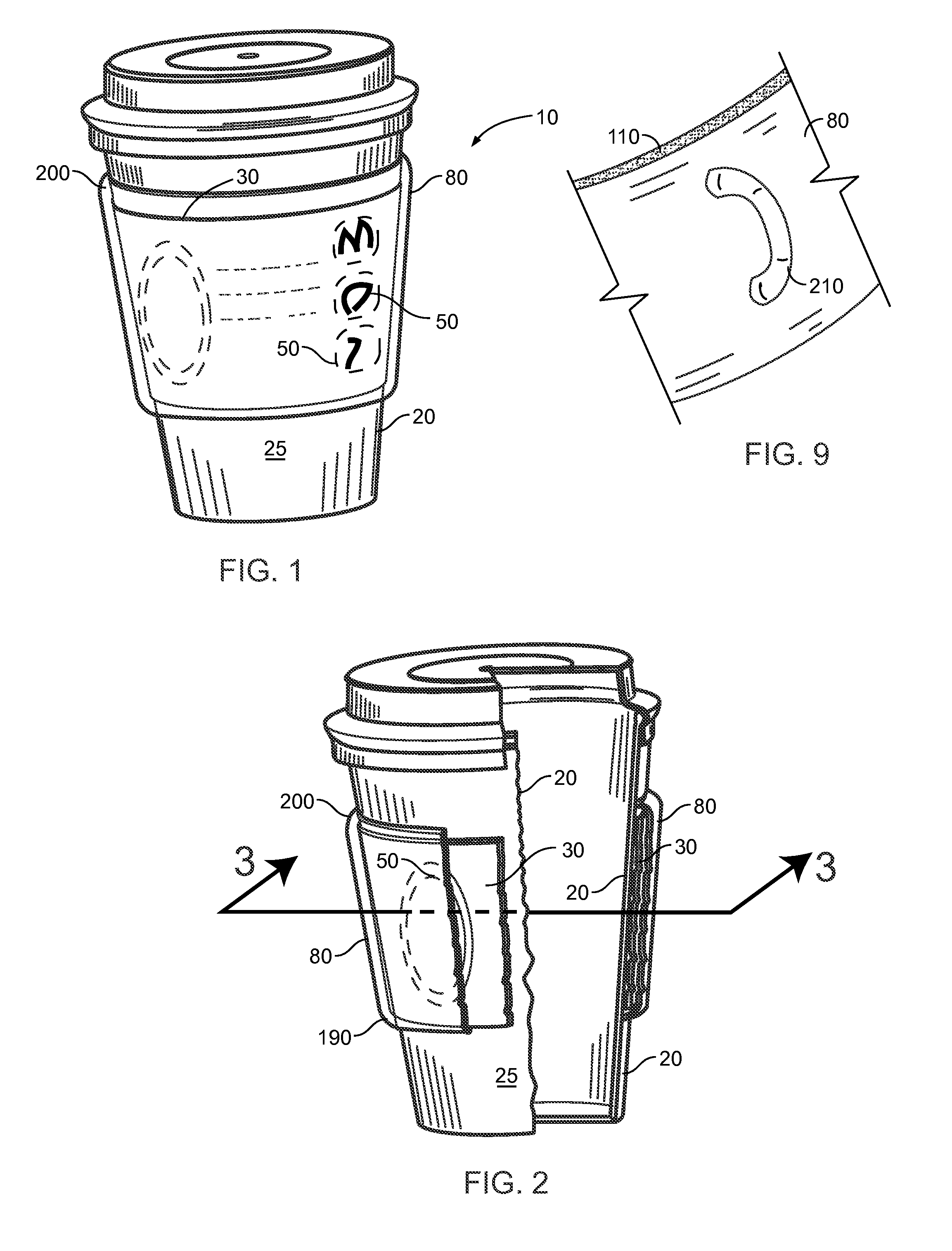

InactiveUS7922031B1Excellent heat insulating propertyFacilitate combinationContainer decorationsLevel indicationsEngineeringOuter Cannula

An insulating sleeve combination for a frusto-conical beverage cup having an outer peripheral surface is disclosed, as well as a method of use thereof. The combination includes an opaque frusto-conical inner sleeve and a frusto-conical outer sleeve. At least a portion of the outer sleeve is transparent or translucent, such that indicia on the inner sleeve is visible or at least partially visible therethrough. The outer surface of the outer sleeve may includes a textured gripping surface, facilitating the manual grasping of the combination by the user. As such, a customized inner sleeve may be marked to indicate a favorite drink of the user, for example, with the markings being visible through the outer sleeve. The combination of the present invention is designed for repeated use, rendering prior art disposable sleeves unnecessary.

Owner:PRINCE KEVIN R

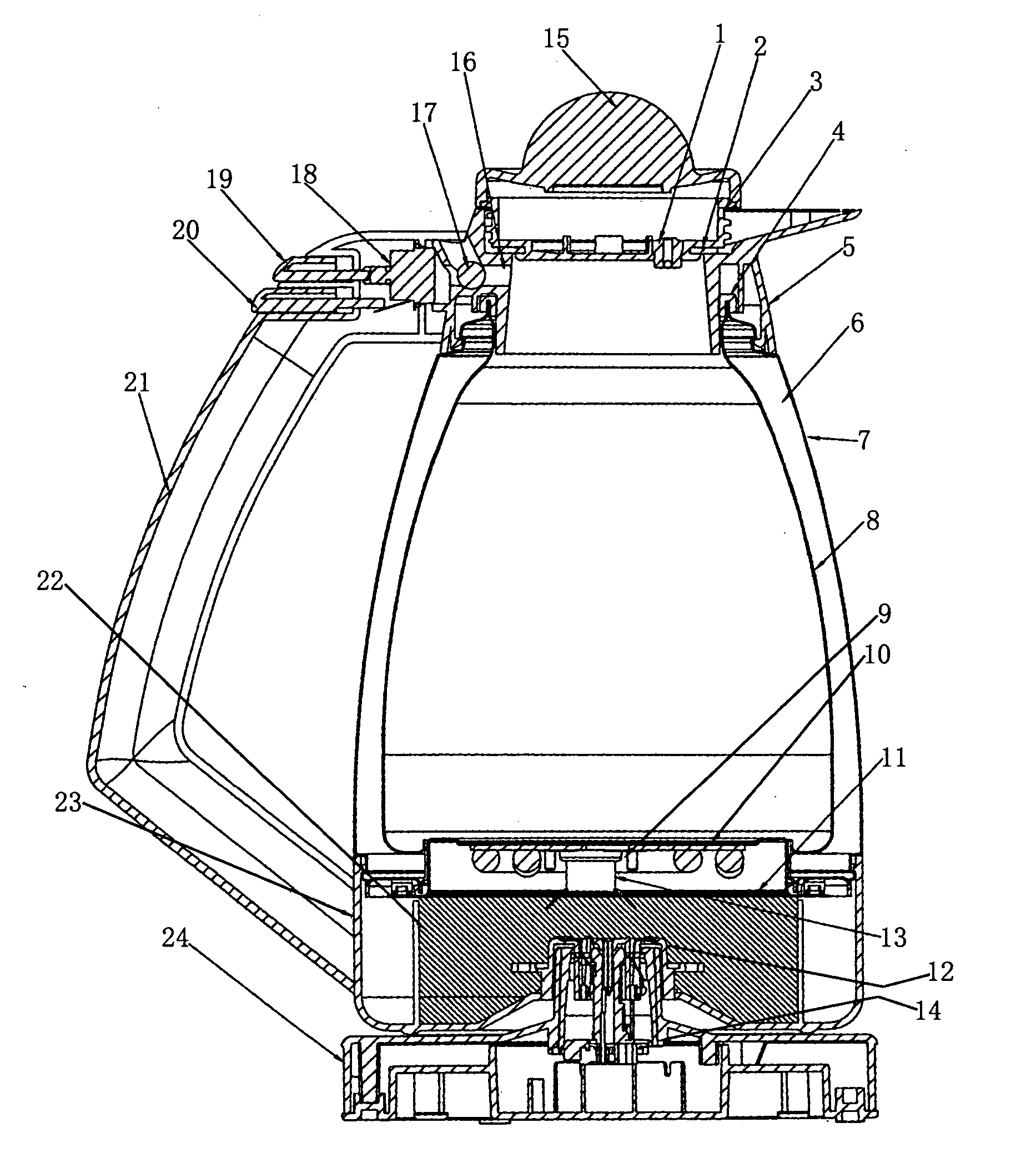

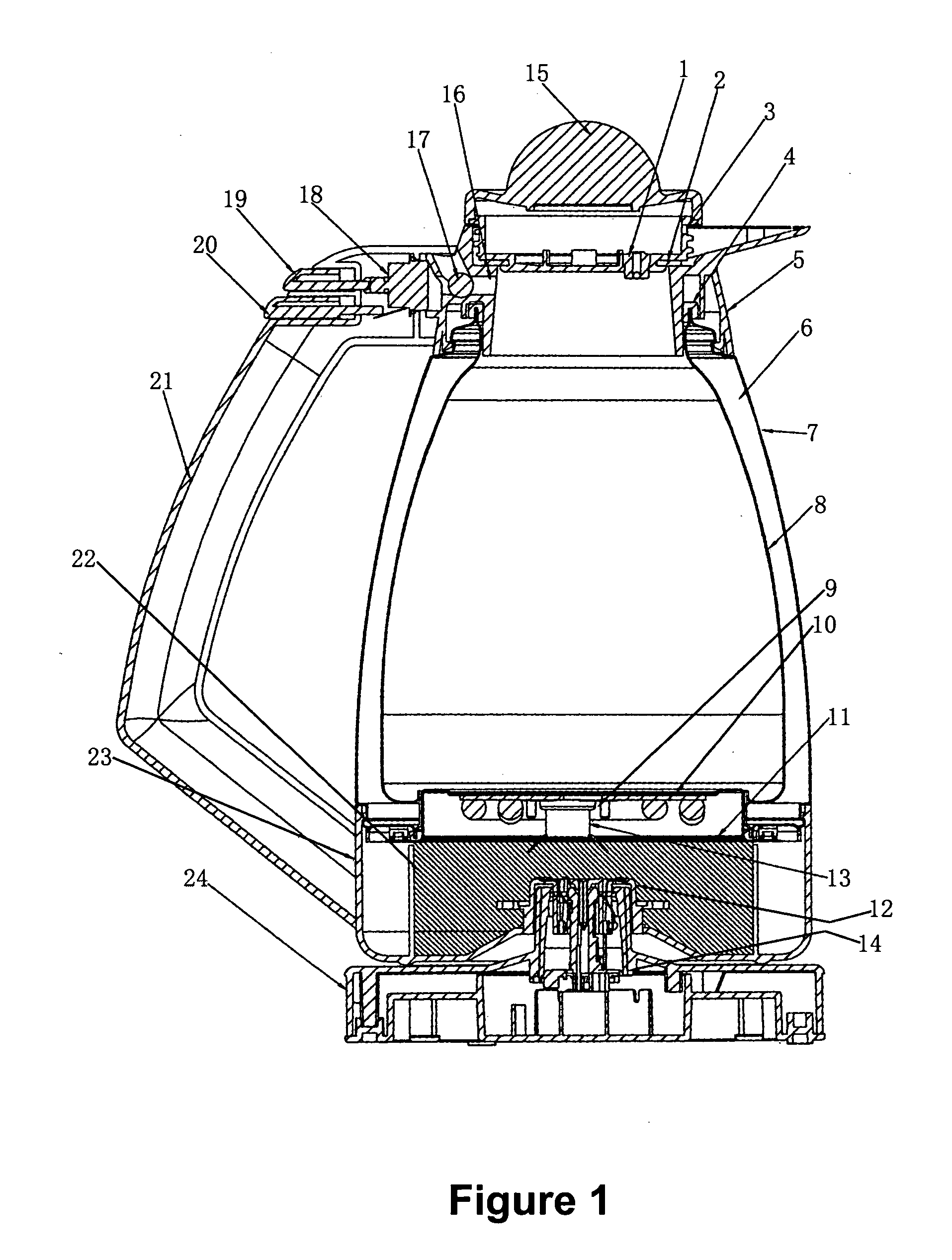

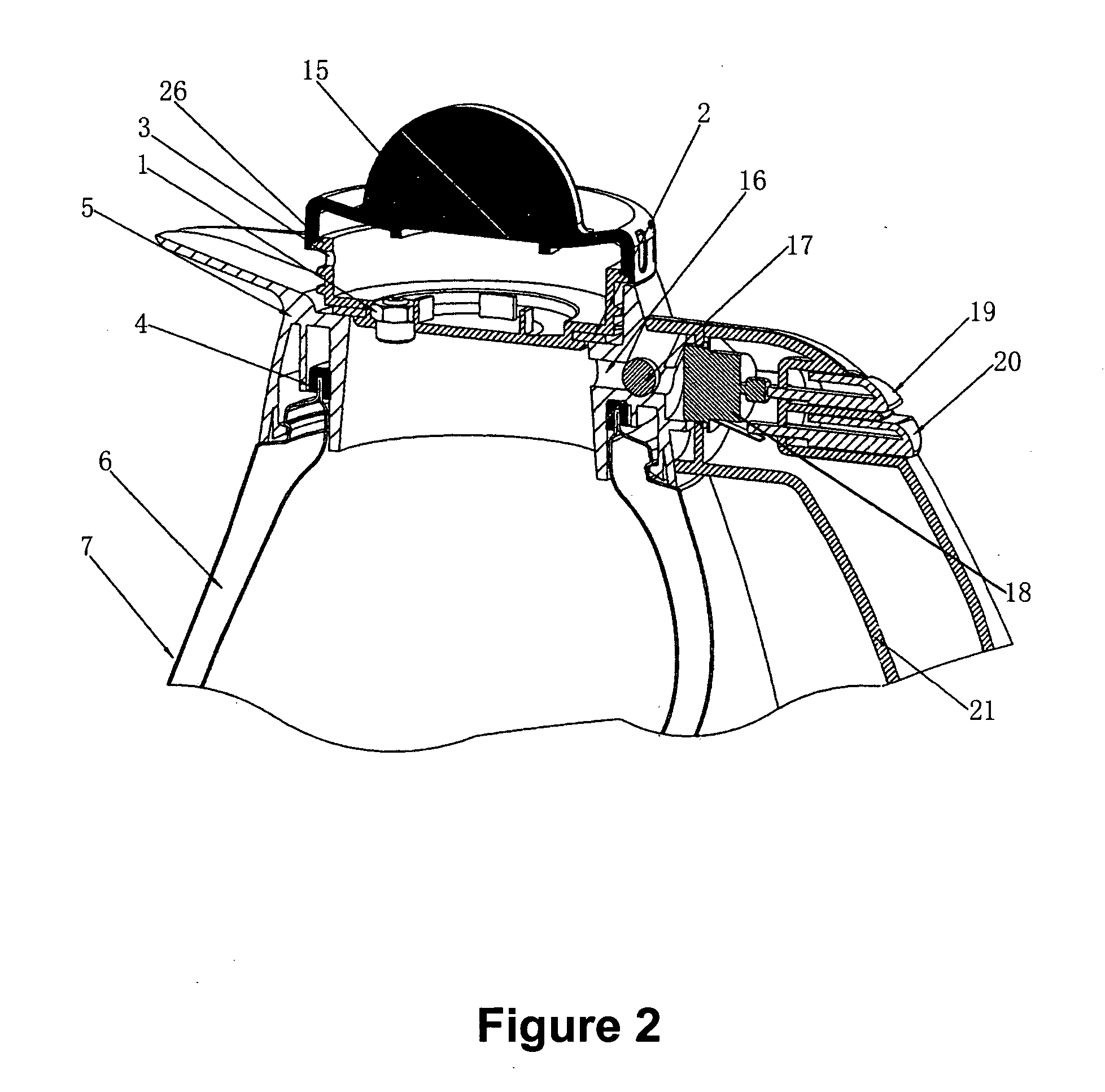

Electric thermos jug

InactiveUS20050284861A1Easy to useImprove air tightnessCooking-vessel materialsDomestic cooling apparatusWater qualityEngineering

An electric thermos jug comprises generally from the top to the bottom a lid assembly, a spout assembly, a double-layer vacuum body, a heating element, an underbody, and a base. An insulating plate and an insulating material layer are provided under the heating element inside the underbody of the jug. The lid is two-layer structure comprising an upper lid and lower lid with an air plenum in between. The electric thermos is convenient for use and effective in heat insulation due to the excellent air tightness of the components. The temperature inside the jug can be maintained for a long time without the need of repetitive heating. As a result, it can maintain a good water quality and is energy efficient. A safety valve is also employed.

Owner:FUNG SHIU PO

Honeycomb concrete

InactiveCN101239837ASolve the problem of "cold bridge"Extended service lifeCeramicwarePortland cementFilling materials

The present invention relates to a honeycomb concrete belong to a building material. The honeycomb concrete comprises the mother material and supplementary material with the following weight proportion: quick hardening sulfaluminous cement or ultrastrength cement: 30-70 parts; filling material: 25-60 parts; ordinary Portland cement: 5-10 parts; waterproofing agent: 1-1.5 parts; bleeding agent: 2.0-3.0 parts; suspension agent: 2.0-5.0 parts; foam stabilizer: 0.1-0.5 parts; and honeycomb agent: 38-60 parts. The invention has the following advantages and beneficial effects: light weight, high strength, long service lifetime, heat preserving with high efficiency, heat insulation, sound insulation, self-water-proofing, non combustibility, impact resistance, small contraction percentage, convenient construction and installation, reducing the weight of the building, increasing the using area, convenient product preparation and construction, the concrete not only can be made in factory but also can be made at the construction site.

Owner:徐东亮 +2

Water-soluble non-combustible ceramic anti-radiation coating and preparation method thereof

InactiveCN102585570AReduce pollutionHigh durability, impervious and waterproofFireproof paintsReflecting/signal paintsCrack resistanceBrick

The invention relates to a water-soluble non-combustible ceramic anti-radiation coating and a preparation method thereof. The coating comprises an active material, an inorganic filler, a shrinkage reducing agent, a thickening agent, a flame retardant, a silicate binder, a reflection reinforcing agent and an aid in a mass ratio of (2-2.8):(0.5-1):0.40:(0.01-0.04):(0.4-0.8):2.13:(0.067-0.2):0.3. The coating is formed by fully mixing the components uniformly and can be used for painting or spraying, and a layer of modified fluoro-silicone emulsion is painted on the surface of the coating after the coating is surface-dried. The coating can be used as an exterior wall coating (base coat), and also can be used as a protective coating for the surfaces of an exterior wall thermal insulation plate, mortar, a sintered brick and a building enclosure structure; and the water-soluble ceramic coating has the characteristics of high durability, light weight, high strength, high efficiency, flame retardance, fire resistance, controllable quality, water resistance, alkali resistance, freezing and thawing resistance, cracking resistance, falling resistance and the like.

Owner:WUHAN UNIV OF TECH

Anticorrosive waterproof nano industrial coating and its preparing method

InactiveCN1709994ASignificant heavy-duty anti-corrosion performanceSignificant coating acid resistanceCoatingsUltravioletSolvent

The invention discloses a kind of new industry dope. It comprises of two kinds of materials of following weight shares: Component A 95 - 105 and Component B 2 - 8 shares; thereinto, Component A is made from such materials as membrane forming object, pigment, filling agent, auxiliary agent, compound nanometer dispersing agent and solvent; Component B is made from nanometer Sb2O3 and mixed organic solvent carriers. The dope of the invention has following advantages: at room temperature, it has prominent heavy anticorrosion performance, and has excellent performances of acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it also has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:王继征

Reflector, heating crucible equipped with reflector and process for preparation of radiation image storage panel

InactiveUS20070003718A1Uneven thermal distributionReduces and minimizesLayered productsVacuum evaporation coatingElectricityCrucible

A heating crucible which generates heat when electricity is supplied and an insulating reflector having a shape surrounding and covering the crucible is combined.

Owner:FUJIFILM CORP +1

Solar-architectural material and building integrative solar energy utilization

InactiveUS20080209907A1Upgrade cost efficiencyExclude leakage riskSolar heating energySolar heat devicesBuilding materialThermal energy

The present invention provides a kind of solar-architectural materials which receive solar radiation and transfer it into heat energy and at the same time works as building finishing and decoration material, and thereof a system of building integrative solar heat utilization in which comprise a kind of heat-energy-conflux-device via metal matching surface impinging on each other without leakage possibility of liquid as heat transfer medium in the system.

Owner:XIAO WENZHAO +3

Self-contained gel insulated container

InactiveUS7299652B2Improve insulation performanceImprove energy efficiencyDomestic stoves or rangesLighting and heating apparatusElectrical and Electronics engineeringStorage area

Owner:GAGNON FRANCOIS

Process and apparatus for insulating building roof

InactiveUS7017315B2Easy to installEffective insulationBuilding repairsHeat proofingRafterElectrical and Electronics engineering

Owner:CORWIN THOMAS N

Load-bearing, lightweight, and compact super-insulation system

ActiveUS20050047871A1Easy to installEasy maintenanceDrilling rodsService pipe systemsEngineeringInsulation system

A lightweight and compact super-insulation system that is also capable of supporting a high level of compressive load is described. The system utilizes spacers to provide structural support and utilize controlled buckling of a thin protective outer skin supported by spacers to form strong catenary surfaces to protect insulation material underneath. The spacers may comprise an aerogel, or an aerogel may provide insulation separate from the spacer yet contained within the thin outer skin. The system will be useful for thermal management of variety of deep underwater structures such as pipe-in-pipe apparatus, risers or subsea trees for ultra-deep water oil-and-gas exploration.

Owner:ASPEN AEROGELS INC

Water cooling balance

ActiveCN104180966AEliminate the effects of aerodynamic measurementsExtended service lifeAerodynamic testingLeaking waterCooling effect

The invention discloses a water cooling balance which comprises a rod-type balance and a water-cooled jacket. Two water flow pipelines are arranged in the rod-type balance. The two ends of each water flow pipeline are arranged on the two end faces of the rod-type balance respectively. A switching joint is arranged between the water-cooled jacket and the rod-type balance and fixed to one end face of the rod-type balance through a screw. A water inlet switching pipeline and a water outlet switching pipeline are arranged on the switching joint. One end of the water inlet switching pipeline and one end of the water outlet switching pipeline correspond to openings of the two water flow pipelines on the end faces of the rod-type balance in position and the other end of the water inlet switching pipeline and the other end of the water outlet switching pipeline correspond to a water inlet and a water outlet of the water-cooled jacket in position. The defects that a corrugated pipe type water cooling balance is large in drag measurement error and inconvenient to install and use and a corrugated pipe is prone to being damaged and leaking water are overcome. In addition, due to the fact that corrugated pipe related devices are omitted, the length of the balance is reduced, the diameter of the balance is increased, the rigidity and the cooling effect of the balance are greatly improved, the temperature effect is reduced, and measurement uncertainty is obviously reduced.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Biological soluble fiber mat, preparation method thereof and vacuum insulated panel using mat

ActiveCN105274728AEffective insulationWith green characteristicsFibreboardThermal insulationAdhesiveSoluble fiber

The invention relates to a biological soluble fiber mat, a preparation method thereof and a vacuum insulated panel using the mat. The mat is a fiber mat containing biological soluble fibers including 85-100wt% of biological soluble fibers and 0-15wt% of cured adhesives. The biological soluble fibers penetrate through one another and intertwine or are in overlapping joint in the form of single filaments or distributed in an interwoven mode. Few biological soluble fibers extend close to the thickness direction of the mat. The adhesives are dispersed among signal filaments, closely adhered to one another and do not independently exist. The average fiber diameter of a biological soluble fibers is less than or equal to 30 [mu]m and the average fiber length is less than or equal to 250 mm. Harm of fiber dust generated during manufacture and usage of the fiber mat to human bodies can be effectively avoided.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

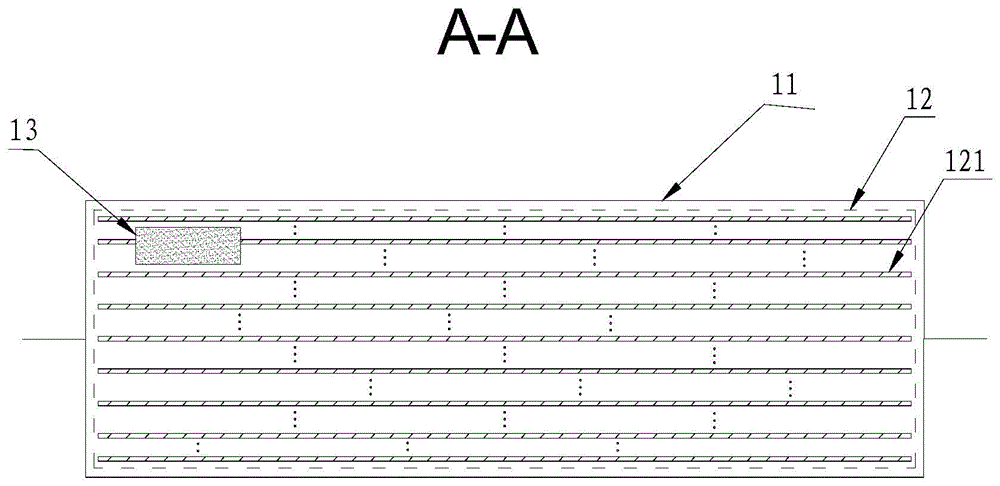

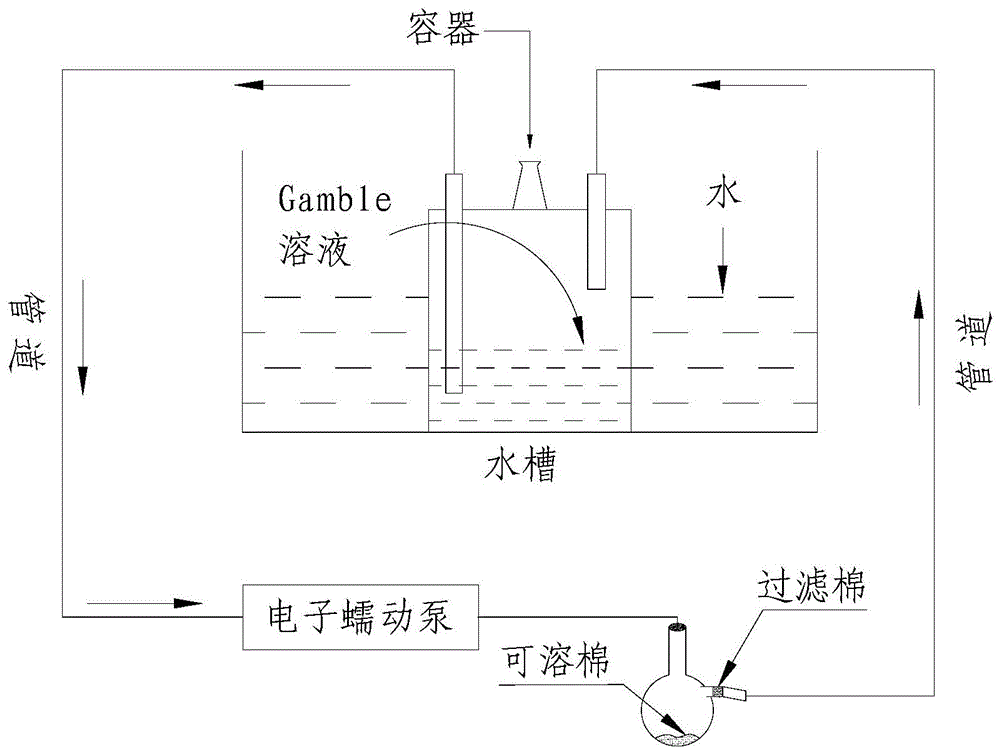

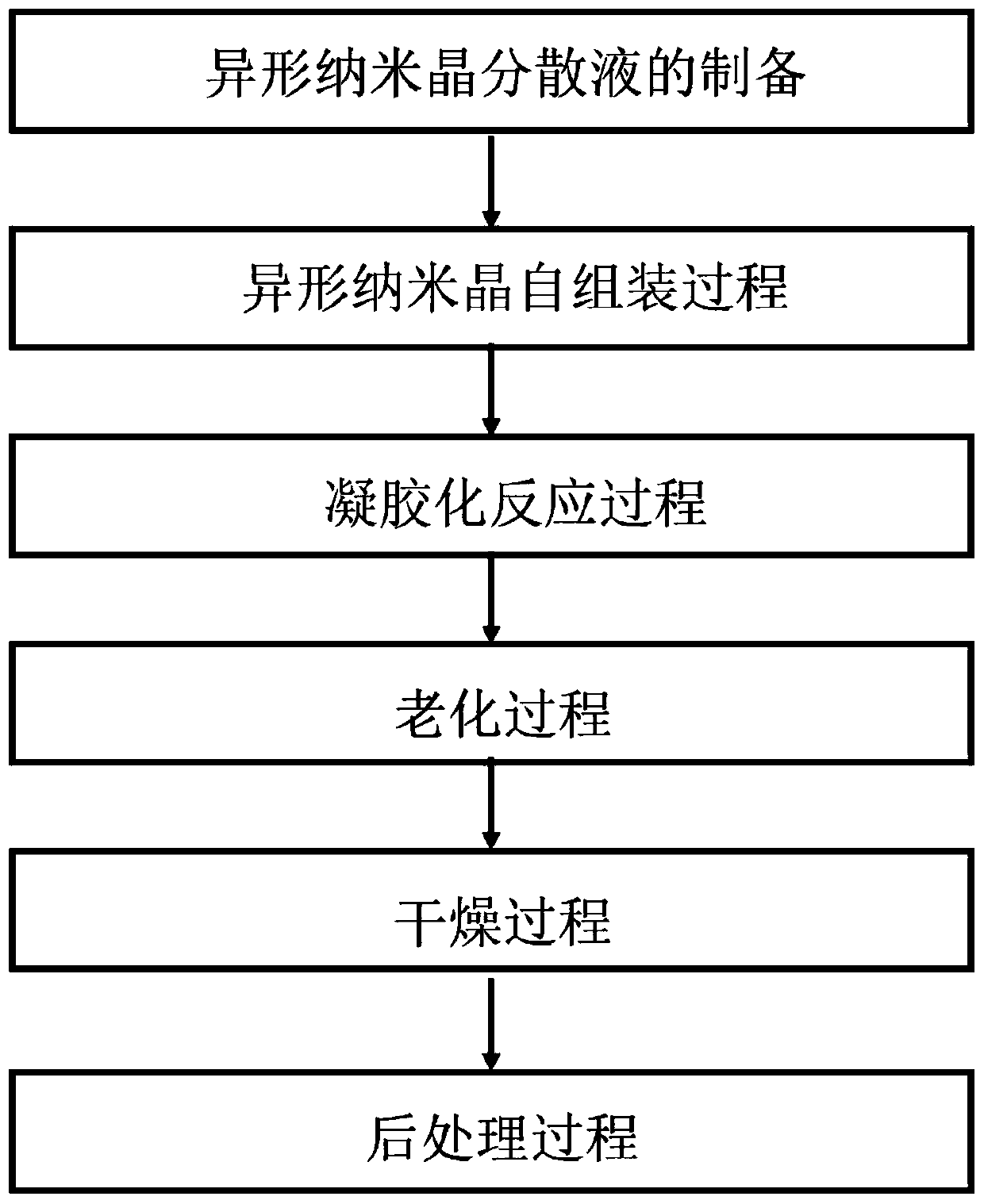

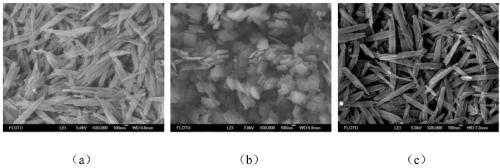

High-temperature-resistant heteromorphic nanocrystalline aerogel material and preparation method thereof

The invention relates to a high-temperature-resistant heteromorphic nanocrystalline aerogel material and a preparation method thereof. The method is as follows: preparing heteromorphic nanocrystal dispersion liquid; mixing the heteromorphic nanocrystal dispersion liquid and an assembly agent evenly by stirring and ultrasonic treatment to obtain a mixture phase first solution; then adding a catalyst solution, performing a gelation reaction process by stirring and ultrasonic treatment, and then performing a vacuum pumping process to obtain gelation reaction liquid; and performing an aging step and a drying step to obtain a heteromorphic nanocrystalline aerogel material; the heteromorphic nanocrystalline aerogel material is subjected to post-treatment in two or more different temperature stages to obtain the high temperature-resistant heteromorphic nanocrystalline aerogel material. The invention performs a staged heat treatment process on the aerogel material in the post-treatment process, thereby realizing the strengthening and toughening of themicrostructure of the aerogel material, so that the structural strength of the aerogel material is remarkably improved, the high temperature resistance performance and the large specific surface area after the heat treatment are realized, and the preparation of the high-temperature-resistant heteromorphic nanocrystalline aerogel material capable of high-efficient heat insulation is realized.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

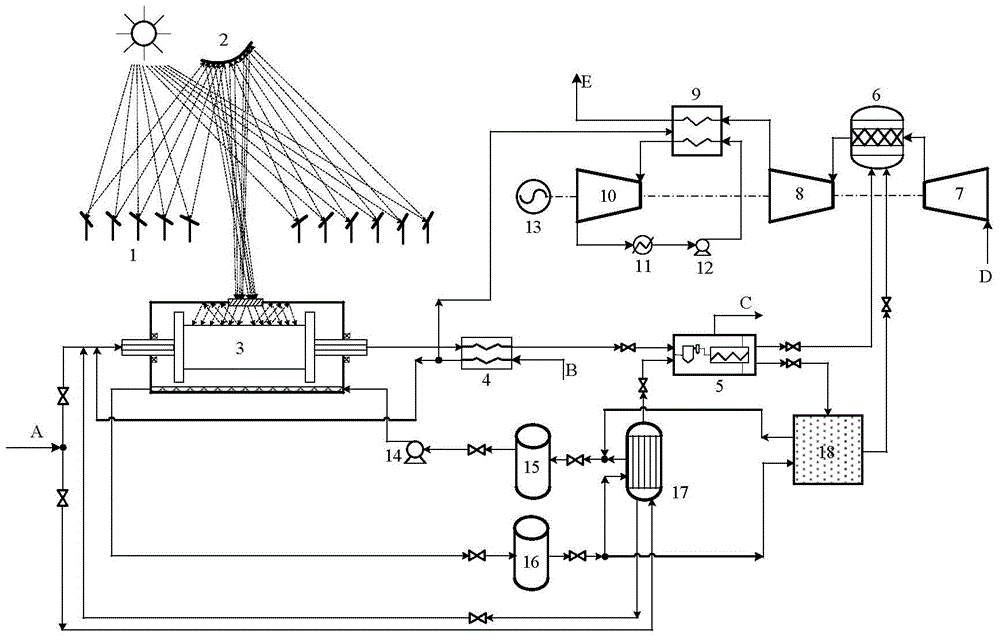

Solar energy and biomass complementary combined cycle power generating system capable of continuously running all day

ActiveCN104895675AEfficient use ofContinuous operation throughout the daySolar heating energySolar heat devicesCombustion chamberLiquid fuel

The invention discloses a solar energy and biomass complementary combined cycle power generating system capable of continuously running all day. Under the adequate light condition, the system directly utilizes high-temperature concentrating solar energy for completing the gasification reaction of solid hydrocarbon fuel by means of a high-temperature rotating type solar energy gasification reactor, and generated synthesis gas is purified and then is conveyed to a combustion chamber of the gas-steam combined cycle power generating system to generate powder; when the light condition is inadequate, the system utilizes a pyrolysis reactor and utilizes high-temperature molten salt storage solar energy for driving the solid hydrocarbon fuel for the pyrolytic reaction, and an atomizer is utilized for atomizing liquid fuel; and the atomized liquid fuel is conveyed to the combustion chamber of the gas-steam combined cycle system for power generation. The requirement that the solar energy is utilized for continuously converting the solid hydrocarbon fuel into the excellent fuel capable of being used by the gas-steam combined cycle system all day, and meanwhile, the system also can be suitable for other kinds of hydrocarbon solid hydrocarbon fuel like coal.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com