Preparation method of hydrophobic self-cleaning spray

A production method and spray technology, which are applied in the field of production of hydrophobic self-cleaning sprays, can solve problems such as human injury, and achieve the effects of simple production, increased safety, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

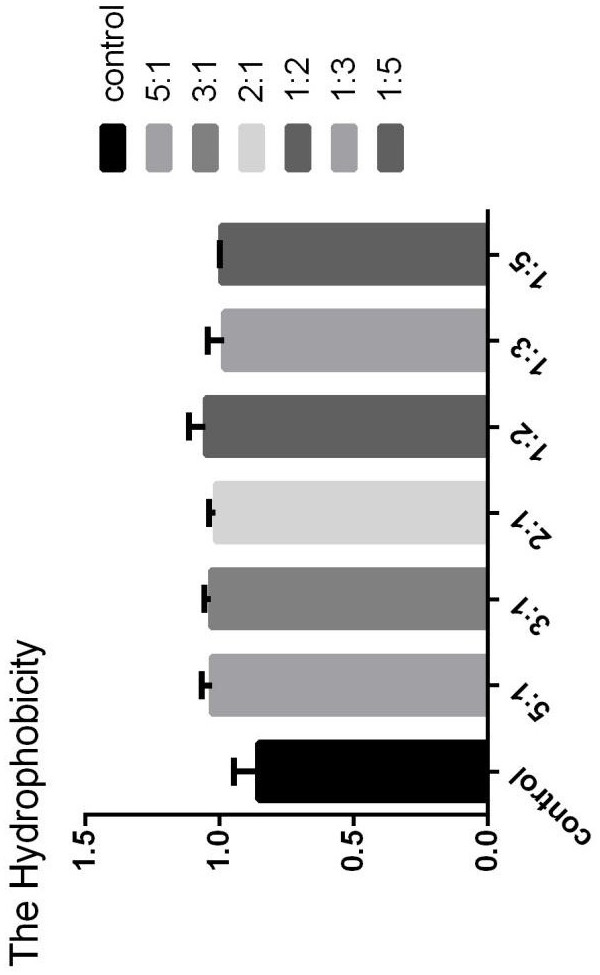

Image

Examples

Embodiment 1

[0023] A kind of preparation method of hydrophobic self-cleaning spray, concrete steps are as follows:

[0024] A. Purchase simethicone oil with a viscosity of 10mpa.s, and use a pure water machine to prepare ultrapure water with a resistivity of 18.2MΩ.CM;

[0025] B. Pour simethicone and ultrapure water in a ratio of 2:1 into a spray bottle and shake well to make a hydrophobic self-cleaning spray;

[0026] C. Mix and shake 6 times before use, 2 seconds each time, after shaking, spray the hydrophobic self-cleaning spray evenly on the surface of the object, and wait for 30 seconds to achieve the hydrophobic effect.

Embodiment 2

[0028] A kind of preparation method of hydrophobic self-cleaning spray, concrete steps are as follows:

[0029] A. Purchase simethicone oil with a viscosity of 20mpa.s, and use a pure water machine to prepare ultrapure water with a resistivity of 18.2MΩ.CM;

[0030] B. Pour simethicone and ultrapure water in a ratio of 3:2 into a spray bottle and shake well to make a hydrophobic self-cleaning spray;

[0031] C. Mix and shake 8 times before use, 2 seconds each time. After shaking, spray the hydrophobic self-cleaning spray evenly on the surface of the object, and wait for 30 seconds to achieve the hydrophobic effect.

Embodiment 3

[0033] A kind of preparation method of hydrophobic self-cleaning spray, concrete steps are as follows:

[0034] A. Purchase simethicone oil with a viscosity of 30mpa.s, and use a pure water machine to prepare ultrapure water with a resistivity of 18.2MΩ.CM;

[0035] B. Pour simethicone and ultrapure water in a ratio of 2:3 into a spray bottle and shake well to make a hydrophobic self-cleaning spray;

[0036] C. Mix and shake 10 times before use, 2 seconds each time, after shaking, spray the hydrophobic self-cleaning spray evenly on the surface of the object, and wait for 30 seconds to achieve the hydrophobic effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com