Connecting copper plate for crimping main branch cable conductor in pre-branch cable processing process

A processing and pre-branching technology, applied in the direction of conductive connection, permanent deformation, connection, connection, etc., can solve the problem of "C" type tube being too large or too small, and achieve the effect of avoiding poor quality of conductor crimping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

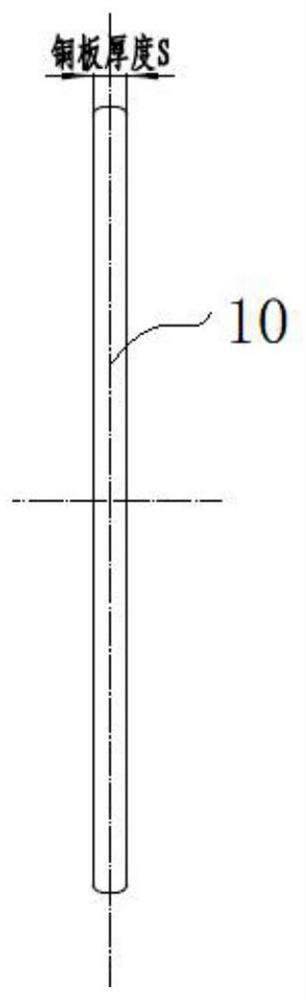

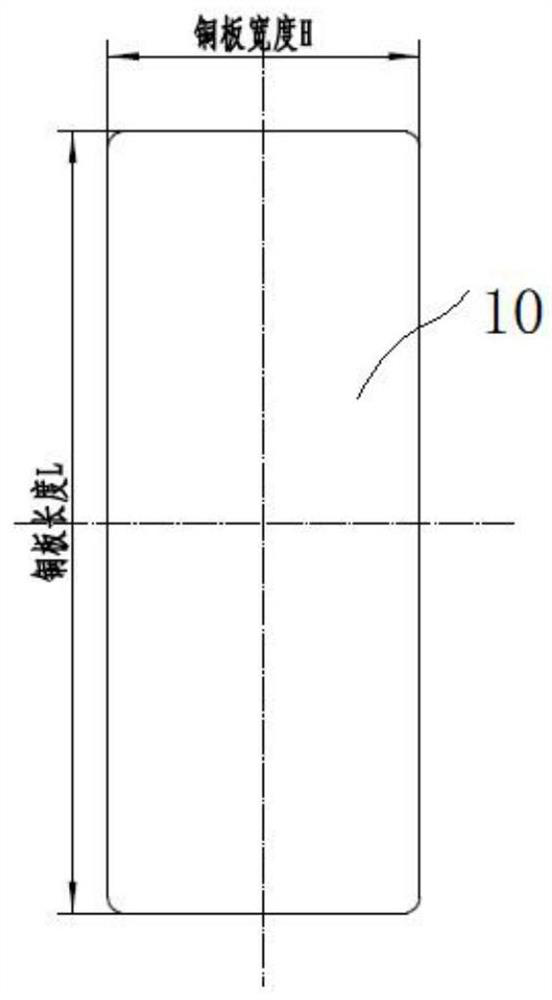

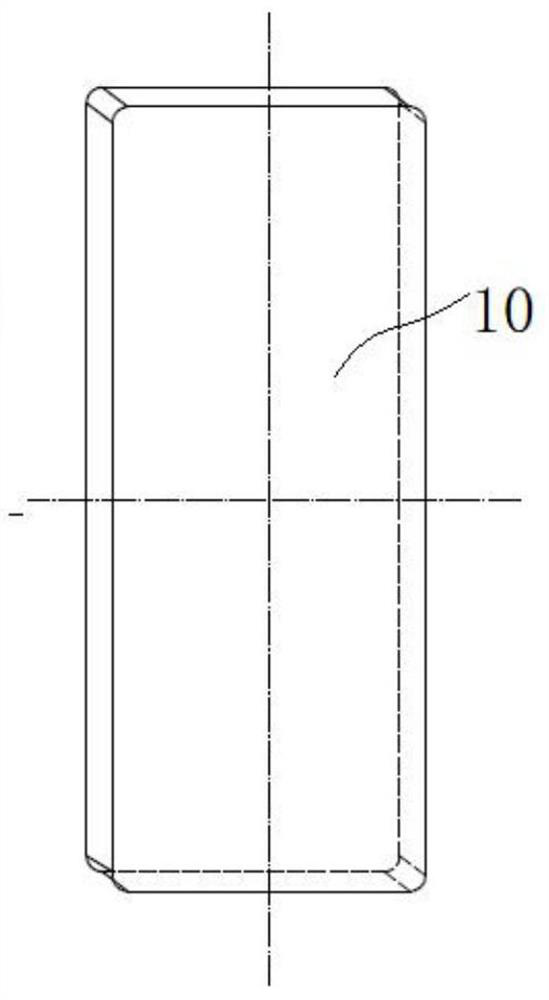

[0017] see Figure 1 to Figure 3 , the thickness S of the connecting copper plate 10 shown in the figure is determined. According to the actual size of the main cable conductor 20 section, refer to the appendix of JB / T106360-2006 "Rated Voltage 0.6 / 1kV (Um=1.2kV) Copper Core Plastic Insulated Prefabricated Branch Cable" A determines the thickness S of the connecting copper plate 10, and as the sum of the cross-sectional areas of the main cable conductor 20 and the branch cable conductor 30 increases, the thickness S of the connecting copper plate 10 increases gradually.

[0018] The width H of the connecting copper plate 10 is determined, the thickness H of the connecting copper plate 10 is determined according to the outer diameter D1 of the branch cable conductor 30, and the width H of the connecting copper plate 10 gradually widens as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com