Construction method for hoisting tube row of high temperature reheater

A construction method and reheater technology, which are used in steam superheating, lighting and heating equipment, boiler support/positioning devices, etc., can solve the problems of inconvenient construction and small interspersed gaps, and achieve short in-position time and erection engineering. The effect of less, good economic benefits and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

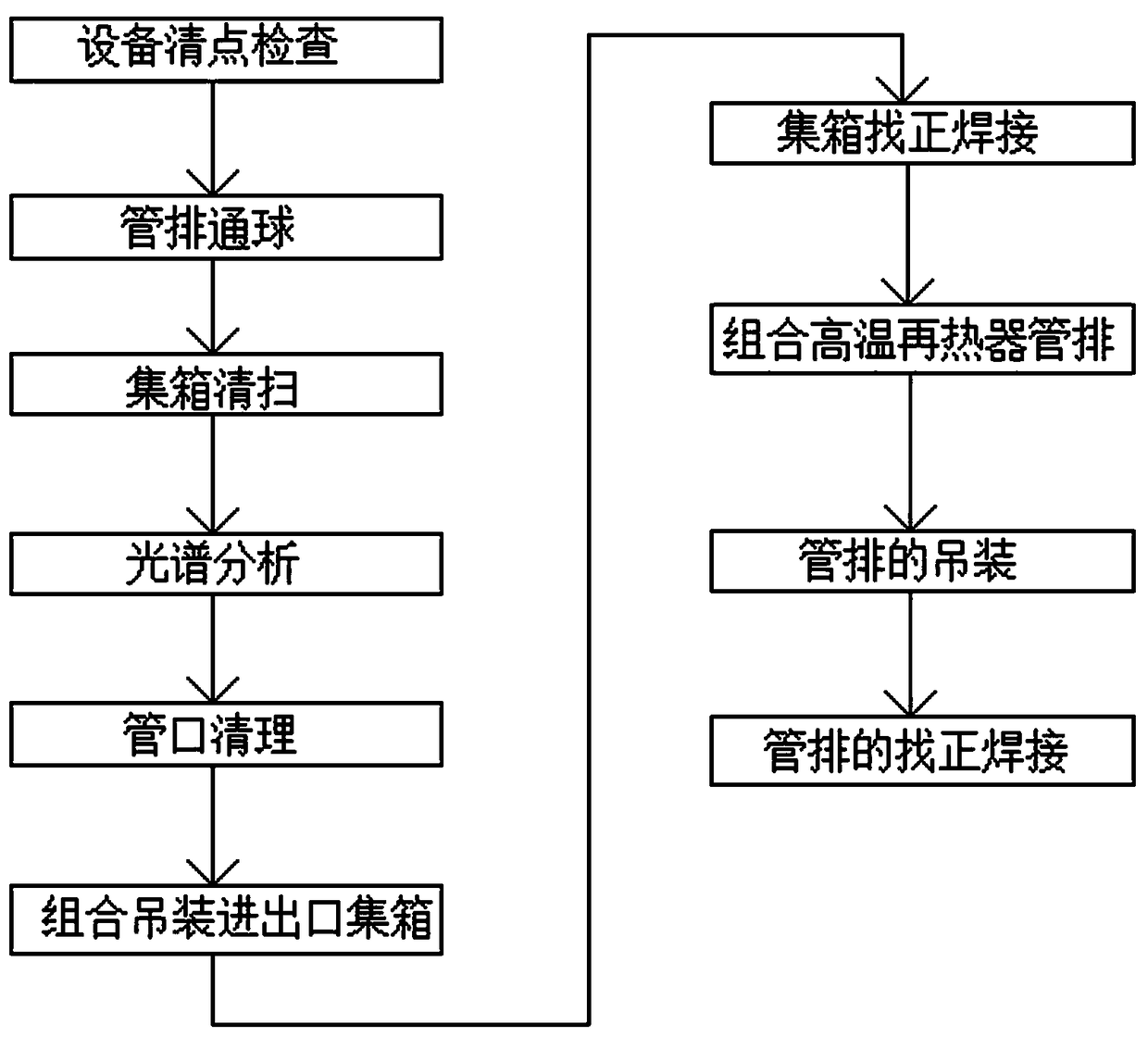

[0024] Embodiment: A construction method for hoisting tube rows of a high-temperature reheater, comprising the following steps:

[0025] (1) Equipment inventory inspection: check the size of the equipment, pipe outer diameter, wall thickness, surface quality and overall appearance, the surface quality of headers and pipe rows should be good, without obvious cracks, heavy skin, rust, pits and other defects , carefully check the boxed parts, and make a record. The size of the header and pipe row, the specifications of the pipe seat and the pipe should meet the requirements of the drawing. Check whether the high-temperature reheater header hanger, hanger, etc. If problems are found, they should be recorded in time, and reported to the construction director and technical director in time. The checked boxes, especially the pins, nuts, washers, cotter pins and other connecting parts of the pressure part hanger should be put into storage, according to the specifications. , models, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com