Fabricated structural system of steel plate reinforced concrete shear walls and construction method of fabricated structural system

A technology of steel plate concrete and shear walls, applied in the direction of load-bearing elongated structural members, structural elements, walls, etc., can solve the problems of dense arrangement of steel bars and studs, increased project cost, and limited application range, etc. To achieve the effect of improving construction efficiency, reducing cost and ensuring common force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

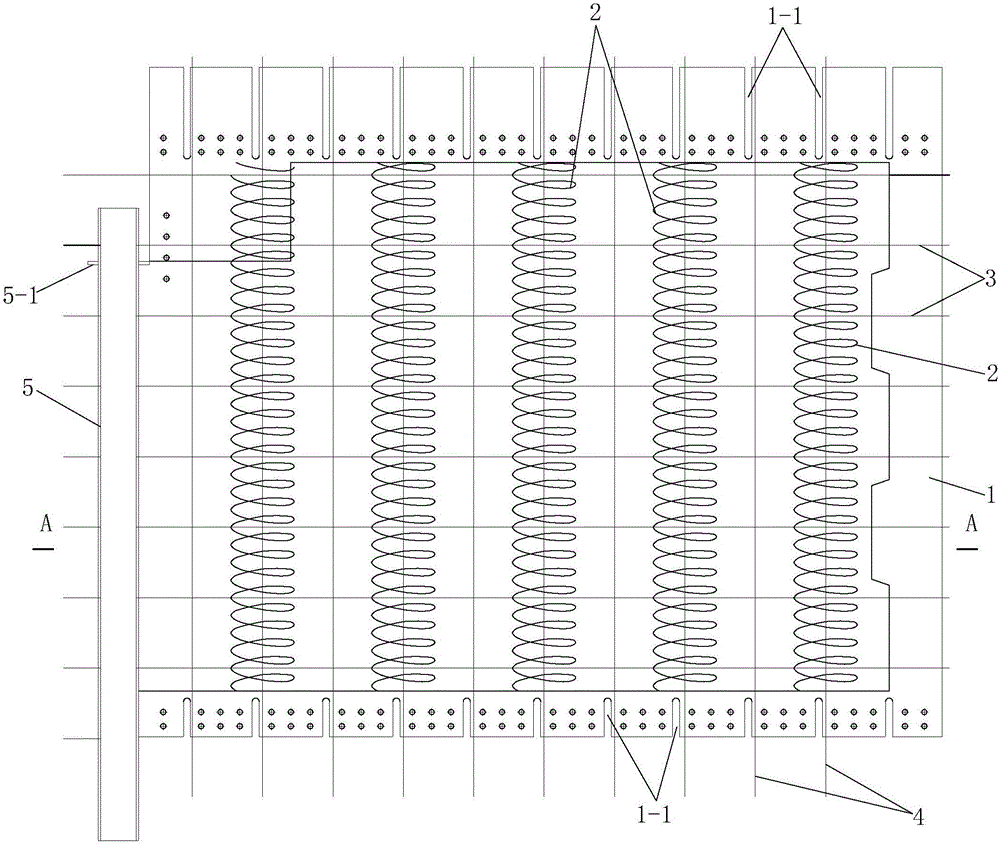

[0079] Such as figure 1 , figure 2 , image 3 and Figure 4 A prefabricated structural system of steel plate concrete shear walls is shown, including beam members 7, steel plate concrete shear walls and floor slabs, and sleeve connectors for connecting the steel plate concrete shear walls and beam members 7 8. The steel plate concrete shear wall includes a concrete wall 6 and a vertical steel plate 1 embedded in the concrete wall 6, and a continuous spiral stirrup 2 is fixed on the vertical steel plate 1, and the vertical steel plate 1 is provided with a plurality of holes for the continuous spiral stirrup 2 to pass through the vertical steel plate 1 from top to bottom or from bottom to top, and the concrete wall 6 is provided with vertical steel bars 4 and wall The horizontal reinforcing bar 3 of the body of the wall, the vertical reinforcing bar 4 of the body of the wall is bound on the continuous spiral stirrup 2, and the horizontal reinforcing bar 3 of the body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com