Pile foundation soaking load test method based on creep-strain separation

A technology of load test and pile foundation, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., and can solve the problems of large errors in the calculation results of the axial force of the pile body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

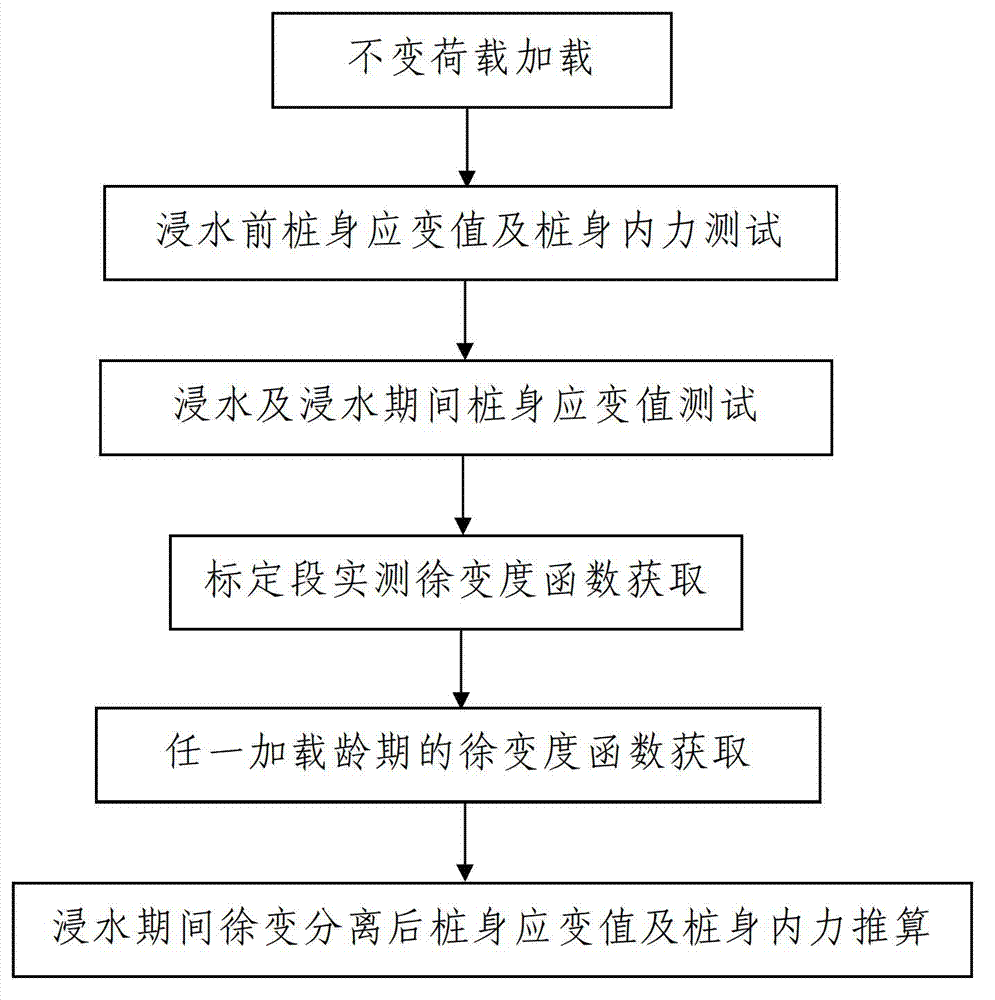

[0071] Such as figure 1 , figure 2 Shown, the pile foundation flooding load test method based on creep strain separation of the present invention, comprises the following steps:

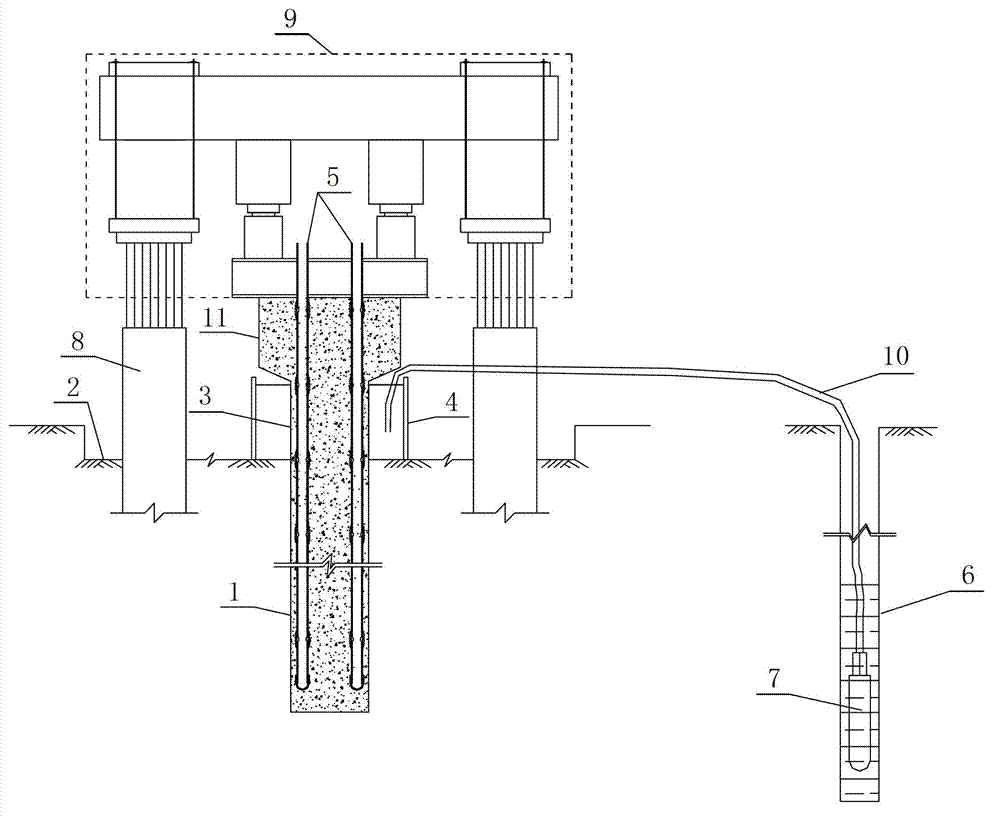

[0072] Step 1. Constant load loading: Load the completed test pile 1 from top to bottom, and the load on the top of the test pile 1 is F N ; The stress applied on the top of the test pile 1 pile In the formula, A is the pile cross-sectional area of test pile 1.

[0073] The test pile 1 is vertically arranged on a concrete pile in the collapsible loess stratum, and the test pile 1 has a pile head above the ground.

[0074] In this embodiment, the test pile 1 is a cylindrical pile, and the surrounding side of the test pile 1 is excavated to form a test pit 2 for the pile foundation immersion load test. The test pit 2 is a flat-bottomed pit, and the test pit 2 Mark one is flush with the pit bottom of the flat-bottomed pit. A water tank 4 is arranged on the outside of the calibration section 3 ,...

Embodiment 2

[0171] Such as Figure 4 As shown, in this embodiment, the difference from Embodiment 1 is that the test pile 1 described in step 1 is a prestressed pipe pile; A measuring pipe 5 is installed in the stress pipe pile, and the measuring pipe 5 is arranged vertically in the middle of the pipe pile core of the prestressed pipe pile; of the target. Moreover, the number of the measuring tube 5 is one. The cross section of the pile body of the prestressed pipe pile is circular, and because the bottom of the pile is closed, the cross section of the end of the prestressed pipe pile is circular.

[0172] After the installation of the measuring pipe 5 is completed, the filling material 12 is injected into the cavity between the pipe pile core of the prestressed pipe pile and the measuring pipe 5 from bottom to top using the grouting equipment, and the filling material 12 is It is a mixed slurry formed by uniform mixing of water, cement and bentonite according to the weight ratio of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

| Pile length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com