Steel die and reinforced concrete integrated combination beam structure

An integrated, composite beam technology, applied in the direction of structural elements, elongated structural members for load-bearing, bridges, etc., can solve the problems of high construction cost, low progress and efficiency, occupying a large prefabricated site, etc., and achieve low cost. , The construction progress is simplified and the construction is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

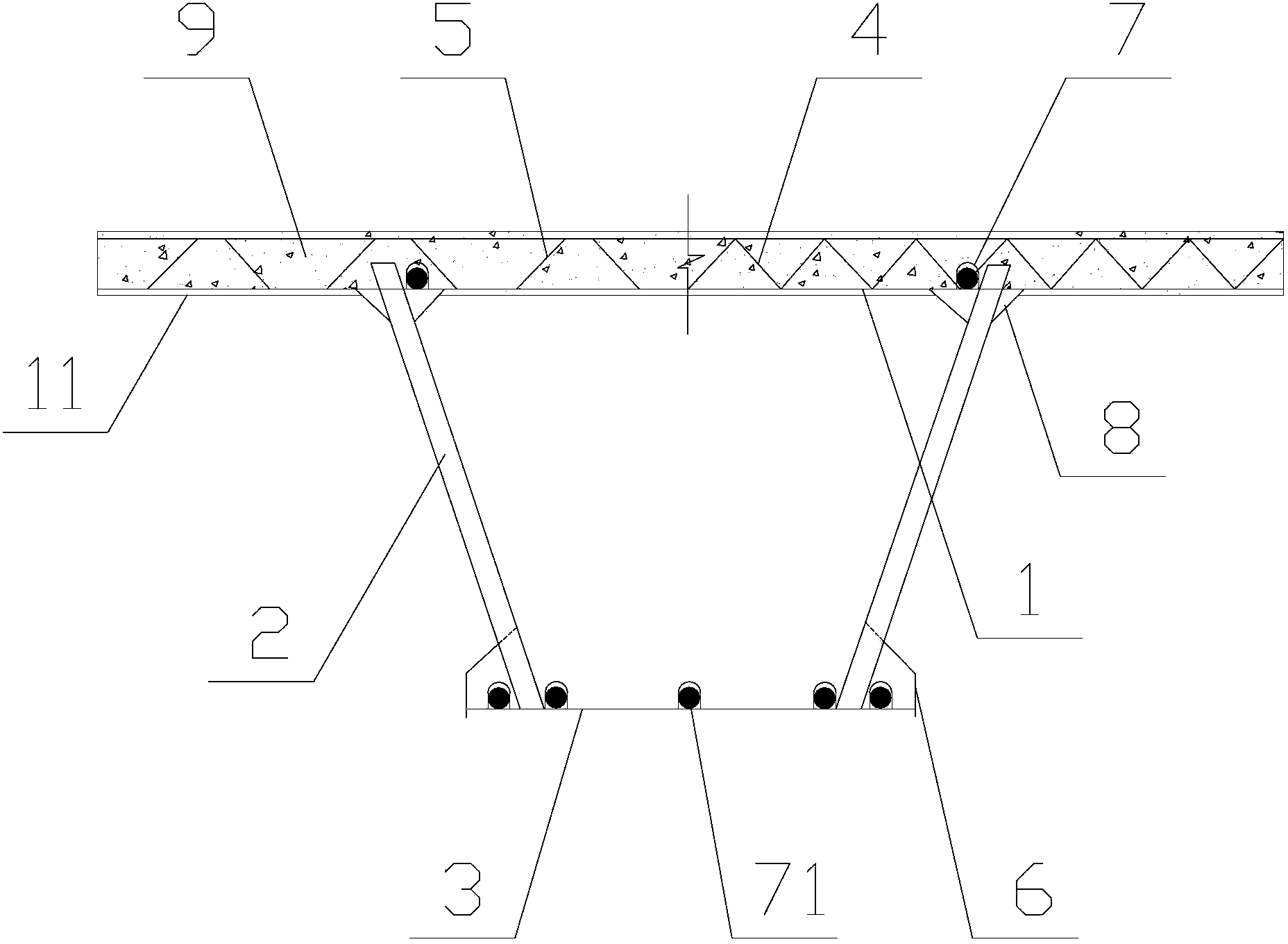

[0025] Steel mold steel concrete integrated composite beam structure, such as figure 1 , 3 , 4, including steel top plate 1, steel bottom plate 3, corrugated steel plate 2, described corrugated steel plate 2 connects steel top plate 1 and steel bottom plate 3, pours reinforced concrete 9 on steel top plate 1, and steel top plate 1 is arranged on corrugated steel plate 2 The corrugated steel plate 2 is inserted into the reinforced concrete 9 through the steel top plate 1 on both sides. The steel top plate 1 and the corrugated steel plate 2 are respectively provided with pegs.

[0026] The steel top plate 1 is provided with a micro-strain wave 11, the micro-strain wave 11 is a micro-strain wave with a convex crest, and the wave height of the micro-strain wave 11 is less than 3-20 times of the thickness of the steel top plate 1, and the micro-strain wave 11 The distance between adjacent wave crests is greater than 500 mm; the steel base plate 3 is provided with a micro strain w...

Embodiment 2

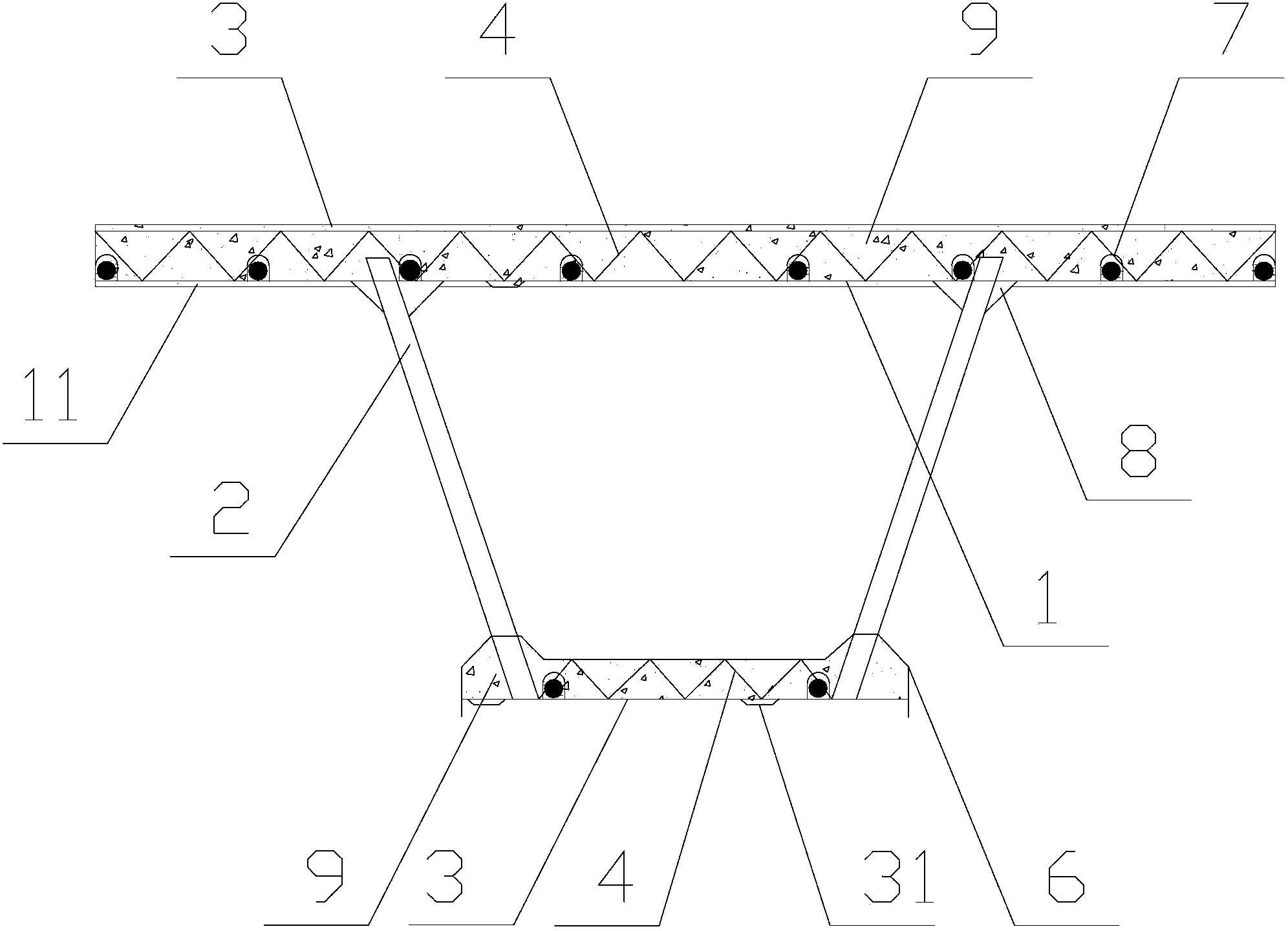

[0033] Steel mold steel concrete integrated composite beam structure, such as figure 2 , 3 , 4, including steel top plate 1, steel bottom plate 3, corrugated steel plate 2, described corrugated steel plate 2 connects steel top plate 1 and steel bottom plate 3, pours reinforced concrete 9 on steel top plate 1, and steel top plate 1 is arranged on corrugated steel plate 2 The corrugated steel plate 2 is inserted into the reinforced concrete 9 through the steel top plate 1 on both sides. The steel top plate 1 and the corrugated steel plate 2 are respectively provided with pegs.

[0034] The corrugated steel plate 2 is welded to the steel base plate 3, and the steel base plate 3 is poured with reinforced concrete 9.

[0035]The steel top plate 1 is provided with a micro-strain wave 11, the micro-strain wave 11 is a micro-strain wave with a convex crest, and the wave height of the micro-strain wave 11 is less than 3-20 times of the thickness of the steel top plate 1, and the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com