Al and Zn strengthened Mg-Sn-RE-based high-toughness heat-resistant magnesium alloy

A mg-sn-re and mg-sn-sr technology is applied in the field of modification of room temperature performance and high temperature performance, which can solve the problem of deteriorating alloy room temperature mechanical properties, high economic cost of heat-resistant magnesium alloys, and unsatisfactory room temperature performance, etc. Problems, to achieve obvious grain refinement, improve casting process performance, and good development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

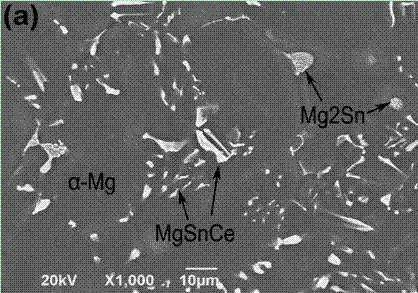

[0031] Example 1-1: A Mg-Sn-Ce-based high-strength and tough heat-resistant magnesium alloy strengthened by adding Al, the mass percentage of each component in the alloy is: 5% Sn, 2% Ce, 2% Al, and the balance is Mg and unavoidable impurities. The tensile strength of the alloy at room temperature as cast is 210MPa; the elongation is 14.4%, and the steady-state creep rate at 175°C and 55MPa is 3.9 x10 -7 / % s.

Embodiment 1-2

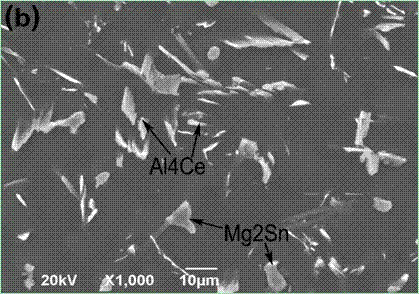

[0032] Example 1-2: A Mg-Sn-Ce-based high-strength and tough heat-resistant magnesium alloy strengthened by adding Al, the mass percentage of each component in the alloy is: 5% Sn, 2% Ce, 4% Al, and the balance is Mg and unavoidable impurities. The as-cast room temperature tensile strength of the alloy is 244MPa, and the elongation is 12.0%; the steady-state creep rate at 175°C and 55MPa is 1.6 x10 -7 / % s.

[0033] Example class two: a Zn-added reinforced Mg-Sn-RE based high-strength and tough heat-resistant magnesium alloy.

Embodiment 2-1

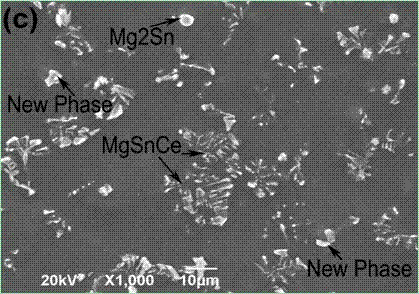

[0034] Example 2-1: A Mg-Sn-Ce-based high-strength and toughness heat-resistant magnesium alloy strengthened by adding Zn, the mass percentage of each component in the alloy is: 5% Sn, 2% Ce, 2% Zn, and the balance is Mg and unavoidable impurities. The tensile strength of the alloy at room temperature as cast is 220MPa, and the elongation is 15.0%; the steady-state creep rate at 175°C and 55MPa is 5.0 x10 -7 / % s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com