AE series thermo-stable die-casting magnesium alloy containing cerium and lanthanide

A technology of hot pressing and casting magnesium, which is applied in the field of magnesium alloy materials, can solve the problems of poor alloy plasticity, easy hot cracking, lack of high temperature performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

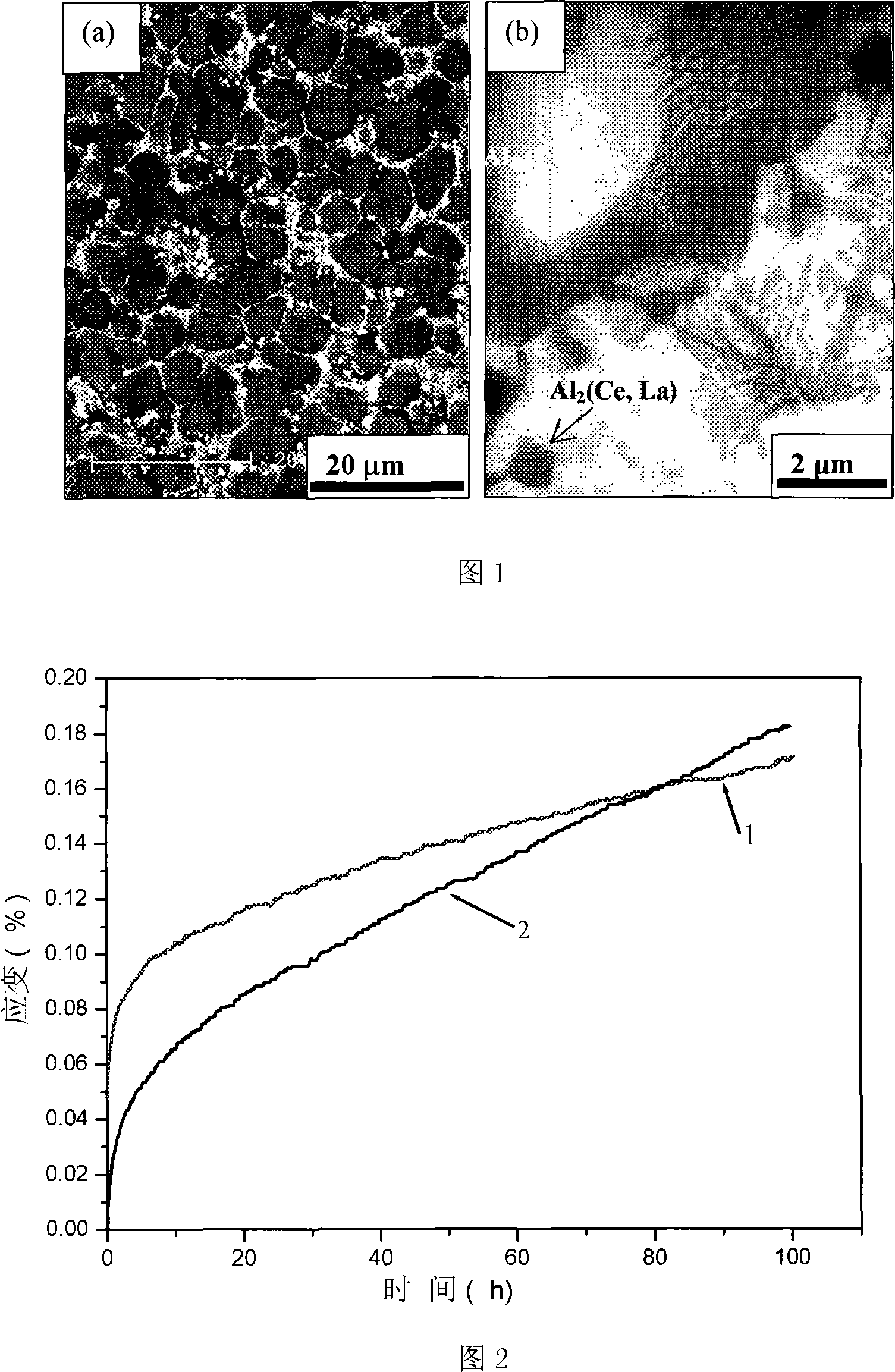

[0013] Embodiment 1 AlCeLa3, 0.6, 0.4 alloy

[0014] AE series heat-resistant die-casting magnesium alloy containing cerium and lanthanum, its mass percentage ratio is: aluminum: 3%, cerium: 0.6%, lanthanum: 0.4%, manganese: 0.2%, the total amount of impurity elements Fe, Cu and Ni Less than 0.03%, the balance is magnesium. Alloy properties are shown in Table 1 and Table 2.

Embodiment 2

[0015] Embodiment 2 AlCeLa5, 1.2, 0.8 alloy

[0016] AE series heat-resistant die-casting magnesium alloy containing cerium and lanthanum, its mass percentage ratio is: aluminum: 5%, cerium: 1.2%, lanthanum: 0.8%, manganese: 0.4%, the total amount of impurity elements Fe, Cu and Ni Less than 0.03%, the balance is magnesium. Alloy properties are shown in Table 1 and Table 2.

Embodiment 3

[0017] Embodiment 3 AlCeLa4, 1.8, 1.2 alloy

[0018] AE series heat-resistant die-casting magnesium alloy containing cerium and lanthanum, its mass percentage ratio is: aluminum: 4%, cerium: 1.8%, lanthanum: 1.2%, manganese: 0.4%, the total amount of impurity elements Fe, Cu and Ni Less than 0.03%, the balance is magnesium. Alloy properties are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com