High-heat-strength aluminum-silicon alloy material and manufacturing method thereof

A technology of an aluminum-silicon alloy and a manufacturing method, applied in the field of high-strength alloys and their preparation, can solve problems such as restricting the development of pistons, and achieve the effects of refining grains and inhibiting recrystallization behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

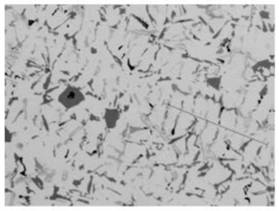

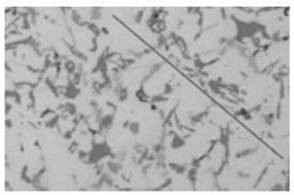

[0033] Example 1: A high-heat-strength aluminum-silicon alloy material, including components by mass percentage: Si: 8.5-10%; Cu: 3.0-4.5%; Ni: 2.0-3.0%; Mg: 1.0-2.5%; Zr: 0.05-0.3%; Ti: 0.05-0.3%; Er: 0.05-0.3%; Pt: 0.05-0.23%, and the rest is Al.

[0034] Furthermore, Zr is added in an amount of 0.05% to 0.25% in the aluminum-silicon alloy, and zirconium and aluminum form a ZrAl3 compound, which can hinder the recrystallization process and refine the recrystallization grains. Zirconium can also refine the casting structure, but the effect is smaller than that of titanium. Since zirconium has less effect on quenching sensitivity than chromium and manganese, it is advisable to use zirconium instead of chromium and manganese to refine the recrystallized structure

[0035] Further, the composition by mass percentage is included: Zr: 0.08-0.16%. Zr particles have a good coherent relationship with Al. AlgZr particles are small and densely distributed. During the peritectic react...

Embodiment 2

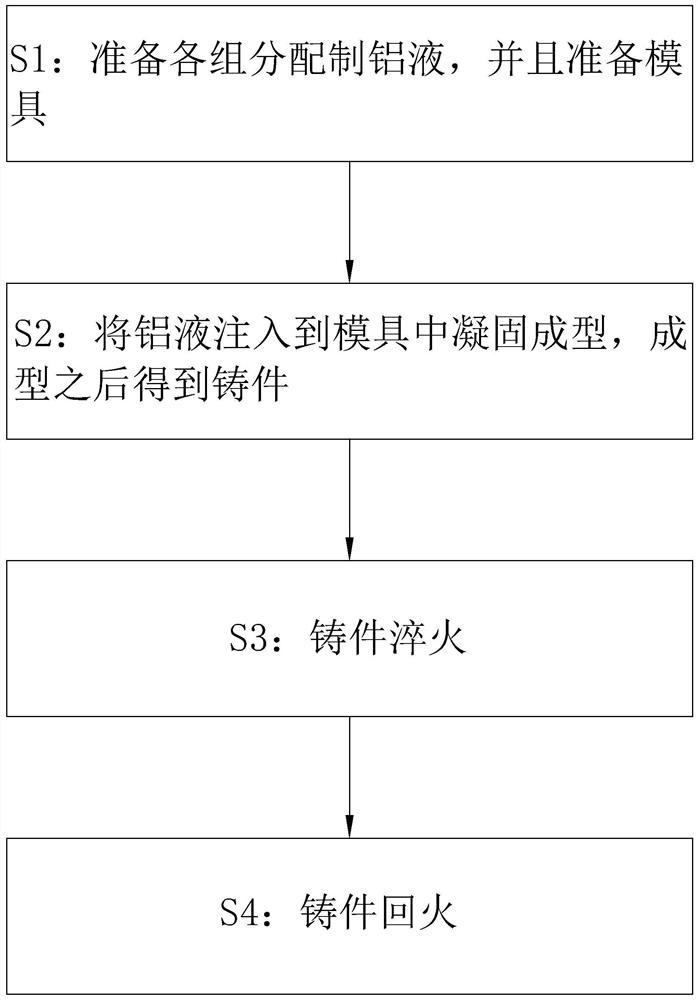

[0040] Embodiment 2: a kind of manufacturing method of high thermal strength aluminum-silicon alloy material, such as figure 1 shown, including the following steps:

[0041] S1. Prepare each component to prepare liquid aluminum, and prepare the mold.

[0042] S2. Heat the molten aluminum to 760°C and smoothly fill the mold into the inner cavity through the mold runner, and use the rapid cooling casting method to cool the key parts of the piston. temperature control. Make sure the top riser is up. After the molten aluminum is cooled and solidified, the mold is opened and the casting is taken out after forming.

[0043] S3. Put it into a water tank at 60-80°C for as-cast quenching, and its water level is controlled at the center of the pin hole.

[0044] S4. Put the quenched casting into an oven, and temper at 230°C for 15 hours to ensure that the hardness of the tempered material is controlled at 105-140HB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com