Preparation method of active carbon fiber porous tungsten disulfide nano composite material

A technology of nanocomposite materials and activated carbon fibers, which is applied in the direction of nanotechnology, hybrid capacitor electrodes, etc., to achieve the effects of reducing agglomeration, good application prospects, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

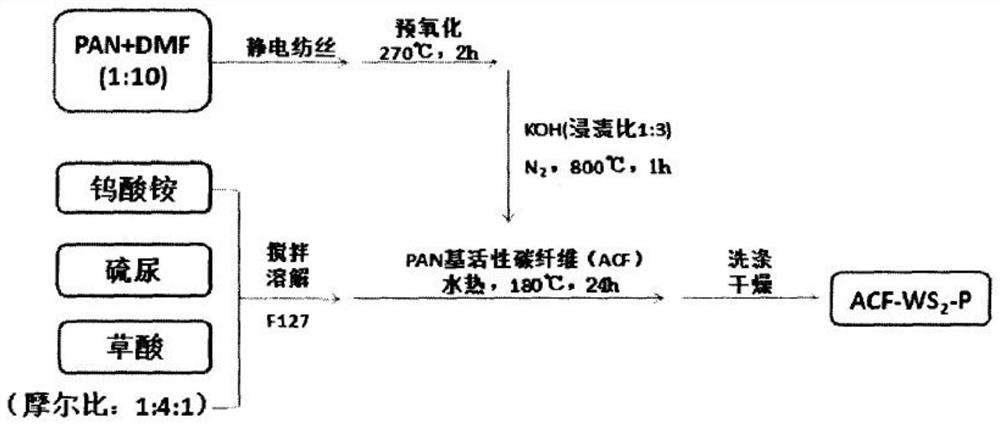

[0025] S1, preparation of activated carbon fiber: using polyacrylonitrile (PAN) as a precursor, using DMF (N, N-dimethylformamide) as a solvent, preparing a 10% DMF solution of PAN as a spinning solution, and using electrospinning Technology Under the conditions of high voltage 14kV, low pressure -2kV, and spinning distance of 18cm, PAN fiber precursors are prepared, and then the obtained PAN fiber precursors are placed in a tube furnace with air circulation at 260 ° C for 1 hour to complete pre-oxidation;

[0026] S2, adding 1g of preoxidized fiber and 3gKOH obtained in the S1 step, in the tube furnace, N 2 Under the atmosphere, keep warm at 800°C for 1h, and the heating rate is 5°Cmin -1 , to achieve the purpose of carbonization and activation in one step, and obtain activated carbon fiber (ACF);

[0027] S3. Add ammonium tungstate as the tungsten source, thiourea as the sulfur source, and a certain amount of oxalic acid and F127 pore-forming agent into an appropriate amoun...

Embodiment 2

[0030] S1, preparation of activated carbon fiber: using polyacrylonitrile (PAN) as a precursor, using DMF (N, N-dimethylformamide) as a solvent, preparing a 10% DMF solution of PAN as a spinning solution, and using electrospinning Technology Under the conditions of high voltage 14kV, low pressure -2kV, and spinning distance of 18cm, PAN fiber precursors are prepared, and then the obtained PAN fiber precursors are placed in a tube furnace with air circulation at 260 ° C for 1 hour to complete pre-oxidation;

[0031] S2. Add 2g of pre-oxidized fiber and 6gKOH obtained in the step of S1, in a tube furnace, under a helium atmosphere, keep warm at 800°C for 1h, and the heating rate is 5°Cmin -1 , to achieve the purpose of carbonization and activation in one step, and obtain activated carbon fiber (ACF);

[0032] S3. Add ammonium tungstate as the tungsten source, thiourea as the sulfur source, and a certain amount of oxalic acid and F127 pore-forming agent into an appropriate amount...

Embodiment 3

[0035] S1, preparation of activated carbon fiber: using polyacrylonitrile (PAN) as a precursor, using DMF (N, N-dimethylformamide) as a solvent, preparing a 10% DMF solution of PAN as a spinning solution, and using electrospinning Technology Under the conditions of high voltage 14kV, low pressure -2kV, and spinning distance of 18cm, PAN fiber precursors are prepared, and then the obtained PAN fiber precursors are placed in a tube furnace with air circulation at 260 ° C for 1 hour to complete pre-oxidation;

[0036] S2, add the preoxidized fiber and 9gKOH gained in the 3gS1 step, in tube furnace, N 2 Under the atmosphere, keep warm at 800°C for 1h, and the heating rate is 5°Cmin -1 , to achieve the purpose of carbonization and activation in one step, and obtain activated carbon fiber (ACF);

[0037] S3. Add ammonium tungstate as the tungsten source, thiourea as the sulfur source, and a certain amount of oxalic acid and F127 pore-forming agent into an appropriate amount of deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com