Preparation method of 6111 aluminum alloy plate for automobile body

A technology for aluminum alloy sheets and automobile bodies, which is applied in the field of preparation of 6111 aluminum alloy sheets for automobile bodies, can solve the problems of hindering the large-scale replacement of steel sheets by 6111 aluminum sheets, high production costs, etc., improve deep drawing performance and paint hardening performance, and improve The effect of improving efficiency and press formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

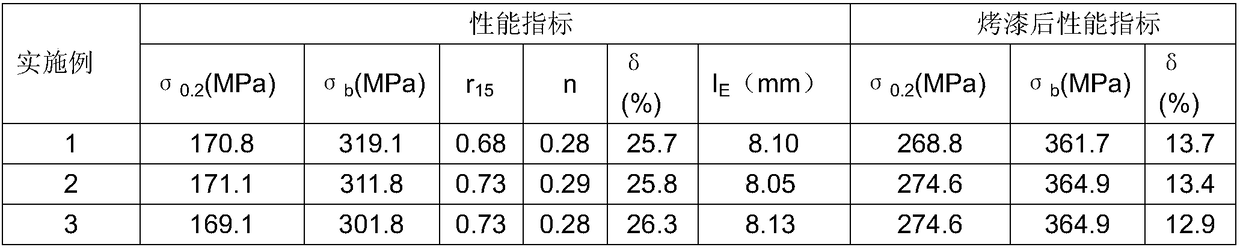

Embodiment 1

[0040] A preparation method of 6111 aluminum alloy plate, comprising the following steps:

[0041] (1) Ingot preparation: 6111 aluminum alloy ingots were prepared by semi-continuous casting;

[0042] (2) Pretreatment and hot rolling: heat the 6111 aluminum alloy ingot to 200°C and keep it warm for 4 hours; then raise the temperature to 460°C, keep it warm for 3 hours, and then hot-roll it out of the furnace to obtain a hot-rolled sheet with a thickness of 4mm;

[0043] (3) Intermediate annealing: After heating the hot-rolled sheet to 480°C in a circulating cyclone furnace and keeping it warm for 6 hours, the cooling method is air cooling to room temperature to obtain an annealed rolled sheet;

[0044] (4) Cold rolling: the annealed plate is cold-rolled to obtain a cold-rolled plate; the final rolling thickness of the cold-rolled plate is 0.9mm;

[0045] (5) Solution treatment: solution treatment is performed on the cold-rolled sheet to obtain a solution-treated plate; wherein...

Embodiment 2

[0064] A preparation method of 6111 aluminum alloy plate, comprising the following steps:

[0065] (1) Ingot preparation: 6111 aluminum alloy ingots were prepared by semi-continuous casting;

[0066] (2) Pretreatment and hot rolling: heat the ingot of 6111 aluminum alloy to 260°C and keep it warm for 5 hours; then raise the temperature to 470°C, hold it for 3 hours and then hot-roll it out of the furnace to obtain a hot-rolled sheet with a thickness of 5mm;

[0067] (3) Intermediate annealing: heat the hot-rolled sheet at 495°C for 5 hours, then cool it in air to room temperature to obtain an annealed rolled sheet;

[0068] (4) Cold rolling: the annealed plate is cold-rolled to obtain a cold-rolled plate; the final rolling thickness of the cold-rolled plate is 0.9mm;

[0069] (5) Solution treatment: solution treatment is performed on the cold-rolled sheet to obtain a solution-treated plate; wherein, the heating temperature for solution is 540° C., the holding time is 14 minut...

Embodiment 3

[0075] A preparation method of 6111 aluminum alloy plate, comprising the following steps:

[0076] (1) Ingot preparation: 6111 aluminum alloy ingots were prepared by semi-continuous casting;

[0077] (2) Pretreatment and hot rolling: heat the ingot of 6111 aluminum alloy to 390°C and keep it warm for 6h; then raise the temperature to 475°C, hold it for 3h and then hot-roll it out of the oven to obtain a hot-rolled sheet with a thickness of 4mm;

[0078] (3) Intermediate annealing: heat the hot-rolled sheet at 495°C for 5 hours, then cool it in air to room temperature to obtain an annealed rolled sheet;

[0079] (4) Cold rolling: the annealed plate is cold-rolled to obtain a cold-rolled plate; the final rolling thickness of the cold-rolled plate is 0.9mm;

[0080] (5) Solution treatment: solution treatment is performed on the cold-rolled sheet to obtain a solution-treated plate; wherein, the heating temperature for solution is 540° C., the holding time is 14 minutes, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com