Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "Guaranteed Yield Strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength Al-Mg-Si-Cu alloy and preparation method thereof

The invention relates to high-strength Al-Mg-Si-Cu alloy and a preparation method thereof. The alloy comprises 0.8-1.4wt% of Mg, 0.8-1.6wt% of Si, 0.2-0.8wt% of Cu, 0.2-1.0wt% of Mn, 0.1-0.4wt% of Cr, 0.01-0.1wt% of Ti, not more than 0.25wt% of Fe, not more than 0.15wt% of all inevitable impurities and the balance of Al. The preparation method of the alloy comprises the following steps of: preparing an alloy cast ingot by adopting a semi-continuous casting mode, heating the semi-continuous cast ingot along with the furnace to 300-350 DEG C, then heating to 520-570 DEG C at a heating rate of 1-10 DEG C / min, carrying out heat insulation for 4-10 hours, cooling in air, heating the homogenized cast ingot again to 450-500 DEG C, and forging, wherein the final forging temperature is not lower than 350 DEG C; and carrying out T6 heat treatment on the forged piece.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

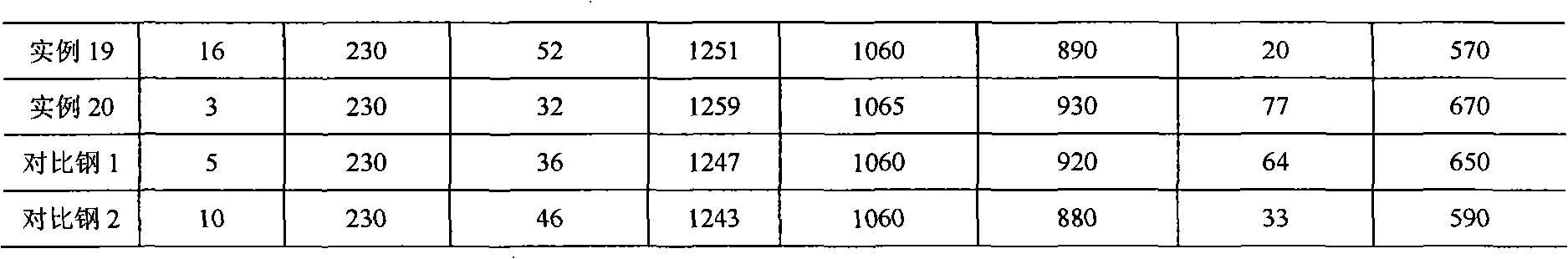

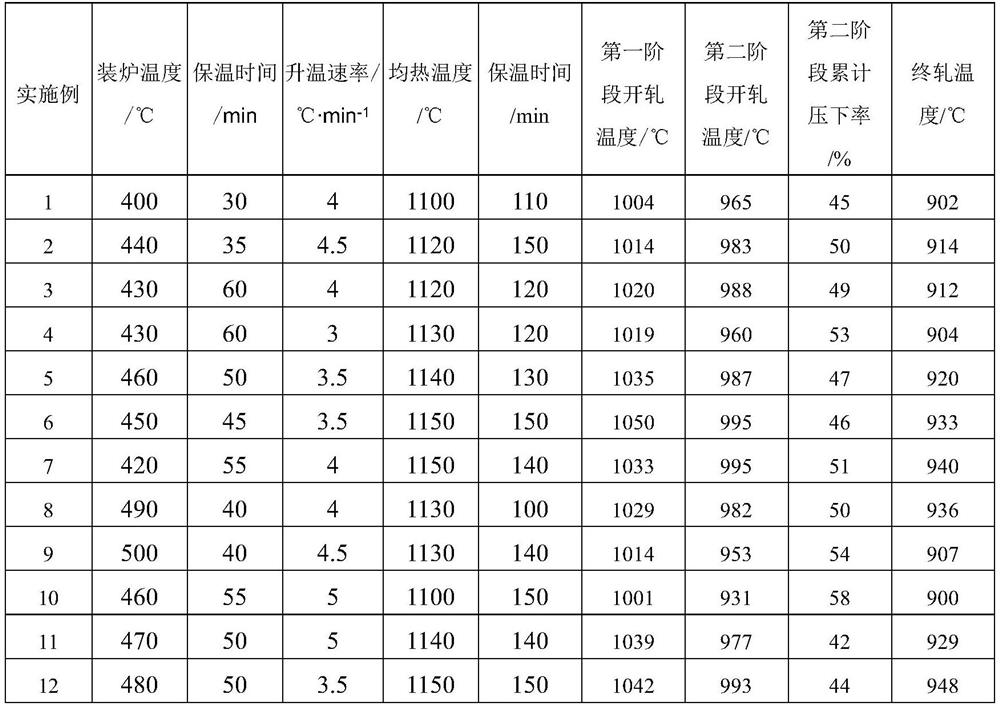

Hot galvanizing steel plate with yield strength more than or equal to 550MPa, and manufacturing method thereof

ActiveCN102796949AHigh yield strengthHigh strengthHot-dipping/immersion processesReduction rateSheet steel

The invention discloses a hot galvanizing steel plate with yield strength more than or equal to 550MPa, and a manufacturing method of the hot galvanizing steel plate; the hot galvanizing steel plate with the yield strength more than or equal to 550MPa comprises the following components by mass percent: 0.05-0.12% of C, less than or equal to 0.08% of Si, 0.3-0.9% of Mn, 0.020-0.060% of Als, less than or equal to 0.03% of P, less than or equal to 0.03% of S and the balance of Fe and unavoidable impurities; the manufacturing method of the hot galvanizing steel plate with the yield strength more than or equal to 550MPa comprises the steps of cast steel plate (CSP) continuous casting and rolling, steel plate pickling cold rolling and steel plate continuous zinc coating; according to the invention, the chemical components of the hot galvanizing steel plate are designed in an optimal way, alloying elements with high price are not added into the hot galvanizing steel plate, the strength of products can be improved by structure strengthening and solution strengthening of C and Mn, and the production cost is greatly reduced; the grain size is reduced, and the product strength is improved by reducing the CSP rolling temperature; the product strength is improved by controlling the acid rolling reduction rate; and the yield strength of the products can be guaranteed by controlling the galvanized annealing temperature and speed as well as the hydrogen content.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Cold-rolled steel strip for double-layer welded tube

ActiveCN102925794ALower yield strengthReduce hardnessTemperature control deviceControllabilityContinuous rolling

The invention relates to a cold-rolled steel strip, and especially relates to a cold-rolled steel strip for a double-layer welded tube and its manufacturing method to mainly solve technical problems comprising bad product yield and bad performance uniformity because of cover annealing generally adopted in the manufacturing of the double-layer welded tube. The chemical components of the cold-rolled steel strip for the double-layer welded tube comprise 0.015-0.054wt% of C, 0.034wt% or less of Si, 0.15-0.25wt% of Mn, 0.020wt% or less of P, 0.020wt% or less of S, 0.015-0.050wt% of Alt, and the balance Fe and inevitable impurity elements. In the invention, low carbon and low silicon are adopted, aluminum deoxidization is adopted as a crystal grain refinement element, and impurity form control, hot continuous rolling control cooling, continuous annealing temperature control and continuous flattening technologies are utilized to produce, so it is helpful for the guarantee of the yield strength, the percentage elongation after fracture and the hardness of the steel in prescribed requirement ranges. The cold-rolled steel strip makes the tube manufactured through using it have the advantages of good full-length performance uniformity, good roll bend formability, good tube barrel lap rebound controllability, good weldability, and good tube bending performance, and can guarantee the yield in the complete tube manufacturing flow.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

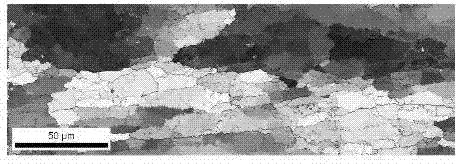

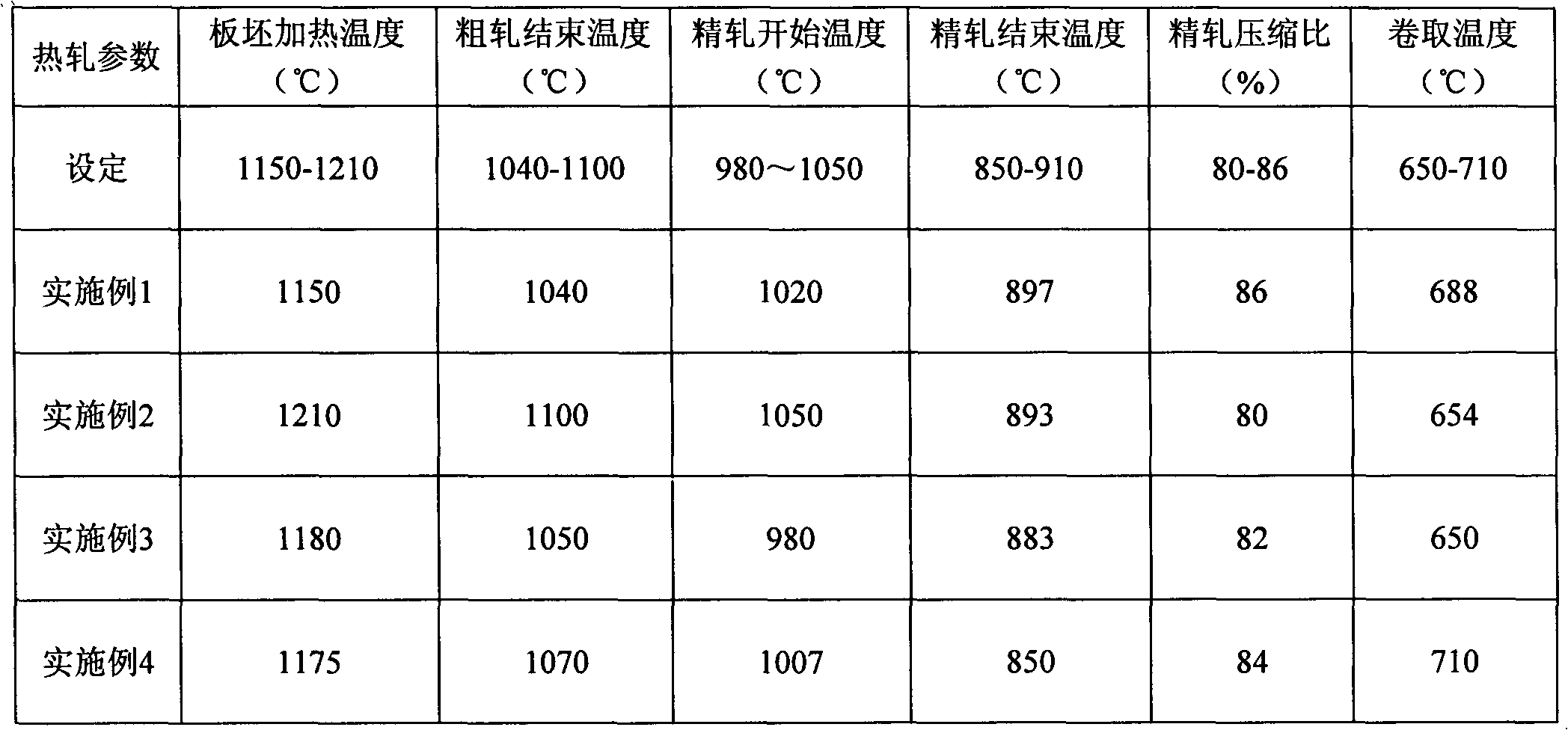

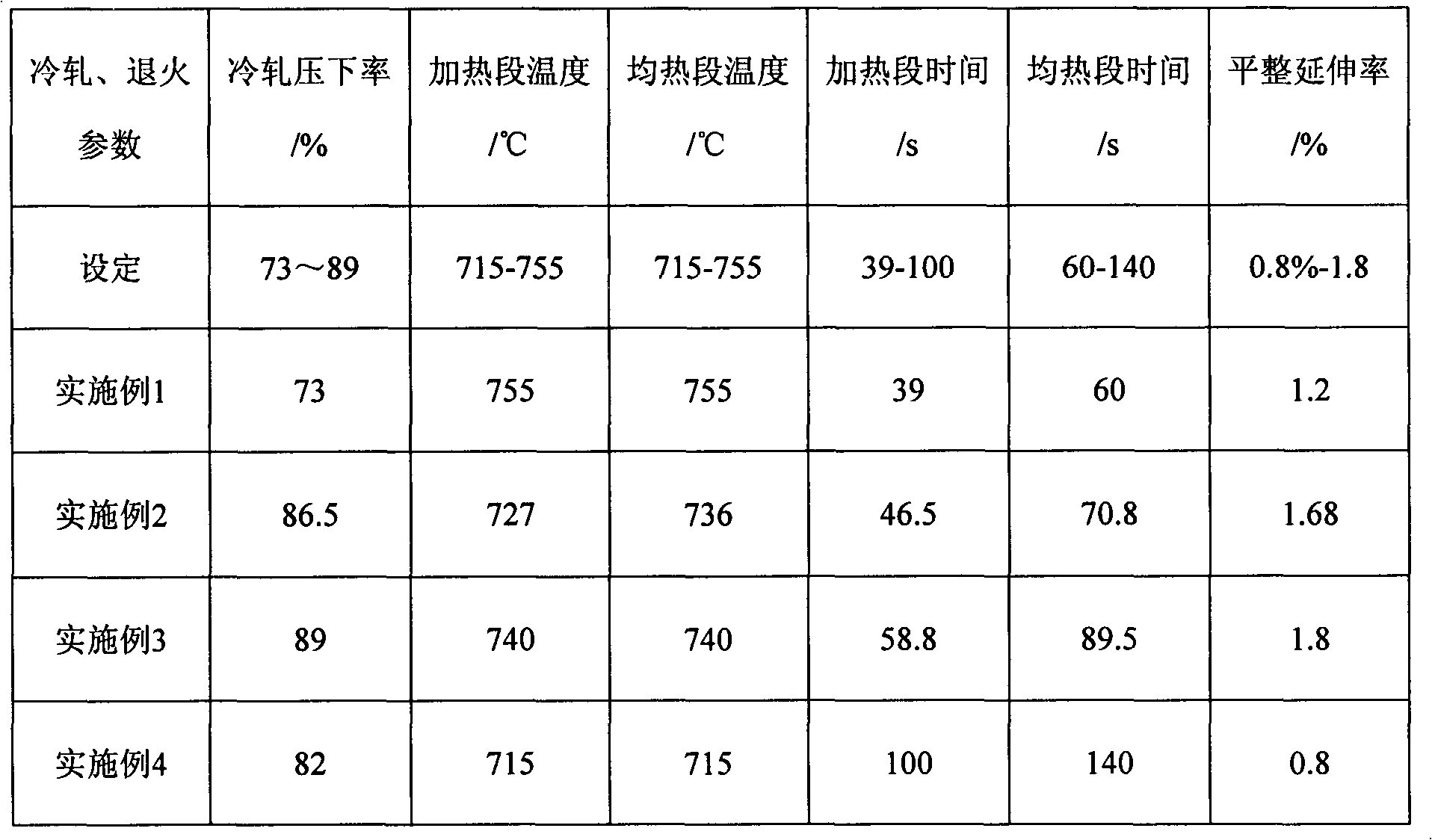

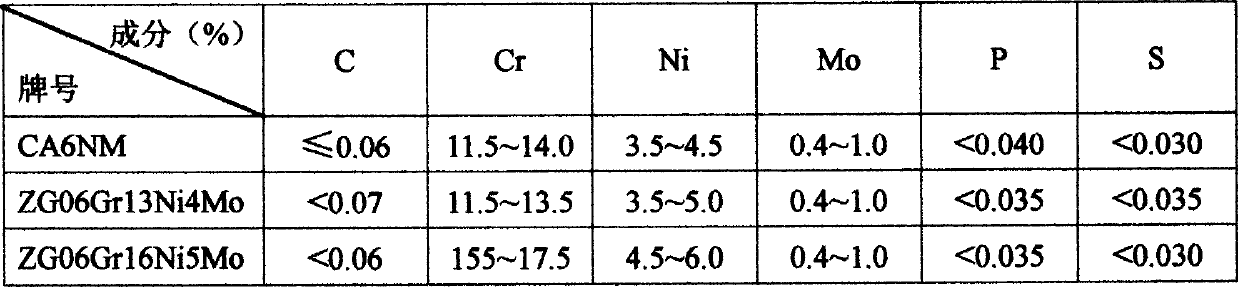

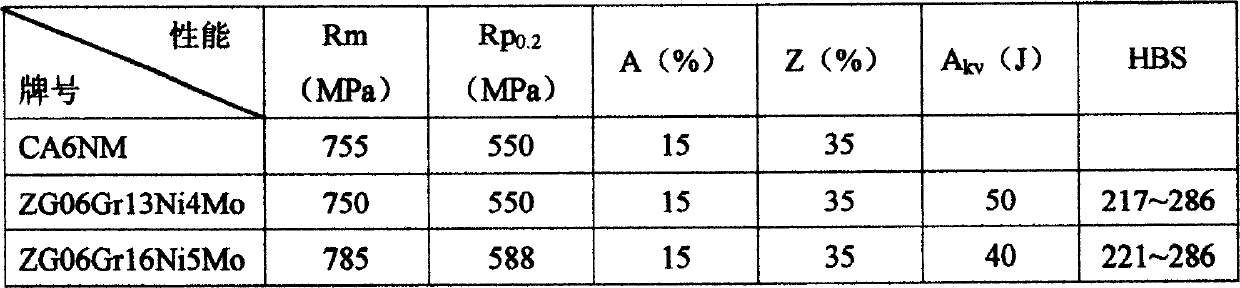

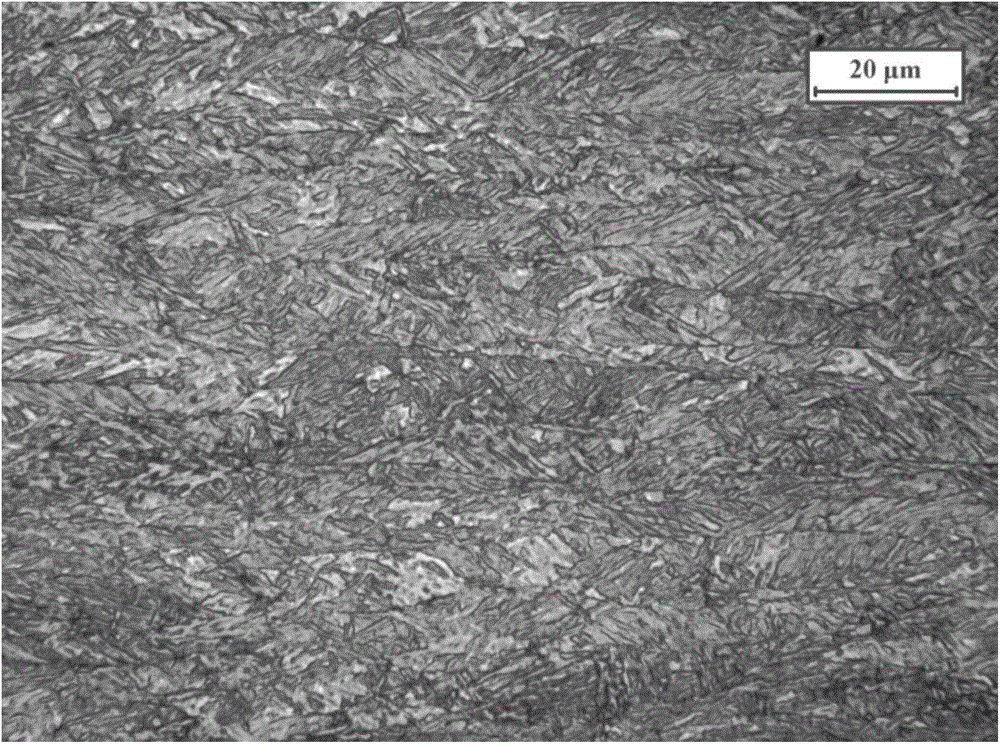

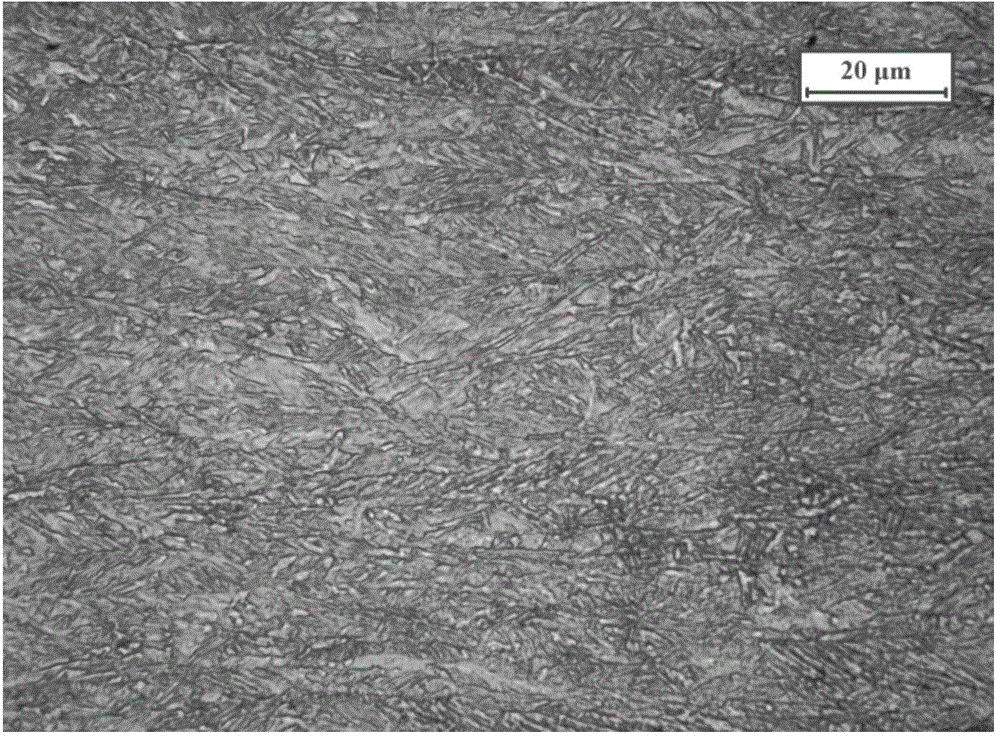

High-yield-ratio, high-strong toughness cast martensite stainless steel and production method thereof

The invention is martensitic stain less steel with high yield ratio and high ductility, the character is that it contains: C is not more than 0.06%, Cr 11-16.5%, Ni 3.50-6.0%, Mn is not more than 2%, Mo 0.5-2%, Si is less than 1%, the residue are Fe and a little impurity. The impurity includes Al, [O], [N], [H], S, P, the content of then are Al <0.15%, [O]<0.01%, [N]<0.03%, [H] is not more than 0.0005%, S is not more than 0.020%, P is not more than 0.025%. The invention can enhances the synthesis performance index (high density, high rigidity, high ductility and yield ratio, excellent welding processing property, and fatigue preventing property under water) greatly, it can ensure that the stress of large wheel is smaller than 1 / 3 of material yield ratio, the stress of large welding wheel is smaller than 1 / 2 of material yield density. It maintains the higher etching preventing property and sand grinding resisting property.

Owner:SHENYANG RES INST OF FOUNDRY

High strength steel with yield strength to be 900-1000MPa grade and production method of high strength steel

The invention discloses a high strength steel with yield strength to be 900-1000MPa grade and a production method of the high strength steel. The high strength steel is prepared from the following components in percentage by weight: 0.07-0.15 percent of C, 0.10-0.30 percent of Si, 0.80-1.60 percent of Mn, 0.20-0.70 percent of Cr, 0.10-0.45 percent of Mo, 0.10-0.50 percent of Ni, 0.010-0.030 percent of Nb, 0.010-0.030 percent of Ti, 0.010-0.050 percent of V, 0.0005-0.0030 percent of B, 0.02-0.06 percent of Al, 0.001-0.004 percent of Ca, 0.002-0.005 percent of N, P no larger than 0.020 percent, S no larger than 0.010 percent, O no larger than 0.008 percent and the balance of Fe and inevitable impurities, wherein Ceq accounts for 0.42-0.52 percent and is equal to C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15; Mo+0.8Ni+0.4Cr+6V is no less than 0.8 percent and no larger than 1.3 percent; Ti / N is no less than 3.7 and no larger than 7.0, and Ca / S is no less than 1.0 and no larger than 3.0. According to the production method disclosed by the invention, processes of online quenching and tempering are adopted, so that the yield strength of the produced steel plate is 900-1080MPa, the tensile strength is 950-1200MPa, the elongation is larger than 10 percent, and the impact energy at the temperature of 40 DEG C below zero is larger than 27J.

Owner:BAOSHAN IRON & STEEL CO LTD

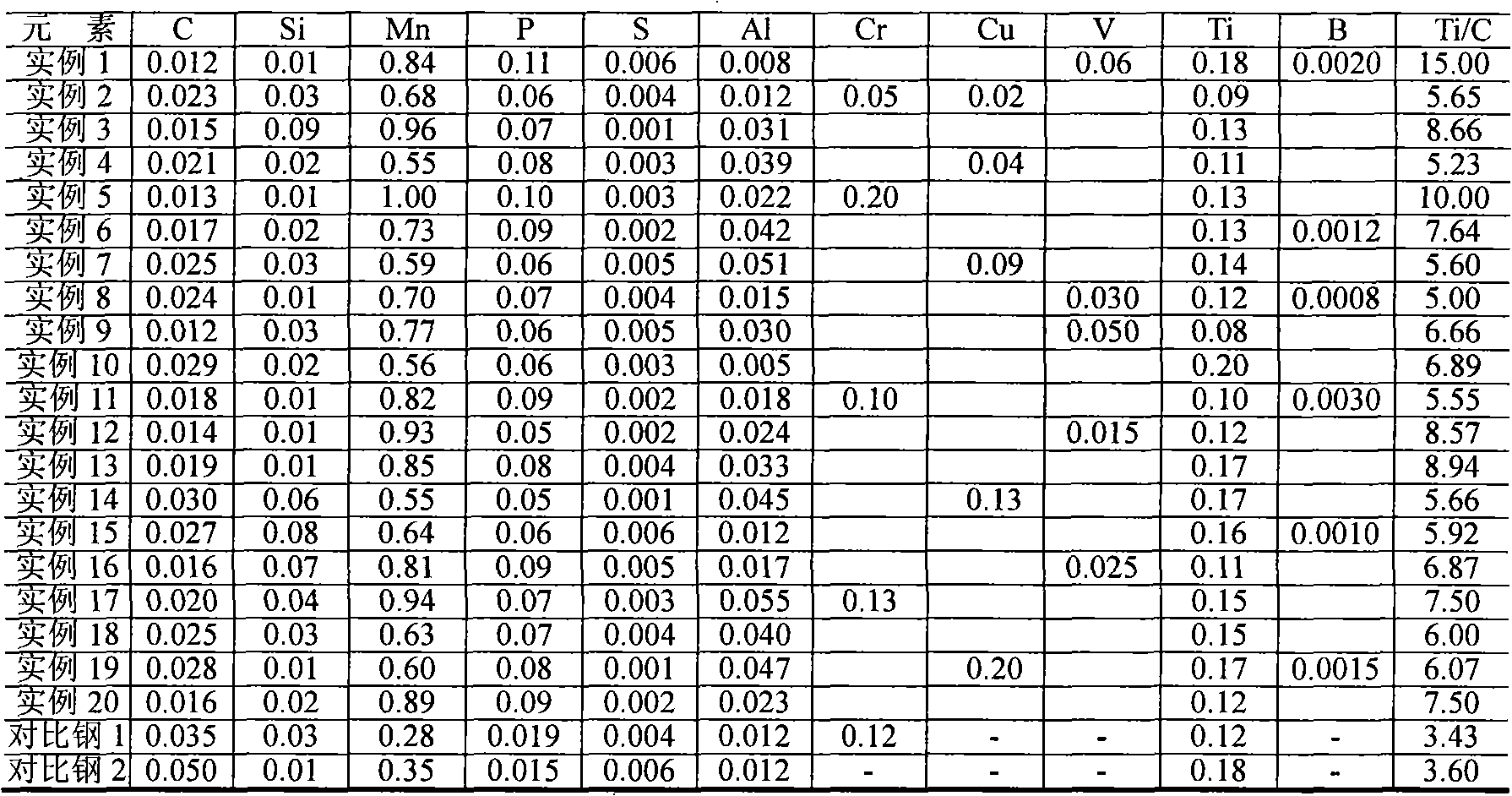

High-strength hot rolled steel plate for counter enameling and manufacturing method thereof

The invention relates to a high-strength hot rolled steel plate for counter enameling and a manufacturing method thereof. The high-strength hot rolled steel plate for counter enameling comprises the following smelting components in weight percent: 0.012-0.03 percent of carbon (C), not greater than 0.10 percent of silicon (Si), 0.55-1.0 percent of manganese (Mn), 0.05-0.11 percent of phosphorus (P), not greater than 0.006 percent of sulfur (S), not greater than 0.005 percent of nitrogen (N), 0.08-0.20 percent of titanium (Ti), 0.005-0.055 percent of aluminum sulfide (Als), 5-15 percent of Ti / C and the balance of ferrum and inevitable impurities, wherein more than one or two of vanadium, boron (B), copper (Cu) and chromium (Cr) is selectively added. The manufacturing method comprises the following steps: producing a plate blank through continuous casting; evenly heating the plate blank to 1180-1260 DEG C; then, removing phosphorous with high-pressure water and carrying out rough rolling to prepare an intermediate blank; carrying out 5-7-pass finish rolling to target thickness; carrying out laminar flow cooling to 570-680 DEG C and coiling. The high-strength hot rolled steel plate for the counter enameling has no phosphorus explosion; the yield strength is higher than 280MPa after the high-strength hot rolled steel plate for the counter enameling is enameled under the conditions that the temperature is 800-920 DEG C and the thickness is greater than 8mm. The high-strength hot rolled steel plate for the counter enameling is suitable for roll forming, bend forming and simple punch forming and is a reliable special steel plate material for a counter enameling assembly structure.

Owner:ANGANG STEEL CO LTD

Super-hard austenitic stainless steel and preparation method thereof

The invention discloses a super-hard austenitic stainless steel and a preparation method thereof. The super-hard austenitic stainless steel comprises the following chemical components by weight percent: 0.08-0.13% of C, 0.3-1.0% of Si, less than 2.0% and greater than or equal to 0.5% of Mn, 16.5-17.5% of Cr, 6.5-7.5% of Ni, 0.03-0.08% of N, 0.5-0.8% of Mo, greater than or equal to 0.040% of P, greater than or equal to 0.01% of S, Fe and unavoidable impurities; the temperature of Md30 is 30-60 DEG C. By controlling the tempering and cold rolling reduction rate to 35-45%, controlling the rolling speed to less than or equal to 5m / s and the rolling temperature to less than or equal to 30 DEG C, the transformation from the austenite to the deformation martensite is created and the hardness of the material is greatly increased under the same deformation; when the tempering and cold-rolling reduction rate is 35%, the hardness HV is greater than 550 and the anisotropy of the super-hard state steel is reduced.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

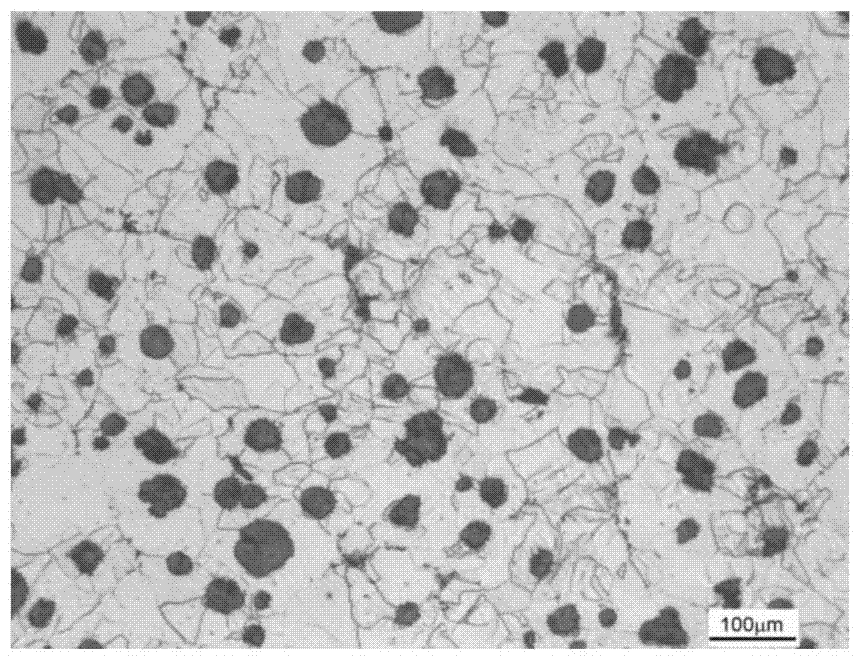

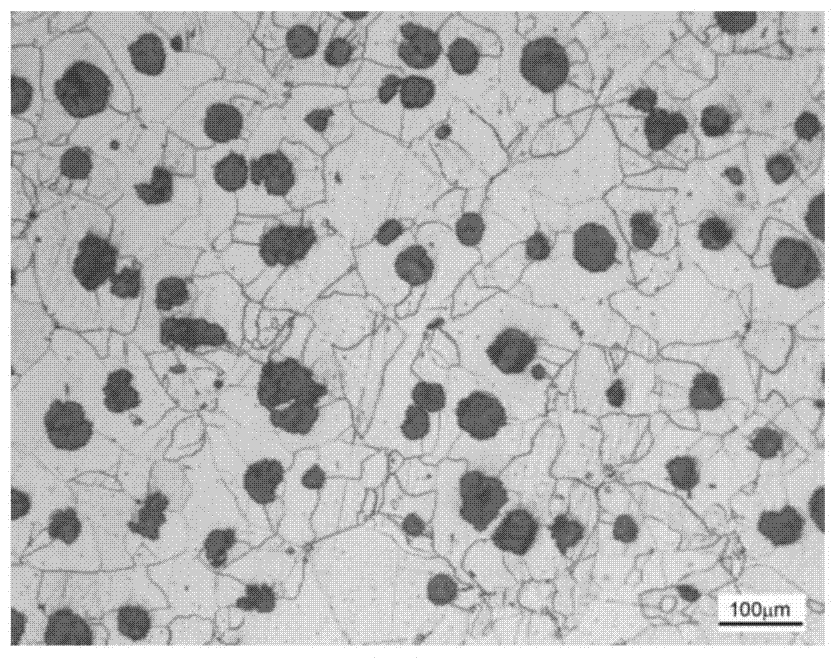

High-strength high-toughness low-temperature-resistant ferritic nodular cast iron

InactiveCN102703802AIncreased toughness-brittle transition temperatureReduce shockImpact toughnessDuctile iron

The invention discloses high-strength high-toughness low-temperature-resistant ferritic nodular cast iron. The high-strength high-toughness low-temperature-resistant ferritic nodular cast iron comprises the following components in percentage by weight: 3.62 to 3.80 percent of C, 1.90 to 2.35 percent of Si, less than 0.20 percent of Mn, 0.007 to 0.018 percent of RE, 0.043 to 0.060 percent of Mg, less than 0.035 percent of P, less than or equal to 0.020 percent of S, and the balance of iron and other impurity elements, wherein in the impurity elements, Mo is controlled to be less than 0.010 percent, and Ti is controlled to be less than 0.025 percent; and the ratio of the Si to the C is 0.50-0.63. Through a lot of test and research, the Si-C ratio is reasonably controlled, low-temperature nodular cast iron can obtain relatively high tensile strength and yield strength, and the low-temperature impact toughness of -40 DEG C can also be ensured; and the ideal low-temperature impact toughness is obtained while the function of a silicon reinforced metallic matrix is exerted, so that the performance requirements are met, and the cost is also greatly reduced.

Owner:上海宏钢电站设备铸锻有限公司

Non-tombarthite ferrite ball iron and preparing method thereof

The invention relates to a ferrite ball iron, and the invention also discloses a technic by adopting a cutting-in method to prepare the ferrite ball iron. According to the technical scheme, the ferrite ball iron comprises the following compositions by mass percent: 3.6 percent-3.9 percent of C, 1.7 percent-3.0 percent of Si, 0.1 percent-0.4 percent of Mn, 0.035 percent-0.045 percent of Mg, tombarthite< 0.001 percent, and the impurity elements are P and S, wherein the P is controlled to be less than or equal to 0.040 percent, and the S is controlled to be less than or equal to 0.012 percent, and the rest is iron. The elongation and low-temperature impact-resistance value of the ferrite ball iron reach or are over the standard required value, and the extension strength and yield strength also reach the requirement, and the preparing method is simple and easy.

Owner:JIANGSU FAW FOUNDRY

Tensile strength 700 MPa-grade high broaching hot-rolled steel plate and manufacturing method thereof

The invention relates to a tensile strength 700 MPa-grade high broaching hot-rolled steel plate and a manufacturing method thereof, and solves the technical problems of weak broaching and flanging performance of a traditional tensile strength 700 MPa-grade high broaching hot-rolled steel plate. The tensile strength 700 MPa-grade high broaching hot-rolled steel plate comprises the following chemical components in percentage by weight: 0.05-0.09% of C, 0.15-0.35% of Si, 1.20-1.80% of Mn, P not more than 0.015%, S not more than 0.008%, 0.015-0.050% of Al, 0.08-0.13% of Ti, 0.035-0.065% of V, and the balance of iron and inevitable impurities. The hot-rolled steel plate can be used for manufacturing vehicle structural parts.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

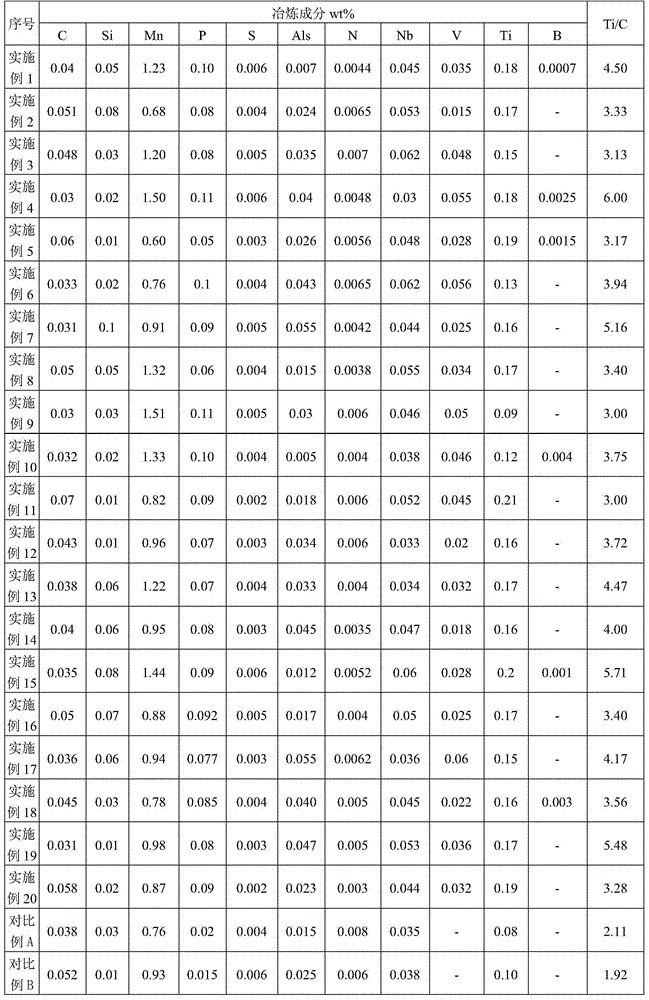

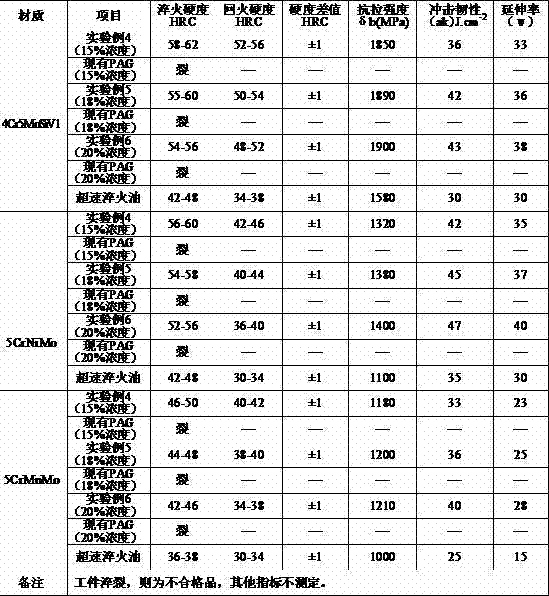

Hot-rolled steel plate for enameled high-strength double-face enamel and manufacturing method of steel plate

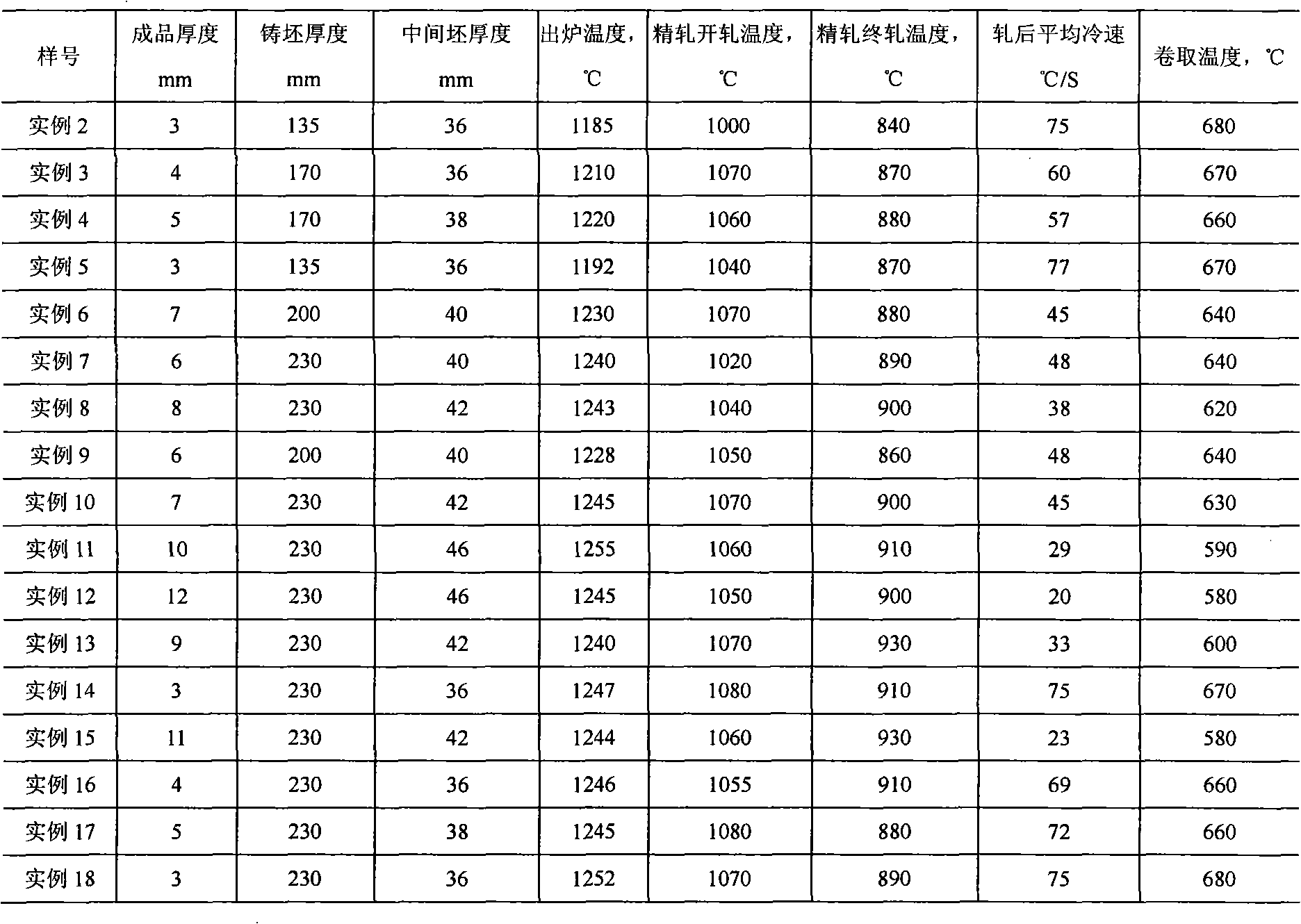

InactiveCN106480368AExcellent anti-scale explosion performanceGuaranteed Yield StrengthHigh pressure waterHigh pressure

The invention discloses a hot-rolled steel plate for enameled high-strength double-face enamel and a manufacturing method of the steel plate. When the thickness of the steel plate is smaller than or equal to 8 mm, the chemical components in the steel comprise, by weight percent, 0.030% to 0.070% of C, not larger than 0.10% of Si, 0.60% to 1.5% of Mn, 0.05% to 0.11% of P, not larger than 0.006% of S, not larger than 0.008% of N, 0.09% to 0.21% of Ti, 0.03% to 0.07% of Nb, 0.015% to 0.060% of V, 0.005% to 0.055% of Als, 3.0% to 6.0% of Ti / C and the balance is Fe and inevitable impurities, when the thickness of the steel plate is larger than 8 mm, B is added, the content of the B ranges from 0.0005% to 0.005%,. The casting blank with the above component is heated to 1180 DEG C to 1250 DEG C, after soaking, high-pressure water descaling and rough rolling cogging are carried out, the finish rolling cogging temperature ranges from 880 DEG C to 1100 DEG C, the finish rolling temperature ranges from 880 DEG C to 930 DEG C, rapid cooling to the reeling temperature is achieved with the cooling speed larger than or equal to 30 DEG C / S after rolling, and the reeling temperature ranges from 630 DEG C to 700 DEG C.

Owner:ANGANG STEEL CO LTD

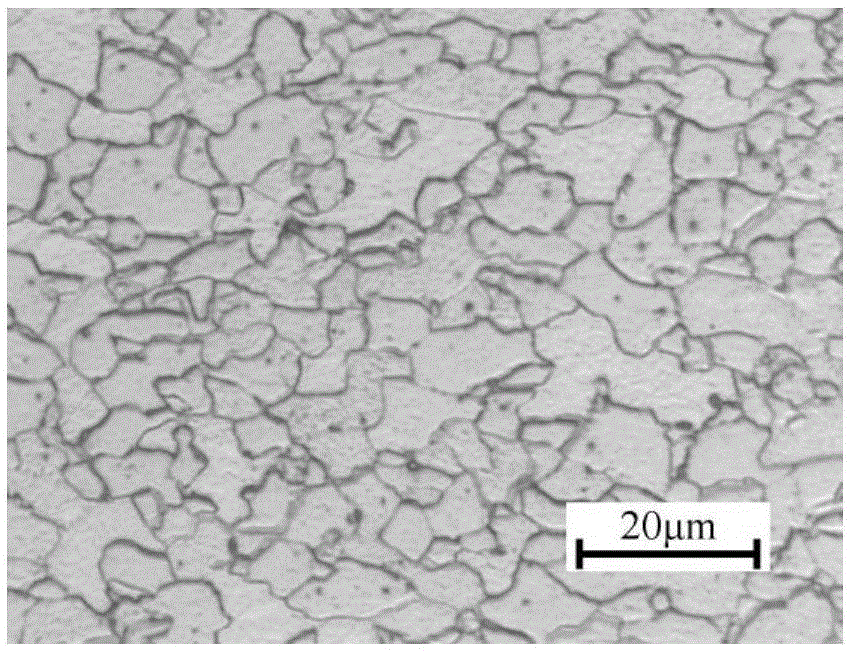

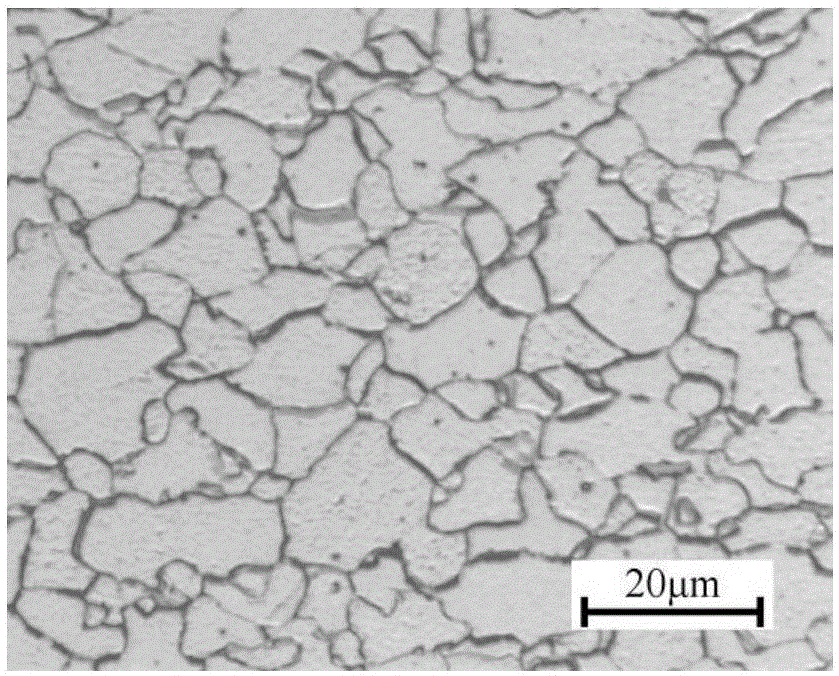

Water-soluble quenching medium for hot die steel

The invention discloses a water-soluble quenching medium for hot die steel. The water-soluble quenching medium is prepared by mixing polyalkylene glycol, polyvinyl pyrrolidone, rust inhibitor, bactericide, pH regulator, settling agent, defoaming agent and water uniformly in a ratio. The water-soluble quenching medium is low in production cost, non-flammable and environment-friendly. The water-soluble quenching medium replaces oil quenching media, and fully meets the quenching requirements of the hot die steel such as 4Cr5MoSiV1, 5CrMnMo and 5CrNiMo.

Owner:LIAONING HAIMING CHEM PROD

Method of improving toughness of novel martensite heat-resistant steel A355P91 welding seam

ActiveCN103643025AGuaranteed tensile strengthGuaranteed Yield StrengthFurnace typesHeat treatment furnacesTemperature controlTempering

The invention discloses a method of improving toughness of a novel martensite heat-resistant steel A355P91 welding seam, belonging to the technical field of welding and thermal treatment. The method comprises the following steps: pre-heating a welding piece of the novel martensite heat-resistant steel A355P91 within a pre-heating temperature interval of 200 DEG C-250 DEG C, and keeping the temperature constant for two hours; controlling an interlayer temperature at 200 DEG C-250 DEG C; cooling in air to 100 DEG C-120 DEG C after welding, and keeping the temperature constant for 2 hours within the temperature of 100 DEG C-120 DEG C; carrying out post-heat treatment, heating the welding piece of the novel martensite heat-resistant steel A355P91 to 300 DEG C-350 DEG C and keeping the temperature constant for 2 hours, then naturally cooling; and carrying out thermal treatment after the post-heat treatment, wherein a high-temperature tempering temperature interval is 770 DEG C-780 DEG C. The method disclosed by the invention not only ensures tensile strength and yield strength of the welding seam, but also lowers surface hardness by strictly controlling a temperature curve in the process of welding, post-heat treatment and thermal treatment; and moreover, impact toughness of the welding seam is increased.

Owner:ANHUI SANXING TESTING +1

Q500qE bridge steel plate and production method thereof

ActiveCN108624744APrecise control of water temperaturePrecisely control the red temperatureSheet steelYield ratio

The invention relates to the technical field of bridge steel plate smelting, in particular to a Q500qE bridge steel plate and a production method thereof. After rolling control is finished, the steelplate is relaxed for 10-160 seconds after rolling is finished, and then enters a laminar flow cooling area to be cooled to 300-650 DEG C with the cooling rate of 20 DEG C / s; and the relaxation time and the finished cooling temperature of steel plates of different thicknesses are different. After the steel plate is subjected to controlled cooling, the steel plate is straightened for more than two passes through a heat straightening machine, the poor external plate shape caused by online quenching is eliminated, then the steel plate is cooled to below 400 DEG C on a cooling bed and then is straightened by a cold straightening machine, the finished straightening temperature is controlled to be 200-400 DEG C, and the poor plate shape caused by transformation stress is eliminated. The Q500qE bridge steel plate and the production method thereof have the advantages that the yield ratio is low, the welding performance is good, the plate shape is good, the production process is simple in procedure, the production period is short, and the production cost is low.

Owner:ANGANG STEEL CO LTD

High-strength Al-Mg-Si-Cu alloy for hot working and preparation method thereof

The invention relates to a high-strength Al-Mg-Si-Cu alloy for hot working and a preparation method thereof. The alloy comprises 0.8-1.4wt% of Mg, 0.8-1.6wt% of Si, 0.2-0.8wt% of Cu, 0.2-1.0wt% of Mn, 0.1-0.4wt% of Cr, 0.01-0.1wt% of Ti, no larger than 0.25wt% of Fe, no larger than 0.15wt% of inevitable impurities, and the balance of Al. The preparation method comprising the following steps: heating an alloy ingot to 520-570 DEG C in a cycle wind furnace with the heating rate of 0.1-10 DEG C / min, preserving the heat for 4-10 h, and conducting air cooling; heating up the uniformized ingot to 450-500 DEG C, then conducting hot working to deform, wherein the ending temperature is no less than 350 DEG C; conducting T6 heat treatment, conducting solution treatment at 530-570 DEG C for 1-2h, quenching, and then conducting aging treatment at 170-200 DEG C for 4-9h.

Owner:苏州有色金属研究院有限公司

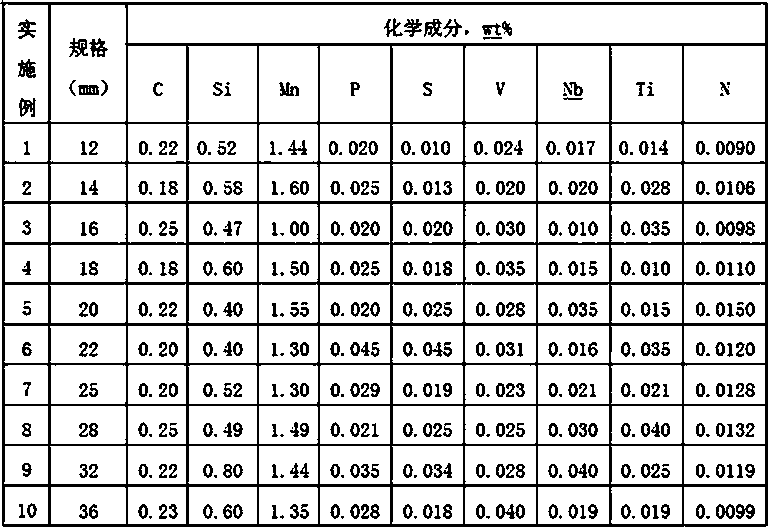

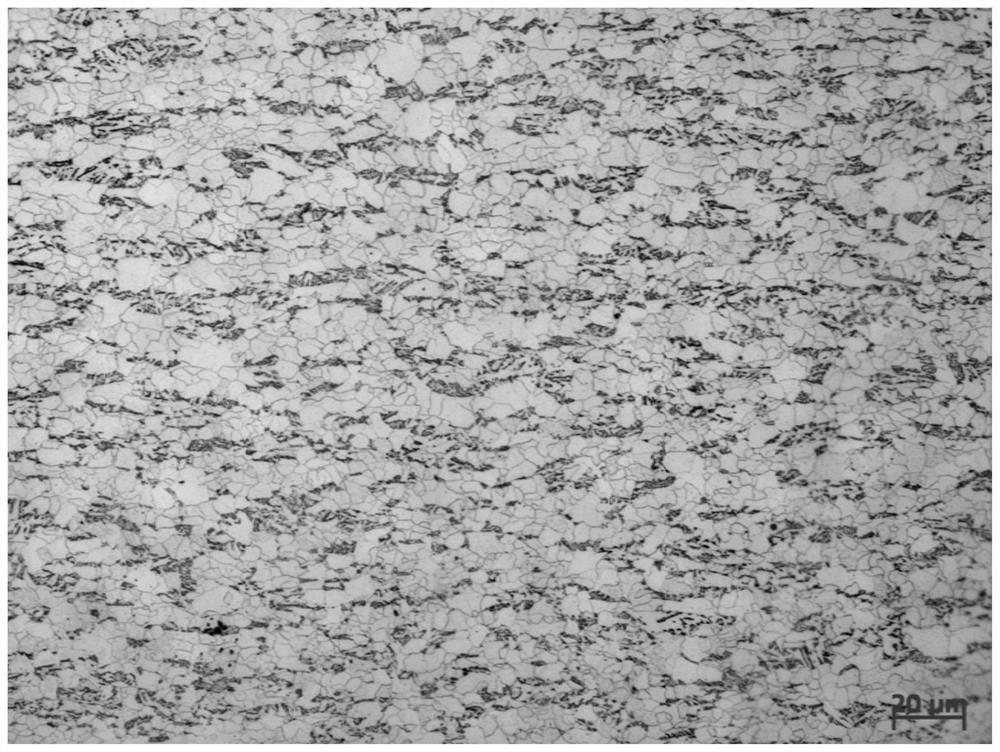

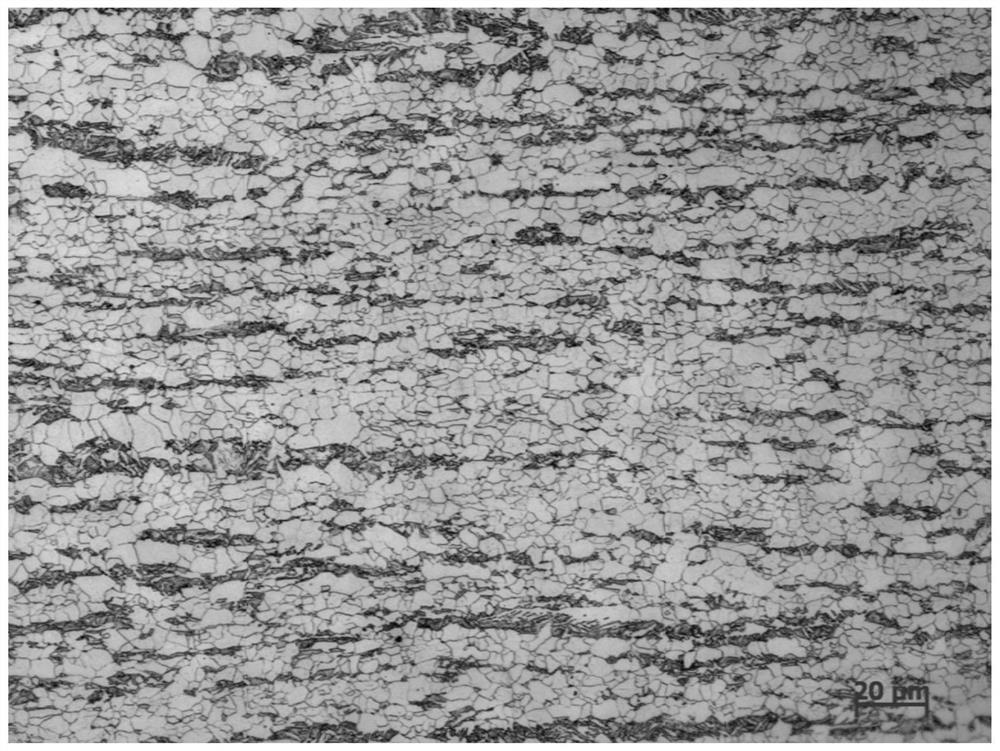

500 MPa level high-nitrogen composite microalloyed steel bar and production method thereof

InactiveCN109576583AImprove pourabilityGuaranteed Yield StrengthChemical compositionNational standard

The invention relates to a 500 MPa level high-nitrogen composite microalloyed steel bar and a production method thereof. The 500 MPa level high-nitrogen composite microalloyed steel bar comprises thefollowing chemical components of, by mass, 0.18-0.25 parts of C, 0.40-0.80 parts of Si, 1.30-1.60 parts of Mn, less than or equal to 0.045 parts of P, less than or equal to 0.045 parts of S, 0.020-0.040 parts of V, 0.010-0.040 parts of Nb, 0.010-0.040 parts of Ti, 0.0090-0.0150 parts of N, and the balance iron and unavoidable impurity elements. In the production method, after the continuous casting process is completed, a continuous casting billet is heated to 1130-1250 DEG C and subjected to heat preservation for 90-150 minutes, and then cooled to 1020-1120 DEG C for rolling; after the rolling, water cooling is carried out with the water pressure being 0.1-0.5 MPa and the temperature of an upper cooling bed being controlled at 920-1010 DEG C; and the steel bar is naturally cooled after entering the cooling bed, so that the high-nitrogen composite microalloyed steel bar is obtained. The mechanical properties of the steel bar meet the requirements of the national standard, the production cost is low and a production process is simple and easy to implement.

Owner:HANDAN IRON & STEEL GROUP +1

Low-yield-ratio high-toughness TMCP type bridge steel plate and production method thereof

ActiveCN112322995AImprove performanceLow yield ratioTemperature control deviceToughnessMaterials science

The invention discloses a low-yield-ratio high-toughness TMCP type bridge steel plate and a production method thereof. The steel comprises the following chemical components in percentage by weight of0.07 to 0.12% of C, 0.11 to 0.18% of Si, 1.42 to 1.52% of Mn, 0.008 to 0.015% of P, 0.002 to 0.010% of S, 0.08 to 0.16% of Cr, 0.012 to 0.018% of Nb, 0.008 to 0.016% of Ti, 0.020 to 0.050% of Alt, 0.002 to 0.005% of N, the balance iron and impurities and 0.350 to 0.369% of carbon equivalent. According to the production method, a continuous casting billet is subjected to heating, controlled rollingincluding recrystallization zone rolling, temperature waiting and non-recrystallization zone rolling and controlled cooling including ferrite zone cooling, temperature waiting and bainite zone cooling, and the bridge steel plate is manufactured. The obtained bridge steel plate is low in yield ratio, high in toughness and excellent in welding performance.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

Corrosion-resistant and biological-adhesion-resistant EH690 steel plate and manufacturing method thereof

The invention discloses a corrosion-resistant and biological-adhesion-resistant EH690 steel plate and a manufacturing method thereof. The steel comprises 0.09%-0.12% of C, 0.15%-0.35% of Si, 1.0%-1.5%of Mn, 0.02%-0.03% of P, less than or equal to 0.01% of S, 0.01%-0.03% of Als, 1.5%-3.0% of Ni, 0.3%-0.6% of Cr, 0.3%-0.5% of Mo, 0.5%-1.5% of Cu, 0.03%-0.06% of V, 0.005%-0.02% of Ti, 0.0005%-0.001%of B, 0.005%-0.3% of Sb, 0.005%-0.3% of Sn and the balance iron and inevitable impurities. The initial rolling temperature of the first stage is 1000-1050 DEG C, the initial rolling temperature of the second stage is 900-1000 DEG C, the cumulative reduction rate of the second stage rolling is 40%-60%, and the final rolling temperature is 900-950 DEG C; and the quenching temperature is 830-870 DEGC, the heat preservation time is 1.0-2.0 min / mm, the tempering temperature is 600-630 DEG C, the heat preservation time is 2-3 min / mm, and the cooling rate after tempering is 5-15 DEG C / s. The steelplate has excellent marine environment corrosion resistance.

Owner:ANGANG STEEL CO LTD

Processing technique of 6008 aluminum alloy crash box

The invention relates to the field of alloys and particularly relates to a processing technique of a 6008 aluminum alloy crash box, comprising the steps of A, during smelting of 6008 aluminum rods, using 99.9% magnesium ingots to add magnesium and 21% aluminum-silicon alloy to add silicon, wherein molten aluminum is at 752 DEG C during adding; B, subjecting the molten aluminum to double-level filtering, wherein filter plates are 40 and 50 in mesh respectively; C, using a hydraulic casting machine and a casting tray as well as a water-curtain cooling system including crystallizer and cooled byfed water to perform continuous casting so as to obtain aluminum rods; D, subjecting the aluminum rods to homogenous annealing at 560 DEG C for 7 H; E, extruding the aluminum rods to obtain a finishedcrack box; f, aging at 215 DEG C for 5 H. The magnesium and silicon alloy content in the 6008 aluminum alloy is adjusted, and the aging process is modified; after modification, the finished crash meets the requirements for both crushing and sectional bearing capacity and yielding strength.

Owner:SHANGHAI UNISON ALUMINUM PRODS

Normalization heat treatment method of heavy-gauge low-alloy steel plates

InactiveCN102732696ALow costGuaranteed Yield StrengthFurnace typesHeat treatment furnacesNucleationUltimate tensile strength

The invention provides a normalization heat treatment method of heavy-gauge low-alloy steel plates. The method concretely comprises the steps of heating, heat insulating and cooling. The steel plates prepared through the method of the invention comprise the following components: 0.18% or less of C, 0.50% or less of Si, 1.60% or less of Mn, 0.020% or less of P, 0.010% or less of S, 0.06% or less of Nb, 0.02-0.06% of Al, 0.03% or less of Ti, 0.08% or less of V, and the balance Fe and inevitable impurities. Different heat insulation time and cooling technologies are adopted according to different thicknesses of the steel plates, the heat insulation period is 1.8min / mm and a rolling transmission and collector spray water laminar flow mode is adopted to cool when the thicknesses of the steel plates are equal to or less than 100mm, and the heat insulation period is 2.0-2.2min / mm and a water tank cooling mode is adopted to cool when the thicknesses of the steel plates are greater than 100mm. The normalizing heat treatment technology of the invention allows the cooling intensity and the cooling speed of cores of the steel plates to be improved, the nucleation rate of the steel plates to be improved, tissues in the centers of the steel plates to be refined, the quality of the steel plates to be guaranteed and bad tissues and performances caused by uneven heavy-gauge steel plate cooling to be effectively solved, and is especially suitable for heat treatment technologies of thick steel plates.

Owner:WUYANG IRON & STEEL +1

Sandblasting-free, directly-coated and weathering-resistant steel and production method thereof

The invention discloses a sandblasting-free, directly-coated and weathering-resistant steel and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.04-0.12 percent of C, 0.20-0.50 percent of Si, 0.25-0.5 percent of Mn, less than or equal to 0.008 percent of S, less than or equal to 0.03 percent of P, 0.25-0.45 percent of Cu, 0.30-0.60 percent of Cu, 0.20-0.50 percent of Ni, 0.015-0.025 percent of TI, less than or equal to 0.03 percent of Als and the balance of iron and inevitable impurities. The protection method comprises the following steps: converter smelting, refining, continuous casting, heating, rolling, controlled cooling, reeling and finishing, wherein the controlled cooling is laminar flow cooling and adopts front section pulled cooling, and the concentration of Cl in laminar flow circulating cooling water is less than or equal to 100 mg / L; the reeling temperature is controlled to be 540-560 DEG C; a flatting roll is used for flatting, the surface textured roughness of the flatting roll Ra is 50-100 <mu>m, RPc is 45-70 pcs / cm, and the reduced quantity of the strip steel is 1-4 percent. The sandblasting-free, directly-coated and weathering-resistant steel has good weathering resistance, can be directly coated without a sand blasting pretreatment process, has a strong coating adhesion force and has low probability of falling off.

Owner:武汉钢铁有限公司

Submerged arc welding wire used for pipeline steel of carbon dioxide corrosion resistant 65 ksi strength grade

InactiveCN103121149AGuaranteed StrengthAvoid generatingWelding/cutting media/materialsSoldering mediaCarbon corrosionCarbon dioxide corrosion

The invention relates to a submerged arc welding wire used for pipeline steel of a carbon dioxide corrosion resistant 65 ksi strength grade. The technical scheme of the submerged arc welding wire used for the pipeline steel of the carbon dioxide corrosion resistant 65 ksi strength grade is that chemical constituents of the submerged arc welding wire is: carbon (C) is 0.001-0.05 wt%, manganese (Mn) is 0.40-0.80 wt%, silicon (Si) is 0.10-0.30 wt%, chromium (Cr) is 3.00-6.00 wt%, copper (Cu) is 0.20-0.40 wt%, (vanadium+ niobium+ titanium) is 0.04-0.10 wt%, sulphur (S) is less than or equal to -0.001 wt%, phosphorus (P) is less than or equal to 0.002 wt%, and the balance are ferrum (Fe) and inevitable impurities. Elements of an alloy are simple, the prepared submerged arc welding wire is matched with welding flux SJ 101, mechanical property and corrosion resistant property of formed welding metal are matched with the property of the pipeline steel of the carbon dioxide corrosion resistant 65 ksi strength grade, and the technical requirement of welding prepared oil and gas pipelines can be met, and the submerged arc welding wire used for the pipeline steel of the carbon dioxide corrosion resistant 65 ksi strength grade has good corrosion resistant property.

Owner:WUHAN UNIV OF SCI & TECH

J55-grade low-yield-ratio steel for electric resistance welding casing pipe and manufacturing method of J55-grade low-yield-ratio steel

The invention discloses J55-grade low-yield-ratio steel for an electric resistance welding casing pipe and a manufacturing method of the J55-grade low-yield-ratio steel. The J55-grade low-yield-ratio steel comprises chemical components including, by weight percent, 0.090%-0.128% of C, 0.10%-0.35% of Si, 1.02%-1.25% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S, 0.01%-0.03% of Nb, 0.010%-0.030% of Ti, 0.30%-0.40% of Cr, 0.02%-0.06% of Als, smaller than or equal to 0.008% of N and the balance Fe and inevitable elements. The method is characterized in that a continuous casting sheet billet is heated to 1160-1200 DEG C through a heating furnace, and the final rolling temperature in the first stage is larger than 980 DEG C; the rolling starting temperature in the second stage ranges from 980 DEG C to 1020 DEG C, and the final rolling temperature ranges from 810 DEG C to 865 DEG C; laminar flow intermittent cooling is adopted for a rolled steel strip, and the cooling speed ranges from 12 DEG C / s to 18 DEG C / s; and coiling is conducted at the temperature ranging from 590 DEG C to 680 DEG C. The J55-grade low-yield-ratio steel has the beneficial effects that the carbon content is relatively low, and weldability and the impact toughness are good; and a proper number of Cr alloy is added, the safety of a steel pipe is good, and it is ensured that the yield strength and the tensile strength meet the standard requirement.

Owner:ANGANG STEEL CO LTD

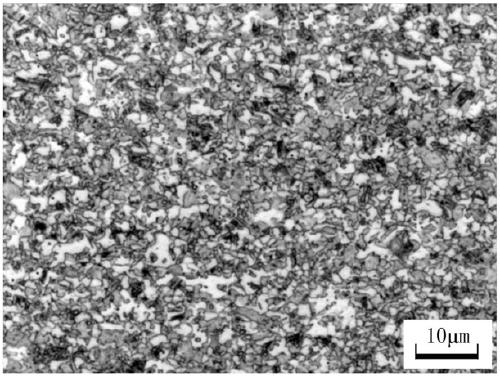

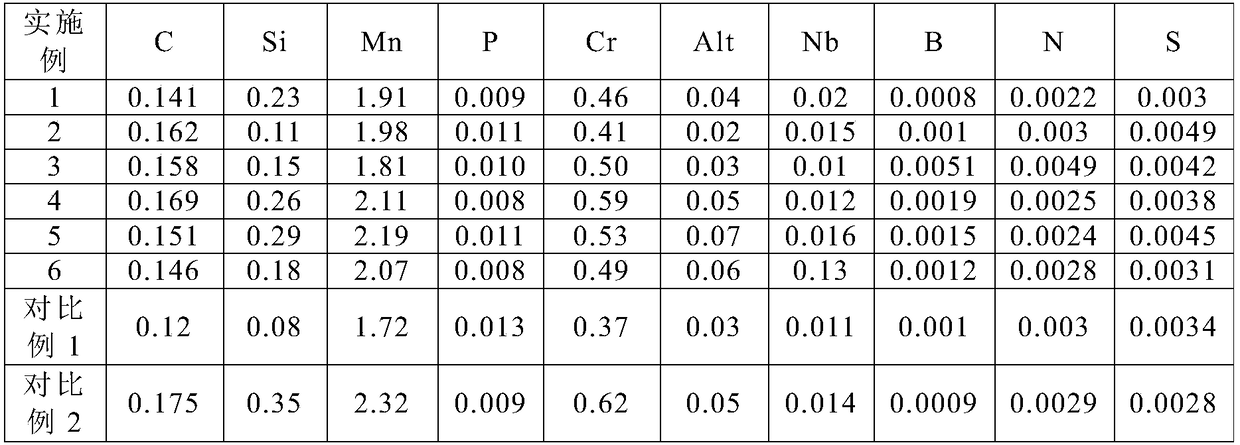

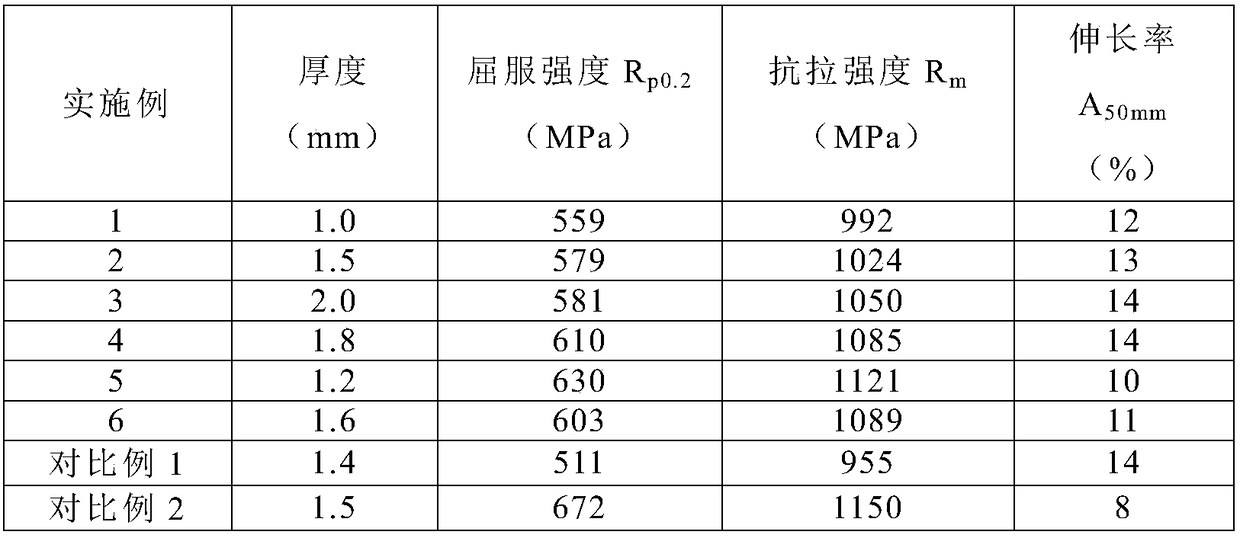

980MPa grade cold-rolled dual-phase steel with low requirements for cooling capacity of production line and manufacturing method thereof

ActiveCN109023149AFast cooling rate is not requiredGuaranteed Yield StrengthChemical compositionDual-phase steel

The invention discloses 980MPa grade cold-rolled dual-phase steel with low requirements for cooling capacity of a production line and a manufacturing method thereof, and belongs to the technical fieldof steelmaking. The 980MPa grade cold-rolled dual-phase steel consists of the following chemical composition of, by mass, 0.14-0.17% of C, 0.10-0.30% of Si, 1.8-2.2% of Mn, less than or equal to 0.012% of P, 0.4-0.6% of Cr, 0.02-0.07% of Alt, 0.01-0.02% of Nb, 0.0005-0.002% of B, less than or equal to 0.005% of S, less than or equal to 0.005% of N, and the balance Fe and unavoidable impurities. According to the chemical composition, the 980MPa grade cold-rolled dual-phase steel is manufactured through smelting and slab casting process, and slab heating, hot rolling, coiling, pickling, cold rolling and continuous annealing process. In the continuous annealing process, the annealing temperature is controlled to be 800-820 DEG C, the cooling rate of a slow cooling section is less than 8 DEGC / s, the finish temperature of the slow cooling section is 620-640 DEG C, the finish temperature of a rapid cooling section is 300-320 DEG C, the cooling rate of the rapid cooling section is less than30 DEG C / s, and the over aging temperature is 270-310 DEG C. The dual-phase steel is prepared according to the chemical composition and the process of the 980MPa grade cold-rolled dual-phase steel with the low requirements for the cooling capacity of the production line and the manufacturing method thereof, the requirements for the rapid cooling rate in the production line are low, and the 980MPagrade cold-rolled dual-phase steel with the low requirements for the cooling capacity of the production line and the manufacturing method thereof can be used in a conventional common production line.

Owner:武汉钢铁有限公司

Hot-dip galvanized low-alloy high-strength steel with yield strength of 700Mpa and preparation method thereof

ActiveCN114525452AGuaranteed Yield StrengthGuaranteed tensile strengthHot-dipping/immersion processesProcess efficiency improvementAlloyContinuous annealing

The invention discloses hot-dip galvanized low-alloy high-strength steel with yield strength of 700Mpa and a preparation method of the hot-dip galvanized low-alloy high-strength steel. The hot-dip galvanized low-alloy high-strength steel comprises the following chemical components in percentage by weight: 0.07-0.12% of C; 0.2 to 0.5 percent of Si; mn: 1.1 to 1.5%; 0.02% to 0.06% of Nb; 0.06% to 0.12% of Ti; less than or equal to 0.020% of P; s is less than or equal to 0.012%; the content of Als is 0.02 to 0.06 percent; n is less than or equal to 0.006%, and the balance is Fe and inevitable impurities. The preparation method comprises the procedures of smelting, hot rolling, cold rolling and hot galvanizing. Through reasonable design of low-carbon, Nb and Ti microalloying components, hot rolling, cold rolling reduction rate and a hot dipping continuous annealing process are matched, a certain amount of temper mill extension is used, the precipitation strengthening effect of a steel plate is strengthened, and the hot-dip galvanized low-alloy high-strength steel which is uniform in structure, stable in mechanical performance, good in cold bending performance and high in corrosion resistance is obtained.

Owner:HANDAN IRON & STEEL GROUP +1

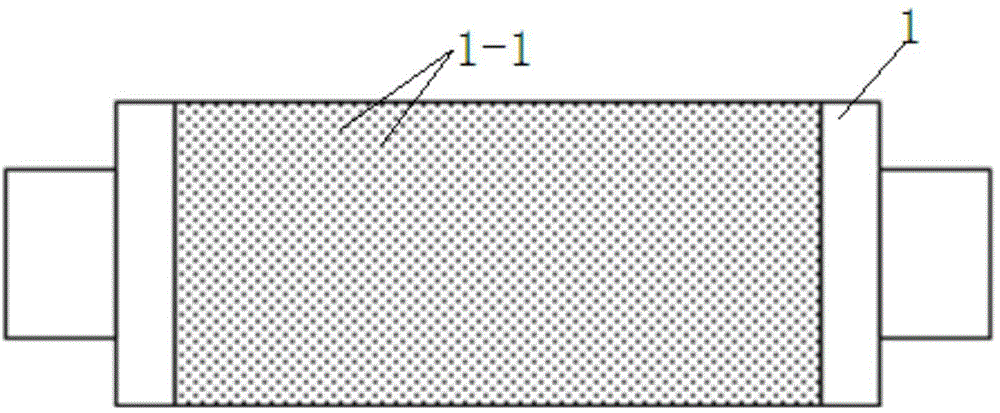

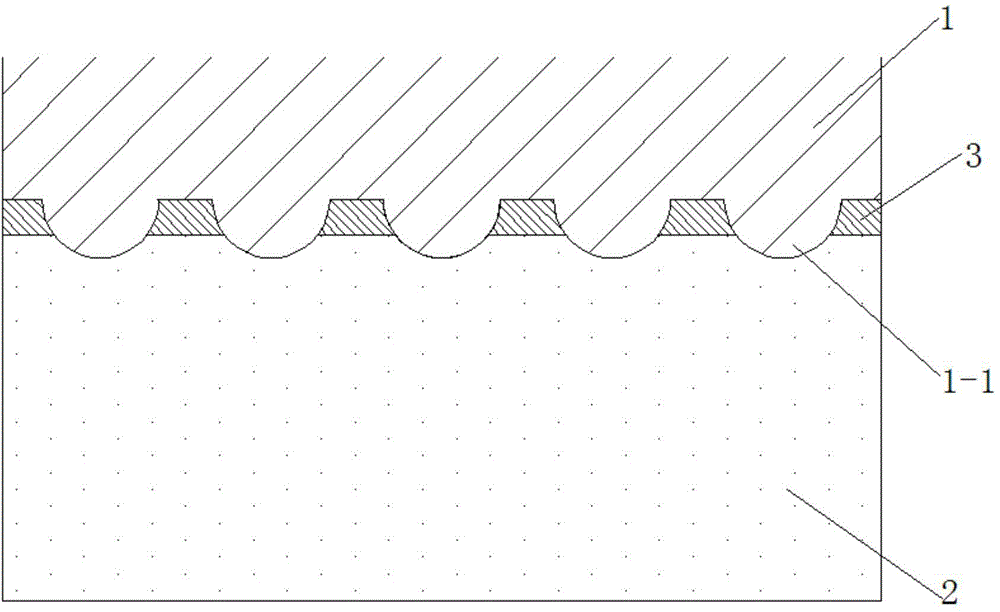

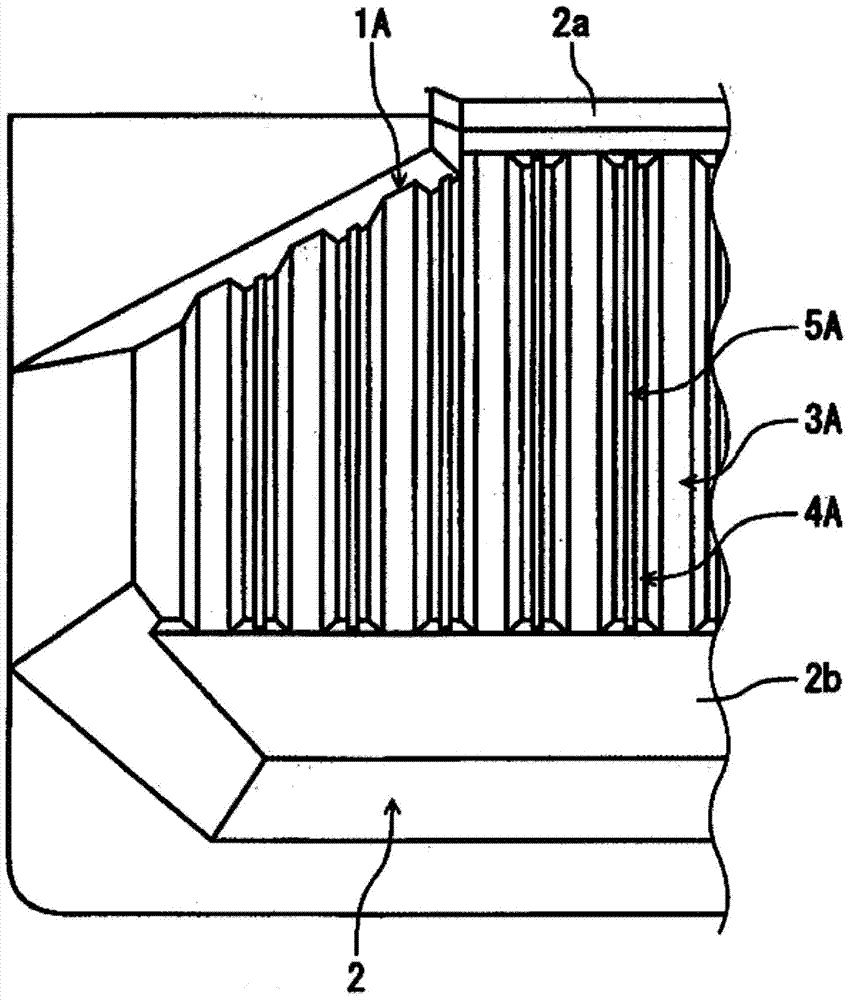

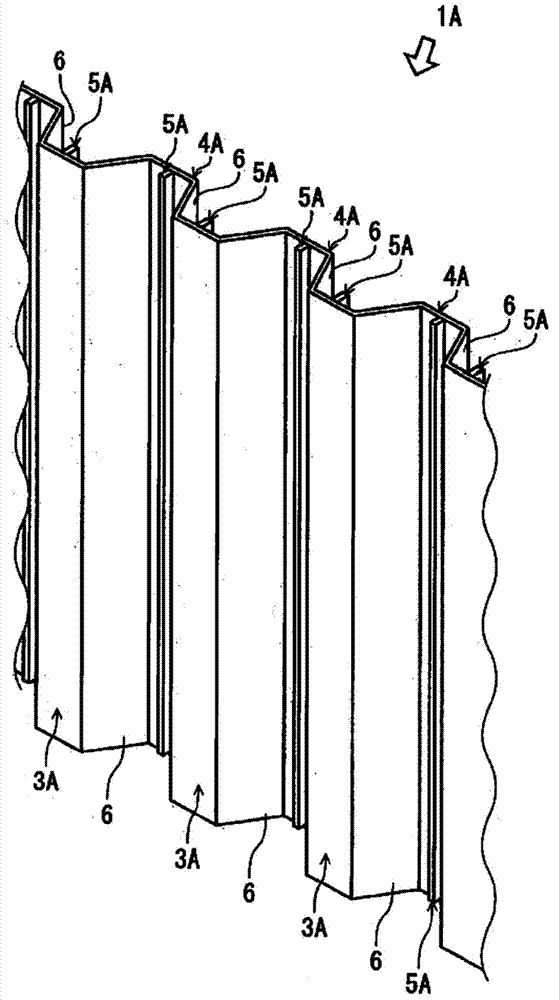

Ship bulkhead

[Problem] To provide a ship bulkhead that limits increases in the weight of the bulkhead as much as possible, that maintains the load bearing capability with respect to a vertical compression load that is required of the bulkhead, and that is capable of preventing buckling of the bulkhead. [Solution] Provided is a ship bulkhead that comprises a thick metal plate that divides the hold of a ship, that has a wave shape in which a plurality of surface members that are formed to have a plate shape that extends in the vertical direction and follows the width direction of the bulkhead protrude in an alternating manner on the front surface side and the rear surface side of the bulkhead, and wherein a rib is provided at least to a buckling risk area (A) within the range of 95-100% from the top edge of the vertical height of each of the surface members.

Owner:NIPPON STEEL CORP

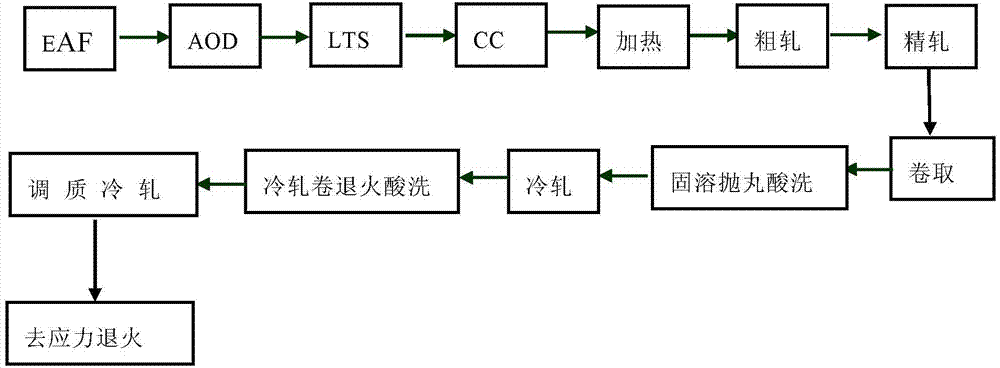

Manufacturing method of ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting

ActiveCN108866427AMeet technical requirementsShorten the setting timeFoundry mouldsFoundry coresNuclear powerDuctile iron

The invention discloses a manufacturing method of an ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting. The spheroidal graphite iron casting is more than 50 tons in weight, is 400mm or more in wall thickness, and is prepared from the following components: 3.6 to 3.7 percent of C, 0.9 to 1.0 percent of Si<original>, 1.9 to 2.0 percent of Si<final>, less than or equal to 0.1 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 0.03 to 0.08 percent of Mg, 0.01 to 0.02 percent of RE, 0.6 to 0.8 percent of Ni and0.003 to 0.005 percent of Sb. During manufacturing, the technical measures of ''high-temperature pure base iron melt, water-cooled metal mold, cold iron, spheroidizing agent 5800, compound strengthening inoculation, alloying and low-temperature box beating'' are adopted, so that the prepared ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting can meet the quality standard of a spheroidal graphite iron casting of which the license number is QT400-18, and can meet the technical requirements of ultra-large-section spheroidal graphite iron castings applied to wind power, nuclear power and the like.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

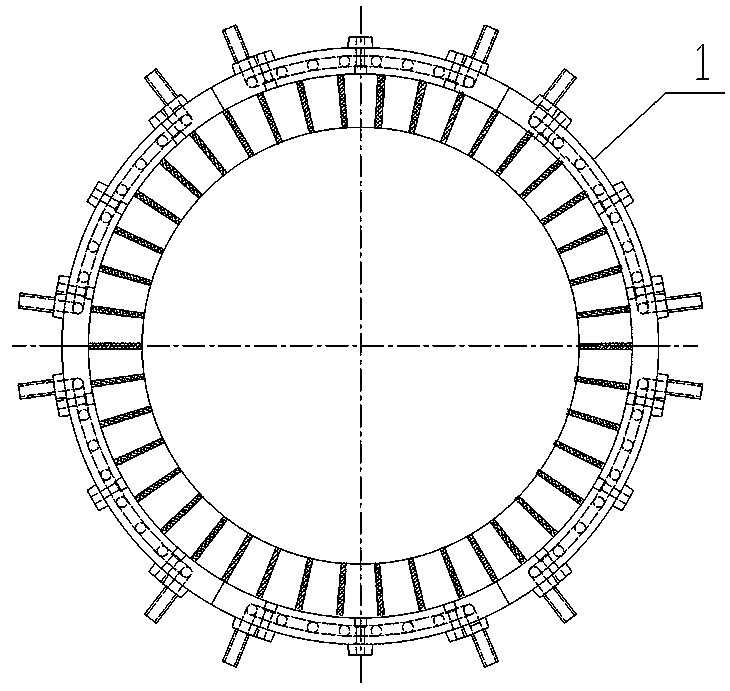

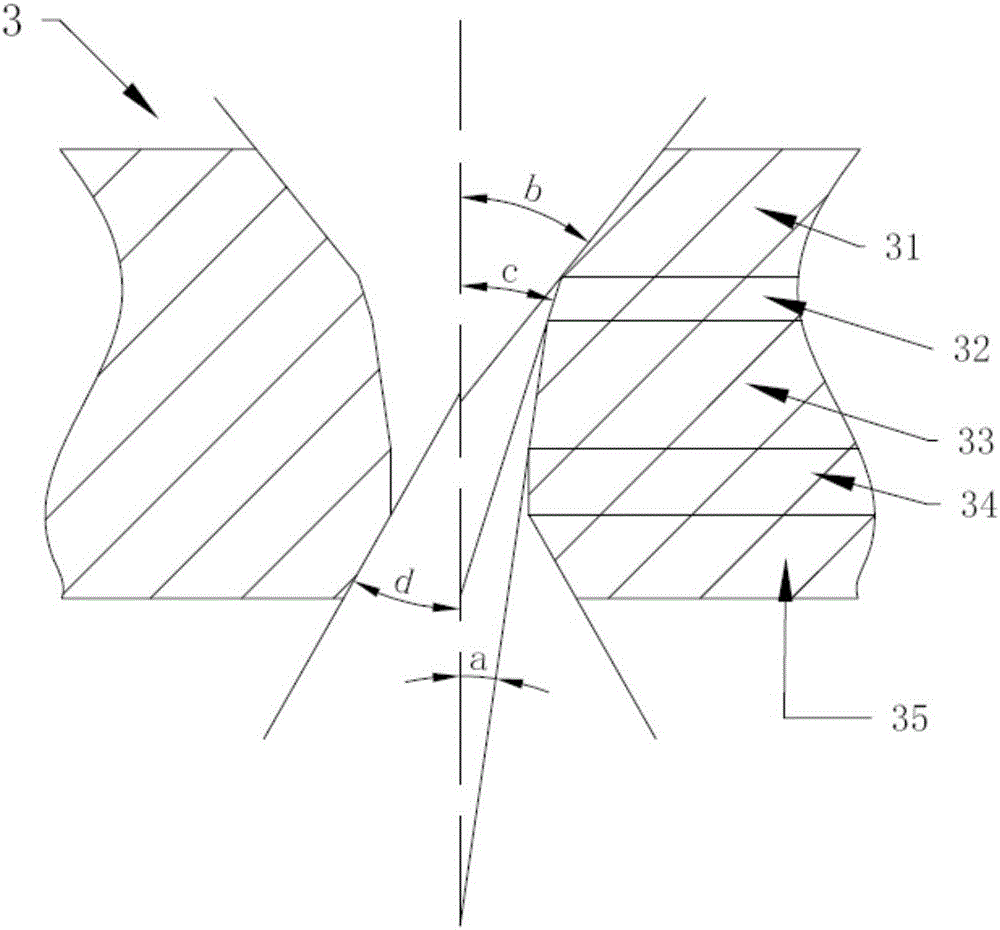

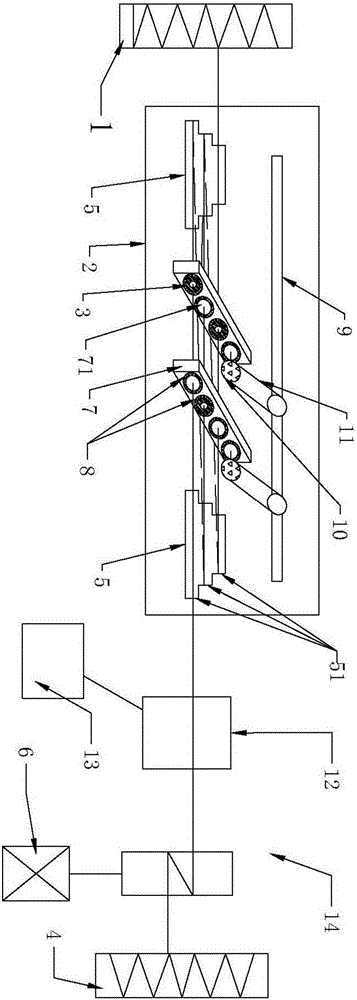

Drawing die and drawing system for metal wire

The invention discloses a drawing die and a drawing system for a metal wire. The drawing die comprises a tapered inlet region, a lubricating region, a tapered compression region, a cylindrical sizing region and a tapered outlet region which are sequentially connected through a circular arc transition portion; and the angle of the taper angle of the die decreases gradually from the tapered inlet region to the compression region, and the angle of the taper angle of the compression region ranges from 5 degrees to 12 degrees. The drawing system comprises a pay-off device, a drawing box body, at least one supporting seat, a traction device and a take-up device. The supporting seats are obliquely arranged on the inner wall of the drawing box body. The drawing die is mounted in mounting holes of the supporting seats. When the metal wire passes the compression region of the drawing die, compared with a drawing die in the prior art, by the adoption of the drawing die and the drawing system, if the same metal wire compression rate and the small reduction of the area are reached, the required traction force provided by the traction device is minimum, the loss of the internal gold phase structure of the metal wire material is small, a die core is not destroyed, the service life of the drawing die is prolonged, and the surface of the drawn metal wire is smooth.

Owner:NANTONG HUIFENG ELECTRONICS TECH

Melting technique for producing QT450-18 nodular cast iron through silicon solid solution reinforced ferrite

ActiveCN106929746AImprove processing performanceGood hardness uniformityProcess efficiency improvementYttriumScrap

The invention discloses a melting technique for producing QT450-18 nodular cast iron through silicon solid solution reinforced ferrite. In the melting process, 60-70% of nodular iron pig iron by weight is added firstly, then 15-25% of scrap returns by weight are added, finally, 8-20% of carbon steel scrap by weight is added, and the temperature is 1320-1390 DEG C; a pouring process is adopted for nodularizing-inoculating treatment, specifically, auxiliary materials are added in a nodulizing ladle according to the weight percentage of the auxiliary materials accoundting for the total amount of nodulizing iron liquid, 1.20-1.40% of a yttrium-based heavy rare earth nodulizing agent is evenly laid on one side of the bottom, the nodulizing agent is evenly covered with 1.60-1.90% of a high-calcium-barium nucleating agent, and 0.003-0.006% of an antimony ingot is added before discharging; and according to the original iron liquid analysis result, 0-0.20% of ferromanganese is additionally added, and the temperature is 1450-1480 DEG C. A casting prepared through the melting technique is good in hardness uniformity and cutting performance, and the machining cost of the casting is reduced.

Owner:德阳广大东汽新材料有限公司

A kind of preparation technology of medium-strength corrosion-resistant high-magnesium aluminum alloy plate

The invention discloses a preparation process of a medium-strength, corrosion-resistant, high-magnesium aluminum alloy plate, which belongs to the technical field of aluminum alloy processing. A preparation process for a medium-strength corrosion-resistant high-magnesium aluminum alloy plate, including batching; smelting; degassing, filtering; casting; homogenizing annealing; sawing, milling; preheating; hot rolling; Stretching; sawing; Wherein, the stretching refers to that after the plate is naturally cooled, it is first trimmed, and then stretched on the stretching machine, and the stretching amount is 3‑7%. Compared with the high-magnesium aluminum alloy plate prepared by the traditional cold rolling method, the preparation process of the present invention can break through the limitation of the opening of the cold rolling mill and produce a plate with a larger thickness. The obtained plate has high flatness, low internal stress, and low cold deformation. Uniform, excellent corrosion performance.

Owner:广西南南铝加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com