Corrosion-resistant and biological-adhesion-resistant EH690 steel plate and manufacturing method thereof

A technology of EH690 and manufacturing method, which is applied in the field of steel material preparation, can solve the problem of inability to produce high-strength and large-thickness steel plates, large thickness, seawater corrosion-resistant ultra-high-strength marine steel plates, yield strength and steel plate thickness that cannot meet marine Requirements for the key structure of the engineering platform and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

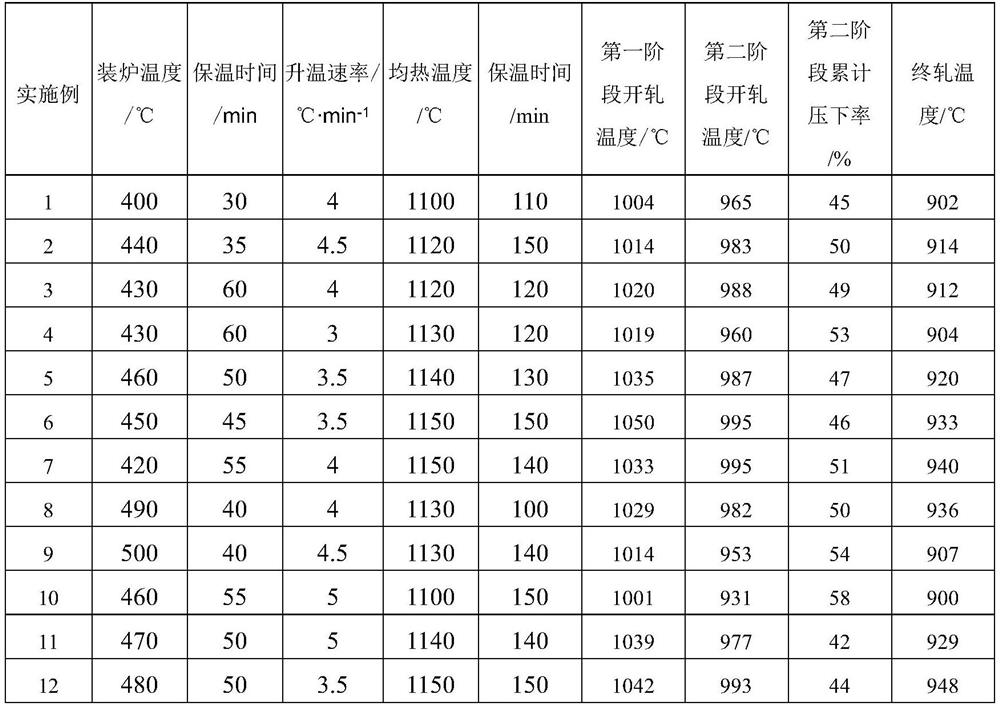

[0042] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

[0043] The chemical composition of the steel of the embodiment of the present invention is shown in Table 1, the heating and rolling process of the steel slab of the embodiment of the present invention is shown in Table 2, the quenching and tempering treatment process of the steel of the embodiment of the present invention is shown in Table 3, and the mechanical properties of the steel plate of the embodiment of the present invention are shown in Table 1. 4. See Table 5 and Table 6 for the resistance to marine environment corrosion of steel plates in the examples of the present invention.

[0044] Table 1 steel chemical composition wt% of the embodiment of the present invention

[0045] Example C Si mn P S al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com