Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

574results about How to "Guaranteed tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

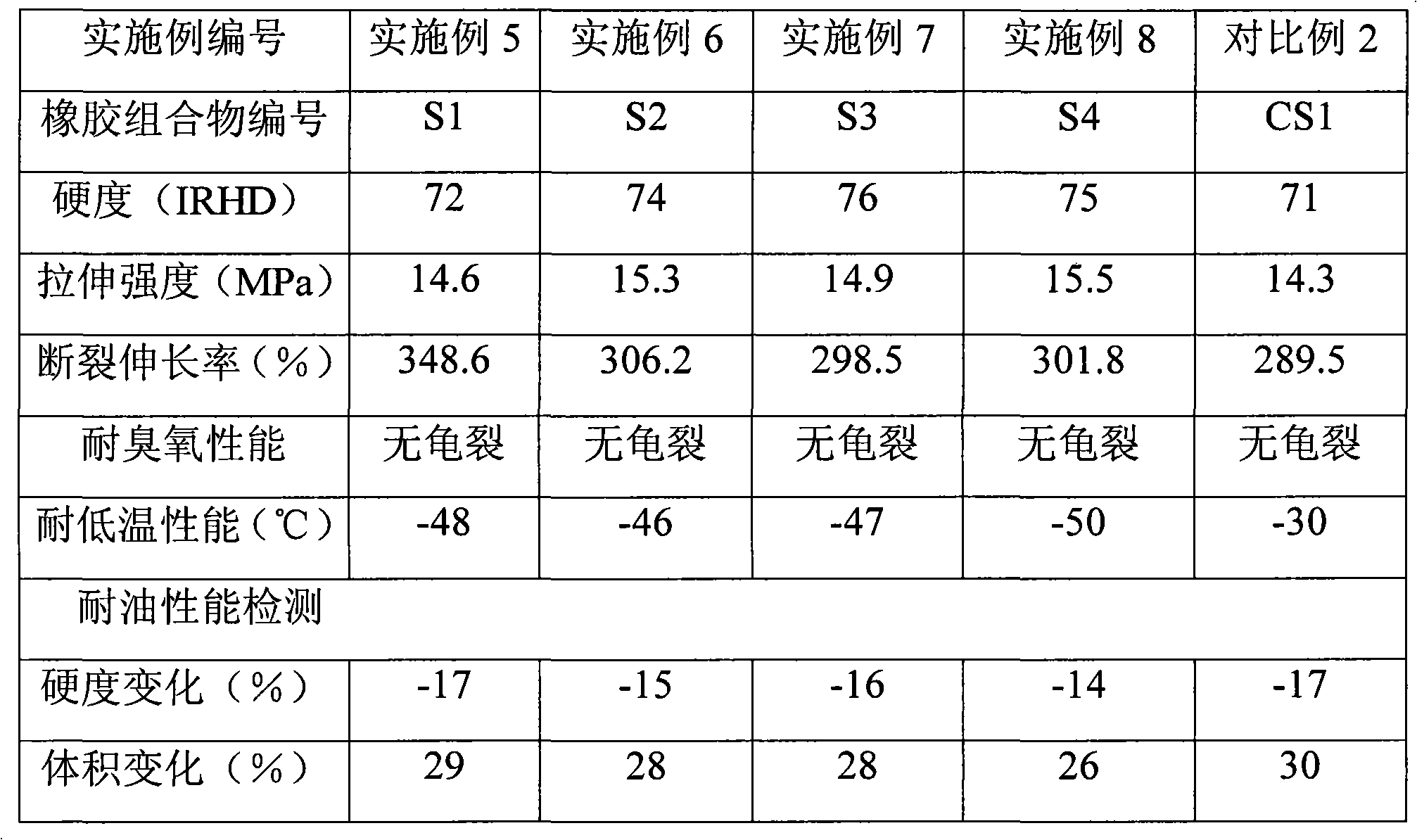

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

Silicon rubber with high refractive index and high transparency for optical encapsulation and preparation method thereof

ActiveCN103122149AHigh refractive indexImprove mechanical propertiesSemiconductor devicesHydrogenPolymer science

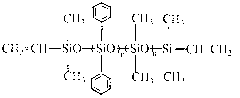

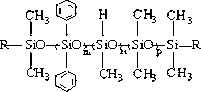

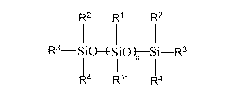

The invention relates to silicon rubber with high refractive index and high transparency for optical encapsulation and a preparation method thereof. The silicon rubber is prepared from a phenyl vinyl polysiloxane component A, a silicon resin component B containing phenyl vinyl, a phenyl component C containing hydrogen polyoxyalkylene, a platinum catalyst component D, a catalytic inhibitor component E, a modified polysiloxane component F, and a water remover component G in a mixing manner. The silicon rubber not only has over 1.50 of refractive index, but also is good in transparency, excellent in adhesion, and stable in performance, can resist heat and ultraviolet radiation for a long period of time, can meet various requirements of LED (light-emitting diode) encapsulation, and is an ideal encapsulation material of the LED. The silicon rubber can be packaged into a bi-component product; the product has good storage stability; and high transparency is still kept after the product is stored for over 6 months.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Aluminum alloy and casting method thereof, and method for extruding profile

The invention belongs to the technical field of aluminum alloys, and particularly relates to an aluminum alloy, a method for casting a cast ingot from the aluminum alloy, and a method for extruding a profile from the cast ingot. The invention aims to provide an aluminum alloy which has high strength and favorable processability. The high-strength aluminum alloy provided by the invention comprises the following components in percentage by weight: 0.5-1.5% of Mg, 0.25-1.2% of Si, 0.6-1.2% of Cu, 0.1-0.8% of Mn, 0.01-0.2% of Cr, 0.01-0.15% of Ti and the balance of Al. The yield strength of the hollow profile of the alloy in the T6 state (after completing aging treatment) is up to 350 MPa, the tensile strength is up to 400 MPa, and the plasticity is higher than 10%; and the hollow profile has favorable welding performance and fatigue resistance.

Owner:SNTO TECH GRP

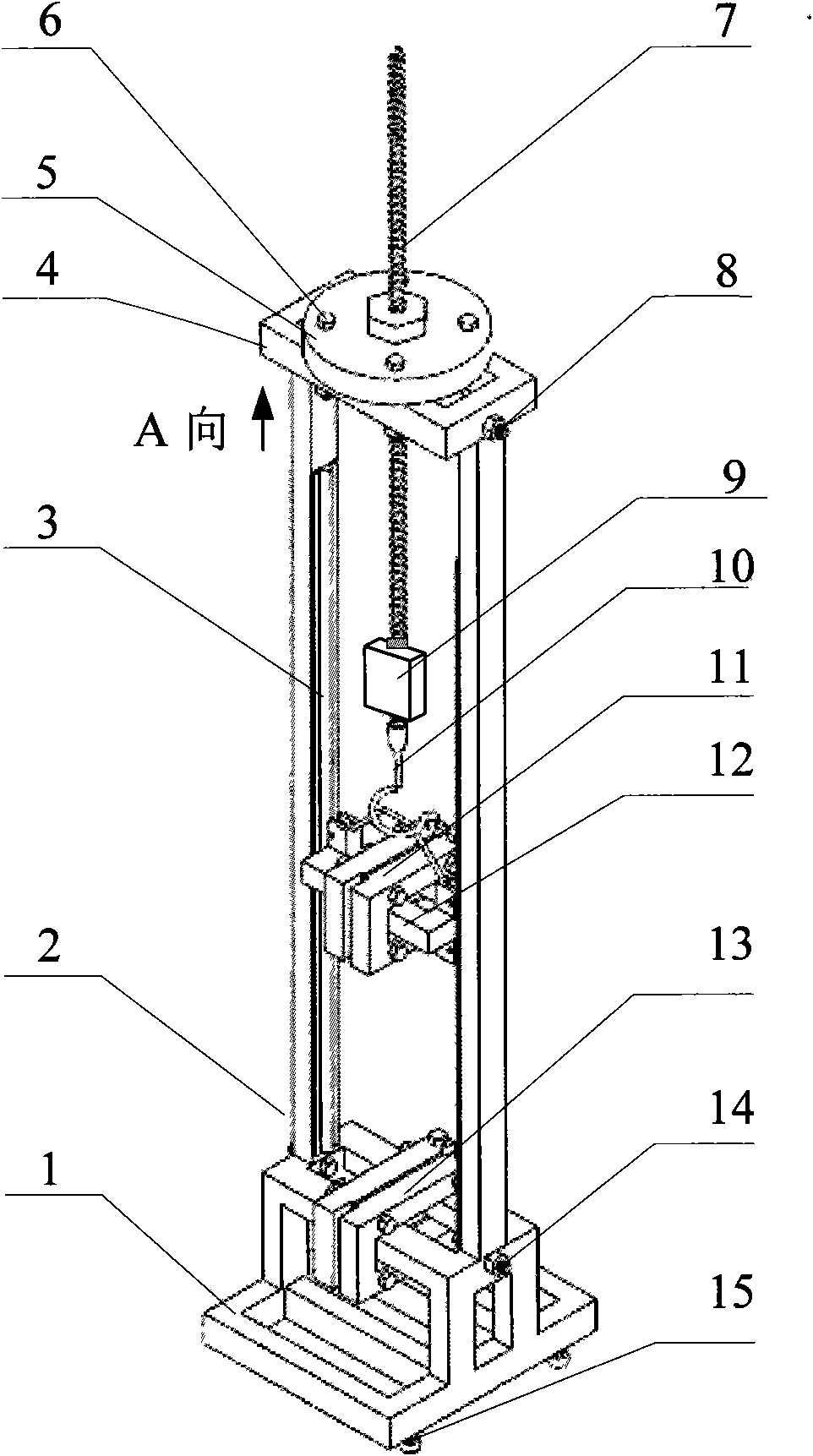

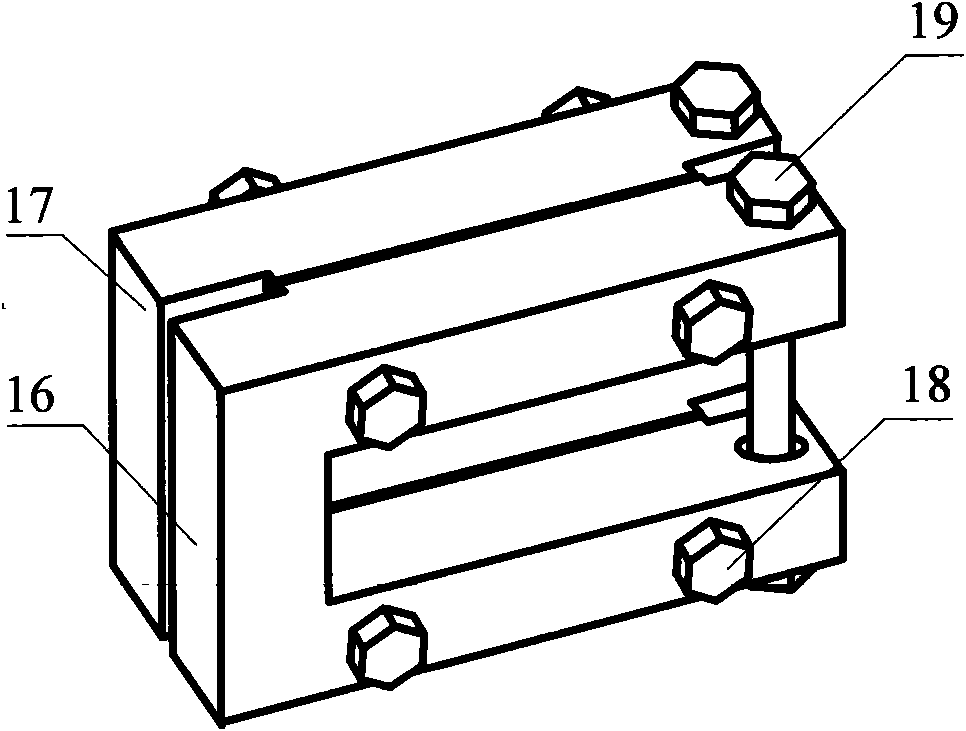

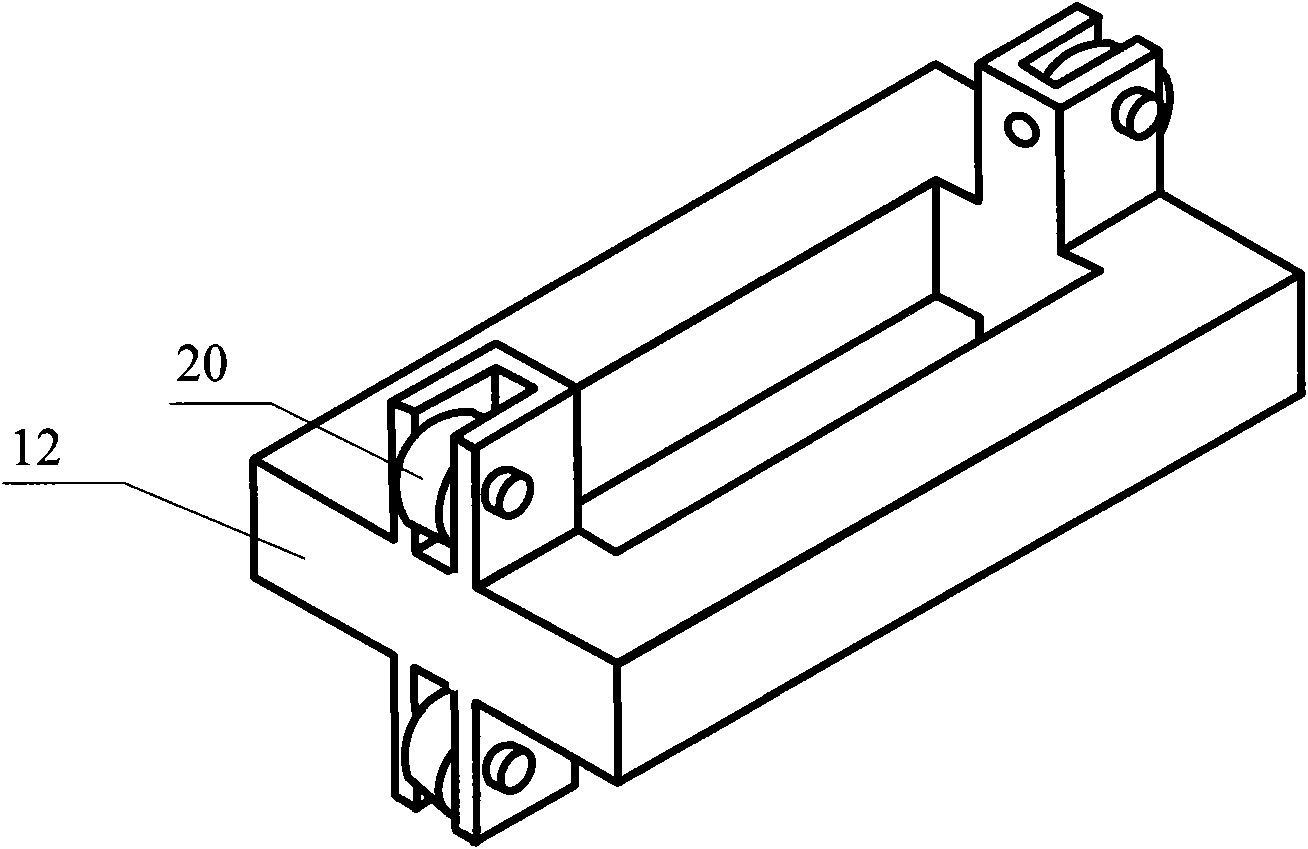

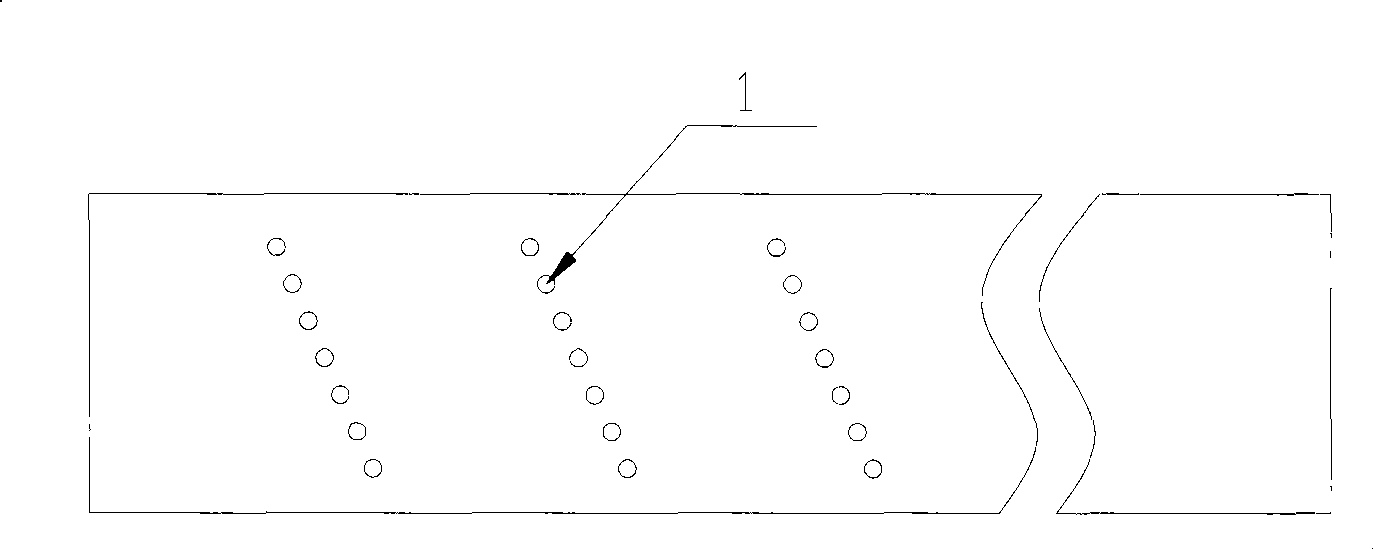

Field portable experiment system for tensile mechanical property of plant root system

InactiveCN101603899AGuaranteed tensile strengthImprove reliabilityMaterial strength using tensile/compressive forcesUsing optical meansPlant rootsPull force

The invention relates to a field portable experiment system for tensile mechanical property of a plant root system, which consists of a machine, a testing system, a notebook computer and a test recording software, wherein the machine comprises a fixing stand, a vertical guiding traction mechanism and a root system clamping system; the testing system comprises a left infrared distance measuring sensor, a right infrared distance measuring sensor, a tensile sensor, a tensile transducer, a data acquisition card and a sensor power module; the plant root system can be clamped by an upper clamping mechanism and a lower clamping mechanism of the root system clamping mechanism; when the upper clamping mechanism is lifted, the tensile force and deformation born by the root system is measured out by the testing system and transmitted to the portable notebook computer; a signal is analyzed through the test recording software; and the record is stored. The parts of the machine of the system can be detached into various parts or single piece, are convenient to carry, reduce spatial dimension, can be conveniently transported to a field needing to test the tensile mechanical property of the root system and test the tensile strength, deformation, strain and tensile elasticity modulus of the plant root system.

Owner:KUNMING UNIV OF SCI & TECH

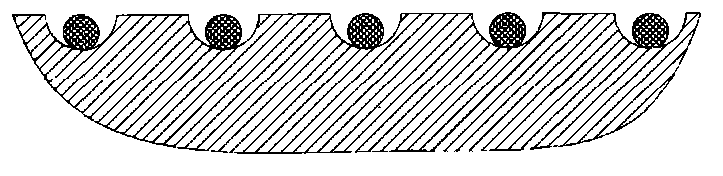

Lithium battery current collecting body, high capacity cylindrical lithium ionic cell and preparation

InactiveCN101364644AAvoid breakingReliable contactFinal product manufactureElectrode carriers/collectorsCurrent collectorLithium electrode

The invention discloses a current collector of a lithium ion battery, wherein stress dispersing holes are formed on the current collector. The invention further discloses a high-capacity cylindrical lithium ion battery including the current collector, and the preparation method thereof. The prepared lithium ion battery has the advantages of high capacity and higher safety performance.

Owner:SHENZHEN BAK BATTERY CO LTD

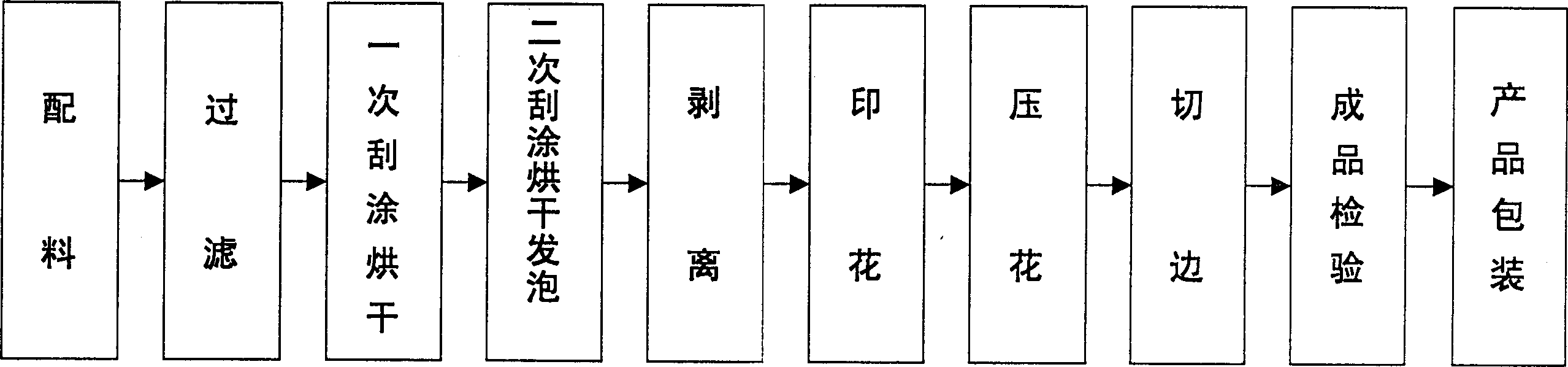

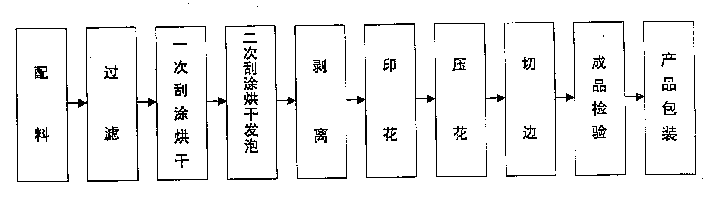

Decorative wall leather and its making method

InactiveCN1404989AImprove flame retardant performanceGood anti-mold and moisture-proof performanceSynthetic resin layered productsParaffin waxSurface layer

The decorative wall leather is formed from surface layer and bottom layer, the composition of surface layer comprises PVC base material 100, diisodecyl phthalate 30-60, chlorinated paraffin wax 0-25, barium-zinc liquid compound stabilizer 1-2, azoformamide 0-3, antimony oxide 0-5 and oil soluble dry film mildew inhibitor 0.2-1.5, and the composition of bottom layer contans PVC base material 100, diisodecyl phthalate 40-62, chlorinated paraffin wax 0-25, barium-zinc liquid compound stabilizer 1.5-3.5%, azoformamide 2-6, antimony oxide 2-8 and oil soluble dry film mildew inhibitor 0.2-2. Its preparation process includes the following steps: preparing materials, filtering, first knife coating, drying, secondary knife coating, drying, foaming, stripping, printing, embossing, edge-cutting, check finished product and packaging.

Owner:SICHUAN JINLU GRP

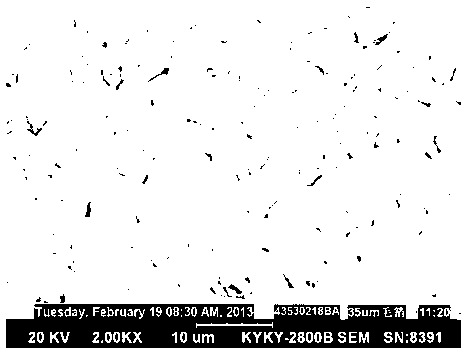

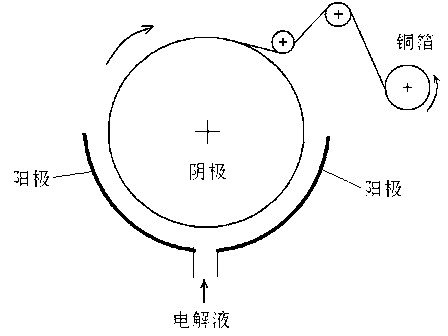

Mixed additive for removing internal stress of electrolytic copper foil and method for producing low-stress copper foil

ActiveCN103173812AThe production process is easy to controlProduct quality is stableCopper foilHydroxyethyl cellulose

The invention relates to a mixed additive for removing internal stress of an electrolytic copper foil and a method for producing a low-stress copper foil and belongs to the technical field of production of a high-precision electrolytic copper foil. The mixed additive for removing internal stress of the electrolytic copper foil comprises gelatin, hydroxyethyl cellulose and liquid additive. The method for producing the low-stress copper foil by using the mixed additive comprises the steps of preparing high-purity cathode copper and sulfuric acid into mixed solution of sulfuric acid and copper sulfate at 60-95 DEG C under the condition of stirring in the presence of air, wherein Cu<2+> is 85-100g / L and H2SO4 is 100-120g / L; adjusting the temperature of electrolyte to 45-60 DEG C and the flow to 50-70m<3> / h; adding 20-50mg / L of Cl<->, adding the mixed additive, with a drum titanium tube which continuously rotates as a cathode and arc titanium as an anode, carrying out copper electrolytic deposition and lastingly stripping to obtain 12-70 microns copper foil under the condition of the direct current of which the current density is 55-70A / dm<2>. The thickness of the copper foil is controlled by adjusting the rotation speed of the cathode; and the obtained copper foil has excellent performances.

Owner:SHANDONG JINBAO ELECTRONICS

Warp-knitting polyester fabric and processing method thereof

InactiveCN101709531AGuaranteed tensile strengthGreat tractionPattern makingWarp knittingPolyesterSurface layer

The invention relates to a warp-knitting polyester fabric and a processing method thereof, which belong to the fields of a polyester fibre product and a processing technique thereof. The warp-knitting polyester facing material comprises a surface layer tissue, a bottom layer tissue and an inner layer tissue positioned between the surface layer tissue and the bottom layer tissue, wherein the used raw material of the surface layer tissue is FDY bright yarn of 50D / 36F; the used raw material of the bottom layer tissue is spandex yarn of 40D; and the used raw material of the inner layer tissue is FDY bright yarn of 50D / 36F or 75D / 36F. Because the invention adopts the raw materials of the surface layer tissue, the inner layer tissue and the bottom layer tissue to form the warp-knitting polyester fabric, favorable pull tension exists between the surface layer tissue and the bottom layer tissue, and the tensile strength of the facing material is ensured, so that the warp-knitting polyester fabric has durability; the raw materials of the surface layer tissue and the inner layer tissue adopt the bright yarn, so that a beautiful feel can be presented; the bottom layer tissue adopts the spandex yarn, so that elasticity can be presented; and the technological steps adopted by the method can prevent floss faces from generating the phenomena of wool collapse and wool reversal, so that flosses have strong upright feel, and the floss faces are plump.

Owner:XIONGYING KNITTING & DYEING CHANGSHU

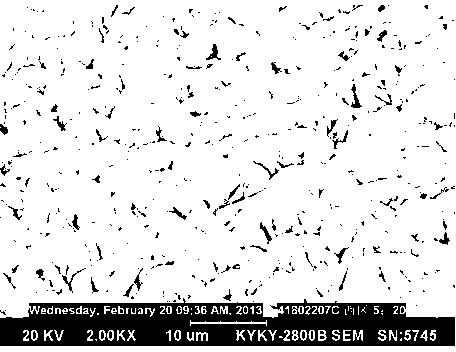

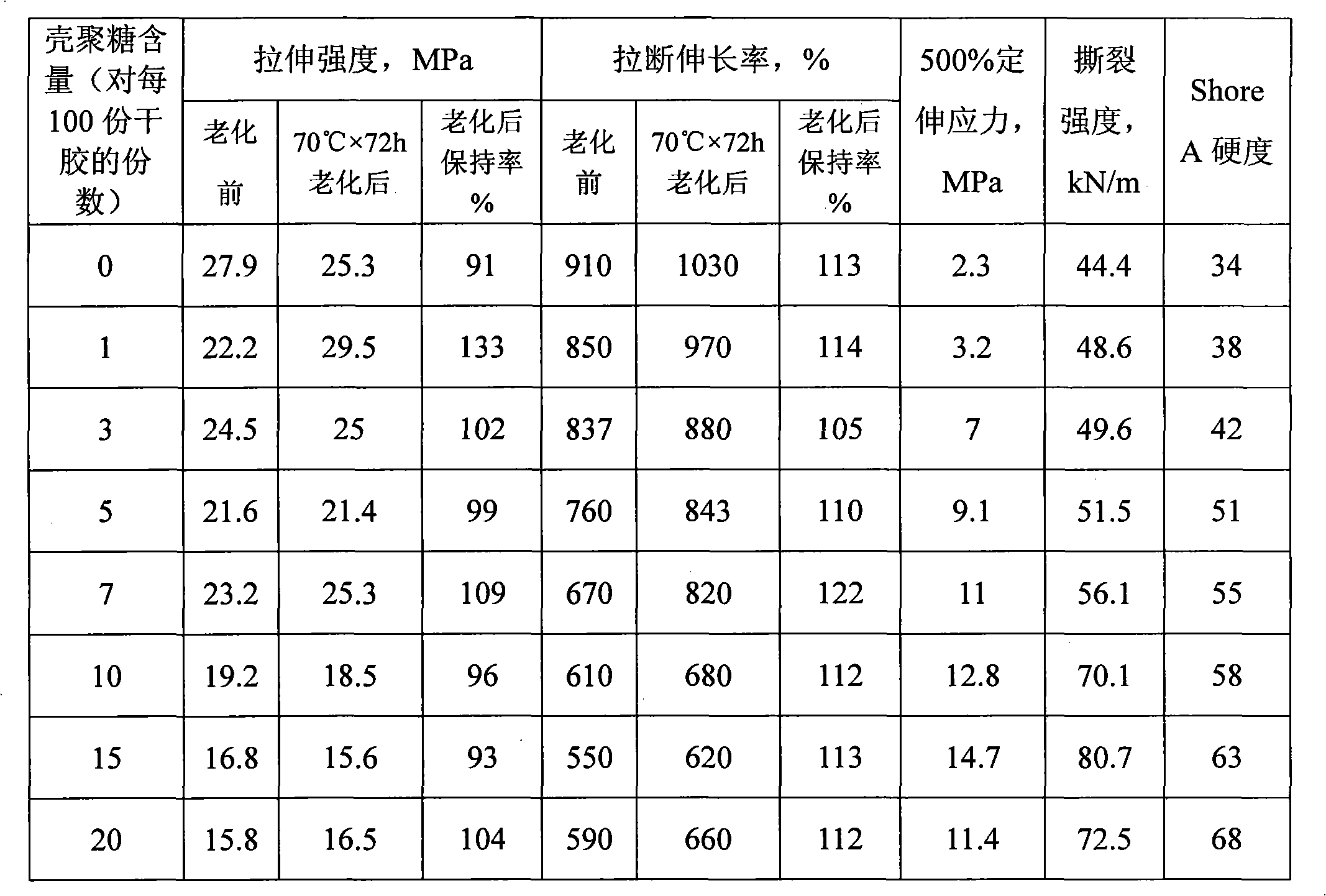

Pre-vulcanized natural rubber latex/chitosan blended membrane material and preparation method thereof

InactiveCN101870778AGuaranteed tensile strengthHigh elongationNatural rubber coatingsHyaluronic acid coatingsNatural rubber latexBiocompatibility Testing

The invention provides a pre-vulcanized natural rubber latex / chitosan blended membrane material and a preparation method thereof. The blended membrane material comprises the following components in part by dry weight: 100 parts of pre-vulcanized natural rubber latex and 1 to 20 parts of chitosan. The preparation method comprises the following steps of: pre-vulcanizing condensed natural rubber latex, fully stabilizing the pre-vulcanized natural rubber latex by using a stabilizing agent, then regulating the pH value of the pre-vulcanized natural rubber latex to 4 by using a regulator, then adding acetic acid solution of the chitosan into the pre-vulcanized natural rubber latex, and preparing the pre-vulcanized natural rubber latex / chitosan blended membrane material by a conventional process for producing rubber latex products with consolidation forming, leaching, drying and the like. The material has better tensile property, tearing resistance, ageing resistance, hydrophilic property and biocompatibility than the natural rubber latex, and can be used for the production of medicinal rubber latex products such as surgery gloves, medicinal examination gloves, catheters, condoms, drainage tubes and the like.

Owner:湛江市博大橡胶制业有限公司

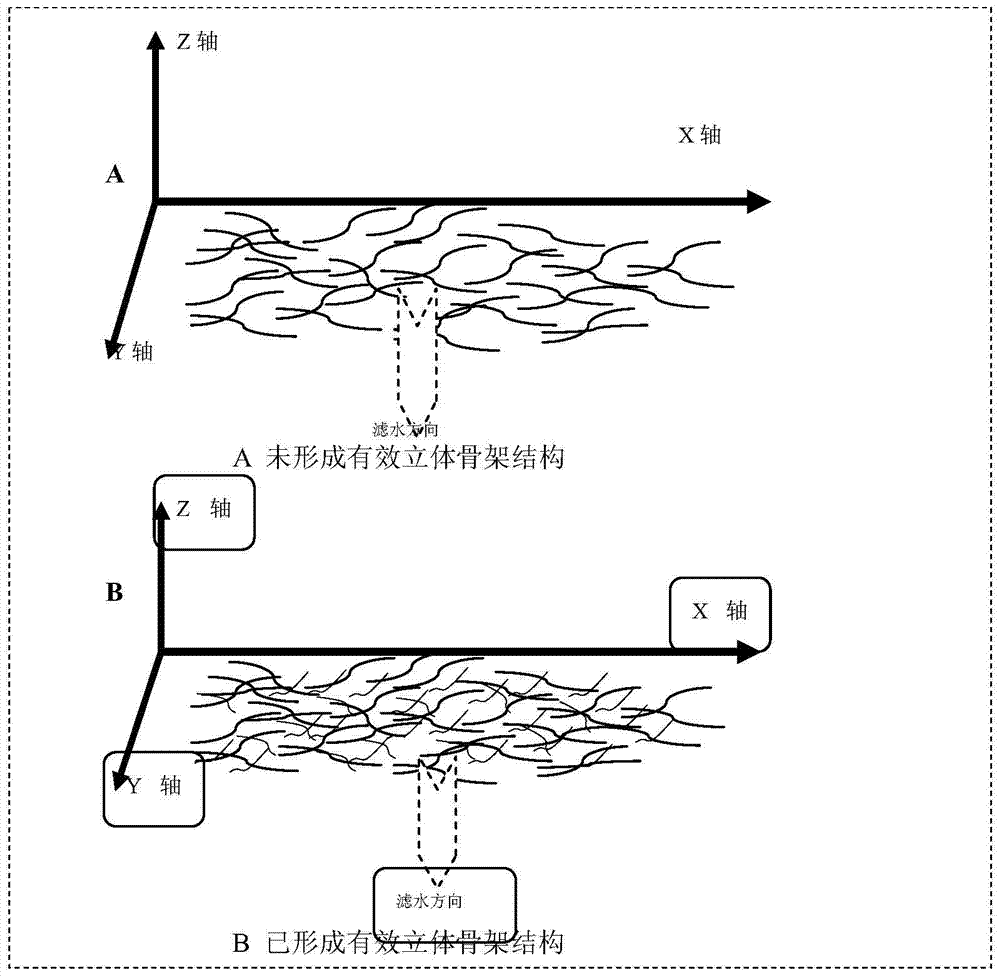

High-bulk papermaking method reconstruction tobacco leaf fiber composition and preparation method and application

ActiveCN106993820AAchieve absorbency and bulkImprove filler retentionTobacco preparationCo releaseTobacco leaf

The invention belongs to the special papermaking production field, and specifically relates to a high-bulk papermaking method reconstruction tobacco leaf fiber composition and a preparation method and application; the reconstruction tobacco leaf comprises a tobacco raw material, wood long fibers and wood short fibers, and is prepared by mixing said compositions; the short fibers are arranged in a Z-type in a water filtering process, thus effectively improving the bulk property and spreading rate while fully ensuring the substrate tensile strength and paper machine operationability, improving filling material retention rate and product yield, reducing production cost, improving product fully combustion level, and reducing CO release amount.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

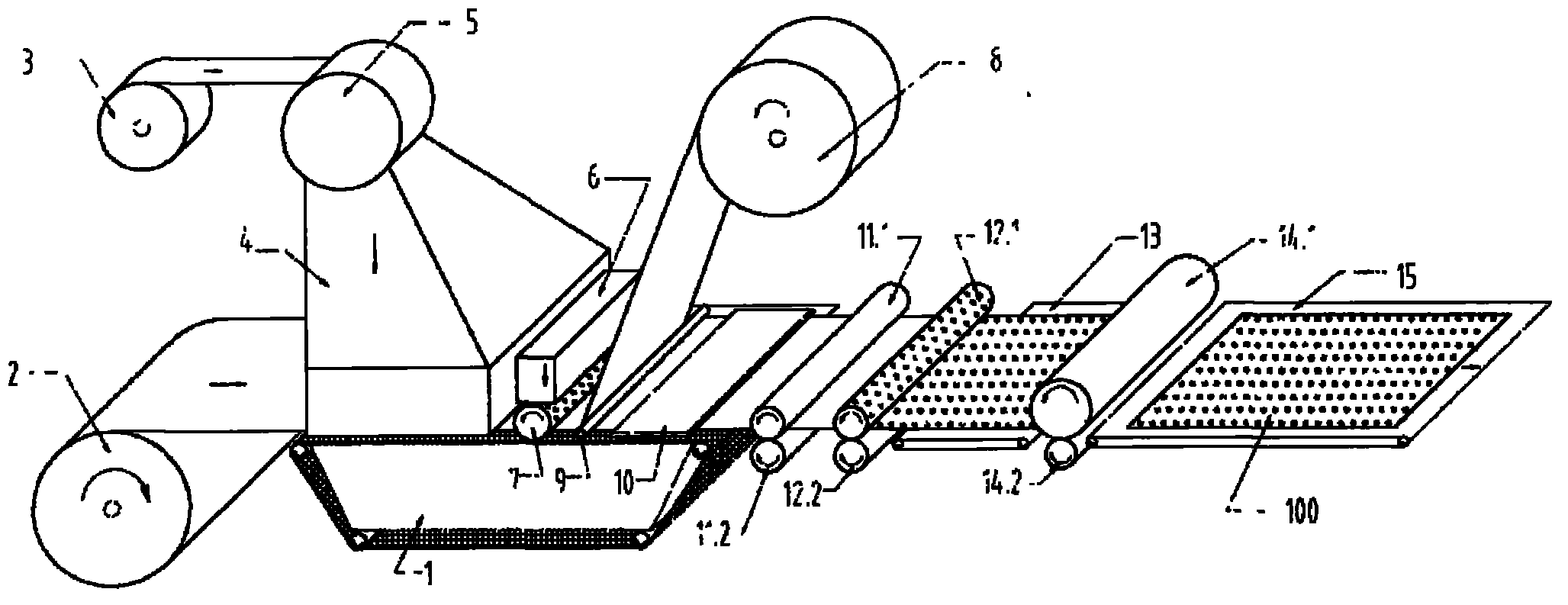

Health nursing pad absorber processing method and equipment thereof

ActiveCN103381114AImprove liquid absorption capacityIncrease liquid absorptionAbsorbent padsBaby linensEngineeringFiber

The invention discloses a health nursing pad absorber processing method and equipment thereof. The method comprises the following three steps: A, adsorbing wood pulp fiber and mixing the wood pulp fiber with polymer absorbent materials, B, compacting and dotted solidifying the absorber, and C, forming the absorber; the equipment is provided to realize the method. The method provided by the invention is suitable for various nursing pad products, can enhance extension strength of the nursing pad product, simplifies and realizes the manufacturing of absorber of nursing pad product, and reduces manufacturing cost of the nursing pad. The absorber produced by the invention adopts a novel structure made of polymer absorbent materials and wood pulp fiber, the polymer absorbent materials are uniformly disturbed in the wood pulp fiber, the sliding and moving of polymer absorbent materials are confined through doted solidification, so as to guarantee liquid absorption of the nursing pad product.

Owner:BEIJING BEISHUTE MATERNITY & CHILD ARTICLES

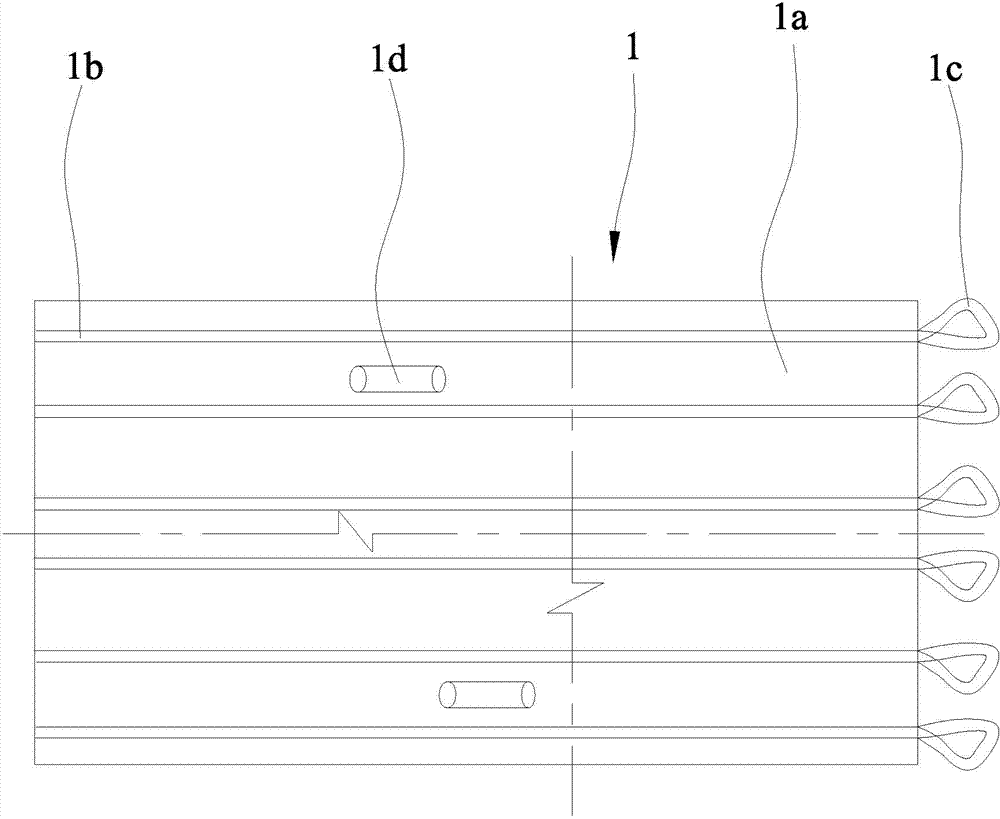

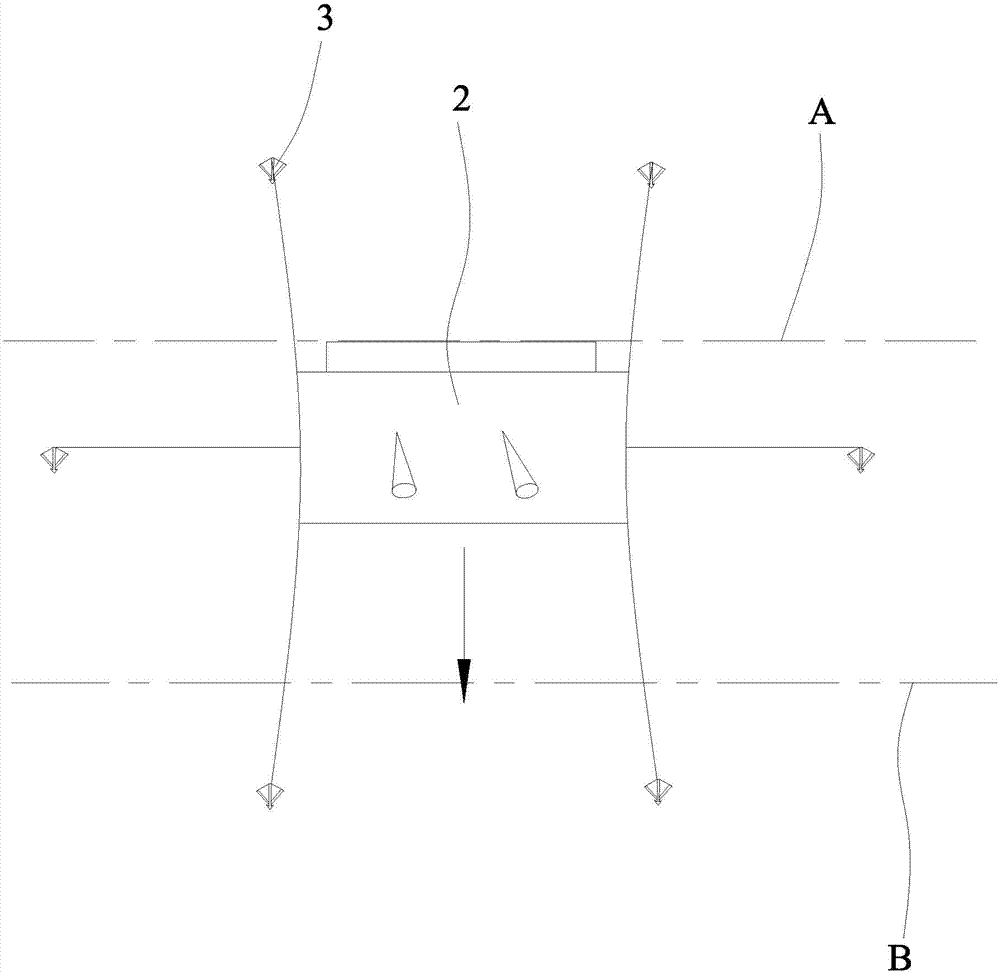

Method for carrying out deepwater laying on large-volume reinforced mud-filling tubular bags by using geotextiles-laying vessels

The invention relates to a method for carrying out deepwater laying on large-volume reinforced mud-filling tubular bags by using geotextiles-laying vessels, which comprises the following steps of: carrying out measurement on the underwater terrain by using a GPS (global position system), drawing a cross-section diagram, and marking an embankment axis and a construction side line in a construction area; determining the length of the mud-filling tubular bag according to the measured data and the size of a cross section, determining the width of a bag body according to the length of a roller, and sewing a reinforced belt on the surface of the bag body, wherein the bag body is provided with a mud inlet; rolling the mud inlet of the mud-filling tubular bag inwards on the roller; anchoring a geotextiles-laying vessel with the rolled bag body on the construction side line, and preparing a sand carrier and a sand blowing pump; filling the head part of the mud-filling tubular bag firstly, placing the mud-filling tubular bag on the construction side line, moving the mud-filling tubular bag and continuing to fill the mud-filling tubular bag until the mud-filling tubular bag is completely submerged in an original beach face or on the lower bag body, and then taking back a connecting rope; moving the vessel transversely, and laying the next mud-filling tubular bag. The method disclosed by the invention is accurate in positioning; through carrying out reinforcement treatment on mud-filling tubular bags, the strength of bag bodies is significantly increased, and the influence on construction caused by rising and falling tide is small; and the construction is assisted by using large vessels, so that the operating risk of workers is reduced, and the construction efficiency is improved.

Owner:安徽水利开发有限公司 +1

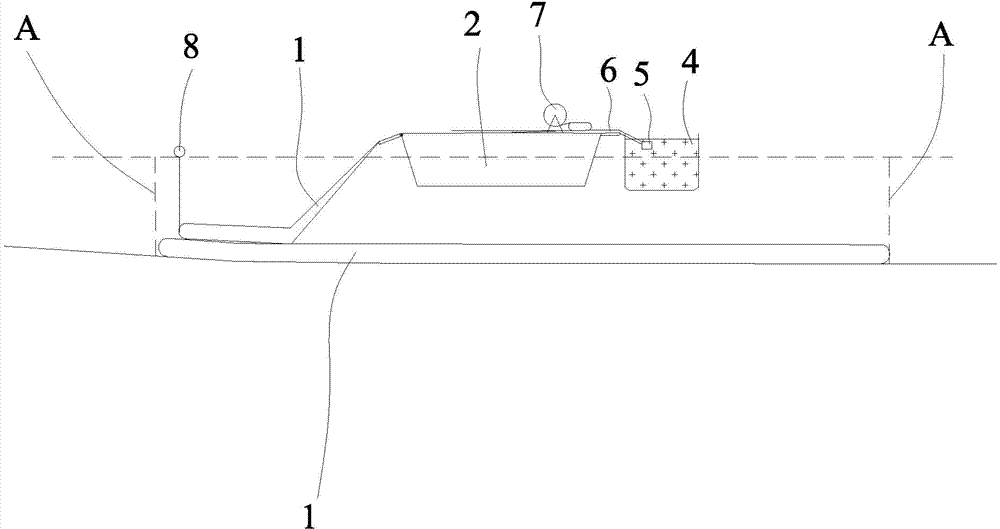

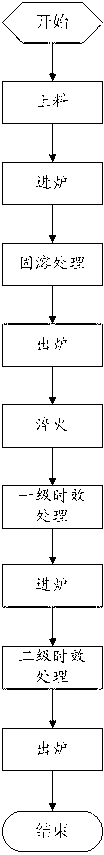

Aluminum alloy wheel heat treatment process

InactiveCN102912265AImprove overall performanceImprove plasticity and toughnessFurnace typesHeat treatment furnacesQuenchingSpoke

The invention discloses an aluminum alloy wheel heat treatment process comprising the steps of: loading, furnace feeding, solid solution treatment, discharging, quenching, primary aging treatment, feeding, secondary aging treatment, and discharging. During the solid solution treatment, a solid solution temperature is 540-550 DEG C, and a solid solution temperature maintenance time is 3.5-4.5h. During the primary aging treatment, the material is kept under room temperature for 24h. During the secondary aging treatment, the aging temperature is 115-125 DEG C, and an aging temperature maintenance time is 2.5-3.5h. With the aluminum alloy wheel heat treatment process provided by the invention, product comprehensive performance can be improved. On a basis that product hardness and tensile strength are ensured, product plasticity and toughness are substantially improved. Especially, impact toughness of the product is improved. With the process, impact strengths of thin spokes and wheels requiring lightweights can be greatly improved, such that requirements of high-requirement automotive main engine factories can be satisfied.

Owner:DARE TECH

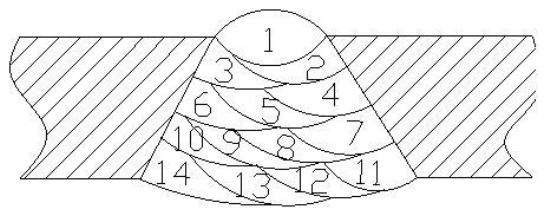

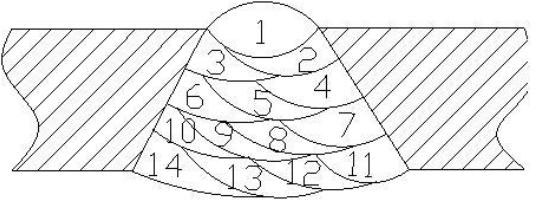

Method for welding butt-jointed seam of upward plate through manual arc welding

The invention relates to a method for welding a butt-jointed seam of an upward plate through manual arc welding, which comprises the following steps of: (1) burnishing the groove and 10-15 mm range of the surface of a test piece to have metallic luster, assembling and pairing the test piece, wherein the included angle between the groove face and the central vertical face is 30-35 DEG, the length of a root gap is 3.0-4.0 mm, the length of the truncated edge is 1.5-2.0 mm, and the unfitness of butt joint is less than 0.5 mm; (2) performing positioned welding on both ends of the test piece, wherein the length of the welding spot is 10-15 mm; and (3) adopting a layered lane welding process for the welding sequence. In the method, a linear or lateral small swing electrode manipulation manner is adopted for welding, therefore, the operation is simple and easy to master; welding joints are reduced, and the defects of porosity, slag inclusion, incomplete fusion and the like at the joints are prevented; the temperature of the molten bath is effectively controlled, and weld beading formed by the burnthrough of the root layer is prevented; the heat input of the weld seam is reduced, and the plasticity and the tenacity of the weld seam are effectively increased.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

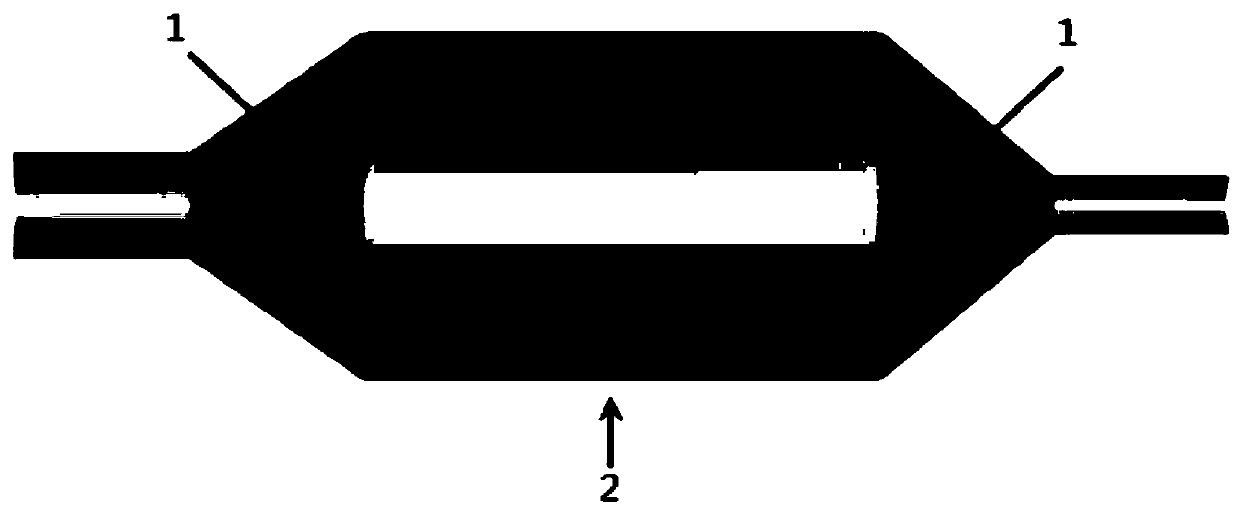

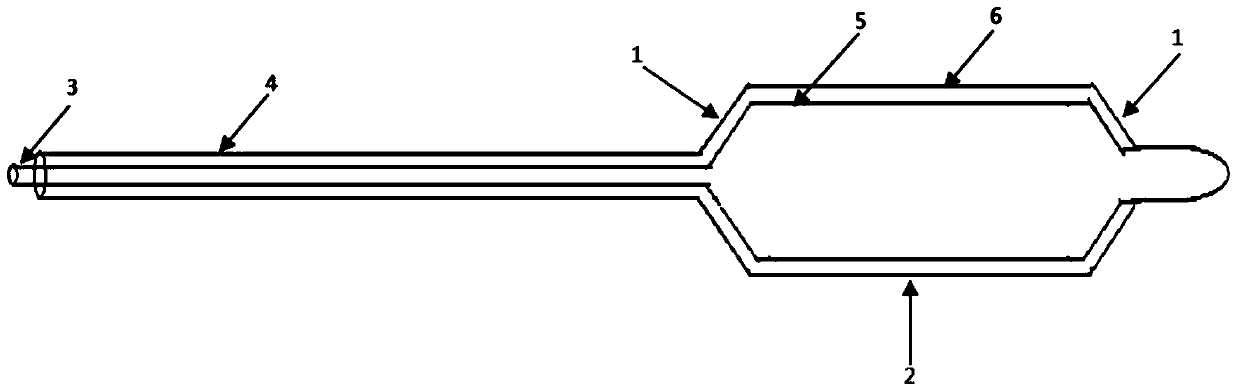

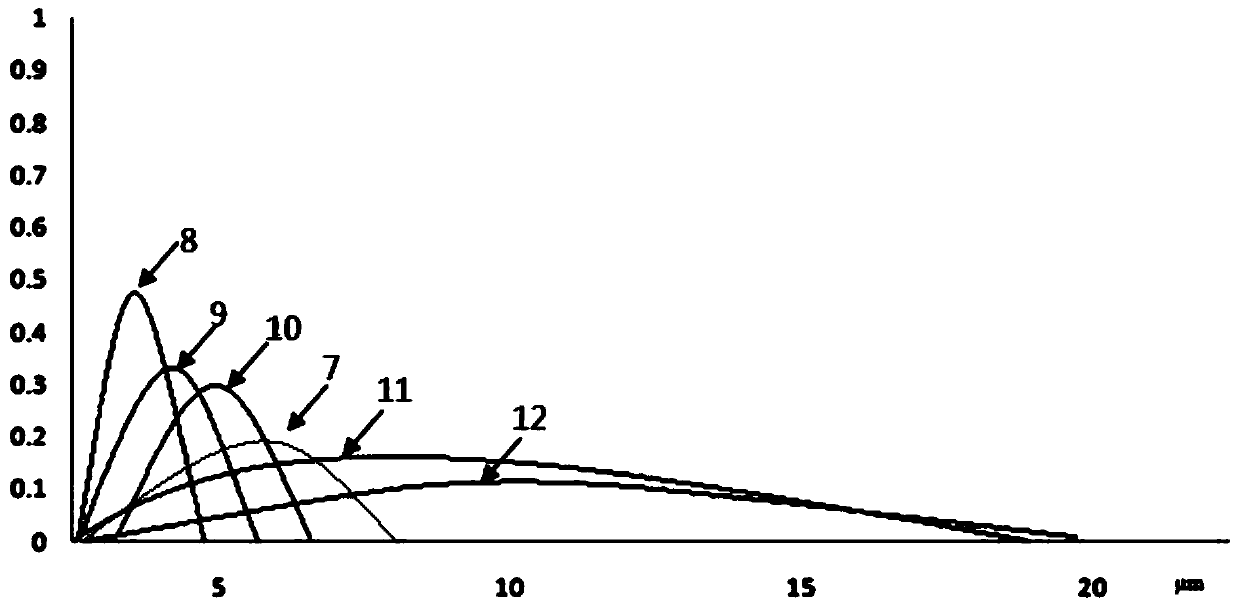

Drug delivery balloon dilating catheter

ActiveCN103623497ASatisfied with repeated expansionMeet shrinking needsSurgeryDilatorsPorosityBalloon dilatation catheter

The invention provides a drug delivery balloon dilating catheter of a double-layer balloon structure. The drug delivery balloon dilating catheter comprises a pressurizing hole-free inner balloon body and an outer balloon body with a drug-permeable micro-hole permeable membrane. Compared with the prior art, the hole diameter of the drug delivery balloon dilating catheter is even, and the high porosity and the high mechanical strength are achieved. The invention further discloses a manufacturing method of the drug delivery balloon dilating catheter of the double-layer balloon structure, the drug delivery balloon dilating catheter is made of materials such as polyethylene or nylon 12, the micro-hole permeable membrane is manufactured with a thermally induced phase separation method, and the drug delivery balloon dilating catheter has the advantages of being simple in manufacturing process, suitable for large-scale production, low in manufacturing cost and the like.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

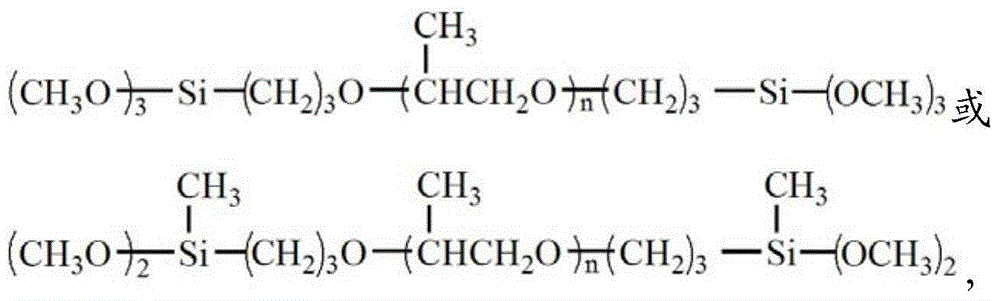

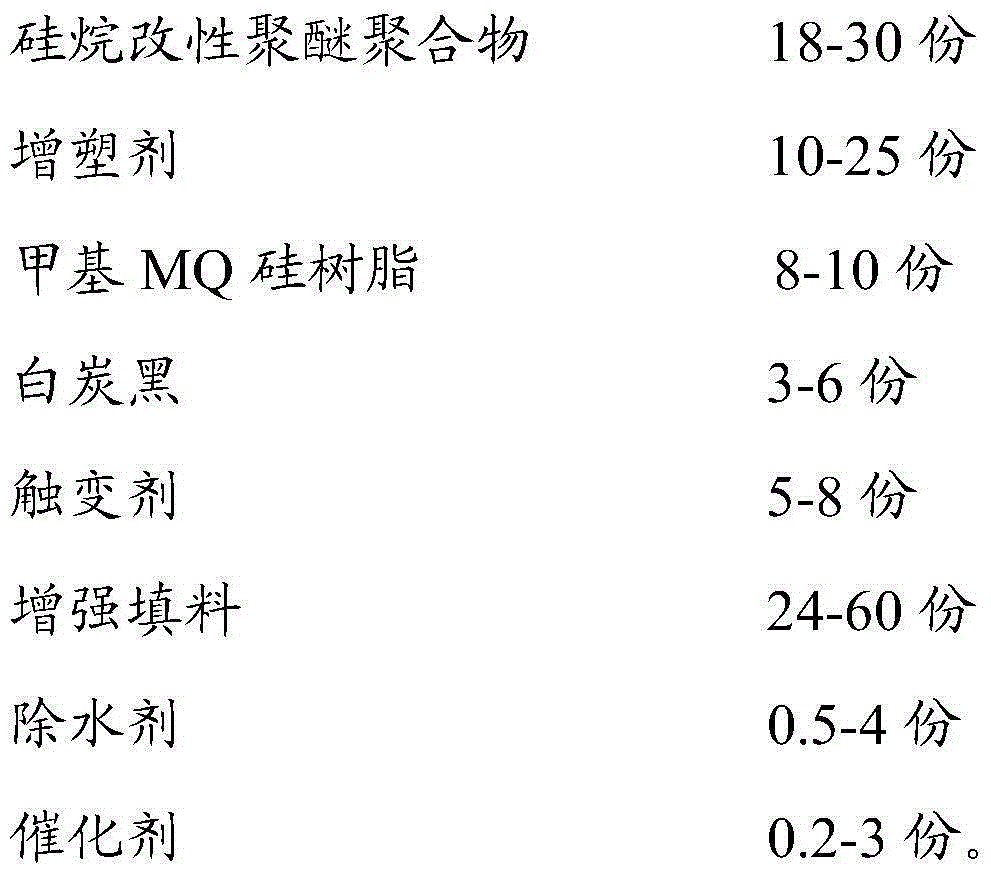

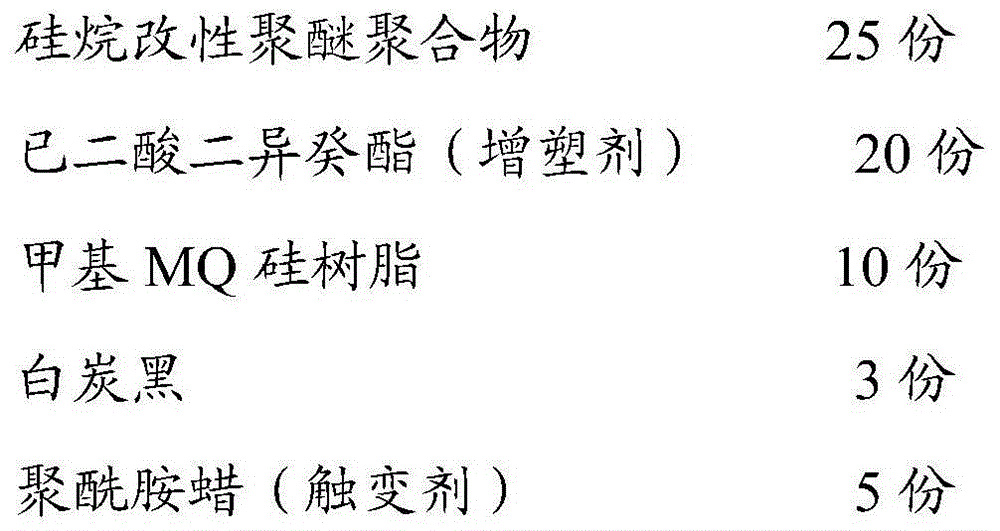

Environment-friendly nail-free glue and preparation method thereof

ActiveCN104449523AWell mixedEvenly dispersedNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilanesPlasticizer

The invention discloses environment-friendly nail-free glue and a preparation method of the environment-friendly nail-free glue. The environment-friendly nail-free glue comprises, by weight, 10-50 parts of silane-modified polyether polymers, 5-30 parts of plasticizer, 5-10 parts of methyl MQ silicon resin, 3-10 parts of white carbon black, 0-8 parts of thixotropic agents, 24-60 parts of reinforcing filler, 0.5-4 parts of dewatering agents and 0.2-3 parts of catalysts. The environment-friendly nail-free glue is good in comprehensive performance, high in construction efficiency, free of solvent, environmentally friendly and capable of replacing traditional iron nails to achieve a good bonding and fixing effect, and has very broad application prospect along with enhancement of the safety and environmental protection sense of people.

Owner:GUANGZHOU BAIYUN CHEM IND

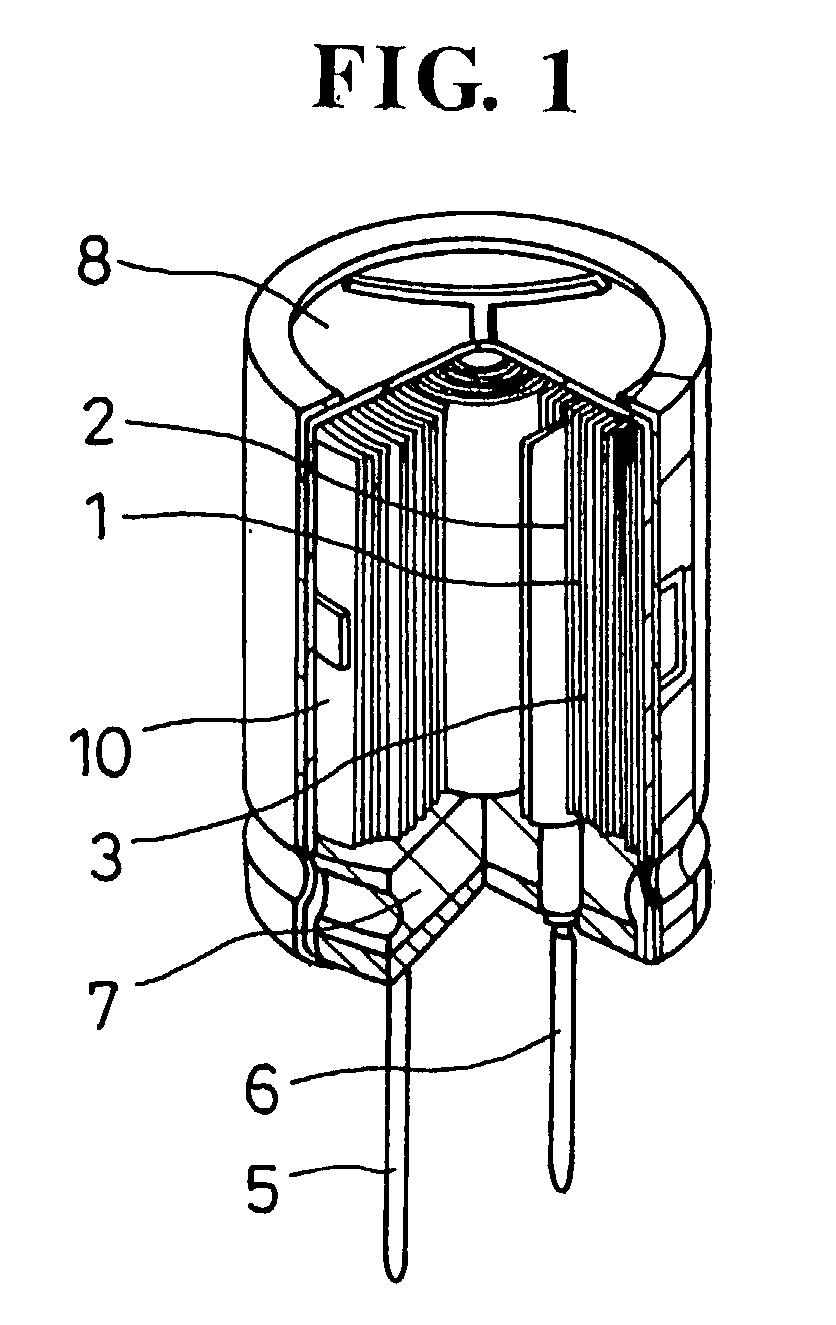

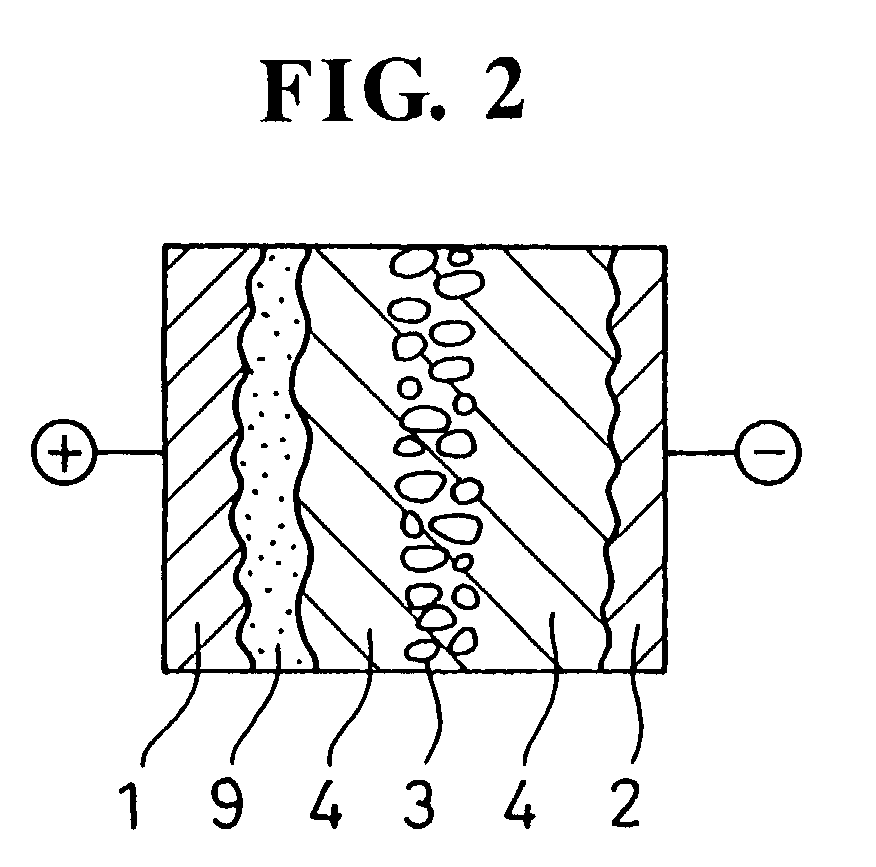

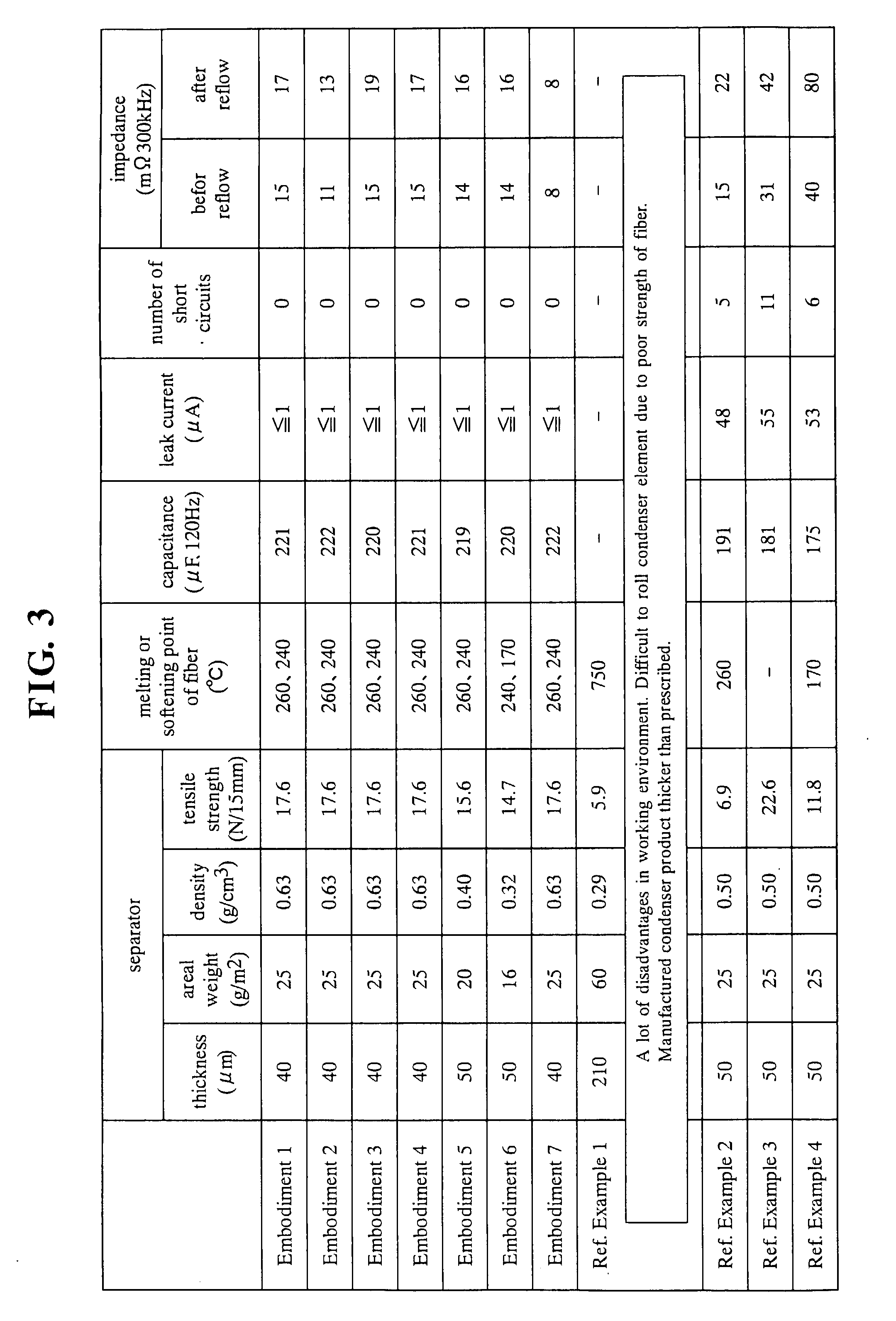

Separator for solid electrolyte condenser and solid electrolyte condenser using the same

ActiveUS20020117394A1High frequencyReduce resistanceHybrid capacitor separatorsHybrid capacitor electrolytesChemistryElectrolyte

An object of the present invention is to provide a separator which is excellent in sticking and adhesion capability with the solid electrolyte, physically strong and highly heat-resistive and to provide a solid electrolyte condenser which is excellent in the impedance characteristic and leak current characteristic. In a solid electrolyte condenser comprising an anode foil, a cathode foil, a separator, the separator is made of a nonwoven fabric containing polyester resin or its derivative manufactured by the wet method. The condenser element is formed by rolling the anode foil and the cathode foil together with the separator between them. The solid electrolyte is provided between the anode foil and the cathode foil of the condenser element.

Owner:NIPPON KODOSHI +1

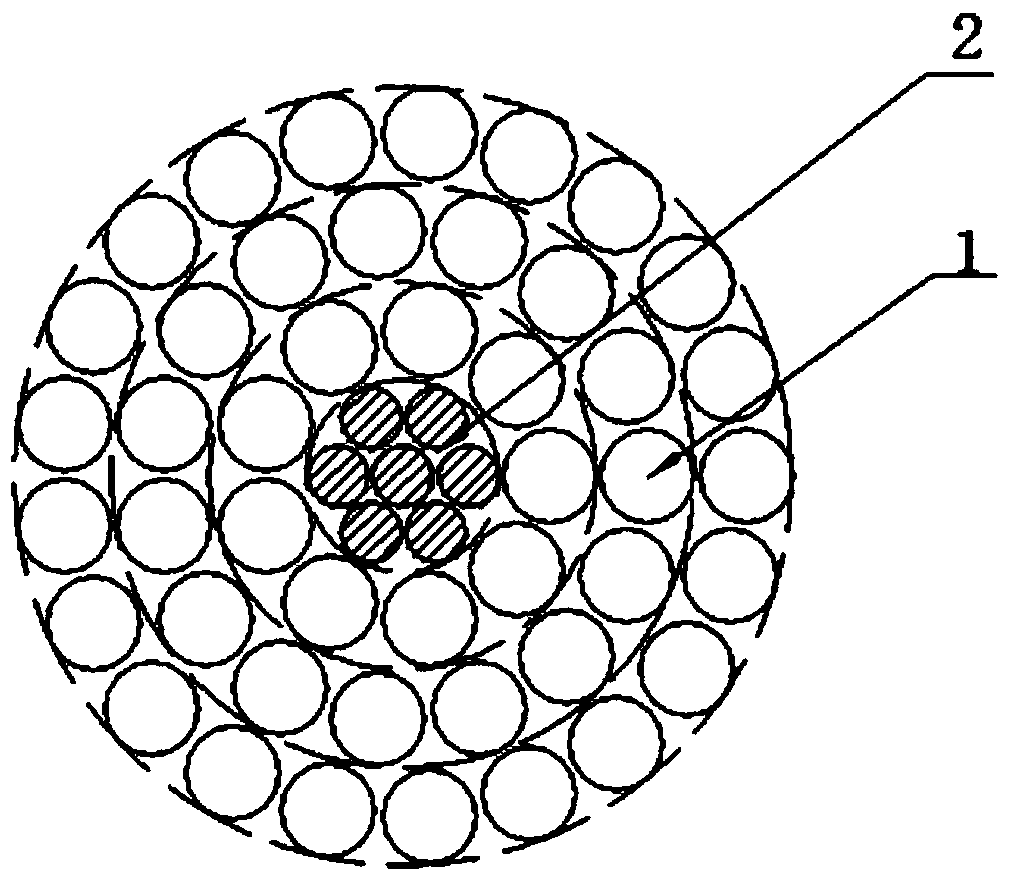

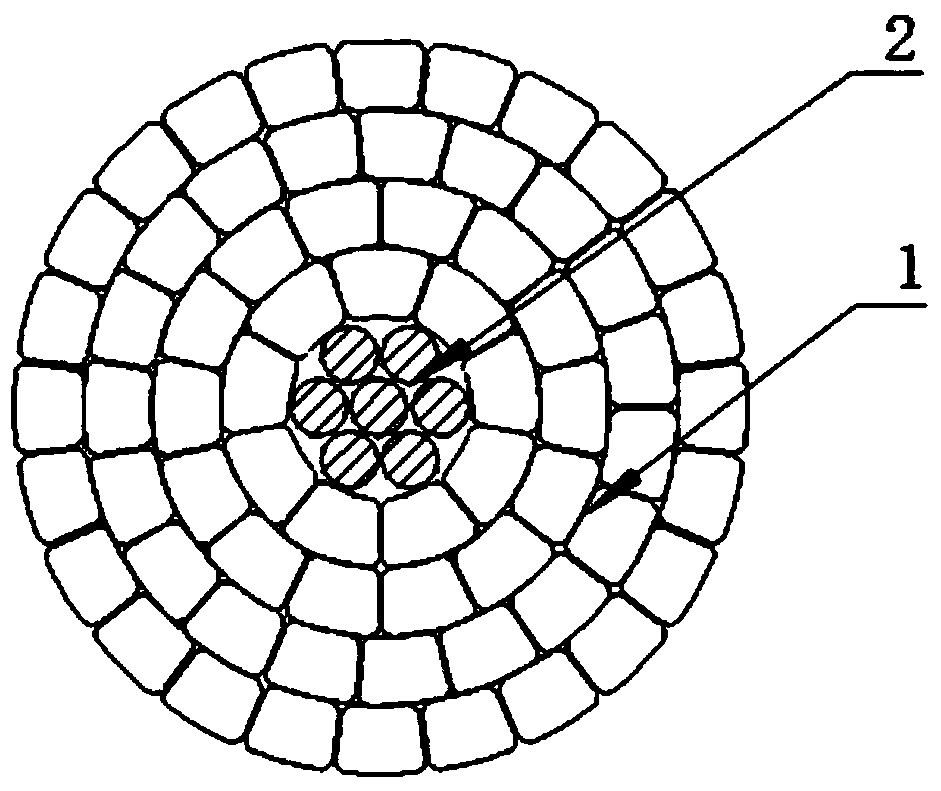

Hamburg type hemp fiber board and preparation method thereof

The invention relates to a hamburg type fibrilia plate and a preparation method thereof, and belongs to the technical field of automobile decoration fittings. The hamburg type fibrilia plate is characterized in that: the hamburg type fibrilia plate comprises three layers of a surface layer (1), a fibrilia felt layer (2) and a bottom layer (3). The surface layer (1) and bottom layer (3) are both needle-punched non-woven fabrics layers. Components of the needle-punched non-woven fabrics comprise, by mass, 40-60% of polypropylene fiber, 8-20% of 4080 fiber and 30-50% of polyester fiber. Components of the fibrilia felt comprise, by mass, 10-30% of palm fiber and the fibrilia, 30-40% of the polyester fiber and 40-50% of the polypropylene fiber. The preparation method comprises: 1, preparing the needle-punched non-woven fabrics; 2, preparing a composite substrate half finished product, wherein one side of the composite substrate half finished product is the needle-punched non-woven fabrics,the other side of the composite substrate half finished product is the fibrilia felt; 3, carrying out one-time mould-pressing to prepare the finished product. The prepared hamburg type fibrilia platehas characteristics of high strength, good stretching resistance, collapsing and deformation resistance, good flatness, low probability of moisten and mildewing, no toxicity and environmental protection.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

Environment-friendly and green secondary slurry of electronic-grade glass fiber cloth

InactiveCN101880964AGuaranteed tensile strengthImprove protectionFibre treatmentGlass fiberMetallurgy

The invention relates to secondary warp slurry used in the technical field of electronic-grade glass fiber cloth. The secondary slurry comprises the following components by weight percentage: 5-10 percent of main slurry starch, 0.5-1 percent of smoothing agent, 0.5-1 percent of binder, 0.01-0.05 percent of surfactant, and the balance of deionized water. The invention is warp slurry of electronic-grade glass fiber cloth for a printed circuit board with high-precision, high-uniformity and high-performance, the electronic-grade glass fiber cloth produced by the slurry formula has the advantages of excellent fabric appearance quality, smaller fabric thickness and energy saving and environment-friendly production process. The glass fiber cloth is applicable for insulation enhancing material of the printed circuit board, and is widely used in high-end products such as mobile phone boards, notebook computers, automotive sheets, digital cameras, digital players, navigation devices and the like.

Owner:SHANGHAI GRACE FABRIC

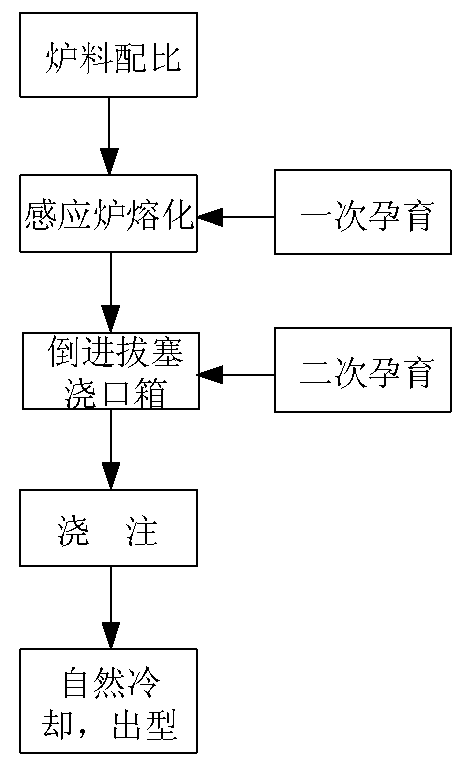

High-strength high-toughness low-temperature-resistant ferritic nodular cast iron

InactiveCN102703802AIncreased toughness-brittle transition temperatureReduce shockImpact toughnessDuctile iron

The invention discloses high-strength high-toughness low-temperature-resistant ferritic nodular cast iron. The high-strength high-toughness low-temperature-resistant ferritic nodular cast iron comprises the following components in percentage by weight: 3.62 to 3.80 percent of C, 1.90 to 2.35 percent of Si, less than 0.20 percent of Mn, 0.007 to 0.018 percent of RE, 0.043 to 0.060 percent of Mg, less than 0.035 percent of P, less than or equal to 0.020 percent of S, and the balance of iron and other impurity elements, wherein in the impurity elements, Mo is controlled to be less than 0.010 percent, and Ti is controlled to be less than 0.025 percent; and the ratio of the Si to the C is 0.50-0.63. Through a lot of test and research, the Si-C ratio is reasonably controlled, low-temperature nodular cast iron can obtain relatively high tensile strength and yield strength, and the low-temperature impact toughness of -40 DEG C can also be ensured; and the ideal low-temperature impact toughness is obtained while the function of a silicon reinforced metallic matrix is exerted, so that the performance requirements are met, and the cost is also greatly reduced.

Owner:上海宏钢电站设备铸锻有限公司

Non-tombarthite ferrite ball iron and preparing method thereof

The invention relates to a ferrite ball iron, and the invention also discloses a technic by adopting a cutting-in method to prepare the ferrite ball iron. According to the technical scheme, the ferrite ball iron comprises the following compositions by mass percent: 3.6 percent-3.9 percent of C, 1.7 percent-3.0 percent of Si, 0.1 percent-0.4 percent of Mn, 0.035 percent-0.045 percent of Mg, tombarthite< 0.001 percent, and the impurity elements are P and S, wherein the P is controlled to be less than or equal to 0.040 percent, and the S is controlled to be less than or equal to 0.012 percent, and the rest is iron. The elongation and low-temperature impact-resistance value of the ferrite ball iron reach or are over the standard required value, and the extension strength and yield strength also reach the requirement, and the preparing method is simple and easy.

Owner:JIANGSU FAW FOUNDRY

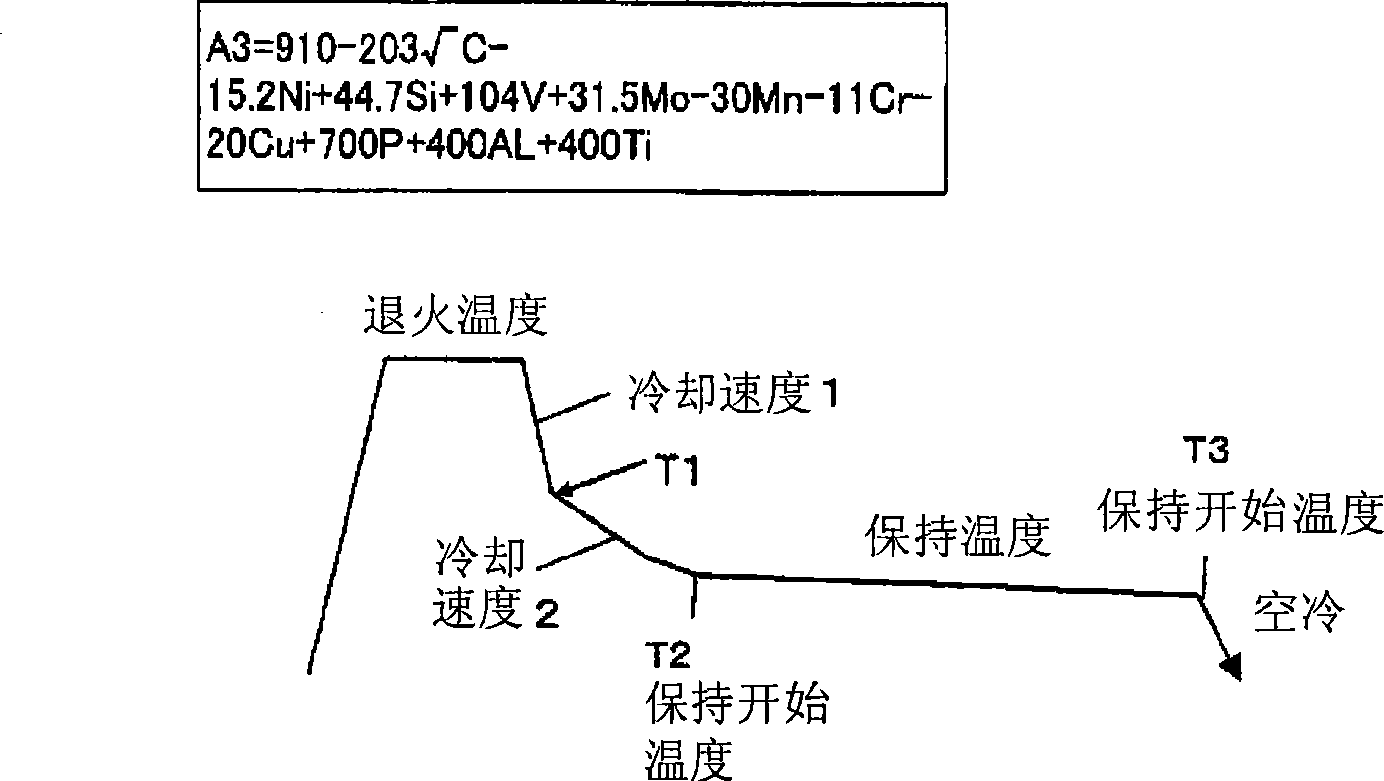

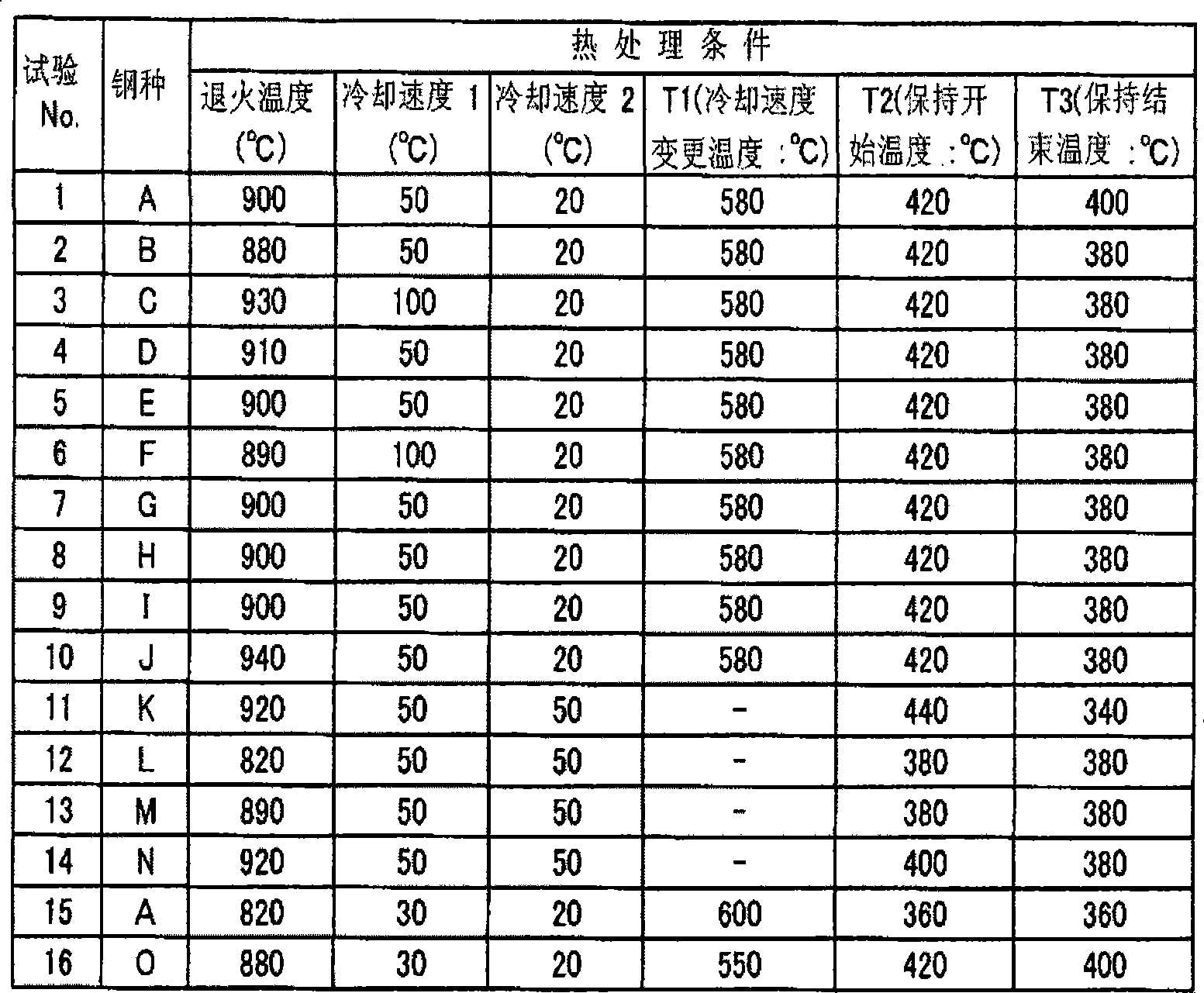

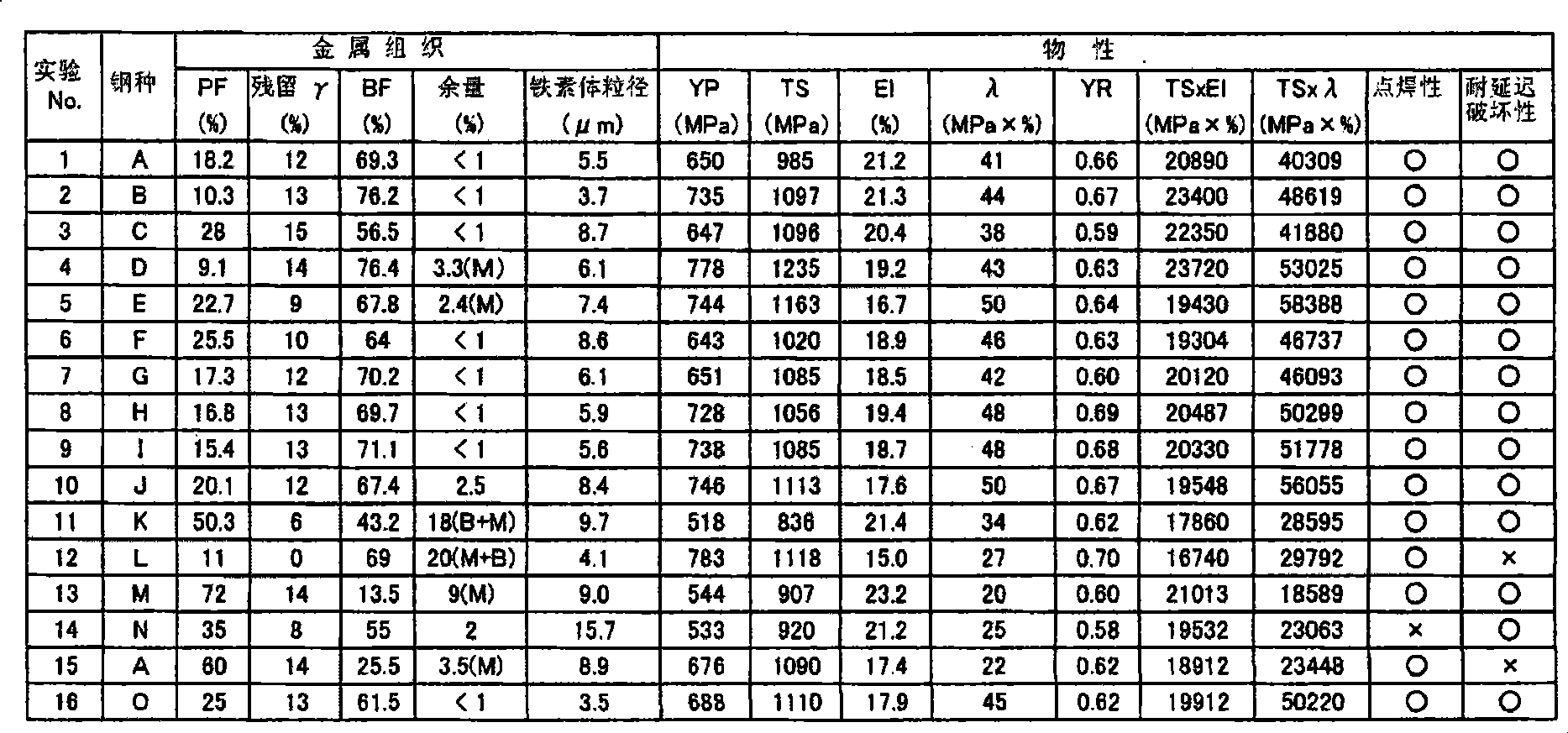

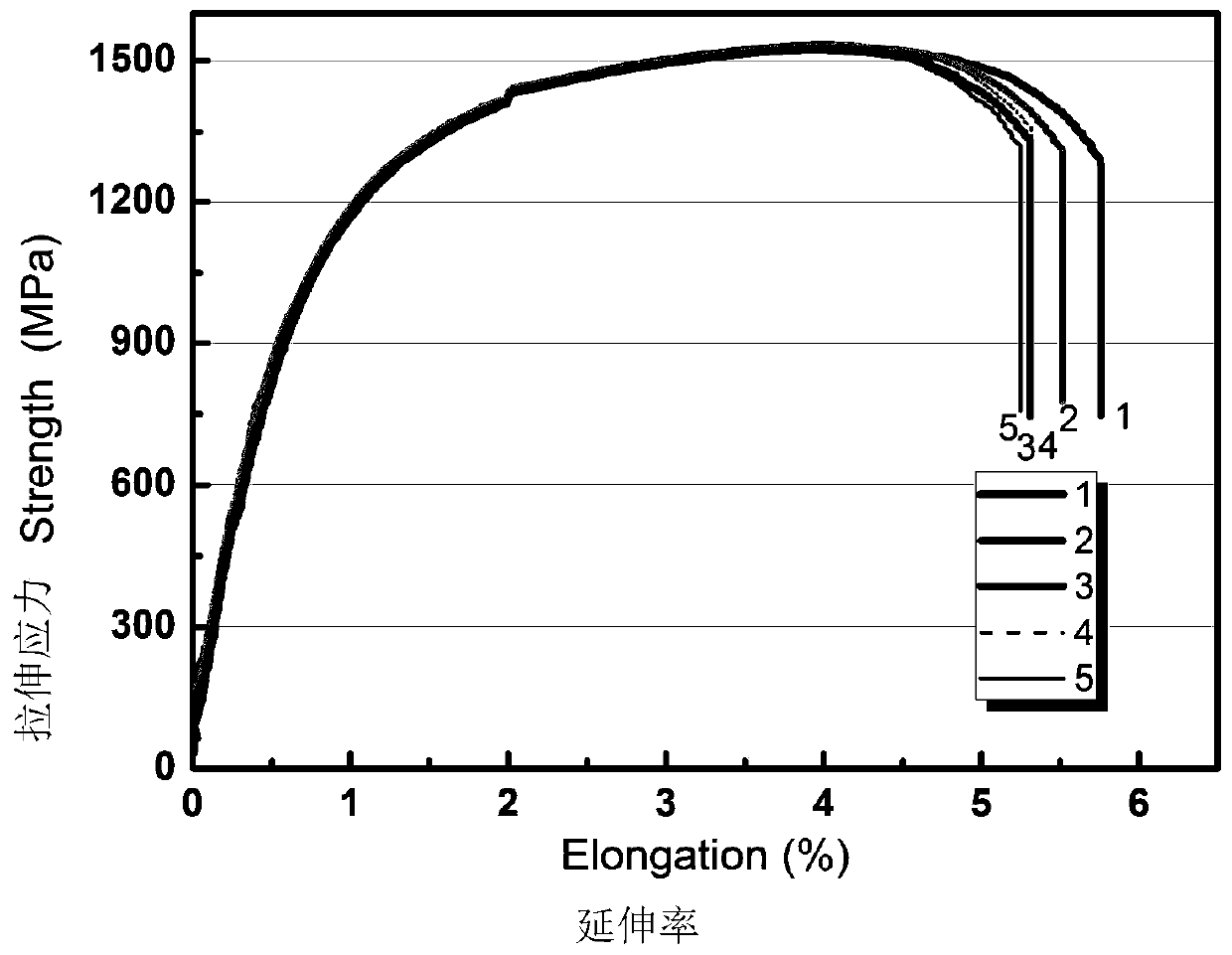

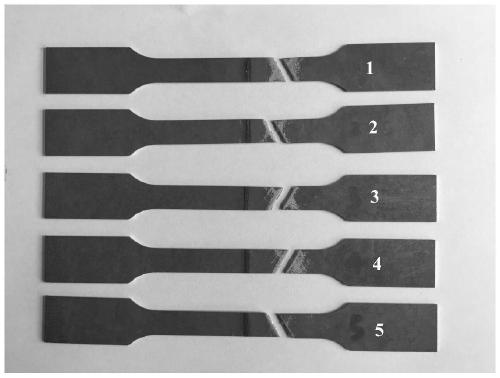

High-strength composite steel sheet having excellent moldability and delayed fracture resistance

InactiveCN101460646AGuaranteed tensile strengthGood formabilityFurnace typesHeat treatment furnacesChemical compositionHigh intensity

Disclosed is a high-strength composite steel sheet having a tensile strength of 980 MPa or greater and excellent in moldability, delayed fracture resistance and spot weldability. The steel sheet comprises a steel having the following chemical composition: C: 0.12-0.25%, Si: 1.0-3.0%, Mn: 1.5-3.0%, P: 0.15% or less, S: 0.02% or less, Al: 0.4% or less, and Cr: 1.0% or less, with the remainder being iron and unavoidable impurities, wherein the contents of Si, Al, Mn and Cr satisfy the relationship expressed by the following formula: (Si+Al) / Mn or (Si+Al) / (Mn+Cr)=0.74-1.26 and the steel sheet has a specified microstructure.

Owner:KOBE STEEL LTD

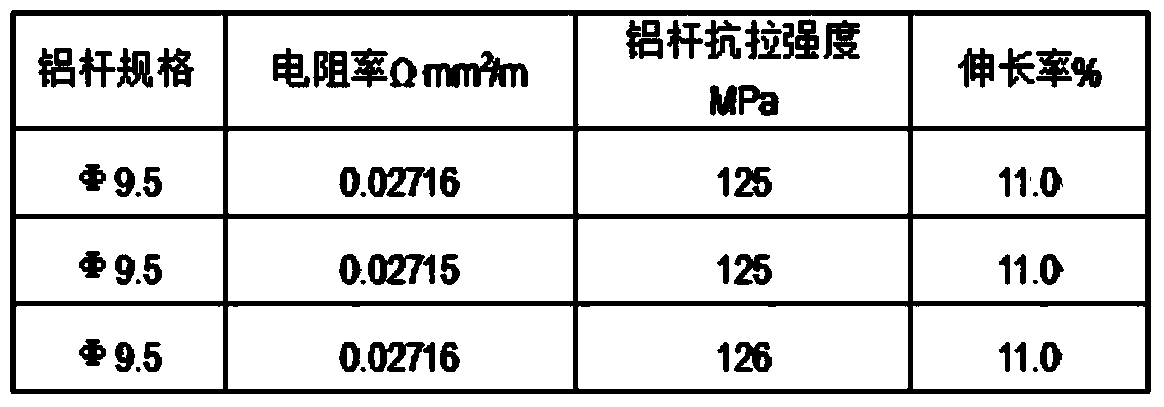

High-conductivity hard aluminum wire and preparing technology thereof

ActiveCN103854807AGuaranteed tensile strengthImprove conductivityNon-insulated conductorsCable/conductor manufactureCarrying capacityAtmospheric pressure

The invention discloses a high-conductivity (63 percent IACS) hard aluminum wire and a preparing technology thereof. The preparing technology of the high-conductivity hard aluminum wire comprises the following steps that firstly, a high-conductivity aluminum rod is prepared in a continuous casting and rolling mode; secondly, the high-conductivity aluminum rod is drawn into high-conductivity aluminum wires which are drawn through various dies, wherein the coefficient of elongation of the last die is controlled within 1.35-1.50, and the coefficients of elongation of the other dies are controlled within 1.30-1.40; thirdly, a plurality of high-conductivity aluminum wires are twisted, the pay-off tension is controlled in the twisting process, the control air pressure is smaller than or equal to 3 kilograms, the tensile strength of the manufactured single hard aluminum wire is larger than or equal to 160 MPa, and the conductor resistance is smaller than or equal to 0.027366 Omega*mm<2> / m when the temperature is 20 DEG C. The tensile strength of the manufactured single hard aluminum wire in an overhead conductor is larger than or equal to 160 MPa, the conductor resistance is smaller than or equal to 0.027366 Omega*mm<2> / m when the temperature is 20 DEG C, the tensile strength of the hard aluminum wire is kept, the conductivity of the hard aluminum wire is increased to 63 percent IACS, and the conductivity is increased by 3.28 percent compared with the stipulated conductivity of a hard aluminum wire in common GB / T17937-2009. The high-conductivity hard aluminum wire is used in the overhead conductor, the loss of the circuit electric energy can be greatly reduced, the circuit operation cost is reduced, and the carrying capacity of the wire can be obviously improved.

Owner:FAR EAST CABLE +2

Method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings

ActiveCN111230301APromote homogenizationImprove hardenabilityArc welding apparatusWelding/cutting media/materialsHot stampingMetal alloy

Provided is a method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings. A steel plate to be welded comprises a base body and at least one coating on the surface of the base body. Each coating comprises an intermetallic compound alloy layer in contact with the base body and a metal alloy layer on the intermetallic compound alloy layer. Thecoatings do not need to be removed or thinned before welding or in the welding process; by presetting the welding gap and using a carbon manganese steel welding wire, a welding process and protectivegas for welding, after a welding component is subjected to hot stamping treatment, the tensile strength of a weld joint is greater than the tensile strength of a base material, the extension rate of the weld joint is greater than 4%, and the application requirement of the equal-strength welding components in the hot stamping field is met.

Owner:BAOSHAN IRON & STEEL CO LTD

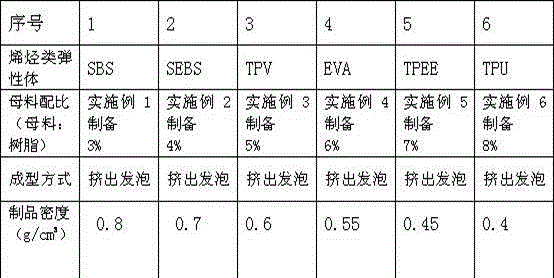

TPE (thermoplastic elastomer) foamed master batch and preparation method thereof

The invention relates to TPE (thermoplastic elastomer) foamed master batch and a preparation method thereof and belongs to the field of new chemical materials. The TPE foamed master batch is prepared from raw materials in parts by weight as follows: 10-30 parts of a styrene-butadiene block copolymer, 10-30 parts of an ethylene-octylene block copolymer, 30-80 parts of white oil, 20-80 parts of a microsphere foaming agent, 10-50 parts of a chemical foaming agent, 1-3 parts of a lubricating agent and 1-3 parts of a dispersing agent. The prepared TPE foamed master batch has high modulus, fine and uniform foam holes and adjustable density.

Owner:FUZHOU HAOWANG MATERIALS TECH CO LTD

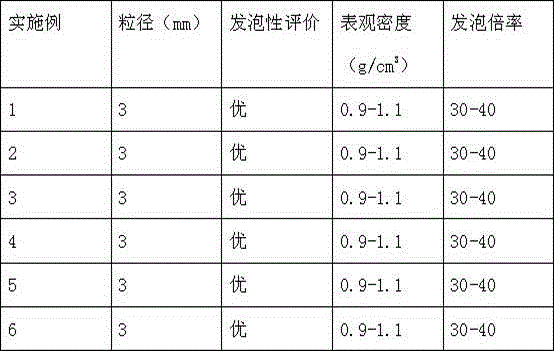

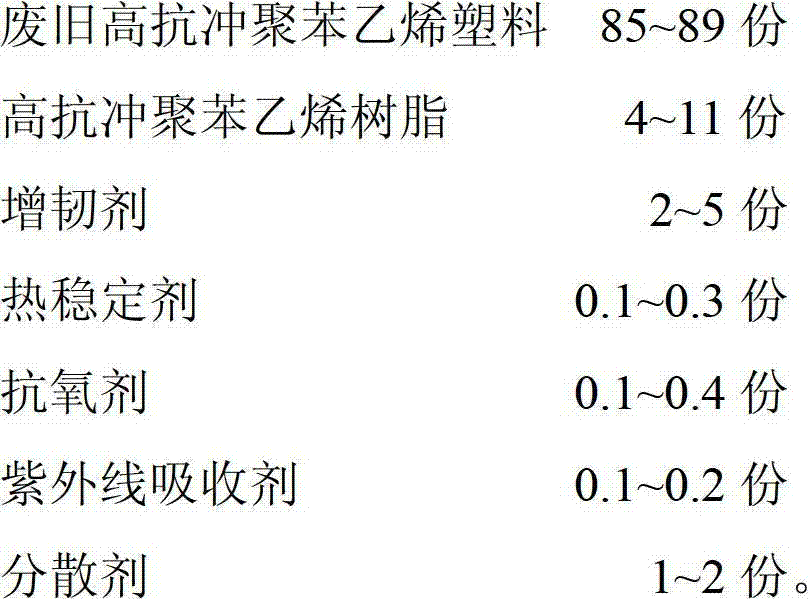

Modified high-impact polystyrene plastic

InactiveCN102786761AImprove impact strengthGuaranteed tensile strength and flexural strengthPlastic recyclingFlexural strengthAntioxidant

The invention relates to the technical field of modification treatment of waste plastics, in particular to modified high-impact polystyrene plastic. The modified high-impact polystyrene plastic comprises, by weight, 85-95 parts of waste high-impact polystyrene plastics, 2-15 parts of high-impact polystyrene resin, 2-10 parts of flexibilizers, 0.1-0.4 part of heat stabilizers, 0.1-0.4 part of antioxidants, 0.1-0.3 part of ultraviolet absorbers and 1-3 parts of dispersing agents. By adding certain quantities of novel high-impact polystyrene and plastic additives, the impact resistance of the waste HIPS (high-impact polystyrene plastic) is increased while the tensile strength and the flexure strength of the plastic are guaranteed, mechanical properties of the plastic reach standards of fresh materials, the waste HIPS plastic can be recovered effectively, and affection to environments is low.

Owner:四川长虹格润环保科技股份有限公司

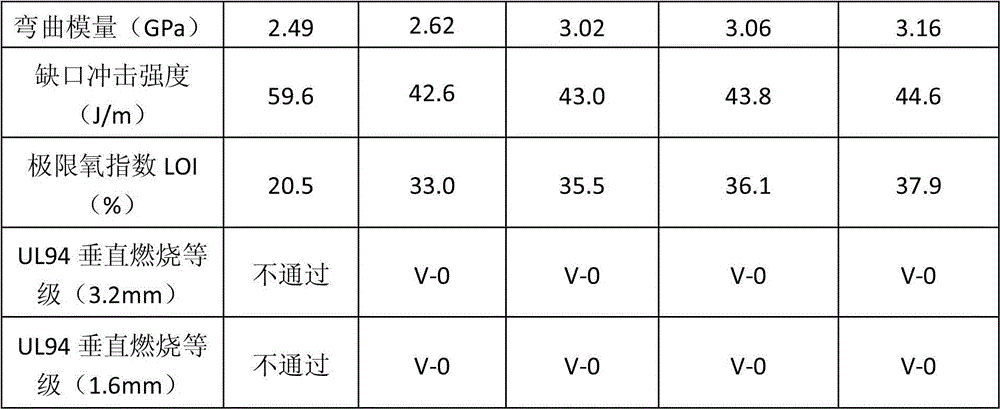

Flame-retardant chain-extended polybutylene terephthalate composition and preparation method thereof

ActiveCN102911485AReduce dosageObvious flame retardant synergistic effectPolytetramethylene terephthalateEpoxy

The invention discloses a flame-retardant chain-extended polybutylene terephthalate (PBT) composition and a preparation method of the PBT composition. The composition comprises the following raw materials by weight: 85%-90% of PBT, 9%-12% of aluminum diethylphosphinate, 0.4%-3% of polysiloxane containing an epoxy group in the side group, and 0.3%-0.7% of processing agent, wherein the processing agent is an antioxidant and an anti-dripping agent. According to the invention, the adopted polysiloxane containing the epoxy group in the side group and aluminum diethylphosphinate have obvious flame retardant synergistic effects on PBT. When the flame retardant property reaches to UL94V-0@1.6mm, the dose of aluminum diethylphosphinate is reduced by about 20% and the total flame retardant dose is reduced by about 12%. Under the premise of same flame retardant level, the mechanical properties of the composition provided by the invention is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Stainless steel A-TIG welding active agent and welding method

InactiveCN108247236AImprove securityAvoid harmArc welding apparatusWelding/cutting media/materialsActive agentStainless steel welding

The invention belongs to the technical field of stainless steel welding, and particularly relates to a stainless steel A-TIG welding active agent and a welding method. To solve the problem that an existing stainless steel A-TIG welding active agent contains halide, influences are caused to the human body health, the stainless steel A-TIG welding active agent is disclosed. The stainless steel A-TIGwelding active agent comprises active agent powder. The active agent powder comprises, by mass percent, 10%-30% of SiO2 powder, 5%-20% of Cr2O3 powder, 15%-50% of Al2O3 powder, 10%-20% of TiO2 powder, 5%-20% of MnO2 powder, 5%-20% of Fe2O3 powder, 5%-30% of B2O3 powder and 3%-8% of La2O3 powder. The active agent is adopted for conducting stainless steel A-TIG welding, influences of the halide onthe operator health can be avoided, and the welding efficiency can be improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

Preparation method of nano calcium carbonate for MS glue

InactiveCN109650431ADetermining performanceThe process steps are the sameCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesCarbonizationSlurry

The invention discloses a preparation method of nano calcium carbonate for MS glue, which comprises the following steps: removing impurities from calcium hydroxide (Ca (OH) 2) slurry obtained after the digestion reaction of quicklime (CaO) and water (H2O), preserving heat and aging, adding a crystal form control agent, performing primary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2), adding a post-treatment agent, aging for a certain time, performing secondary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2) to obtain calcium carbonate (CaCO3) cooked slurry, adding a modifier into the cooked slurry, performing filter pressing dehydration, drying, crushing and grading after the reaction is finished to obtain the nano calcium carbonate for MS glue. The nano calcium carbonate crystal prepared by the method is a standard cube, and the crystal is mono-disperse, and the average particle diameter is only 100-150nm, and the specific surface area is 16-18m <2 > / g, and the nano calcium carbonate crystal is used for MS glue, and the thixotropy is good, and the extrusion property is good, and the storage stability is good, and the surface finish after gluing is good, and the tensile strength is high, and the elongation is high and the bonding property is also good. The preparation method of nano calcium carbonate for MS glue has the advantages of simple and feasible process, low cost, low price and better economic benefit.

Owner:卢氏国嵩莱纳米科技有限公司

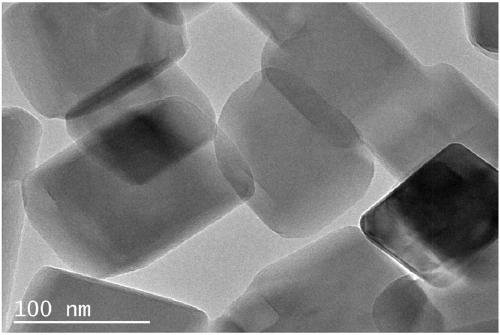

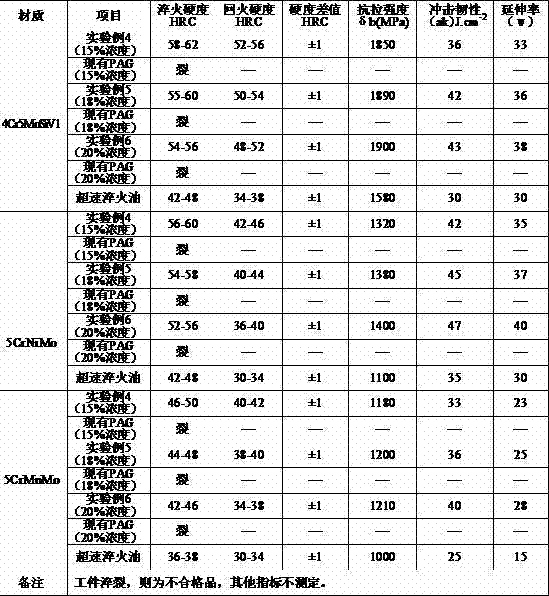

Water-soluble quenching medium for hot die steel

The invention discloses a water-soluble quenching medium for hot die steel. The water-soluble quenching medium is prepared by mixing polyalkylene glycol, polyvinyl pyrrolidone, rust inhibitor, bactericide, pH regulator, settling agent, defoaming agent and water uniformly in a ratio. The water-soluble quenching medium is low in production cost, non-flammable and environment-friendly. The water-soluble quenching medium replaces oil quenching media, and fully meets the quenching requirements of the hot die steel such as 4Cr5MoSiV1, 5CrMnMo and 5CrNiMo.

Owner:LIAONING HAIMING CHEM PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com