Modified high-impact polystyrene plastic

A polystyrene plastic, high-impact technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of high-impact polystyrene plastic performance degradation, not easy to degrade, land occupation, etc., to ensure tensile strength and Bending strength, good economic and social benefits, and the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

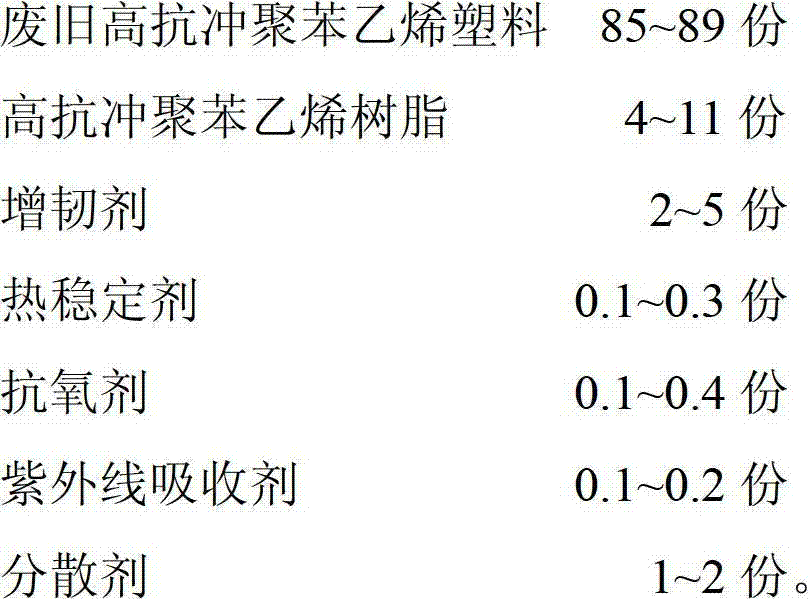

[0042] First, get waste and old HIPS plastics, HIPS new material (unused HIPS resin), toughening agent, heat stabilizer, antioxidant, ultraviolet absorber and other components, put all the raw materials in parts by weight according to the following composition formula Blending into the mixer:

[0043] Waste HIPS plastic (recycled material from waste TV casings of our company): 89 copies;

[0044] New HIPS material (Zhenjiang Chimei, model HP-88): 4 copies;

[0045] Toughening agent (SBS): 5 parts;

[0046] Heat stabilizer (zinc stearate): 0.25 parts;

[0047] Antioxidant (a mixture of antioxidants 1010 and 168 in a weight ratio of 1:1): 0.4 parts;

[0048] Ultraviolet absorber (UV-531): 0.2 parts;

[0049] Dispersant (CPE resin): 1 part;

[0050] Secondly, the above-mentioned blend is added to a twin-screw extruder at 150-210 ° C to extrude and granulate, and the obtained particles are injection-molded by an injection molding machine to make a standard spline, and finally...

Embodiment 2

[0052] First, take waste and old HIPS plastics, new HIPS materials, toughening agents, heat stabilizers, antioxidants, ultraviolet absorbers and other components, and put all the raw materials into the mixer for blending according to the following composition formula in parts by weight:

[0053] Waste HIPS plastic (recycled material from waste TV casings of our company): 88 parts;

[0054] New HIPS material (Zhenjiang Chimei, HP-88): 7 copies;

[0055] Toughener (KT-19): 4 parts;

[0056] Heat stabilizer (zinc stearate): 0.25 parts;

[0057] Antioxidant (antioxidant 1076, DLTDP mixture with a weight ratio of 1:1): 0.4 parts;

[0058] Ultraviolet absorber (UV-531): 0.1 parts;

[0059] Dispersant (CPE resin): 1 part;

[0060] Secondly, the above-mentioned blended material was added into a twin-screw extruder to extrude and granulate, and the obtained particles were injection-molded by an injection molding machine to make a standard sample. The test results are shown in Table...

Embodiment 3

[0062]First, take waste and old HIPS plastics, HIPS new materials, toughening agents, heat stabilizers, antioxidants, ultraviolet absorbers and other components, and put all the raw materials into the mixer for blending according to the following composition formula in parts by weight:

[0063] Waste HIPS plastic (recycled material from waste TV casings of our company): 85 copies;

[0064] New HIPS material (Zhenjiang Chimei, HP-88): 11 copies;

[0065] Toughener (KT-19): 4 parts;

[0066] Heat stabilizer (calcium stearate): 0.25 parts;

[0067] Antioxidant (antioxidant 1076, DLTDP mixture with a weight ratio of 1:1): 0.4 parts;

[0068] Ultraviolet absorber (UV-531): 0.1 parts;

[0069] Dispersant (CPE resin): 1 part;

[0070] Secondly, the above-mentioned blended materials were added into a twin-screw extruder to extrude and granulate, and the obtained particles were injection-molded by an injection molding machine to make a standard sample. The test results are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com