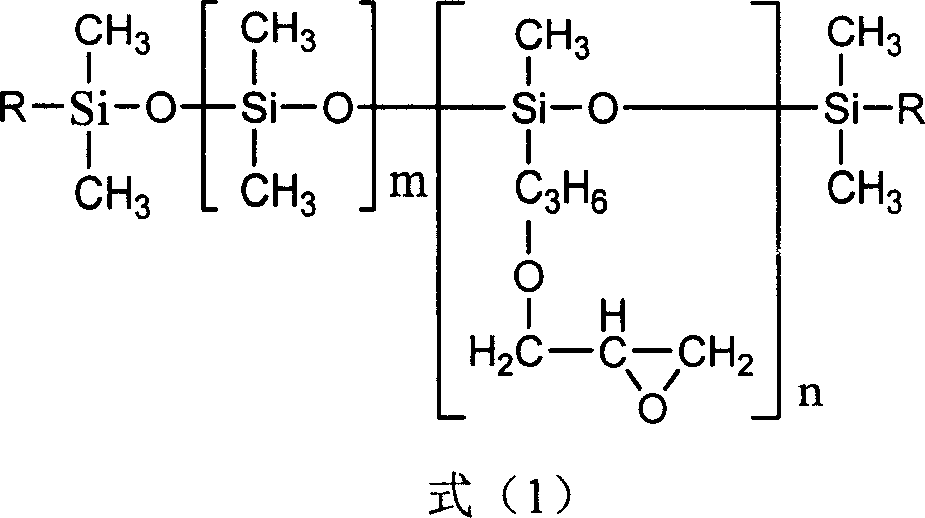

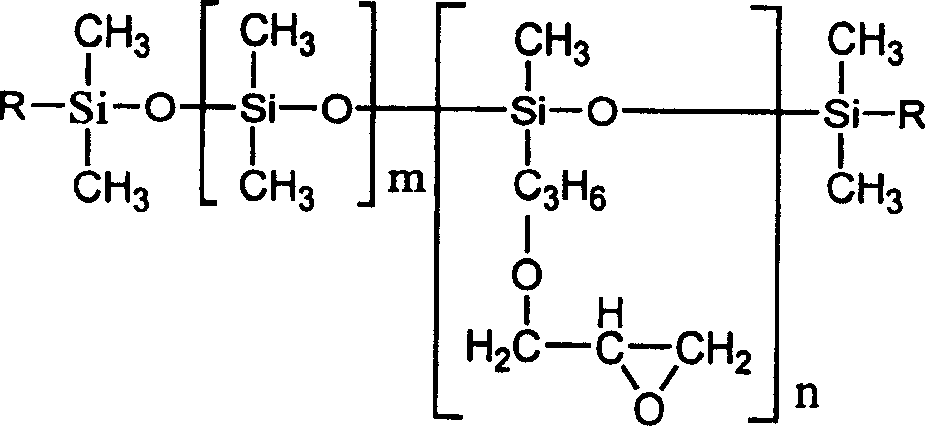

Epoxidation silicon oil modified three kinds of composite material of epoxy resin

A technology for epoxidizing silicone oil and epoxy resin, which is applied in the field of epoxidizing silicone oil modified epoxy resin composite materials, can solve the problems of reducing material toughness, reducing mechanical strength and heat resistance, etc., and achieves the effect of high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 100g of E-51 epoxy resin with an epoxy value of 0.51mol / 100g and 0.1g of epoxy silicone oil with an epoxy value of 0.16mol / 100g, put them in a beaker, stir, then add p, p'-diaminodi 25.26g of phenylmethane, then heated to dissolve p,p'-diaminodiphenylmethane, stirred, degassed, poured into the mold, and cured according to the curing process of 80°C / 3h+150°C / 2h+175°C / 1h to obtain Epoxy silicone oil modified epoxy resin composite material, the measured tensile strength is 41.31MPa, the elongation at break is 5.42%, and the impact strength is 10.24KJ m -2 , The glass transition temperature is 158°C.

Embodiment 2

[0027] Take 100g of F-51 epoxy resin with an epoxy value of 0.51mol / 100g and 80g of epoxy silicone oil with an epoxy value of 0.01mol / 100g and put them in a beaker, heat and stir, then add diaminodiphenyl sulfone 29.78 g, then heat to dissolve the diaminodiphenyl sulfone, stir again, defoam, pour the mold, and cure according to the curing process of 80°C / 1h+160°C / 2h+180°C / 2h to obtain epoxy silicone oil modified epoxy Resin composites. The measured tensile strength is 43.47MPa, the elongation at break is 6.71%, and the impact strength is 11.62KJ m -2 , The glass transition temperature is 163°C.

Embodiment 3

[0029]After dissolving 100 g of epoxidized silicone oil with an epoxy value of 0.16 mol / 100 g in dimethylformamide, place it in a reactor with 32 g of p-, p-diaminodiphenylmethane, while heating and stirring in an oil bath , and then reflux at 140°C for 3 hours. After the reaction, the reaction mixture was distilled under reduced pressure to remove dimethylformamide to obtain a modified epoxy silicone oil. Stir 100g of E-44 epoxy resin in a beaker evenly, then add 5g of dicyandiamide, and cure according to the curing process of 80℃ / 1h+160℃ / 1h+180℃ / 0.5h to obtain epoxy silicone oil modified epoxy resin Resin composites. The measured tensile strength is 47.54MPa, the elongation at break is 11.38%, and the impact strength is 14.45KJ m -2 , The glass transition temperature is 171°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com