Drug delivery balloon dilating catheter

A technology for dilating catheters and balloon catheters, which is applied in the field of medical devices, can solve problems such as unsuitable for large-scale industrial production, rupture of microporous permeable membranes, and complicated manufacturing processes, and achieve easy and rapid delivery, satisfying repeated expansion and contraction, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Preparation of Nylon12 Drug Delivery Balloon Dilatation Catheter

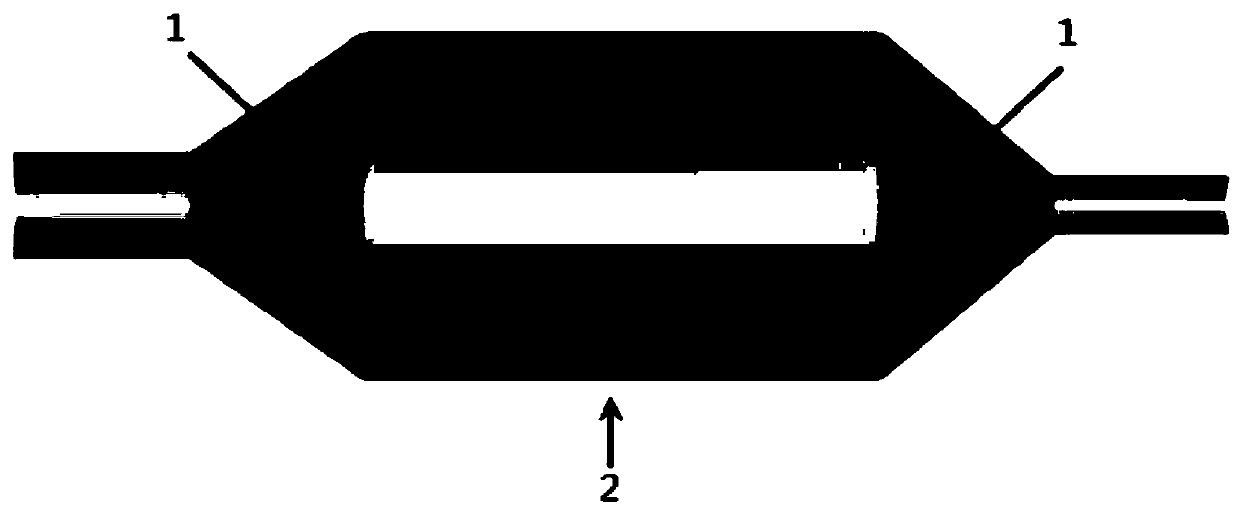

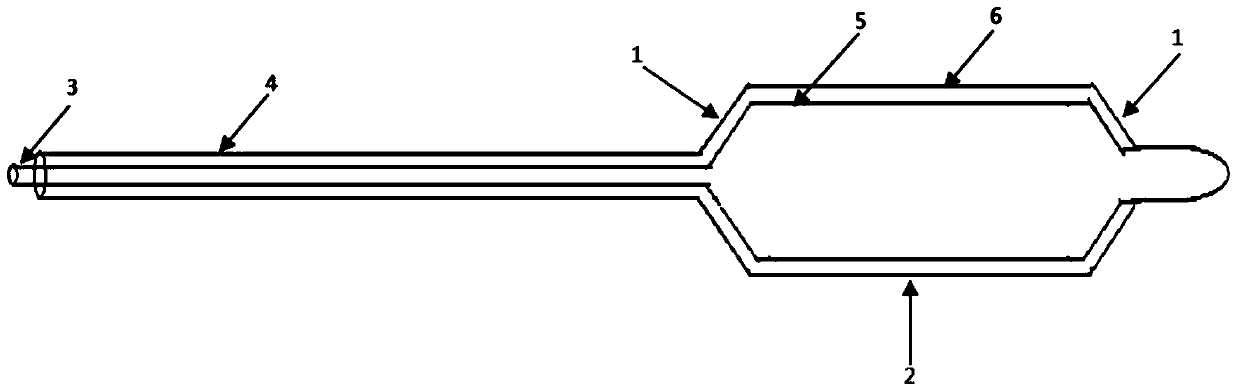

[0046] Mix 1g of Nylon12 and 0.6g of PEG, melt at 220°C to form a homogeneous solution, and inject it into the mold (see attached figure 1 ), after cooling and solidifying at an appropriate temperature, extract PEG 3 to 4 times with acetone, about 6 hours each time; vacuum dry in a vacuum oven at 50°C for 14 hours, and then take out the microporous membrane balloon. Finally, (see attached figure 2 ) insert the prepared non-porous inner balloon 5 and the connected inflation catheter 3 into the microporous permeable membrane outer balloon 6, and use the microporous membrane balloon as the outer balloon 6 by laser welding And the non-porous balloon is used as the inner balloon 5, which is fused together to achieve a bonded state to form a double-layer balloon structure, and then the proximal part of the catheter is welded to form a balloon dilation catheter.

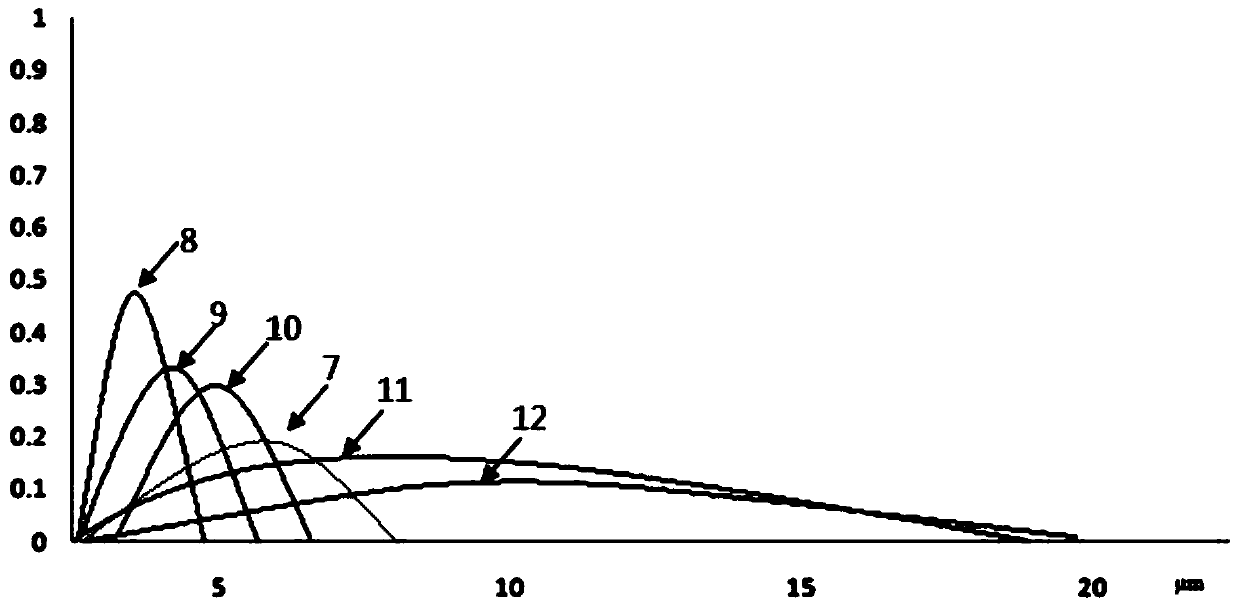

[0047] The porosity is 50.37%, and...

Embodiment 2

[0049] Example 2 Preparation of ethylene-acrylic acid drug delivery balloon dilatation catheter:

[0050] Mix 1 g of ethylene-acrylic acid (EEA) and 0.9 g of diphenyl ether (DPE), melt at 180 °C to form a homogeneous solution, and inject it into the mold (see attached figure 1 ); after cooling and solidifying at an appropriate temperature, extract the DPE with methanol 3 to 4 times, about 6 hours each time; vacuum dry in a vacuum oven at 50°C for 14 hours, and then take out the microporous membrane balloon. Finally, (see attached figure 2 ) insert the prepared non-porous inner balloon 5 and the connected inflation catheter 3 into the microporous permeable membrane outer balloon 6, and use the microporous membrane balloon as the outer balloon 6 by laser welding And the non-porous balloon is used as the inner balloon 5, which is fused together to achieve a bonded state to form a double-layer balloon structure, and then the proximal part of the catheter is welded to form a ball...

Embodiment 3

[0053] Example 3 Preparation of Ethylene-Vinyl Alcohol Drug Delivery Balloon Dilatation Catheter:

[0054] Mix 1g of ethylene-vinyl alcohol and 0.8g of PEG, melt at 220°C to form a homogeneous solution, and inject it into the mold (see attached figure 1 ); phase separation occurs after cooling, and the polymer phase and the diluent phase form an interphase structure; then the diluent PEG is removed with the extractant acetone, and the space occupied by the original diluent in the mixture becomes micropores, that is, a coherent microporous permeable membrane is formed structure of the balloon. Finally, (see attached figure 2 ) insert the prepared non-porous inner balloon 5 and the connected inflation catheter 3 into the microporous permeable membrane outer balloon 6, and use the microporous membrane balloon as the outer balloon 6 by laser welding And the non-porous balloon is used as the inner balloon 5, which is fused together to achieve a bonded state to form a double-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com