Automobile steering device installing and fixing sleeve necking-down device

A technology of automobile steering gear and fixed sleeve, which is applied in the field of automation, can solve problems such as difficulty in ensuring shrinkage accuracy and uniformity of batch specifications, and achieve the effect of high-efficiency, high-precision shrinkage, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

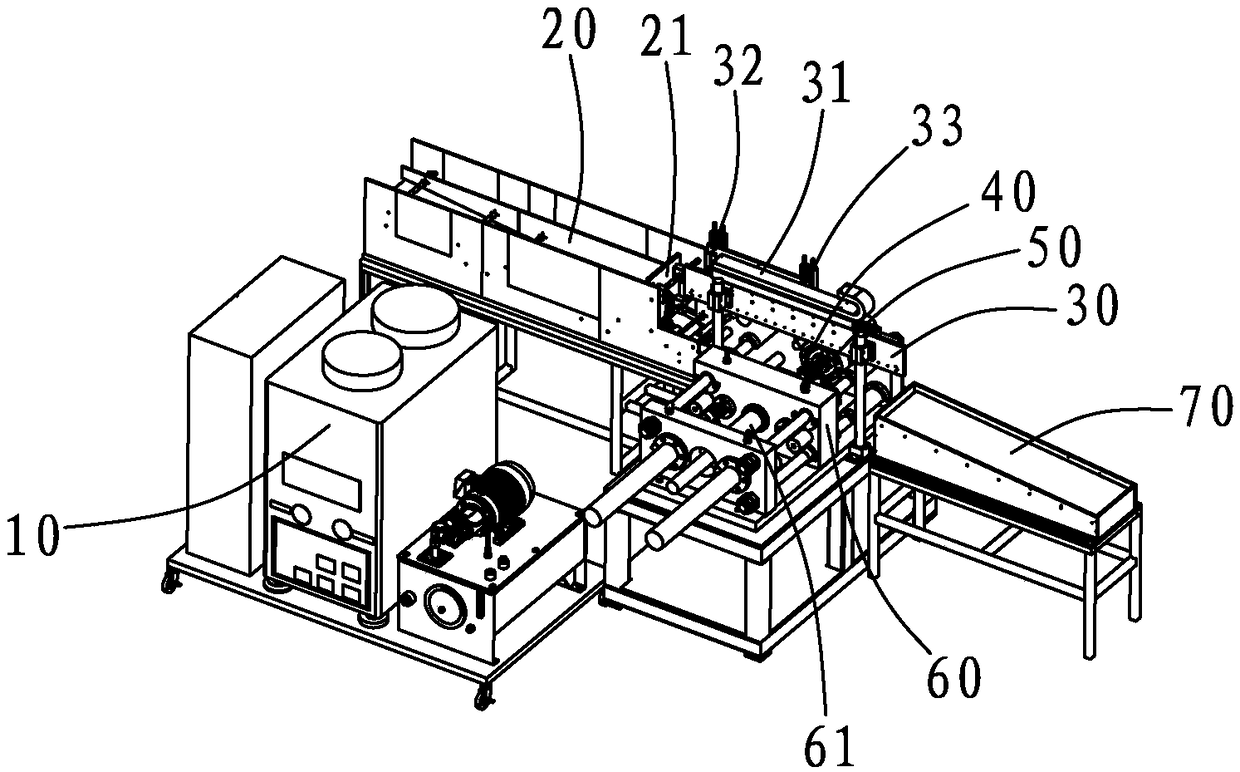

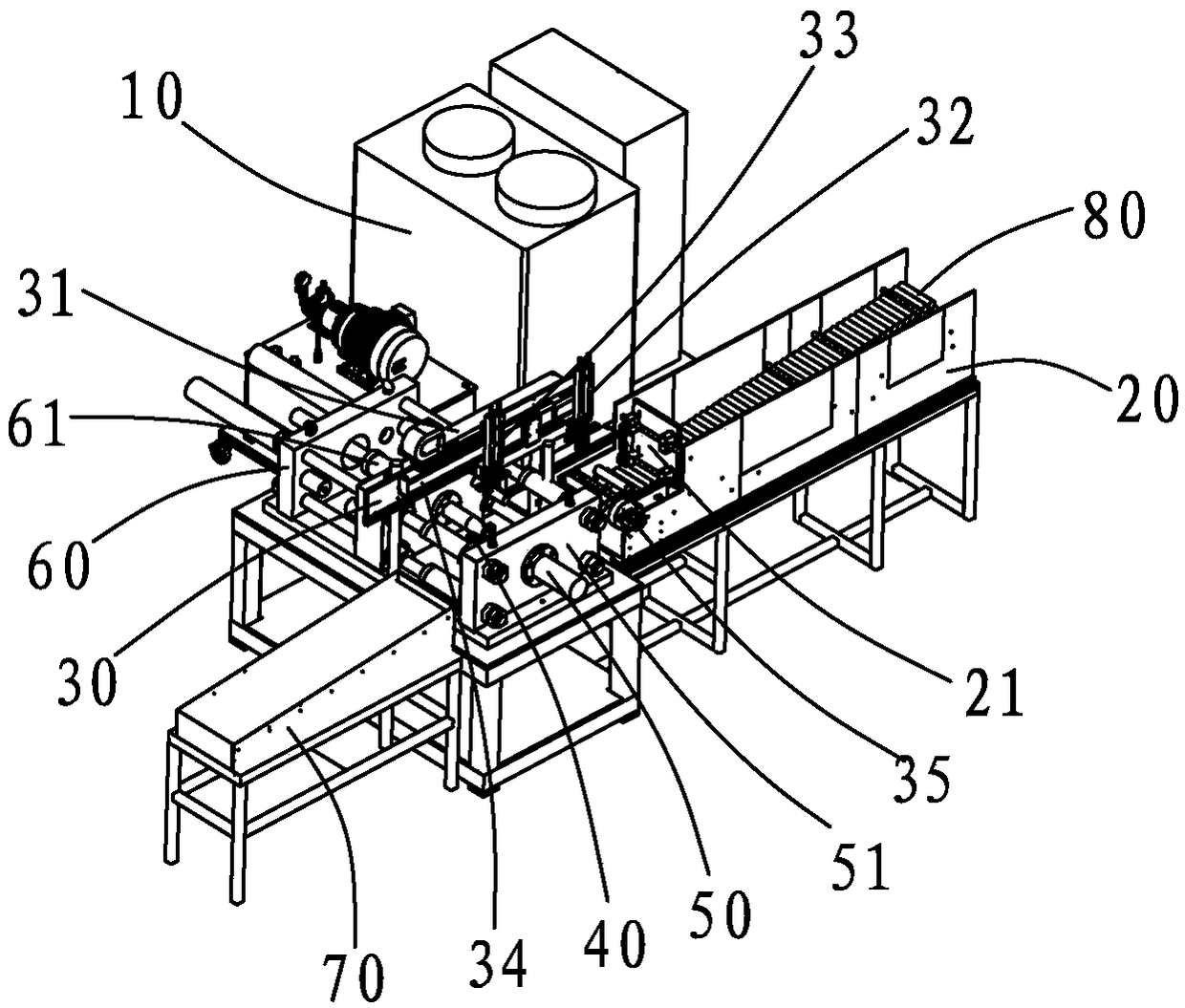

[0022] refer to Figure 1-2 , the automotive steering gear installation fixed sleeve necking device provided by the present invention includes a control module 10, a feeding module 20 controlled by the control module 10, a material shifting module, a necking module and a blanking module 70 The feed chute outlet of the feeding module 20 is provided with a pneumatically controlled feeding baffle 21 for individual feeding control; the feed trough outlet of the feeding module 20 is also provided with a monolithic module, and the monolithic module includes The monolithic baffle, the monolithic cylinder, and the monolithic block 35 driven by the monolithic cylinder, the monolithic baffle and the monolithic block 35 correspond to the two ends of the sleeve 80 respectively, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com